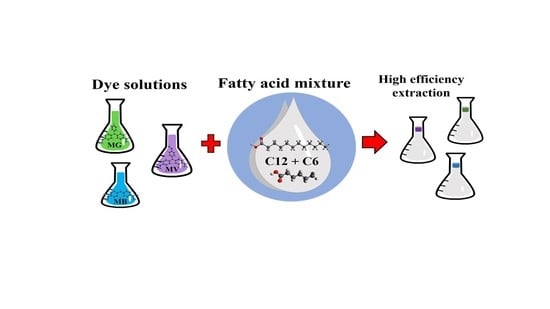

A Simple Microextraction Method for Toxic Industrial Dyes Using a Fatty-Acid Solvent Mixture

Abstract

:1. Introduction

2. Results and Discussion

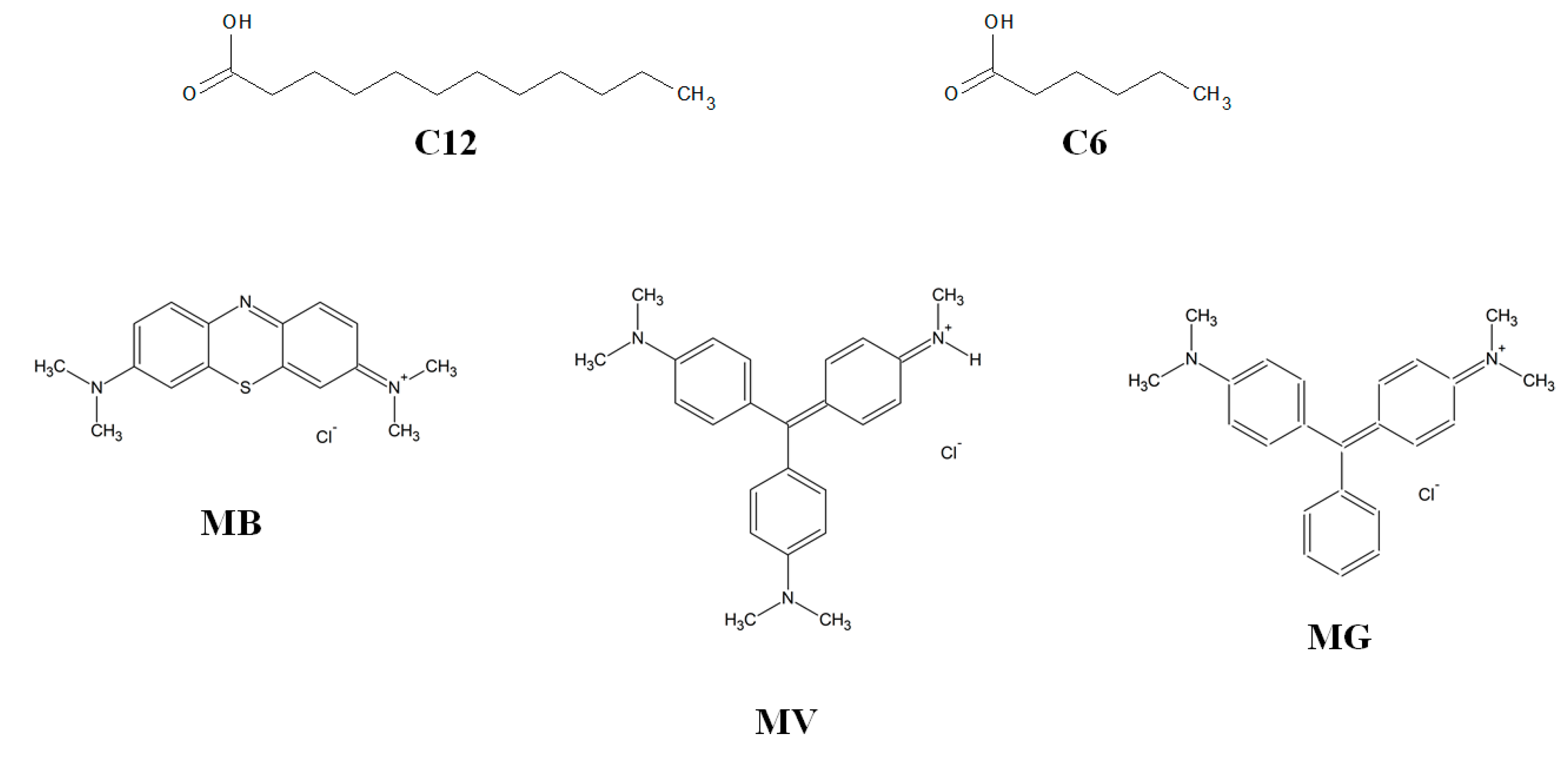

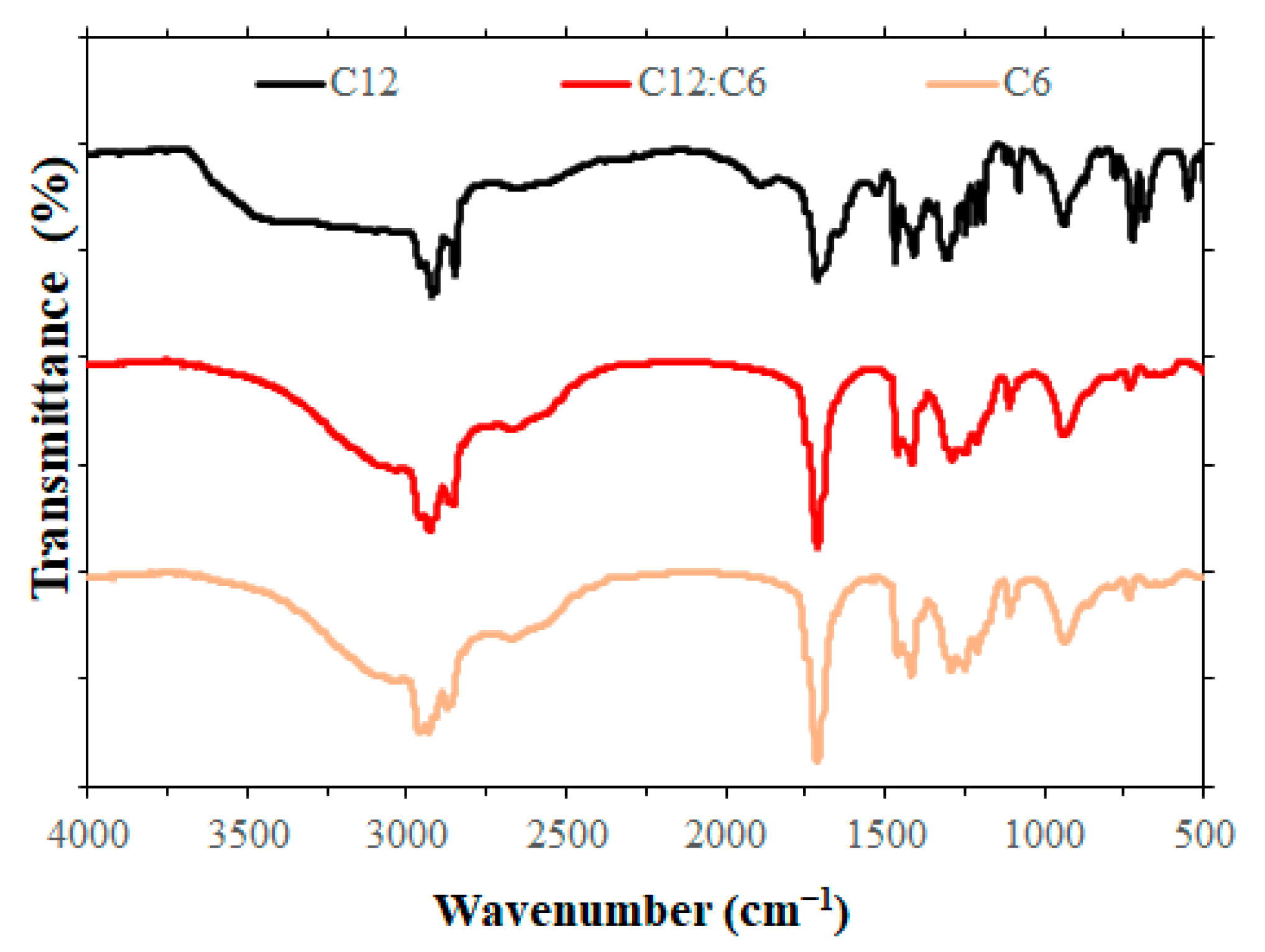

2.1. FTIR and 1H NMR Measurements

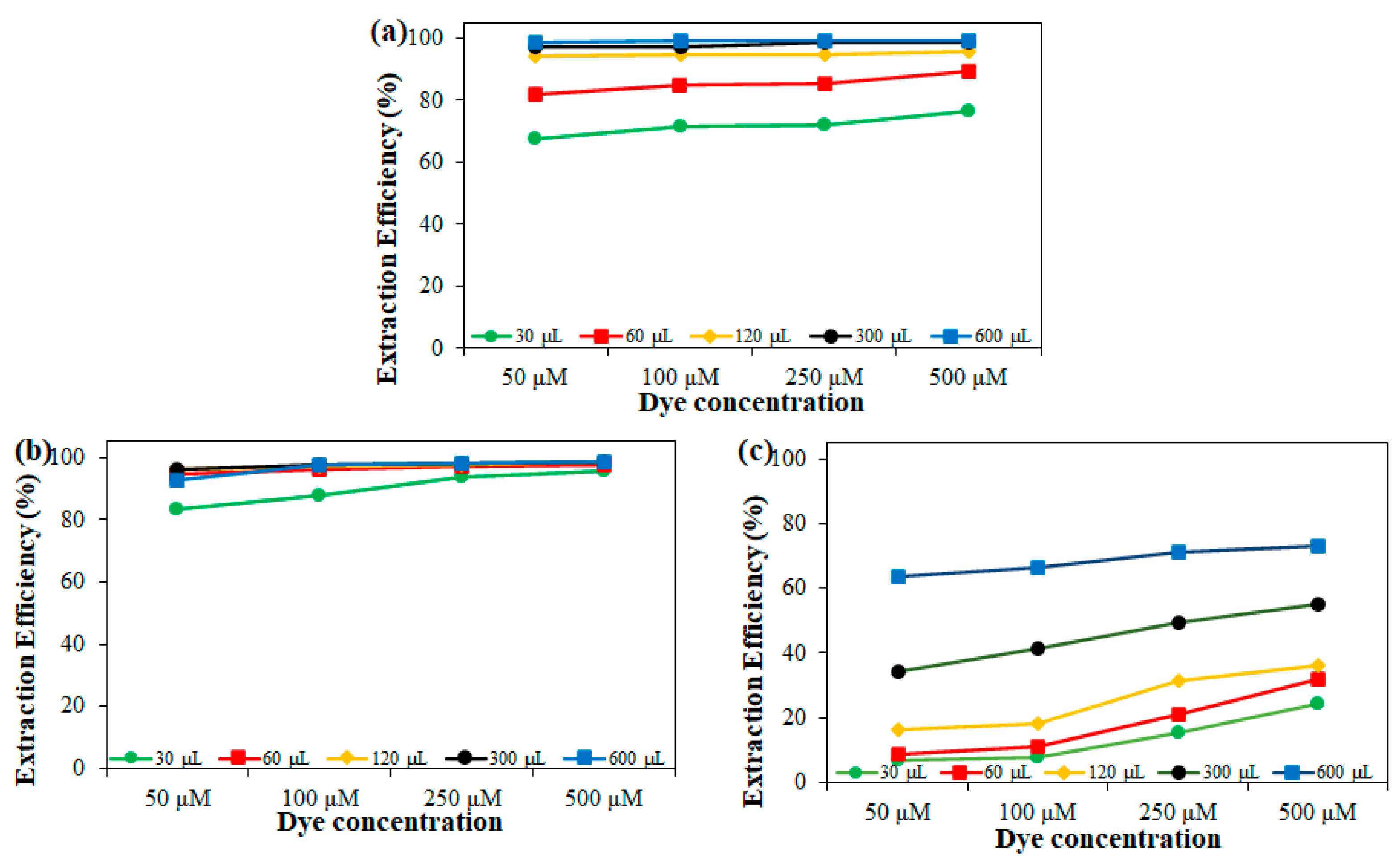

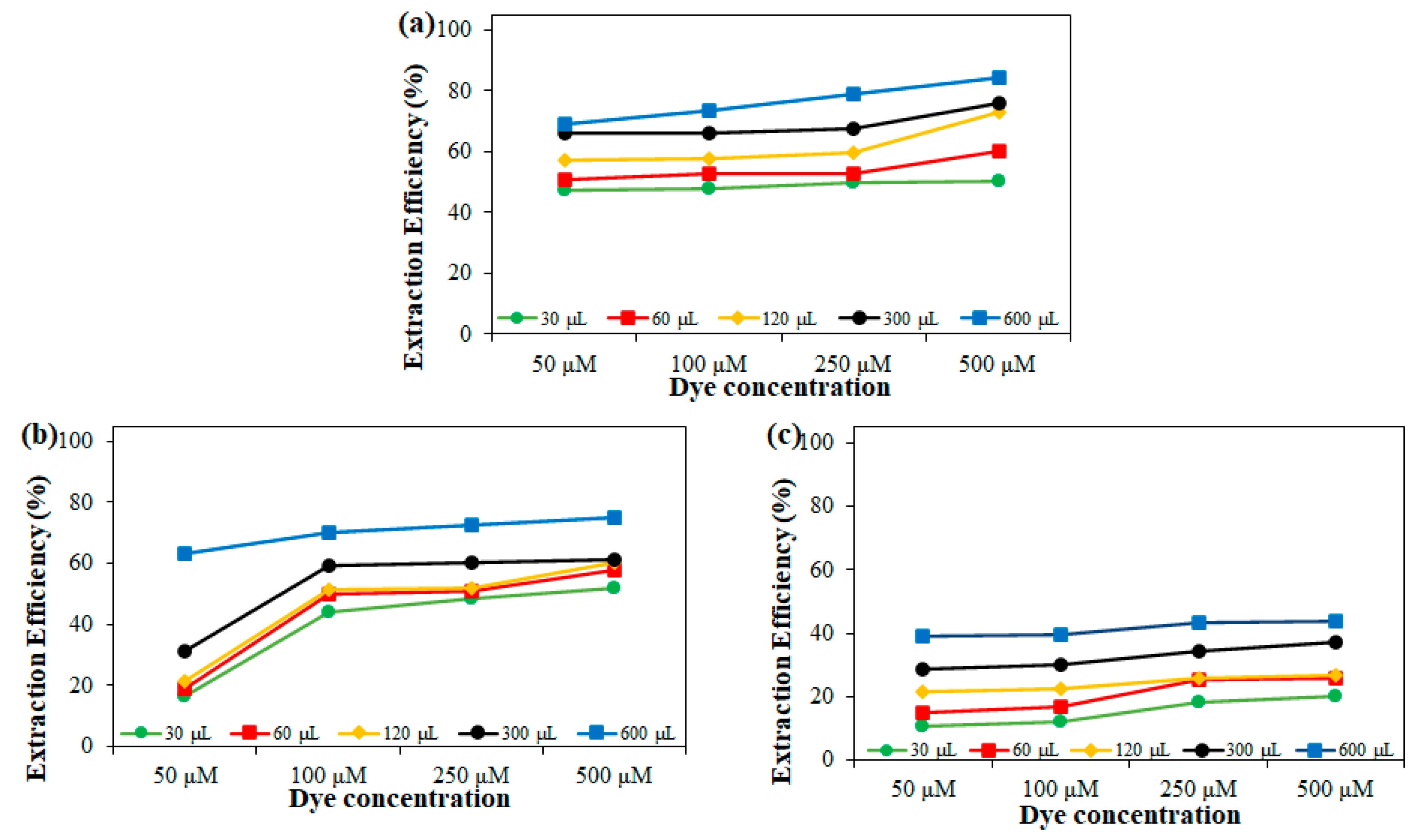

2.2. Liquid–Liquid Microextraction

3. Materials and Methods

3.1. Materials

3.2. FTIR and 1H NMR Measurements

3.3. Liquid–liquid Dye Microextraction Procedure

3.4. Analytical Performance Parameters

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Janssens, I.; Tanghe, T.; Verstraete, W. Micropollutants: A Bottleneck in Sustainable Wastewater Treatment. Water Sci. Technol. 1997, 35, 13–26. [Google Scholar] [CrossRef]

- Atas, M.S.; Dursun, S.; Akyildiz, H.; Citir, M.; Yavuz, C.T.; Yavuz, M.S. Selective Removal of Cationic Micro-Pollutants Using Disulfide-Linked Network Structures. RSC Adv. 2017, 7, 25969–25977. [Google Scholar] [CrossRef] [Green Version]

- Margot, J.; Rossi, L.; Barry, D.P.A.; Holliger, C. A Review of the Fate of Micropollutants in Wastewater Treatment Plants. Wiley Interdiscip. Rev. Water 2015, 2, 457–487. [Google Scholar] [CrossRef] [Green Version]

- Gopinathan, R.; Kanhere, J.; Banerjee, J. Effect of Malachite Green Toxicity on Non Target Soil Organisms. Chemosphere 2015, 120, 637–644. [Google Scholar] [CrossRef]

- Schneider, K.; Hafner, C.; Jäger, I. Mutagenicity of Textile Dye Products. J. Appl. Toxicol. 2004, 24, 83–91. [Google Scholar] [CrossRef] [PubMed]

- Dos Anjos, F.S.C.; Vieira, E.F.S.; Cestari, A.R. Interaction of Indigo Carmine Dye with Chitosan Evaluated by Adsorption and Thermochemical Data. J. Colloid Interface Sci. 2002, 253, 243–246. [Google Scholar] [CrossRef] [PubMed]

- Chandran, C.B.; Singh, D.; Nigam, P. Remediation of Textile Effluent Using Agricultural Residues. Appl. Biochem. Biotechnol. 2002, 102–103, 207–212. [Google Scholar] [CrossRef]

- Nguyen, T.A.; Juang, R.-S. Treatment of Waters and Wastewaters Containing Sulfur Dyes: A Review. Chem. Eng. J. 2013, 219, 109–117. [Google Scholar] [CrossRef]

- Shi, B.; Li, G.; Wang, D.; Feng, C.; Tang, H. Removal of Direct Dyes by Coagulation: The Performance of Preformed Polymeric Aluminum Species. J. Hazard. Mater. 2007, 143, 567–574. [Google Scholar] [CrossRef] [PubMed]

- Isosaari, P.; Srivastava, V.; Sillanpää, M. Ionic Liquid-Based Water Treatment Technologies for Organic Pollutants: Current Status and Future Prospects of Ionic Liquid Mediated Technologies. Sci. Total Environ. 2019, 690, 604–619. [Google Scholar] [CrossRef]

- Verma, P.; Samanta, S.K. Microwave-Enhanced Advanced Oxidation Processes for the Degradation of Dyes in Water. Environ. Chem. Lett. 2018, 16, 969–1007. [Google Scholar] [CrossRef]

- Kandelbauer, A.; Guebitz, G.M. Bioremediation for the Decolorization of Textile Dyes—A Review. In Environmental Chemistry; Springer: Berlin/Heidelberg, Germany, 2005; pp. 269–288. [Google Scholar]

- Sharma, B.; Dangi, A.K.; Shukla, P. Contemporary Enzyme Based Technologies for Bioremediation: A Review. J. Environ. Manag. 2018, 210, 10–22. [Google Scholar] [CrossRef] [PubMed]

- Kahwaji, S.; Johnson, M.B.; Kheirabadi, A.C.; Groulx, D.; White, M.A. Fatty Acids and Related Phase Change Materials for Reliable Thermal Energy Storage at Moderate Temperatures. Sol. Energy Mater. Sol. Cells 2017, 167, 109–120. [Google Scholar] [CrossRef]

- Cellat, K.; Beyhan, B.; Güngör, C.; Konuklu, Y.; Karahan, O.; Dündar, C.; Paksoy, H. Thermal Enhancement of Concrete by Adding Bio-Based Fatty Acids as Phase Change Materials. Energy Build. 2015, 106, 156–163. [Google Scholar] [CrossRef]

- Zhou, D.; Zhou, Y.; Liu, Y.; Luo, X.; Yuan, J. Preparation and Performance of Capric-Myristic Acid Binary Eutectic Mixtures for Latent Heat Thermal Energy Storages. J. Nanomater. 2019, 2019, 1–9. [Google Scholar] [CrossRef]

- Florindo, C.; Romero, L.; Rintoul, I.; Branco, L.C.; Marrucho, I.M. From Phase Change Materials to Green Solvents: Hydrophobic Low Viscous Fatty Acid–Based Deep Eutectic Solvents. ACS Sustain. Chem. Eng. 2018, 6, 3888–3895. [Google Scholar] [CrossRef]

- Arcon, D.P.; Franco, F.C. All-Fatty Acid Hydrophobic Deep Eutectic Solvents towards a Simple and Efficient Microextraction Method of Toxic Industrial Dyes. J. Mol. Liq. 2020, 318, 114220. [Google Scholar] [CrossRef]

- Ma, W.; Row, K.H. PH-Induced Deep Eutectic Solvents Based Homogeneous Liquid-Liquid Microextraction for the Extraction of Two Antibiotics from Environmental Water. Microchem. J. 2021, 160, 105642. [Google Scholar] [CrossRef]

- Shih, H.-K.; Shu, T.-Y.; Ponnusamy, V.K.; Jen, J.-F. A Novel Fatty-Acid-Based in-Tube Dispersive Liquid–Liquid Microextraction Technique for the Rapid Determination of Nonylphenol and 4-Tert-Octylphenol in Aqueous Samples Using High-Performance Liquid Chromatography–Ultraviolet Detection. Anal. Chim. Acta 2015, 854, 70–77. [Google Scholar] [CrossRef]

- Gao, M.; Wang, J.; Song, X.; He, X.; Dahlgren, R.A.; Zhang, Z.; Ru, S.; Wang, X. An Effervescence-Assisted Switchable Fatty Acid-Based Microextraction with Solidification of Floating Organic Droplet for Determination of Fluoroquinolones and Tetracyclines in Seawater, Sediment, and Seafood. Anal. Bioanal. Chem. 2018, 410, 2671–2687. [Google Scholar] [CrossRef] [Green Version]

- El-Deen, A.K.; Shimizu, K. A Green Air Assisted-Dispersive Liquid-Liquid Microextraction Based on Solidification of a Novel Low Viscous Ternary Deep Eutectic Solvent for the Enrichment of Endocrine Disrupting Compounds from Water. J. Chromatogr. A 2020, 1629, 461498. [Google Scholar] [CrossRef]

- Ke, H. Phase Diagrams, Eutectic Mass Ratios and Thermal Energy Storage Properties of Multiple Fatty Acid Eutectics as Novel Solid-Liquid Phase Change Materials for Storage and Retrieval of Thermal Energy. Appl. Therm. Eng. 2017, 113, 1319–1331. [Google Scholar] [CrossRef]

- He, H.; Yue, Q.; Gao, B.; Zhang, X.; Li, Q.; Wang, Y. The Effects of Compounding Conditions on the Properties of Fatty Acids Eutectic Mixtures as Phase Change Materials. Energy Convers. Manag. 2013, 69, 116–121. [Google Scholar] [CrossRef]

- Van Osch, D.J.G.P.; Dietz, C.H.J.T.; van Spronsen, J.; Kroon, M.C.; Gallucci, F.; van Sint Annaland, M.; Tuinier, R. A Search for Natural Hydrophobic Deep Eutectic Solvents Based on Natural Components. ACS Sustain. Chem. Eng. 2019, 7, 2933–2942. [Google Scholar] [CrossRef]

- Hao, L.; Su, T.; Hao, D.; Deng, C.; Ren, W.; Lü, H. Oxidative Desulfurization of Diesel Fuel with Caprolactam-Based Acidic Deep Eutectic Solvents: Tailoring the Reactivity of DESs by Adjusting the Composition. Chin. J. Catal. 2018, 39, 1552–1559. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, C.; Zhang, B.; Li, Z.; Hao, J. All-In-One Deep Eutectic Solvent Toward Cobalt-Based Electrocatalyst for Oxygen Evolution Reaction. ACS Sustain. Chem. Eng. 2019, 7, 8964–8971. [Google Scholar] [CrossRef]

- Florindo, C.; Branco, L.C.; Marrucho, I.M. Development of Hydrophobic Deep Eutectic Solvents for Extraction of Pesticides from Aqueous Environments. Fluid Phase Equilibria 2017, 448, 135–142. [Google Scholar] [CrossRef]

- Arora, K.; Singh, G.; Singh, G.; Kang, T.S. Aggregation Behavior of Sodium Dioctyl Sulfosuccinate in Deep Eutectic Solvents and Their Mixtures with Water: An Account of Solvent’s Polarity, Cohesiveness, and Solvent Structure. ACS Omega 2018, 3, 13387–13398. [Google Scholar] [CrossRef]

- Vilková, M.; Płotka-Wasylka, J.; Andruch, V. The Role of Water in Deep Eutectic Solvent-Base Extraction. J. Mol. Liq. 2020, 304, 112747. [Google Scholar] [CrossRef]

- Shamsipur, M.; Zohrabi, P.; Hashemi, M. Application of a Supramolecular Solvent as the Carrier for Ferrofluid Based Liquid-Phase Microextraction for Spectrofluorimetric Determination of Levofloxacin in Biological Samples. Anal. Methods 2015, 7, 9609–9614. [Google Scholar] [CrossRef]

- Dutta, B.K. Principles of Mass Transfer and Separation Processes; PHI Learning Private Limited: New Delhi, India, 2007. [Google Scholar]

- Frisch, M.J.; Trucks, G.W.; Schlegel, H.B.; Scuseria, G.E.; Robb, M.A.; Cheeseman, J.R.; Scalmani, G.; Barone, V.; Petersson, G.A.; Nakatsuji, H.; et al. Gaussian16 B.01. Available online: www.gaussian.com (accessed on 18 August 2021).

- Takeshita, J.; Hasegawa, Y.; Yanai, K.; Yamamoto, A.; Ishii, A.; Hasegawa, M.; Yamanaka, M. Organic Dye Adsorption by Amphiphilic Tris-Urea Supramolecular Hydrogel. Chem. Asian J. 2017, 12, 2029–2032. [Google Scholar] [CrossRef] [PubMed]

- Tong, A.; Wu, Y.; Tan, S.; Li, L.; Akama, Y.; Tanaka, S. Aqueous Two-Phase System of Cationic and Anionic Surfactant Mixture and Its Application to the Extraction of Porphyrins and Metalloporphyrins. Anal. Chim. Acta 1998, 369, 11–16. [Google Scholar] [CrossRef]

- Jiang, H.; Xu, D.; Zhang, L.; Ma, Y.; Gao, J.; Wang, Y. Vapor–Liquid Phase Equilibrium for Separation of Isopropanol from Its Aqueous Solution by Choline Chloride-Based Deep Eutectic Solvent Selected by COSMO-SAC Model. J. Chem. Eng. Data 2019, 64, 1338–1348. [Google Scholar] [CrossRef]

- Jeliński, T.; Cysewski, P. Application of a Computational Model of Natural Deep Eutectic Solvents Utilizing the COSMO-RS Approach for Screening of Solvents with High Solubility of Rutin. J. Mol. Model. 2018, 24, 180. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Extraction Efficiency (%) | ||

|---|---|---|

| Lowest | Highest | |

| MB | 6.7 | 73.1 |

| MV | 83.2 | 98.6 |

| MG | 67.5 | 99.3 |

| Dye | ΔGsolv (kcal/mol) |

|---|---|

| Malachite green | −34.07 |

| Methyl violet | −34.16 |

| Methylene blue | −39.79 |

| Parameter | Methylene Blue | Methyl Violet | Malachite Green |

|---|---|---|---|

| Coefficient of determination (R2) | 0.9997 | 0.9998 | 0.9965 |

| Linear equation | y = 53170x − 0.0327 | y = 44782x − 0.0212 | y = 48699x + 0.0099 |

| Accuracy (%) | 102.45 ± 4.95 | 100.39 ± 1.57 | 92.95 ± 14.37 |

| Linearity range (×10−6 mol/L) | 1–50 | 1–50 | 0.5–50 |

| Standard error of intercept | 0.0131 | 0.0074 | 0.0435 |

| Standard deviation of intercept | 0.0292 | 0.0195 | 0.1065 |

| Limit of detection (LOD, ×10−6) | 1.81 | 1.44 | 7.21 |

| Limit of quantification (LOQ, ×10−6) | 5.49 | 4.36 | 21.9 |

| Extraction Efficiency (%) | ||

|---|---|---|

| Lowest | Highest | |

| MB | 10.8 | 43.6 |

| MV | 16.7 | 75.0 |

| MG | 47.2 | 84.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arcon, D.P.; Franco, F.C. A Simple Microextraction Method for Toxic Industrial Dyes Using a Fatty-Acid Solvent Mixture. Separations 2021, 8, 135. https://doi.org/10.3390/separations8090135

Arcon DP, Franco FC. A Simple Microextraction Method for Toxic Industrial Dyes Using a Fatty-Acid Solvent Mixture. Separations. 2021; 8(9):135. https://doi.org/10.3390/separations8090135

Chicago/Turabian StyleArcon, Danielle P., and Francisco C. Franco. 2021. "A Simple Microextraction Method for Toxic Industrial Dyes Using a Fatty-Acid Solvent Mixture" Separations 8, no. 9: 135. https://doi.org/10.3390/separations8090135

APA StyleArcon, D. P., & Franco, F. C. (2021). A Simple Microextraction Method for Toxic Industrial Dyes Using a Fatty-Acid Solvent Mixture. Separations, 8(9), 135. https://doi.org/10.3390/separations8090135