Structure Design of UVA VCSEL for High Wall Plug Efficiency and Low Threshold Current

Abstract

1. Introduction

2. Device Structure and Simulation Method

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hjort, F.; Enslin, J.; Cobet, M.; Bergmann, M.A.; Gustavsson, J.; Kolbe, T.; Knauer, A.; Nippert, F.; Hausler, I.; Wagner, M.R.; et al. A 310 nm Optically Pumped AlGaN Vertical-Cavity Surface-Emitting Laser. ACS Photonics 2021, 8, 135–141. [Google Scholar] [CrossRef] [PubMed]

- Kearns, J.A.; Hamaguchi, T.; Hayashi, K.; Ohara, M.; Makino, T.; Ito, M.; Kobayashi, N.; Jyoukawa, T.; Nakayama, E.; Nagane, S.; et al. Longitudinal mode control in long cavity VCSELs with a curved mirror. Appl. Phys. Express. 2022, 15, 072009. [Google Scholar] [CrossRef]

- Cardinali, G.; Hjort, F.; Prokop, N.; Enslin, J.; Cobet, M.; Bergmann, M.A.; Gustavsson, J.; Ciers, J.; Hausler, I.; Kolbe, T.; et al. Low-threshold AlGaN-based UVB VCSELs enabled by post-growth cavity detuning. Appl. Phys. Lett. 2022, 121, 103501. [Google Scholar] [CrossRef]

- Khan, M.A.; Maeda, N.; Jo, M.; Akamatsu, Y.; Tanabe, R.; Yamada, Y.; Hirayama, H. 13 mW operation of a 295-310 nm AlGaN UVB LED with a p-AlGaN transparent contact layer for real world applications. J. Mater. Chem. C 2019, 7, 143–152. [Google Scholar] [CrossRef]

- Lu, T.C.; Chen, J.R.; Chen, S.W.; Kuo, H.-C.; Kuo, C.-C.; Lee, C.-C.; Wang, S.-C. Development of GaN-based vertical-cavity surface-emitting lasers. IEEE J. Sel. Top. Quant. 2009, 15, 850–860. [Google Scholar]

- Redwing, J.M.; Loeber, D.A.S.; Anderson, N.G.; Tischler, M.A.; Flynn, J.S. An optically pumped GaN-AlGaN vertical cavity surface emitting laser. Appl. Phys. Lett. 1996, 69, 1–3. [Google Scholar] [CrossRef]

- Someya, T.; Werner, R.; Forchel, A.; Catalano, M.; Cingolani, R.; Arakawa, Y. Room Temperature Lasing at Blue Wavelengths in Gailium Nitride Microcavities. Science 1999, 285, 1905–1906. [Google Scholar] [CrossRef]

- Zhou, H.L.; Diagne, M.; Makarona, E.; Nurmikko, A.V.; Han, J.; Waldrip, K.E.; Figiel, J.J. A Near ultraviolet optically pumped vertical cavity laser. Electron. Lett. 2000, 36, 1777–1779. [Google Scholar] [CrossRef]

- Lu, T.C.; Chen, S.W.; Wu, T.T.; Tu, P.M.; Chen, C.K.; Chen, C.H.; Li, Z.Y.; Kuo, H.C.; Wang, S.C. Continuous wave operation of current injected GaN vertical cavity surface emitting lasers at room temperature. Appl. Phys. Lett. 2010, 97, 071114. [Google Scholar] [CrossRef]

- Chen, R.; Sun, H.D.; Wang, T.; Hui, K.N.; Choi, H.W. Optically pumped ultraviolet lasing from nitride nanopillars at room temperature. Appl. Phys. Lett. 2010, 96, 241101. [Google Scholar] [CrossRef]

- Liu, Y.S.; Haq, A.F.M.S.; Mehta, K.; Kao, T.T.; Wang, S.; Xie, H.; Shen, S.C.; Yoder, P.D.; Ponce, F.A.; Detchprohm, T.; et al. Optically pumped vertical-cavity surface-emitting laser at 374.9 nm with an electrically conducting n-type distributed Bragg reflector. Appl. Phys. Express 2016, 9, 111002. [Google Scholar] [CrossRef]

- Wang, Y.K.; Zheng, Z.M.; Long, H.; Mei, Y.; Zhang, B.P. Development and Challenges of Nitride Vertical-cavity Surface-emitting Lasers (Invited). Acta Photonica Sinica 2022, 51, 0251203. [Google Scholar]

- Detchprohm, T.; Li, X.; Shen, S.C.; Yoder, P.D.; Dupuis, R.D. III-N Wide Bandgap Deep-Ultraviolet Lasers and Photodetectors; Elsevier: Amsterdam, The Netherlands, 2017; pp. 121–166. [Google Scholar]

- Hamaguchi, T.; Nakajima, H.; Fuutagawa, N. GaN-based Vertical-Cavity Surface-Emitting Lasers Incorporating Dielectric Distributed Bragg Reflectors. Appl. Sci. 2019, 9, 733. [Google Scholar] [CrossRef]

- Matsui, K.; Kozuka, Y.; Ikeyama, K.; Horikawa, K.; Furuta, T.; Akagi, T.; Takeuchi, T.; Kamiyama, S.; Iwaya, M.; Akasaki, I. GaN-based vertical cavity surface emitting lasers with periodic gain structures. Jpn. J. Appl. Phys. 2016, 55, 05FJ08. [Google Scholar] [CrossRef]

- Zhou, M.; Zhao, D.G. Barrier and well thickness designing of InGaN/GaN multiple quantum well for better performances of GaN based laser diode. Acta Phys. Sin. 2016, 65, 077802. [Google Scholar] [CrossRef]

- Meel, K.; Mahala, P.; Singh, S. Design and Fabrication of Multi Quantum well based GaN/InGaN Blue LED. IOP Conf. Ser. Mater. Sci. Eng. 2018, 331, 012008. [Google Scholar] [CrossRef]

- Lai, F.; Lin, L.; Gai, R.; Lin, Y.Z.; Huang, Z.G. Determination of optical constants and thicknesses of In2O3:Sn films from transmittance data. Thin Solid Films. 2007, 515, 7387–7392. [Google Scholar] [CrossRef]

- Konig, T.A.F.; Ledin, P.A.; Kerszulis, J.; Mahmoud, M.A.; Ei-Sayed, M.A.; Reynolds, J.R.; Tsukruk, V.V. Electrically Tunable Plasmonic Behavior of Nanocube Polymer Nanomaterials Induced by a Redox Active Electrochromic Polymer. ACS Nano 2014, 8, 6182–6192. [Google Scholar] [CrossRef]

- Wu, H.C.; Li, H.; Kuo, S.Y.; Chen, B.Y.; Lu, T.C.; Huang, H.M. High Output Power GaN-Based Green Resonant-Cavity Light-Emitting Diodes with Trapezoidal Quantum Wells. IEEE Trans. Electron Dev. 2020, 67, 3650–3654. [Google Scholar] [CrossRef]

- Yu, C.T.; Lai, W.C.; Yen, C.H.; Chang, S.J. Effects of InGaN layer thickness of AlGaN/InGaN superlattice electron blocking layer on the overall efficiency and efficiency droops of GaN-based light emitting diodes. Opt. Express 2014, 22 (Suppl. 3), A663–A670. [Google Scholar] [CrossRef]

- Wang, C.H.; Ke, C.C.; Lee, C.Y.; Chang, W.T.; Li, J.C.; Li, Z.Y.; Yang, H.C.; Kuo, H.C.; Lu, T.C.; Wang, S.C. Hole injection and efficiency droop improvement in InGaN/GaN light-emitting diodes by band-engineered electron blocking layer. Appl. Phys. Lett. 2010, 97, 261103. [Google Scholar] [CrossRef]

- Chung, R.B.; Han, C.; Pan, C.C.; Pfaff, N.; Speck, J.S.; DenBaars, S.P.; Nakamura, S. The reduction of efficiency droop by Al0.82In0.18N/GaN superlattice electron blocking layer in (0001) oriented GaN-based light emitting diodes. Appl. Phys. Lett. 2012, 101, 131113. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Yin, Y.A. Performance enhancement of blue light-emitting diodes with a special designed AlGaN/GaN superlattice electron-blocking layer. Appl. Phys. Lett. 2011, 99, 221103. [Google Scholar] [CrossRef]

- Shen, C.C.; Hsu, T.C.; Yeh, Y.W.; Kang, C.Y.; Lu, Y.T.; Lin, H.W.; Tseng, H.Y.; Chen, C.Y.; Lin, C.C.; Wu, C.H.; et al. Design, Modeling, and Fabrication of High-Speed VCSEL with Data Rate up to 50 Gb/s. Nanoscale Res. Lett. 2019, 14, 276. [Google Scholar] [CrossRef] [PubMed]

- Shen, C.C.; Lu, Y.T.; Yeh, Y.W.; Chen, C.Y.; Chen, Y.T.; Sher, C.W.; Lee, P.T.; Shih, Y.H.; Lu, T.C.; Wu, T.Z.; et al. Design and Fabrication of the Reliable GaN Based Vertical-Cavity Surface-Emitting Laser via Tunnel Junction. Crystals 2019, 9, 187. [Google Scholar] [CrossRef]

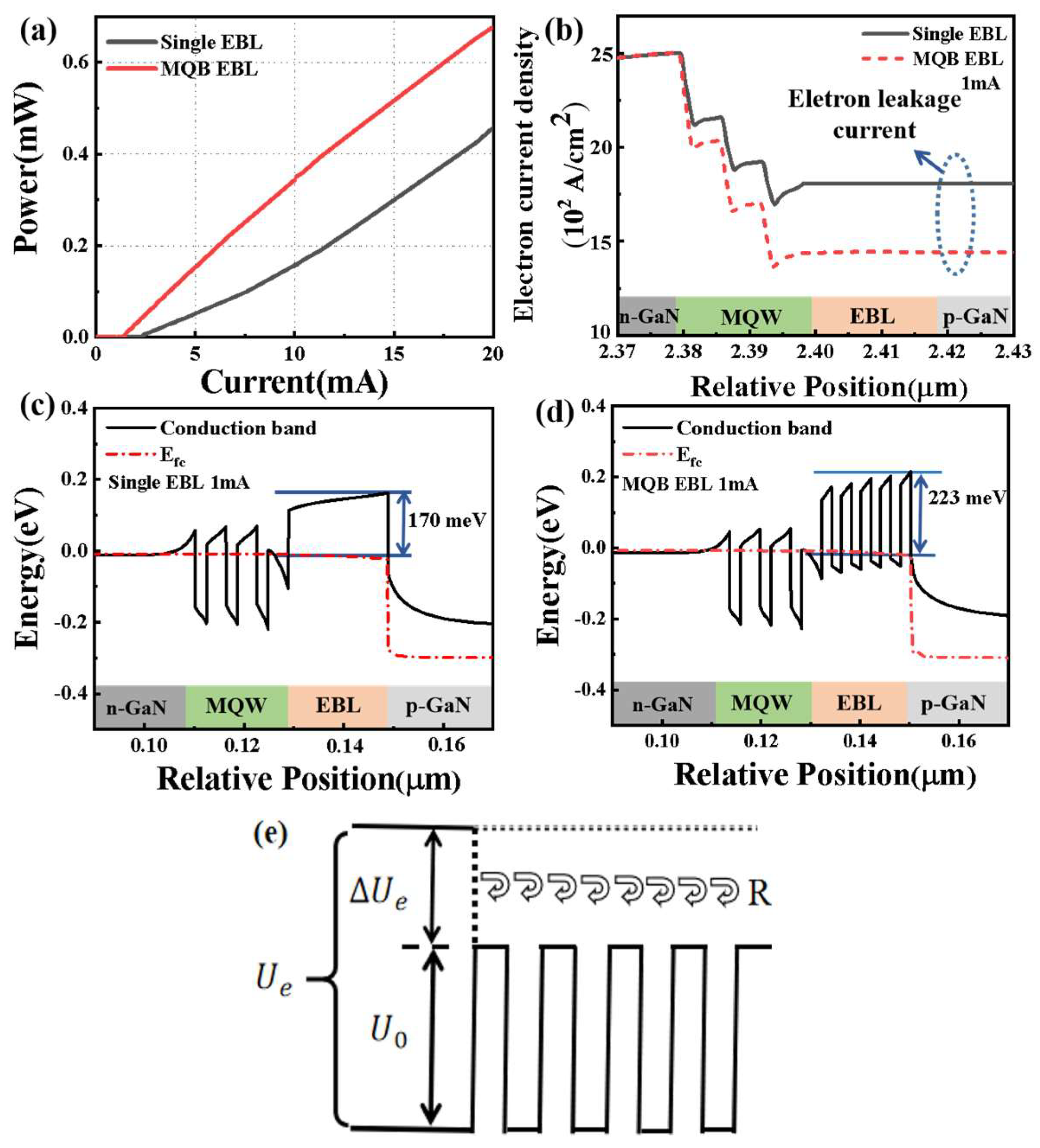

- Hsieh, D.H.; Tzou, A.J.; Kao, T.S.; Lai, F.I.; Lin, D.W.; Lu, T.C.; Lai, W.C.; Chen, C.H.; Kuo, H.C. Improved carrier injection in GaN-based VCSEL via AlGaN/GaN multiple quantum barrier electron blocking layer. Opt. Express. 2015, 23, 27145–27151. [Google Scholar] [CrossRef] [PubMed]

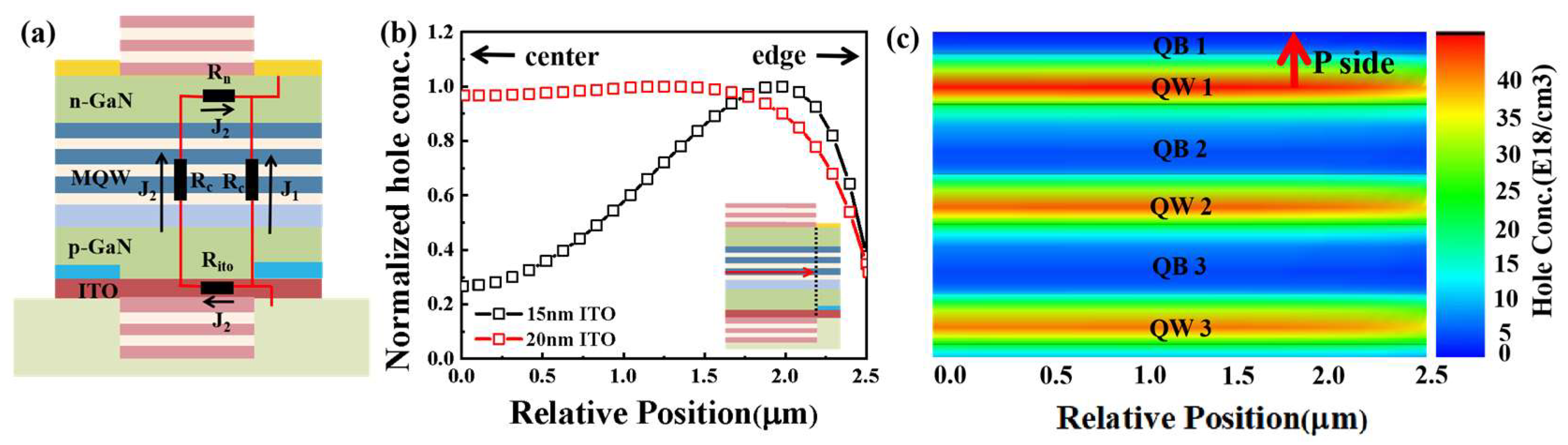

- Hang, S.; Zhang, Y.H.; Gao, Y.B.; Qiu, X.J.; Kou, J.Q.; Tian, K.K.; Zhang, Z.H. On the origin for the hole confinement into apertures for GaN-based VCSELs with buried dielectric insulators. Opt. Express. 2020, 28, 8668–8679. [Google Scholar] [CrossRef] [PubMed]

- Piprek, J. Efficiency droop in nitride-based light-emitting diodes. Phys. Status Solidi A 2010, 207, 2217–2225. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Tan, S.T.; Kyaw, Z.; Ji, Y.; Liu, W.; Ju, Z.G.; Hasanov, N.; Sun, X.W.; Demir, H.V. InGaN/GaN light-emitting diode with a polarization tunnel junction. Appl. Phys. Lett. 2013, 102, 193508. [Google Scholar] [CrossRef]

- Kuo, Y.K.; Liou, B.T.; Chen, M.L.; Yen, S.H.; Lin, C.Y. Effect of band-offset ratio on analysis of violet–blue InGaN laser characteristics. Opt. Commun. 2004, 231, 395–402. [Google Scholar] [CrossRef]

- Mnatsakanov, T.T.; Levinshtein, M.E.; Pomortseva, L.I.; Yurkov, S.N.; Simin, G.S.; Khan, M.A. Carrier mobility model for GaN. Solid State Electron. 2003, 47, 111–115. [Google Scholar] [CrossRef]

- Wang, Y.C.; Yang, T.; Shi, L.; Chen, Y.H.; Mei, Y.; Zhang, B.P. Simulation of performance enhancement of GaN-based VCSELs by composition gradient InGaN last-quantum barrier. Semicond. Sci. Tech. 2023, 38, 125003. [Google Scholar] [CrossRef]

- Kuramoto, M.; Kobayashi, S.; Akagi, T.; Tazawa, K.; Tanaka, K.; Saito, T.; Takeuchi, T. High-output-power and high-temperature operation of blue GaN-based vertical-cavity surface-emitting laser. Appl. Phys. Express. 2018, 11, 112101. [Google Scholar] [CrossRef]

- Chuang, C.M.; Cheng, Y.H.; Wu, Y.R. Electro-Optical Numerical Modeling for the Design of UVA Nitride-Based Vertical-Cavity Surface-Emitting Laser Diodes. IEEE J. Sel. Top. Quant. 2022, 28, 1–6. [Google Scholar] [CrossRef]

- Becerra, D.L.; Cohen, D.A.; Farrell, R.M.; DenBaars, S.P.; Nakamura, S. Effects of active region design on gain and carrier injection and transport of CW semipolar InGaN laser diodes. Appl. Phys. Express. 2016, 9, 092104. [Google Scholar] [CrossRef]

- Nakamura, S.; Senoh, M.; Nagahama, S.; Iwasa, N.; Matsushita, T.; Mukai, T. Blue InGaN-based laser diodes with an emission wavelength of 450 nm. Appl. Phys. Lett. 2000, 76, 22–24. [Google Scholar] [CrossRef]

- Takeuchi, T.; Wetzel, C.; Yamaguchi, S.; Sakai, H.; Amano, H.; Akasaki, I. Determination of piezoelectric fields in strained GaInN quantum wells using the quantum-confined Stark effect. Appl. Phys. Lett. 1998, 73, 1691–1693. [Google Scholar] [CrossRef]

- Nardelli, M.B.; Rapcewicz, K.; Bernholc, J. Polarization field effects on the electron-hole recombination dynamics in In0.2Ga0.8N/In1−xGaxN multiple quantum wells. Appl. Phys. Lett. 1997, 71, 3135–3137. [Google Scholar] [CrossRef]

- Xia, C.S.; Hu, W.D.; Wang, C.; Li, Z.F.; Chen, X.S.; Lu, W.; Simon Li, Z.M.; Li, Z.Q. Simulation of InGaN/GaN multiple quantum well light-emitting diodes with quantum dot model for electrical and optical effects. Opt. Quant. Electron. 2007, 38, 1077–1089. [Google Scholar] [CrossRef]

- Shi, W.; Huang, L.R.; Duan, Z.G.; Feng, Y.C. Non-Uniform Distribution of Injected Carriers in Multiple Quantum Wells. Acta Photonica Sin. 2005, 35, 1313–1316. [Google Scholar]

- Silfvenius, C.; Landgren, G.; Marcinkevicius, S. Hole Distribution in InGaAsP 1.3um Multiple-Quantum-Well Laser Structures with Different Hole Confinement Energies. IEEE J. Quantum Elect. 1999, 35, 603–607. [Google Scholar] [CrossRef]

- Kuo, Y.K.; Chang, Y.A. Effects of electronic current overflow and inhomogeneous carrier distribution on InGaN quantum-well laser performance. IEEE J. Quantum Elect. 2004, 40, 437–444. [Google Scholar]

- Chiang, J.L.; Li, S.W.; Yadlapalli, B.K.; Wuu, D.S. Deposition of high-transmittance ITO thin films on polycarbonate substrates for capacitive-touch applications. Vacuum 2021, 186, 110046. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, W.; Peng, M.; Dai, J.N.; Chen, C.G. Light-extraction enhancement of GaN-based 395 nm flip-chip light-emitting diodes by an Al-doped ITO transparent conductive electrode. Opt. Lett. 2018, 43, 2684–2687. [Google Scholar] [CrossRef] [PubMed]

- Mehta, K.; Liu, Y.S.; Wang, J.; Jeong, H.; Detchprohm, T.; Park, Y.J.; Alugubelli, S.R.; Wang, S.; Ponce, F.A.; Shen, S.C.; et al. Lateral Current Spreading in III-N Ultraviolet Vertical-Cavity Surface-Emitting Lasers Using Modulation-Doped Short Period Superlattices. IEEE J. Quantum Elect. 2018, 54, 1–7. [Google Scholar] [CrossRef]

- Zheng, Z.M.; Wang, Y.K.; Mei, Y.; Long, H.; Ying, L.Y.; Zheng, Z.W.; Zhang, B.P. Current spreading structure of GaN-based vertical-cavity surface-emitting lasers. Opt. Lett. 2023, 48, 5141–5144. [Google Scholar] [CrossRef]

- Takagi, T.; Koyama, F.; Iga, K. Design of Multiquantum Barrier (MQB) and Experimental Verification of Electron Wave Reflection by MQB. Electr. Commun. Jpn. 1992, 75, 527–535. [Google Scholar] [CrossRef]

- Bright, T.J.; Watjen, J.I.; Zhang, Z.M.; Muratore, C.; Voevodin, A.A. Optical properties of HfO2 thin films deposited by magnetron sputtering: From the visible to the far-infrared. Thin Solid Films 2012, 520, 6793–6802. [Google Scholar] [CrossRef]

| Type | Material | Thickness (nm) | Doping Concentration (cm−3) |

|---|---|---|---|

| Top DBRs | HfO2/SiO2 | (51/67) * 9 pairs | |

| n-GaN | GaN | 610 | n:5e18 |

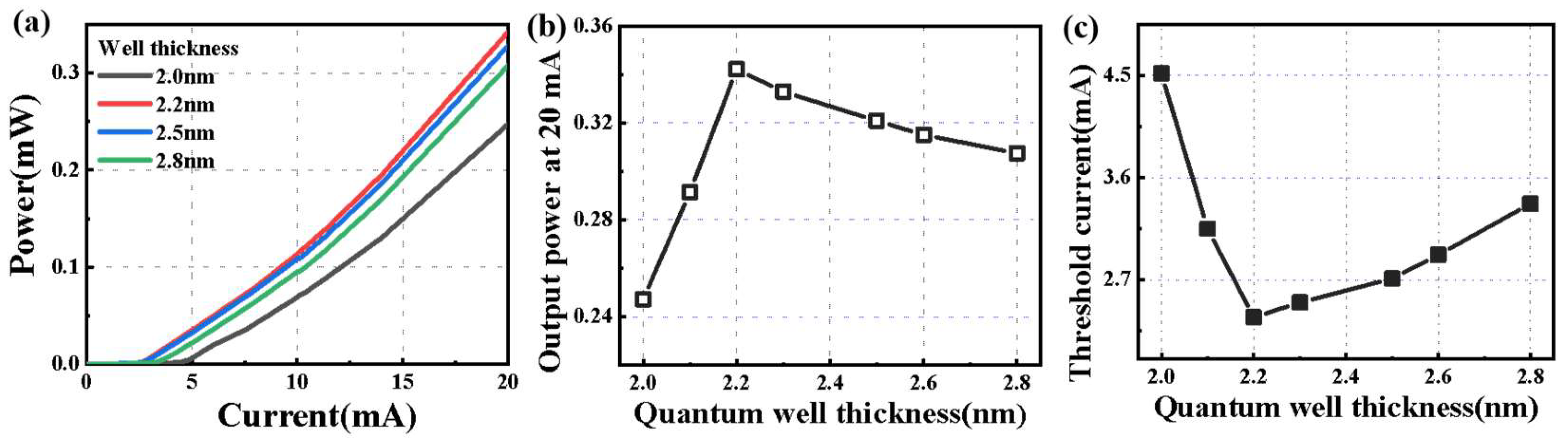

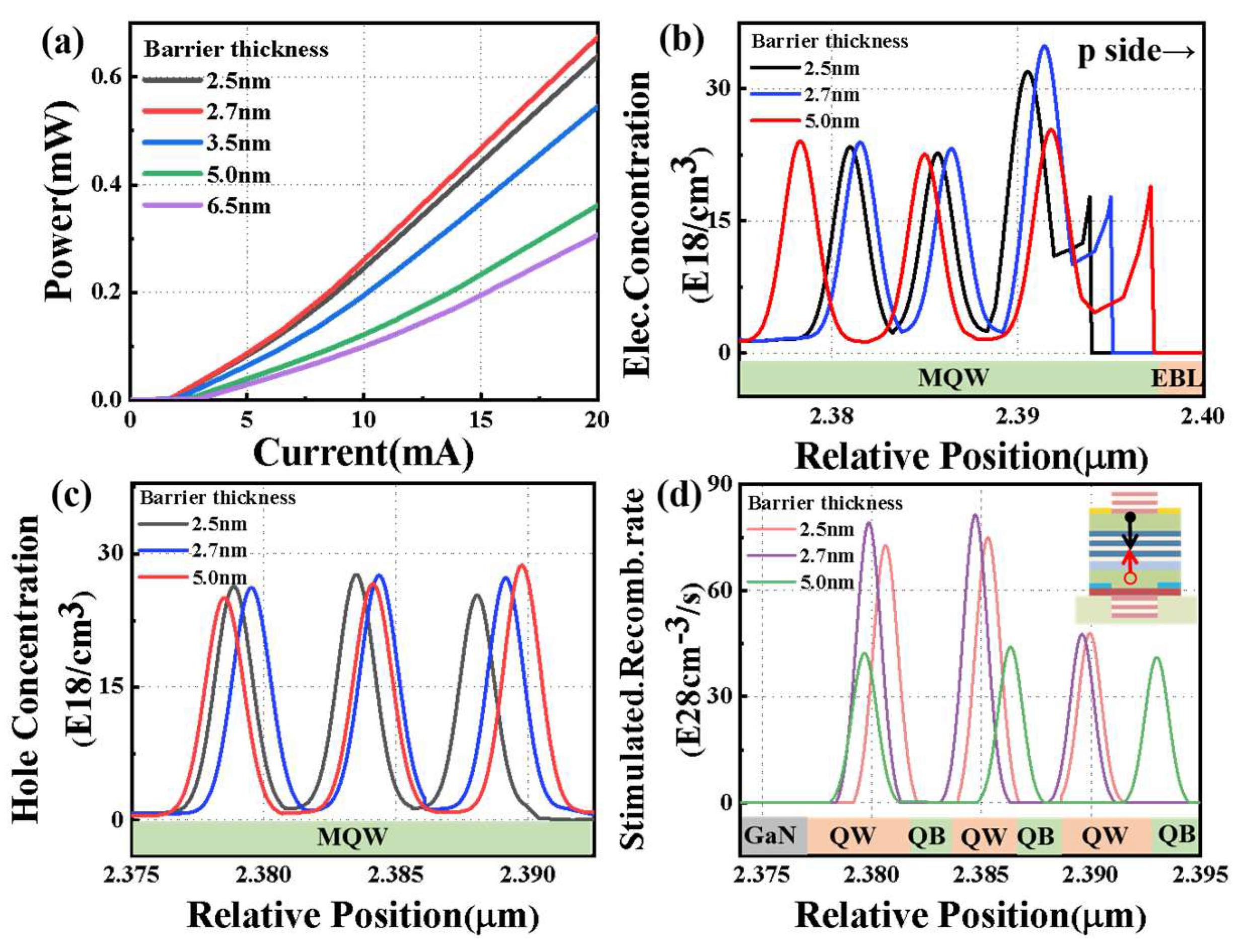

| MQW | In0.08Ga0.92N/GaN | (2.2/2.7) * 3 pairs | |

| EBL | Al0.2Ga0.8N | 20 | p:3e18 |

| p-GaN | GaN | 67 | p:3e18 |

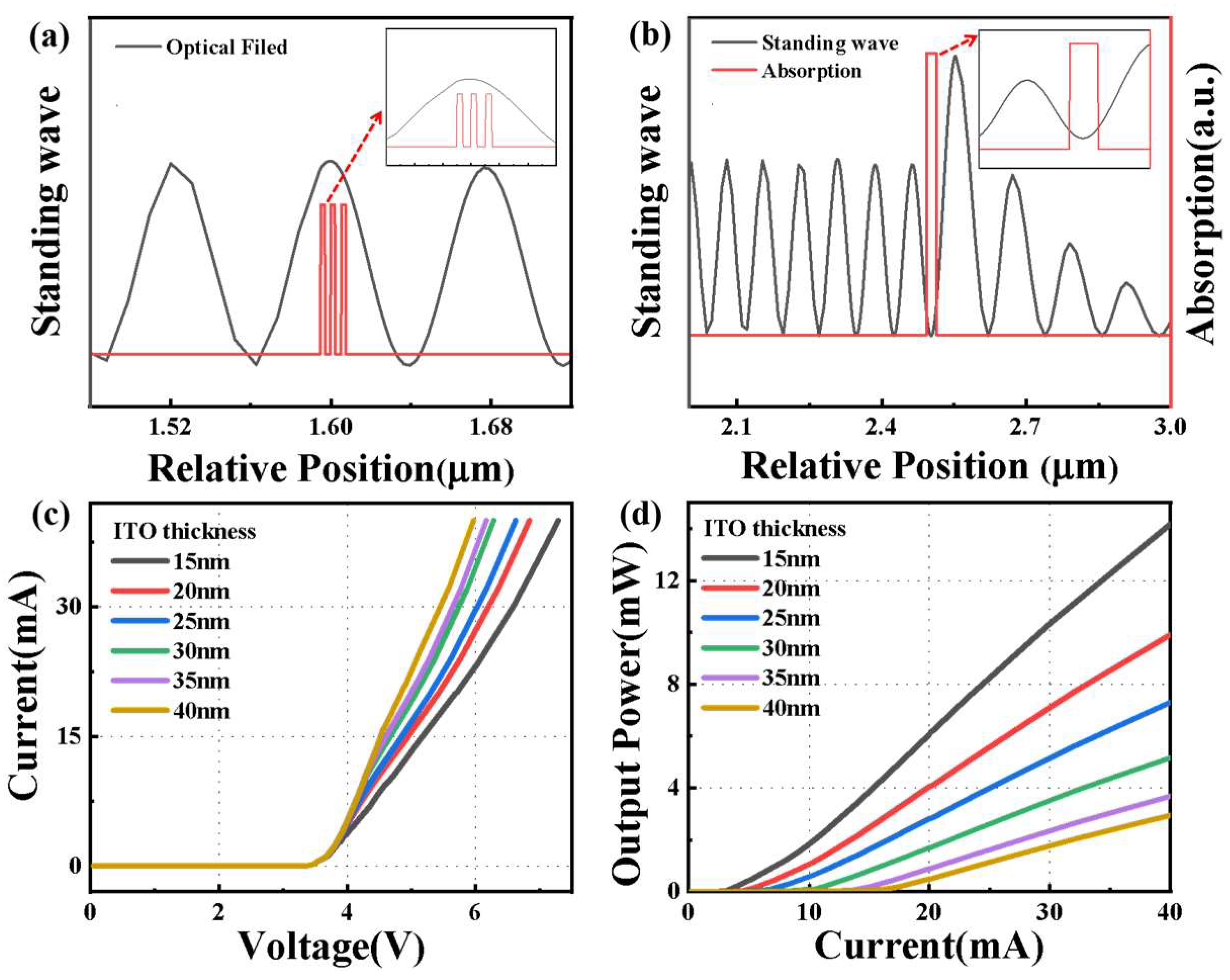

| Insulating layer | SiO2 | 10 | |

| Current spreading layer | ITO | 20 | |

| Bottom DBRs | HfO2/SiO2 | (51/67) * 18.5 pairs |

| Parameter | Value | Unit |

|---|---|---|

| Auger recombination coefficient | 1.4 × 10−31 | cm6/s |

| SRH recombination lifetime | 1.0 × 10−8 | s |

| The band offset ratio for MQW | 70:30 | — |

| The band offset ratio for AlGaN/GaN interface | 50:50 | — |

| Polarization ratio | 40% | — |

| Electron mobility | 100 | |

| Hole mobility | 10 | |

| Absorption coefficient of ITO | 4000 | cm−1 |

| Average optical background loss | 10 | cm−1 |

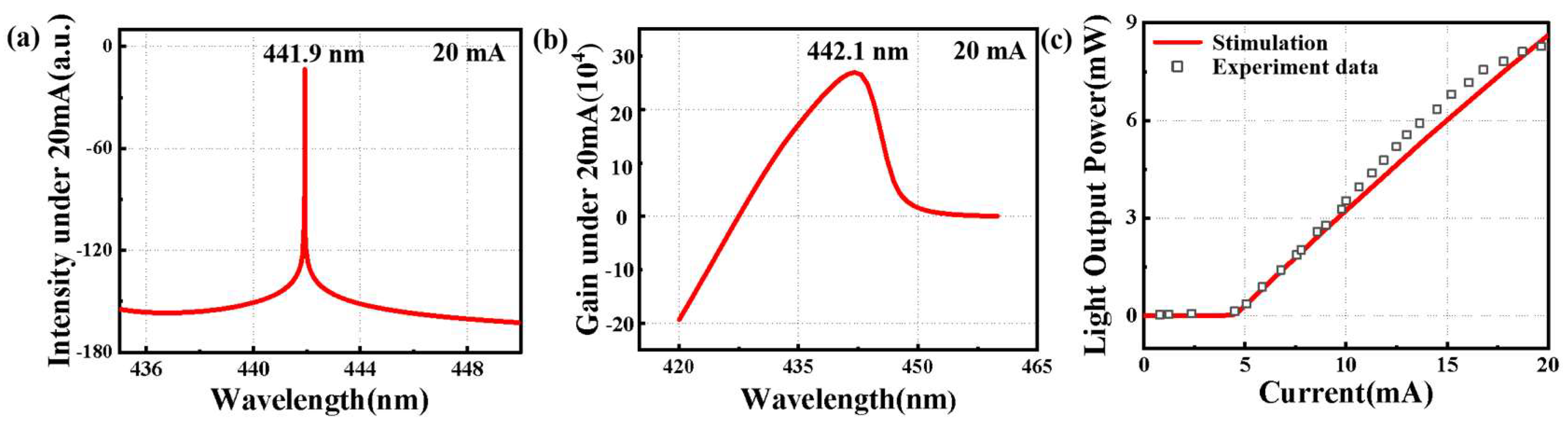

| Material | Simulation | Experiment (Ref. [34]) | |

|---|---|---|---|

| Top DBRs | AlInN/GaN | 42 pairs | 42 pairs |

| n-GaN | GaN | 680 nm | 660 nm |

| MQW | InGaN/GaN | 39 nm | 39 nm |

| EBL | p-AlGaN | 20 nm | 20 nm |

| p-GaN | GaN | 84 nm | not mentioned |

| Insulating layer | SiO2 | 20 nm | 20 nm |

| Current spreading layer | ITO | 20 nm | 20 nm |

| Bottom DBRs | SiO2/Nb2O5 | 10.5 pairs | 10.5 pairs |

| Wavelength (nm) | Threshold | LOP at 5 mA(mW) | LOP at 10 mA(mW) | LOP at 18 mA(mW) | Wall Plug Efficiency(%) | Ref. |

|---|---|---|---|---|---|---|

| 410 | 8.5 kA/cm2 | — | 2.1 | — | 2.1 at 10 mA | [26] |

| 412 | 10.6 kA/cm2 | — | — | 0.9 | 0.53 at 23 kA/cm2 | [27] |

| 370 | 370 | 0.7 | — | — | 2.8 at 5 mA | [46] |

| 395 | 6.06 kA/cm2 (1.19 mA) | 0.45 | 1.66 | 5.3 | 5.0 at 20 mA | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, B.; Wang, Y.; Wang, Y.; Zou, Z.; Mei, Y.; Long, H.; Zheng, Z.; Zhang, B. Structure Design of UVA VCSEL for High Wall Plug Efficiency and Low Threshold Current. Photonics 2024, 11, 1012. https://doi.org/10.3390/photonics11111012

An B, Wang Y, Wang Y, Zou Z, Mei Y, Long H, Zheng Z, Zhang B. Structure Design of UVA VCSEL for High Wall Plug Efficiency and Low Threshold Current. Photonics. 2024; 11(11):1012. https://doi.org/10.3390/photonics11111012

Chicago/Turabian StyleAn, Bing, Yukun Wang, Yachao Wang, Zhijie Zou, Yang Mei, Hao Long, Zhiwei Zheng, and Baoping Zhang. 2024. "Structure Design of UVA VCSEL for High Wall Plug Efficiency and Low Threshold Current" Photonics 11, no. 11: 1012. https://doi.org/10.3390/photonics11111012

APA StyleAn, B., Wang, Y., Wang, Y., Zou, Z., Mei, Y., Long, H., Zheng, Z., & Zhang, B. (2024). Structure Design of UVA VCSEL for High Wall Plug Efficiency and Low Threshold Current. Photonics, 11(11), 1012. https://doi.org/10.3390/photonics11111012