Research on Tip Characterization Techniques Based on Two-Dimensional Self-Traceable Nano-Gratings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of 2D Gratings

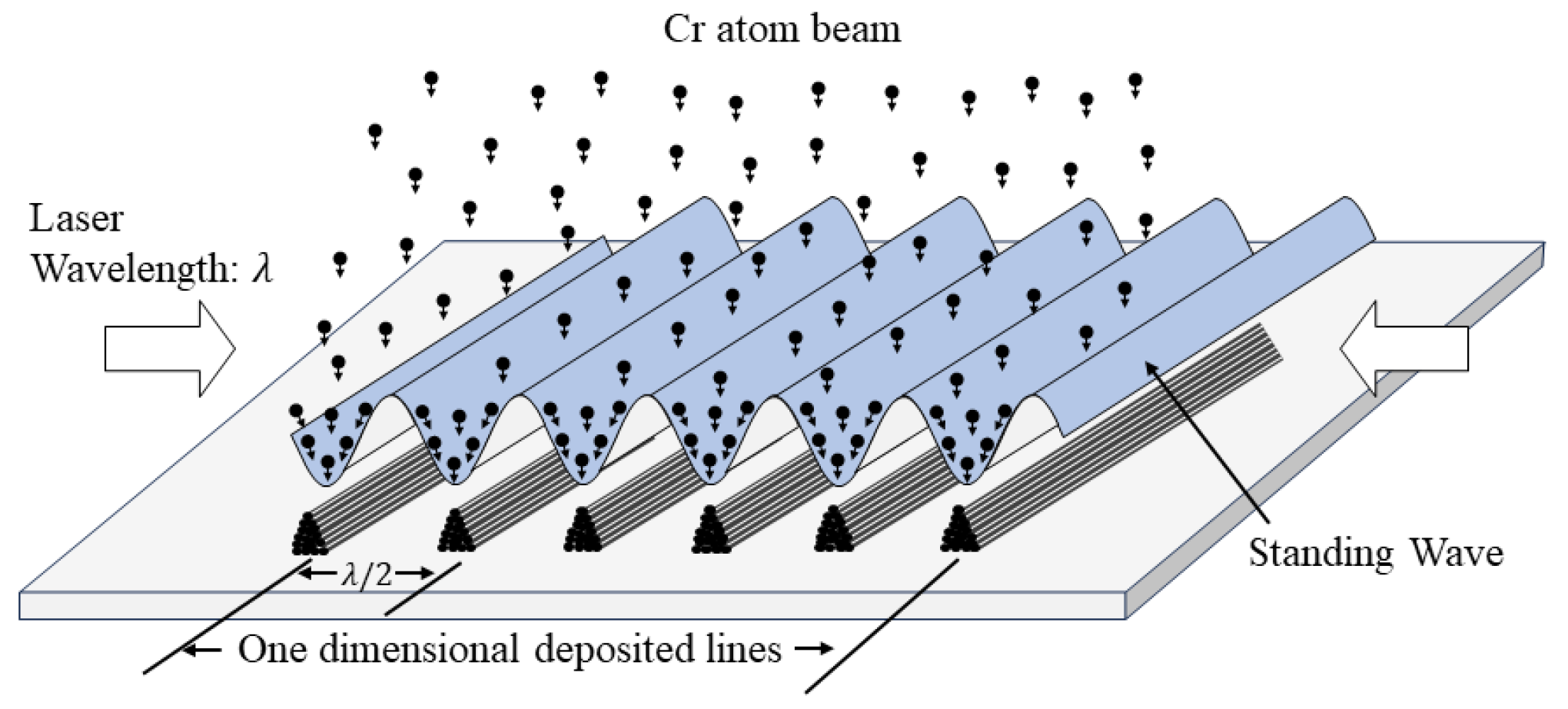

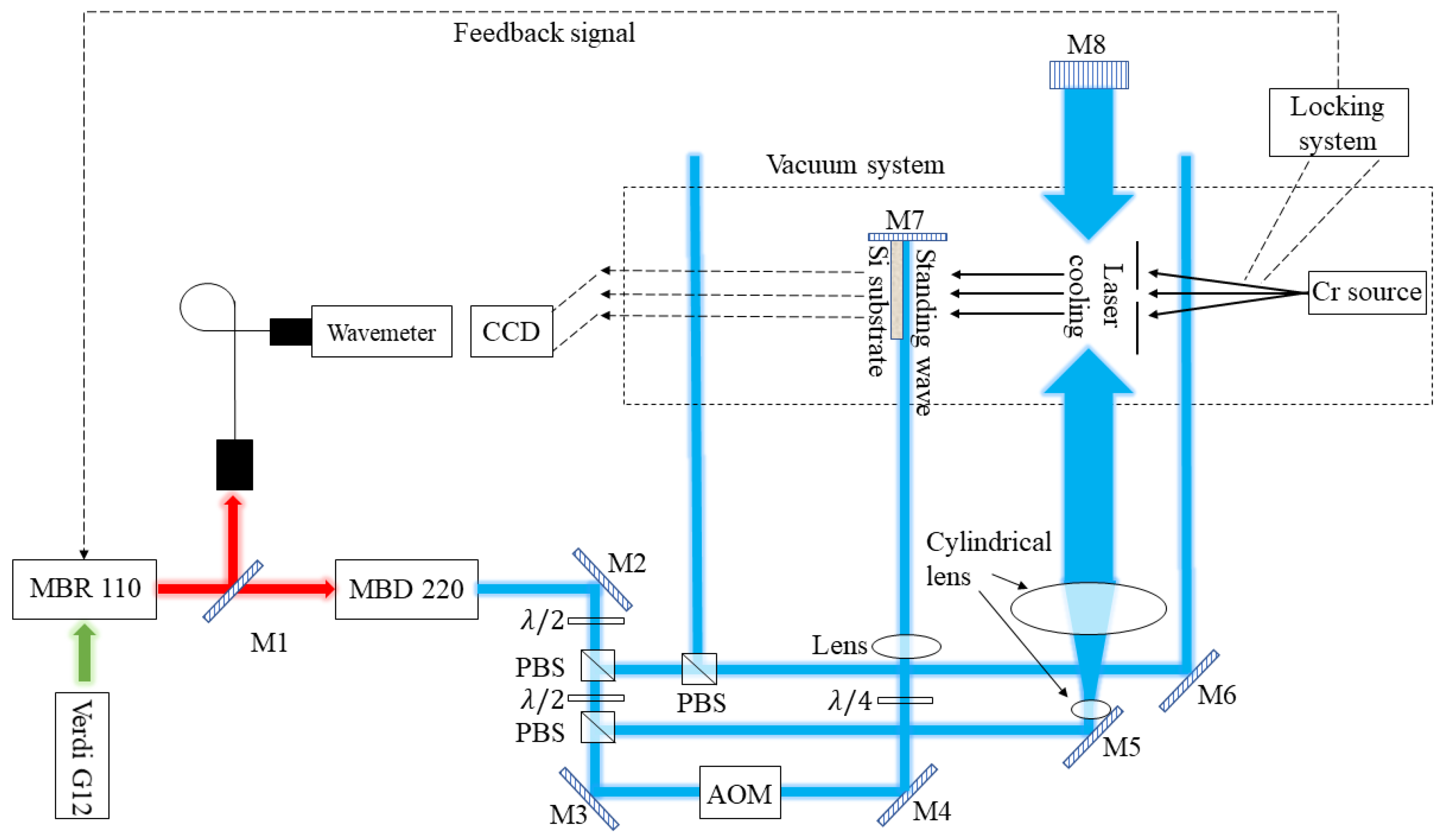

2.1.1. Laser-Focused Chromium Atom Deposition

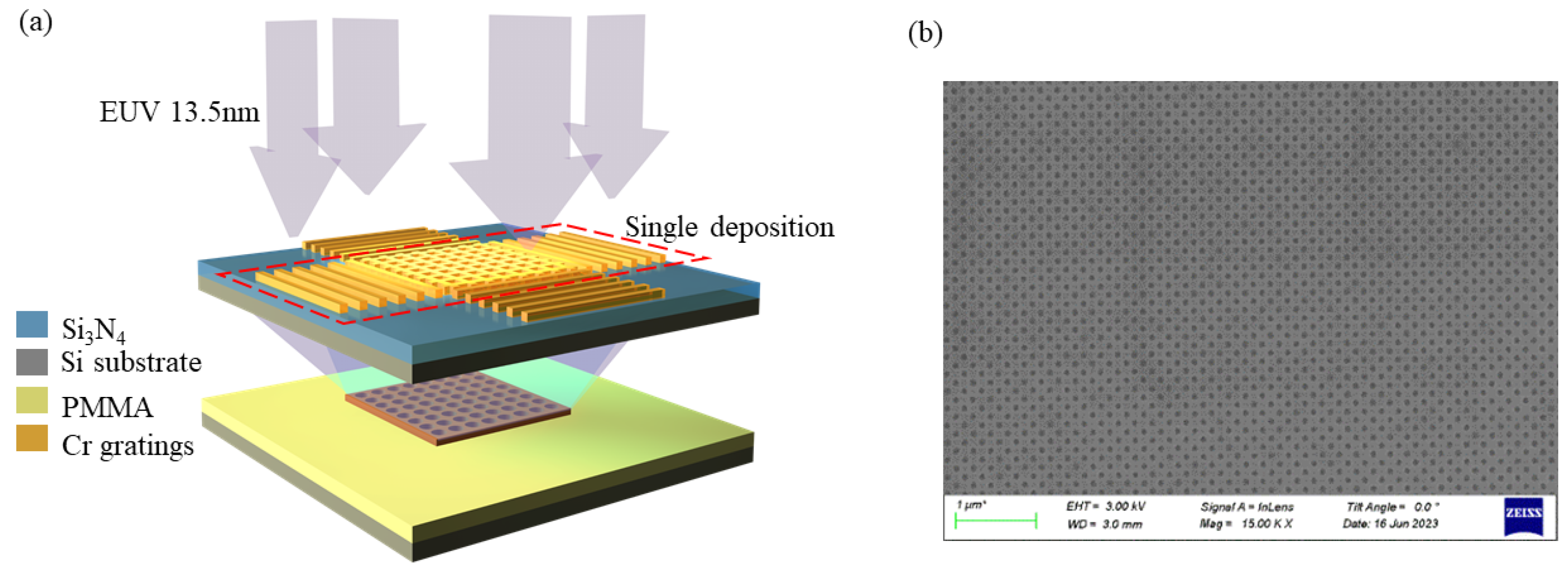

2.1.2. Extreme Ultraviolet Interference Lithography

2.2. Inflation Effect

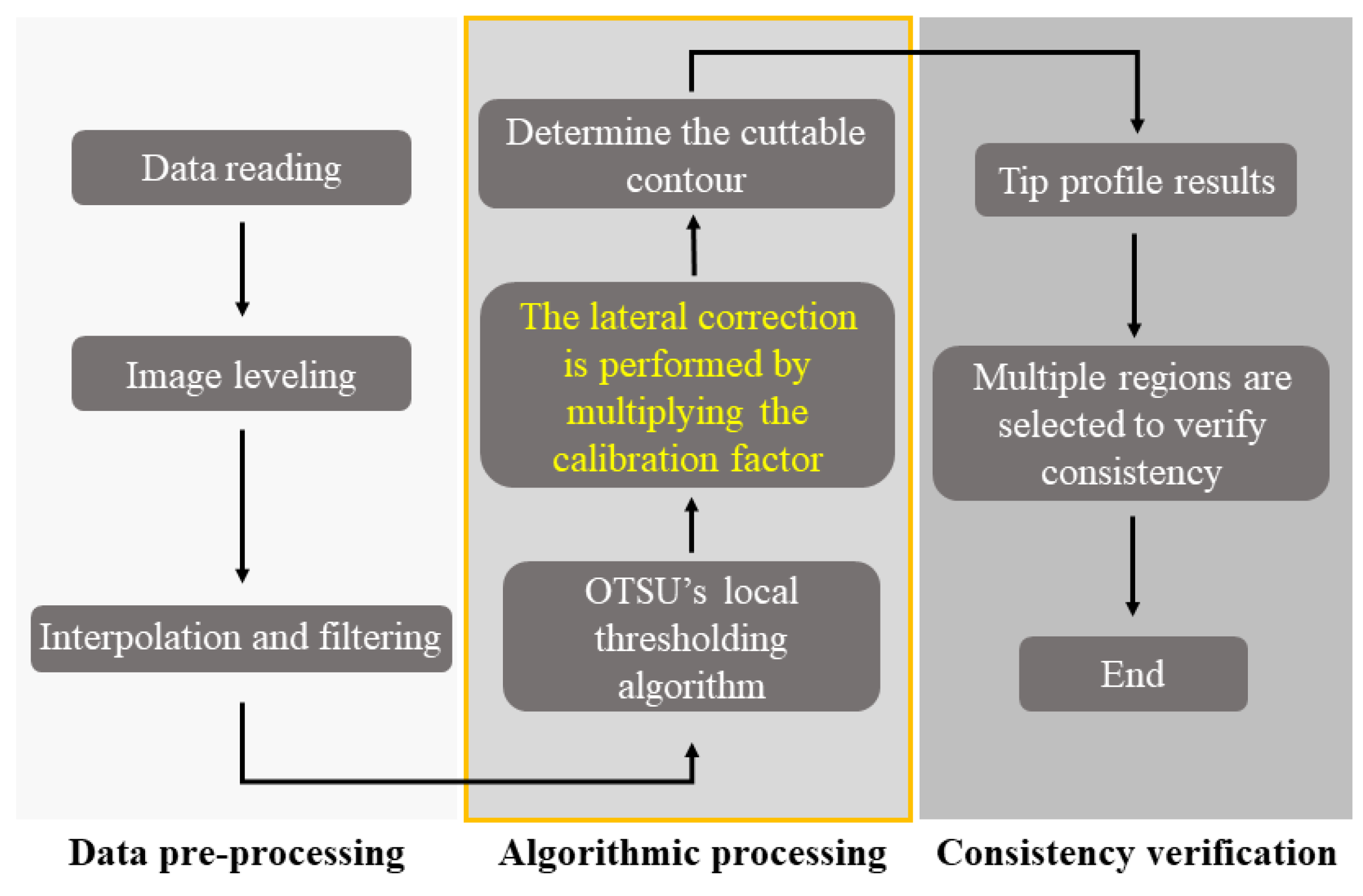

2.3. Characterization Process

3. Results

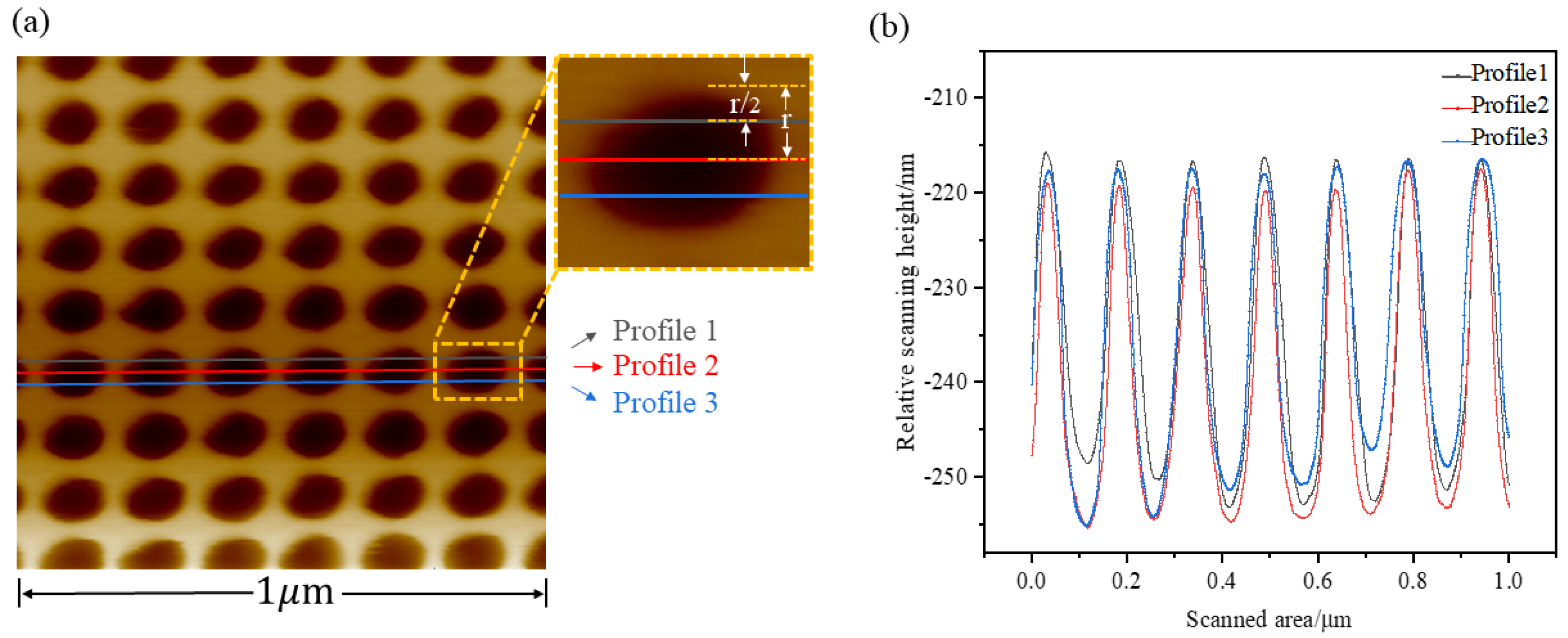

3.1. Periodic Stability Analysis of the Samples

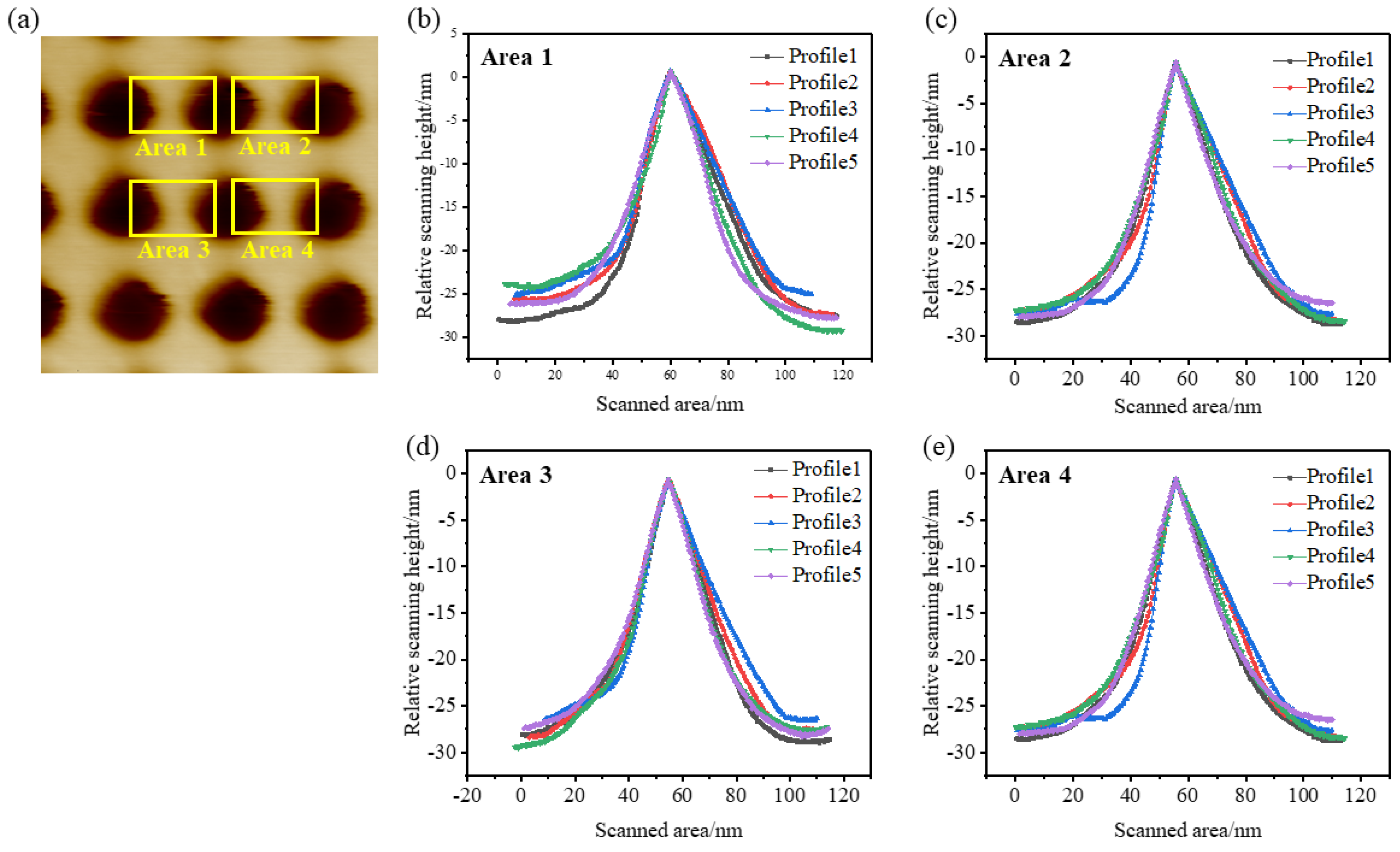

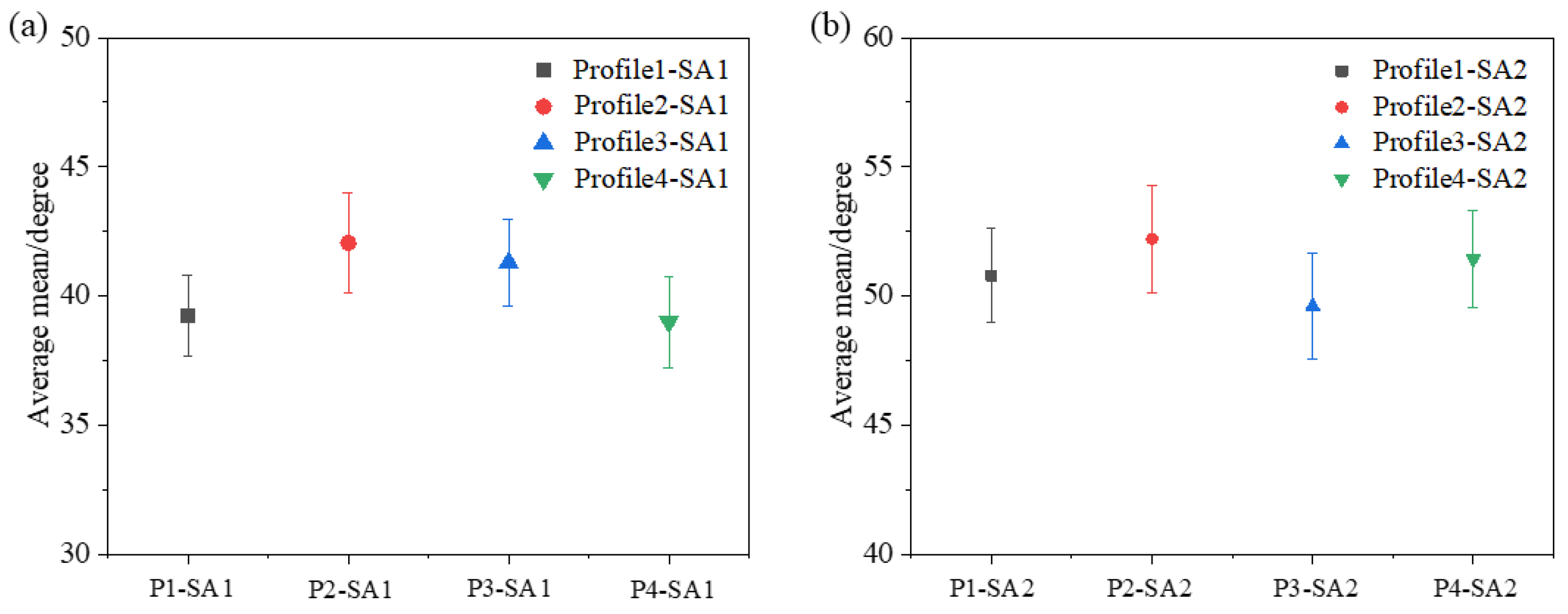

3.2. Tip Characterization Results

3.2.1. The Tip’s X Direction Characterizes the Results

3.2.2. The Tip’s Y Direction Characterizes the Results

4. Discussion

- (1)

- Sample preservation is an urgent issue to address. Given that the primary material of the grating sample is silicon, it is prone to oxidation when exposed to air. This results in the formation of an oxide film approximately 1–2 nm thick on the surface. While the presence of an oxide layer theoretically has a minimal impact on the characterization of the tip sample, it may reduce the surface consistency of the sample and can potentially affect the periodic stability during scanning.

- (2)

- When AFM characterizes in the Y direction, the scanning direction of the tip results in distortion in the vertical direction after a 90° rotation, meaning that the vertical holes are no longer perpendicular. Whether this distortion, resulting from the altered scanning direction of the AFM tip, affects the lateral characterization outcomes will be a significant point of discussion in future studies.

- (3)

- The possibility of performing probe characterization on a two-dimensional chromium grating is worth exploring, despite the challenges posed by the non-uniform energy distribution of extreme ultraviolet (EUV) light and variations in diffraction efficiency within the grating structure. It is worth noting that the fabrication of the two-dimensional chromium grating is achieved through direct deposition, which results in minimal morphological differences between individual grating structures. Additionally, the grating exhibits self-traceable properties. Given these characteristics, the feasibility of a combined characterization of the scanning tip on both the two-dimensional chromium grating and the two-dimensional silicon grating is a topic worthy of investigation.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Foucher, J.; Figueiro, N.G.S.; Rouxel, J.; Therese, R. Hybrid Metrology for Critical Dimension based on Scanning Methods for IC Manufacturing. In Proceedings of the Conference on Scanning Microscopies-Advanced Microscopy Technologies for Defense, Homeland Security, Forensic, Life, Environmental and Industrial Sciences, Baltimore, MD, USA, 24–26 April 2012; Volume 8378. [Google Scholar]

- Deng, X.; Dai, G.L.; Liu, J.; Hu, X.K.; Bergmann, D.; Zhao, J.; Tai, R.Z.; Cai, X.Y.; Li, Y.; Li, T.B.; et al. A new type of nanoscale reference grating manufactured by combined laser-focused atomic deposition and x-ray interference lithography and its use for calibrating a scanning electron microscope. Ultramicroscopy 2021, 226, 5. [Google Scholar] [CrossRef] [PubMed]

- Levi, S.; Schwarzband, I.; Weinberg, Y.; Cornell, R.; Adan, O.; Cohen, G.M.; Gignac, L.; Bangsaruntip, S.; Hand, S.; Osborne, J. CDSEM AFM hybrid metrology for the characterization of gate-all-around silicon nano wires. In Proceedings of the Metrology, Inspection, and Process Control for Microlithography XXVIII, San Jose, CA, USA, 24–27 February 2014. [Google Scholar]

- Orji, N.G.; Itoh, H.; Wang, C.; Dixson, R.G.; Walecki, P.S.; Schmid, S.W.; Irmer, B. Tip characterization method using multi-feature characterizer for CD-AFM. Ultramicroscopy 2016, 162, 25–34. [Google Scholar] [CrossRef] [PubMed]

- Thiesler, J.; Tutsch, R.; Fromm, K.; Dai, G.L. True 3D-AFM sensor for nanometrology. Meas. Sci. Technol. 2020, 31, 11. [Google Scholar] [CrossRef]

- Orji, N.G.; Badaroglu, M.; Barnes, B.M.; Beitia, C.; Bunday, B.D.; Celano, U.; Kline, R.J.; Neisser, M.; Obeng, Y.; Vladar, A.E. Metrology for the next generation of semiconductor devices (vol 1, pg 532, 2018). Nat. Electron. 2018, 1, 662. [Google Scholar] [CrossRef]

- Yamaguchi, A.; Steffen, R.; Kawada, H.; Iizumi, T. Bias-free measurement of LER/LWR with low damage by CD-SEM. In Proceedings of the Conference on Metrology, Inspection, and Process Control for Microlithography XX, San Jose, CA, USA, 19–24 February 2006; Volume 6152. [Google Scholar]

- Dai, G.L.; Zhu, F.; Heidelmann, M.; Fritz, G.; Bayer, T.; Kalt, S.; Fluegge, J. Development and characterisation of a new line width reference material. Meas. Sci. Technol. 2015, 26, 115006. [Google Scholar] [CrossRef]

- Takamasu, K.; Okitou, H.; Takahashi, S.; Konno, M.; Inoue, O.; Kawada, H. Sub-nanometer line width and line profile measurement for CD-SEM calibration by using STEM. In Proceedings of the Conference on Metrology, Inspection, and Process Control for Microlithography XXV, San Jose, CA, USA, 28 February–3 March 2011; Volume 7971. [Google Scholar]

- Takamasu, K.; Okitou, H.; Takahashi, S.; Konno, M.; Inoue, O.; Kawada, H. Sub-nanometer calibration of line width measurement and line edge detection by using STEM and sectional SEM. In Proceedings of the Conference on Metrology, Inspection, and Process Control for Microlithography XXVI, San Jose, CA, USA, 13–16 February 2012; Volume 8324. [Google Scholar]

- Mingxia, H.; Yan, M. Simulation of surface reconstruction of the one-dimensional rectangle grating AFM images by blind reconstructed tip. Opt. Instrum. 2018, 40, 52–59. [Google Scholar]

- Villarrubia, J.S. Algorithms for scanned probe microscope image simulation, surface reconstruction, and tip estimation. J. Res. Natl. Inst. Stand. Technol. 1997, 102, 425–454. [Google Scholar] [CrossRef] [PubMed]

- Ziruo, W.; Yanni, C.; Xingrui, W.; Longfei, Z.; Xiao, D.; Xinbin, C.; Tongbao, L. Investigation of AFM tip characterization based on multilayer gratings. Infrared Laser Eng. 2020, 49, 229–234. [Google Scholar] [CrossRef]

- Dai, G.L.; Xu, L.Y.; Hahm, K. Accurate tip characterization in critical dimension atomic force microscopy. Meas. Sci. Technol. 2020, 31, 12. [Google Scholar] [CrossRef]

- Dai, G.L.; Hahm, K.; Bosse, H.; Dixson, R.G. Comparison of line width calibration using critical dimension atomic force microscopes between PTB and NIST. Meas. Sci. Technol. 2017, 28, 12. [Google Scholar] [CrossRef]

- Dixson, R.G.; Allen, R.A.; Guthrie, W.F.; Cresswell, M.W. Traceable calibration of critical-dimension atomic force microscope linewidth measurements with nanometer uncertainty. J. Vac. Sci. Technol. B 2005, 23, 3028–3032. [Google Scholar] [CrossRef]

- Kwak, G.Y.; Chang, H.J.; Na, M.Y.; Ryu, S.K.; Kim, T.G.; Woo, J.C.; Kim, K.J. Calibration of high magnification in the measurement of critical dimension by AFM and SEM. Appl. Surf. Sci. 2021, 565, 150481. [Google Scholar] [CrossRef]

- Wei, L.; Yushu, S.; Qi, L.; Lu, H.; Shi, L.; Sitian, G. Progress and Application on the Measurement Technique of Single Crystal Silicon Lattice Spacing. J. Synth. Cryst. 2021, 50, 151–157+178. [Google Scholar]

- Cai, Y.N.; Deng, X.; Wang, X.P.; Yang, F. The effects of thermocompression bonding on Si/SiO2 multilayer thin-film based critical dimension structures. In Proceedings of the International Conference on Optoelectronic and Microelectronic Technology and Application, Nanjing, China, 20–22 October 2020; Volume 11617. [Google Scholar]

- Wu, Z.; Cai, Y.; Wang, X.; Zhang, L.; Deng, X.; Cheng, X.; Li, T. Amorphous Si critical dimension structures with direct Si lattice calibration. Chin. Phys. B 2019, 28, 030601. [Google Scholar] [CrossRef]

- Tang, Z.; Zhao, J.; Deng, X.; Tan, W.; Wu, Y.; Tai, R.; Cheng, X.; Li, T. Fabrication of 53.2 nm pitch self-traceable gratings by laser-focused atomic deposition combined with extreme ultraviolet interference lithography. Optik 2023, 279, 170735. [Google Scholar] [CrossRef]

- Tan, W.; Tang, Z.; Xiao, G.; Yao, Y.; Lei, L.; Li, Q.; Jin, T.; Deng, X.; Cheng, X.; Li, T. Calibrate the non-orthogonal error of AFM with two-dimensional self-traceable grating. Ultramicroscopy 2023, 249, 113734. [Google Scholar] [CrossRef] [PubMed]

- Deng, X.; Tan, W.; Tang, Z.; Lin, Z.; Cheng, X.; Li, T. Scanning and Splicing Atom Lithography for Self-traceable Nanograting Fabrication. Nanomanuf. Metrol. 2022, 5, 179–187. [Google Scholar] [CrossRef]

- Bhandari, A.K.; Kumar, A.; Singh, G.K. Modified artificial bee colony based computationally efficient multilevel thresholding for satellite image segmentation using Kapur’s, Otsu and Tsallis functions. Expert Syst. Appl. 2015, 42, 1573–1601. [Google Scholar] [CrossRef]

- Tang, Z.; Zhao, J.; Deng, X.; Xiao, G.; Yin, Z.; Wu, Y.; Tai, R.; Cheng, X.; Li, T. Two-dimensional sub-200 nm pitch Si gratings with natural orthogonality. Appl. Phys. Express 2023, 16, 106501. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, Y.; Gou, J.; Tang, Z.; Xiao, G.; Lei, L.; Song, S.; Deng, X.; Cheng, X. Research on Tip Characterization Techniques Based on Two-Dimensional Self-Traceable Nano-Gratings. Photonics 2023, 10, 1272. https://doi.org/10.3390/photonics10111272

Xiong Y, Gou J, Tang Z, Xiao G, Lei L, Song S, Deng X, Cheng X. Research on Tip Characterization Techniques Based on Two-Dimensional Self-Traceable Nano-Gratings. Photonics. 2023; 10(11):1272. https://doi.org/10.3390/photonics10111272

Chicago/Turabian StyleXiong, Yingfan, Jinming Gou, Zhaohui Tang, Guangxu Xiao, Lihua Lei, Song Song, Xiao Deng, and Xinbin Cheng. 2023. "Research on Tip Characterization Techniques Based on Two-Dimensional Self-Traceable Nano-Gratings" Photonics 10, no. 11: 1272. https://doi.org/10.3390/photonics10111272

APA StyleXiong, Y., Gou, J., Tang, Z., Xiao, G., Lei, L., Song, S., Deng, X., & Cheng, X. (2023). Research on Tip Characterization Techniques Based on Two-Dimensional Self-Traceable Nano-Gratings. Photonics, 10(11), 1272. https://doi.org/10.3390/photonics10111272