Low-Cost and Eco-Friendly Hydroxyapatite Nanoparticles Derived from Eggshell Waste for Cephalexin Removal

Abstract

:1. Introduction

2. Experimental

2.1. Reagents and Materials

2.2. Characterization Techniques and Apparatus

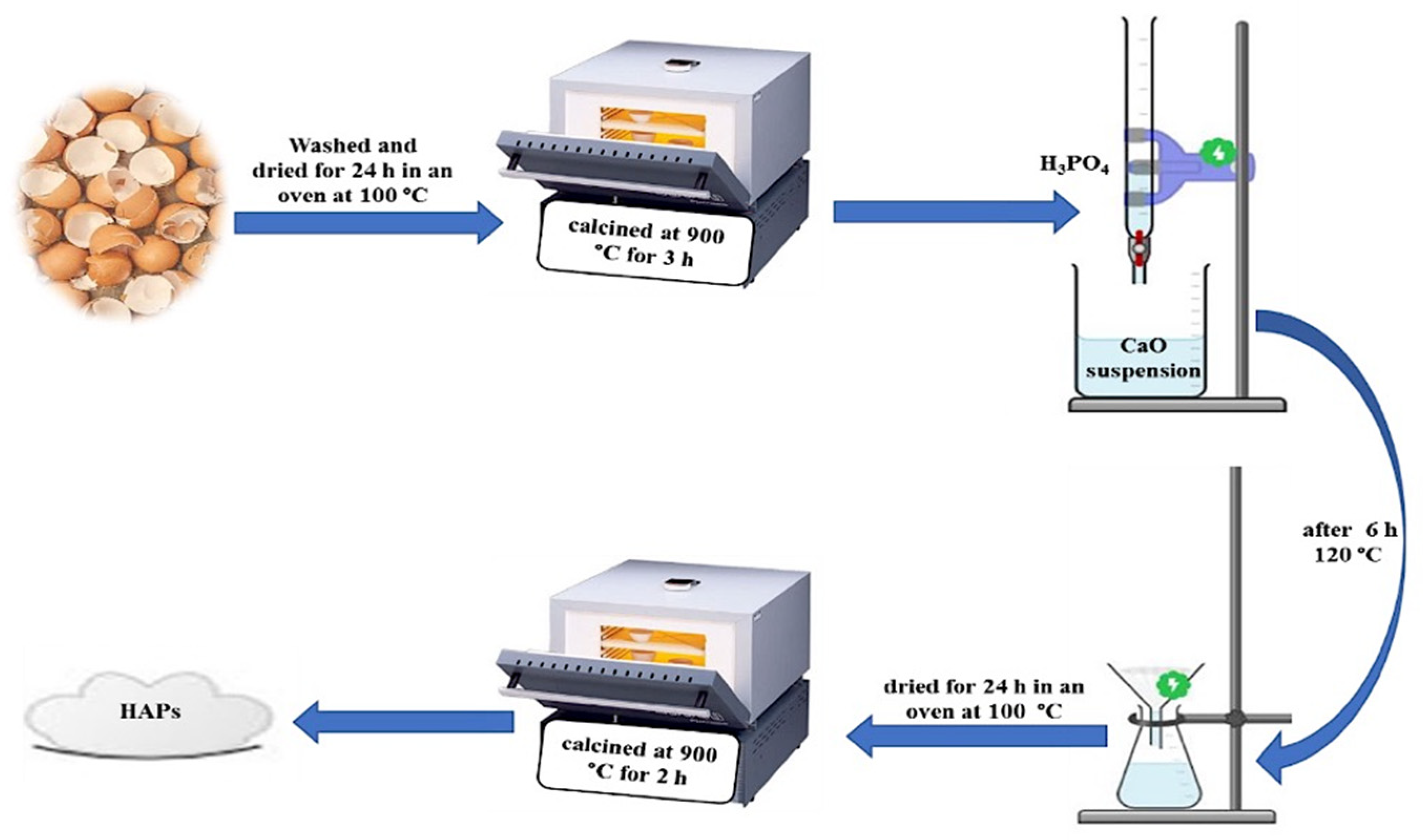

2.3. Preparation of HAP Nanoparticles from Eggshells

2.4. Step of Batch Extraction

3. Results and Discussions

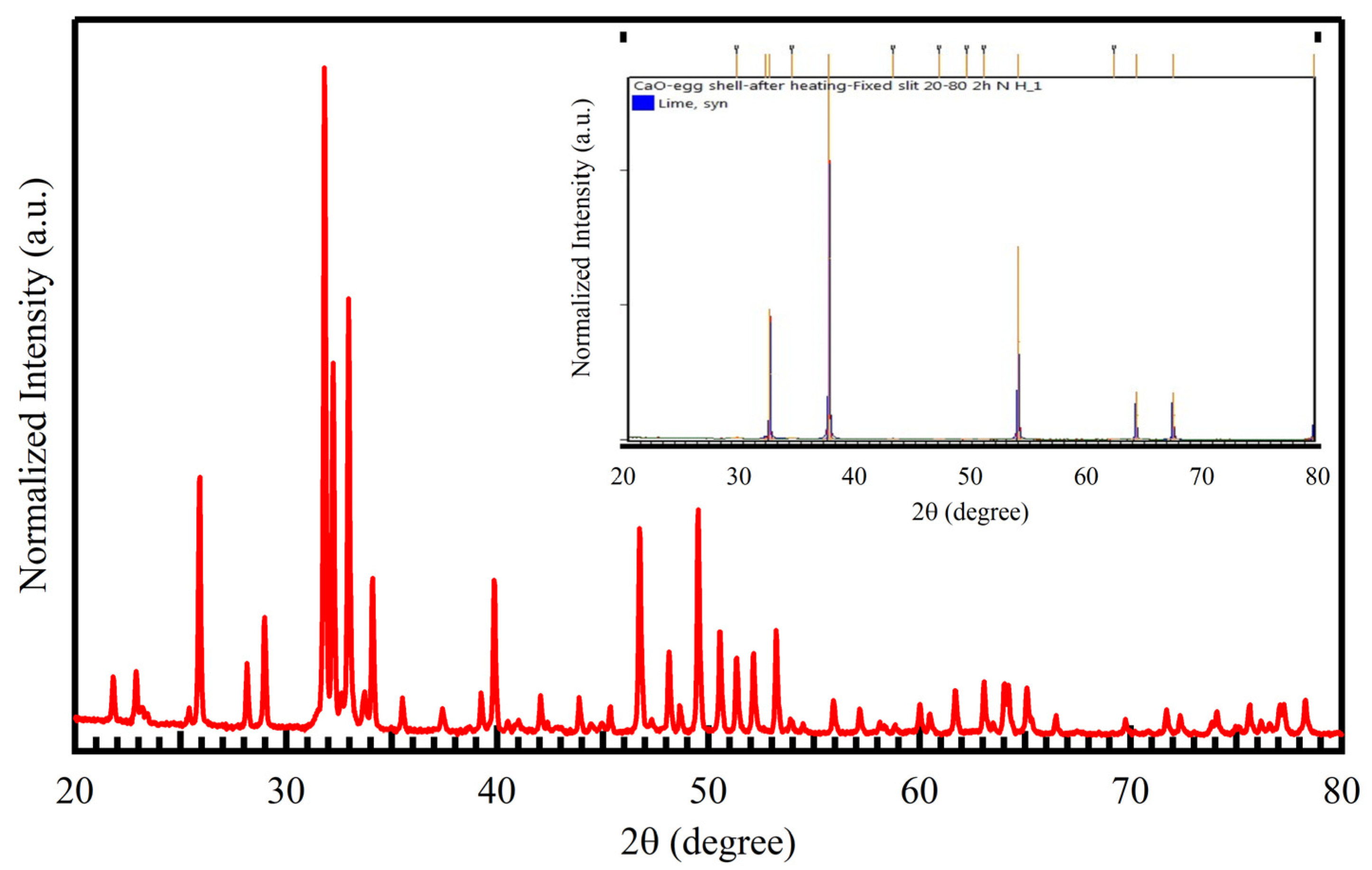

3.1. Characterizations of HAP

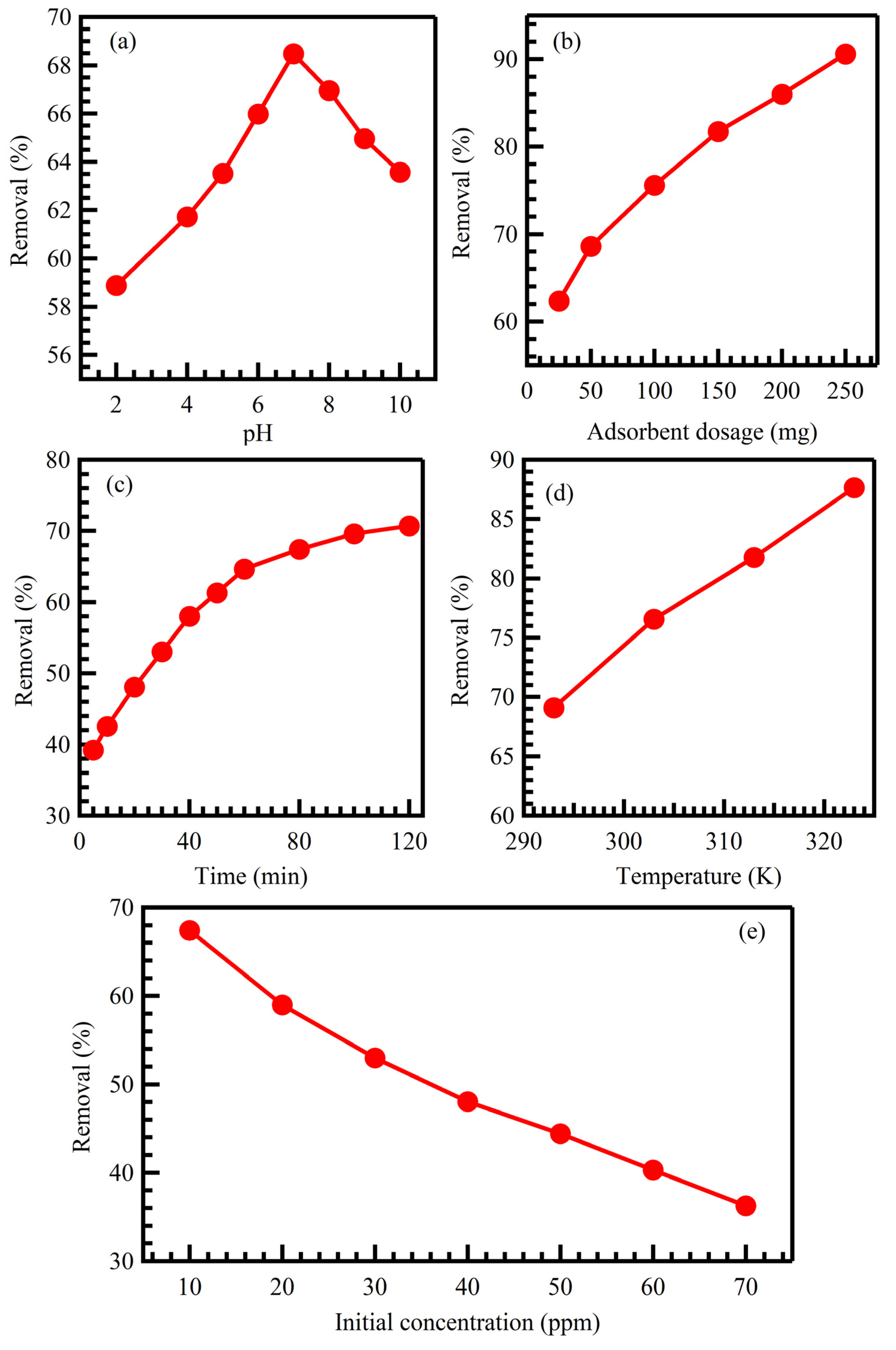

3.2. Batch Adsorption Studies

3.2.1. Retention Profile of Ceph from Aqueous Solution onto HAP

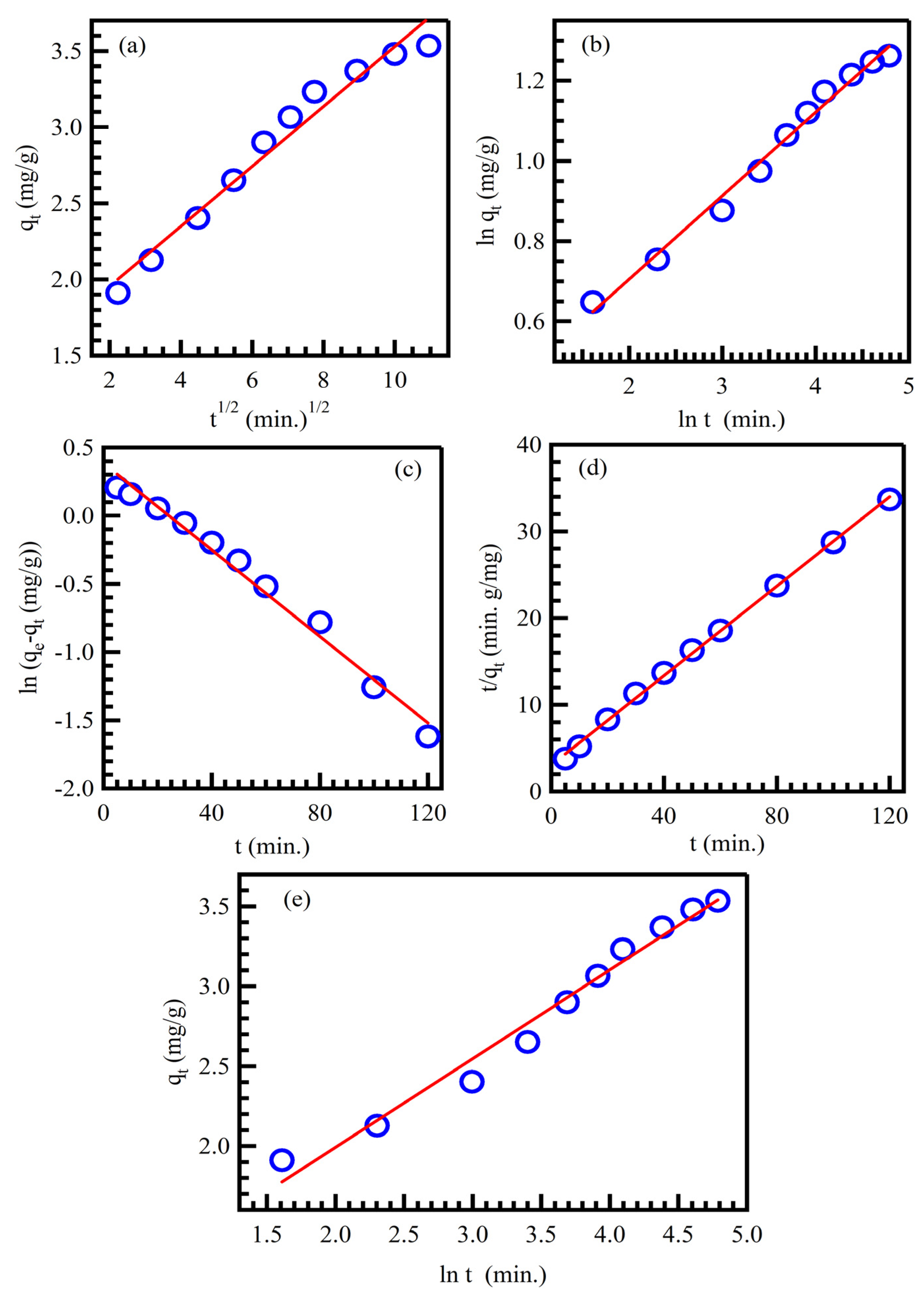

3.2.2. Kinetic Behavior of Ceph Sorption onto HAP

3.2.3. Sorption Isotherms of Ceph onto HAP Sorbents

3.3. Thermodynamic Properties of Ceph Retention onto HAP

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bound, J.P.; Kitsou, K.; Voulvoulis, N. Household disposal of pharmaceuticals and perception of risk to the environment. Environ. Toxicol. Pharmacol. 2006, 21, 301–307. [Google Scholar] [CrossRef]

- Bilal, M.; Mehmood, S.; Rasheed, T.; Iqbal, H.M.N. Antibiotics traces in the aquatic environment: Persistence and adverse environmental impact. Curr. Opin. Environ. Sci. Health 2020, 13, 68–74. [Google Scholar] [CrossRef]

- Afsa, S.; Hamden, K.; Martin, P.A.L.; Mansour, H.B. Occurrence of 40 pharmaceutically active compounds in hospital and urban wastewaters and their contribution to Mahdia coastal seawater contamination. Environ. Sci. Pollut. Res. 2020, 27, 1941–1955. [Google Scholar] [CrossRef]

- Liu, H.; Liu, W.; Zhang, J.; Zhang, C.; Ren, L.; Li, Y. Removal of cephalexin from aqueous solutions by original and Cu (II)/Fe (III) impregnated activated carbons developed from lotus stalks Kinetics and equilibrium studies. J. Hazard. Mater. 2011, 185, 1528–1535. [Google Scholar] [CrossRef]

- Harrison, C.J.; Bratcher, D. Cephalosporins: A review. Pediatrics Rev. 2008, 29, 264. [Google Scholar] [CrossRef] [Green Version]

- Bottoni, P.; Caroli, S. Presence of residues and metabolites of pharmaceuticals in environmental compartments, food commodities and workplaces: A review spanning the three-year period 2014–2016. Microchem. J. 2018, 136, 2–24. [Google Scholar] [CrossRef]

- Sivagami, K.; Vignesh, V.J.; Srinivasan, R.; Divyapriya, G.; Nambi, I.M. Antibiotic usage, residues and resistance genes from food animals to human and environment: An Indian scenario. J. Environ. Chem. Eng. 2020, 8, 102221. [Google Scholar] [CrossRef]

- Mirzaei, R.; Yunesian, M.; Nasseri, S.; Gholami, M.; Jalilzadeh, E.; Shoeibi, S.; Mesdaghinia, A. Occurrence and fate of most prescribed antibiotics in different water environments of Tehran, Iran. Sci. Total Environ. 2018, 619, 446–459. [Google Scholar] [CrossRef]

- Vobecká, L.; Tichá, L.; Atanasova, A.; Slouka, Z.; Hasal, P.; Přibyl, M. Enzyme synthesis of cephalexin in continuous-flow microfluidic device in ATPS environment. Chem. Eng. J. 2020, 396, 125236. [Google Scholar] [CrossRef]

- Seid-Mohammadi, A.; Asgarai, G.; Ghorbanian, Z.; Dargahi, A. The removal of cephalexin antibiotic in aqueous solutions by ultrasonic waves/hydrogen peroxide/nickel oxide nanoparticles (US/H2O2/NiO) hybrid process. Sep. Sci. Technol. 2020, 55, 1558–1568. [Google Scholar] [CrossRef]

- Basturk, I.; Varank, G.; Murat-Hocaoglu, S.; Yazici-Guvenc, S.; Can-Güven, E.; Oktem-Olgun, E.E.; Canli, O. Simultaneous degradation of cephalexin, ciprofloxacin, and clarithromycin from medical laboratory wastewater by electro-Fenton process. J. Environ. Chem. Eng. 2021, 9, 104666. [Google Scholar] [CrossRef]

- Zhao, R.; Ma, T.; Zhao, S.; Rong, H.; Tian, Y.; Zhu, G. Uniform and stable immobilization of metal-organic frameworks into chitosan matrix for enhanced tetracycline removal from water. Chem. Eng. J. 2020, 382, 122893. [Google Scholar] [CrossRef]

- Rathi, B.S.; Kumar, P.S. Application of adsorption process for effective removal of emerging contaminants from water and wastewater. Environ. Pollut. 2021, 280, 116995. [Google Scholar] [CrossRef]

- Naeem, H.; Ajmal, M.; Qureshi, R.B.; Muntha, S.T.; Farooq, M.; Siddiq, M. Facile synthesis of graphene oxide–silver nanocomposite for decontamination of water from multiple pollutants by adsorption, catalysis and antibacterial activity. J. Environ. Manag. 2019, 230, 199–211. [Google Scholar] [CrossRef]

- Krasucka, P.; Pan, B.; Ok, Y.S.; Mohan, D.; Sarkar, B.; Oleszczuk, P. Engineered biochar–A sustainable solution for the removal of antibiotics from water. Chem. Eng. J. 2021, 405, 126926. [Google Scholar] [CrossRef]

- Nazari, G.; Abolghasemi, H.; Esmaieli, M. Batch adsorption of cephalexin antibiotic from aqueous solution by walnut shell-based activated carbon. J. Taiwan Inst. Chem. Eng. 2016, 58, 357–365. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Al-Musawi, T.J.; Kareem, S.L.; Zarrabi, M.; Al-Ma’abreh, A.M. Simultaneous adsorption of tetracycline, amoxicillin, and ciprofloxacin by pistachio shell powder coated with zinc oxide nanoparticles. Arab. J. Chem. 2020, 13, 4629–4643. [Google Scholar] [CrossRef]

- Gashtasbi, F.; Yengejeh, R.J.; Babaei, A.A. Photocatalysis assisted by activated-carbon-impregnated magnetite composite for removal of cephalexin from aqueous solution. Korean J. Chem. Eng. 2018, 35, 1726–1734. [Google Scholar] [CrossRef]

- Fernandez-Garcia, M.; Martinez-Arias, A.; Hanson, J.C.; Rodriguez, J.A. Nanostructured oxides in chemistry: Characterization and properties. Chem. Rev. 2004, 104, 4063–4104. [Google Scholar] [CrossRef]

- Singh, A.; Gautam, P.K.; Verma, A.; Singh, V.; Shivapriya, P.M.; Shivalkar, S.; Sahoo, A.K.; Samanta, S.K. Green synthesis of metallic nanoparticles as effective alternatives to treat antibiotics resistant bacterial infections: A review. Biotechnol. Rep. 2020, 25, e00427. [Google Scholar] [CrossRef]

- Habeeb, O.A.; Ramesh, K.; Ali, G.A.M.; Yunus, R.M. Low-cost and eco-friendly activated carbon from modified palm kernel shell for hydrogen sulfide removal from wastewater: Adsorption and kinetic studies. Desalination Water Treat. 2017, 84, 205–214. [Google Scholar] [CrossRef] [Green Version]

- Ali, G.A.M.; Habeeb, O.A.; Algarni, H.; Chong, K.F. CaO impregnated highly porous honeycomb activated carbon from agriculture waste: Symmetrical supercapacitor study. J. Mater. Sci. 2018, 54, 683–692. [Google Scholar] [CrossRef]

- Habeeb, O.A.; Ramesh, K.; Ali, G.A.M.; Yunus, R.M. Application of response surface methodology for optimization of palm kernel shell activated carbon preparation factors for removal of H2S from industrial wastewater. J. Teknol. 2017, 79, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Ummartyotin, S.; Pechyen, C. Strategies for development and implementation of bio-based materials as effective renewable resources of energy: A comprehensive review on adsorbent technology. Renew. Sustain. Energy Rev. 2016, 62, 654–664. [Google Scholar] [CrossRef]

- Irtiseva, K.; Lapkovskis, V.; Mironovs, V.; Ozolins, J.; Thakur, V.K.; Goel, G.; Baronins, J.; Shishkin, A. Towards Next-Generation Sustainable Composites Made of Recycled Rubber, Cenospheres, and Biobinder. Polymers 2021, 13, 574. [Google Scholar] [CrossRef]

- Sultan, M. Hydroxyapatite/polyurethane composites as promising biomaterials. Chem. Pap. 2018, 72, 2375–2395. [Google Scholar] [CrossRef]

- Ragab, A.; Ahmed, I.; Bader, D. The removal of brilliant green dye from aqueous solution using nano hydroxyapatite/chitosan composite as a sorbent. Molecules 2019, 24, 847. [Google Scholar] [CrossRef] [Green Version]

- Bee, S.-L.; Hamid, Z.A.A. Hydroxyapatite derived from food industry bio-wastes: Syntheses, properties and its potential multifunctional applications. Ceram. Int. 2020, 46, 17149–17175. [Google Scholar] [CrossRef]

- Habeeb, O.A.; Ramesh, K.; Ali, G.A.M.; Yunus, R.M. Isothermal modelling based experimental study of dissolved hydrogen sulfide adsorption from waste water using eggshell based activated carbon. Malays. J. Anal. Sci. 2017, 21, 334–345. [Google Scholar]

- AbdelGhany, G.S.; Ebrahiem, E.E.; Mohamed, H.F.M.; Ali, G.A.M.; Shehata, N. Eco-friendly activated carbon developed from rice hulls for chromium and iron ion removal. J. Environ. Eng. Sci. 2021, 40, 1–14. [Google Scholar] [CrossRef]

- Moosavi, S.; Lai, C.W.; Akbarzadeh, O.; Johan, M.R. Recycled Activated Carbon-Based Materials for the Removal of Organic Pollutants from Wastewater. In Waste Recycling Technologies for Nanomaterials Manufacturing; Makhlouf, A.S.H., Ali, G.A.M., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 513–539. [Google Scholar] [CrossRef]

- Ali, G.A.M.; Makhlouf, A.S.H. Fundamentals of Waste Recycling for Nanomaterial Manufacturing. In Waste Recycling Technologies for Nanomaterials Manufacturing; Makhlouf, A.S.H., Ali, G.A.M., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 3–24. [Google Scholar] [CrossRef]

- Akram, M.; Ahmed, R.; Shakir, I.; Ibrahim, W.A.W.; Hussain, R. Extracting hydroxyapatite and its precursors from natural resources. J. Mater. Sci. 2014, 49, 1461–1475. [Google Scholar] [CrossRef]

- Esmaeilkhanian, A.; Sharifianjazi, F.; Abouchenari, A.; Rouhani, A.; Parvin, N.; Irani, M. Synthesis and characterization of natural nano-hydroxyapatite derived from turkey femur-bone waste. Appl. Biochem. Biotechnol. 2019, 189, 919–932. [Google Scholar] [CrossRef] [PubMed]

- Ummartyotin, S.; Manuspiya, H. Eggshell waste: An effective source of hydroxyapatite for photocatalyst. J. Met. Mater. Miner. 2018, 28, 124–135. [Google Scholar]

- Boonyang, U.; Chaopanich, P.; Wongchaisuwat, A.; Senthongkaew, P.; Siripaisarnpipat, S. Effect of phosphate precursor on the production of hydroxyapatite from crocodile eggshells. J. Biomim. Biomater. Tissue Eng. 2010, 5, 31–37. [Google Scholar] [CrossRef]

- Kamalanathan, P.; Ramesh, S.; Bang, L.T.; Niakan, A.; Tan, C.Y.; Purbolaksono, J.; Chandran, H.; Teng, W.D. Synthesis and sintering of hydroxyapatite derived from eggshells as a calcium precursor. Ceram. Int. 2014, 40, 16349–16359. [Google Scholar] [CrossRef]

- Chaudhuri, B.; Mondal, B.; Modak, D.K.; Pramanik, K.; Chaudhuri, B.K. Preparation and characterization of nanocrystalline hydroxyapatite from egg shell and K2HPO4 solution. Mater. Lett. 2013, 97, 148–150. [Google Scholar] [CrossRef]

- Ummartyotin, S.; Tangnorawich, B. Utilization of eggshell waste as raw material for synthesis of hydroxyapatite. Colloid Polym. Sci. 2015, 293, 2477–2483. [Google Scholar] [CrossRef]

- Sadegh, H.; Ali, G.A.M.; Agarwal, S.; Gupta, V.K. Surface Modification of MWCNTs with carboxylic-to-amine and their superb adsorption performance. Int. J. Environ. Res. 2019, 13, 523–531. [Google Scholar] [CrossRef]

- Agarwal, S.; Sadegh, H.; Monajjemi, M.; Makhlouf, A.S.H.; Ali, G.A.M.; Memar, A.O.H.; Shahryari-ghoshekandi, R.; Tyagi, I.; Gupta, V.K. Efficient removal of toxic bromothymol blue and methylene blue from wastewater by polyvinyl alcohol. J. Mol. Liq. 2016, 218, 191–197. [Google Scholar] [CrossRef] [Green Version]

- Gupta, V.K.; Agarwal, S.; Sadegh, H.; Ali, G.A.M.; Bharti, A.K.; Hamdy, A.S. Facile route synthesis of novel graphene oxide-β-cyclodextrin nanocomposite and its application as adsorbent for removal of toxic bisphenol A from the aqueous phase. J. Mol. Liq. 2017, 237, 466–472. [Google Scholar] [CrossRef] [Green Version]

- Sadegh, H.; Ali, G.A.M.; Makhlouf, A.S.H.; Chong, K.F.; Alharbi, N.S.; Agarwal, S.; Gupta, V.K. MWCNTs-Fe3O4 nanocomposite for Hg(II) high adsorption efficiency. J. Mol. Liq. 2018, 258, 345–353. [Google Scholar] [CrossRef]

- Maleki, A.; Safdari Shadloo, M.; Rahmat, A. Application of Artificial Neural Networks for Producing an Estimation of High-Density Polyethylene. Polymers 2020, 12, 2319. [Google Scholar] [CrossRef] [PubMed]

- Aqliliriana, C.M.; Ernee, N.M.; Irmawati, R. Preparation and characterization of modified calcium oxide from natural sources and their application in the transesterification of palm oil. Int. J. Sci. Technol. Res. 2015, 4, 168–175. [Google Scholar]

- Kaya, I.; Şahin, M.C.; Cingöz, İ.D.; Aydin, N.; Atar, M.; KizmazoĞLu, C.; Kavuncu, S.; Aydin, H.E. Three dimensional printing and biomaterials in the repairment of bone defects; hydroxyapatite PLA filaments. Turk. J. Med. Sci. 2019, 49, 922–927. [Google Scholar] [CrossRef]

- Dastgheib, S.A.; Rockstraw, D.A. A systematic study and proposed model of the adsorption of binary metal ion solutes in aqueous solution onto activated carbon produced from pecan shells. Carbon 2002, 40, 1853–1861. [Google Scholar] [CrossRef]

- Rusu, L.; Grigoraș, C.G.; Simion, A.I.; Suceveanu, E.M.; Șuteu, D.; Harja, M. Application of saccharomyces cerevisiae/calcium alginate composite beads for cephalexin antibiotic biosorption from aqueous solutions. Materials 2021, 14, 4728. [Google Scholar] [CrossRef]

- Tavasol, F.; Tabatabaie, T.; Ramavandi, B.; Amiri, F. Photocatalyst production from wasted sediment and quality improvement with titanium dioxide to remove cephalexin in the presence of hydrogen peroxide and ultrasonic waves: A cost-effective technique. Chemosphere 2021, 284, 131337. [Google Scholar] [CrossRef]

- Al-Gheethi, A.; Lalung, J.; Noman, E.; Ismail, N. Removal of cephalexin antibiotic and heavy metals from pharmaceutical effluents using Bacillus subtilis strain. Expert Opin. Environ. Biol. 2015, 4, 2. [Google Scholar]

- Mohseni-Bandpi, A.; Al-Musawi, T.J.; Ghahramani, E.; Zarrabi, M.; Mohebi, S.; Vahed, S.A. Improvement of zeolite adsorption capacity for cephalexin by coating with magnetic Fe3O4 nanoparticles. J. Mol. Liq. 2016, 218, 615–624. [Google Scholar] [CrossRef]

- Pouretedal, H.R.; Sadegh, N. Effective removal of amoxicillin, cephalexin, tetracycline and penicillin G from aqueous solutions using activated carbon nanoparticles prepared from vine wood. J. Water Process Eng. 2014, 1, 64–73. [Google Scholar] [CrossRef]

- Jin, Y.; Ni, Y.; Pudukudy, M.; Zhang, H.; Wang, H.; Jia, Q.; Shan, S. Synthesis of nanocrystalline cellulose/hydroxyapatite nanocomposites for the efficient removal of chlortetracycline hydrochloride in aqueous medium. Mater. Chem. Phys. 2022, 275, 125135. [Google Scholar] [CrossRef]

- Martínez-Olivas, A.; Torres-Pérez, J.; Balderas-Hernández, P.; Reyes-López, S.Y. Oxytetracycline Sorption onto Synthetized Materials from Hydroxyapatite and Aluminosilicates. Water Air Soil Pollut. 2020, 231, 264. [Google Scholar] [CrossRef]

- Chen, Y.; Lan, T.; Duan, L.; Wang, F.; Zhao, B.; Zhang, S.; Wei, W. Adsorptive removal and adsorption kinetics of fluoroquinolone by nano-hydroxyapatite. PLoS ONE 2015, 10, e0145025. [Google Scholar] [CrossRef]

- Al-Saidi, H.M.; Abdel-Fadeel, M.A.; El-Sonbati, A.Z.; El-Bindary, A.A. Multi-walled carbon nanotubes as an adsorbent material for the solid phase extraction of bismuth from aqueous media: Kinetic and thermodynamic studies and analytical applications. J. Mol. Liq. 2016, 216, 693–698. [Google Scholar] [CrossRef]

- Campos, N.F.; Barbosa, C.M.B.M.; Rodríguez-Díaz, J.M.; Duarte, M.M.M.B. Removal of naphthenic acids using activated charcoal: Kinetic and equilibrium studies. Adsorpt. Sci. Technol. 2018, 36, 1405–1421. [Google Scholar] [CrossRef] [Green Version]

- Dalal, R.C. Desorption of soil phosphate by anion-exchange resin. Commun. Soil Sci. Plant Anal. 1974, 5, 531–538. [Google Scholar] [CrossRef]

- Abdel Salam, M. Removal of heavy metal ions from aqueous solutions with multi-walled carbon nanotubes: Kinetic and thermodynamic studies. Int. J. Environ. Sci. Technol. 2013, 10, 677–688. [Google Scholar] [CrossRef]

- Salam, M.A.; Lateefa, A.; Abdel-Fadeel, M.A. Removal of toxic ammonium ions from water using nanographene sheets. Desalination Water Treat. 2018, 129, 168–176. [Google Scholar] [CrossRef]

- Sadegh, H.; Ali, G.A.M.; Nia, H.J.; Mahmoodi, Z. Nanomaterial Surface Modifications for Enhancement of the Pollutant Adsorption From Wastewater. In Nanotechnology Applications in Environmental Engineering; IGI Global: Hershey, PA, USA, 2019; p. 143. [Google Scholar]

- Arabi, S.M.S.; Lalehloo, R.S.; Olyai, M.R.T.B.; Ali, G.A.M.; Sadegh, H. Removal of congo red azo dye from aqueous solution by ZnO nanoparticles loaded on multiwall carbon nanotubes. Phys. E Low-Dimens. Syst. Nanostructures 2019, 106, 150–155. [Google Scholar] [CrossRef]

- Sadegh, H.; Ali, G.A.M.; Abbasi, Z.; Nadagoud, M.N. Adsorption of Ammonium Ions onto Multi-Walled Carbon Nanotubes. Studia Univ. Babes-Bolyai Chem. 2017, 62, 233–245. [Google Scholar] [CrossRef]

- Reichenberg, D. Properties of ion-exchange resins in relation to their structure. III. Kinetics of exchange. J. Am. Chem. Soc. 1953, 75, 589–597. [Google Scholar] [CrossRef]

- Hameed, S.A.; Abdel-Fadeel, M.A.; Al-Saidi, H.M.; Salam, M.A. Simultaneous removal of the toxic tungsten ions and rhodamine B dye by graphene nanosheets from model and real water. Desalination Water Treat. 2020, 188, 266–276. [Google Scholar] [CrossRef]

| Adsorbent | Contaminant | Removal (%) | Ref. |

|---|---|---|---|

| Cerevisiae/calcium alginate composite | Cephalexin | 86.23 | [48] |

| Wasted sediment (sludge waste from shipping docks) | Cephalexin | 76 (urban water) 63 (hospital wastewater) | [49] |

| Bacillus subtilis Strain | Cephalexin | 21–27 | [50] |

| Natural zeolite | Cephalexin | 28 | [51] |

| Activated carbon nanoparticles | Cephalexin | 43.52 (unmodified carbon) 47.65 (2 M NaCl) 60.01 (5 M HNO3) 62.02 (3 M ZnCl2) | [52] |

| Cellulose/hydroxyapatite nanocomposites | Chlortetracycline hydrochloride | 70.81 | [53] |

| Hydroxyapatite and aluminosilicates | Oxytetracycline | 50 | [54] |

| Hydroxyapatite | Fluoroquinolone | 47.3–51.6 | [55] |

| Hydroxyapatite | Cephalexin | 70.70 | This study |

| Model | Parameter and Value | |||

|---|---|---|---|---|

| Weber—Morris | Kd | C | R2 | |

| 0.24 | 0.09 | 0.969 | ||

| Fractional power function | a | b | R2 | |

| 1.33 | 0.21 | 0.989 | ||

| Pseudo-first-order (Lagergren) | qe,exp (mg/g) | qe,calc (mg/g) | KLag | R2 |

| 3.54 | 2.4 | 0.037 | 0.985 | |

| Pseudo-second-order | qe,exp (mg/g) | qe,calc (mg/g) | KS | R2 |

| 3.54 | 3.9 | 2.1 × 10−2 | 0.999 | |

| Elovich | α (g/mg min) | β (mg/g min) | R2 | |

| 8.739 | 0.555 | 0.978 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhasan, H.S.; Alahmadi, N.; Yasin, S.A.; Khalaf, M.Y.; Ali, G.A.M. Low-Cost and Eco-Friendly Hydroxyapatite Nanoparticles Derived from Eggshell Waste for Cephalexin Removal. Separations 2022, 9, 10. https://doi.org/10.3390/separations9010010

Alhasan HS, Alahmadi N, Yasin SA, Khalaf MY, Ali GAM. Low-Cost and Eco-Friendly Hydroxyapatite Nanoparticles Derived from Eggshell Waste for Cephalexin Removal. Separations. 2022; 9(1):10. https://doi.org/10.3390/separations9010010

Chicago/Turabian StyleAlhasan, Huda S., Nadiyah Alahmadi, Suhad A. Yasin, Mohammed Y. Khalaf, and Gomaa A. M. Ali. 2022. "Low-Cost and Eco-Friendly Hydroxyapatite Nanoparticles Derived from Eggshell Waste for Cephalexin Removal" Separations 9, no. 1: 10. https://doi.org/10.3390/separations9010010

APA StyleAlhasan, H. S., Alahmadi, N., Yasin, S. A., Khalaf, M. Y., & Ali, G. A. M. (2022). Low-Cost and Eco-Friendly Hydroxyapatite Nanoparticles Derived from Eggshell Waste for Cephalexin Removal. Separations, 9(1), 10. https://doi.org/10.3390/separations9010010