High–Power 792 nm Fiber–Coupled Semiconductor Laser

Abstract

:1. Introduction

2. Laser Module Design Simulation and Preparation

2.1. 792 nm Semiconductor Laser Structure Design

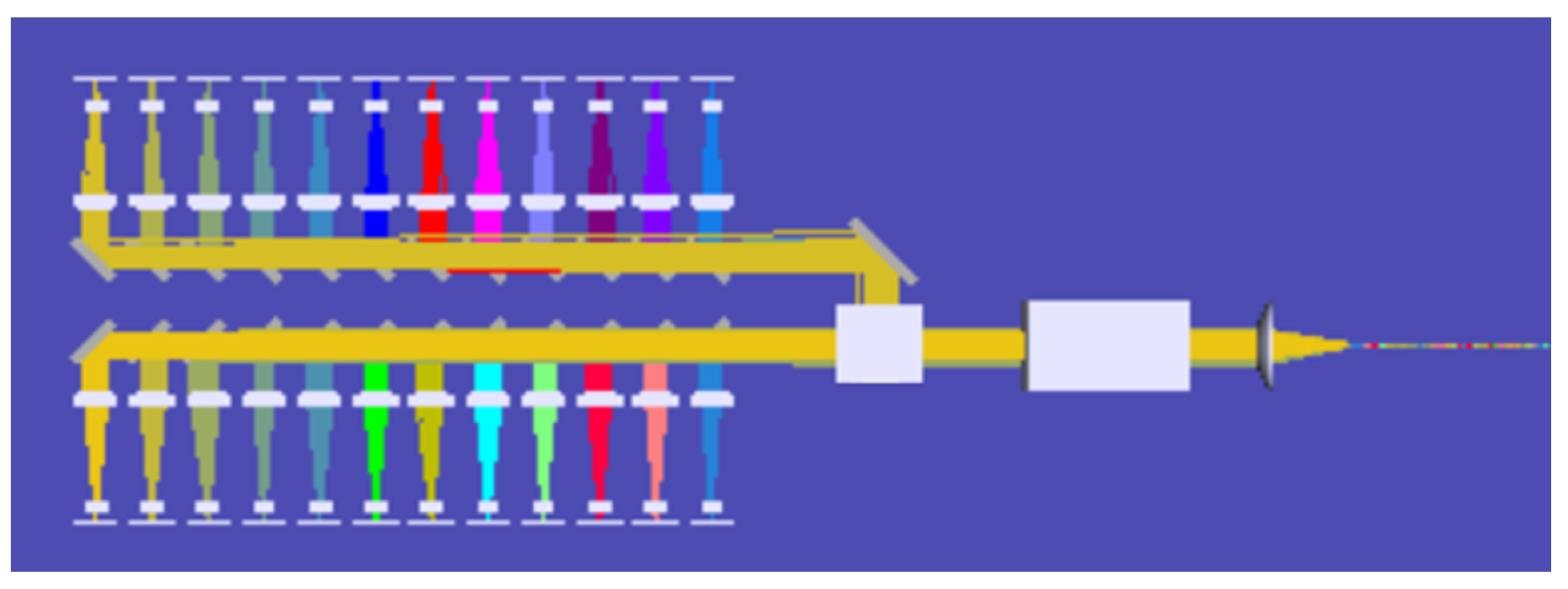

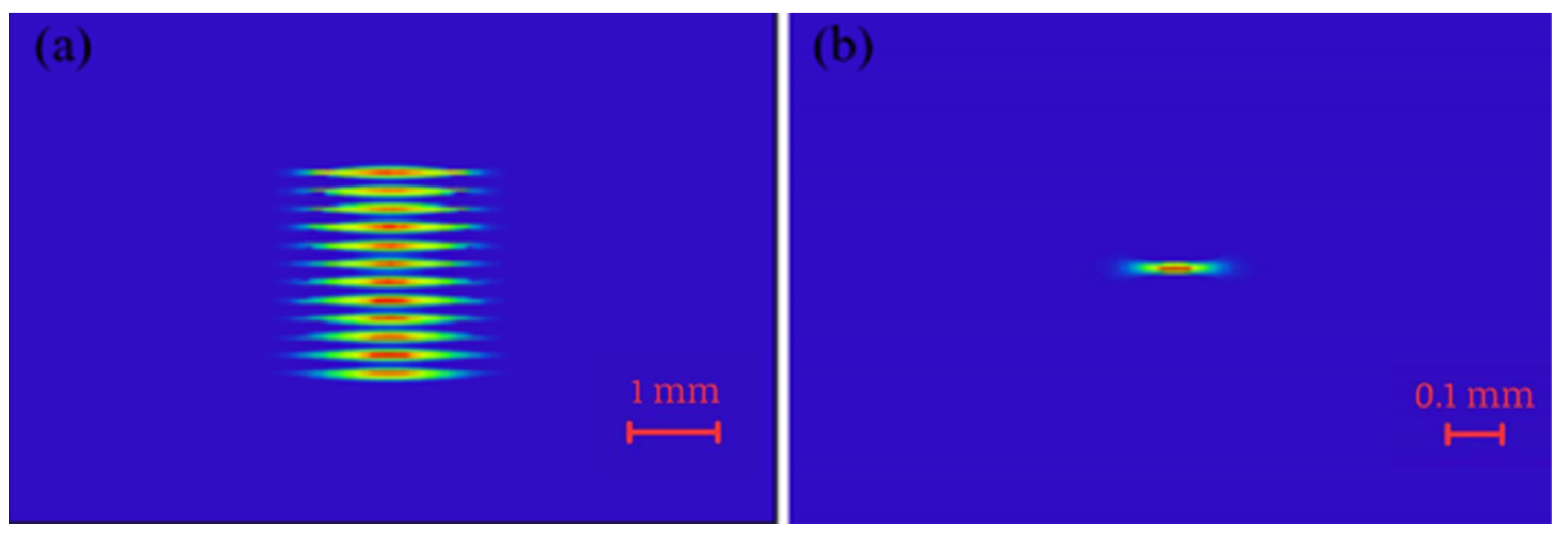

2.2. ZEMAX Simulation and Analysis

2.3. Fiber−Coupled Laser Module Design and Preparation

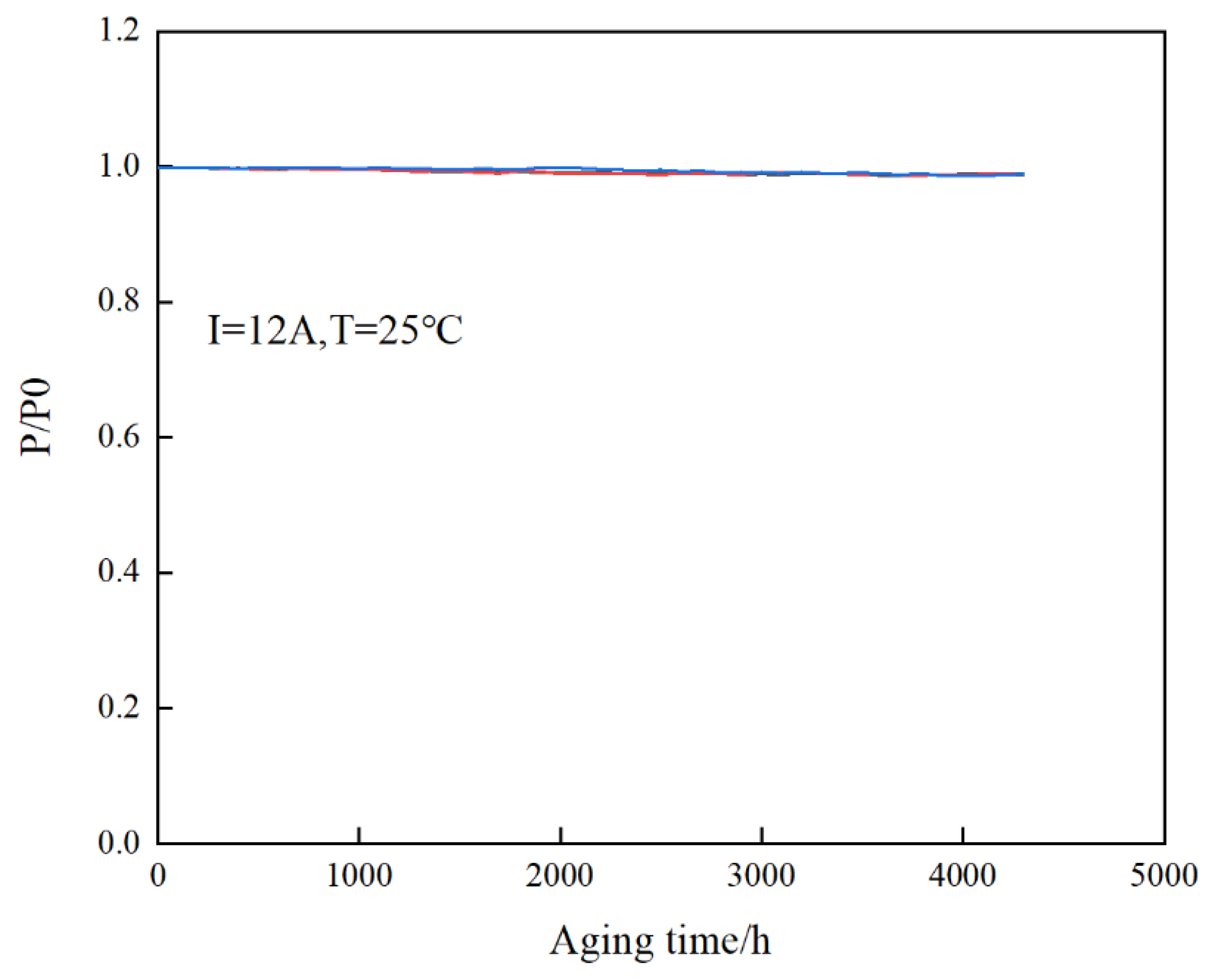

3. Experimental Results and Discussion

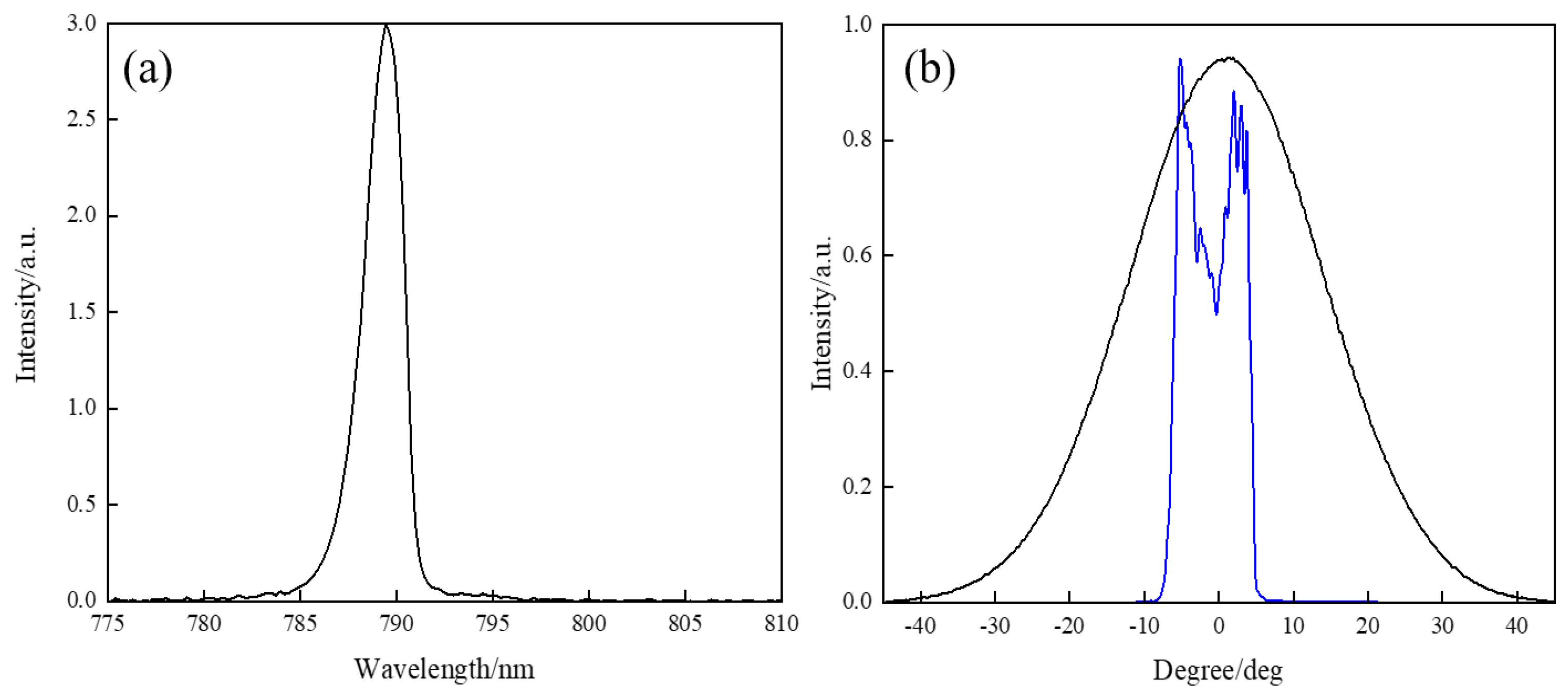

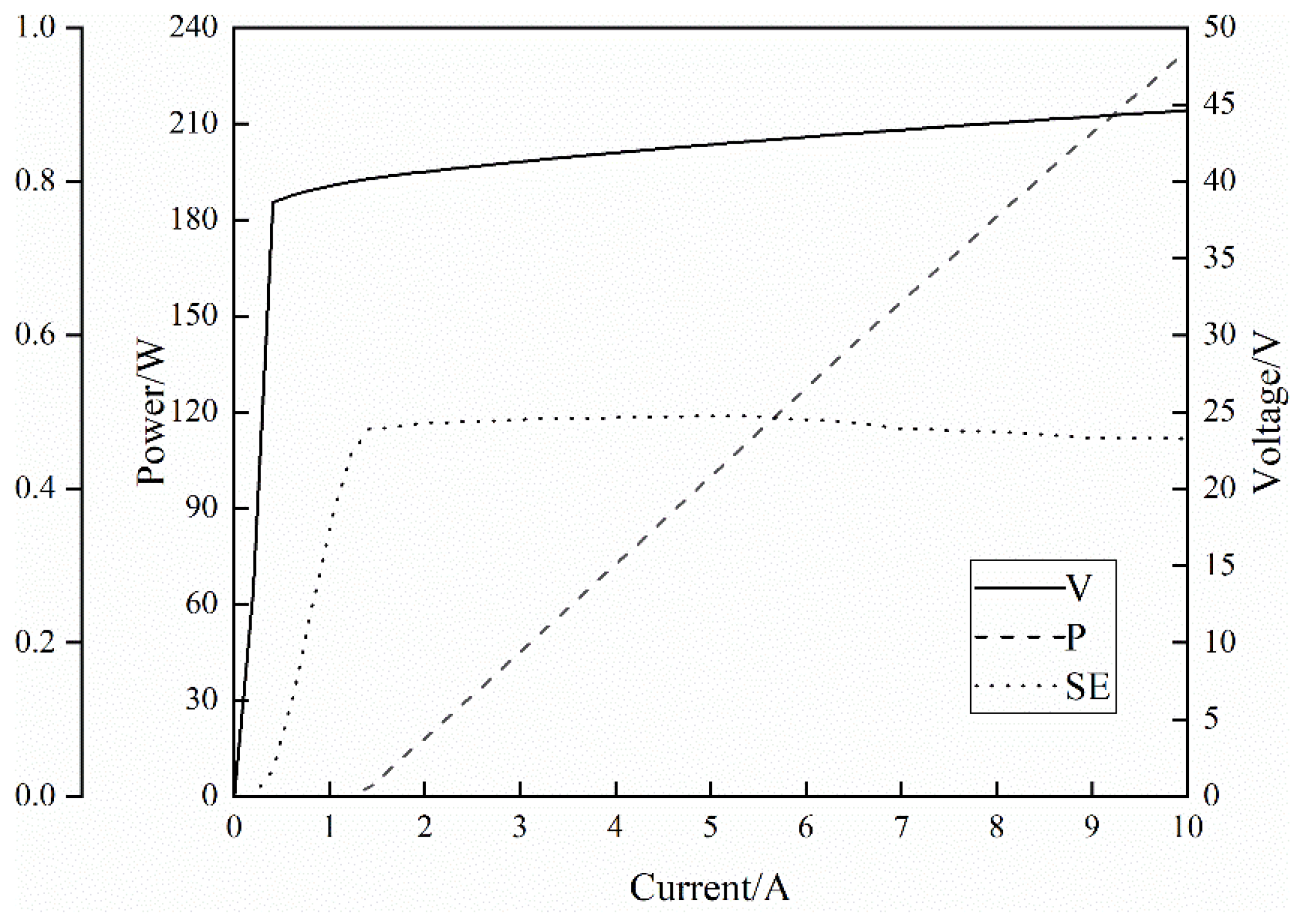

3.1. Single Emitter Semiconductor Laser Test Results

3.2. Test Results of Fiber Coupling Module

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Witte, U.; Traub, M.; Di Meo, A.; Hamann, M.; Rubel, D.; Hengesbach, S.; Hoffmann, D. Compact 35 µm fiber coupled diode laser module based on dense wavelength division multiplexing of NBA mini-bars. High-Power Diode Laser Technology and Applications XIV. SPIE 2016, 9733, 83–94. [Google Scholar]

- Ma, X.; Zhang, N.; Zhong, L.; Liu, S.; Jing, H. Research progress of high power semiconductor laser pump source. High Power Laser Part. Beams 2020, 32, 121010. [Google Scholar]

- Cao, C.; Wang, X.; Zeng, X.; Pan, Z.; Luo, L.; Cheng, Y. The problem with beam quality for semiconductor laser. Optik 2016, 127, 3701–3702. [Google Scholar]

- Miah, M.; Strohmaier, S.; Urban, G.; Bimberg, D. Beam quality improvement of high−power semiconductor lasers using laterally inhomogeneous waveguides. Appl. Phys. Lett. 2018, 113, 221107. [Google Scholar] [CrossRef]

- Ren, T.; Wu, C.; Yu, Y.; Dai, T.; Chen, F.; Pan, Q. Development Progress of 3–5μm Mid−Infrared Lasers: OPO, Solid-State and Fiber Laser. Appl. Sci. 2021, 11, 11451. [Google Scholar] [CrossRef]

- Ebert, C.; Guiney, T.; Irwin, D.; Patterson, S. New advancements in 793 nm fiber−coupled modules for Th fiber laser pumping, including packages optimized for low SWaP applications. SPIE 2016, 9834, 102–110. [Google Scholar]

- Lancaster, D.; Sabella, A.; Hemming, A.; Bennetts, S.; Jackson, S. Power-Scalable Thulium and Holmium Fibre Lasers Pumped by 793 nm Diode-Lasers; Optical Society of America: Washington, DC, USA, 2007. [Google Scholar]

- Hemenway, M.; Chen, Z.; Kanskar, M.; Urbanek, W.; Dawson, D.; Bao, L. Wavelength stabilized fiber−coupled laser modules for DPSS and fiber laser pumping. SPIE 2020, 11262, 101–109. [Google Scholar]

- Liu, G.; Lehkonen, S.; Li, J.; Winhold, H.; Rothacker, T.; Ahmed, F.; Peters, M.; Wolf, P.; Ahlert, S.; Kissel, H.; et al. High power and reliable 793nm T−bar and single emitter for thulium-doped fiber laser pumping. SPIE 2020, 11262, 51–59. [Google Scholar]

- Hasler, K.; Wenzel, H.; Crump, P.; Knigge, S.; Maasdorf, A.; Platz, R.; StaskE, R.; Erbert, G. Comparative theoretical and experimental studies of two designs of high−power diode lasers. Semicond. Sci. Technol. 2014, 29, 045010. [Google Scholar] [CrossRef]

- Lee, J.; Mawst, J.; Botez, D. Asymmetric broad waveguide diode lasers (λ = 980 nm) of large equivalent transverse spot size and low temperature sensitivity. IEEE Photonics Technol. Lett. 2002, 14, 1046–1048. [Google Scholar] [CrossRef]

- Tomm, W.; Ziegler, M.; Hempel, M.; Elsaesser, T. Mechanisms and fast kinetics of the catastrophic optical damage (COD) in GaAs−based diode lasers. Laser Photonics Rev. 2011, 5, 422–441. [Google Scholar] [CrossRef]

- Wang, Z.; Koenning, T. Fiber coupled diode laser beam parameter product calculation and rules for optimized design. SPIE 2011, 7918, 86–94. [Google Scholar]

- Ren, Z.; Li, Q.; Li, B.; Song, K. High wall-plug efficiency 808-nm laser diodes with a power up to 30.1 W. J. Semicond. 2020, 41, 61–63. [Google Scholar] [CrossRef]

- Kanskar, M.; Bao, L.; Bai, J.; Chen, Z.; Dahlen, D.; Devito, M.; Dong, W.; Grimshaw, M.; Guan, X. High reliability of high power and high brightness diode lasers, High−Power Diode Laser Technology and Applications XII. SPIE 2014, 8965, 52–61. [Google Scholar]

- Bao, L.; Kanskar, M.; DeVito, M.; Hemenway, M.; Urbanek, W.; Grimshaw, M.; Chen, Z.; Dong, W.; Guan, X.; Zhang, S.; et al. High reliability demonstrated on high-power and high-brightness diode lasers. SPIE 2015, 9348, 88–97. [Google Scholar]

| Layer | Material | Thickness (nm) | Doping (cm−3) |

|---|---|---|---|

| Contact | GaAs | 200 | >1 × 1019 |

| P-cladding | Al0.2Ga0.3In0.5P | 1000 | 1 × 1018 |

| P-waveguide | Ga0.5In0.5P | 450 | − |

| Quantum well | In0.6Ga0.4As0.3P | 9 | − |

| N-waveguide | Ga0.5In0.5P | 900 | − |

| N-cladding | Al0.1Ga0.4In0.5P | 1500 | 1 × 1018 |

| Buffer | GaAs | 200 | 2 × 1018 |

| Number | Power (W) | Wavelength (nm) | Number | Power (W) | Wavelength (nm) |

|---|---|---|---|---|---|

| 1 | 10.40 | 789.1 | 13 | 10.43 | 789.3 |

| 2 | 10.44 | 789.4 | 14 | 10.45 | 789.4 |

| 3 | 10.45 | 789.3 | 15 | 10.41 | 789.1 |

| 4 | 10.38 | 789.3 | 16 | 10.43 | 789.3 |

| 5 | 10.42 | 789.1 | 17 | 10.44 | 789.2 |

| 6 | 10.44 | 789.5 | 18 | 10.42 | 789.1 |

| 7 | 10.42 | 789.3 | 19 | 10.40 | 789.3 |

| 8 | 10.43 | 789.2 | 20 | 10.44 | 789.2 |

| 9 | 10.42 | 789.1 | 21 | 10.45 | 789.4 |

| 10 | 10.40 | 789.4 | 22 | 10.41 | 789.1 |

| 11 | 10.39 | 789.2 | 23 | 10.43 | 789.2 |

| 12 | 10.41 | 789.1 | 24 | 10.39 | 789.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Sun, W.; Sun, X.; Zhu, Z.; Qin, H.; Su, J.; Liu, C.; Tang, W.; Jiang, K.; Xia, W.; et al. High–Power 792 nm Fiber–Coupled Semiconductor Laser. Photonics 2023, 10, 619. https://doi.org/10.3390/photonics10060619

Liu P, Sun W, Sun X, Zhu Z, Qin H, Su J, Liu C, Tang W, Jiang K, Xia W, et al. High–Power 792 nm Fiber–Coupled Semiconductor Laser. Photonics. 2023; 10(6):619. https://doi.org/10.3390/photonics10060619

Chicago/Turabian StyleLiu, Peng, Wanggen Sun, Xiao Sun, Zhen Zhu, Huabing Qin, Jian Su, Chengcheng Liu, Wenjing Tang, Kai Jiang, Wei Xia, and et al. 2023. "High–Power 792 nm Fiber–Coupled Semiconductor Laser" Photonics 10, no. 6: 619. https://doi.org/10.3390/photonics10060619

APA StyleLiu, P., Sun, W., Sun, X., Zhu, Z., Qin, H., Su, J., Liu, C., Tang, W., Jiang, K., Xia, W., & Xu, X. (2023). High–Power 792 nm Fiber–Coupled Semiconductor Laser. Photonics, 10(6), 619. https://doi.org/10.3390/photonics10060619