Direct Laser Writing of Diffractive Structures on Bi-Layer Si/Ti Films Coated on Fused Silica Substrates

Abstract

1. Introduction

2. Materials and Methods

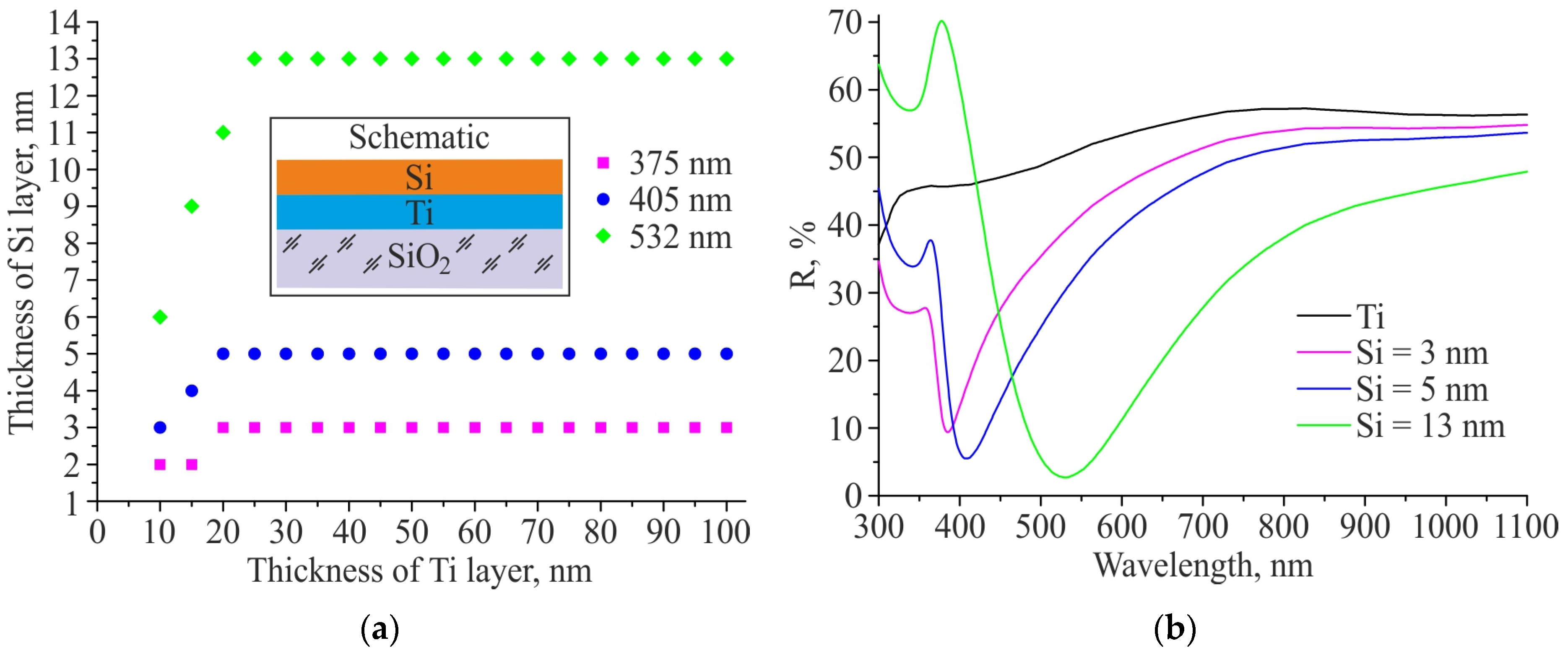

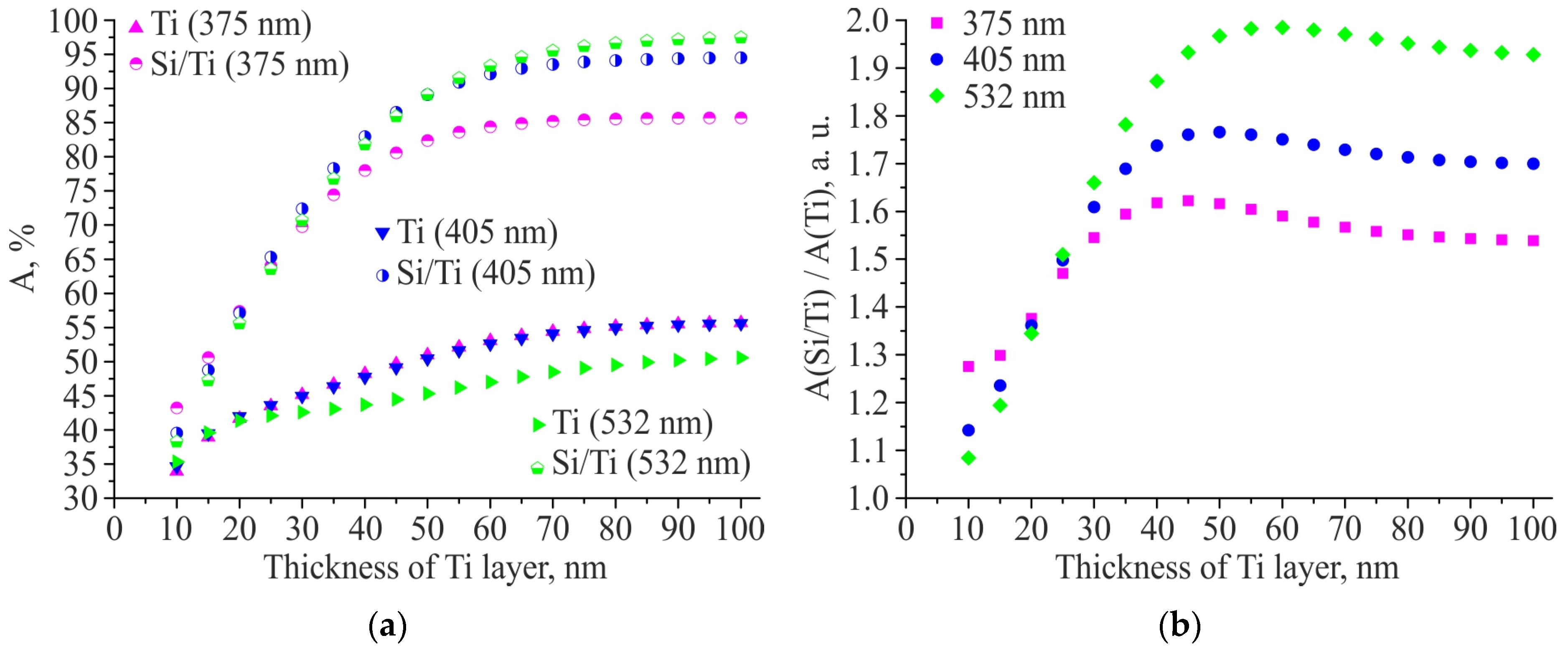

2.1. Theoretical Evaluation of the Parameters and Characteristics of Bi-Layer Si/Ti Films

2.2. Deposition of Ti and Si/Ti Films

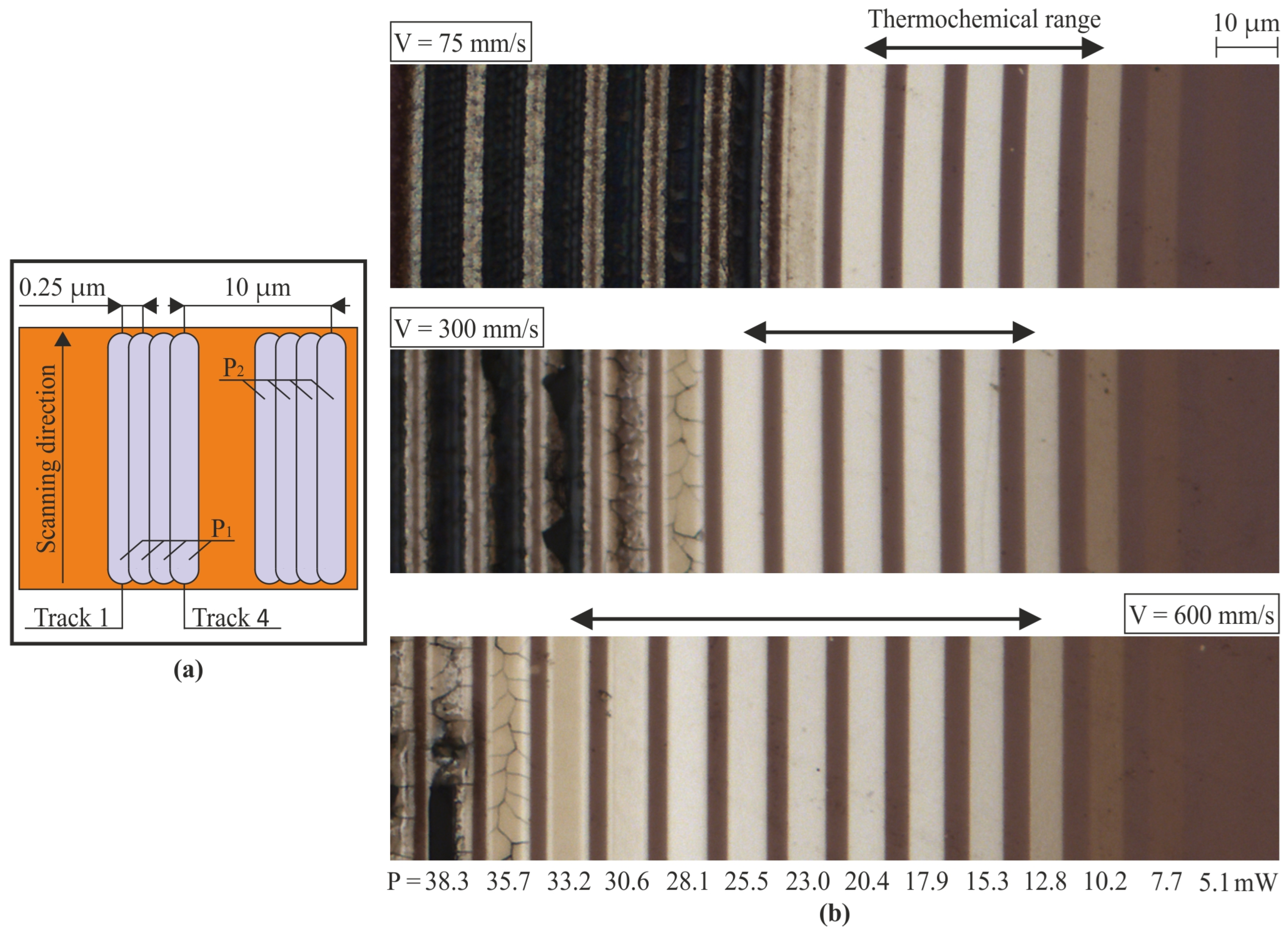

2.3. Formation Test Structures on a Circular Laser Writing System

2.4. Analysis of Structure and Topography of the Films

3. Results

3.1. Optimization of Layer Thicknesses and Experimental Verification

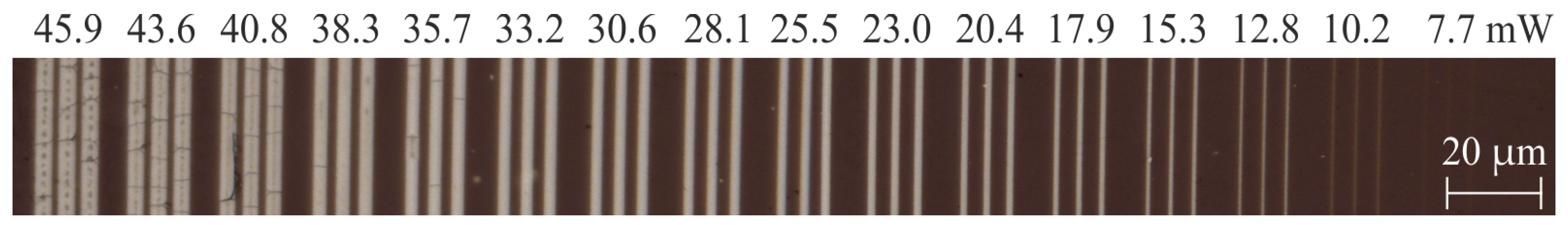

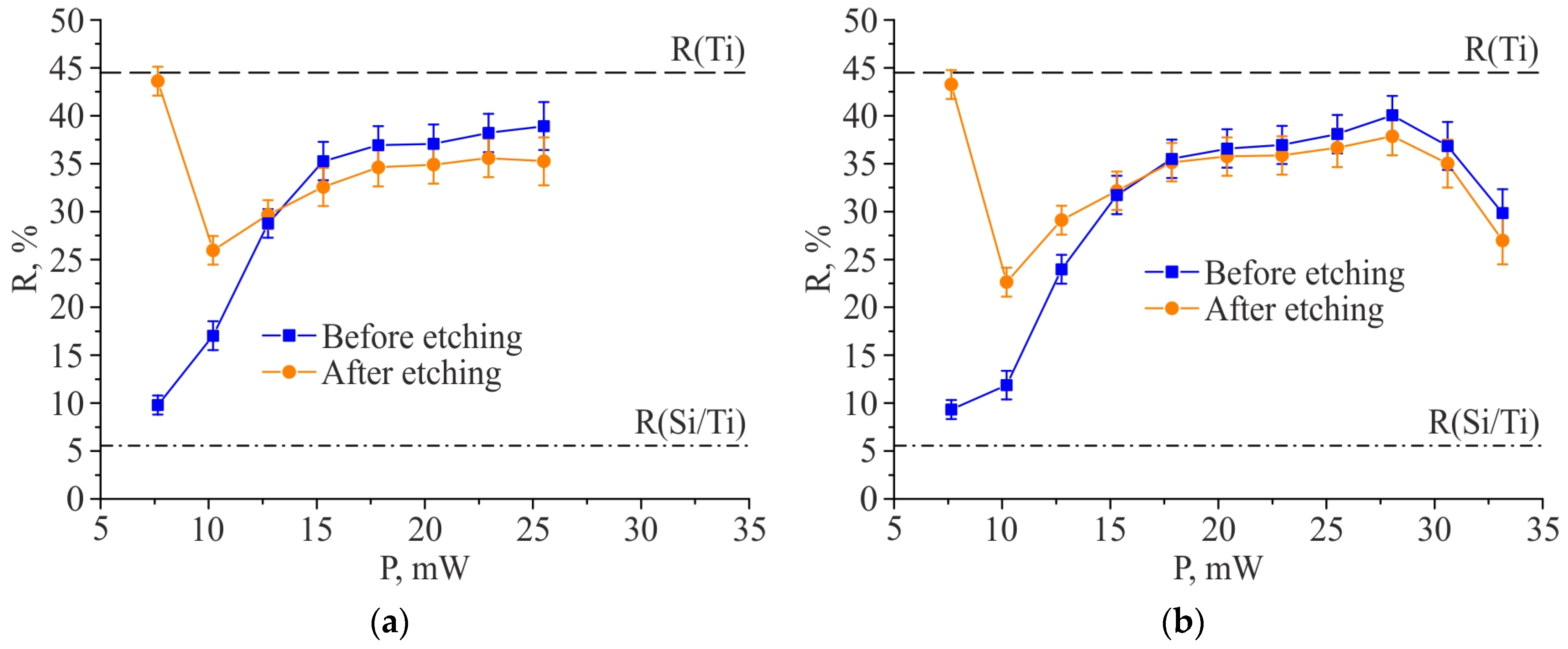

3.2. Direct Laser Writing on Bi-Layer Si/Ti Films

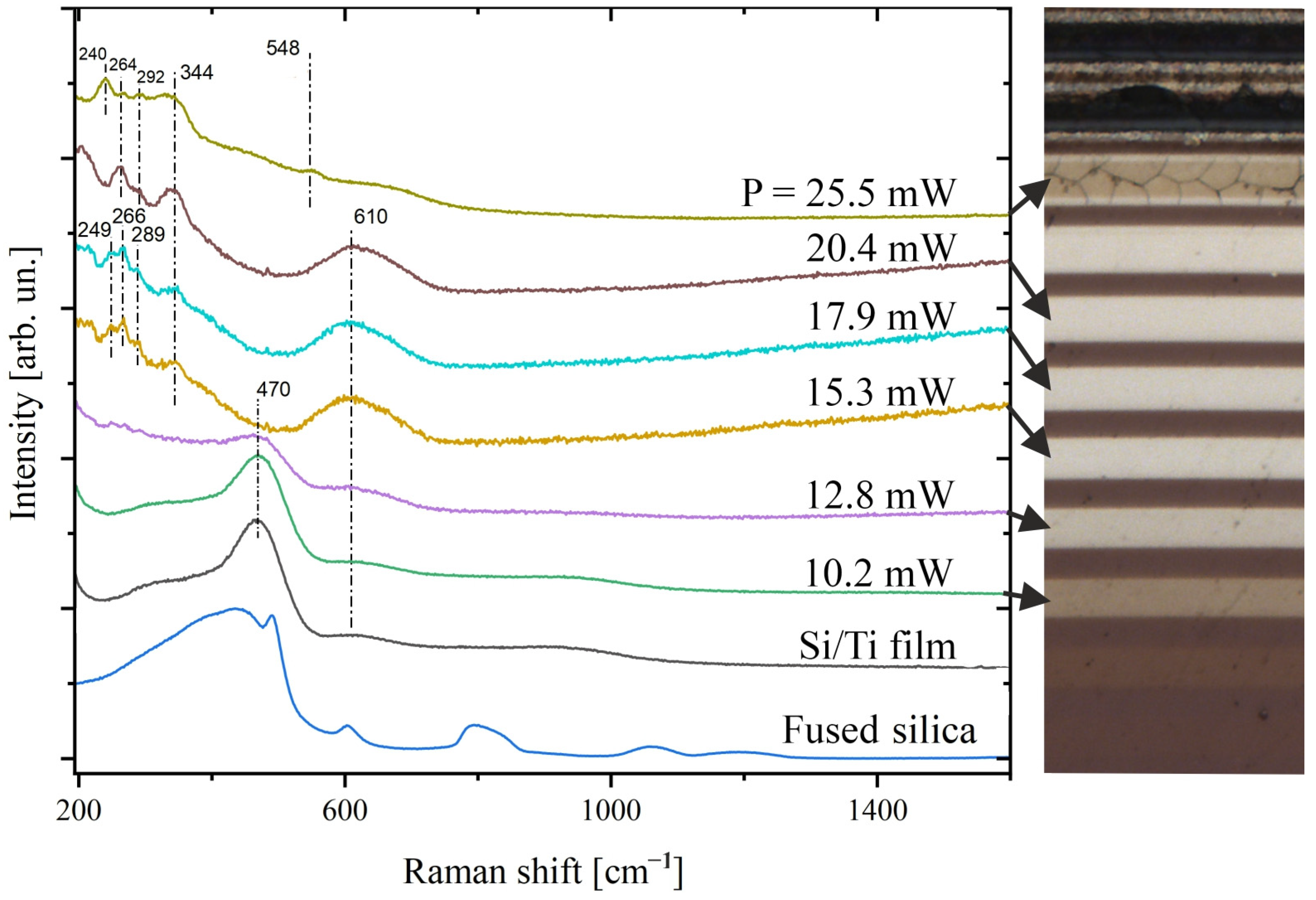

3.3. Raman Spectra Analysis

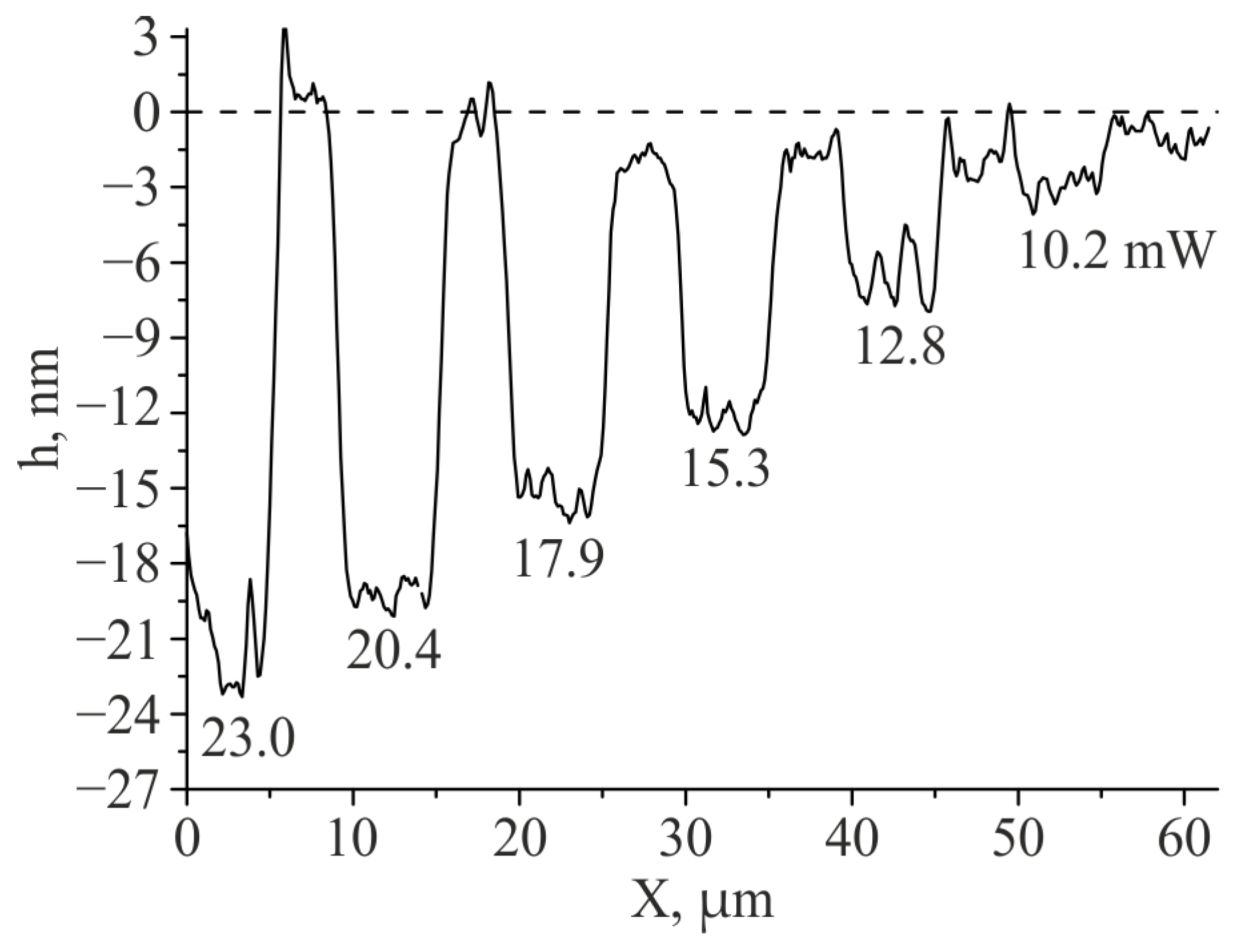

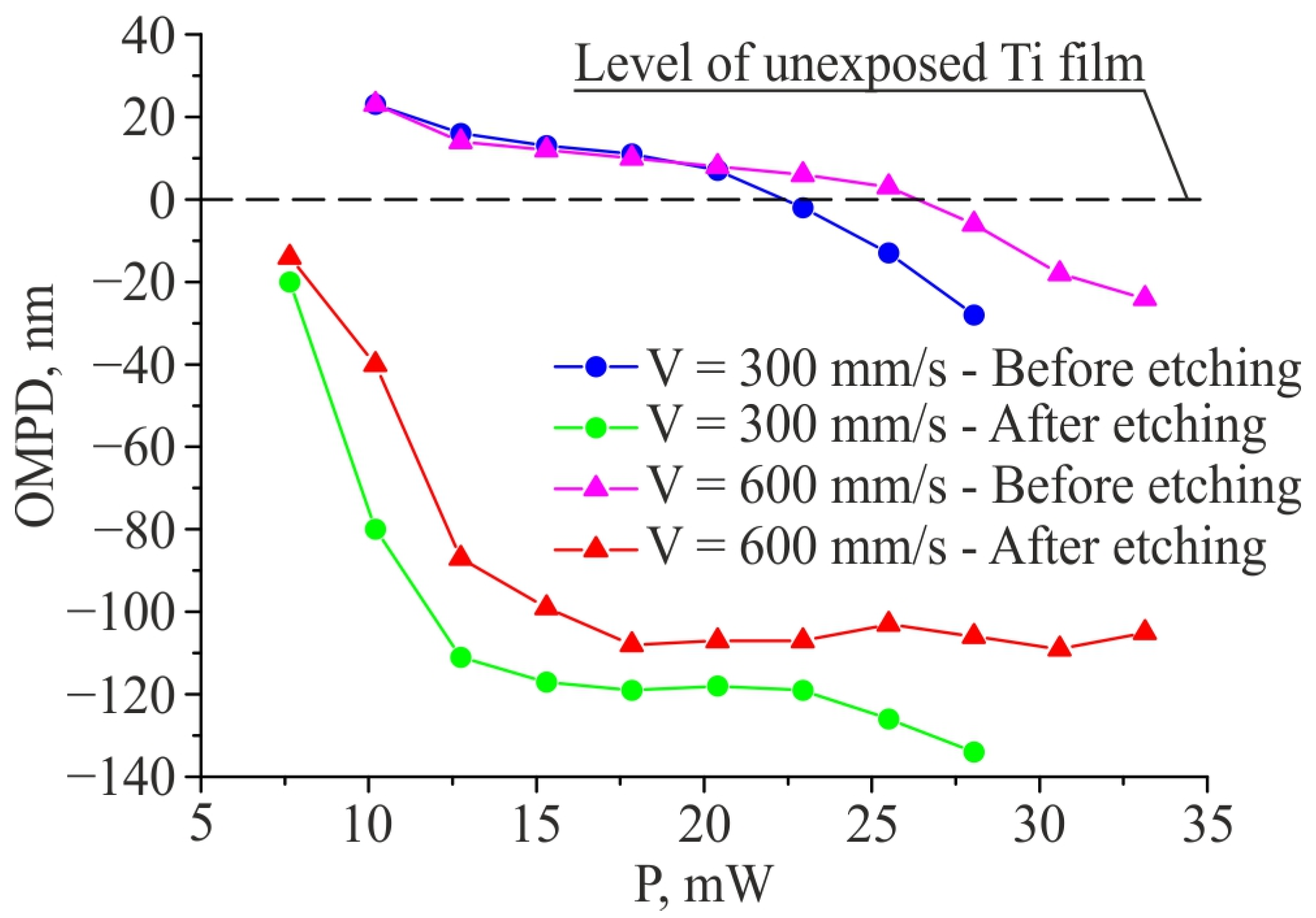

3.4. Measurement of Profile Depth

3.5. Etching the Capping Si Layer from the Structures Formed on the Si/Ti Film

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- d’Auria, L.; Huignard, J.P.; Roy, A.M.; Spitz, E. Photolithographic fabrication of thin film lenses. Opt. Commun. 1972, 5, 232–235. [Google Scholar] [CrossRef]

- Gale, M.T.; Rossi, M.; Pedersen, J.; Schuetz, H. Fabrication of continuous-relief micro-optical elements by direct laser writing in photoresists. Opt. Eng. 1994, 33, 3556–3566. [Google Scholar] [CrossRef]

- Sohn, J.S.; Lee, M.B.; Kim, W.C.; Cho, E.H.; Kim, T.W.; Yoon, C.Y.; Park, N.C.; Park, Y.P. Design and fabrication of diffractive optical elements by use of gray-scale photolithography. Appl. Opt. 2005, 44, 506–511. [Google Scholar] [CrossRef] [PubMed]

- Veiko, V.P.; Korolkov, V.P.; Poleshchuk, A.G.; Sinev, D.A.; Shakhno, E.A. Laser technologies in micro-optics. Part 1. Fabrication of diffractive optical elements and photomasks with amplitude transmission. Optoelectron. Instrum. Data Process. 2017, 53, 474–483. [Google Scholar] [CrossRef]

- Korolkov, V.P.; Nasyrov, R.K.; Khomutov, V.N.; Belousov, D.A.; Kutz, R.I. Development of methods for the formation and control of a given distribution of the photoresist thickness for conformal correctors fabrication. In Optical Design and Testing XI; SPIE: Bellingham, WA, USA, 2021; Volume 11895, p. 118951J. [Google Scholar]

- Poleshchuk, A.G.; Kutanov, A.A.; Bessmeltsev, V.P.; Korolkov, V.P.; Shimanskii, R.V.; Malyshev, A.I.; Matochkin, A.E.; Goloshevskii, N.V.; Makarov, K.V.; Makarov, V.P.; et al. Microstructuring of optical surfaces: Technology and device for direct laser writing of diffractive structures. Optoelectron. Instrum. Data Process. 2010, 46, 171–180. [Google Scholar] [CrossRef]

- Veiko, V.; Yarchuk, M.; Zakoldaev, R.; Gedvilas, M.; Račiukaitis, G.; Kuzivanov, M.; Baranov, A. Picosecond laser registration of interference pattern by oxidation of thin Cr films. Appl. Surf. Sci. 2017, 404, 63–66. [Google Scholar] [CrossRef]

- Clark, P.P.; Londono, C. Production of kinoforms by single point diamond machining. Opt. News 1989, 15, 39–40. [Google Scholar] [CrossRef]

- Saastamoinen, T.; Väyrynen, J.; Mutanen, J.; Tuovinen, H.; Eronen, A.; Mönkkönen, K.; Kuittinen, M. Fabrication of hybrid optical line generator by direct machining. Opt. Express. 2018, 26, 2335–2340. [Google Scholar] [CrossRef]

- Fang, F.Z.; Zhang, X.D.; Weckenmann, A.; Zhang, G.X.; Evans, C. Manufacturing and measurement of freeform optics. CIRP Ann. Manuf. Technol. 2013, 62, 823–846. [Google Scholar] [CrossRef]

- Koronkevich, V.P.; Poleshchuk, A.G.; Churin, E.G.; Yurlov, Y.I. Laser thermochemical technology for synthesizing optical diffraction elements utilizing chromium films. Sov. J. Quantum Electron. 1985, 15, 494. [Google Scholar] [CrossRef]

- Veiko, V.P.; Sinev, D.A.; Shakhno, E.A.; Poleshchuk, A.G.; Sametov, A.R.; Sedukhin, A.G. Researching the features of multibeam laser thermochemical recording of diffractive microstructures. Comput. Opt. 2012, 36, 562–571. [Google Scholar]

- Poleshchuk, A.G.; Churin, E.G.; Koronkevich, V.P.; Korolkov, V.P.; Kharissov, A.A.; Cherkashin, V.V.; Kiryanov, V.P.; Kiryanov, A.V.; Kokarev, S.A.; Verhoglyad, A.G. Polar coordinate laser pattern generator for fabrication of diffractive optical elements with arbitrary structure. Appl. Opt. 1999, 38, 1295–1301. [Google Scholar] [CrossRef] [PubMed]

- Korolkov, V.P.; Sedukhin, A.G.; Mikerin, S.L. Technological and optical methods for increasing the spatial resolution of thermochemical laser writing on thin metal films. Opt. Quantum Electron. 2019, 51, 389. [Google Scholar] [CrossRef]

- Gorbunov, A.A.; Eichler, H.; Pompe, W.; Huey, B. Lateral self-limitation in the laser-induced oxidation of ultrathin metal films. Appl. Phys. Lett. 1996, 69, 2816–2818. [Google Scholar] [CrossRef]

- Wang, Y.; Miao, J.; Tian, Y.; Guo, C.; Zhang, J.; Ren, T.; Liu, Q. TiO2 micro-devices fabricated by laser direct writing. Opt. Express. 2011, 19, 17390–17395. [Google Scholar] [CrossRef] [PubMed]

- Shakhno, E.A.; Sinev, D.A.; Kulazhkin, A.M. Features of laser oxidation of thin films of titanium. J. Opt. Technol. 2014, 81, 298–302. [Google Scholar] [CrossRef]

- Xia, F.; Jiao, L.; Wu, D.; Li, S.; Zhang, K.; Kong, W.; Yun, M.; Liu, Q.; Zhang, X. Mechanism of pulsed-laser-induced oxidation of titanium films. Opt. Mater. Express. 2019, 9, 4097–4103. [Google Scholar] [CrossRef]

- Korolkov, V.P.; Nasyrov, R.K.; Sametov, A.R.; Malyshev, A.I.; Belousov, D.A.; Mikerin, S.L.; Kuts, R.I. Direct laser writing of high-NA computer-generated holograms on metal films of the titanium group and chromium. In Holography, Diffractive Optics, and Applications IX; SPIE: Bellingham, WA, USA, 2019; Volume 11188, p. 111880R. [Google Scholar]

- Korolkov, V.P.; Sedukhin, A.G.; Belousov, D.A.; Shimansky, R.V.; Khomutov, V.N.; Mikerin, S.L.; Spesivtsev, E.V.; Kutz, R.I. Increasing the spatial resolution of direct laser writing of diffractive structures on thin films of titanium group metals. In Holography: Advances and Modern Trends VI; SPIE: Bellingham, WA, USA, 2019; Volume 11030, p. 110300A. [Google Scholar]

- Belousov, D.A.; Bronnikov, K.A.; Okotrub, K.A.; Mikerin, S.L.; Korolkov, V.P.; Terentyev, V.S.; Dostovalov, A.V. Thermochemical Laser-Induced Periodic Surface Structures Formation by Femtosecond Laser on Hf Thin Films in Air and Vacuum. Materials 2021, 14, 6714. [Google Scholar] [CrossRef]

- Korolkov, V.P.; Nasyrov, R.K.; Sedukhin, A.G.; Belousov, D.A.; Kuts, R.I. New methods of manufacturing high-aperture computer-generated holograms for reference wavefront shaping in interferometry. Optoelectron. Instrum. Data Process. 2020, 56, 140–149. [Google Scholar] [CrossRef]

- Korolkov, V.P.; Kuts, R.I.; Malyshev, A.I.; Belousov, D.A.; Matochkin, A.E. Usage of dry processes for the formation of diffractive structures on Ti and Ti/Si films. In Optical Fabrication, Testing, and Metrology VII; SPIE: Bellingham, WA, USA, 2021; Volume 11873, p. 1187307. [Google Scholar]

- Hass, G.; Bradford, A.P. Optical properties and oxidation of evaporated titanium films. JOSA 1957, 47, 125–129. [Google Scholar] [CrossRef]

- Polasko, K.J.; Griffing, B.F. Thin silicon films used as antireflection coatings for metal coated substrates. In Advances in Resist Technology and Processing III; SPIE: Bellingham, WA, USA, 1986; Volume 631, pp. 180–186. [Google Scholar]

- Naghshine, B.B.; Kiani, A. Laser processing of thin-film multilayer structures: Comparison between a 3D thermal model and experimental results. Beilstein J. Nanotechnol. 2017, 8, 1749–1759. [Google Scholar] [CrossRef] [PubMed]

- Ihlemann, J.; Rubahn, K.; Thielsch, R. Laser ablation patterning of dielectric layer stacks for 193-nm mask fabricaton. In Second International Symposium on Laser Precision Microfabrication; SPIE: Bellingham, WA, USA, 2002; Volume 4426, pp. 437–440. [Google Scholar]

- Filmetrics—Reflectance Calculator. Available online: https://www.filmetrics.com/reflectance-calculator (accessed on 25 June 2023).

- Poleshchuk, A.G.; Korolkov, V.P. Laser writing systems and technologies for fabrication of binary and continuous relief diffractive optical elements. In International Conference on Lasers, Applications, and Technologies 2007: Laser-assisted Micro-and Nanotechnologies; SPIE: Bellingham, WA, USA, 2007; Volume 6732, p. 67320X. [Google Scholar]

- Refractiveindex.info. Available online: https://refractiveindex.info/?shelf=main&book=Si&page=Pierce (accessed on 25 June 2023).

- Bronnikov, K.; Dostovalov, A.; Cherepakhin, A.; Mitsai, E.; Nepomniaschiy, A.; Kulinich, S.A.; Zhizhchenko, A.; Kuchmizhak, A. Large-scale and localized laser crystallization of optically thick amorphous silicon films by near-IR femtosecond pulses. Materials 2020, 13, 5296. [Google Scholar] [CrossRef]

- Parker, J.C.; Siegel, R.W. Calibration of the Raman spectrum to the oxygen stoichiometry of nanophase TiO2. Appl. Phys. Lett. 1990, 57, 943–945. [Google Scholar] [CrossRef]

- Vála, L.; Vavruňková, V.; Jandová, V.; Křenek, T. Laser ablation of silicon monoxide and titanium monoxide in liquid: Formation of mixed colloidal dispersion with photocatalytic activity. J. Phys. Conf. Ser. 2020, 1527, 012046. [Google Scholar] [CrossRef]

- Morgan, A.E.; Broadbent, E.K.; Ritz, K.N.; Sadana, D.K.; Burrow, B.J. Interactions of thin Ti films with Si, SiO2, Si3N4, and SiOxNy under rapid thermal annealing. J. Appl. Phys. 1988, 64, 344–353. [Google Scholar] [CrossRef]

- Levy, D.; Ponpon, J.P.; Grob, A.; Grob, J.J.; Stuck, R. Rapid thermal annealing and titanium silicide formation. Appl. Phys. A 1985, 38, 23–29. [Google Scholar] [CrossRef]

- Micheli, F. Argon Laser Oxidation of Silicon. Ph.D. Thesis, University of London United Kingdom, London, UK, 1990. [Google Scholar]

- Pilipenko, V.A.; Anishchik, V.M.; Ponomar, V.N.; Pilipenko, I.V. Electrophysical and mechanical properties of titanium disilicide produced by using rapid heat treatment. Bull. BSU 2001, 2, 29–34. [Google Scholar]

- Pilipenko, V.A.; Ponomar, V.N.; Ponariadov, V.V.; Pilipenko, I.V.; Gorushko, V.A. Features of the structure and phase transitions in the titanium-silicon system during the rapid thermal treatment. In Proceedings of the 4-th International Conference «Interaction of Radiation with Solids», Minsk, Belarus, 3–5 October 2001. [Google Scholar]

- Chen, S.Y.; Shen, Z.X.; Chen, Z.D.; See, A.K.; Chan, L.H.; Zhang, T.J.; Tee, K.C. Laser-induced formation of titanium silicides. Surf. Interface Anal. 1999, 28, 200–203. [Google Scholar] [CrossRef]

- Walker, P.; Tarn, W.H. CRC Handbook of Metal Etchants; CRC Press LLC: Boca Raton, FL, USA, 1990. [Google Scholar]

- Jaso, M.A.; Robey, S.W.; Oehrlein, G.S. Etch Selectivity of Silicon Dioxide over Titanium Silicide Using CF 4/H 2 Reactive Ion Etching. J. Electrochem. Soc. 1989, 136, 3812–3815. [Google Scholar] [CrossRef]

| Probe Beam Wavelength (λ), nm | Writing Power (P), mW | DE, % |

|---|---|---|

| 532 | 17.8 | 1.4 |

| 12.8 | 0.8 | |

| 405 | 17.8 | 2.1 |

| 12.8 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belousov, D.A.; Kuts, R.I.; Okotrub, K.A.; Korolkov, V.P. Direct Laser Writing of Diffractive Structures on Bi-Layer Si/Ti Films Coated on Fused Silica Substrates. Photonics 2023, 10, 771. https://doi.org/10.3390/photonics10070771

Belousov DA, Kuts RI, Okotrub KA, Korolkov VP. Direct Laser Writing of Diffractive Structures on Bi-Layer Si/Ti Films Coated on Fused Silica Substrates. Photonics. 2023; 10(7):771. https://doi.org/10.3390/photonics10070771

Chicago/Turabian StyleBelousov, Dmitrij A., Roman I. Kuts, Konstantin A. Okotrub, and Victor P. Korolkov. 2023. "Direct Laser Writing of Diffractive Structures on Bi-Layer Si/Ti Films Coated on Fused Silica Substrates" Photonics 10, no. 7: 771. https://doi.org/10.3390/photonics10070771

APA StyleBelousov, D. A., Kuts, R. I., Okotrub, K. A., & Korolkov, V. P. (2023). Direct Laser Writing of Diffractive Structures on Bi-Layer Si/Ti Films Coated on Fused Silica Substrates. Photonics, 10(7), 771. https://doi.org/10.3390/photonics10070771