Fiber Laser Sensor Configurations for Refractive Index, Temperature and Strain: A Review

Abstract

1. Introduction

2. Fiber Laser Sensor Configurations and the Principle of Operation

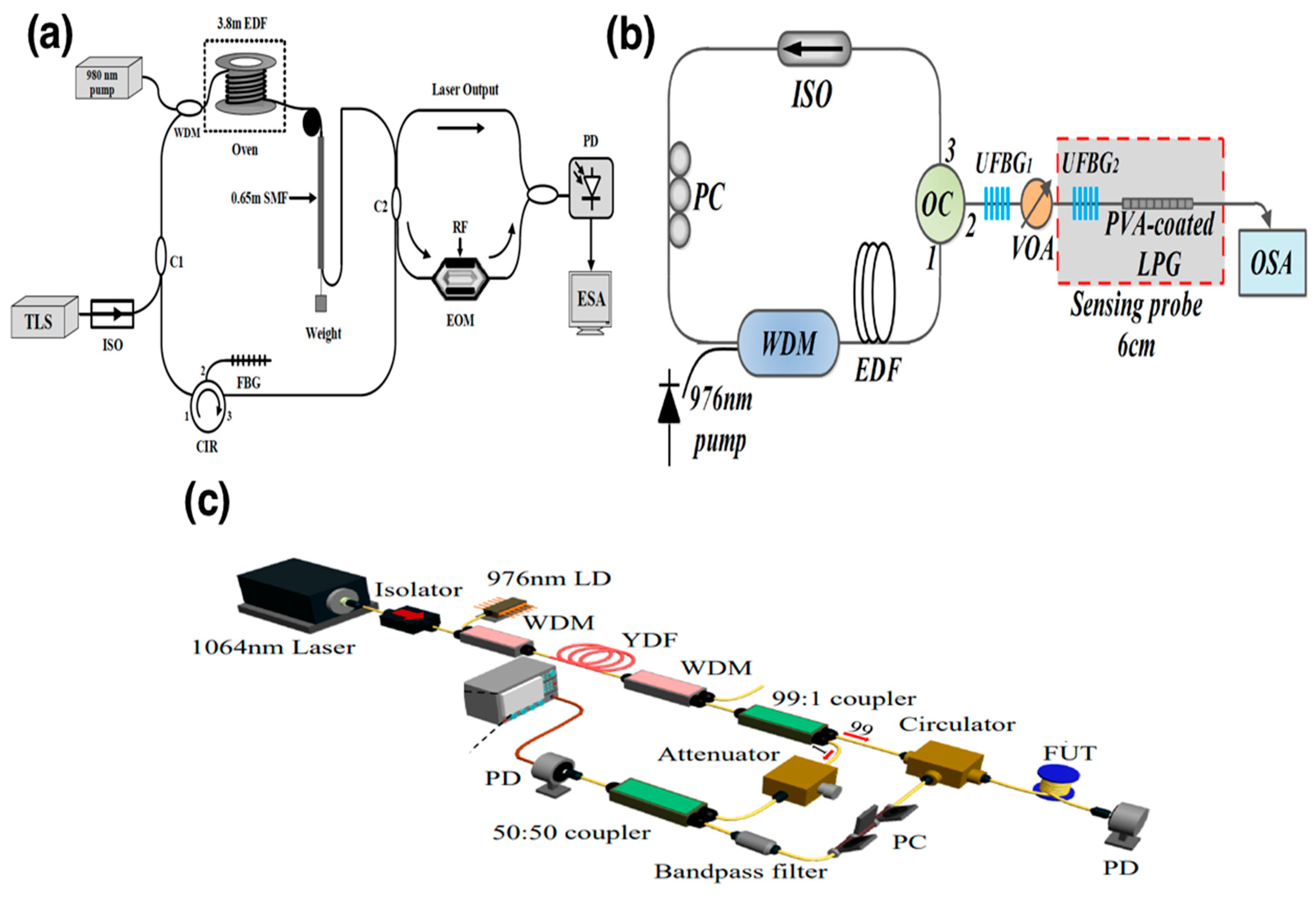

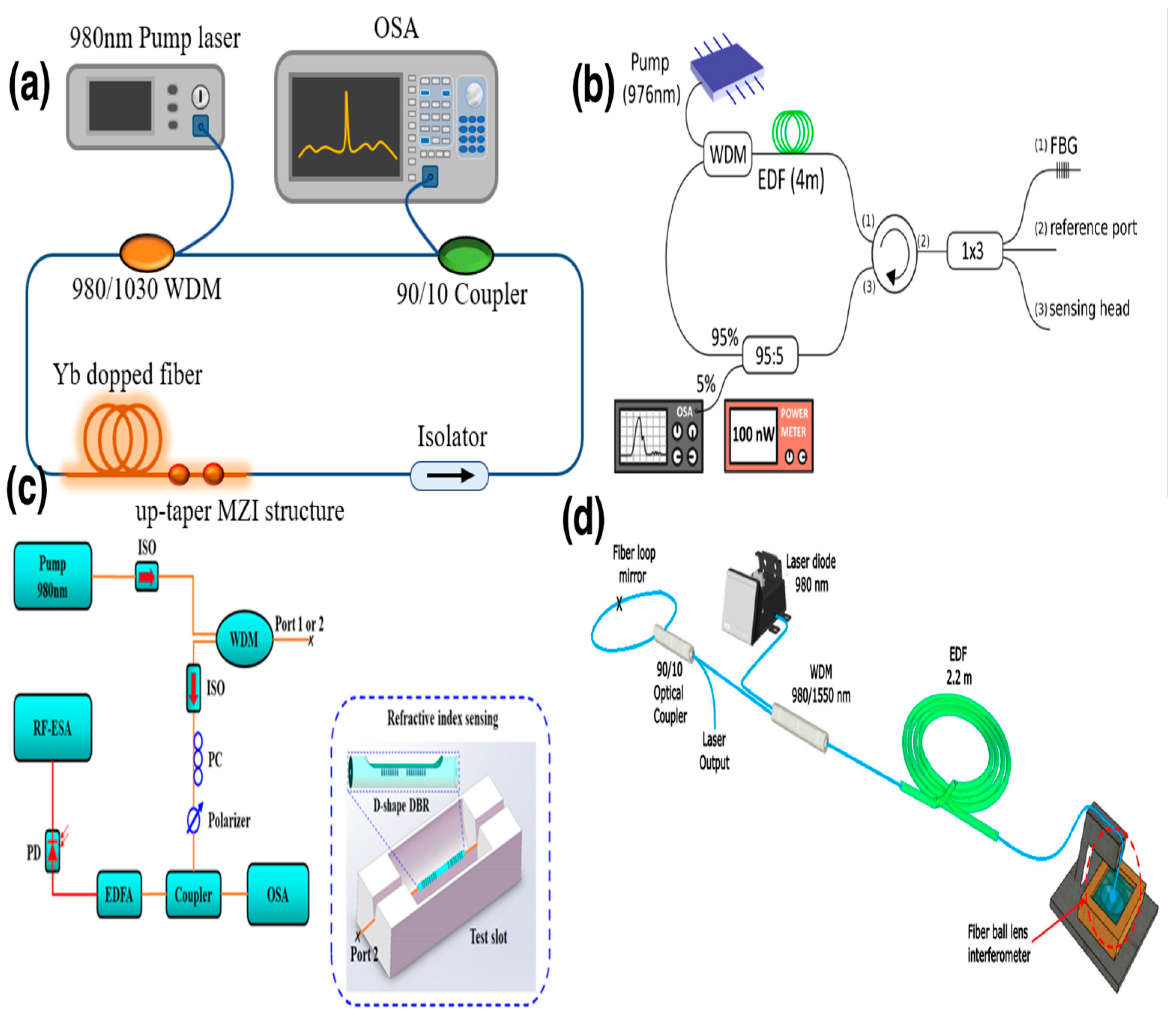

2.1. Continuous Wave (CW) Fiber Laser

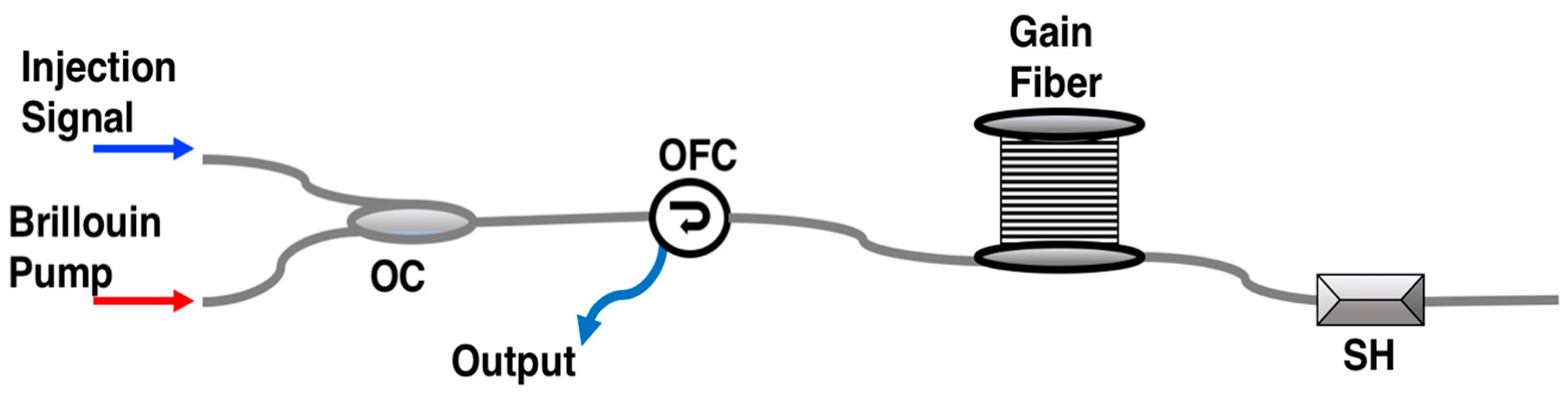

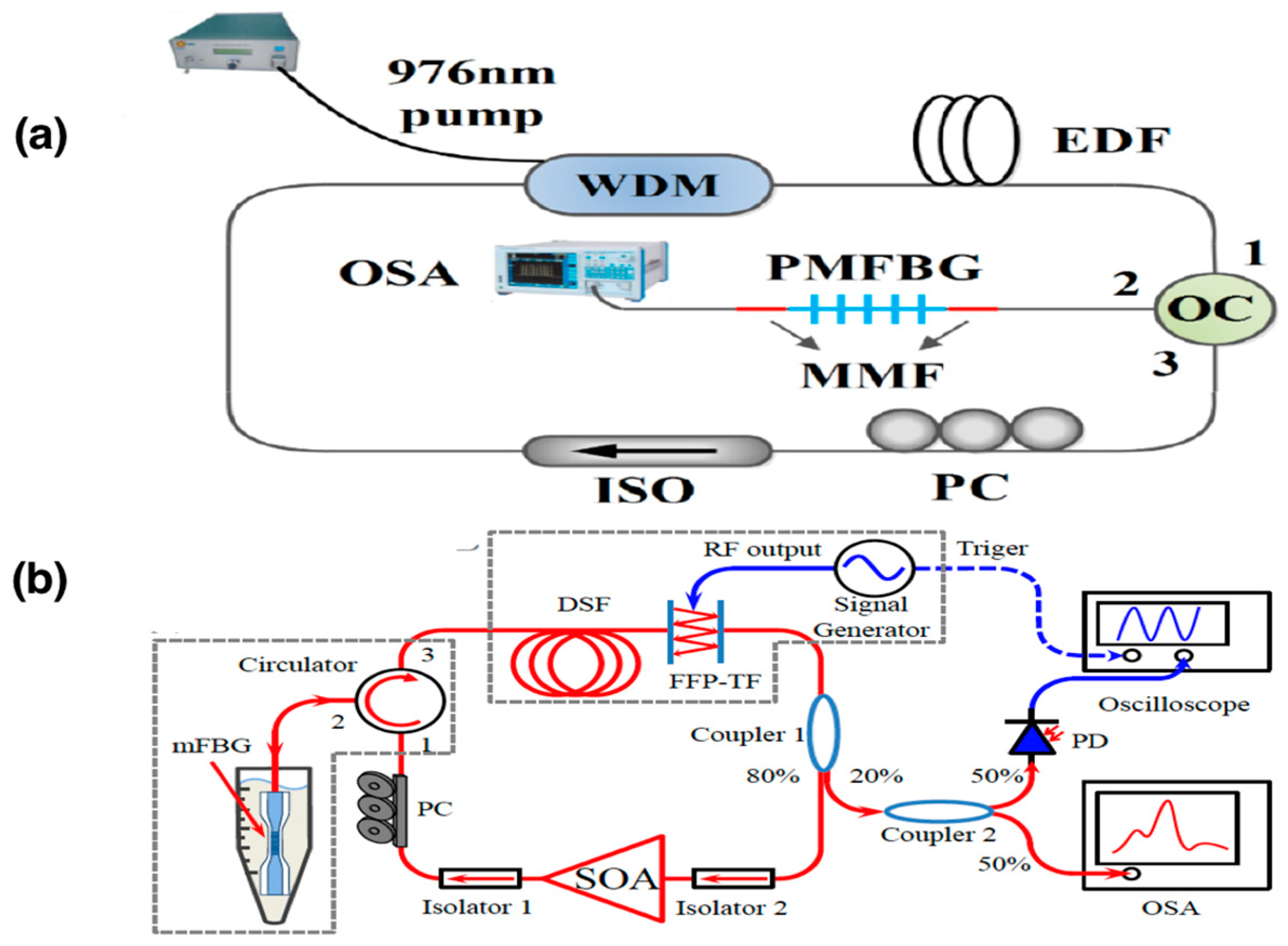

2.2. Brillouin Fiber Laser Sensor

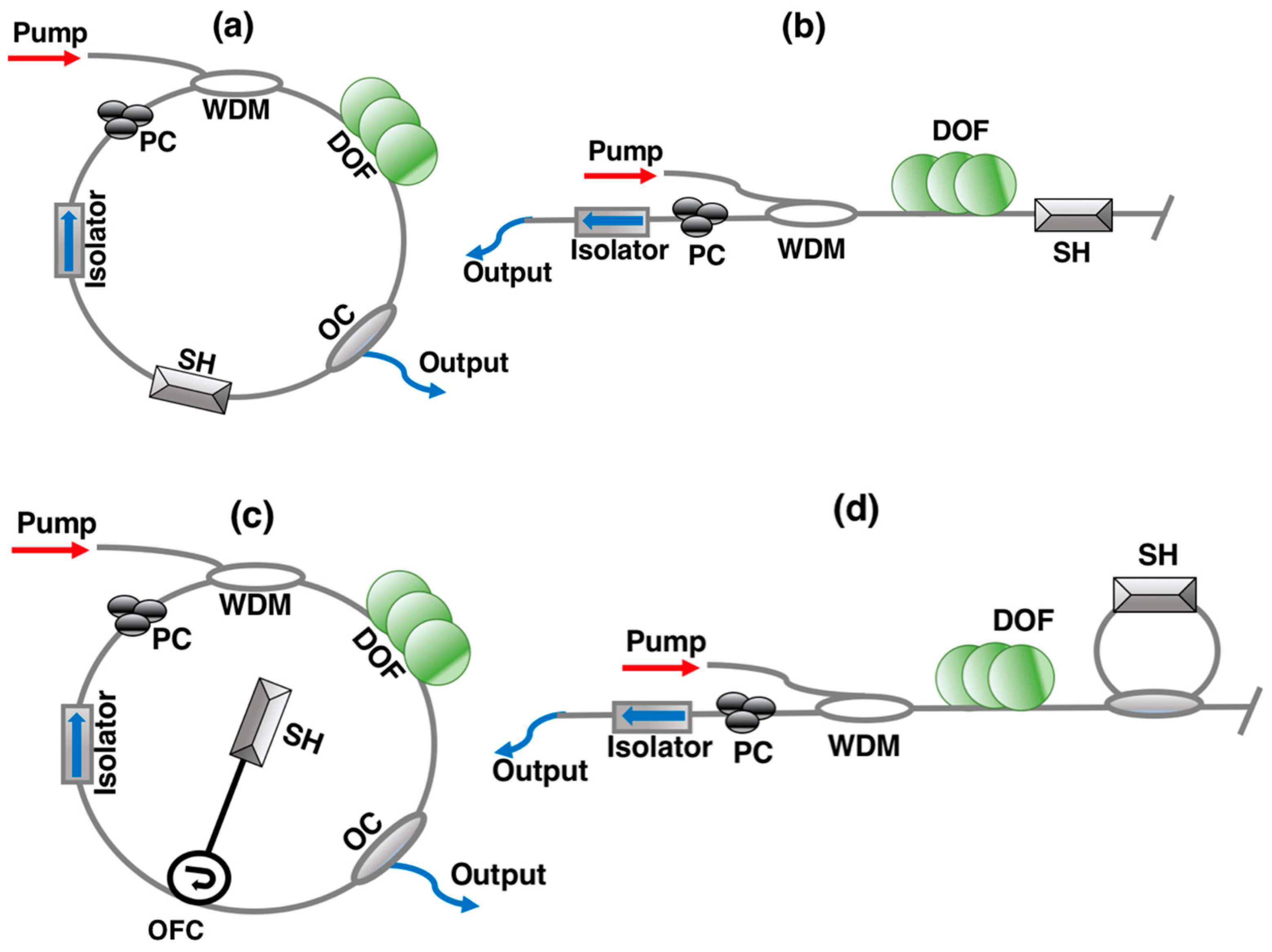

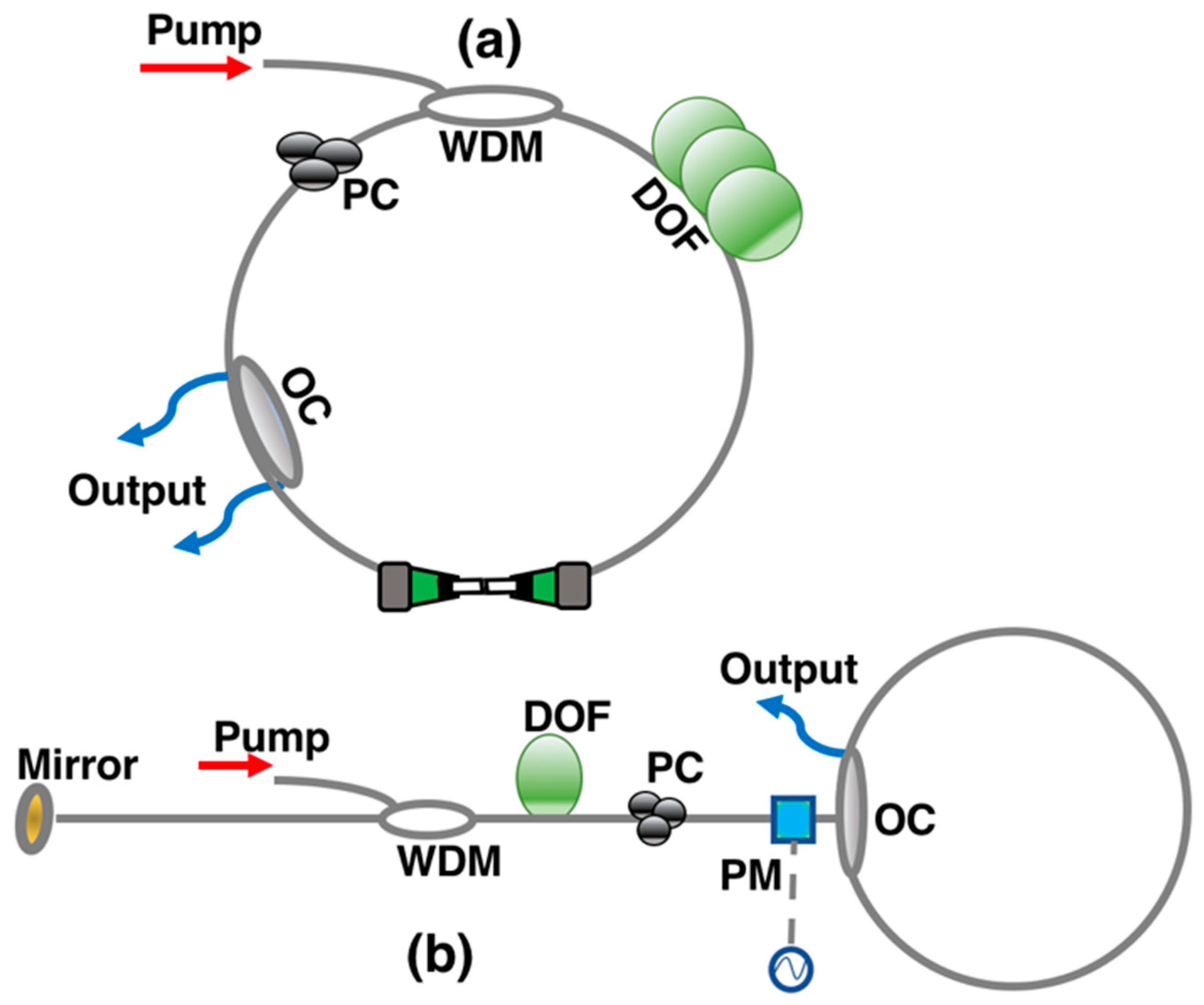

2.3. Mode-Locked Fiber Laser Sensor

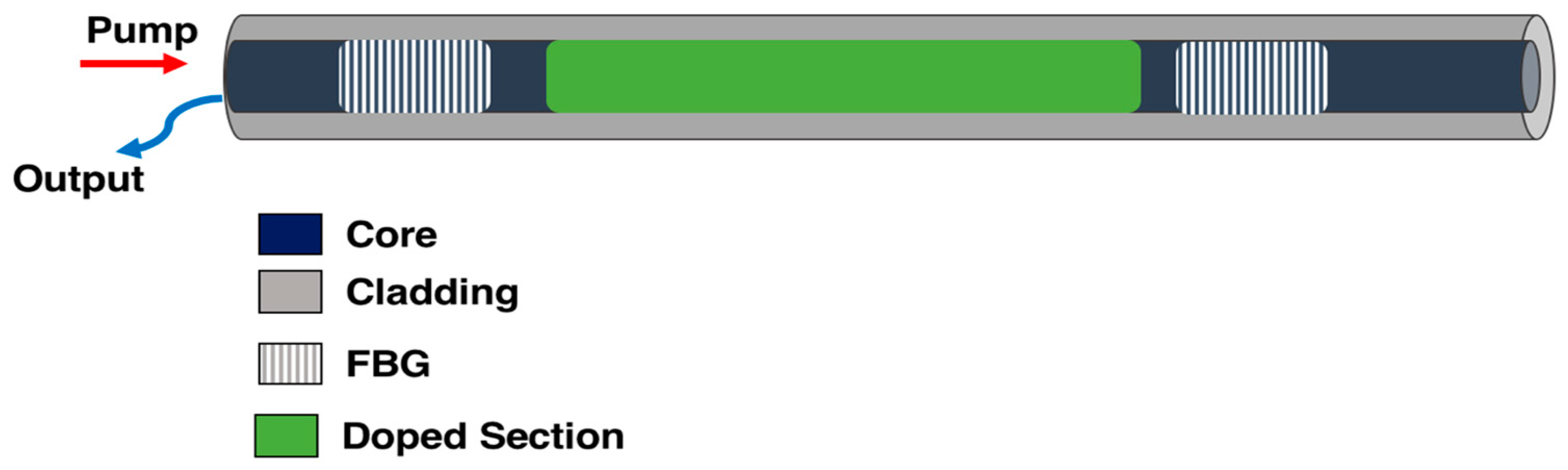

2.4. Distributed-Feedback Fiber Laser Sensor

3. Refractive Index Fiber Laser Sensors

4. Temperature Fiber Laser Sensors

5. Fiber Laser Sensors for Strain Monitoring

6. Fiber Laser Sensors for Other Parameters

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maiman, T.H. Stimulated Optical Radiation in Ruby. Nature 1960, 187, 493–494. [Google Scholar] [CrossRef]

- Kissinger, C.D. Fiber Optic Proximity Probe. U.S. Patent 3327584A, 27 June 1967. [Google Scholar]

- Koester, C.J.; Snitzer, E. Amplification in a Fiber Laser. Appl. Opt. 1964, 3, 1182–1186. [Google Scholar] [CrossRef]

- Payne, D.N. Low-threshold tunable CW and Q-switched fibre laser operating at 1.55 μm. Electron. Lett. 1986, 22, 159–160. [Google Scholar]

- Desurvire, E.; Simpson, J.R.; Becker, P.C. High-gain erbium-doped traveling-wave fiber amplifier. Opt. Lett. 1987, 12, 888–890. [Google Scholar] [CrossRef] [PubMed]

- Alavie, A.T.; Karr, S.E.; Measures, R.M.; Othonos, A. A Multiplexed Bragg Grating Fiber Laser Sensor System. IEEE Photonics Technol. Lett. 1993, 5, 1112–1114. [Google Scholar] [CrossRef]

- Ball, G.A.; Morey, W.W.; Cheo, P.K. Fiber Laser Source/Analyzer for Bragg Grating Sensor Array Interrogation. J. Light. Technol. 1994, 12, 700–703. [Google Scholar] [CrossRef]

- Zarinetchi, F.; Smith, S.P.; Ezekiel, S. Stimulated Brillouin fiber-optic laser gyroscope. Opt. Lett. 1991, 16, 229–231. [Google Scholar] [CrossRef]

- Jeon, M.Y.; Jeong, H.J.; Kim, B.Y. Mode-locked fiber laser gyroscope. Opt. Lett. 1993, 18, 320. [Google Scholar] [CrossRef]

- Kim, H.K.; Park, H.G.; Kim, B.Y.; Kim, S.K. Polarimetric fiber laser sensors. Opt. Lett. 1993, 18, 317. [Google Scholar] [CrossRef]

- Lee, B.W.; Jeong, H.J.; Kim, B.Y. High-sensitivity mode-locked fiber laser gyroscope. Opt. Lett. 1997, 22, 129. [Google Scholar] [CrossRef]

- Dong, X.; Ngo, N.Q.; Shum, P.; Guan, B.-O.; Tam, H.-Y.; Dong, X. Concentration-induced nonuniform power in tunable erbium-doped fiber lasers. Opt. Lett. 2004, 29, 358. [Google Scholar] [CrossRef] [PubMed]

- Melle, S.M.; Alavie, A.T.; Karr, S.; Coroy, T.; Liu, K.; Measures, R.M. A Bragg grating-tuned fiber laser strain sensor system. IEEE Photonics Technol. Lett. 1993, 5, 263–266. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, M.; Jin, W. Sensitivity enhancement in erbium-doped fiber laser intra-cavity absorption sensor. Sens. Actuators A Phys. 2003, 104, 183–187. [Google Scholar] [CrossRef]

- Cranch, G.A.; Flockhart, G.M.H.; Kirkendall, C.K. Distributed feedback fiber laser strain sensors. IEEE Sens. J. 2008, 8, 1161–1172. [Google Scholar] [CrossRef]

- Ames, G.H.; Maguire, J.M. Erbium fiber laser accelerometer. IEEE Sens. J. 2007, 7, 557–561. [Google Scholar] [CrossRef]

- Frazão, O.; Correia, C.; Baptista, J.M.; Marques, M.B.; Santos, J.L. Ring fibre laser with interferometer based in long period grating for sensing applications. Opt. Commun. 2008, 281, 5601–5604. [Google Scholar] [CrossRef]

- Fu, H.; Shu, X.; Mou, C.; Zhang, L.; He, S.; Bennion, I. Transversal loading sensor based on tunable beat frequency of a dual-wavelength fiber laser. IEEE Photonics Technol. Lett. 2009, 21, 987–989. [Google Scholar] [CrossRef]

- Nakazaki, Y.; Yamashita, S. Fast and wide tuning range wavelength-swept fiber laser based on dispersion tuning and its application to dynamic FBG sensing. Opt. Express 2009, 17, 8310. [Google Scholar] [CrossRef]

- Galindez, C.A.; Madruga, F.J.; Ullan, A.; Lopez-Amo, M.; Lopez-Higuera, J.M. Temperature sensing in multiple zones based on Brillouin fiber ring laser. J. Phys. Conf. Ser. 2009, 178, 012017. [Google Scholar] [CrossRef]

- Frazão, O.; Marques, J.M.; Santos, J.L.; Marques, M.B.; Baptista, J.M. Brillouin fibre laser discrete sensor for simultaneous strain and temperature measurement. Appl. Phys. B Lasers Opt. 2007, 86, 555–558. [Google Scholar] [CrossRef]

- Frazão, O. Fiber ring laser sensor for strain-temperature discrimination based on four-wave mixing effect. Opt. Eng. 2007, 46, 010502. [Google Scholar] [CrossRef]

- Jackson, D.A. High temperature Fabry-Perot probe interrogated with tunable fibre ring laser. Electron. Lett. 2008, 44, 898–899. [Google Scholar] [CrossRef]

- Xu, O.; Lu, S.; Feng, S.; Jian, S. A novel fiber-laser-based fiber Bragg grating strain sensor with high-birefringence Sagnac fiber loop mirror. Chin. Opt. Lett. 2008, 6, 818–820. [Google Scholar] [CrossRef]

- Chen, W.; Zhu, H.N.; Man, W.J.; Xiong, S.; Xie, L. Discretely tunable fiber ring laser using FBG tunable filter and Mach-Zehnder interferometer. Microw. Opt. Technol. Lett. 2009, 51, 2595–2598. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, M.; Jin, W.; Ho, H.L.; Demokan, M.S.; Fang, X.H.; Culshaw, B.; Stewart, G. Investigation of erbium-doped fiber laser intra-cavity absorption sensor for gas detection. Opt. Commun. 2004, 234, 435–441. [Google Scholar] [CrossRef]

- Zhang, W.; Ying, Z.; Yuan, S.; Tong, Z. A fiber laser sensor for liquid level and temperature based on two taper structures and fiber Bragg grating. Opt. Commun. 2015, 342, 243–246. [Google Scholar] [CrossRef]

- Sun, C.; Dong, Y.; Wang, M.; Jian, S. Liquid level and temperature sensing by using dual-wavelength fiber laser based on multimode interferometer and FBG in parallel. Opt. Fiber Technol. 2018, 41, 212–216. [Google Scholar] [CrossRef]

- Zhao, Z.Q.; Lu, Y.; Duan, L.C.; Wang, M.T.; Zhang, H.W.; Yao, J.Q. Fiber ring laser sensor based on hollow-core photonic crystal fiber. Opt. Commun. 2015, 350, 296–300. [Google Scholar] [CrossRef]

- Lopez-Dieguez, Y.; Estudillo-Ayala, J.M.; Jauregui-Vazquez, D.; Herrera-Piad, L.A.; Sierra-Hernandez, J.M.; Garcia-Mina, D.F.; Gallegos-Arellano, E.; Hernandez-Garcia, J.C.; Rojas-Laguna, R. Erbium ring fiber laser cavity based on tip modal interferometer and its tunable multi-wavelength response for refractive index and temperature. Appl. Sci. 2018, 8, 1337. [Google Scholar] [CrossRef]

- Wang, Z.; Tan, Z.; Xing, R.; Liang, L.; Qi, Y.; Jian, S. Liquid level sensor based on fiber ring laser with single-mode-offset coreless-single-mode fiber structure. Opt. Laser Technol. 2016, 84, 59–63. [Google Scholar] [CrossRef]

- Shi, J.; Xu, D.; Xu, W.; Wang, Y.; Yan, C.; Zhang, C.; Yan, D.; He, Y.; Tang, L.; Zhang, W.; et al. Humidity Sensor Based on Fabry-Perot Interferometer and Intracavity Sensing of Fiber Laser. J. Light. Technol. 2017, 35, 4789–4795. [Google Scholar] [CrossRef]

- Xing, R.; Wang, Z.; Gao, Y.; Qi, Y.; Jian, S. RI Ring Laser Sensor Based on Concatenating CLF and SMF with One Core-Offset Joint. IEEE Photonics Technol. Lett. 2016, 28, 1225–1228. [Google Scholar] [CrossRef]

- Mou, C.; Zhou, K.; Davies, E.; Zhang, L.; Bennion, I. Fiber laser incorporating an intracavity microchannel for refractive index and temperature sensing. IEEE Photonics Technol. Lett. 2009, 21, 1559–1561. [Google Scholar] [CrossRef]

- Martin-Vela, J.A.; Sierra-Hernandez, J.M.; Martinez-Rios, A.; Estudillo-Ayala, J.M.; Gallegos-Arellano, E.; Toral-Acosta, D.; Porraz-Culebro, T.E.; Jauregui-Vazquez, D. Curvature Sensing Setup Based on a Fiber Laser and a Long-Period Fiber Grating. IEEE Photonics Technol. Lett. 2019, 31, 1265–1268. [Google Scholar] [CrossRef]

- Sun, C.; Wang, M.; Liu, J.; Ye, S.; Liang, L.; Jian, S. Fiber Ring Cavity Laser Based on Modal Interference for Curvature Sensing. IEEE Photonics Technol. Lett. 2016, 28, 923–926. [Google Scholar] [CrossRef]

- Othonos, A.; Alavie, A.T.; Melle, S.; Karr, S.E.; Measures, R.M. Fiber Bragg grating laser sensor. Opt. Eng. 1993, 32, 2841–2846. [Google Scholar] [CrossRef]

- Yin, B.; Wang, M.; Wu, S.; Tang, Y.; Feng, S.; Wu, Y.; Zhang, H. Fiber ring laser based on MMF-PMFBG-MMF filter for three parameters sensing. Opt. Express 2017, 25, 30946. [Google Scholar] [CrossRef]

- Gao, L.; Chen, L.; Huang, L.; Liu, S.; Yin, Z.; Chen, X. Simultaneous measurement of strain and load using a fiber laser sensor. IEEE Sens. J. 2012, 12, 1513–1517. [Google Scholar] [CrossRef]

- Gonzalez-Reyna, M.A.; Alvarado-Mendez, E.; Estudillo-Ayala, J.M.; Vargas-Rodriguez, E.; Sosa-Morales, M.E.; Sierra-Hernandez, J.M.; Jauregui-Vazquez, D.; Rojas-Laguna, R. Laser temperature sensor based on a fiber bragg grating. IEEE Photonics Technol. Lett. 2015, 27, 1141–1144. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, H.; Dai, W.; Yang, J. Highly discriminative simultaneous measurement of level, refractive index and temperature of liquid by dual-wavelength fiber ring-cavity laser sensor. Measurement 2022, 204, 112055. [Google Scholar] [CrossRef]

- Liang, L.; Ren, G.; Yin, B.; Peng, W.; Liang, X.; Jian, S. Refractive index and temperature sensor based on fiber ring laser with STCS fiber structure. IEEE Photonics Technol. Lett. 2014, 26, 2201–2204. [Google Scholar] [CrossRef]

- Yin, Z.; Gao, L.; Liu, S.; Zhang, L.; Wu, F.; Chen, L.; Chen, X. Fiber ring laser sensor for temperature measurement. J. Light. Technol. 2010, 28, 3403–3408. [Google Scholar] [CrossRef]

- Shi, J.; Wang, Y.; Xu, D.; Zhang, H.; Su, G.; Duan, L.; Yan, C.; Yan, D.; Fu, S.; Yao, J. Temperature Sensor Based on Fiber Ring Laser with Sagnac Loop. IEEE Photonics Technol. Lett. 2016, 28, 794–797. [Google Scholar] [CrossRef]

- Bai, X.; Yuan, J.; Gu, J.; Wang, S.; Zhao, Y.; Pu, S.; Zeng, X. Magnetic field sensor using fiber ring cavity laser based on magnetic fluid. IEEE Photonics Technol. Lett. 2016, 28, 115–118. [Google Scholar] [CrossRef]

- Cheng, L.; Han, J.; Jin, L.; Guo, Z.; Guan, B.-O. Sensitivity enhancement of Faraday effect based heterodyning fiber laser magnetic field sensor by lowering linear birefringence. Opt. Express 2013, 21, 30156. [Google Scholar] [CrossRef] [PubMed]

- Liang, X.; Liu, Z.; Wei, H.; Li, Y.; Jian, S. Detection of Liquid Level with an MI-Based Fiber Laser Sensor Using Few-Mode EMCF. IEEE Photonics Technol. Lett. 2015, 27, 805–808. [Google Scholar] [CrossRef]

- Liu, X.; Wang, F.; Yang, J.; Zhang, X.; Du, X. Fiber ring laser directional torsion sensor with ultra-wide linear response. Sensors 2019, 19, 3613. [Google Scholar] [CrossRef]

- Hong, J.B.; Yeo, Y.B.; Lee, B.W.; Kim, B.Y. Phase sensitive detection for mode-locked fiber laser gyroscope. IEEE Photonics Technol. Lett. 1999, 11, 1030–1032. [Google Scholar] [CrossRef]

- Yang, X.; Duan, L.; Zhang, H.; Lu, Y.; Wang, G.; Yao, J. Highly sensitive dual-wavelength fiber ring laser sensor for the low concentration gas detection. Sens. Actuators B Chem. 2019, 296, 126637. [Google Scholar] [CrossRef]

- Shi, J.; Wang, Y.; Xu, D.; He, Y.; Jiang, J.; Xu, W.; Zhang, H.; Su, G.; Yan, C.; Yan, D.; et al. Remote Gas Pressure Sensor Based on Fiber Ring Laser Embedded with Fabry-Pérot Interferometer and Sagnac Loop. IEEE Photonics J. 2016, 8, 6804408. [Google Scholar] [CrossRef]

- Meng, D.; Zhang, X.; Wang, D.; Miao, C.; Shi, J.; Li, X.; Bai, H.; Chen, H.; Guo, C.; Yao, J. Gas Pressure Sensor with Low Detection Limit Based on Fabry-Perot Interferometer and Intracavity Sensing of Fiber Ring Laser. IEEE Sens. J. 2022, 22, 6606–6611. [Google Scholar] [CrossRef]

- Mądry, M.; Alwis, L.; Binetti, L.; Pajewski, Ł.; Bereś-Pawlik, E. Simultaneous Measurement of Temperature and Relative Humidity Using a Dual-Wavelength Erbium-Doped Fiber Ring Laser Sensor. IEEE Sens. J. 2019, 19, 9215–9220. [Google Scholar] [CrossRef]

- Fan, H.; Chen, L.; Bao, X. Fiber-Optic Sensor Based on Core-Offset Fused Unequal-Length Fiber Segments to Improve Ultrasound Detection Sensitivity. IEEE Sens. J. 2020, 20, 9148–9154. [Google Scholar] [CrossRef]

- Bellemare, A.; Karásek, M.; Riviere, C.; Babin, F.; He, G.; Roy, V.; Schinn, G.W. A broadly tunable erbium-doped fiber ring laser: Experimentation and modeling. IEEE J. Sel. Top. Quantum Electron. 2001, 7, 22–29. [Google Scholar] [CrossRef]

- Paschotta, R.; Nilsson, J.; Reekie, L.; Trooper, A.C.; Hanna, D.C. Single-frequency ytterbium-doped fiber laser stabilized by spatial hole burning. Opt. Lett. 1997, 22, 40. [Google Scholar] [CrossRef]

- Sierra-Hernandez, J.M.; Rojas-Laguna, R.; Vargas-Rodriguez, E.; Estudillo-Ayala, J.M.; Jauregui-Vazquez, D.; Guzḿan-Chávez, A.D.; Zaca-Moran, P. A tunable multi-wavelength erbium doped fiber laser based on a Mach-Zehnder interferometer and photonic crystal fiber. Laser Phys. 2013, 23, 125103. [Google Scholar] [CrossRef]

- Merza, H.Q.; Al-Hayali, S.K.; Al-Janabi, A.H. All-fiber Mach–Zehnder interferometric comb filter based on macrobend single-mode optical fiber for selecting lasing performance in 1-micron region. Opt. Commun. 2021, 493, 127017. [Google Scholar] [CrossRef]

- Martin-Vela, J.A.; Sierra-Hernandez, J.M.; Jauregui-Vazquez, D.; Estudillo-Ayala, J.M.; Hernandez-Garcia, J.C.; Reyes-Ayona, J.R.; Garcia-Mina, D.F.; Rojas-Laguna, R. Highly Sensitive Fiber Ring Laser Sensor for Curvature Using a Modal Interferometer. IEEE Sens. J. 2020, 20, 9864–9870. [Google Scholar] [CrossRef]

- Bai, Y.; Yan, F.; Feng, T.; Han, W.; Zhang, L.; Cheng, D.; Bai, Z.; Wen, X. Temperature fiber sensor based on single longitudinal mode fiber laser in 2 μm band with Sagnac interferometer. Opt. Fiber Technol. 2019, 51, 71–76. [Google Scholar] [CrossRef]

- Smith, S.P.; Zarinetchi, F.; Ezekiel, S. Narrow-linewidth stimulated Brillouin fiber laser and applications. Opt. Lett. 1991, 16, 393. [Google Scholar] [CrossRef]

- Harun, S.W.; Shirazi, M.R.; Ahmad, H. Multiple wavelength Brillouin fiber laser from injection of intense signal light. Laser Phys. Lett. 2007, 4, 678–680. [Google Scholar] [CrossRef]

- Kotlicki, O.; Scheuer, J.; Shahriar, M.S. Theoretical study on Brillouin fiber laser sensor based on white light cavity. Opt. Express 2012, 20, 28234. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhang, M.; Wang, P.; Li, L.; Wang, Y.; Bao, X. Multiwavelength Single-Longitudinal-Mode Brillouin-Erbium Fiber Laser Sensor for Temperature Measurements with Ultrahigh Resolution. IEEE Photonics J. 2015, 7, 6802809. [Google Scholar] [CrossRef]

- Murray, J.B.; Cerjan, A.; Redding, B. Distributed Brillouin fiber laser sensor. Optica 2022, 9, 80. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, C.Q. Actively Q-switched fiber lasers: Switching dynamics and nonlinear processes. Prog. Quantum Electron. 2007, 31, 131–216. [Google Scholar] [CrossRef]

- Ippen, E.P. Principles of passive mode locking. Appl. Phys. B Laser Opt. 1994, 58, 159–170. [Google Scholar] [CrossRef]

- Rønnekleiv, E.; Ibsen, M.; Zervas, M.N.; Laming, R.I. Characterization of fiber distributed-feedback lasers with an index-perturbation method. Appl. Opt. 1999, 38, 4558. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, W.; Xu, T.; He, J.; Zhang, F.; Li, F. Fiber laser sensing system and its applications. Photonic Sens. 2011, 1, 43–53. [Google Scholar] [CrossRef]

- Hadeler, O.; Ibsen, M.; Zervas, M.N. Distributed-feedback fiber laser sensor for simultaneous strain and temperature measurements operating in the radio-frequency domain. Appl. Opt. 2001, 40, 3169. [Google Scholar] [CrossRef]

- Kringlebotn, J.T.; Loh, W.H.; Laming, R.I. Polarimetric Er3+-doped fiber distributed-feedback laser sensor for differential pressure and force measurements. Opt. Lett. 1996, 21, 1869. [Google Scholar] [CrossRef]

- Kim, H.K.; Kim, S.K.; Kim, B.Y. Polarization control of polarimetric fiber-laser sensors. Opt. Lett. 1993, 18, 1465. [Google Scholar] [CrossRef]

- Shao, L.Y.; Liang, J.; Zhang, X.; Pan, W.; Yan, L. High-resolution refractive index sensing with dual-wavelength fiber laser. IEEE Sens. J. 2016, 16, 8463–8467. [Google Scholar] [CrossRef]

- Yang, X.; Luo, S.; Chen, Z.; Ng, J.H. Refractive index sensor based on fiber laser. Microw. Opt. Technol. Lett. 2007, 49, 916–918. [Google Scholar] [CrossRef]

- Arellano-Sotelo, H.; Barmenkov, Y.O.; Kir’yanov, A.V. The use of erbium fiber laser relaxation frequency for sensing refractive index and solute concentration of aqueous solutions. Laser Phys. Lett. 2008, 5, 825–829. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Z.; Chen, W.; Zhang, X. Refractive index and temperature sensor based on fiber ring laser with tapered seven core fiber structure in 2 μm band. Opt. Fiber Technol. 2021, 61, 102388. [Google Scholar] [CrossRef]

- Lin, W.; Zhou, S.; Shao, L.Y.; Vai, M.I.; Shum, P.P.; Zhao, F.; Liu, S.; Hu, J.; Liu, Y. In-Fiber Mach-Zehnder Interferometer Based on Er Doped Up-Taper and Peanut-Shaped Fiber Structure in Fiber Ring Laser. IEEE Access 2021, 9, 128126–128132. [Google Scholar] [CrossRef]

- Hu, X.-g.; Zhao, Y.; Peng, Y.; Tong, R.-j.; Zheng, H.-k.; Zhao, J.; Hu, S. In-fiber optofluidic michelson interferometer for detecting small volume and low concentration chemicals with a fiber ring cavity laser. Sens. Actuators B Chem. 2022, 370, 132467. [Google Scholar] [CrossRef]

- Cai, L.; Zhao, Y.; Li, X. gang A fiber ring cavity laser sensor for refractive index and temperature measurement with core-offset modal interferometer as tunable filter. Sens. Actuators B Chem. 2017, 242, 673–678. [Google Scholar] [CrossRef]

- Zhao, Y.; Cai, L.; Li, X.G. In-Fiber Mach-Zehnder Interferometer Based on Up-Taper Fiber Structure with Er3+ Doped Fiber Ring Laser. J. Light. Technol. 2016, 34, 3475–3481. [Google Scholar] [CrossRef]

- Lin, W.; Liu, Y.; Shum, P.P.; Shao, L. In-Line Mach Zehnder Interferometer Based on Ytterbium Doped Fiber with Up-Taper Structure in Fiber Ring Laser and Its Application in Sensing. Sensors 2022, 22, 9196. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, L.; Lu, Z.; Wang, G.; Wang, X.; Ran, Y.; Feng, X.; Guan, B. High-speed refractive index sensing system based on Fourier domain mode locked laser. Opt. Express 2019, 27, 7988. [Google Scholar] [CrossRef]

- Liu, J.; Wang, M.; Liang, X.; Dong, Y.; Xiao, H.; Jian, S. Erbium-doped fiber ring laser based on few-mode-singlemode-few-mode fiber structure for refractive index measurement. Opt. Laser Technol. 2017, 93, 74–78. [Google Scholar] [CrossRef]

- Yin, B.; Wu, S.; Wang, M.; Liu, W.; Li, H.; Wu, B.; Wang, Q. High-sensitivity refractive index and temperature sensor based on cascaded dual-wavelength fiber laser and SNHNS interferometer. Opt. Express 2019, 27, 252. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, J.; Zhang, C.; Guo, C.; Bai, H.; Xu, W.; Chen, L.; Miao, C. Refractive Index Fiber Laser Sensor by Using Tunable Filter Based on No-Core Fiber. IEEE Photonics J. 2016, 8, 6805008. [Google Scholar] [CrossRef]

- Shi, J.; Wang, Y.; Xu, D.; Liu, T.; Xu, W.; Zhang, C.; Yan, C.; Yan, D.; Tang, L.; He, Y.; et al. Temperature Self-Compensation High-Resolution Refractive Index Sensor Based on Fiber Ring Laser. IEEE Photonics Technol. Lett. 2017, 29, 1743–1746. [Google Scholar] [CrossRef]

- Perez-Herrera, R.A.; Soares, L.; Silva, S.; Frazão, O. Ring Cavity Erbium-Doped Fiber for Refractive Index Measurements. Sensors 2022, 22, 9315. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Bandyopadhyay, S.; Shao, L.Y.; Xiao, D.; Gu, G.; Song, Z. Side-Polished DBR Fiber Laser with Enhanced Sensitivity for Axial Force and Refractive Index Measurement. IEEE Photonics J. 2019, 11, 7101910. [Google Scholar] [CrossRef]

- Álvarez-Tamayo, R.I.; Prieto-Cortés, P. Refractive Index Fiber Laser Sensor by Using a Fiber Ball Lens Interferometer with Adjustable Free Spectral Range. Sensors 2023, 23, 3045. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Z.; Xie, L.; Peng, W. Refractive Index Sensor Based on Fiber Ring Laser. IEEE Photonics Technol. Lett. 2016, 28, 524–527. [Google Scholar] [CrossRef]

- Li, M.M.; Liu, B.; Liang, Y.Z.; Liang, H.; Li, J.; Guan, B.O. Refractive Index Detection Based on Beat-frequency of Cladding-carved DBR Fiber Lasers. Guangzi Xuebao/Acta Photonica Sin. 2017, 46, 15–17. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Sun, T.; Grattan, K.T.V.; Palmer, A.W. Erbium-doped intrinsic fiber sensor for cryogenic temperature measurement. Sens. Actuators A Phys. 1998, 71, 183–186. [Google Scholar] [CrossRef]

- Mandal, J.; Shen, Y.; Pal, S.; Sun, T.; Grattan, K.T.V.; Augousti, A.T. Bragg grating tuned fiber laser system for measurement of wider range temperature and strain. Opt. Commun. 2005, 244, 111–121. [Google Scholar] [CrossRef]

- Mandal, J.; Pal, S.; Sun, T.; Grattan, K.T.V.; Augousti, A.T.; Wade, S.A. Bragg Grating-Based Fiber-Optic Laser Probe for Temperature Sensing. IEEE Photonics Technol. Lett. 2004, 16, 218–220. [Google Scholar] [CrossRef]

- Han, Y.-G.; Tran, T.V.A.; Kim, S.-H.; Lee, S.B. Multiwavelength Raman-fiber-laser-based long-distance remote sensor for simultaneous measurement of strain and temperature. Opt. Lett. 2005, 30, 1282. [Google Scholar] [CrossRef]

- Alvarez-Chavez, J.A. Modeling of temperature sensitivity on tapered Yb-doped fiber lasers. Opt. Eng. 2012, 51, 074203. [Google Scholar] [CrossRef]

- Fukushima, K.; Wada, A.; Tanaka, S.; Ito, F. EDF laser temperature sensor using double-pass cascaded-chirped long-period fiber grating in sigma-cavity configuration. Opt. Commun. 2022, 508, 127713. [Google Scholar] [CrossRef]

- Gao, L.; Huang, L.; Chen, L.; Chen, X. Simultaneous measurement of strain and temperature with a multi-longitudinal mode erbium-doped fiber laser. Opt. Commun. 2013, 297, 98–101. [Google Scholar] [CrossRef]

- Pinto, A.M.R.; Lopez-Amo, M.; Kobelke, J.; Schuster, K. Temperature Fiber laser sensor based on a hybrid cavity and a random mirror. J. Light. Technol. 2012, 30, 1168–1172. [Google Scholar] [CrossRef]

- Yang, X.; Lu, Y.; Liu, B.; Yao, J. Fiber Ring Laser Temperature Sensor Based on Liquid-Filled Photonic Crystal Fiber. IEEE Sens. J. 2017, 17, 6948–6952. [Google Scholar] [CrossRef]

- Ahmad, H.; Zulkhairi, A.S.; Azzuhri, S.R. Temperature sensor and fiber laser based on optical microfiber knot resonator. Optik 2018, 154, 294–302. [Google Scholar] [CrossRef]

- Lin, W.; Hu, J.; Zhao, F.; Sun, S.; Liu, Y.; Liu, S.; Yu, F.; Mak, P.U.; Pun, S.H.; Shum, P.P.; et al. Adaptive Fiber-Ring Lasers Based on Isopropanol Filled Microfiber Coupler for High-Sensitivity Temperature Sensing. Micromachines 2022, 13, 1697. [Google Scholar] [CrossRef] [PubMed]

- Xie, H.; Sun, J.; Feng, D. Simultaneous measurement of strain and temperature based on hybrid EDF/Brillouin laser. Opt. Express 2016, 24, 11475. [Google Scholar] [CrossRef] [PubMed]

- Yin, B.; Sang, G.; Yan, R.; Wu, Y.; Wu, S.; Wang, M.; Liu, W.; Li, H.; Wang, Q. Wavelength-and Intensity-Demodulated Dual-Wavelength Fiber Laser Sensor for Simultaneous RH and Temperature Detection. IEEE Access 2020, 8, 52091–52099. [Google Scholar] [CrossRef]

- Song, S.; Jung, A.; Oh, K. High-temperature sensitivity in stimulated brillouin scattering of 1060 nm single-mode fibers. Sensors 2019, 19, 4731. [Google Scholar] [CrossRef] [PubMed]

- Lin, W.; Liu, Y.; Shao, L.; Vai, M.I. A fiber ring laser sensor with a side polished evanescent enhanced fiber for highly sensitive temperature measurement. Micromachines 2021, 12, 586. [Google Scholar] [CrossRef]

- Lin, W.; Shao, L.; Yibin, L.; Bandyopadhyay, S.; Yuhui, L.; Weijie, X.; Shuaiqi, L.; Jie, H.; Vai, M.I. Temperature Sensor Based on Fiber Ring Laser with Cascaded Fiber Optic Sagnac Interferometers. IEEE Photonics J. 2021, 13, 2–11. [Google Scholar] [CrossRef]

- Shi, J.; Yang, F.; Xu, W.; Xu, D.; Bai, H.; Guo, C.; Wu, Y.; Zhang, S.; Liu, T.; Yao, J. High-Resolution Temperature Sensor Based on Intracavity Sensing of Fiber Ring Laser. J. Light. Technol. 2020, 38, 2010–2014. [Google Scholar] [CrossRef]

- Diaz, S.; Lopez-Amo, M. Multiwavelength operation of erbium-doped fiber-ring laser for temperature measurements. Opt. Laser Technol. 2016, 78, 134–138. [Google Scholar] [CrossRef]

- Hao, X.; Tong, Z.; Zhang, W.; Cao, Y. A fiber laser temperature sensor based on SMF core-offset structure. Opt. Commun. 2015, 335, 78–81. [Google Scholar] [CrossRef]

- Frazo, O.; Correia, C.; Santos, J.L.; Baptista, J.M. Raman fibre Bragg-grating laser sensor with cooperative Rayleigh scattering for strain-temperature measurement. Meas. Sci. Technol. 2009, 20, 045203. [Google Scholar] [CrossRef]

- Lin, W.; Zhou, S.; Liu, Y.; Vai, M.I.; Shao, L. Liquid crystal-embedded hollow core fiber temperature sensor in fiber ring laser. Appl. Sci. 2021, 11, 7103. [Google Scholar] [CrossRef]

- Lin, W.; Zhao, F.; Shao, L.Y.; Vai, M.I.; Shum, P.P.; Sun, S. Temperature Sensor Based on Er-Doped Cascaded-Peanut Taper Structure In-Line Interferometer in Fiber Ring Laser. IEEE Sens. J. 2021, 21, 21594–21599. [Google Scholar] [CrossRef]

- Zou, H.; Ma, L.; Xiong, H.; Zhang, Y.; Li, Y.T. Fiber ring laser sensor based on Fabry-Perot cavity interferometer for temperature sensing. Laser Phys. 2018, 28, 015102. [Google Scholar] [CrossRef]

- Luo, J.; Cai, X.; Wang, H.; Fu, H. Temperature sensing technique by using a microwave photonics filter based on an actively mode-locked fiber laser. Microw. Opt. Technol. Lett. 2021, 63, 2535–2540. [Google Scholar] [CrossRef]

- Luo, J.; Wang, H.; Cai, X.; Luo, Z.; Fu, H. Temperature-sensing scheme based on a passively mode-locked fiber laser via beat frequency demodulation. Chin. Opt. Lett. 2023, 21, 20603. [Google Scholar] [CrossRef]

- Yang, X.; Luo, S.; Chen, Z.; Ng, J.H.; Lu, C. Fiber Bragg grating strain sensor based on fiber laser. Opt. Commun. 2007, 271, 203–206. [Google Scholar] [CrossRef]

- Guo, K.; He, J.; Xu, G.; Wang, Y. Dual-polarization distributed feedback fiber laser sensor based on femtosecond laser-inscribed in-fiber stressors for simultaneous strain and temperature measurements. IEEE Access 2020, 8, 97823–97829. [Google Scholar] [CrossRef]

- Gao, L.; Chen, L.; Huang, L.; Chen, X. Multimode fiber laser for simultaneous measurement of strain and temperature based on beat frequency demodulation. Opt. Express 2012, 20, 22517. [Google Scholar] [CrossRef]

- Yu, K.; Wu, C.; Sun, M.; Lu, C.; Tam, H.Y.; Zhao, Y.; Shao, L. Fiber laser sensor for simultaneously axial strain and transverse load detection. Measurement 2015, 62, 137–141. [Google Scholar] [CrossRef]

- Kang, Z.; Sun, J.; Bai, Y.; Jian, S. Twin-Core Fiber-Based Erbium-Doped Fiber Laser Sensor for Decoupling Measurement of Temperature and Strain. IEEE Sens. J. 2015, 15, 6828–6832. [Google Scholar] [CrossRef]

- Liu, D.; Ngo, N.Q.; Tjin, S.C.; Dong, X. A dual-wavelength fiber laser sensor system for measurement of temperature and strain. IEEE Photonics Technol. Lett. 2007, 19, 1148–1150. [Google Scholar] [CrossRef]

- Tan, Y.-N.; Zhang, Y.; Jin, L.; Guan, B.-O. Simultaneous strain and temperature fiber grating laser sensor based on radio-frequency measurement. Opt. Express 2011, 19, 20650. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Gonzalez, A.; Perez-Herrera, R.A.; Roldan-Varona, P.; Duran-Escudero, M.; Rodriguez-Cobo, L.; Lopez-Higuera, J.M.; Lopez-Amo, M. A Dual-Wavelength Fiber Laser Sensor with Temperature and Strain Discrimination. Sensors 2022, 22, 6888. [Google Scholar] [CrossRef] [PubMed]

- Yin, Z.; Liu, S.; Zhang, L.; Gao, L.; Chen, X. Studies on multi-wavelength fiber Bragg grating laser strain sensor. Opt. Commun. 2010, 283, 4996–4999. [Google Scholar] [CrossRef]

- Tian, J.; Hou, M.-j.; Jiang, Y.; Luo, H.; Tang, C.-y. Fiber ring laser cavity for strain sensing via beat frequency demodulation. Opt. Commun. 2020, 476, 126326. [Google Scholar] [CrossRef]

- Martins, H.F.; Marques, M.B.; Frazão, O. Temperature-insensitive strain sensor based on four-wave mixing using Raman fiber Bragg grating laser sensor with cooperative Rayleigh scattering. Appl. Phys. B Lasers Opt. 2011, 104, 957–960. [Google Scholar] [CrossRef]

- Liu, Z.B.; Li, Y.; Liu, Y.; Tan, Z.W.; Jian, S. A static axial strain fiber ring cavity laser sensor based on multi-modal interference. IEEE Photonics Technol. Lett. 2013, 25, 2050–2053. [Google Scholar] [CrossRef]

- Wang, J.; Ge, S.; Ren, H.; Huang, T.; Yang, P.; Xu, P.; Bai, S.; Dai, S.; Du, J.; Nie, Q. High-sensitivity micro-strain sensing using a broadband wavelength-tunable thulium-doped all-fiber structured mode-locked laser. Opt. Lett. 2022, 47, 34. [Google Scholar] [CrossRef]

- Guo, J.; Ding, Y.; Xiao, X.; Kong, L.; Yang, C. Multiplexed static FBG strain sensors by dual-comb spectroscopy with a free running fiber laser. Opt. Express 2018, 26, 16147–16154. [Google Scholar] [CrossRef]

- Bai, X.; Fan, D.; Wang, S.; Pu, S.; Zeng, X. Strain Sensor Based on Fiber Ring Cavity Laser with Photonic Crystal Fiber In-Line Mach-Zehnder Interferometer. IEEE Photonics J. 2014, 6, 6801608. [Google Scholar] [CrossRef]

- Guo, W.; Lu, F.; Luo, S.; Yang, X.; Zhou, X.; Lu, C. Interrogation of fiber Bragg grating sensor based on Er-doped fiber laser. Microw. Opt. Technol. Lett. 2006, 48, 1904–1907. [Google Scholar] [CrossRef]

- Contreras-Teran, M.A.; Jauregui-Vazquez, D.; Gallegos-Arellano, E.; Rojas-Laguna, R.; Reyes-Ayona, J.R.; Estudillo-Ayala, J.M.; Hernandez-Garcia, J.C.; Sierra-Hernandez, J.M. High-resolution strain fiber laser-sensor based on core-offset mach-zehnder interferometer. Meas. Sci. Technol. 2023, 34, 55202. [Google Scholar] [CrossRef]

- Kudelin, I.; Sugavanam, S.; Chernysheva, M. Rotation active sensors based on ultrafast fibre lasers. Sensors 2021, 21, 3530. [Google Scholar] [CrossRef]

- Zhang, W.; Xian, T.; Wang, W.; Zhan, L. Advancement and expectations for mode-locked laser gyroscopes. J. Opt. Soc. Am. B 2022, 39, 3159. [Google Scholar] [CrossRef]

- Xiong, H.; Xu, B.; Wang, D.N. Temperature Insensitive Optical Fiber Laser Bend Sensor with a Low Detection Limit. IEEE Photonics Technol. Lett. 2015, 27, 2599–2602. [Google Scholar] [CrossRef]

- Álvarez-Tamayo, R.I.; Durán-Sánchez, M.; Prieto-Cortés, P.; Salceda-Delgado, G.; Castillo-Guzmán, A.A.; Selvas-Aguilar, R.; Ibarra-Escamilla, B.; Kuzin, E.A. All-fiber laser curvature sensor using an in-fiber modal interferometer based on a double clad fiber and a multimode fiber structure. Sensors 2017, 17, 2744. [Google Scholar] [CrossRef]

- Martin-Vela, J.A.; Gallegos-Arellano, E.; Sierra-Hernández, J.M.; Estudillo-Ayala, J.M.; Jauregui-Vázquez, D.; Avila-Garcia, M.S.; Ramírez-Gasca, H.; Rojas-Laguna, R. All single-mode-fiber supercontinuum source setup for monitoring of multiple gases applications. Sensors 2020, 20, 3239. [Google Scholar] [CrossRef]

- Chen, H.; Gao, S.; Zhang, M.; Zhang, J.; Qiao, L.; Wang, T.; Gao, F.; Hu, X.; Li, S.; Zhu, Y. Advances in random fiber lasers and their sensing application. Sensors 2020, 20, 6122. [Google Scholar] [CrossRef]

- Fu, H.; Chen, D.; Cai, Z. Fiber sensor systems based on fiber laser and microwave photonic technologies. Sensors 2012, 12, 5395–5419. [Google Scholar] [CrossRef]

- Shi, W.; Fang, Q.; Zhu, X.; Norwood, R.A.; Peyghambarian, N. Fiber lasers and their applications [Invited]. Appl. Opt. 2014, 53, 6554–6568. [Google Scholar] [CrossRef]

- Addanki, S.; Amiri, I.S.; Yupapin, P. Review of optical fibers-introduction and applications in fiber lasers. Results Phys. 2018, 10, 743–750. [Google Scholar] [CrossRef]

| Fiber Laser Technique | SH | Sensitivity | Gain-Medium | Reference |

|---|---|---|---|---|

| CW | Up-taper | 44.8 nm/RIU | Er Doped Fiber | [80] |

| CW | Bend-loop | 60nm/RIU | Er Doped Fiber | [90] |

| CW | Core-offset joint | 52.3 nm/RIU | Er Doped Fiber | [33] |

| CW | No Core Fiber-FBG | 196.1 dB/RIU | Er Doped Fiber | [86] |

| CW | Up-taper-MZI | 151 nm/RIU | Yb Doped Fiber | [81] |

| CW | Taper Fiber | 163.80 nm/RIU | Er Doped Fiber | [42] |

| CW | No Core Fiber | 113.73 dB/RIU | Er Doped Fiber | [86] |

| CW | FBG | 367.9dB/RIU | Er Doped Fiber | [84] |

| CW | Taper Fiber | 549.599 nm/RIU | Tm Doped Fiber | [77] |

| CW | Michelson Interferometer | 1039.77 nm/RIU | Er Doped Fiber | [78] |

| DFB | Polished-DBR | 240.4MHz/RIU | Er Doped Fiber | [91] |

| DFB | Polished-DBR | 0.1419 GHz/RIU | Er Doped Fiber | [88] |

| Mode-locked | Taper Fiber | 466.3 μs/RIU | SOA | [82] |

| Fiber Laser Technique | SH | Sensitivity/ Temperature Range (°C) | Gain Medium | Reference |

|---|---|---|---|---|

| DFB | FBG | 13.38 pm/°C 22–500 | Er Doped Fiber | [93] |

| CW | FBG | 9.7 pm/°C 25–70 | Er Doped Fiber | [109] |

| CW | Core-offset joint | 44 pm/°C 30–270 | Er Doped Fiber | [110] |

| CW | Sagnac Interferometer | 2 nm/°C 35–31 | Tm Doped Fiber | [61] |

| Raman-Laser | FBG | 30.7 pm/°C 25–55 | Dispersion compensating fiber | [111] |

| EDF/Brillouin Laser | EDF | 1.14 Mhz/°C 25–55 | Er Doped Fiber | [103] |

| CW | Filled Liquid Crystal Hollow Core Fiber | 1.18 nm/°C 22–30 | Er Doped Fiber | [112] |

| CW | Isopropanol Filled optical Coupler | 1.14 nm/°C 20–30 | Er Doped Fiber | [102] |

| CW | Cascaded-Peanut Taper | 571 pm/°C 5–55 | Er Doped Fiber | [113] |

| CW | Fabry-Perot Interferometer | 249 pm/°C 5–55 | Er Doped Fiber | [114] |

| Mode-locked | Long Fiber | 10.27 kHz/°C 30–60 | Er Doped Fiber | [115] |

| Mode-locked | Long Fiber | 44 kHz/°C 20–80 | Er Doped Fiber | [116] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jauregui-Vazquez, D.; Alvarez-Chavez, J.A.; Lozano-Hernandez, T.; Estudillo-Ayala, J.M.; Sierra-Hernandez, J.M.; Offerhaus, H.L. Fiber Laser Sensor Configurations for Refractive Index, Temperature and Strain: A Review. Photonics 2023, 10, 495. https://doi.org/10.3390/photonics10050495

Jauregui-Vazquez D, Alvarez-Chavez JA, Lozano-Hernandez T, Estudillo-Ayala JM, Sierra-Hernandez JM, Offerhaus HL. Fiber Laser Sensor Configurations for Refractive Index, Temperature and Strain: A Review. Photonics. 2023; 10(5):495. https://doi.org/10.3390/photonics10050495

Chicago/Turabian StyleJauregui-Vazquez, D., J. A. Alvarez-Chavez, T. Lozano-Hernandez, J. M. Estudillo-Ayala, J. M. Sierra-Hernandez, and H. L. Offerhaus. 2023. "Fiber Laser Sensor Configurations for Refractive Index, Temperature and Strain: A Review" Photonics 10, no. 5: 495. https://doi.org/10.3390/photonics10050495

APA StyleJauregui-Vazquez, D., Alvarez-Chavez, J. A., Lozano-Hernandez, T., Estudillo-Ayala, J. M., Sierra-Hernandez, J. M., & Offerhaus, H. L. (2023). Fiber Laser Sensor Configurations for Refractive Index, Temperature and Strain: A Review. Photonics, 10(5), 495. https://doi.org/10.3390/photonics10050495