1. Introduction

With the ageing of the world’s population, the proportion of patients with various underlying diseases is gradually increasing, and the demand for high-precision and low-cost human physiological index detection devices in clinical medicine is also increasing simultaneously. For gastrointestinal endoscopy, routine anesthesia monitoring includes blood pressure and oxygen saturation. However, statistics show that the probability of respiratory complications during anesthesia is as high as 20–30% [

1,

2,

3,

4]. Therefore, it is necessary to develop a low-cost device for real-time and continuous-concentration end-tidal carbon dioxide (CO

2) monitoring. The detection of end-tidal CO

2 concentration is more rapid, safe, and non-invasive and easier to operate than blood oxygen saturation detection. Clinical trials have shown that the continuous concentration of end-tidal CO

2 monitoring can evaluate human circulatory function, identify airway obstruction, reduce the occurrence of hypoxemia events (oxygen saturation below 90%), and improve patient survival [

5].

Because of a high sensitivity and the characteristics of small volume, the optical sensor is widely adopted as a gas sensor. Typical applications include hand-held respiratory monitoring sensors [

6] and Capone5, which is a type of end-tidal CO

2 (PetCO

2) pressure monitoring system used in the hospital [

7]. These systems operate based on the non-dispersive infrared (NDIR) absorption principle, guiding the detected gas to a compact gas chamber device for detection [

8,

9]. However, there are some problems with these systems, such as overly long sampling tubes, straightforward blockage or distortion, and abnormal gas dispersion. Therefore, there is an urgent requirement to develop an optical sensor that can monitor exhaled CO

2 in real time.

Micro/nano fibers can be applied in optical sensors due to their strong evanescent field, high sensitivity, ductility, and flexibility. The characteristics of micro/nano optical fibers enable their application to various scenarios, including liquid refractive index measurement, temperature measurement, gas detection, and pressure detection [

10,

11,

12]. In 2023, Wang, S. et al., proposed a micro/nano fiber methane sensor based on tunable diode laser absorption spectroscopy (TDLAS), which utilized the advantages of the micro–nano fiber to produce an extremely high-power density under the condition of a weak light input and realized microgas measurement under low-power conditions [

11]. In 2019, Zhang et al. proposed a gas sensor based on chalcogenide infrared fiber that achieved methane gas detection in the 4.7 μm band with a response time of less than 20 s. However, this device relies on the light source and the detector of a Fourier infrared spectrometer, which is large in size and high in cost, limiting the general application of the sensor in the middle of the infrared band [

13]. For gas sensing, this requires the deposition of a specified polymer functional layer, such as a graphene matrix, onto the surface of the micro/nano fiber to enhance the sensitivity of detection [

13]. For example, Renganathan et al. studied a room-temperature gas sensing potential in a Ceria (CeO

2)-doped nanocrystalline Stannic Oxide (SnO

2)-clad modified fiber optic gas sensor in 2021. This experiment measured the spectral responses of toxic gases with different concentrations [

14]. However, this method also has limitations, including a slow response speed and poor mechanical flexibility, which prevent this sensor from being widely adopted.

In this paper, we exploit an optical micro/nano fiber gas sensor based on the evanescent field absorption principle for monitoring CO2 gas, and the operating light wavelength is 2.004 μm. On the one hand, the micro/nano fiber is used for light transmission and transmits the light emitted by the laser source to the detector. It is also utilized as a sensing area to contact the gas to be measured. It is placed near the nasal cavity of the human body, and the periodic change in the CO2 gas exhaled by the human body is reflected through the periodical change in the light power. In addition, compared with the traditional infrared and silicon photonic integrated gas sensors, the micro/nano fiber sensor has characteristics such as a simple structure, real-time monitoring, and easy preparation.

2. Principle and Simulation Modules

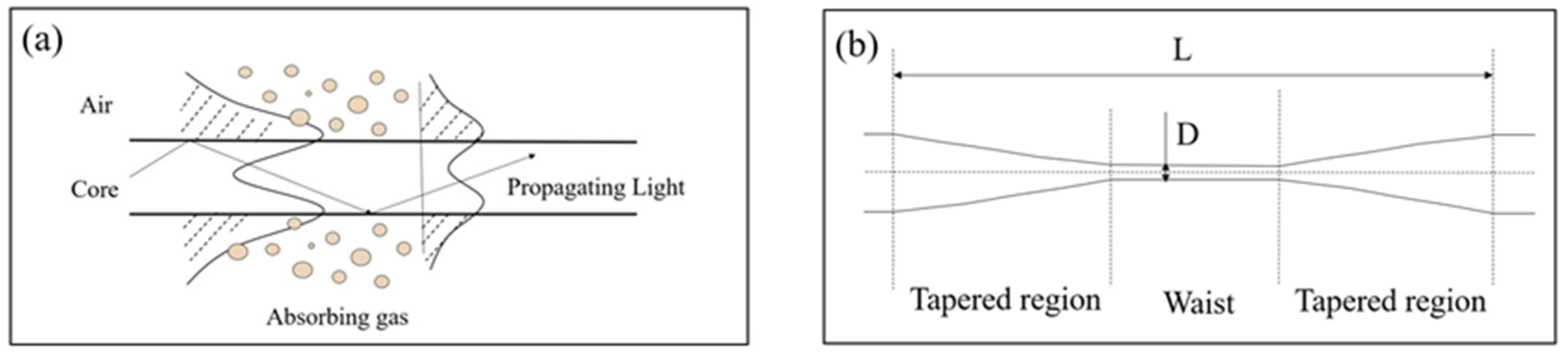

Micro/nano fiber is a guided wave structure with a diameter of several microns. When the diameter of the optical fiber decreases gradually, the basic structure of the optical fiber is destroyed, and the propagating light will be exposed on the surface of the optical fiber, as shown in

Figure 1a. The surface of the fiber generates a robust evanescent field, which is extremely sensitive to the changes in the surrounding environment [

15]. During sensing, the robust evanescent field on the surface of the micro/nano fiber interacts with the exhaled CO

2 gas, resulting in an absorption phenomenon. In

Figure 1b,

L represents the total length of the tapered fiber area, and the diameter of the micro/nano fiber is denoted by

D.

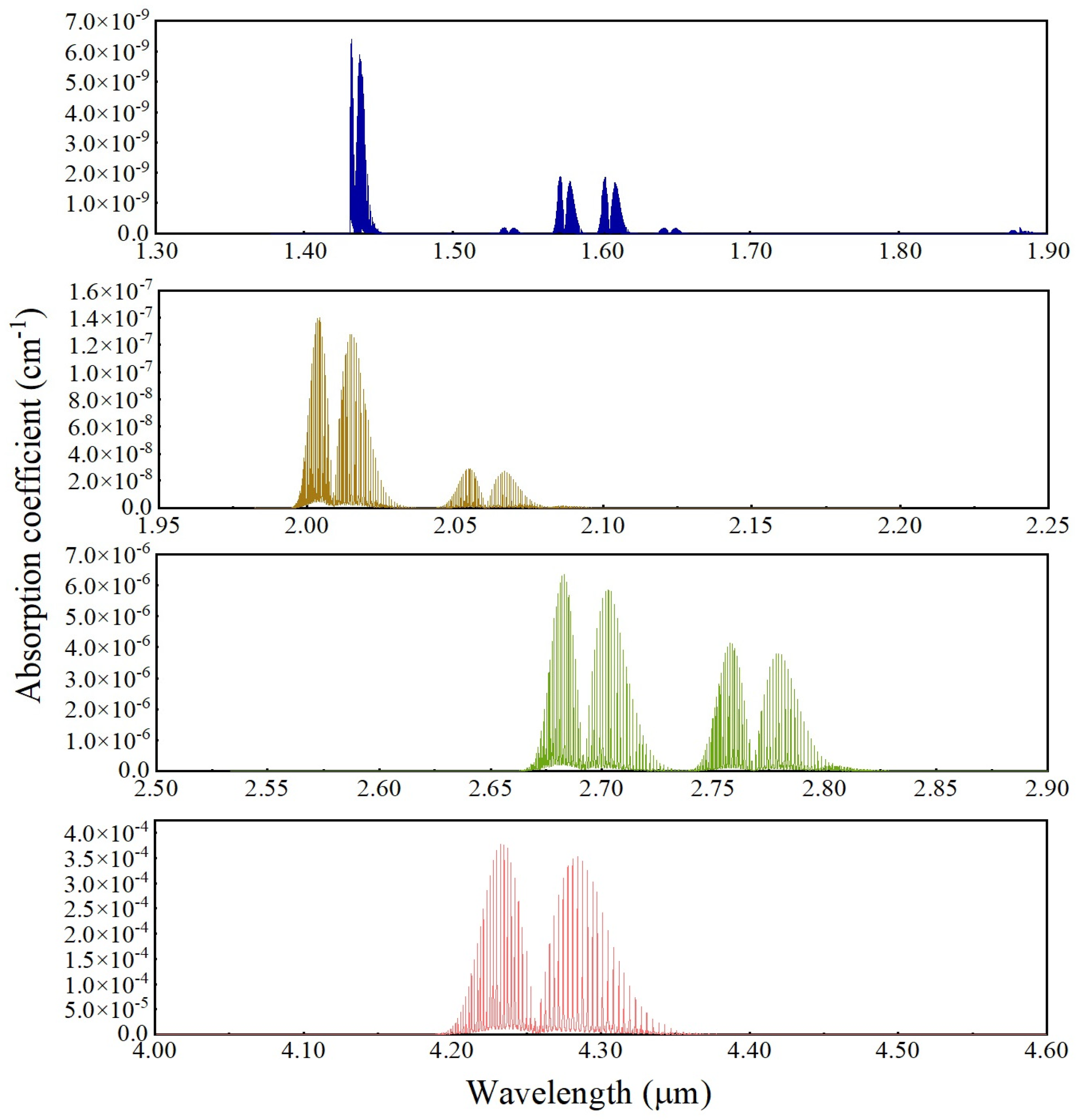

Figure 2 depicts the absorption lines of CO

2 gas molecules at 1 atm and 296 K in different bands. CO

2 gas has multiple absorption windows in the infrared region, as shown in

Figure 2. According to the vertical axis of the image, the intensity of the absorption spectral line gradually increases as the wavelength of the light moves from the near-infrared to the mid-infrared. For the 4.23 μm band, the absorption of CO

2 gas is high enough, but the light source in this band is more expensive than in other bands, and thus, the corresponding optical fiber and other equipment need to be customized. The 1.55 μm band light source is more common in market applications and is compatible with most types of optical fibers on the market. However, its absorption coefficient is relatively low, resulting in a low sensor sensitivity. In addition, there is a cross-absorption peak between water and CO

2 near 2.68 to 2.80 μm. Therefore, we determined that the working wavelength is 2.004 μm, which corresponds to the intense absorption wavelength of CO

2 gas [

16], and its spectral absorption intensity can reach 1.39 × 10

−21 (cm

−1/molecule∙cm

−2).

The attenuation of light intensity can reflect the concentration of the gas to be measured, and it follows the Beer–Lambert law [

18].

For the CO

2 gas sensor,

c and

L are the detected gas’s concentration and absorption length, respectively,

ε is the absorption coefficient of CO

2, and

I and

I0 are the output and input light field intensities, respectively. The proportion of the evanescent field outside the optical fiber to the total energy is

η and can be calculated using the following formula:

Ptotal and

Pgas are the optical power of the measured gas-covered and full-field areas, respectively.

Pz represents the Poynting vector in the propagation direction of the

z-axis [

19]. It can be seen from Formula (1) that

η affects the attenuation of optical power and, thus, the effect of sensing. The higher the contact area between the light and gas to be measured, the better the effect of the gas and micro/nano fiber, and the more pronounced the absorption phenomenon of light is.

Finite element analysis was used to simulate and calculate the variation in

η with the diameter

D of the tapered fiber when the operating wavelength was 2.004 μm in order to determine the influence of different micro/nano fiber parameters on the experimental results.

Figure 3a–c show the distribution of electric field modes of micro/nano fibers with different diameters.

Figure 3d shows the change in

η with the diameter

D of the tapered fiber, in which the refractive index of the core is 1.45, and the operating wavelength is 2.004 μm, which corresponds to a strong absorption peak of CO

2. When the micro/nano fiber’s diameter decreases, the evanescent field effect on the tapered fiber surface is enhanced; however, the transmission loss can also increase.

3. Experiment and Results

A micro/nano fiber is typically fabricated by physically stretching a single-mode fiber (SMF). Different kinds of micro/nano fibers were prepared via the optical micro/nano fiber drawing mechanism, and the fibers were heated using hydrogen and oxygen flames. A torch is used to melt and burn the fiber to fabricate the micro/nano fiber. As

Figure 4a–d show. the tapered fiber will naturally form a conical transition region. Parameters such as the diameter

D and the length

L can be controlled by adjusting the taper drawing process of the machine.

Through different application process settings, we have prepared five kinds of micro/nano fibers with varying waist and taper length diameters, as shown in

Table 1. The minimum diameter of the prepared micro/nano fiber is 1.0 μm, and its taper length is 60 μm. Based on the previous discussion, a smaller cone diameter means more mode leakage in the fiber, which will improve the sensing effect. However, smaller cone diameters require longer micro/nano fibers, which poses a mechanical challenge. Therefore, the diameter and length of the micro/nano fiber need to be chosen based on a compromise. Subsequently, the exhaled CO

2 gas is monitored with different diameters of micro/nano fiber.

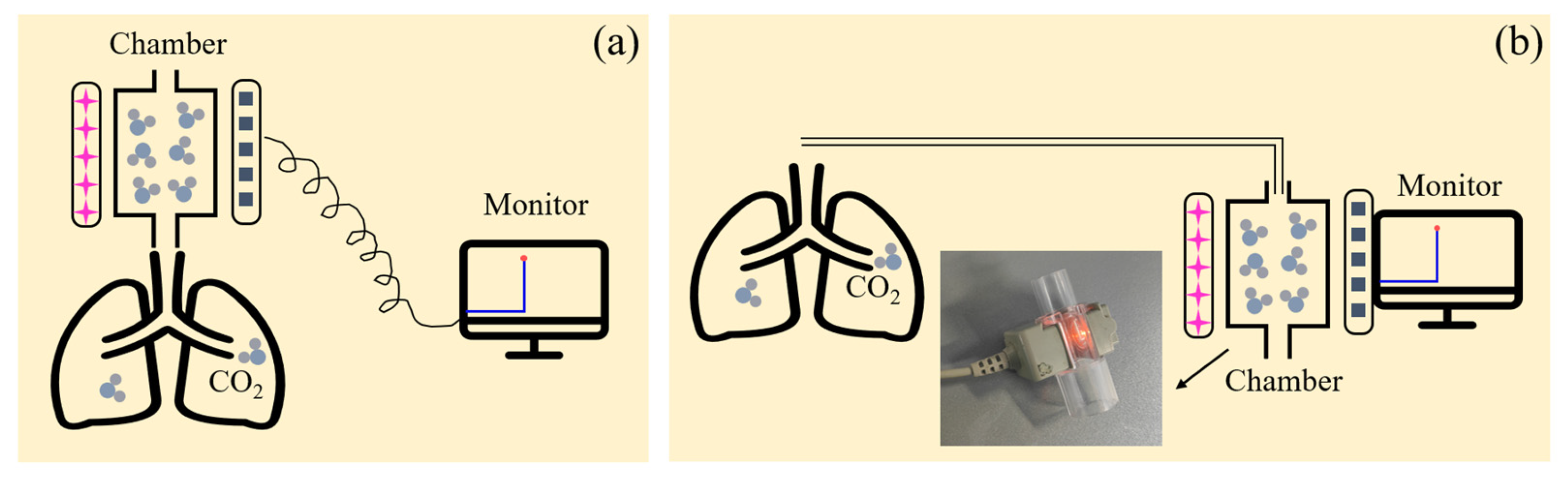

At present, there are two main clinical methods for CO

2 concentration detection: the main-flow method and the side-flow method. A schematic diagram of these is shown in

Figure 5 [

20]. The side-flow method requires attaching a slender tube to the patient’s pharynx. A sample of exhaled CO

2 gas is passed through a long tube into the air chamber, and changes in CO

2 gas concentration are observed using a monitor located away from the patient. On the contrary, the main-flow method to detect CO

2 concentration involves placing the sensor device directly under the nostril, in direct contact with the CO

2 gas exhaled from the human body, and the sensing signal is transmitted to the monitor through an optical fiber. In this paper, the CO

2 concentration was measured using the main-flow method, because the experimental device is smaller in size, and the detection method is more direct and accurate compared with the side-flow method [

21,

22].

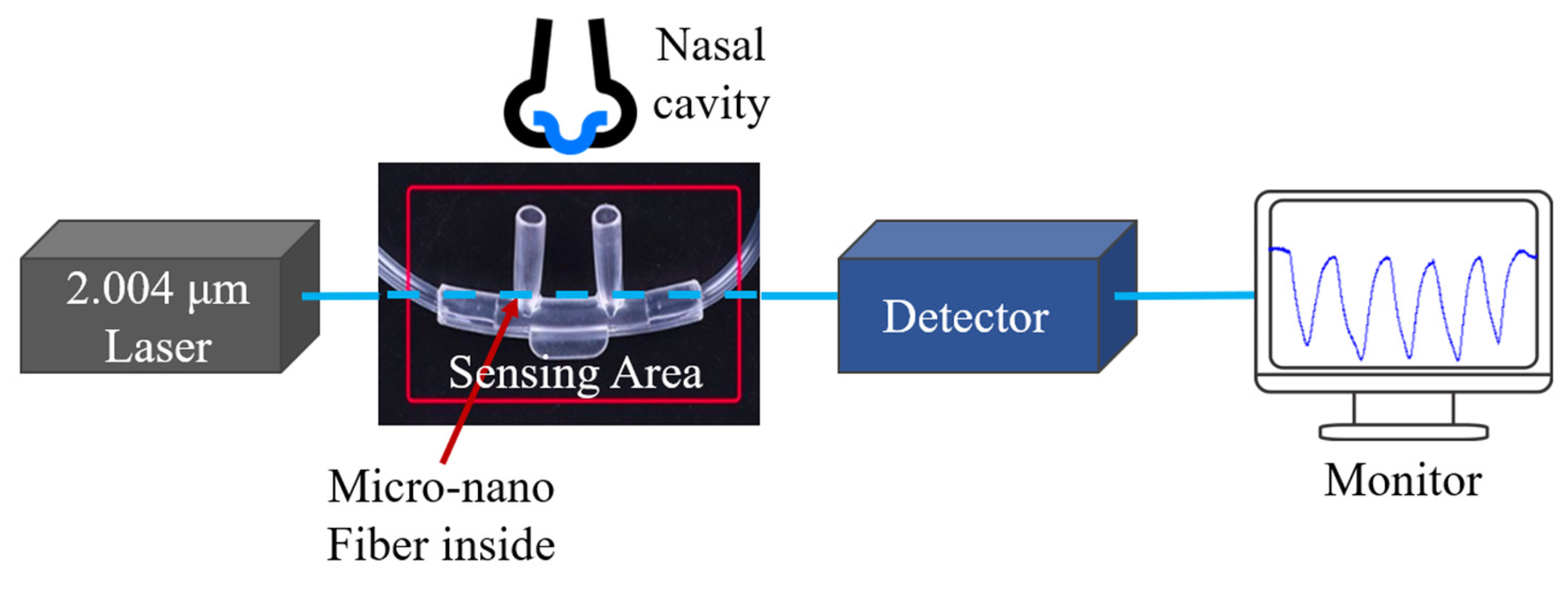

The working principle of the micro/nano optical fiber sensor designed in the experiment is shown in

Figure 6. The working wavelength of the light source (EP2004-0-DM-DX1-FM (Thorlabs; America)) is 2.004 μm. The micro/nano optical fiber is placed in a nasal cavity tube, which is set near the human nasal cavity to directly sense the exhaled CO

2 gas. The influence of the external air disturbance on the results can be avoided at the same time. The change in the concentration of CO

2 in the exhaled gas is characterized by the change in the detector (Thorlabs S401C and Thorlabs PM100USB), in which the periodic change in CO

2 concentration is transferred to the periodic change in optical power. All devices are connected by single-mode optical fibers. Therefore, micro/nano optical fibers can be adopted to monitor relative CO

2 concentration and characterize the respiration cycle process.

Figure 7 shows the optical power change diagram of respiration monitored using the micro/nano fiber at different stages of respiration. When the micro/nano fiber is connected to the detector, its optical power remains stable without sensing, as shown in

Figure 7a. When CO

2 gas is exhaled near the nasal cavity, the gas interacts with the light field on the surface of the micro/nano fiber, and evanescent field absorption occurs. Hence, the optical power reaching the detector will decline as the power curve in

Figure 7a decreases. When the air is inhaled near the nasal cavity, the CO

2 gas concentration near the nasal cavity becomes rarefied, and the absorption phenomenon is weakened. These factors enable the power of the detector to increase and maintain the power level with the initial time until the next respiratory cycle begins. When the monitoring is finished, the optical power remains stable and is close to the initial optical power, as shown in

Figure 7b.

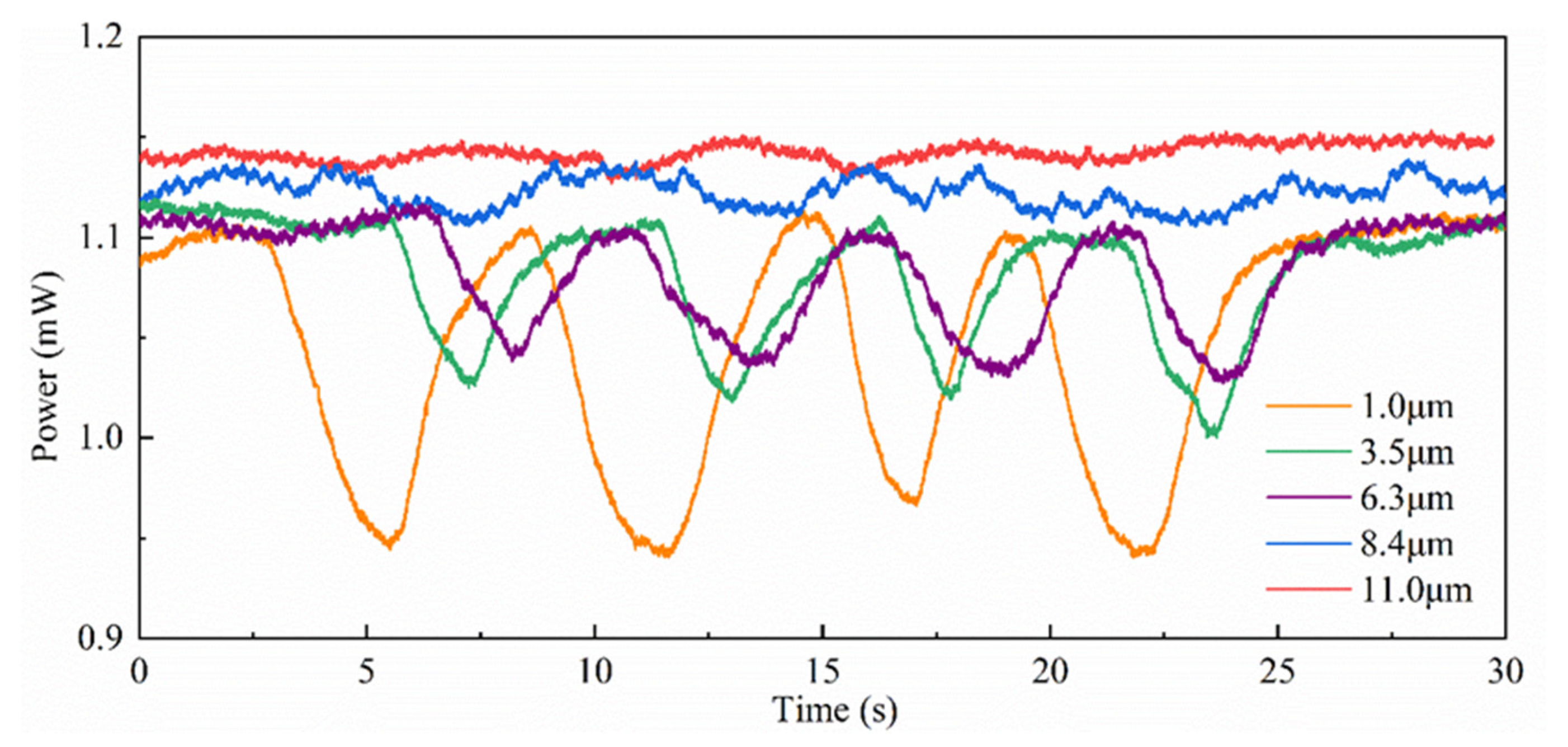

Illustrated in

Figure 8 is the dynamic change in optical power, employed explicitly in the surveillance of CO

2 concentration levels proximate to the nasal cavity. Compared with CO

2 (near 2.004 μm), the absorption coefficients of nitrogen (N

2), oxygen (O

2), and water vapor (H

2O) in the exhaled gas are all negligible [

17]. Therefore, it can be assumed that the change in optical power measured in the experiment is entirely caused by the change in relative CO

2 concentration. This examination is conducted across a spectrum of micro/nano fiber diameters. Notably, the initial power level exhibits discernible disparities contingent upon the specific micro/nano fiber under consideration. This phenomenon emerges due to the inherent diversity in transmission losses, with smaller diameters typically afflicting a heightened degree of transmission loss [

23].

In addition, the change in the amplitude of the optical power is different with different micro/nano fiber diameters. When the diameter of the micro/nano fiber increases from

D = 1.0 μm to

D = 11.0 μm, the changes in optical energy become increasingly insignificant. That is to say, the thicker the diameter of the micro/nano fiber, the smaller the transformation of the optical power for monitoring CO

2 gas, which is caused by the gradual weakening of the evanescent field on the surface of the micro/nano fiber. When the micro/nano fiber radius is 11.0 μm, the optical power generally presents a straight line, and the sensing phenomenon is not apparent. The absorption of the evanescent field is relatively weak. In

Figure 8, the change in the amplitude of the optical power is the largest at a diameter

D = 1.0 μm of the micro/nano fiber. Because the diameter of the optical fiber is small, a more evanescent field will be exposed on the surface of the optical fiber. When the CO

2 gas sensing is carried out, the absorption degree is higher, and the optical power attenuation is also elevated. The micro/nano fibers in the experiment were placed in the nasal oxygen tube, as shown in

Figure 6. The distance between the two pores of the nasal oxygen tube is about 1.0 cm. The cone length of the micro/nano fibers is much longer than this value, so the contact area between the gas exhaled by the nasal cavity and the micro/nano fibers is basically constant.

Furthermore, in terms of the frequency of the optical power’s periodic change, the periodical change in exhaled CO

2 gas near the nasal cavity can be deduced by the periodical variation in optical power attenuation. When the micro/nano fiber diameter is 1.0 μm, the optical power attenuation is more prominent, and its sensitivity is higher based on the comparative experiments described above. In addition, the data showed four periodic changes in the optical power within 30 s of the monitoring time, according to the experimental results of 1, 3.5, and 6.3 μm diameters in

Figure 8. Therefore, it can be calculated that the respiratory rate is 10–11 times/minute, and this result is consistent with the average human respiratory rate [

6,

24].

4. Discussion

The above experiments show the optical power variation within exhaled CO

2 gas with different optical micro/nano fiber diameters. One conclusion is that the smaller the diameter of the micro/nano fiber, the higher the evanescent field of the fiber surface and the more sensitive the variation in the light power. However, when the diameter of the micro/nano fiber approaches hundreds of nanometers, fiber breakage will occur quickly, and the transmission loss will be higher, which makes it challenging to prepare. Therefore, the most appropriate micro/nano fiber with a 1.0 μm diameter is applied to monitor the exhaled CO

2 gas near the nasal cavity. The amplitude of the light intensity variation indicates the relative concentration of CO

2 gas, and the periodic variation frequency of the light intensity within 30 s characterizes the respiratory frequency of the nasal cavity. From

Figure 8, it can be calculated that the respiratory rate is 10–11 times/minute.

The micro/nano fiber tapered region with a diameter of 1.0 μm was placed near the nasal cavity for real-time monitoring. With the periodic change in respiration, the optical power of the detector port also presented the same periodic change trend. Therefore, in this scheme, we adopted a periodic change in optical power at the detector end to characterize the periodic change in CO2 gas at the end of human breath and to transform the monitoring of the human respiratory rate into that of an optical power change. The results of this test are consistent with the regular respiratory rate of the human body, which is consistent with the respiratory rate results obtained in other studies.

Compared with the reported off-line exhaled gas detection equipment [

25], the sensor designed in this paper does not need to collect or store the gas, nor does it need to conduct secondary processing, and there is no possibility that the gas to be measured will be contaminated. The direct detection of relative CO

2 concentrations in exhaled gas is more attractive for clinical applications. Although some compact gas sensors can also achieve direct sample detection [

26], their response time is long, and the short-breath pulse analysis is not accurate enough. Therefore, so-called buffered end-tidal sampling is needed to solve this problem [

27], which increases the complexity of the sensing system. In recent years, hand-held breath analyzers that can perform repeatable real-time breath analysis have been proposed [

28]. However, due to their high integration, this method is limited to specific sensor designs. In this paper, we use a micro/nano fiber as the main component of the sensor and use the periodic change in the optical power received by the detector to characterize the human nasal expiratory cycle and the change in the relative CO

2 concentration. At the same time, the sensing effects of micro/nano fibers with different diameters are simulated theoretically and tested experimentally. Compared with the above methods, the scheme designed in this paper has the characteristics of real-time monitoring, low cost, and small volume. The sensor structure does not require a specific test platform, and the extremely low cost of micro/nano fibers makes it possible to use them in clinical applications, avoiding measured gas pollution and cross-infection between users, and thus, leading to more valuable market application prospects.