Adaptive Threshold Algorithm for Outlier Elimination in 3D Topography Data of Metal Additive Manufactured Surfaces Obtained from Focus Variation Microscopy

Abstract

1. Introduction

- Detailed explanation of the construction of a pair of SATP for each -plane to determine the ROF, where the focus position is highly probable;

- Comparison of several constructed SATPs based on different operators;

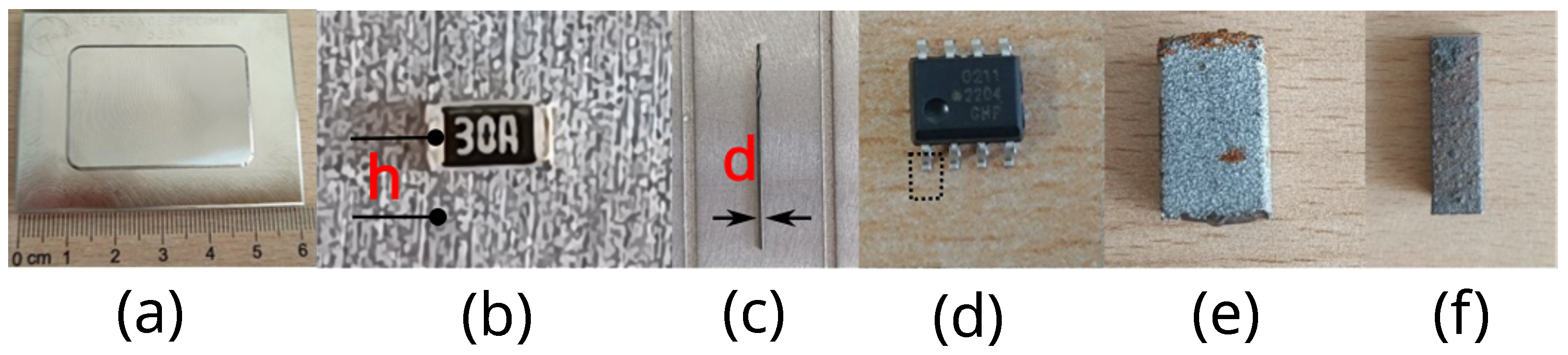

- Validation of the findings by measuring several electrical components with microscale dimensions due to the lack of a standard MAM workpiece, as per the authors’ knowledge;

- Validation of the findings involves measuring the texture of a Rubert precision reference standard 525C, which features quite smooth surfaces, and then adding additional roughness using a virtual FVM instrument.

- Prevention of most artifacts from appearing on the initially reconstructed surface texture, thereby eliminating the need for removing invalid pixels as generally utilized in previous studies.

2. Methodology

2.1. Samples for Simulation, Validation and Experiments

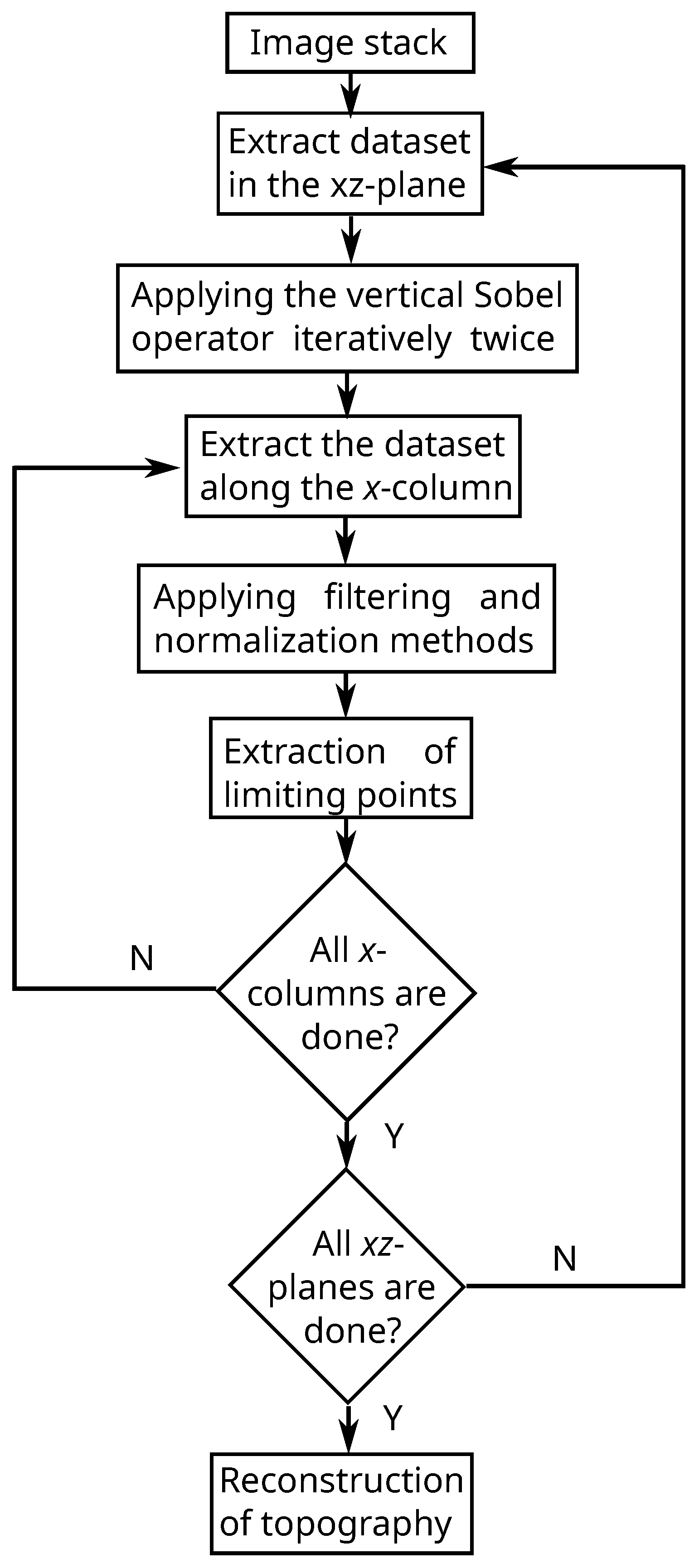

2.2. Proposed Algorithm to Construct the SATP

2.3. Procedure to Characterize Surface Roughness

3. Results and Discussion

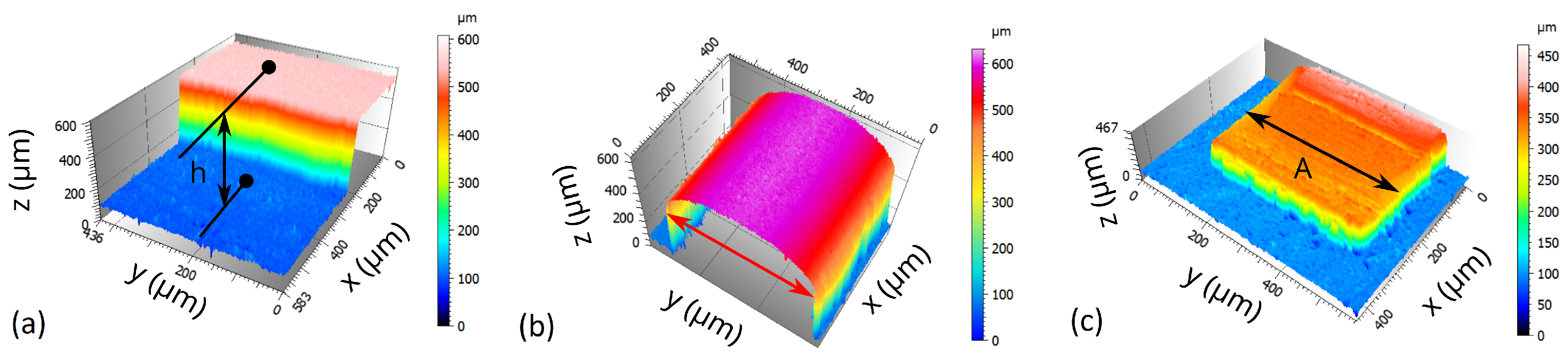

3.1. Validation by Simulation

3.2. Validation by Test Samples

3.3. Measurement Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Leach, R. Optical Measurement of Surface Topography; Springer: Berlin/Heidelberg, Germany, 2011; p. 8. [Google Scholar]

- Safdar, A.; He, H.; Wei, L.; Snis, A.; Paz, L. Effect of process parameters settings and thickness on surface roughness of EBM produced Ti-6Al-4V. Rapid Prototyp. J. 2012, 18, 401–408. [Google Scholar] [CrossRef]

- Fay, M.F.; de Lega, X.C.; de Groot, P. Measuring high-slope and super-smooth optics with high-dynamic-range coherence scanning interferometry. In Proceedings of the Optical Fabrication and Testing, Kohala Coast, HI, USA, 22–26 June 2014; p. OW1B-3. [Google Scholar]

- Mirabal, A.; Loza-Hernandez, I.; Clark, C.; Hooks, D.; McBride, M.; Stull, J. Roughness measurements across topographically varied additively manufactured metal surfaces. Addit. Manuf. 2023, 69, 103540. [Google Scholar] [CrossRef]

- Townsend, A.; Senin, N.; Blunt, L.; Leach, R.; Taylor, J. Surface texture metrology for metal additive manufacturing: A review. Precis. Eng. 2016, 46, 34–47. [Google Scholar] [CrossRef]

- Król, M.; Dobrzański, L.; Reimann, I. Surface quality in selective laser melting of metal powders. Arch. Mater. Sci. 2013, 88, 88. [Google Scholar]

- Kerckhofs, G.; Pyka, G.; Moesen, M.; Van Bael, S.; Schrooten, J.; Wevers, M. High-resolution microfocus X-ray computed tomography for 3D surface roughness measurements of additive manufactured porous materials. Adv. Eng. Mater. 2013, 15, 153–158. [Google Scholar] [CrossRef]

- Fischer, D.; Cheng, K.; Neto, M.; Hall, D.; Bijukumar, D.; Espinoza Orías, A.; Pourzal, R.; Arkel, R.; Mathew, M. Corrosion behavior of selective laser melting (SLM) manufactured Ti6Al4V alloy in saline and BCS solution. J. Bio-Tribo-Corros. 2022, 8, 63. [Google Scholar] [CrossRef]

- Grimm, T.; Wiora, G.; Witt, G. Characterization of typical surface effects in additive manufacturing with confocal microscopy. Surf. Topogr. Metrol. Prop. 2015, 3, 014001. [Google Scholar] [CrossRef]

- Newton, L.; Senin, N.; Gomez, C.; Danzl, R.; Helmli, F.; Blunt, L.; Leach, R. Areal topography measurement of metal additive surfaces using focus variation microscopy. Addit. Manuf. 2019, 25, 365–389. [Google Scholar] [CrossRef]

- Xu, X.; Pahl, T.; Serbes, H.; Lehmann, P. Robust reconstruction of the topography of metal additive surfaces based on focus variation microscopy. In Proceedings of the 60th ISC, Ilmenau Scientific Colloquium, Technische Universität Ilmenau, Ilmenau, Germany, 4–8 September 2023. [Google Scholar]

- Xu, X.; Hagemeier, S.; Lehmann, P. Outlier elimination in rough surface profilometry with focus variation microscopy. Metrology 2022, 2, 263–273. [Google Scholar] [CrossRef]

- Xu, X.; Pahl, T.; Serbes, H.; Krooss, P.; Niendorf, T.; Lehmann, P. Preprocessing method for robust topography reconstruction of surfaces of metal additive manufactured parts based on focus variation microscopy. In tm—Technisches Messen; De Gruyter: Vienna, Austria, 2024; Volume 91, pp. 233–242. [Google Scholar]

- Podulka, P.; Pawlus, P.; Dobrzański, P.; Lenart, A. Spikes removal in surface measurement. J. Phys. Conf. Ser. 2014, 483, 012025. [Google Scholar] [CrossRef]

- Lou, S.; Jiang, X.; Scott, P. Fast algorithm for morphological filters. J. Phys. Conf. Ser. 2011, 311, 012001. [Google Scholar] [CrossRef]

- Pan, Y.; Zhao, Q.; Guo, B. On-machine measurement of the grinding wheels’ 3D surface topography using a laser displacement sensor. In Proceedings of the 7th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Advanced Optical Manufacturing Technologies, SPIE, Harbin, China, 26–29 April 2014; Volume 9281, pp. 87–96. [Google Scholar]

- Lou, S.; Zhu, Z.; Zeng, W.; Majewski, C.; Scott, P.; Jiang, X. Material ratio curve of 3D surface topography of additively manufactured parts: An attempt to characterise open surface pores. Surf. Topogr. Metrol. Prop. 2021, 9, 015029. [Google Scholar] [CrossRef]

- Giusca, C.; Leach, R.; Helary, F.; Gutauskas, T.; Nimishakavi, L. Calibration of the scales of areal surface topography-measuring instruments: Part 1. Measurement noise and residual flatness. Meas. Sci. Technol. 2012, 23, 035008. [Google Scholar] [CrossRef]

- Podulka, P. Suppression of the high-frequency errors in surface topography measurements based on comparison of various spline filtering methods. Materials 2021, 14, 5096. [Google Scholar] [CrossRef] [PubMed]

- Bitenc, M.; Kieffer, D.; Khoshelham, K. Range versus surface denoising of terrestrial laser scanning data for rock discontinuity roughness estimation. Rock Mech. Rock Eng. 2019, 52, 3103–3117. [Google Scholar] [CrossRef]

- Pahl, T.; Rosenthal, F.; Breidenbach, J.; Danzglock, C.; Hagemeier, S.; Xu, X.; Künne, M.; Lehmann, P. Electromagnetic modeling of interference, confocal, and focus variation microscopy. Adv. Photon. Nexus 2024, 3, 016013. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Comparison of results of surface texture measurement obtained with stylus methods and optical methods. Metrol. Meas. Syst. 2018, 25, 589–602. [Google Scholar] [CrossRef]

- Lou, S.; Jiang, X.; Sun, W.; Zeng, W.; Pagani, L.; Scott, P. Characterisation methods for powder bed fusion processed surface topography. Precis. Eng. 2019, 57, 1–15. [Google Scholar] [CrossRef]

- Burger, W.; Burge, M.J. Digital Image Processing: An Algorithmic Introduction; Springer Nature: Cham, Switzerland, 2022. [Google Scholar]

- Subbarao, M.; Choi, T. Accurate recovery of three-dimensional shape from image focus. IEEE Trans. Pattern Anal. Mach. Intell. 1995, 17, 266–274. [Google Scholar] [CrossRef]

- Nwaogu, U.; Tiedje, N.; Hansen, H. A non-contact 3D method to characterize the surface roughness of castings. J. Mater. Process. Technol. 2013, 213, 59–68. [Google Scholar] [CrossRef]

- ISO 25178-601:2010; Geometric Product Specifications (GPS)—Surface Texture: Areal—Nominal Characteristics of Contact (Stylus) Instruments. International Organization for Standardization: Geneva, Switzerland, 2010.

- ISO 25178-2:2012; Geometric Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2012.

- Hagemeier, S.; Schake, M.; Lehmann, P. Sensor characterization by comparative measurements using a multi-sensor measuring system. J. Sens. Sens. Syst. 2019, 8, 111–121. [Google Scholar] [CrossRef]

- Hagemeier, S. Comparison and Investigation of Various Topography Sensors Using a Multisensor Measuring System. Ph.D. Thesis, University of Kassel, Kassel, Germany, 2022. [Google Scholar]

| Optical Components | Specification |

|---|---|

| Coaxial illumination | Single high-power green LED (λ = 520 nm, Pmax = 126 mW); |

| Ring light | Custom-built dome-shaped; |

| approx. 100 red LEDs (λ = 623 nm) arranged in three rings; | |

| Working distance | approx. 19 mm; |

| Objective lens | Magnification: 10; Numerical aperture (NA): 0.45; |

| Camera | ALLIED VISION GF146B ASG Guppy CCD camera (Allied Vision, Stadtroda, Germany); IEEE 1394a interface; |

| 1280 × 960 pixels with a field of view (FOV) of approx. 583 µm × 438 µm; | |

| Depth of field | 5.2 µm (for 520 nm, calculated using ); |

| Lateral resolution | 0.58 µm (for 520 nm, calculated using ); |

| (a) | (b) | (c) | (d) | |

|---|---|---|---|---|

| (µm) | 45.3 | 57.2 | 44.9 | 59.3 |

| (µm) | 452 | 543 | 339 | 413 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Pahl, T.; Hagemeier, S.; Lehmann, P. Adaptive Threshold Algorithm for Outlier Elimination in 3D Topography Data of Metal Additive Manufactured Surfaces Obtained from Focus Variation Microscopy. Photonics 2024, 11, 1011. https://doi.org/10.3390/photonics11111011

Xu X, Pahl T, Hagemeier S, Lehmann P. Adaptive Threshold Algorithm for Outlier Elimination in 3D Topography Data of Metal Additive Manufactured Surfaces Obtained from Focus Variation Microscopy. Photonics. 2024; 11(11):1011. https://doi.org/10.3390/photonics11111011

Chicago/Turabian StyleXu, Xin, Tobias Pahl, Sebastian Hagemeier, and Peter Lehmann. 2024. "Adaptive Threshold Algorithm for Outlier Elimination in 3D Topography Data of Metal Additive Manufactured Surfaces Obtained from Focus Variation Microscopy" Photonics 11, no. 11: 1011. https://doi.org/10.3390/photonics11111011

APA StyleXu, X., Pahl, T., Hagemeier, S., & Lehmann, P. (2024). Adaptive Threshold Algorithm for Outlier Elimination in 3D Topography Data of Metal Additive Manufactured Surfaces Obtained from Focus Variation Microscopy. Photonics, 11(11), 1011. https://doi.org/10.3390/photonics11111011