Abstract

The efficient separation and removal of carbon dioxide () from its mixtures is an important technological challenge to limit effects resulting from the increase of the carbon dioxide concentration in the atmosphere. Membrane technology is an environmentally friendly approach, highly scalable and less energy-consuming than conventional methods such as adsorption, absorption and cryogenic separation. Hybrid membrane materials incorporating inorganic filler nanostructures in polymer matrices having polyethylene glycol (PEG) as a plasticized additive are promising membrane materials given the presence of -philic polar functional groups of PEGs and the structural refinements on the blend matrix consequent to the filler distribution. In this review, literature information on hybrid polymer/PEG membranes are critically reviewed to discuss how filler dispersion in the blend matrix gives rise to enhanced separation performances with respect to those obtained with traditional mixed matrix membranes where filler nanostructures are dispersed in the neat polymer. The discussion will be focused on the correlation between the transport properties, membrane structural properties and defect resulting from the polymer-filler incompatibility. It is shown that hybrid polymer/PEG membranes with dispersed filler nanostructures simultaneously offer improved separation performances and enhanced mechanical properties compared with nanocomposite ones where filler particles are dispersed in the neat polymer matrix. PEG addition enhances the filler-matrix compatibility, delays filler aggregation and limits the formation of filler-matrix interface defects.

1. Introduction

Carbon Capture, Utilization and Storage (CCUS) technologies have emerged as critical components in the effort to limit global warming consequent to emissions from industrial processes and power plants [1]. CCUS technologies are designed to capture directily from the emission sources, thus preventing its release into the atmosphere: the captured carbon dioxide can then be stored in deep geological formations or employed for various applications such as the production of chemicals or fuels using renewable energies, thus offering additional incentives for industries to adopt them [2].

Different capture/separation technologies are industrially employed: absorption (water, physical and chemical scrubbing), adsorption and cryogenic separation [3]. In the adsorption process, gas mixture separation occurs after preferential absorption of components of a gas mixture by a liquid or a solvent: in the water scrubbing process, is absorbed by water, and in the chemical absorption process, by amines [4]. Adsorption involves the physical adsorption of gas components to the surface of an adsorbent solid [5]. Cryogenic separation takes advantage of the different liquefaction points of the gas mixture components under specific pressure and temperature conditions [6]. Each method possesses its proper advantages and disadvantages. Water scrubbing, for example, is a simple but slow process that requires low investment costs but also pre-treatments of the gas mixture to remove contaminants ( and siloxanes); moreover, it needs huge amounts of fresh water. Chemical scrubbing is a fast process but requires high investment costs, is energy-consuming and needs harmful and expensive absorbing substances: research is, in fact, focusing on the preparation of eco-friendly and cheap sorbent materials [7,8,9,10]. Adsorption does not require high investment capital but a complex set-up. Cryogenic separation does not use harmful substances but has high operating costs and, needing compressors and heat exchangers, requires high operative costs [11].

Gas separation by membrane techniques is of great applicative interest because it permits the development of compact systems with high energy efficiency and operational simplicity [12] to contribute to the “Process Intensification” strategy based on the improvement of the manufacturing process through the minimization of equipment volume, energy consumption, waste production and environmental impact [13,14].

Efficient membrane-separation systems have been developed and routinely employed for separation from , and purge gases in ammonia and chemical plants and in oil refineries [15], for purification in synthesis gas [16] and in natural gas treatment [17].

Considering global warming and climate changes, research efforts are nowadays directed to the development of innovative membranes for separation and capture. The challenge is to develop effective membrane materials to be employed in large-scale stationary plants, which can be industrially manufactured at affordable costs; for this application, polymers are the most attractive materials, given their simple and cost-effective fabrication methods [18]. Different applications are envisaged for separation with polymer membranes, which require physical and chemical refinement of the commercial polymeric materials structure to tailor their operative properties [19,20,21].

separation from post-combustion flue gases. Flue gases are discharged at ambient conditions and contain 11 to 14% when their sources are coal-fired power plants and 4 to 8% from natural gas combined cycle power plants [22,23]. Given the low partial pressure, the separation process requires highly permeable and selective membranes [24]. To separate gases with similar molecular sizes and improve the membrane performances, the chemical properties of the polymeric material are changed to improve the solubility by introducing Lewis bases such as, for example, ether and carbonyl oxygen [25] or by -matrix chemical interactions introducing amines [26].

separation in natural gas and biogas sweetening (pre-combustion). Natural gas contains 5 to 70% depending on the geographical location of the source. Carbon dioxide separation is carried out at ambient temperature with gas mixtures at high pressure, 30 to 60 atm. The membrane material should thus offer good mechanical properties and plasticization resistance caused by the high partial pressure and the presence of hydrocarbon species [27]. Plasticization and swelling give rise, in fact, to an increase in the interchain spacing and consequently drastically reduce the sieving selectivity: research is thus focused on the synthesis of shape persisting polymers with high chain rigidity [28]. These high-pressure-related properties are not required for biogas purification as the gas mixture is produced at ambient conditions, with content typically of 38 to 40% and content of 55 to 60% and water vapor of 1 to 2% [29].

separation in syngas processing. Syngas composition is typically 40% , 56% with a balance of water and . Membranes for separation operate at 240 °C temperature and 50 atm pressure [30]: the high transmembrane pressure reduced the requirement of high permeability, but thermally stable membranes with high and selectivity at high temperatures are required [31]. Research activity for the development of more performing membranes for syngas processing is focused on tuning the polymer chain configuration to obtain size-sieving selective membranes [23].

separation in plasma reformed mixtures. The separation and removal of from mixtures containing is gaining increasing interest due to the development of novel processes for utilization using renewable energy such as non-thermal plasma-activated reactions for splitting [32].

Currently, 90% of separation membranes that are used in the commercial module configurations are made of polymer: cellulose acetate (CA), polysulfone (PSf), polyethersulfone (PES) and polyimides (Matrimid®5218) are used at an industrial level, offering at 30 °C acceptable permeability values (from 5.6 Barrer for PES to 10.7 Barrer for Matrimid®5218), selectivity values (from 22 for PES to 44 for Matrimid®5218) and selectivity values (from 22 for PES to 33 for Matrimid®5128) [33,34].

The preferred route to develop innovative polymer membranes with improved separation performance is the modification of commercial materials, as it requires lower costs and an easier approach than the development of new polymeric materials [35]. Improved membrane separation performances are obtained by tailoring the membrane structure to improve the solubility, as, for example, by introducing affine functional groups or developing block copolymer with higher affinity, or to improve the diffusivity by modifying the polymer free volume structure or by combining polymers with nano-dimensional dense or porous filler structures [18,21].

This review describes the operative performances of polymer and polymer nanocomposite membranes modified by blending with poly(ethylene oxide). The PEO macromolecular chain structure contains —philic etheric groups, and PEOs have been widely studied as polymer additives for common polymeric membranes such as polysulfones, polyimides and polycarbonates to enhance their separation properties [36,37]. This plasticizer polymer additive is of great interest as a blending agent for commercial polymers, as it is cheap, available, non-toxic and can be easily combined with different polymers [38].

The novelty of this review is that reported experimental data are discussed to understand how enhanced functional properties are correlated with the membrane structural properties after PEG and filler addition rather than focusing on the obtained separation performances. To this task, separate discussions are carried out on the examined polymeric membrane materials, considering the relation between membrane structure and performances of the nanocomposites (neat polymer with dispersed filler nanoparticles) and then considering the structure-performance relation of the hybrid ones (polymer/PEG blend with dispersed filler nanoparticles). The aim is to underline how the PEG additive enhances the performance of the hybrid membrane with respect to the nanocomposite one. The analysis will focus on polymeric membranes for applications in separation from post-combustion flue gases and in separation in natural gas and biogas sweetening (pre-combustion).

2. Notes on the Gas Transport in Polymeric Membranes

2.1. Solution-Diffusion Model

Gas permeation through dense polymer membranes obeys the solution-diffusion mechanism, which assumes that gas transport follows three steps: (i) Gas phase molecules are absorbed in the near-surface layers of the membrane side exposed to high-pressure feed gas or feed gas mixture (high-pressure side), (ii) absorbed gas molecules diffuse down to their concentration gradient to the membrane side exposed to gas at low pressure (low-pressure side), generally negligible compared with the feed pressure and (iii) here their desorption occurs [39]. Gas molecules absorbed in the polymer membrane are hosted in void-like structures called free volume elements, which are formed by the irregular packing of the polymer chains and by the local thermal fluctuation of chain segments. Free-volume elements have the sub-nanometric size and control the transport of gas molecules because their migration from the high-to the low-pressure side takes place by successive jumps between randomly-formed free volume elements [40].

Two parameters control the gas permeation process: the penetrant solubility which is expressed in cm3 (STP)/cm3 cmHg practical units, and the penetrant diffusivity , which is expressed in cm2/s units. Penetrant sorption is a two-step process involving penetrants’ condensation to a liquid-like density followed by their mixing with the polymer chains [41].

The penetrant solubility depends on temperature as

where the sorption enthalpy is given by the sum of two terms: the condensation enthalpy and the mixing enthalpy of absorbed penetrants with the polymer matrix [41]. In the previous relation, is the pre-exponential solubility factor, and the universal gas constant.

Gas diffusion in polymers is a thermally activated process, and the diffusion constant exhibits an Arrhenius behavior:

where is the effective activation energy for diffusion, and is the pre-exponential factor [41]. Experimental reports indicate interesting regularities. Concerning the solution process, it was observed that in most gas-polymer couples , a strong correlation exists between parameters measuring the gas condensability (the critical temperature or the Lennard-Jones parameter ) and the condensation enthalpy empirically expressed as

where is the Boltzmann constant, while and are constant [41].

The quantity in the Lennard–Jones parameter in Equation (3) is the bond energy of the Lennard–Jones () pair potential , which models the weak van der Waals interaction between molecules: is the distance between molecules, and is the bond length. The and parameters are empirically determined, fitting known properties of the gas [42].

Concerning the diffusion process, it was observed that the diffusion constant increases, decreasing the gas molecular size with the square of a characteristic molecular size as a scaling parameter, thus suggesting that is proportional to the effective cross-sectional area of the gas molecule [41]. Molecular weight, kinetic diameter and Lennard–Jones parameters for , and are reported in Table 1.

Table 1.

Physical and chemical properties of gases involved in carbon dioxide separation [43].

2.2. Operative Membrane Parameters

The product between gas solubility and diffusivity defines the membrane permeability , which is generally reported in Barrer practical units: 1 Barrer = 10−10 cm3 (STP) cm/cm2 s cmHg = 3.35 × 10−16 mol/m s Pa [41]. The permeability value depends on the specific polymer-gas couple spanning over orders of magnitude, and its value changes with the membrane temperature and feed gas pressure . The permeability value is experimentally obtained by measuring the permeation flux through the membrane in stationary transport conditions, which is given by the following relation:

where is the membrane thickness, and is the trans-membrane pressure gradient.

For a given gas couple (), the membrane selectivity is given by the relation , where is the most permeable gas [41]. The selectivity values are mostly determined from permeability measured in single gas tests, and the obtained selectivity is referred to as “ideal”. It is given by

And can be thus portioned into diffusivity-selectivity and solubility-selectivity . Independent determination of the gas diffusivity values and and/or solubility values and allows for the separate evaluation of the and values and permits evincing which is the mechanism responsible for the membrane’s selective properties [41].

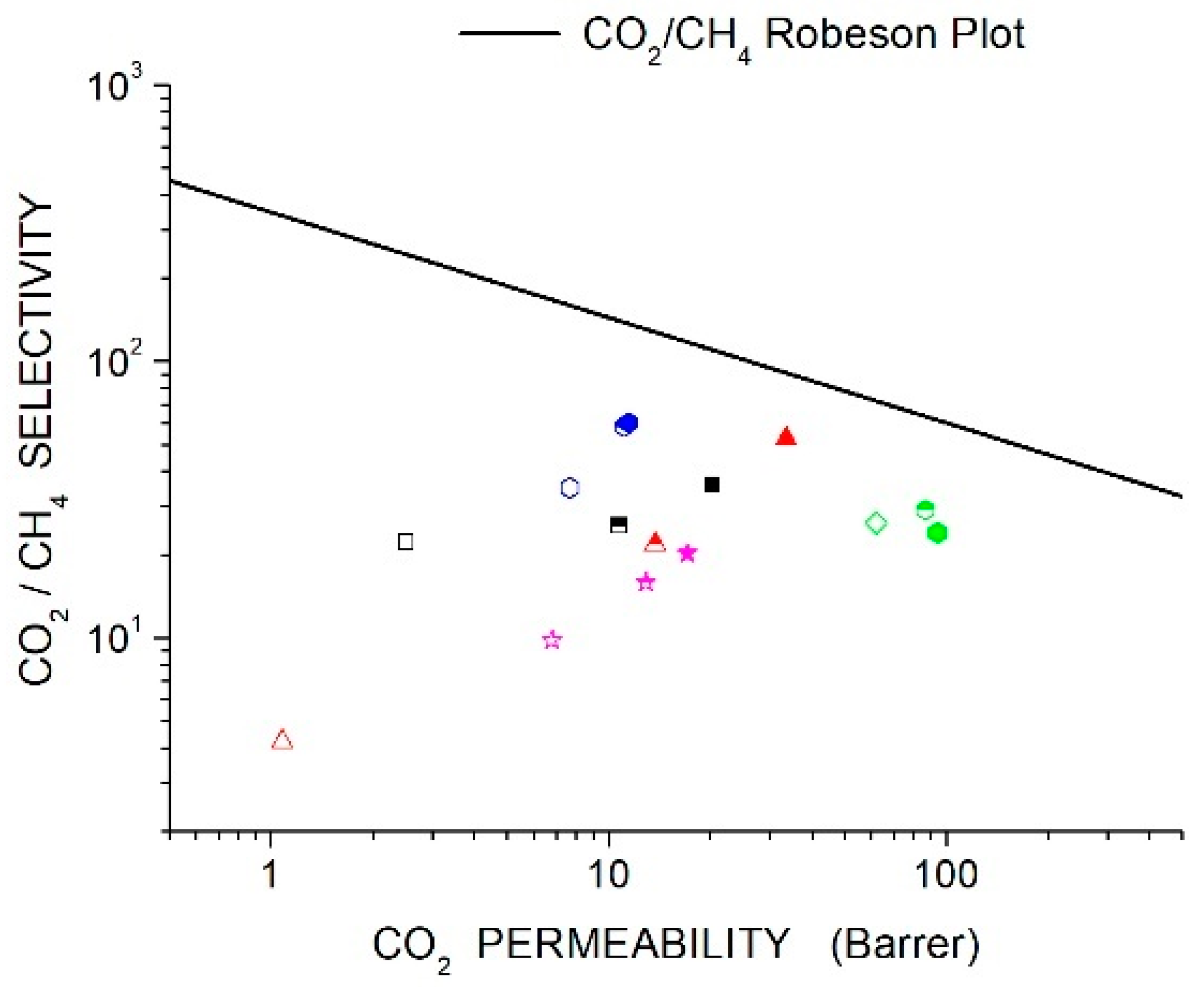

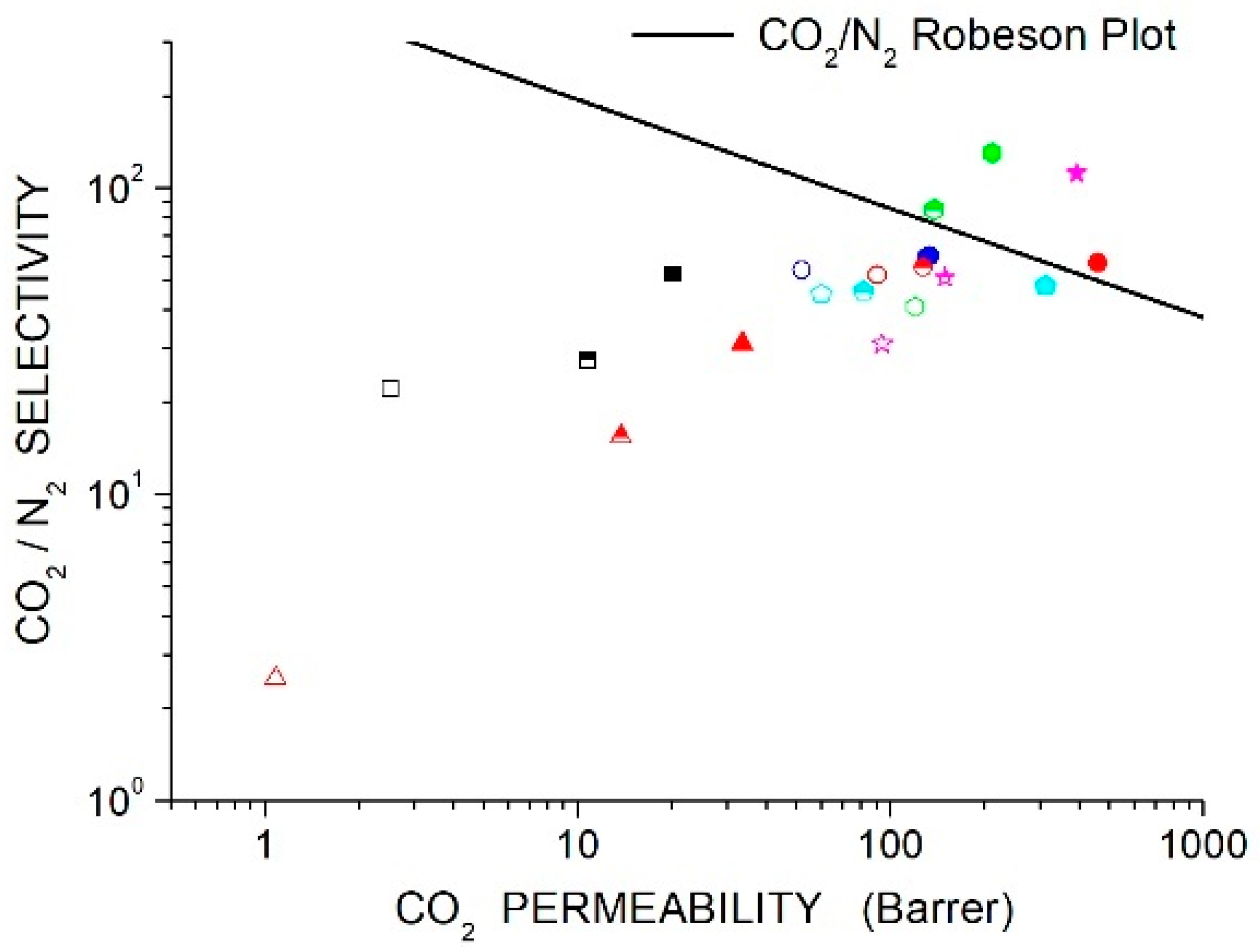

2.3. Robeson Limit

Membrane separation requires membranes with high permeability to a specific gas species A and high selectivity to obtain high purity of the separated gas. The large amount of scientific literature on polymer membranes for gas separation provides evidence that an empirical trade-off exists between permeability and selectivity for any gas couple: polymers exhibiting high selectivity values for gas are generally less permeable to this gas, and vice-versa [44]. Such a trade-off, called the Robeson limit, can be described as an upper bound where all permeability-selectivity data in a log-log scale are below an empirical line.

This upper bound is quantitatively described by a line:

Which reports the evidence that as the permeability for a gas increases, the selectivity of a polymer membrane toward the gas pair decreases. Freeman introduced a semi-quantitative model to predict the values of the and parameters for a given gas pair [45]. The model considered that the parameter depends on the kinetic diameters of the gas molecules and , while the parameter is related to their solubility values and :

where and and are numerical parameters. The parameter depends on the polymer class (e.g., rubbery or glassy), while is universal for all polymers. The parameter changes with the equilibrium inter-chain spacing increasing from rubbery to glassy polymers [45].

The recently proposed and upper bounds lines [44] are reported in Section 11, “Discussion”, and will be presented with experimental data on the membrane systems reviewed in the next sections of this manuscript.

3. Polyethylene Oxide as Polymeric Additive

Polyethylene oxide (PEO) is a family of synthetic water-soluble polymers made of repeated oxyethylene segments forming chemically stable, non-toxic and biodegradable compounds: when the PEO molecular weight is lower than 20,000 PEOs are generally called polyethylene glycol (PEG) [46]. The PEGs’ physical properties depend on the value: the glass transition temperature , for example, and the melting temperature increase with the molecular weight; see Table 2. At ambient conditions, PEGs with < 600 are liquids, PEGs with > 3000 PEGs are solids, and their crystalline degree increases with , while at intermediate values, PEGs are low melting, waxy and partially crystalline solids [47]. PEGs are of great interest for the development of innovative separation membranes because the presence of polar ether groups (, where and are alkyl or aryl groups) in the main chain enhances their affinity with carbon dioxide, increasing the carbon dioxide solubility [47]: the symmetric molecule, in fact, has a permanent quadrupole moment and aligns its oxygen atom near the positively charged carbon region of the ether-containing polymer while the carbon atoms are accommodated near the negatively charged oxygen atoms of the ether group. Their use as additives is widely investigated to improve the operative performances of common polymeric membranes [48].

Table 2.

Physical properties of some PEG [47]. : molecular weight, : mass density, : glass transition temperature, : melting temperature, : crystalline degree.

The use of PEG as an additive in polymeric membranes raises many challenges. Experimental permeation tests have shown that the gas permeability of pure PEG membranes decreases by increasing the PEG molecular weight because increasing the PEG molecular weight increases the crystalline degree of the PEG membrane. The addition of high molecular weight PEG to the polymer matrix can thus worsen the membrane transport properties because dispersed PEG crystals are impermeable to penetrant molecules; consequently, their presence in the matrix increases the tortuosity of the penetrant diffusion path and reduces the membrane free volume [47]. Low molecular weight PEGs are, on the contrary, liquid, do not form crystalline domains in the polymer matrix, and are thus of major interest for the preparation of blend membranes: issues such as their effects on the membrane mechanical properties must be considered as well as their low value ranging from −77 °C to −81 °C for PEG200 and PEG1000, respectively, which raises compatibility issues with the membrane operative conditions [47].

4. Polymer Blends

Polymer blending consists of the physical mixing of two or more polymers (in binary mixtures, generally glassy and rubbery) to fabricate new materials with enhanced and tailored properties in a cost-effective manner by recycling plastic waste. In membrane separation, polymer blends are of interest because they permit the improvement of separation properties together with the possibility of suppressing plasticization and improving mechanical strength [48]. Blends can have a homogeneous or heterogeneous nature (often defined as miscible or immiscible polymers): their miscibility occurs when the following relations hold:

where is the free energy of mixing, and are the enthalpy and entropy of mixing, respectively, and is the temperature. The term is generally negligible compared with because the number of possible configurations of the macromolecular chains is restricted. The value thus controls the sign, which is negative when intermolecular attractive interactions between the two components exist [49,50,51]. In addition to the above-mentioned criterion, for blend miscibility, the following relation must hold:

where represents the volume fraction of a component, and the temperature and pressure; for a polymer blend thus varies with its composition [49,50,51].

Favorable interactions for macromolecular chains mixing of the two polymers, such as hydrogen bonding, form homogeneous blends with single-phase properties. Well-mixed polymer blends exhibit uniform thermal and mechanical properties and offer stable operative performances and, therefore, have high potential interest for commercial production [49,50,51].

The structure of polymer blends and the miscibility of their components are studied by combining different analytical techniques, and, on a laboratory scale, the most employed are Scanning Electron Microscopy (SEM), Differential Scanning Calorimetry (DSC), Fourier Transform Infrared Spectroscopy (FTIR) and X-ray Diffraction (XRD) [52,53].

SEM analysis permits us to examine the polymer blend surface and cross-sectional morphology and reveals good mixing when clear, homogeneous single-phase images appear. On the contrary, immiscible polymers are shown by morphologies such as, for example, dispersion of minor phase into major constituent phase (shown by droplets/domains formation with size and distribution depending on the blend composition) or by the presence of planar alternating phases (lamellae morphology) [54].

The glass transition temperature () value is a thermodynamic parameter describing the temperature at which the polymer undergoes a transition from a glassy, hard and rigid state to a rubbery, soft state. The most used technique to evaluate the value is DSC with scan temperatures from −150 to 700 °C. In DSC testing, the sample will run with two consecutive scans of heating and cooling at a specific heating rate: the first run is used to cancel the thermal history of the sample, while the second one permits determining temperatures where thermal transformation processes occur in the polymer sample: glass transition, crystallization and melting. DSC analysis permits us to obtain information on the mixing degree. In neat and homogeneous well-mixed blend polymers, in fact, a single value is found, while in immiscible polymers, two distinct values are observed, each pertinent to the original polymer. In partially miscible polymers, two values appear that shift to each other depending on the components’ loading [55].

FTIR spectroscopy is widely used for the characterization of polymer blends and the study of the interactions between the macromolecular chains of the blend components. The most common interactions between blend components are hydrogen bonding and dipole-dipole bonds. Their presence in the blend is indicated by variations in the IR absorption bands’ intensity and position after blending, which generally induces miscibility of the blend components, while charge transfer interactions are revealed by the formation of new, distinct absorption bands [56].

Polymers exhibit crystalline, semi-crystalline and amorphous structures. Highly crystalline polyethylene (PE), for example, presents XRD patterns with sharp, well-defined reflection peaks, while amorphous polymers such as polycarbonate present very broad features, often called diffraction halos, not defined by any crystalline model. Semi-crystalline polymers such as polypropylene (PPE) present XRD patterns that are a mix of them. Diffraction patterns are additive: when a polymer is mixed with another polymer, the resulting blend pattern shows contributions from both constituents. The analysis of the blend peaks, namely intensity peak position variation as a function of the additive content, provides information about the variation of the crystalline degree and interchain distance (-parameter) using Bragg’s law [57].

5. Polymer/PEG Blend Membranes for Separation

5.1. Polycarbonate (PC)

Polycarbonate (PC) are glassy thermoplastics containing carbonate groups widely used for industrial and domestic applications: PC membranes are studied for gas separation, offering good thermal resistance and mechanical properties [58].

Hamrahi et al. prepared PC blend membranes with PEG300 at contents up to 5 wt. % and observed that the mass density of the blend samples increased with the additive content from 1.140 g/cm3 for the neat material to 1.223 g/cm3 for the blend with 5 wt. % PEG300 content [59]. SEM micrographs of the pristine PC membrane sample as well as those of blend samples containing 1 and 3 wt. % PEG300 showed homogenous morphology without visible cracks or voids, while at 5 wt.% PEG300 content, and small, liquid PEG300 aggregates were observed, indicating partial phase separation. FTIR absorption spectra suggested the formation of hydrogen bonds between the carbonyl group of the PC chains and the terminal group of PEGs, which explained the good miscibility of the polymer components. DSC analysis showed a single value decreasing from 135 °C for the neat PC membrane to 126, 117 and 105 °C at 1, 3 and 5 wt.%, respectively, thus confirming the good mixing of the polymer components. The XRD pattern of the neat PC membrane showed a broad XRD peak at = 17.63°, indicating the -spacing value of 5.038 Å. This reflection peak shifted to larger angles with the addition of 1 and 3 wt. % PEG, indicating a decrease in the -spacings to 4.582 and 3.619 Å, respectively, while at 5 wt.% PEG300 content increased to 4.065, but a new reflection peak appeared at 2 = 5.91°, confirming partial phase separation at this additive content as suggested by SEM analysis. Results of characterization tests are reported in Table 3.

Table 3.

permeability and selectivity of neat and PC/PEG300 blend membranes with different additive content measured in single gas tests at 25 °C and 3 bar feed pressure. The membrane mass density, the -spacing and the values are also reported (CA average = 21,000 g/mol; Khuzestan Petrochemical, Iran) [59].

and transport tests were carried out by the variable pressure—constant volume method at 3 bar and 25 °C: results showed that increasing the PEG300 content, the permeability slightly decreased while the selectivity slightly increased. The authors suggested that the decrease in the permeability accompanied by the selectivity enhancement was a consequence of the increase in the polymer chain packing, as also suggested by an increase in the mass density, enhancing the selectivity but reducing the blend free volume and thus the membrane permeability.

5.2. Cellulose Acetate (CA)

Cellulose acetate (CA) is a biodegradable cellulose ester commercially produced in the form of thin films for packaging applications given its good mechanical properties, transparency and affordable cost. This biopolymer is of interest for the development of separation membranes for carbon dioxide removal from natural gas, offering acceptable separation properties due to the high solubility [60].

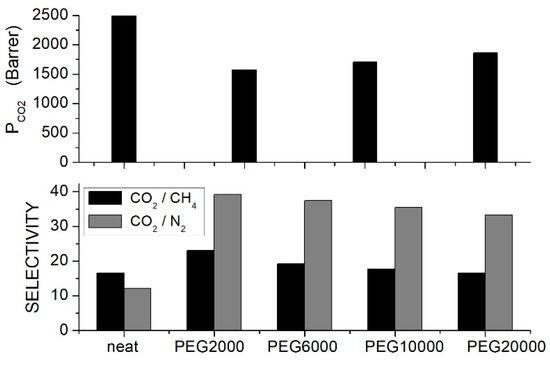

Li et al. prepared CA/PEG blends with different PEG formulations at 10 wt. % content and tested the gas separation performances by the constant volume—variable pressure method at 35 °C and 0.26 bar feed pressure [61]. Results showed that the permeability and selectivity increased with the PEG molecular weight while the , and transport rates decreased; see Figure 1. The optimal separation performances were obtained with the PEG20000 additive: the permeability increased, in fact, from 5.96 Barrer for the neat CA membrane to 7.49 Barrer, the ideal selectivity was ~30 as in the neat membrane, and the ideal selectivity increased from 25.8 to 36.2. Changing the PEG20000 content from 10 to 50 wt. % the permeability showed negligible variation accompanied by a decrease in the and selectivity values. The analysis of the permeation curves evidenced that the improved transport rates were caused by an enhanced diffusivity, which increased from 0.56 × 10−8 cm2/s in the neat sample to 1.00 × 10−8 cm2/s with 10 wt. % PEG 20000; the solubility, on the contrary, decreased from 106.4 × 103 cm3 (STP)/cm3 cmHg to 74.9 × 103 cm3 (STP)/cm3 cmHg. Structural characterization tests were carried out on the neat CA and on the CA/PEG20000 blend membrane. XRD tests indicated that the -spacing reduced from 5.2 nm for the neat sample to 5.0 nm with 10 wt. % PEG20000 and that the chain packing increase was accompanied by a small increase in the membrane mass density. DSC measurements of the neat membrane showed a single value at 185.5, while in the blend membrane with 10 wt. % PEG20000, it was 183.7 °C, evidence of component mixing. At larger contents, a second value was observed at temperatures between −54 and −51 °C, suggesting phase separation between the polymer components. It was suggested that the improved separation properties were connected to the high diffusivity selectivity caused by the increased polymer chain packing.

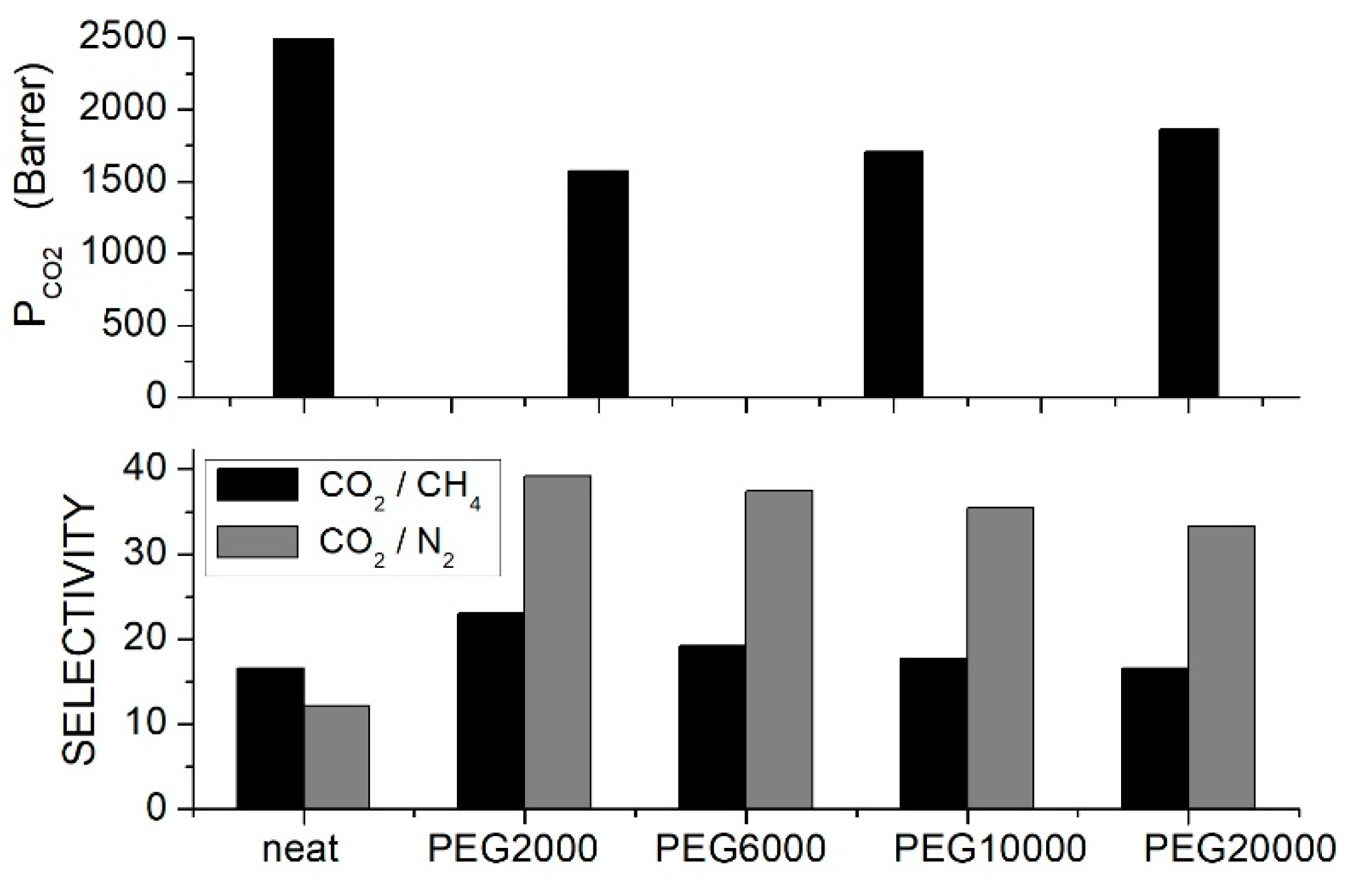

Figure 1.

permeability (upper panel), and selectivity (lower panel) of CA/PEG blend membranes with different PEG formulations (10 wt. % content) measured in single gas tests at 35 °C and 0.25 bar feed pressure [61].

5.3. Matrimid®5218

Matrimid®5218 (3,3′,4,4′-benzophenone tetracarboxylic dianhydride and diaminophenylindane) is a semi-crystalline commercial polyimide that exhibits good thermal and mechanical properties and is highly soluble in organic solvents; it is deeply investigated for the preparation of separation membranes as it offers reasonable separation properties despite low transport rates [62].

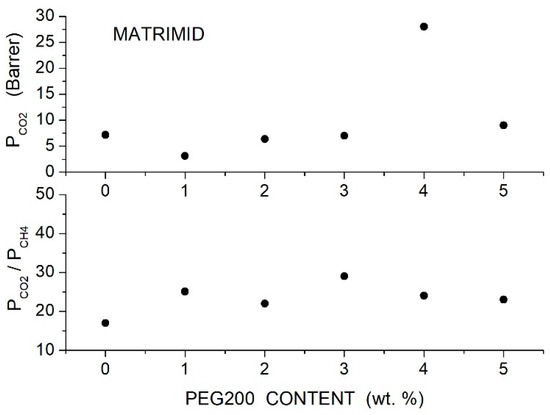

To improve the permeability of Matrimid® membranes, Castro-Munoz et al. prepared Matrimid®5218/PEG200 blend membranes with additive content up to 5 wt. % [63]. DSC analysis showed that PEG addition slightly increased the value from 310 °C for neat Matrimid®5218 to 315 °C for the blend with 5 wt. % PEG content, evidencing good mixing of the two components as a consequence of hydrogen bonding between nitrogen atoms in imide groups of Matrimid and hydrogen atoms in terminal hydroxyl groups of PEG chains, as suggested by FTIR analysis. As a consequence of good component mixing, similar TGAs were observed for the neat and blend samples: the neat membranes showed thermal stability from 300 to 470 °C and slightly better for the blend ones up to 500 °C. SEM analysis showed homogeneous cross-sectional and surface morphology, suggesting partial phase separation at 5 wt. % PEG200 content. Permeation tests were carried out at 25 °C and 8 bar feed pressure with equimolar gas mixtures. Results demonstrated that the PEG200 addition improved the permeability of the Matrimid®5218 matrix and the best performances were obtained with the Matrimid/PEG200 blend containing 4 wt. % additive; see Figure 2. The permeability increased, in fact, from 7.2 to 27.59 Barrer, but the selectivity slightly changed. The authors attributed the improved membrane permeability to the high solubility in PEG due to the interaction between the additive and molecules.

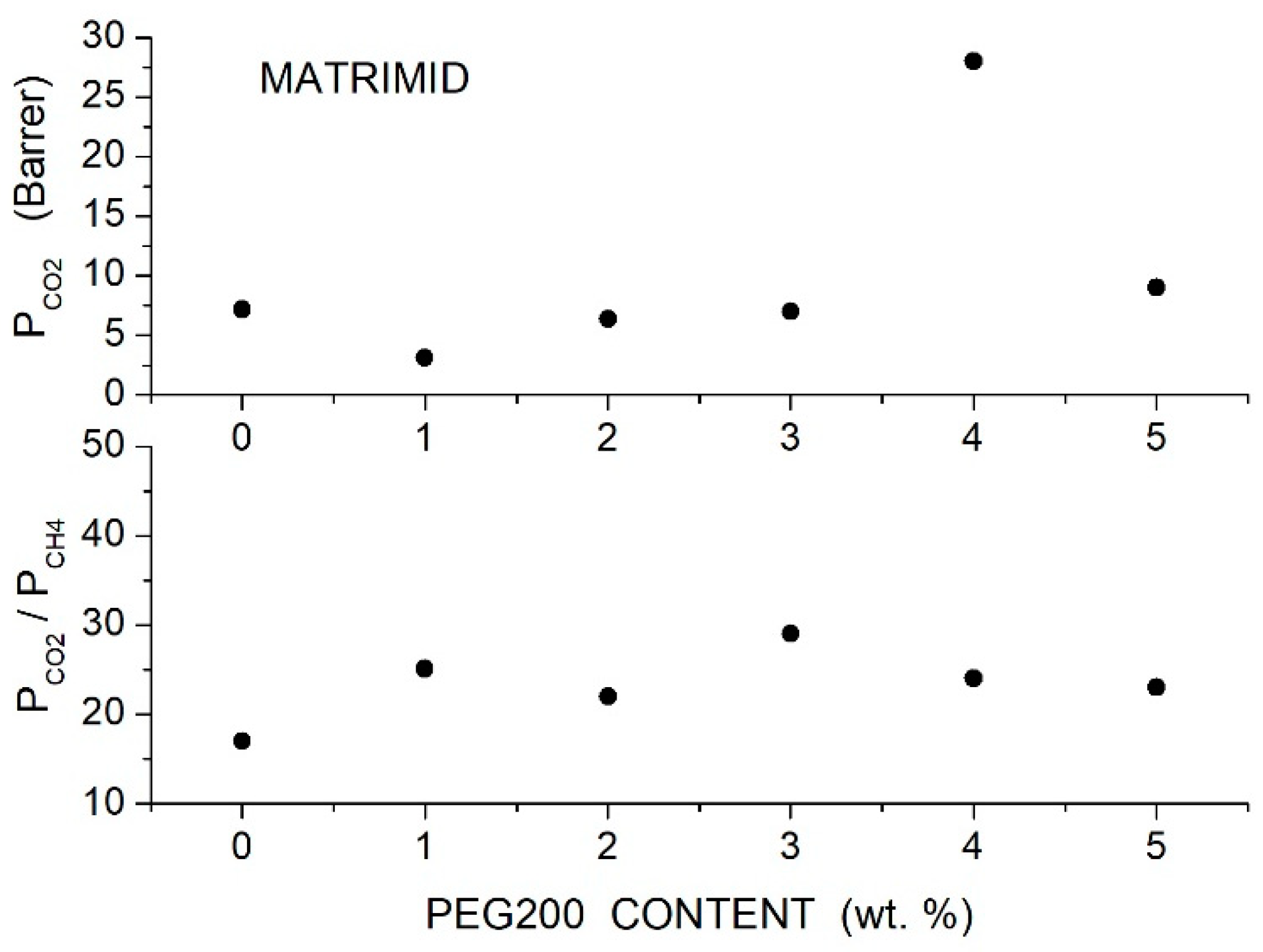

Figure 2.

permeability (upper panel) and and selectivity (lower panel) of Matrimid/PEG blend membranes as a function of PEG200 content measured with equimolar gas mixtures at 25 °C and 8 bar feed pressure [63].

Loloei et al. also prepared Matrimid/PEG200 blend membranes with larger additive content [64]: DSC analysis showed a single value decreasing from 310 °C for the neat membrane to 297 °C at 5 wt. % content, suggesting a good mixing of the polymer components. At larger PEG200 contents, a second value appeared at −30 °C, suggesting phase separation and the formation of PEG200 domains; see Table 4. The good mixing of the polymer components was a consequence of hydrogen bonding interactions between PEG and Matrimid, as suggested by the shift of the Matrimid stretching bands toward lower frequencies with PEG addition. XRD analysis showed that PEG200 addition: (i) reduced the intensity of the broad Matrimid® diffraction peaks at ≅ 14 and 17°, indicating an increase in the blend amorphous fraction, and (ii) shifted the XRD peaks to lower angles, indicating an increase in the -spacing from 0.521 nm in neat Matrimid® to 0.553 nm in the blend with 5 wt. % additive content. SEM analysis of the sample cross-section revealed a dense and homogeneous structure up to 5 wt. % PEG200 content; at larger contents, macroscopic voids and pores formed. Single gas permeation tests were carried out at 35 °C and 10 bar feed pressure. Results revealed that the permeability increased with the additive content from 7.7 Barrers for the neat membrane to 22.0 Barrers for the blend with 20 wt. % PEG200 content, while the selectivity slightly increased from 35 for the neat membrane to 40 for the blend with 5 wt. % PEG200 content and decreased at larger contents; see Table 4. This enhancement was attributed to the strong affinity of with the polar ether segments of PEG by dipole-quadrupole interactions, while the selectivity decrease was observed with 10 to 20 wt. % additive content was attributed to the non-selective voids shown by SEM in the blend membrane; see Table 4.

Table 4.

permeability and selectivity of Matrimid/PEG200 blend membranes as a function of the PEG200 content as obtained in single gas tests at 35 °C and 10 bar feed pressure. The glass transition temperature () and the melting temperature () are also reported [64].

5.4. Polysulfones (PSF) and Polyethersulfones (PES)

Polysulfones (PSF) and Polyethersulfones (PES) are high-performance amorphous thermoplastics that contain aryl--aryl subunits responsible for their mechanical toughness and chemical and thermal stability over a wide temperature range from −100 °C to 160 °C. Thanks to these properties and their low cost, polysulfones are widely used for the fabrication of commercial separation membranes [65].

Nasarian et al. prepared polysulfone/PEG blend membranes with PEG4000, PEG6000 and PEG10000 with a homogeneous and defect-free structure [66]. XRD tests showed the amorphous structure of the neat and blend with the broad halo between = 15 and 25°, shifting to lower angles increasing the additive content: the spacing increased from 2.11 Å for the neat membrane to 3.87 Å for the PSF blend with 20 wt. % PEG10000. No interaction between PSE and PEG chains was shown by the FTIR spectra. DSC tests of the neat PSF and PEG10000 samples showed values of 178.9 and −40.2 °C, respectively. The blend membrane with low molecular weight PEG4000 at 10 wt. % content exhibited two glass transition temperatures, the first one at = 28.3 °C and the second one at 133.1 °C, evidence of partial component mixing. Increasing the PEG molecular weight and content, the miscibility between the two components increased, and the blend with PEG10000 at 20 wt. % presented a single value at 161.1 °C; see Table 5.

Table 5.

The -spacing value, tensile strength and Young’s modulus of the PSF/PEG blend membranes with different additive types and content [66].

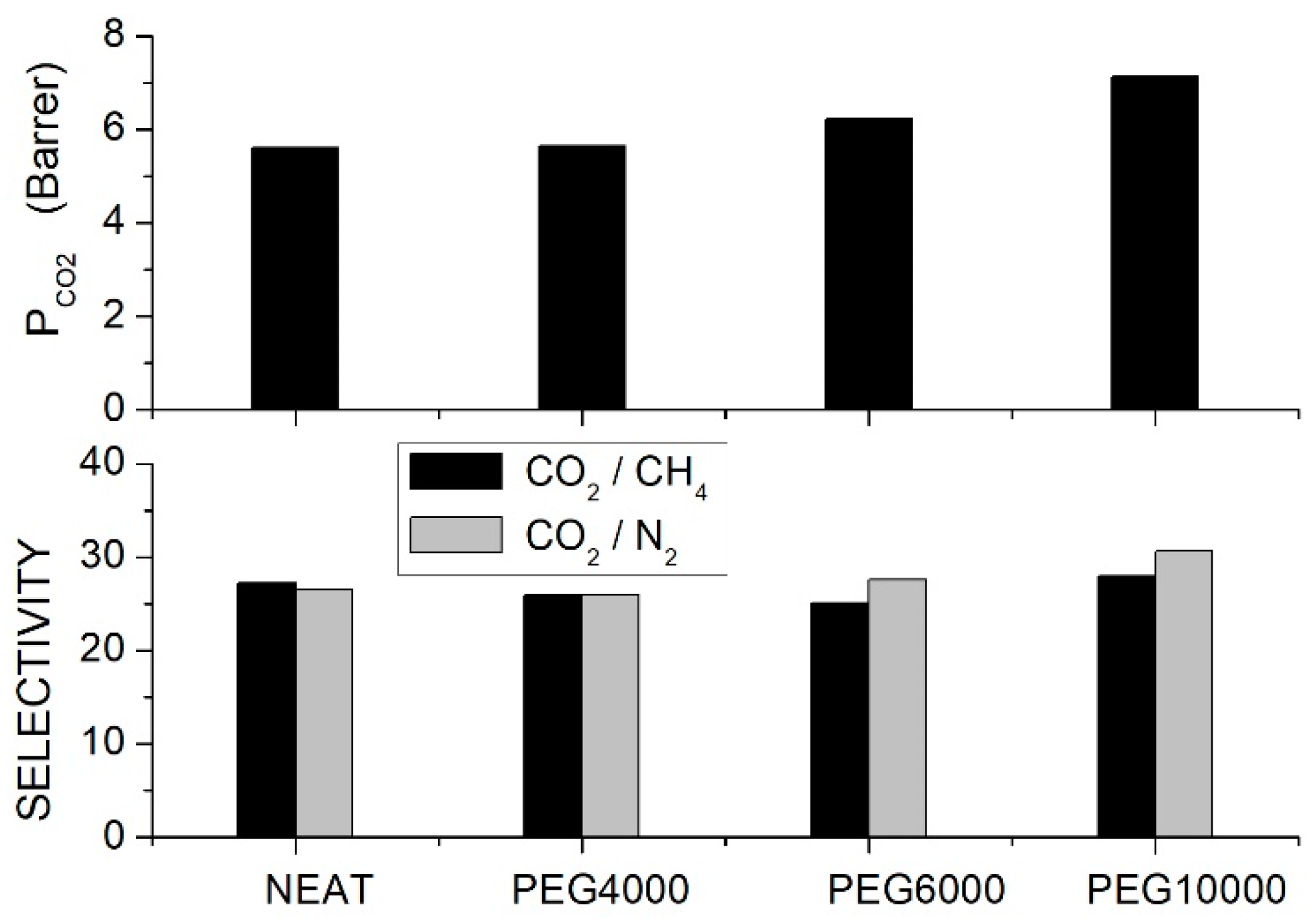

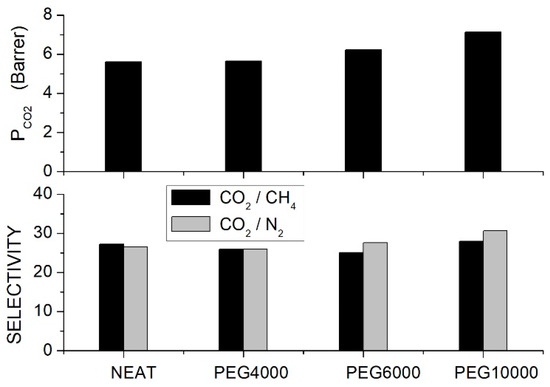

Single gas permeation tests were carried out at 30 °C and 10 bar feed pressure, and results indicated that the permeability increased with PEG content and molecular weight; see Figure 3. Optimal performances were observed with the PEG10000 blend membrane: the permeability increased from 5.61 Barrer for the neat PSF membrane to 7.12 and 7.64 Barrer at 10 and 20 wt. % additive content, respectively. The selectivity of the neat PSF membrane was 27, and negligible variations were observed after blending, while the selectivity slightly increased from 26 for the neat sample to 32 for the blend with 20 wt. % PEG10000 content. The improved penetrant permeability was attributed to the larger interchain spacing increasing the fractional free volume, while the small increase in the selectivity was attributed to the interaction with polyether polar bonds of PEG. The authors observed that component mixing also influenced the blend’s mechanical properties: adding low molecular weight PEG4000 and PEG6000, there was, in fact, a worsening of the blend’s mechanical properties as a consequence of immiscibility between the two components while adding high molecular weight PEG10000 molecularly, the Young’s modulus and the tensile strength were improved with respect to the neat membrane; see Table 5.

Figure 3.

permeability (upper panel) and ideal selectivity (lower panel) of PSF/PEG blend membranes with different PEG formulations (10 wt. % content) as measured in single gas tests at 30 °C and 10 bar feed pressure [66].

5.5. Polymers of Intrinsic Microporosity (PIMs)

Polymers of Intrinsic Microporosity (PIMs) are glassy, organic microporous materials that contain a continuous network of interconnected pores with a size smaller than 2 nm: PIMs have high free volume, high internal surface area, and are thus widely investigated for membrane applications offering high gas permeability values [67].

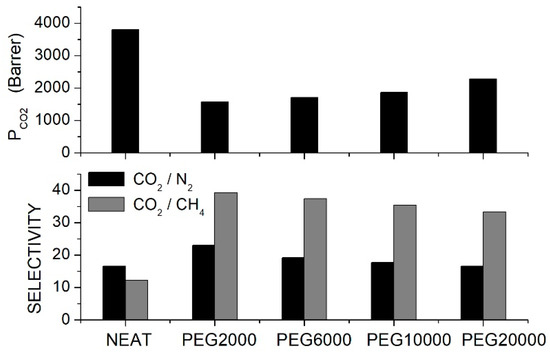

PIM-1, the prototype PIM, is the most studied one given its excellent workability and solubility in common solvents, and different applications ranging from gas adsorption to nanofiltration are envisaged [68,69]. PIM-1 is of interest for the development of an innovative gas separation membrane offering 2300 Barrer permeability and selectivity value close to 25 [68,69]. PIM-1 is synthesized via polymerization of 5,5′,6,6′-tetrahydroxy-3,3,3′,3′-tetramethyl-1,1′-spirobisindane (TTSBI) and 2,3,5,6-tetrafluoroterephthalonitrile (TFTN) by a high-temperature route (120–180 °C) in short process times (from several minutes to few hours) or by a low-temperature route (50–70 °C) in longer process times (72 to 96 h). This is a versatile membrane material because the synthesis conditions strongly influence the structural properties that control the gas permeability and selectivity, such as the chain packing [68,69].

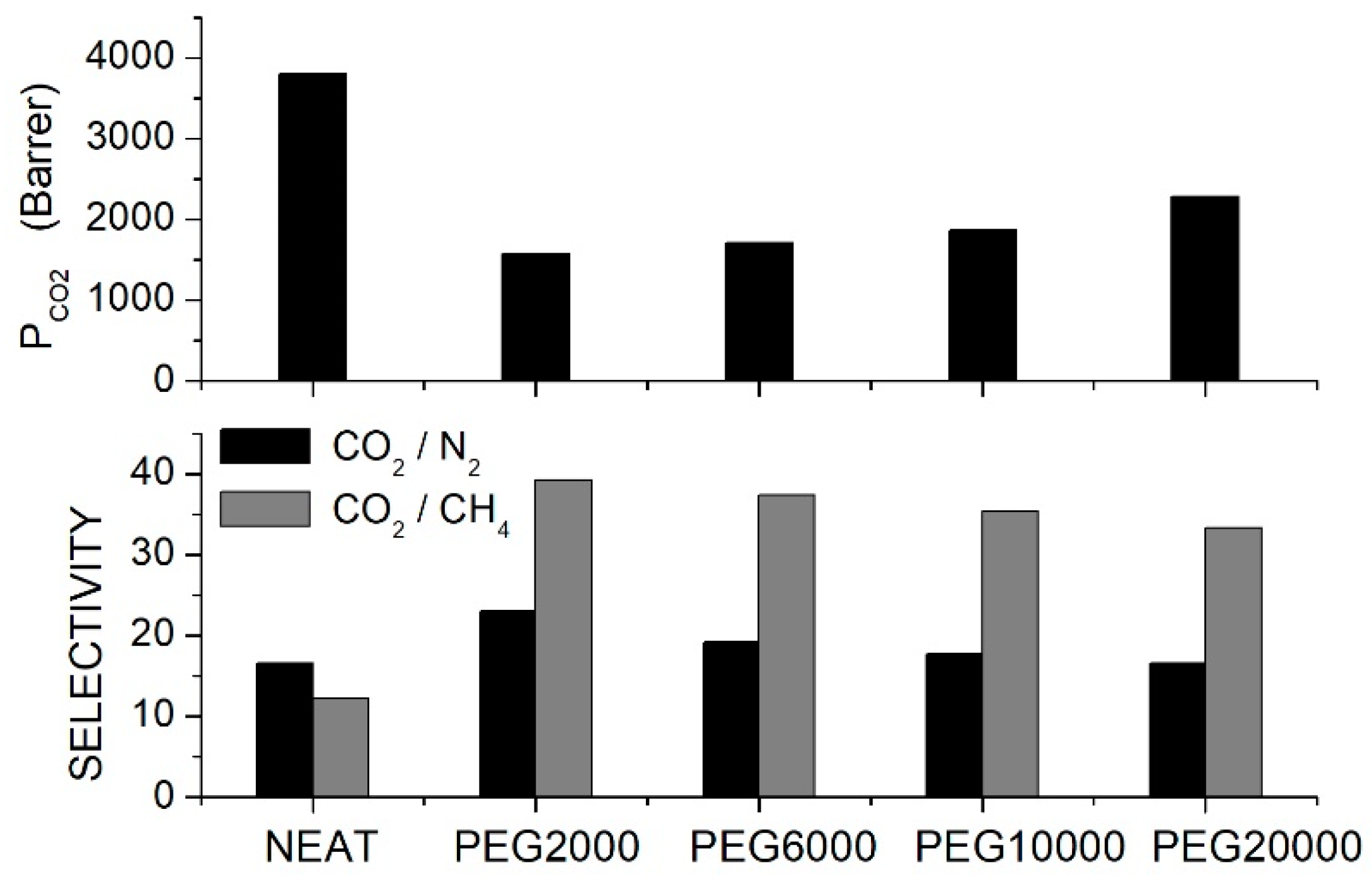

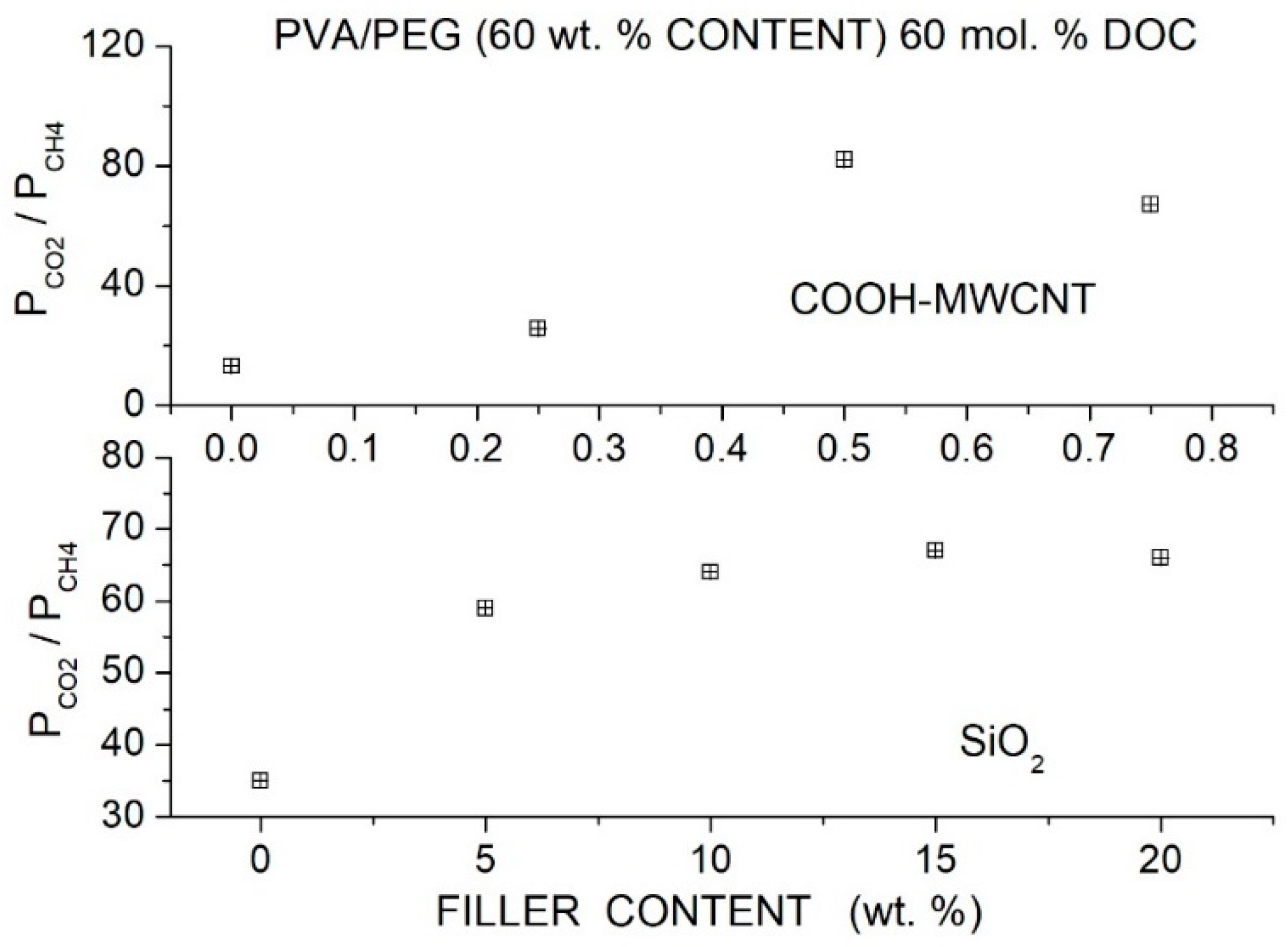

To improve the PIM-1 selective properties, Wu et al. prepared PIM-1 blend membranes with different PEG formulations [70]. SEM analysis showed that up to 2.5 wt. % content, the PEG additive was well distributed in the PIM-1 matrix, forming blends with a homogeneous and uniform structure, while at larger contents PEG, aggregates formed. XRD analysis of the blend samples with additive content not larger than 2.5 wt. % showed diffraction peaks pertinent to the PIM-1 structure with -spacing of 0.66 and 0.49 nm pertinent to loosely packed polymer sites surrounding the micro-pores and to more efficiently packed chains, respectively. PEG addition shifted the reflection peaks to larger diffraction angles, and the authors observed that the larger the PEG molecular weight, the larger the shift was. This indicates that short PEG chains more easily fill the gaps between the PIM-1 chains and increase the matrix packing. In fact, the mass density on the neat membrane, 1.122 g/cm3, increased to 1.152 g/cm3 by adding 2.5 wt. % PEG2000, while it decreased to 1.146, 1.135 and 1.132 g/cm3 with 2.5 wt. % PEG6000, PEG10000 and PEG20000, respectively. Single gas permeation tests were thus carried out at 30 °C and 4 bar feed pressure using blended homogeneous membranes containing PEGs at 2.5 wt. % content. Results showed that the addition of all PEG formulations decreased the permeability of the neat PIM-1 membrane but increased the and selectivity; see Figure 4.

Figure 4.

permeability (upper panel) and selectivity (lower panel) of PIM-1/PEG blend membranes with different PEG formulations (10 wt. % content) as obtained in single gas tests at 4 bar and 30 °C [70].

The reduced permeability was attributed to a reduced fractional free volume, and the increased selectivity was due to the interactions between and the PEG ether oxygen groups. Results also showed that by increasing the PEG molecular weight, the permeability of the blend membrane increased while the selectivity decreased. The authors thus studied the gas transport properties of the membrane blend with PEG20000, changing the additive content from 0.5 to 3.5 wt. %. Results showed that the , and permeability values decreased; the selectivity increased while negligible variations were observed for the selectivity; see Table 6. This trend was attributed to the increased compactness of the blend chain structure, as suggested by the increase in the blend mass density with additive content; see Table 6. At 5 wt. % content, the two polymer components separated, the permeability increased, and the selectivity decreased: this worsening was attributed to the formation of faster and non-selective migration paths for penetrant molecules formed at the interface between the blend membrane and PEG20000 domains.

Table 6.

permeability and selectivity of the blend PIM-1/PEG20000 blend membranes with different additive content as measured in single gas tests at 4 bar and 30 °C. The membrane mass density at different additive contents is reported in the first column [70].

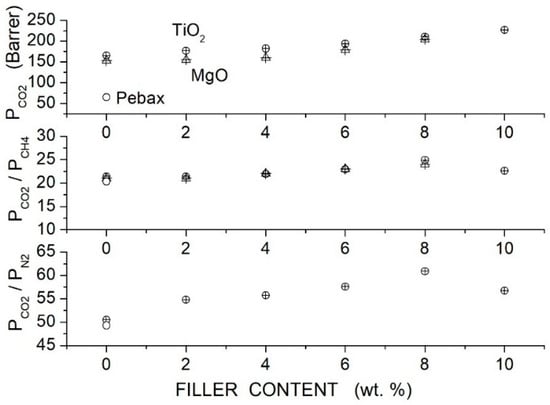

5.6. Polyether Block Amine (PEBA)

Polyether block amine (PEBA) is a family of thermoplastic block copolymers generally known by the commercial name of PEBAX® (Arkema, USA) having general chemical structure: is a rigid, carboxylic acid polyamide (PA6, PA11, PA12) and is an amorphous, soft polyether (PTMG, PTMO, PEG). PEBAs are deeply studied for the development of innovative gas separation membranes because the segments control the mechanical strength, chemical resistance and thermal stability of the matrix while the segments control the elasticity and the hydrophobicity and form the domains where gas transport takes place; see Table 7 [71]. PEBA membranes are of interest for and separation because the linear molecule has a smaller size and a higher affinity with the polar ether blocks than and and thus exhibits larger diffusivity and solubility [72].

Table 7.

Physical properties of Pebax with formulations of interest for the development of gas separation membranes [71].

Car et al. prepared Pebax®MH 1657 (Arkema, USA) blend membranes with PEG200 as an additive at different contents. SEM micrographs of the neat Pebax matrix showed two separated microphases: the crystalline PA phase indicated by oriented polymer lamellar and the amorphous phase formed by the PEO segments [73]. The authors observed that blending with PEG200 destroyed the lamellar structure, decreasing the blend crystalline degree. DSC measurements of the neat Pebax showed the value and two characteristic melting temperatures: the low melting temperature due to the melting of PEO domains, while the high melting one is due to the melting of the PA crystallites. Increasing the PEG content, the value decreased, indicating enhanced chain mobility, while and shifted to lower values, suggesting that the PEG200 addition deteriorated the crystal structure and promoted the formation of smaller and imperfect PA crystallites. The crystalline degree of the blend membrane decreased, in fact, from 38 wt. % for the neat Pebax to 2 wt. % by adding 40 wt. % PEG200. The results of characterization techniques are reported in Table 8. Permeability tests were carried out at 30 °C and 600 mbar feed pressure in single gas tests, and the gas diffusivity was evaluated by the time-lag method. Results showed that the permeability increased with the PEG200 content and that this increase was caused by enhanced diffusivity, while the solubility values did not show variations. The and selectivity values showed negligible variation, changing the additive content. The authors attributed this trend to the decreased crystallinity of the blend membrane and consequent increase in its fractional free volume, as suggested by the decrease in the blend mass density with additive content.

Table 8.

gas transport parameters and selectivity values of the blend Pebax®MH1657 membrane as a function of the PEG200 additive content as measured in single gas tests at 30 °C and 600 mbar feed pressure. units: 10−11 m2/s; units: 10−4 mol/m3 Pa. The glass transition temperature , the melting temperatures and and the crystalline fraction are reported in the first columns [73].

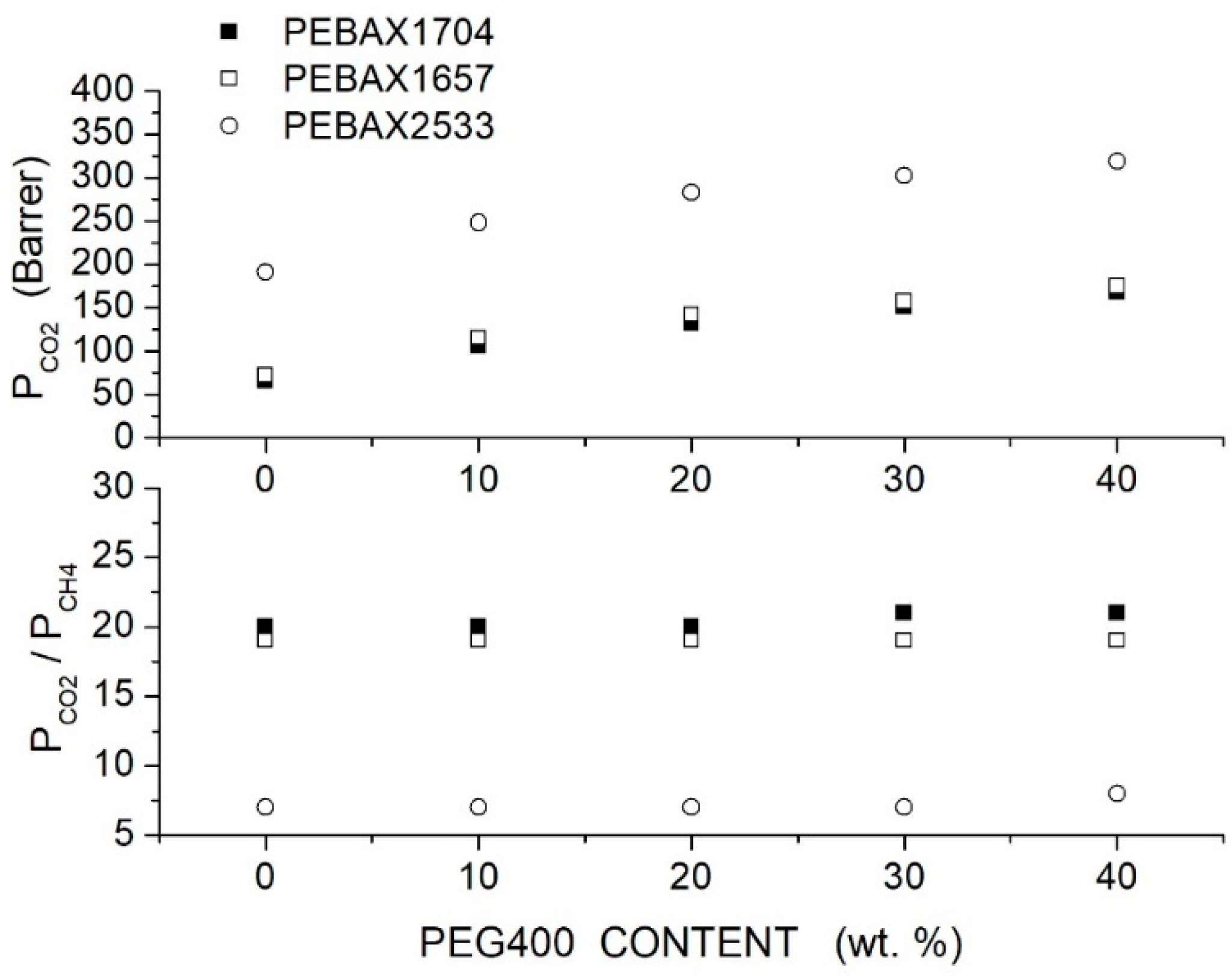

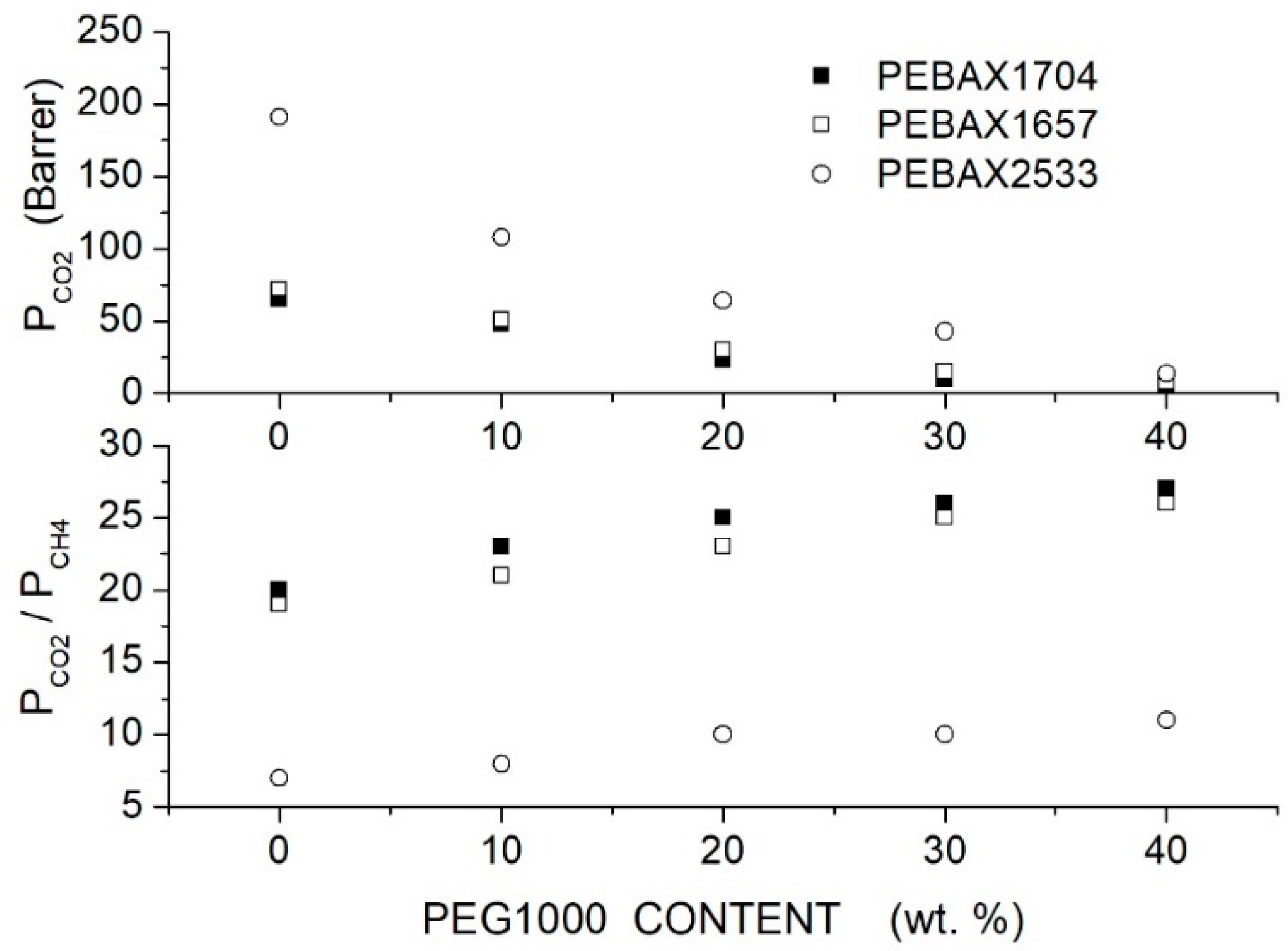

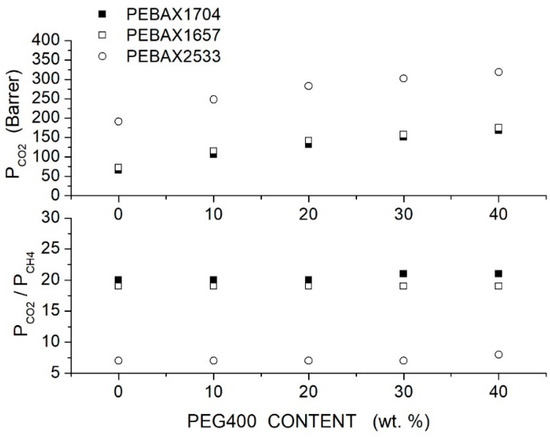

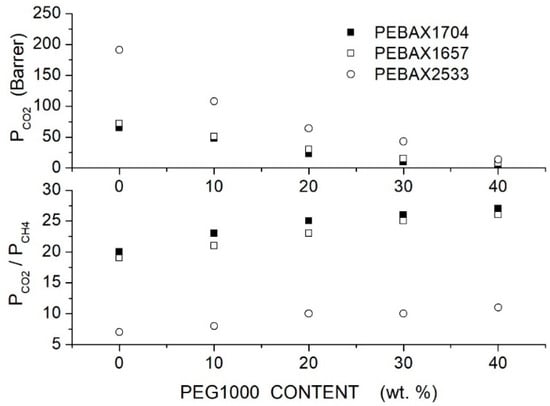

Azizi et al. prepared PEBAX/PEG blend membranes using Pebax1704, Pebax1657 and Pebax2533 and two PEG formulations, PEG400 and PEG1000 [74]. Cross-sectional SEM analysis of the neat PEBAX and PEBAX/PEG400 blend membranes showed a uniform and dense structure without defects such as voids or cracks, while micrographs of the PEBAX/PEG1000 blend membrane suggested partial phase separation. The XRD test evidenced strong diffraction peaks for the neat PEBAX membranes at = 22.5, 21.8 and 20.2°, respectively, attributed to PA crystallites. The PE regions of the neat PEBAX 1074 and PEBAX 1657 membranes provide weak diffraction peaks at = 10.9 and 9.8°, respectively, while the neat PEBAX 2533 membrane does not show any PE diffraction peak. The addition of low molecular mass PEG400 decreased the intensity of the XRD peak and shifted them to lower 2 values, evidence that the membrane crystalline degree is reduced and the -spacing increased. The addition of high molecular mass PEG1000, on the contrary, increased the blend crystalline degree and reduced the -spacing. The comparison between the FTIR spectra of the neat and blend membranes suggested that PEG addition disrupted interchain hydrogen bonds between the PA segments. Permeation tests were carried out in single gas tests at 25 °C and 2 bar feed pressure; results are reported in Figure 5 and Figure 6 for blends with PEG400 and PEG1000, respectively. It can be observed that in all Pebax, increasing the PEG400 content, the and permeability increased without significant variation of the ideal selectivity. The authors suggested that the addition of the PEG400 polar ether groups enhanced the affinity of for the blend membrane, giving rise to an enhanced solubility selectivity but also increased the chain spacing, thus decreasing the sieve property and reducing the diffusivity-selectivity without marked changes to the overall selectivity. On the contrary, increasing the PEG1000 content, there was a significant decrease in the and permeability accompanied by an increase in the ideal selectivity. The improved selectivity was due to the addition of the polar ether groups of PEG1000, enhancing the solubility but decreasing the polymer chain packing, thus enhancing the membrane molecular sieve properties.

Figure 5.

permeability (upper panel) and ideal selectivity (lower panel) of Pebax®/PEG400 blend membranes with different additive contents measured in single gas tests at 25 °C and 2 bar feed pressure [74].

Figure 6.

permeability (upper panel) and ideal selectivity (lower panel) of Pebax®/PEG1000 blend membranes with different additive contents as measured in single gas tests at 25 °C and 2 bar feed pressure [74].

Taheri et al. prepared to blend Pebax®1657 membranes with PEG600, 1500 and 4000 at contents of 10, 20, 30 and 40 wt. % [75]. FTIR of the neat and blend membranes evidenced the interaction of the two blend components by hydrogen bonding between the Pebax carbonyl groups and terminal -OH groups of PEG. SEM analysis showed a dense and uniform structure of the neat membrane and of the blend membrane with PEG600, while phase separation was observed in the blend membranes containing PEG4000 and PEG1500. XRD analysis showed a broad halo at 2 = 20.7°, which became broader and exhibited reduced intensity, adding PEG600, thus suggesting an increase in the membrane amorphous fraction. Adding PEG1500 and 4000, the intensity of the crystalline peak at 2 = 20.7° increased, and the peak shifted to larger angles, indicating a higher crystalline degree and reduced inter-chain -spacing. Moreover, sharp PEG reflection peaks appeared. The crystalline degree of the neat and blend membrane samples was calculated considering the areas under the PEG crystalline peaks and the Pebax amorphous halo: results showed that increasing the PEG600 content, there is a monotonic decrease in the sample amorphous fraction while increasing the PEG1500 and 4000 content, there is a monotonic increase in the crystalline fraction. Permeation tests were carried out by constant volume—variable pressure at 25 °C and 3 to 7 bar feed pressure in single gas conditions; see Table 9. Results revealed that: (i) increasing the PEG600 content there was an increase in the permeability without a markable variation of the selectivity, while (ii) increasing the PEG1500 and 4000 content, the permeability decreased, the selectivity increased, and no significant variation was observed in the selectivity.

Table 9.

Crystalline degree (), permeability and , selectivity values of blend Pebax®1657/PEG membranes with different additives and contents as obtained in single gas tests at 25 °C and 3 bar [75].

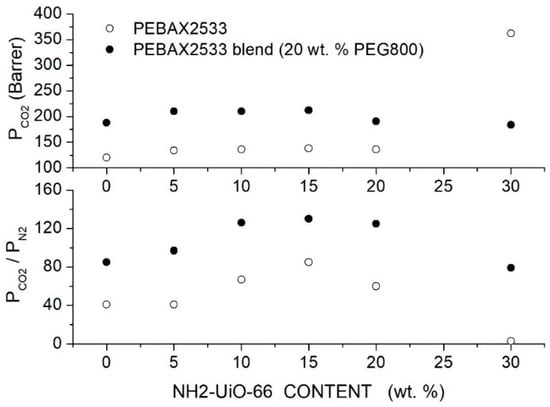

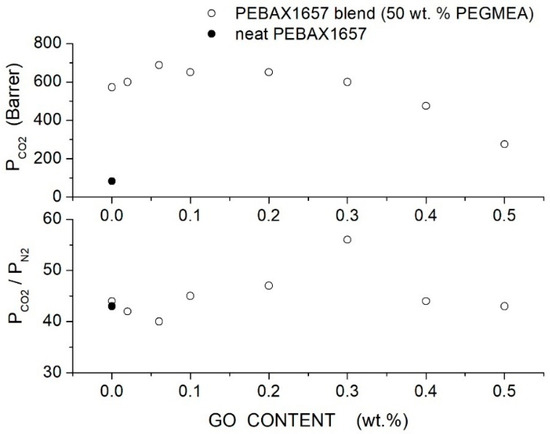

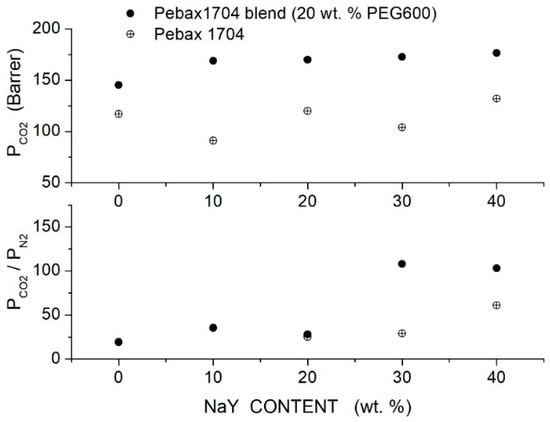

6. Polymer/PEG Hybrid Membranes

Mixed Matrix Membranes (MMM) are an important class of organic-inorganic nanocomposites whose structure consists of nano-sized filler particles such as zeolites, silica, CNTs and MOFs dispersed in a continuous polymeric matrix [76]. These nanocomposite membranes are designed to overcome the separation performances of the neat polymeric matrix and to improve its mechanical properties and thermal/chemical stability, thus ensuring stable membrane operations [77]. Generally, MMMs exhibit improved selectivity with respect to the host matrix when they contain filler particles with tailored, size-selective pores, while changes in the polymer matrix permeability are obtained by adding non-porous nanoparticles, which increase the fractional free volume or act as physical obstacles for migrating gas molecules [78].

Here, we will focus the discussion on hybrid nanocomposite membranes consisting of a polymeric matrix with PEG additive and filler nanoparticles. The aim is to evidence the role of the PEG additive in the enhancement of the membrane performances, aiming to correlate variations of the permeability and selectivity with the membrane structural changes promoted by the additive. The following terms will be thoroughly used: neat membrane (NM) to indicate the membrane made of the matrix polymer, blend membrane (BM) to indicate the membrane made of the matrix polymer and PEG additive, nanocomposite membrane (NCM, also called Mixed Matrix Membranes) to indicate the membrane made of filler nanoparticles dispersed in the polymer matrix, and hybrid membrane (HM) to indicate the membrane made of polymer, PEG additive and dispersed filler nanoparticles.

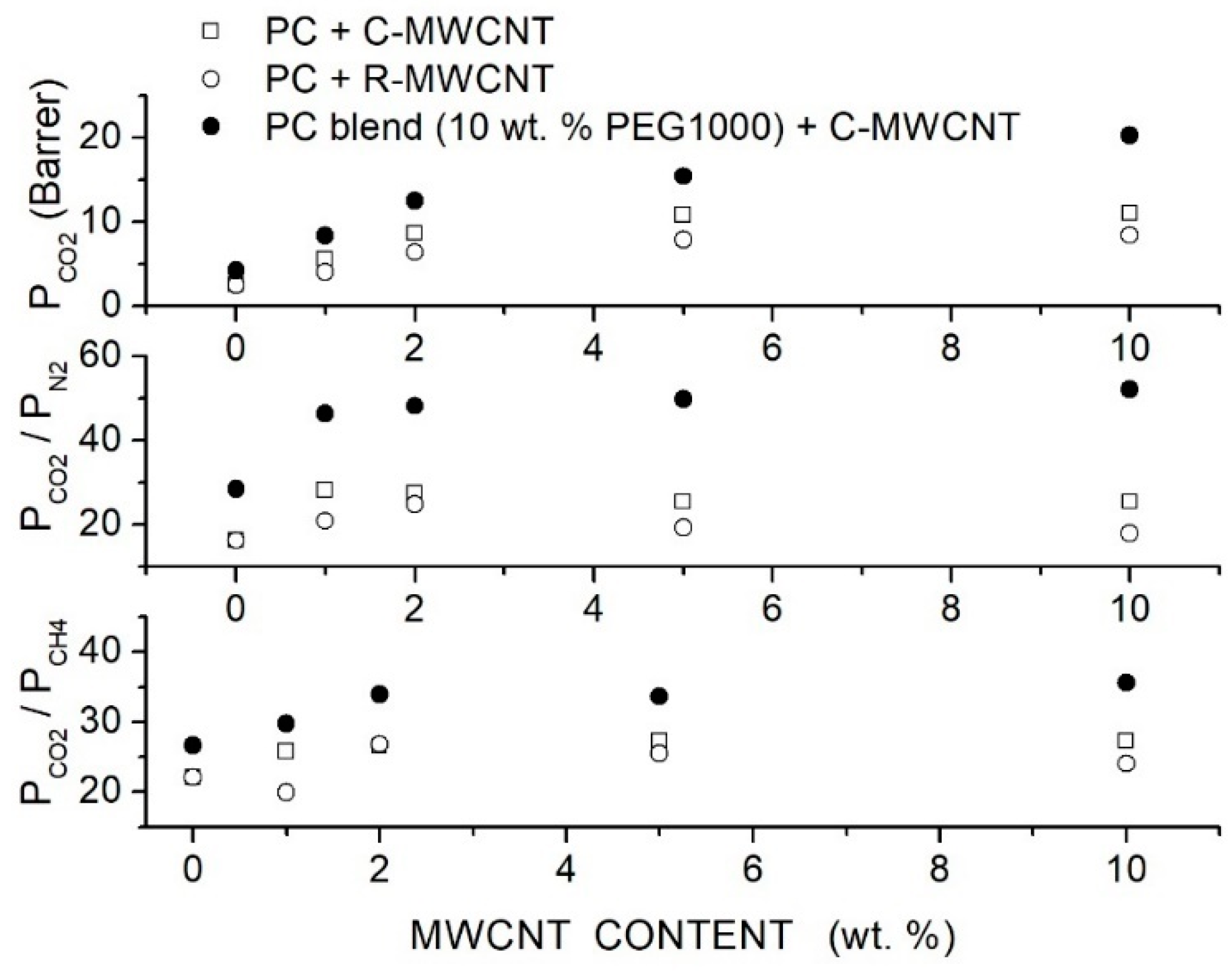

6.1. Polycarbonate-Based Hybrid Membranes

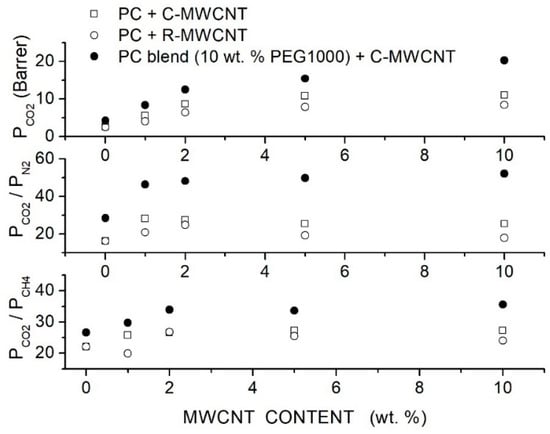

Moghadassi et al. prepared polycarbonate (PC)-hybrid membranes using PEG1000 as a polymer additive and Multiwalled Carbon Nanotubes (MWCNTs) filler nanoparticles [79]. They used raw MWCNT (R-MWCNT) having 10 μm length, 16 nm diameter, 110 Å mean pore diameter and 133 m2/g specific surface area and -functionalized MWCNT (C-MWCNT) with 10 μm length, 8 nm diameter, 98 Å mean pore diameter and 110 m2/g specific surface area. Membrane structural characterization was carried out by SEM surface and cross-sectional analysis. Results showed a non-uniform distribution of raw MWCNTs in the CA matrix. Filler distribution was improved by CA blending and filler functionalization. SEM images showed that the homogeneous filler distribution at contents up to 5 to 10 wt. % was obtained by dispersing the functionalized filler nanoparticles in the blend matrix: the authors suggested that the presence of polar ether groups in the polymer matrix lead to physical interactions of carboxyl functionalized groups in the surface of modified MWCNTs with the blend matrix. Single gas permeation tests were carried out at room temperature with 2 bar feed pressure. The authors observed that the permeability of the neat PC membrane was improved by the dispersion of both raw and functionalized filler nanoparticles; it was also observed that the membrane performances improved with the filler content up to 5 wt. % without significant variations increasing the filler content to 10 wt. %. The optimal performances were offered by the C-MWCNT: at 5 wt. % the permeability was 10.80 Barrer and the and selectivity values were 25.42 and 27.38, respectively; see Figure 7. The blend PC/PEG1000 membrane with 10 wt. % additive exhibited better permeability and selectivity values than the neat PC one and filler dispersion improved its separation performances. It was observed that: (i) the permeability and selectivity increased with the filler content, (ii) at same filler content the blend membrane offered better performances that the neat one and (iii) the permeability and selectivity increased up to 10 wt. % filler content and was 20.32 Barrer with and selectivity values were 52.10 and 35.64; see Figure 7. The previous results suggested that the PEG addition not only improved the transport owing to the affinity between the polar ether links and the acid molecules but also favored the filler dispersion.

Figure 7.

permeability and selectivity of the neat PC, blend PC/PEG1000 (10 wt. %) and hybrid PC/PEG1000 (10 wt. %) membrane with different MWCNT filler contents measured in single gas tests at 25 °C and 2 bar feed pressure [79]. Open circles are pertinent to the nanocomposite membrane containing raw MWCNT, open squares to the nanocomposite membrane containing functionalized MWCNT filler particles, solid circles to the hybrid PC/PEG1000 (10 wt. %) membrane containing functionalized MWCNT.

In fact, the PEG addition was also beneficial for the membrane mechanical properties: the blend PC/PEG1000 membrane containing 5 wt. % C-MWCNT offered improved properties than those of the neat PC membrane and of the MMM containing same filler amount; see Table 10.

Table 10.

Mechanical properties of the neat, nanocomposite PC and hybrid PC/PEG1000 (10 wt. %) membrane [79].

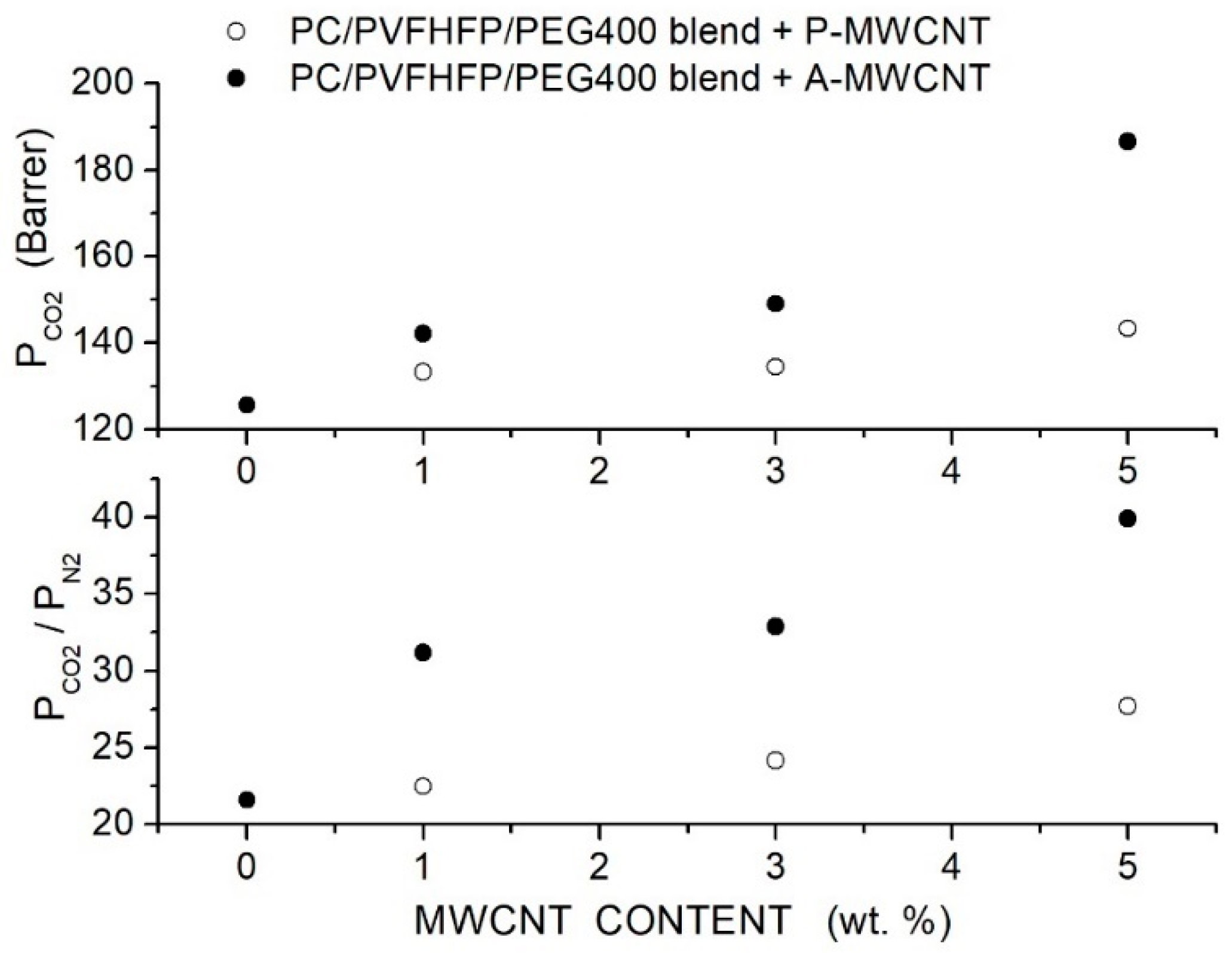

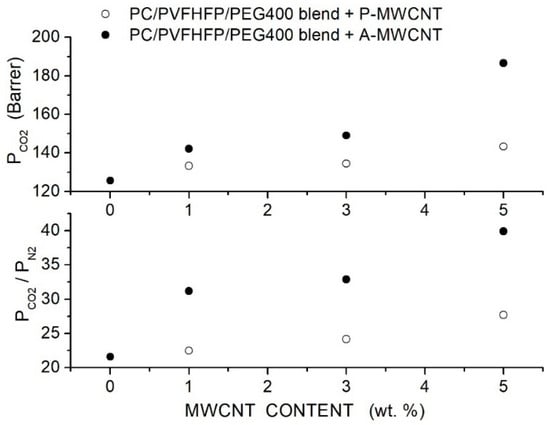

Kausar et al. prepared polycarbonate (PC)-hybrid membranes using polycarbonate with = 50,000, poly(vinylidene fluoride-co-hexafluoropropylene (PVFHFP, = 130,000) and PEG400 used as a compatibilization agent at a composition of 60, 30 and 10 wt. %, respectively [80]. Purified (P-MWCNT) and acid-functionalized (A-MWCNT) multiwalled carbon nanotubes with a 13 nm outer diameter and 2.5 to 20 μm length were used as filler nanoparticles. SEM micrographs of the blend showed that PC formed a continuous phase with PEG acting as compatibilizer, favoring the PVFHFP dispersion. In the blend matrix, the P-MWCNT nanofiller formed large bundles of agglomerates wet by the polymer matrix, while A-MWCNT resulted well dispersed up to 5 wt. % content. FTIR spectra suggested that the improved dispersion of the functionalized nanofillers was a consequence of hydrogen bonding interactions with the matrix. Single gas permeation tests were carried out at 27 °C and 10 psi feed pressure. Results showed that the filler addition improved the permeability and selectivity of the PC/PVFHFP/PEG blend membrane, offering the functionalized filler particles better results, and that the permeability and selectivity increased with the filler content, resulting in 186.6 Barrer and 39.9 at 5 wt. % content; see Figure 8.

Figure 8.

permeability of the neat PC, PC/PVFHFP/PEG400 blend membrane with different P-MWCNT and A-MWCNT filler contents measured in single gas tests at 27 °C and 10 psi feed pressure [80]. Open and solid circles are pertinent to the hybrid membrane containing purified and acidfunctionalized MWCNT filler nanoparticles.

The authors observed that by increasing the A-MWCNT content in the blend matrix, there was no variation in the solubility, evidence that the improved membrane performances were due to improved diffusivity. Filler addition improved the tensile strength and modulus of the hybrid membranes up to 5 wt. % content, offering the A-MWCNT better performances than P-MWCNT, while a decrease in the elongation at break was observed; see Table 11.

Table 11.

Mechanical properties of the neat PC, PC/PVFHFP/PEG400 blend membrane with different P-MWCNT and A-MWCNT filler contents [80].

6.2. CA-Based Hybrid Membranes

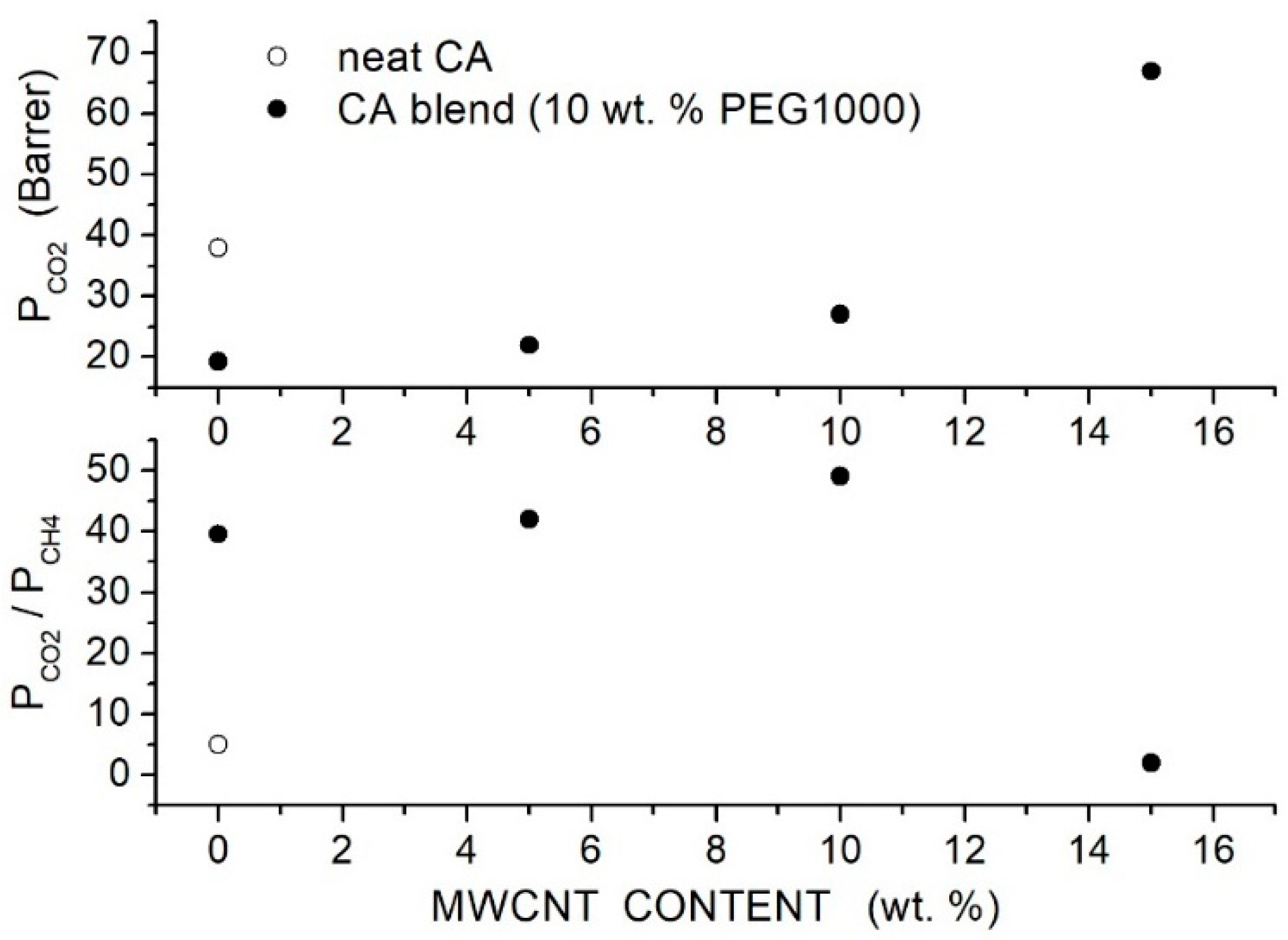

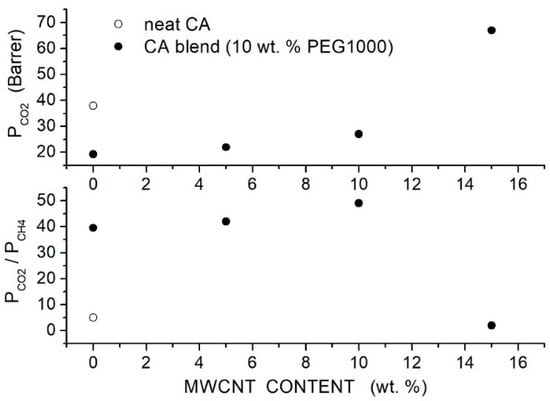

Hussain et al. prepared CA-based hybrid membranes using CA with = 50,000 as matrix PEG1000 as polymer additive and MWCNTs with outer diameter = 8 15 nm and inner diameter = 3 5 nm as filler particles [81] and characterized them by SEM analysis and mechanical testing. The authors prepared blended CA/PEG membranes with 10, 20 and 30 wt. % PEG1000 content and hybrid CA/PEG1000 (10 wt. %) membranes containing 5, 10 and 15 wt. % MWCNT. Room temperature permeation tests were carried out in single gas conditions at 2 bar feed pressure using a mass flow controller. Results showed a decrease in the permeability from 38 Barrer for the neat CA membrane to 19.3 Barrer at 10 wt. % additive content without a markable variation at a larger PEG1000 content. The large permeability of the neat CA membrane was attributed to the presence of non-selective voids between the polymer chains, and results thus suggested that PEG addition promoted the formation of more compact and defect-free membrane structures this point was supported by SEM surface and cross-section analysis revealing the dense and uniform structure of the hybrid membrane. The selectivity, on the contrary, increased from 5 for the neat CA membrane to 39.5 at 10 wt. % PEG1000 and decreased at larger PEG1000 contents. SEM analysis of the hybrid membranes with 10 wt. % additive content evidenced that PEG1000 impeded filler aggregation up to 10 wt. % filler content and avoided the formation of polymer-filler non-selective interface voids. In the hybrid membrane with 10 wt. % PEG1000 content, MWCNTs dispersion increases in the permeability from 19.3 Barrer for the blend to 27 Barrer at 10 wt. % MWCNTs content with selectivity values of 49, respectively, which is a factor of 2 larger than in the blend membrane; see Figure 9. The enhanced membrane performances of the hybrid one were attributed to the formation of preferential diffusion paths for molecules resulting from the dispersed MWCNTs. The formation of MWCNTs agglomerates at 15 wt. % content increased the permeability at the cost of a complete loss of the selectivity. The authors also carried out permeation tests at 2.5 bar feed pressure in mixed gas conditions using a mixture (60 vol. %, 40 vol. %) and observed a decrease in the permeability and selectivity with respect to single gas tests in all examined membrane samples; see Table 12.

Figure 9.

Room temperature permeability (Barrer) (upper panel) and selectivity (lower panel) of neat CA, blend CA/PEG1000 and hybrid CA/PEG1000/MWCNT membranes at 2 bar feed pressure in single gas tests [81].

Table 12.

Room Temperature permeability (Barrer) and selectivity of neat CA, blend CA/PEG1000 and hybrid CA/PEG1000/MWCNT membranes at 2 bar feed pressure in single gas tests. Data marked by (**) were obtained at RT with 2.5 bar feed pressure using a 60:40 vol. % - gas mixture [81].

Mechanical tests showed that the addition of 10 wt. % PEG1000 produced a negligible variation of the membrane stress at break: MWCNT dispersion at 10 wt. % content increased the stress at the break of the hybrid membrane to 13 MPa, but its breakdown occurred at 30% strain, while in the blend membranes, it occurred beyond 40%.

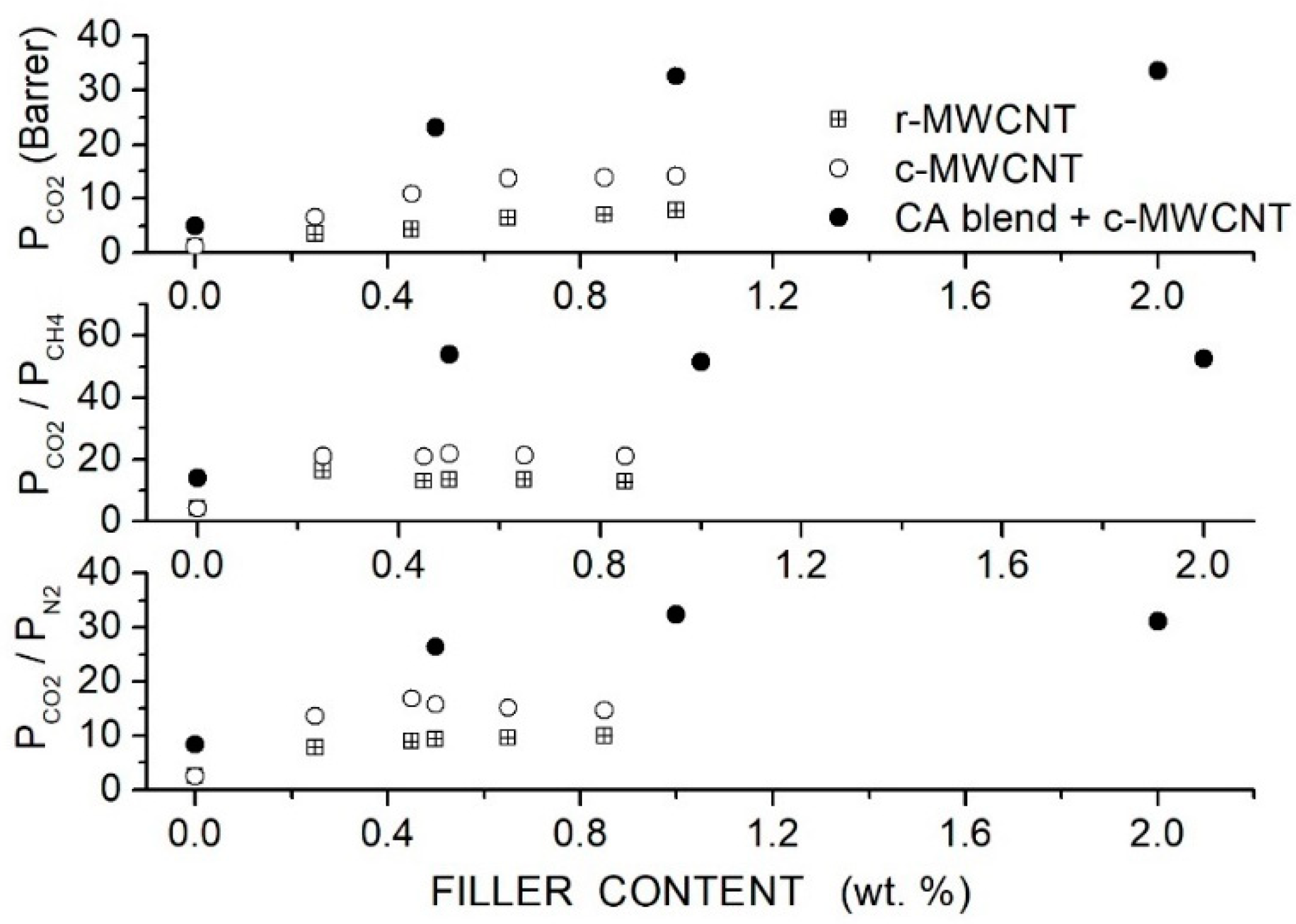

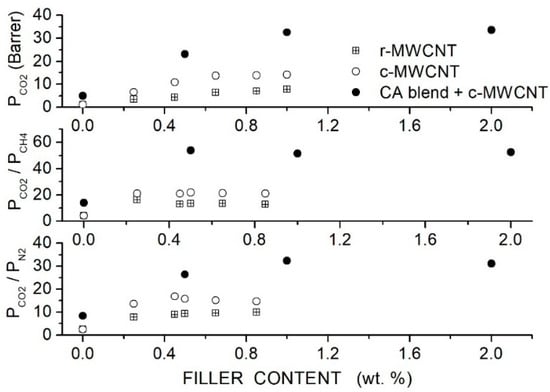

Moghadassi et al. prepared CA-based hybrid membranes using PEG1000 as a polymer additive and raw (R-MWCNT) or carboxyl-functionalized (C-MWCNT) MWCNT as filler nanoparticles and characterized them by SEM analysis and mechanical testing. Single gas permeation tests were carried out at RT and 2 bar feed pressure [82]. Results, see Figure 10, showed that MWCNTs dispersion improved the permeability and selectivity of the neat CA matrix, offering the C-MWCNTs filler particles better performances than the R-MWCNT. The permeability value increased with the C-MWCNTs dispersion from 1.08 Barrer for the neat CA membrane to 13.74 Barrer at 0.65 wt. % without significant variations increasing the filler content up to 1 wt. %. The selectivity values of the neat CA membrane increased from 4.2 to 21.8, and the /N2 selectivity from 2.5 to 15.4. The better membrane performances were obtained with the functionalized MWCNT and were attributed to their higher dispersion degree, as shown by SEM images. PEG addition enhanced the filler dispersion and improved the membrane performances with respect to the MMM at the same filler content: the blend membrane with 10 wt. % PEG1000 addition and 1 wt. % C-MWCNT content, the permeability was 32.58 Barrer with and CO2/N2 selectivity values of 51.5 and 32.2, respectively. No significant variations were observed, increasing the filler content to 2 wt. %.

Figure 10.

Room temperature permeability (upper panel) and selectivity (central and lower panel) of neat CA, blend CA/PEG1000 and hybrid CA/PEG1000/MWCNT membranes at different filler contents obtained at 2 bar feed pressure in single gas tests [82]. Crossed squares and open circles are pertinent to the nanocomposite CA membrane containing raw- and carboxyl-functionalized MWCNT filler nanoparticles.

Filler addition at 1 wt. % to the blend matrix with 10 wt. % PEG1000 improved the mechanical properties of the CA matrix: the stress at break increased from 2.93 to 9.11 MPa and the tensile modulus from 1.22 MPa to 4.37 MPa; see Table 13.

Table 13.

Mechanical properties of neat CA membrane and of selected nanocomposite and hybrid CA/PEG1000/MWCNT membranes [82].

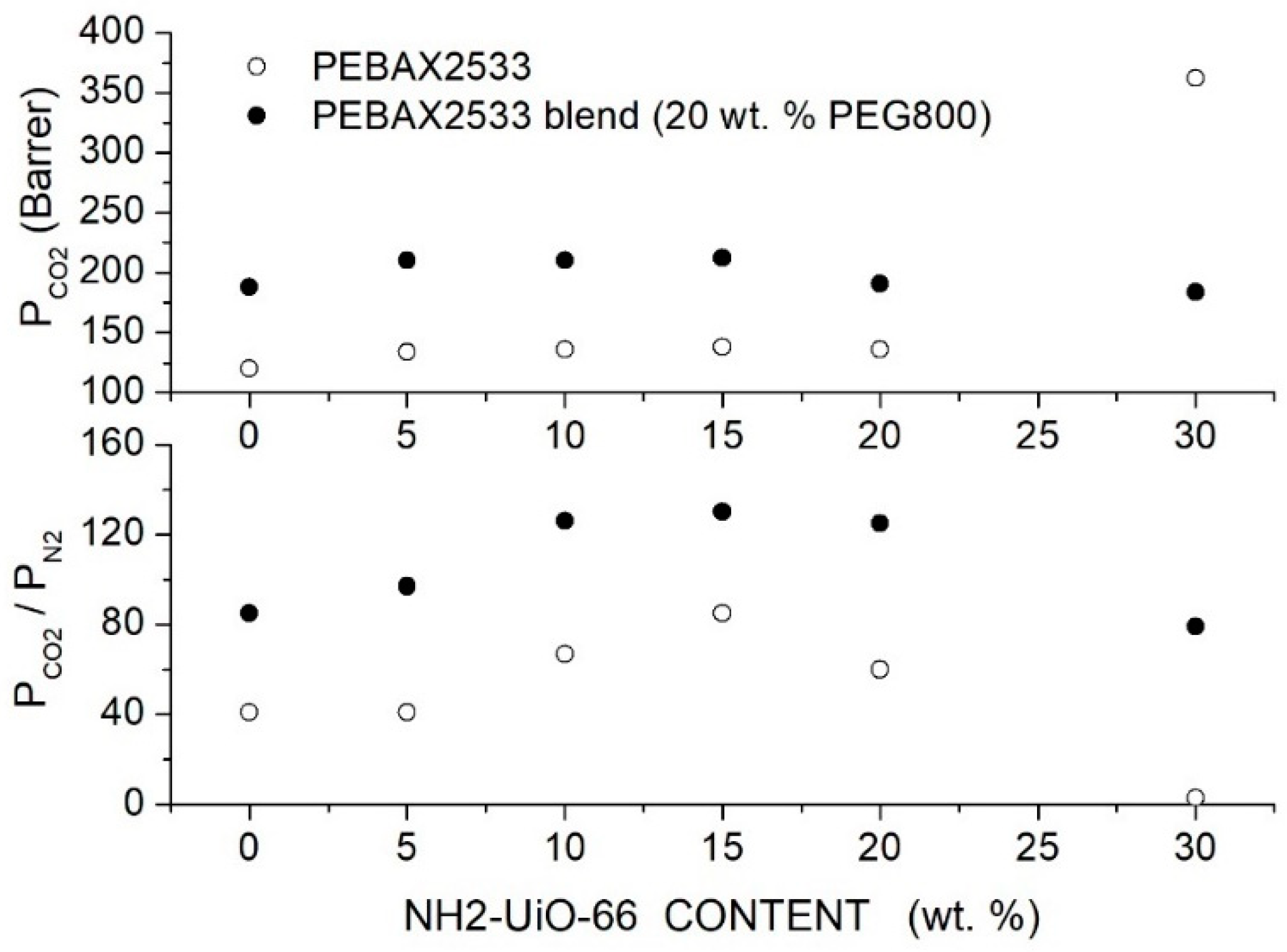

6.3. Matrimid-Based Hybrid Membranes

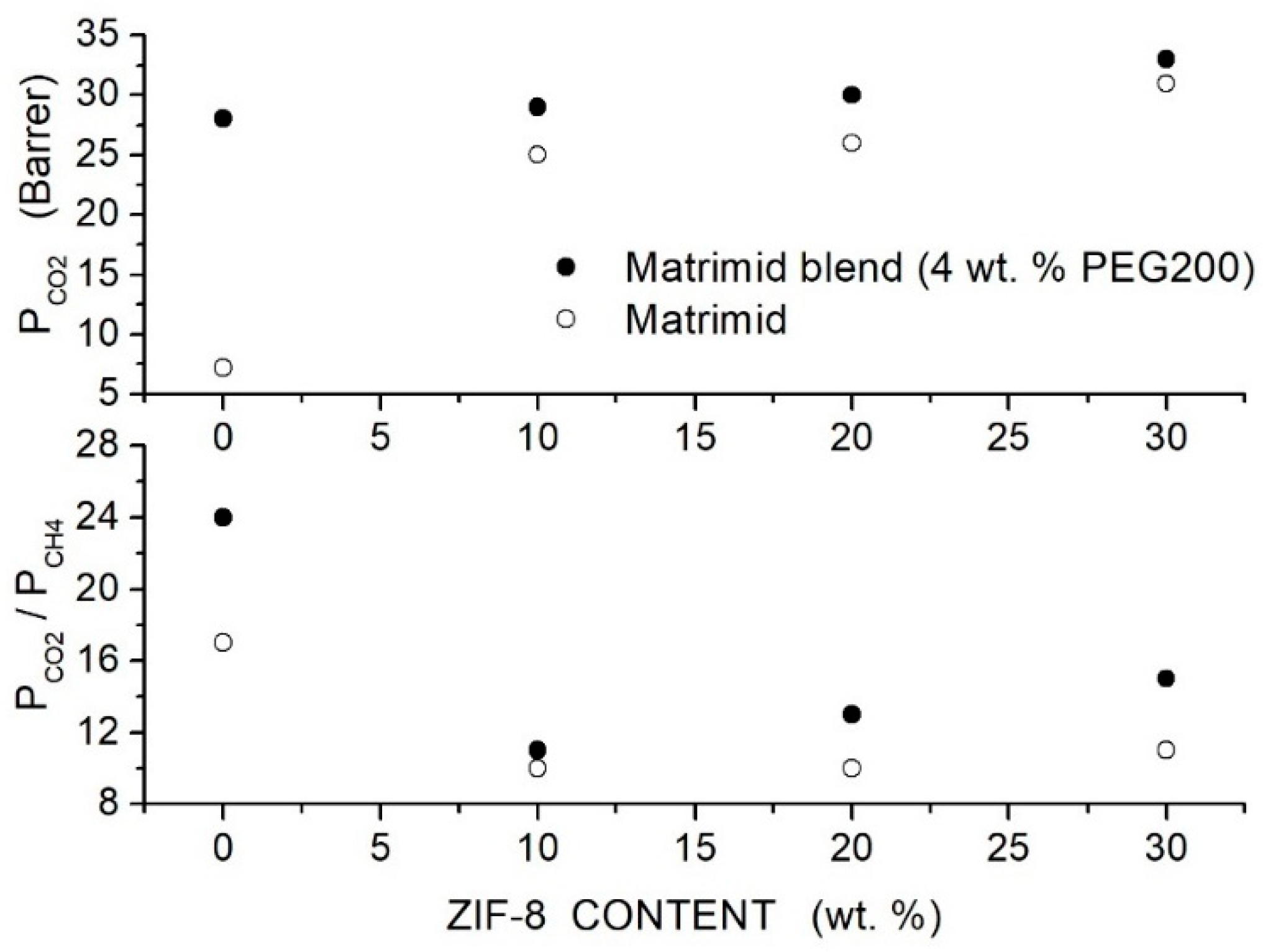

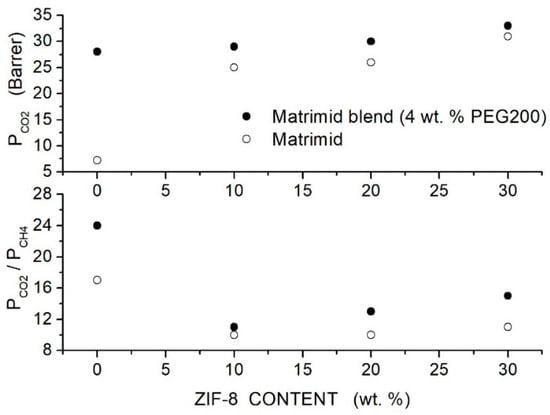

Castro-Munoz et al. prepared Matrimid-based hybrid membranes with 4 wt. % PEG200 as polymer additive and ZIF-8 nanoparticles with 33 nm average size [83]. SEM analysis revealed that filler particles are well dispersed up to 40 wt. % content well embedded in the neat and in the blend matrix without interface voids. PEG200 and ZIF-8 dispersion in Matrimid restricted the polymer chain mobility: DSC tests showed, in fact, that the value increased from 310 °C for the neat membrane to 314 °C for the blend membrane with 4 wt. % additive content and to 371 ÷ 373 °C in the nanocomposite and hybrid Matrimid/PEG200(4 wt. %) membrane with ZIF-8 contents between 10 and 40 wt. %; see Table 14. Permeation tests were carried out at 25 °C and 8 bar feed pressure with equimolar gas mixtures. Results showed that PEG200 addition improved the permeability and the selectivity with best performances obtained with 4 wt. % additive where the permeability raised from 7.2 to 28 Barrer and the selectivity from 17 to 24. The dispersion of the filler particle enhanced the permeability of the neat and blend Matrimid/PEG200 membranes; see Figure 11, but the selectivity of the nanocomposite Matrid/ZIF-8 hybrid Matrimid/PEG200/ZIF-8 membranes decreased anyway with respect to that of the neat one.

Table 14.

Glass transition temperature of the neat Matrimid®, blend Matrimid®/PEG200, nanocomposite Matrimid®/ZIF-8 and hybrid Matrimid®/PEG200/ZIF-8 membranes is reported in the last column [83].

Figure 11.

permeability (upper panel) and selectivity (lower panel) of Matrimid-based membranes at different ZIF-8 filler content obtained at 25 °C and 8 bar with - equimolar gas mixtures [83]. Open circles are pertinent to the nanocomposite Matrimid membranes while solid symbols to the hybrid Matrimid/PEG200 (4 wt. %) membranes.

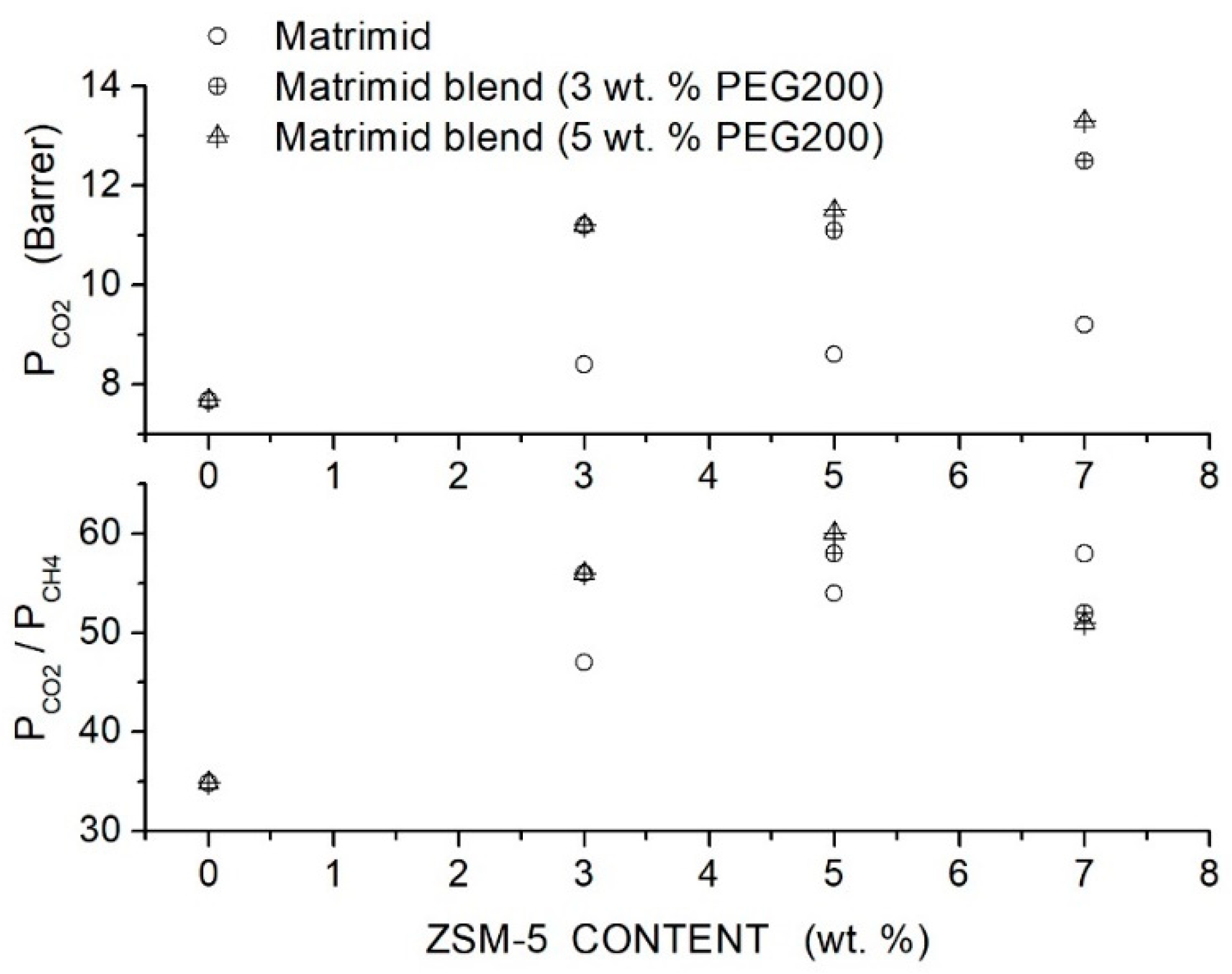

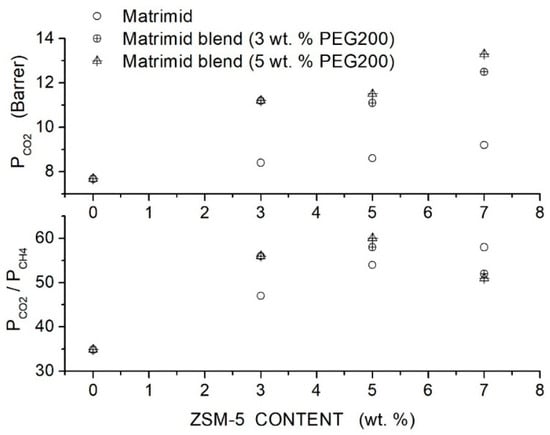

Loloei et al. prepared Matrimid®-based hybrid membranes with PEG200 as a polymer additive and ZSM-5 filler nanoparticles [84]. SEM analysis showed that in the neat Matrimid® membrane, the ZSM-5 nanoparticles are uniformly dispersed without forming interface voids at contents up to 3 wt. %. In blended Matrimid/PEG200 membranes, uniform filler dispersion without interface defects was observed; voids were up to 5 wt. % content, while at larger contents, their agglomeration occurs. FTIR spectra of the blend polymer indicated the formation of hydrogen bonding between PEG and Matrimid®: The improved filler dispersion in the blend membrane is favored by the absorption of PEG chains on the ZSM-5 filler surface. XRD patterns of the neat Matrimid® membrane showed two diffraction peaks at = 14° and 17°, evidence of its semi-crystalline structure: PEG200 addition decreased the Matrimid® crystalline degree and shifted the reflection peaks to lower angles, indicating an increase in the intersegmental distance from 5.21 for the neat membrane to 5.55 Å at 5 wt. % additive content. The addition of PEG200 and filler particles to the Matrimid® matrix transforms its structure from semicrystalline to fully amorphous.

Results of gas transport tests carried out in a single gas condition at 35 °C and 10 bar feed pressure showed that increasing the additive content up to 20 wt. % content monotonically improved the permeability from 7.68 Barrer for the neat membrane to 22.04 Barrer at 20 wt. %; see Table 15. The selectivity of the neat Matrimid® membrane, 34.91, increased to 40.08 at 5 wt. % additive content and then decreased: this behavior was due to the formation of non-selective voids at 10 wt. % additive content, as shown by SEM analysis.

Table 15.

permeability and selectivity of neat and blend Matrimid membranes as obtained in single gas tests at 35 °C and 10 bar feed pressure (values for hybrid membranes with large additive content are also reported; see text) [84].

Filler addition to the neat Matrimid® membrane slightly increased the permeability and selectivity from 8.4 Barrer and 47 at 3 wt. % content to 9.2 Barrer and 58 at 7 wt. % content. Hybrid Matrimid/PEG200/ZSM-5 membranes offered the best performances: the hybrid Matrimid/PEG200 (5 wt. %)/ZSM-5 (5 wt. %) membrane showed, for example, 11.5 Barrer permeability and selectivity of 60; see Figure 12. At PEG200 contents larger than 5 wt. %, the permeability slightly increased, and the selectivity strongly decreased due to the formation of non-selective voids and filler aggregates; see Table 16. The author concluded that the use of the PEG additive at low contents improved the membrane properties, favoring the filler dispersion and impeding the formation of non-selective interfacial voids between polymer layers and ZSM-5.

Figure 12.

permeability (upper panel) and selectivity (lower panel) of Matrimid membranes as a function of the ZSM-5 filler content as obtained in single gas tests at 35 °C and 10 bar feed pressure [84]. Open circles are pertinent to the nanocomposite Matrimid membranes; crossed circles and crossed triangles to the hybrid membranes with 3 and 5 wt. % PEG200 additive content, respectively.

Table 16.

Glass transition temperature values () of the PSF-based membranes as a function of their composition [85].

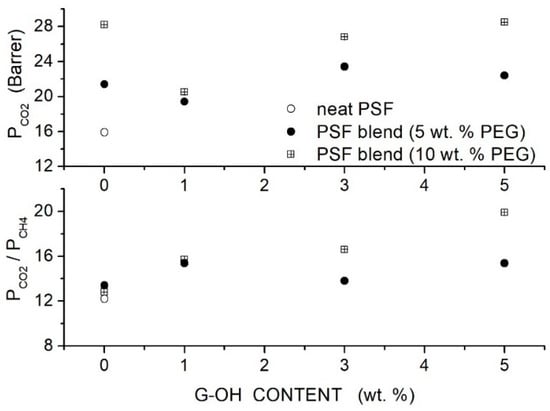

6.4. PSF-Based Membranes

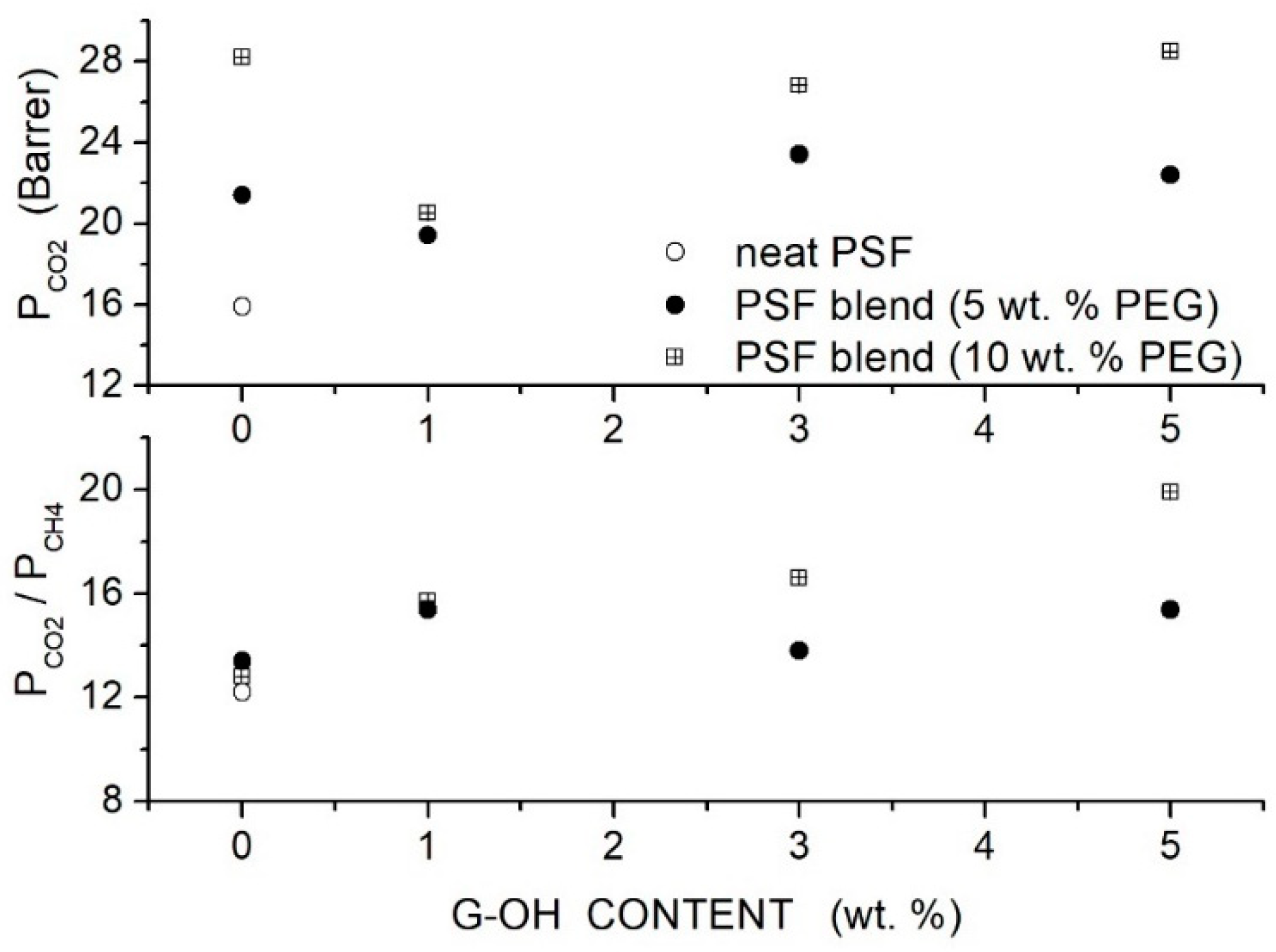

Raouf et al. prepared polysulfone (PSF)-based hybrid membranes using PSF with = 35,000, PEG as a polymer additive, and graphene hydroxide () filler nanoparticles with a thickness < 35 nm [85]. FTIR spectra indicated that physical interaction between positively charged double groups of PEG and electron-withdrawing oxygen of groups of graphene occurred, which improved the filler-matrix interaction and prevented the formation of interface non-selective voids. SEM analysis of the blend membrane with 5 wt. % content showed well-dispersed nanoparticles embedded in the polymer layers. The value of the neat PSF membrane, 190 °C, decreased to 186 and 184 °C when blended with 5 and 10 wt. % PEG content, indicating polymer chain mixing and increased chain mobility; see Table 16. The addition of filler particles increased the value to 190 °C with the PSF/PEG(5 wt. %) membrane and to 186 °C in the PSF/PEG (5 wt. %) membrane, indicating that the interaction between polymer chains and fillers reduced the chain mobility. Single gas permeation tests were carried out at 35 °C and 2 bar feed pressure. Results showed that PEG addition at 5 and 10 wt. % content increased the permeability of the neat PSF membrane from 15.9 Barrer to 21.4 and 28.2 Barrer, respectively, without significant variation on the selectivity value ~13. The permeability value and the selectivity of the blend membranes monotonically increased with the filler content: the best membrane performances were obtained with the hybrid PSF membrane with 10 wt. % additive and 5 wt. % filler content, 28.5 Barrer permeability and 19.9 selectivity; see Figure 13.

Figure 13.

permeability (upper panel) and selectivity (lower panel) of the PSFbased membranes for different G-OH contents at 35 °C and 2 bar feed pressure measured in single gas test [85]. Open circles are pertinent to the nanocomposite membrane, and solid circles and crossed squares were pertinent to the hybrid PSF/PEG membranes with 5 and 10 wt. % additive content, respectively.

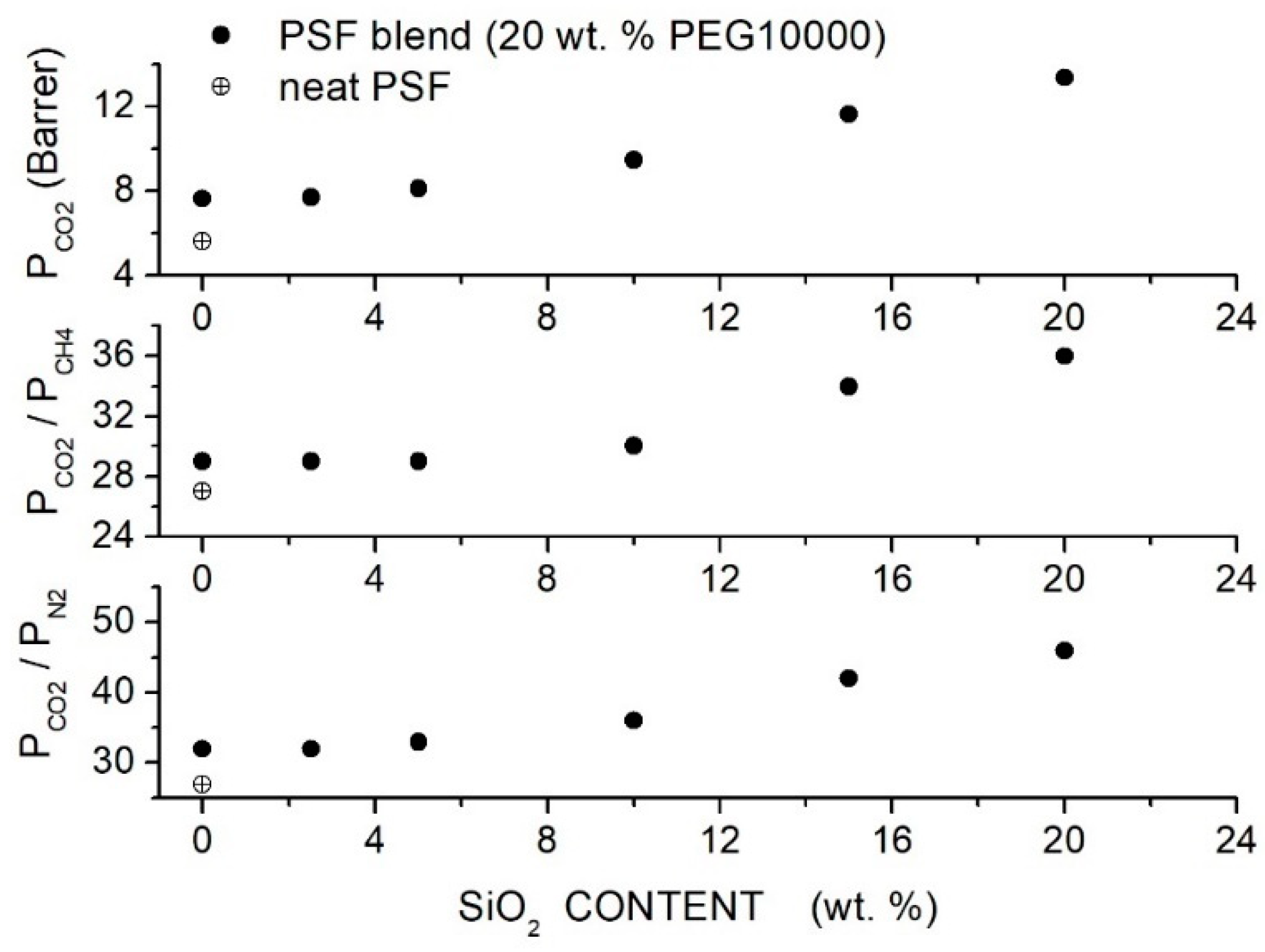

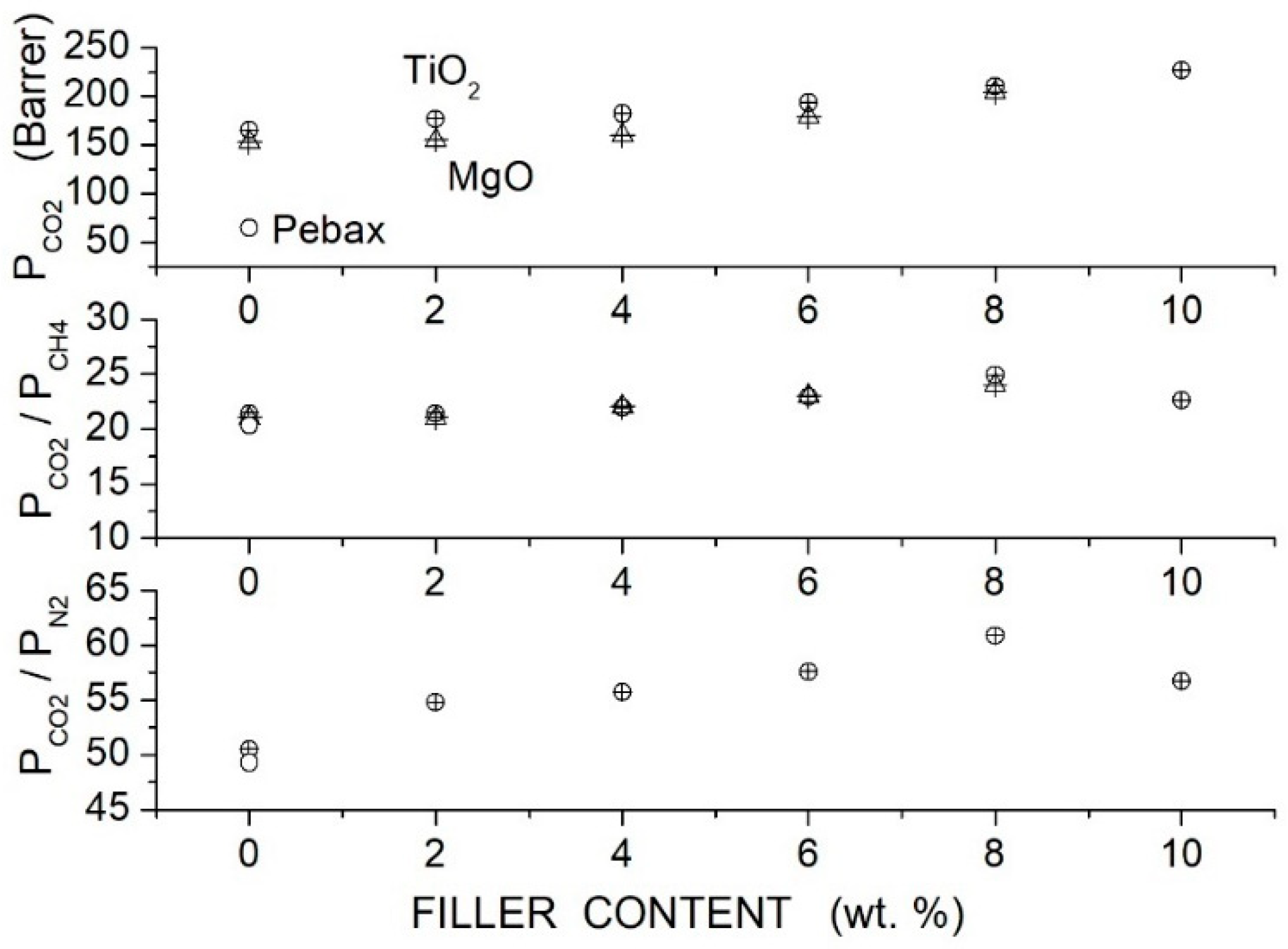

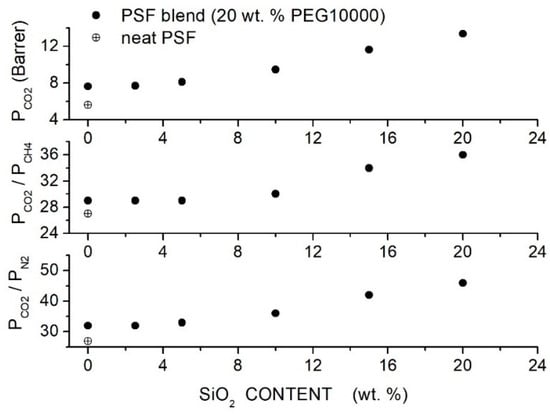

Salahshoori et al. prepared polysulfone-based hybrid membranes (PSF, 442.53 g/mol, 185 °C) using different PEG formulations as polymer additives and filler nanoparticles with a 75 nm average size [86]. Preliminary permeation tests carried out on blend membranes showed that the PSF blend membrane with 20 wt. % PEG10000 content offered the best membrane performances, namely a permeability value of 7.63 Barrer and selectivity value of 27. SEM analysis of the hybrid PES/PEG10000 (20 wt. %) membrane showed that nanoparticles were homogeneously dispersed up to 20 wt. % content without forming interface defects: FTIR analysis suggested that the good filler dispersion was due to the formation of hydrogen bonds between O-H polar groups of silica nanoparticles and ether groups of the PEG additive. XRD patterns of the blend membrane showed a broad halo between 19° and 21°. Increasing the filler content: (i) the halo intensity decreased, and the peak became wider, suggesting an increase in the blend amorphous content, and (ii) the halo shifted to lower angles suggesting that the intersegmental chain spacing increased. DSC tests carried out on the blend membrane evidenced a single value at 135 °C, showing good PEG/PES mixing. Increasing the silica content in the PSF/PEG10000 blend, a slight increase in the value from 165 °C for the neat blend to 174 °C at 20 wt. % was observed, indicating restricted chain mobility; see Table 17. Single gas permeation tests were carried out at 35 °C and 10 bar feed. Results indicated that PEG addition improves the permeability and selectivity of the neat PSF membrane from 5.61 to 7.64 Barrer with a small increase in the from 27 to 29; see Figure 14. The blend of permeability and selectivity increased, adding SiO2 filler particles from 7.71 Barrer and 29 at 2.5 wt. % SiO2 content to 13.36 Barrer and 36 at 20 wt. % content and the selectivity increased from 32 to 46. Mechanical testing indicated increasing the filler content up to 10–15 wt. %; Young’s modulus of the hybrid membrane and the tensile strength simultaneously increased, suggesting good adhesion between the polymer matrix and filler particles and uniform distribution up to this filler loading; see Table 17.

Table 17.

-spacing, glass transition temperature (), tensile strength and Young’s modulus of the neat, PSF/PEG10000 (20 wt. %) and hybrid membranes [86].

Figure 14.

permeability and selectivity values of the PSF-based membranes with different filler content at 30 °C and 10 bar feed pressure measured in single gas test [86]. The crossed circle is pertinent to the neat PSF membrane, and the solid circles are to the hybrid PSF/PEG10000 (20 wt. %) membrane.

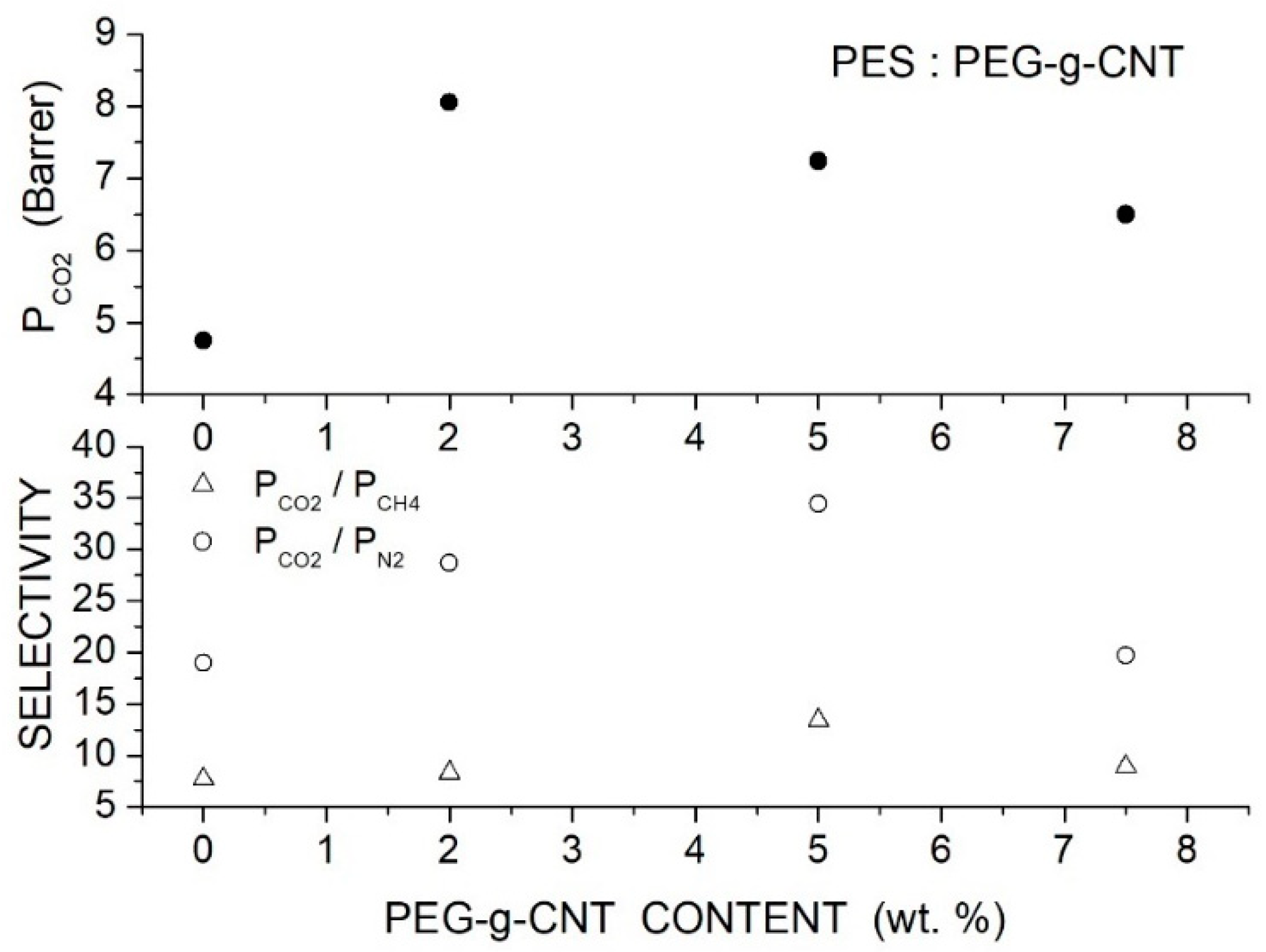

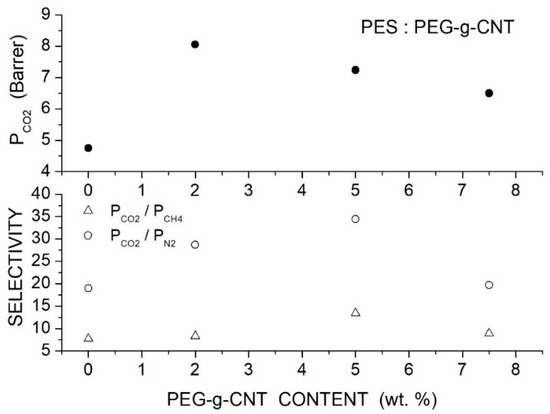

Singh et al. prepared PES-based hybrid membranes with PEG-grafted carbon nanotube filler particles (PEG-g-CNTs, 324 m2/g surface area, 1.57 cm2/g total pore volume, 17.7 average pore size) [87]. SEM micrographs of the hybrid membranes showed good filler dispersion up to 5 wt. % content. The XRD pattern of the neat and PSF/PEG-g-CNT membrane samples showed CNT reflection peaks at 2 = 26.1° and 43.1° and the PSF halo at 18.15°. The intensity of the PSF halo decreased with the filler addition, and the peak shifted to larger 2 angles indicating increased amorphous content and reduction of the interchain -spacing. The FTIR spectrum of hybrid PEG-g-CNT/PES membranes only showed a decrease in the peak intensities with respect to the spectra of the neat PSF membrane and no shift of the peak position. The authors studied the selective properties at 25 °C with 1.5 and 2.5 bar feed pressure and evaluated the gas diffusivity by the time-lag method. The results showed that filler addition improved the permeability of the neat PES membrane as well as the and selectivity. At 5 wt. % loading and 1.5 bar feed pressure, for example, the permeability increases from 4.75 to 7.24 Barrer, the selectivity from 7.7 to 13.4, and the selectivity from 19.0 to 34.4; see Figure 15. The authors attributed the improved permeability to the reduced crystalline degree enhancing penetrant transport and to the PEG polar ether groups enhancing the solubility. Only minor variations in the gas transport properties were observed using gas mixtures.

Figure 15.

permeability (upper panel) and selectivity (lower panel) of the PES membranes with different PEG-g-CNT contents measured at 25 °C and 1.5 and 2.5 bar [87].

Mechanical tests showed an improved tensile modulus and tensile strength with respect to the neat membrane; see Table 18. The elongation at break was anyway reduced due to hindered molecular elongation of the polymer chains by well-dispersed functionalized CNT.

Table 18.

Mechanical properties of the PES-based membranes with different PEG-g-CNT contents [87].

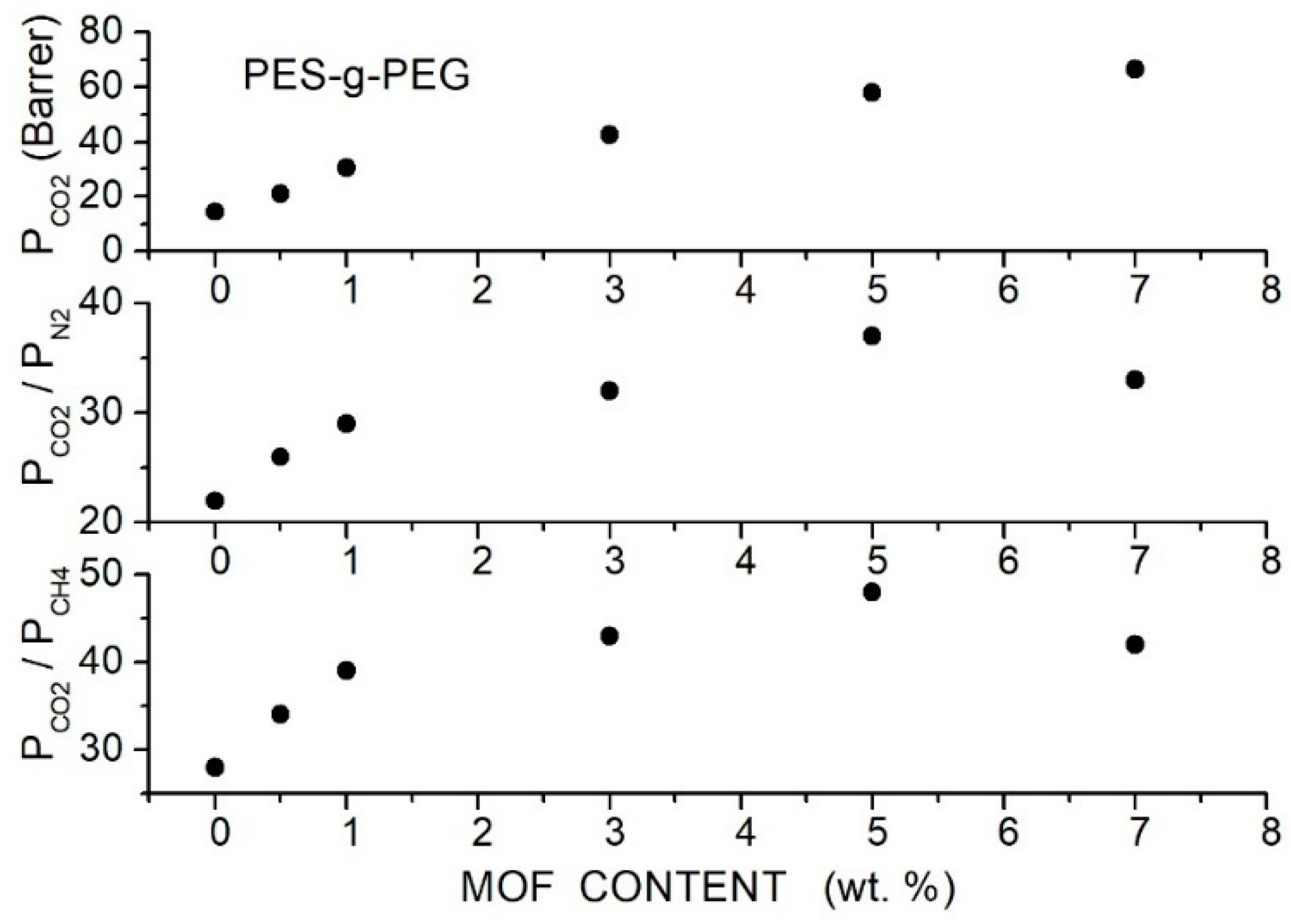

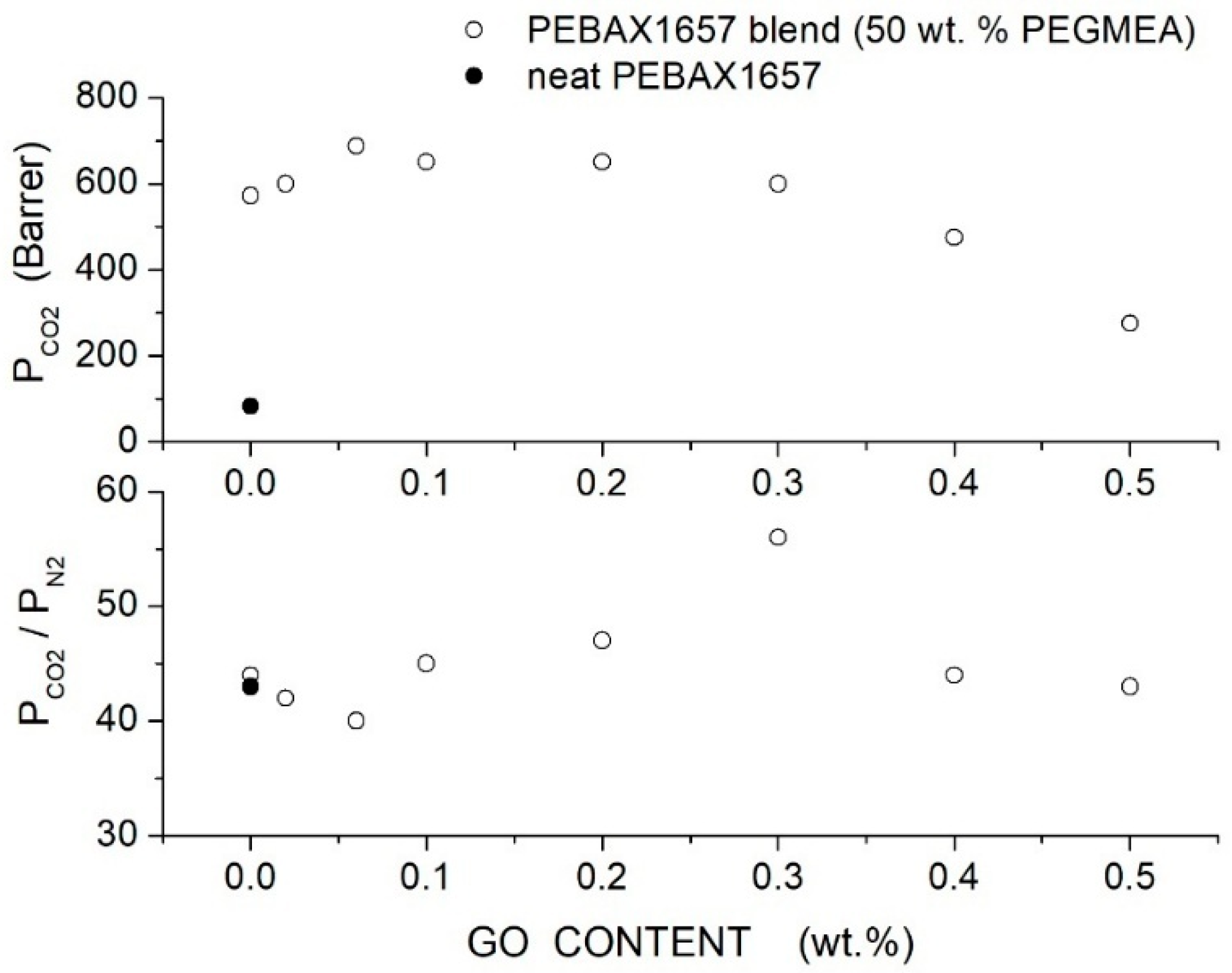

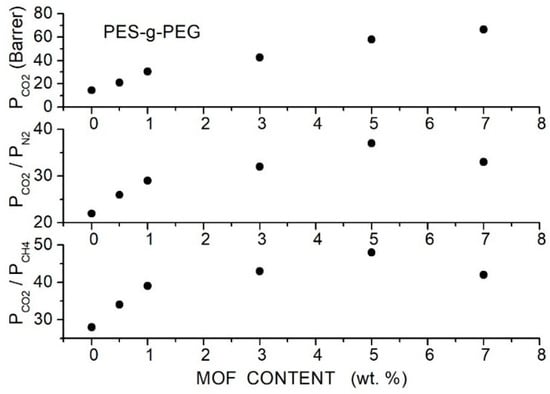

Ma et al. prepared hybrid membranes made of PES-g-PEG copolymer containing porous 2D MOF nanosheets (CuBDC, 5.2 Å pore size, 6 to 10 µm lateral size and few nm thickness) at contents up 7 wt. % [88]. XRD analysis of the hybrid membrane samples showed two narrow peaks MOF reflections at = 17.3° and 34.4° and a broad halo of the PES-g-PEG crystalline fraction centered at = 18.2° without variation of the peak intensity and position increasing the filler content. FTIR spectra showed peaks pertinent to the CuBDC filler particles and PES-g-PEG matrix without noticeable shifts of peak positions. DSC tests showed that decreased, increasing the filler content from 183.5 °C for the neat membrane to 142.6 °C for the hybrid membrane with 7 wt. % MOF content evidence of enhanced chain mobility. SEM analysis of the hybrid membrane evidenced uniform MOF distribution up to 5 wt. % filler content without interface defects showing good compatibility between filler and copolymer matrix. The authors studied the gas transport properties in single gas conditions at 35 °C with 1 bar feed pressures. They observed that the permeability increased with the filler content from 14.3 Barrer for the neat membrane to 58.1 Barrer at 5 wt. % MOF content accompanied by the increase in the and selectivity values; see Figure 16.

Figure 16.

permeability (upper panel) and selectivity (central and lower panel) of the PES-g-PEG hybrid membranes with different MOF filler content as obtained in single gas tests at 35 °C and 1 bar feed pressure [88].

It was observed that increasing the filler content: (i) the diffusivity of all penetrants increased, but this increase was more marked for and (ii) the solubility slightly increased while the and solubility values decreased; see Table 19. The enhanced diffusivity was attributed to the MOF porous structure increasing the membrane-free volume: the free volume increase preferentially enhanced the diffusivity, having a smaller size than the and penetrants. The increase in solubility was attributed to the affinity between the MOF-filled nanoparticles and the penetrant molecules.

Table 19.

diffusivity (units: 10−8 cm2/s) and solubility (units: 10−2 cm3 (STP)/cm3 cmHg) of the PEG-g-PES at different MOF contents. The and diffusive-selectivity and solubility-selectivity terms are also reported [88].

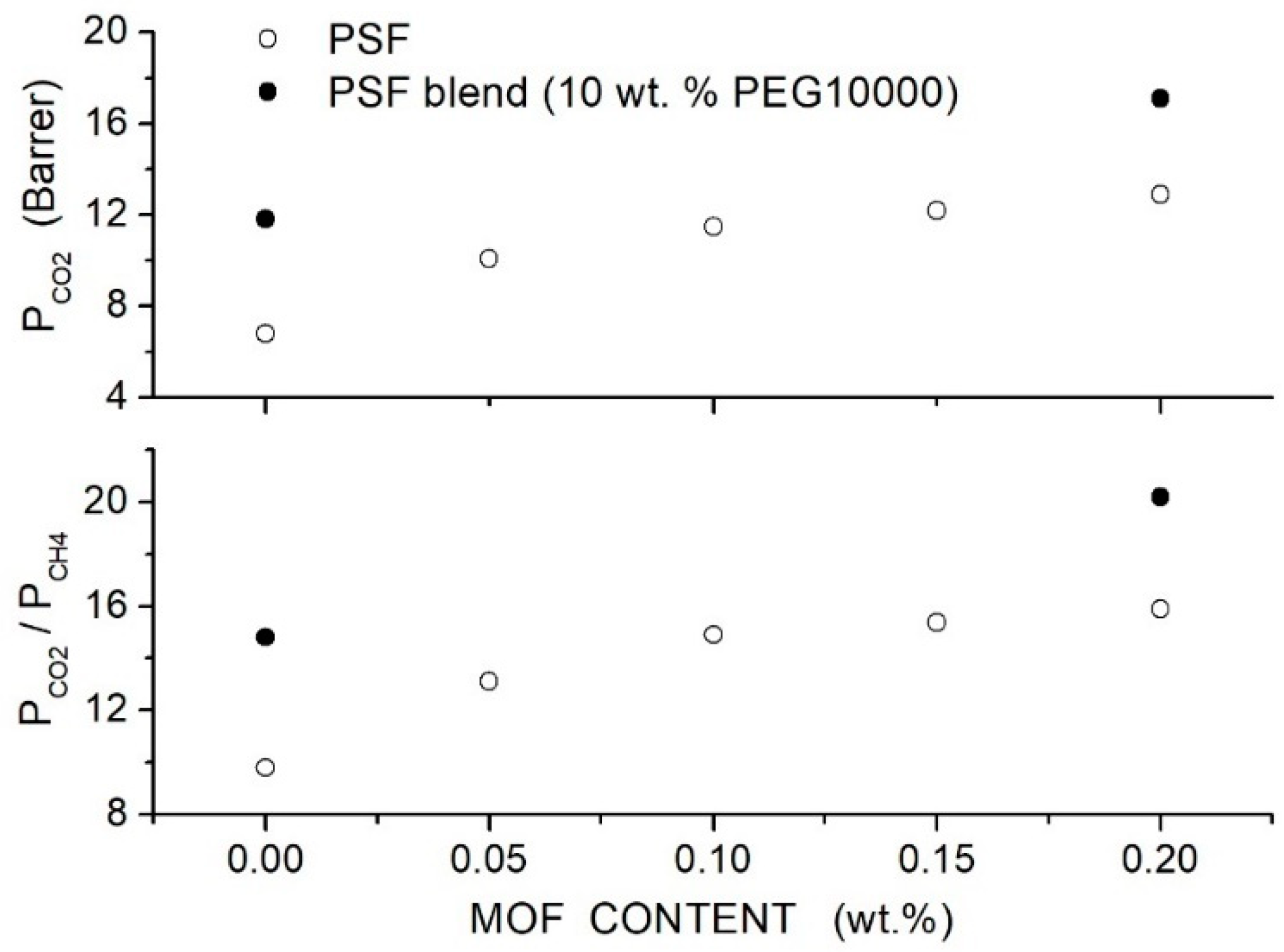

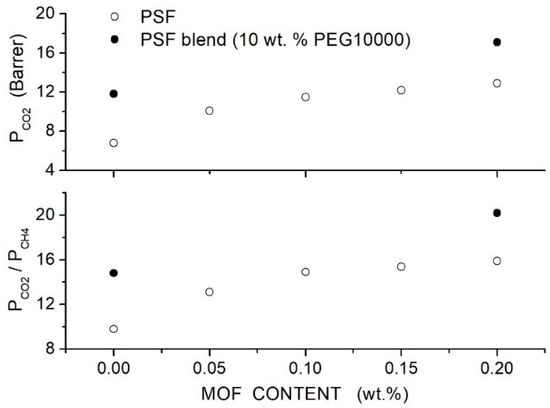

Khan et al. prepared PSF-based hybrid membranes (~35,000) with PEG1000 as a polymer additive, nickel oxide, copper oxide and Pyrazine-functionalized MOF filler particles [89]. The FTIR spectra of the hybrid membrane samples showed shifts of the PSF absorption peaks compared with the blend, suggesting hydrogen-type interactions between Pyrazine-MOF and polyethylene glycol. SEM cross-sectional micrographs of the hybrid membranes showed dense, homogeneous structures with well-dispersed filler particles without interface defects between the functionalized filler particles and the blend matrix. PSF membranes showed a broad XRD reflection peak at angles between 17° and 22° without significant variation, adding PEG and/or MOF. Permeation tests were carried out in single gas conditions at 25 °C and 2 bar feed pressure. Results indicated that the permeability and selectivity were improved by the filler addition; see Figure 17: at 0.2 wt. % MOF content, the permeability and selectivity increased from 6.8 Barrer and 9.8 for the neat membrane to 12.9 Barrer and 15.9. Results indicated that filler addition in the blend PSF/PEG improved separation performances at the same filler content: at 0.2 wt. %, the permeability increased to 17.1 Barrer and the selectivity to 20.2.

Figure 17.

permeability (Barrer) and selectivity (lower panel) of the PSF-based membranes at different MOF content as obtained in single gas tests at 25 °C and 2 bar feed pressure [89].

Mechanical tests showed that by adding filler particles to the PSF matrix, the tensile strength decreased, suggesting the formation of crystalline domains; see Table 20. The tensile strength increases; on the contrary, adding the filler particles to the PSF/PEG blend matrix suggests that PEG favors the compatibility between filler particles and the PSF matrix. A clear trend was, on the contrary, not observed for the strain at the break of all PSF-based membranes.

Table 20.

Tensile strength and strain at break of the PSF-based membranes at different MOF content [89].

6.5. PIM-1 Based Hybrid Membranes

Khan et al. prepared PIM-1 hybrid membranes with MWCNT filler nanoparticles (250 m2/g surface area, 12 to 15 nm diameter and 8 to 12 nm wall thickness) functionalized by covalent bonding with PEG200 polymer chains (f-MWCNT) [90]. SEM micrographs showed that the neat PIM-1 membrane exhibited a defect-free structure; here, pristine MWCNT produced the formation of filler agglomerates. f-MWCNTs resulted, on the contrary, in well-dispersed up to 2 wt. % content, and f-MWCNT aggregates surrounded by interface voids formed at 3 wt. % content. Single gas permeation tests were carried out at 30 °C, and the penetrant diffusivity was evaluated by the time-lag method. Results showed that the permeability of all examined gases increased with the f-MWCNT content up to 2 wt. % content and decreased at 3 wt. %. The selectivity slightly increased from 22 to 24, while the selectivity decreased from 15 to 11; see Table 21.

Table 21.

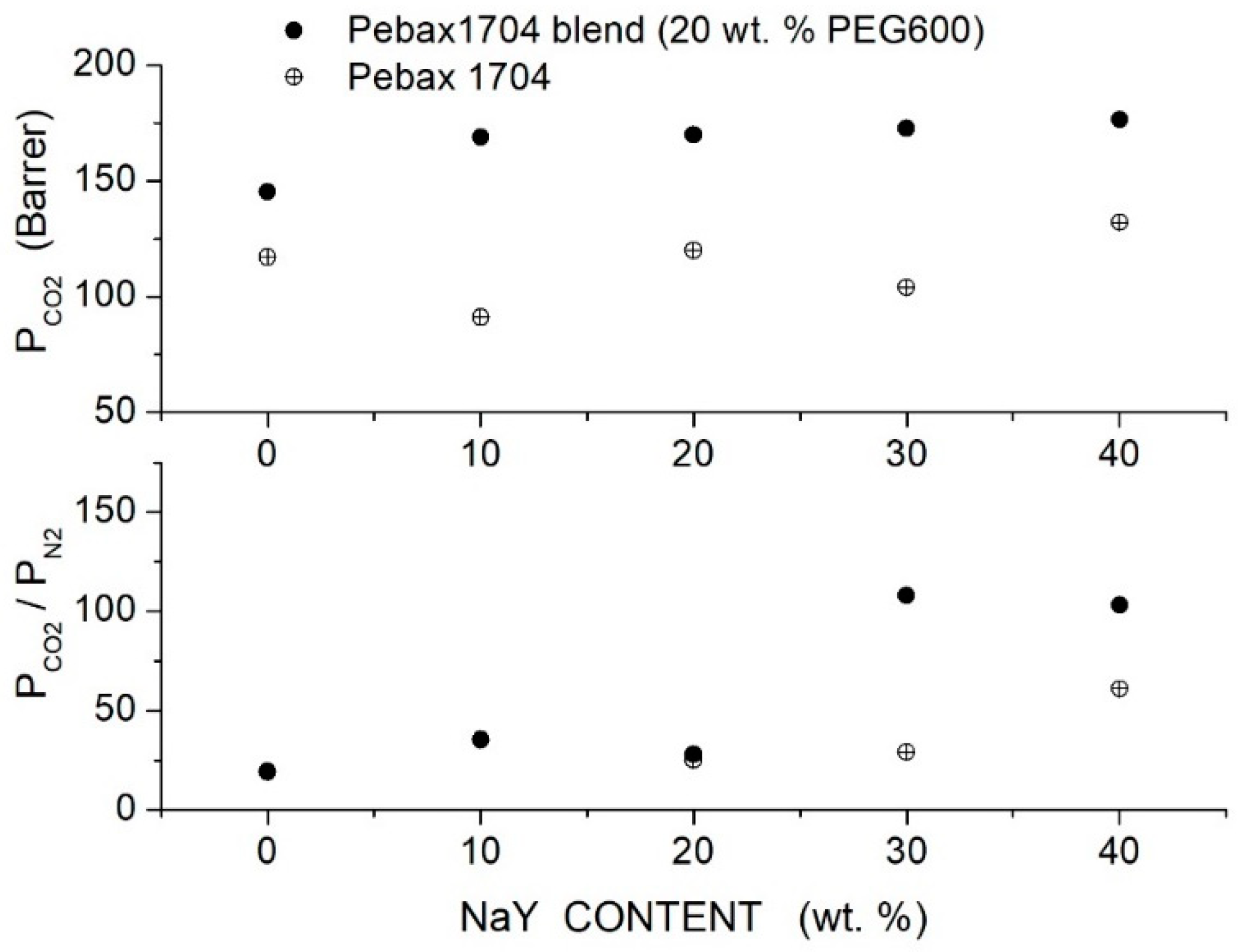

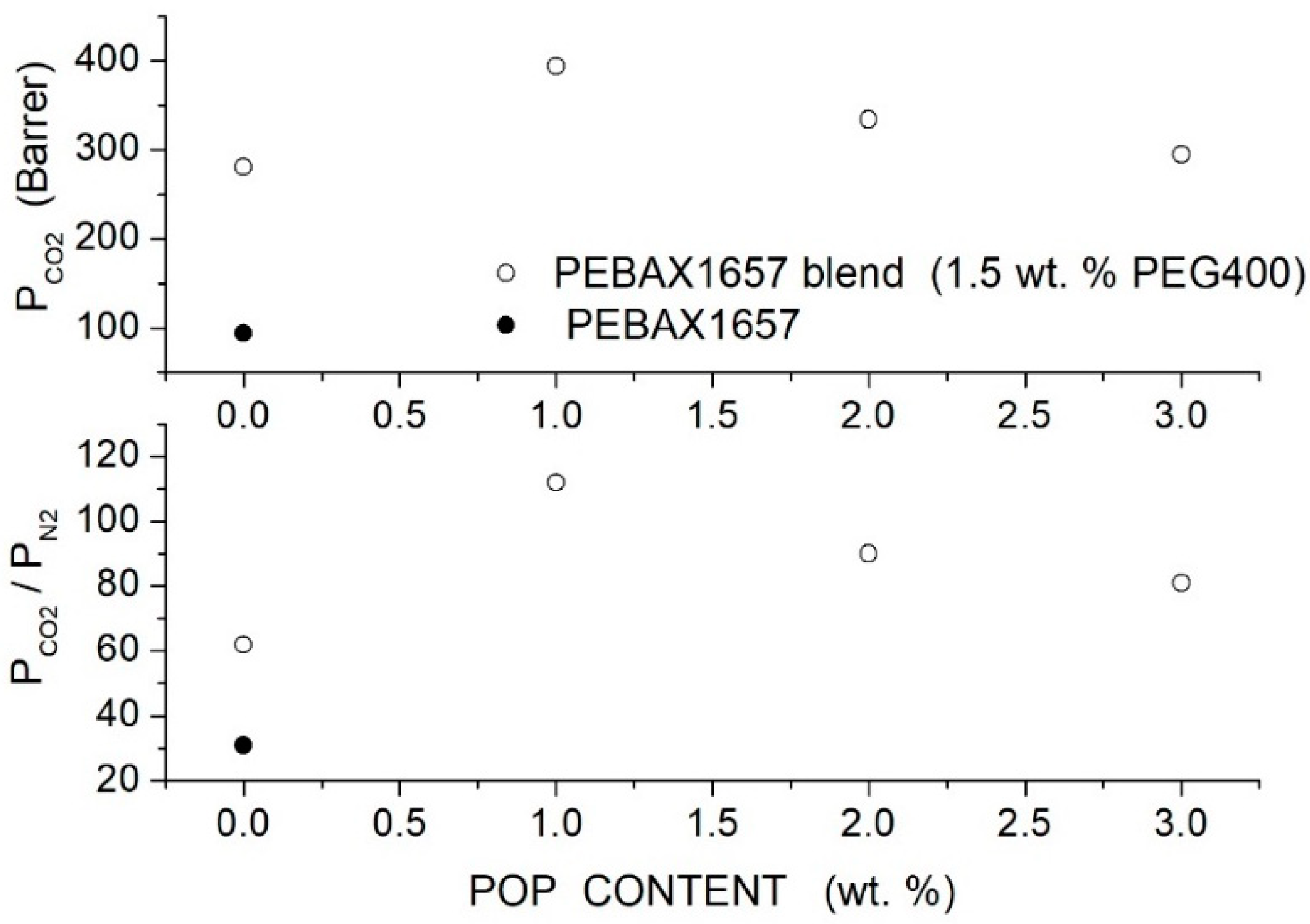

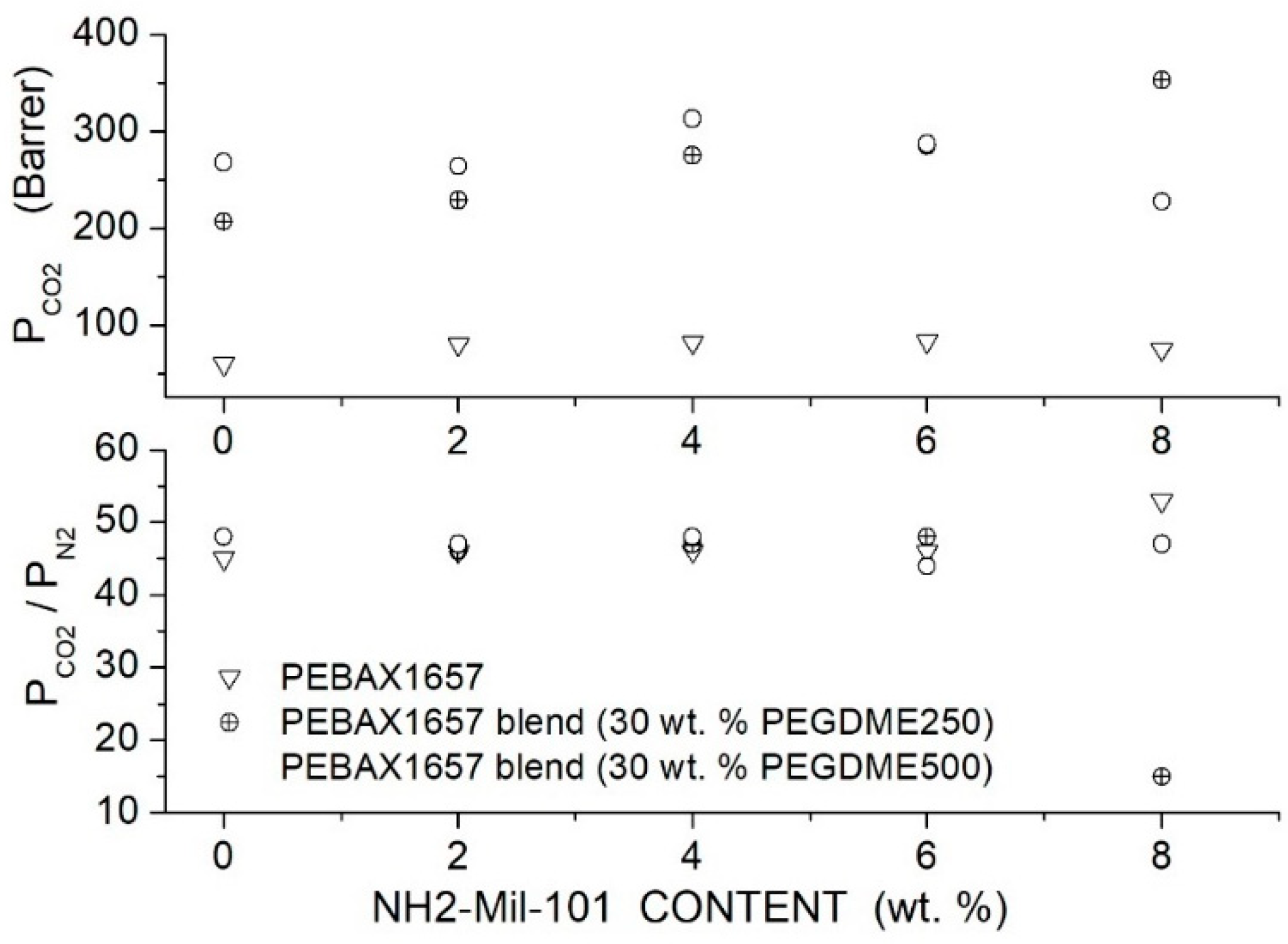

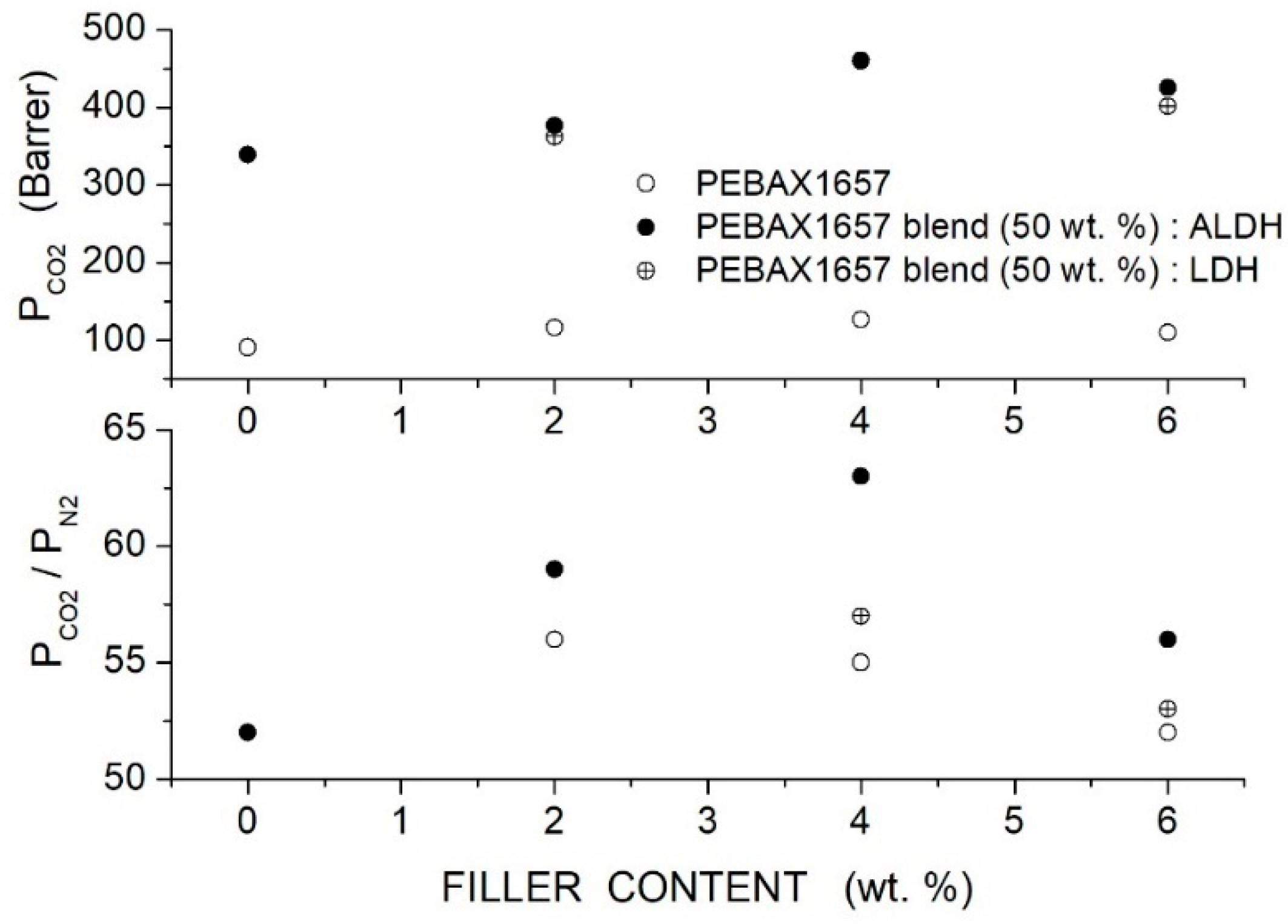

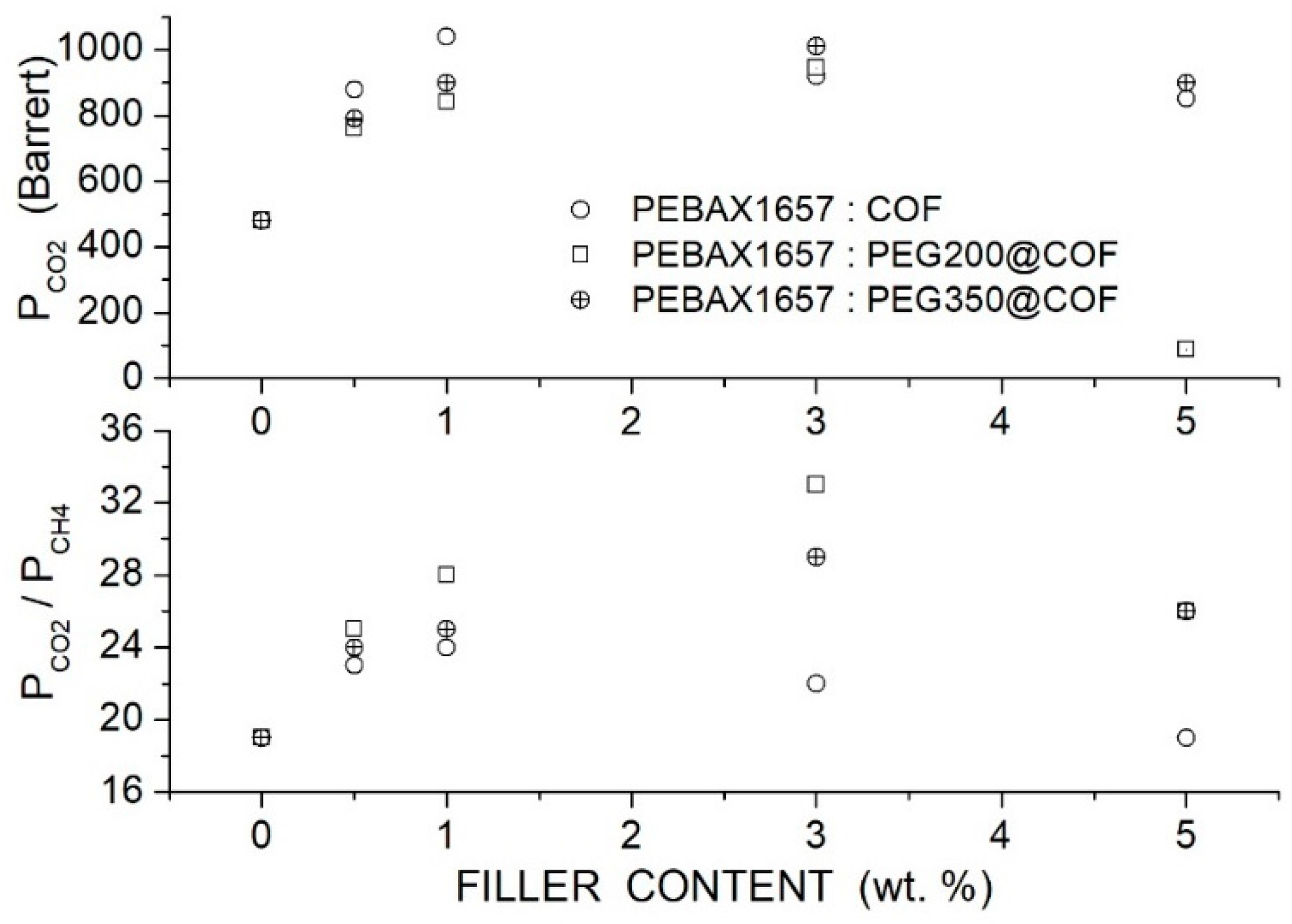

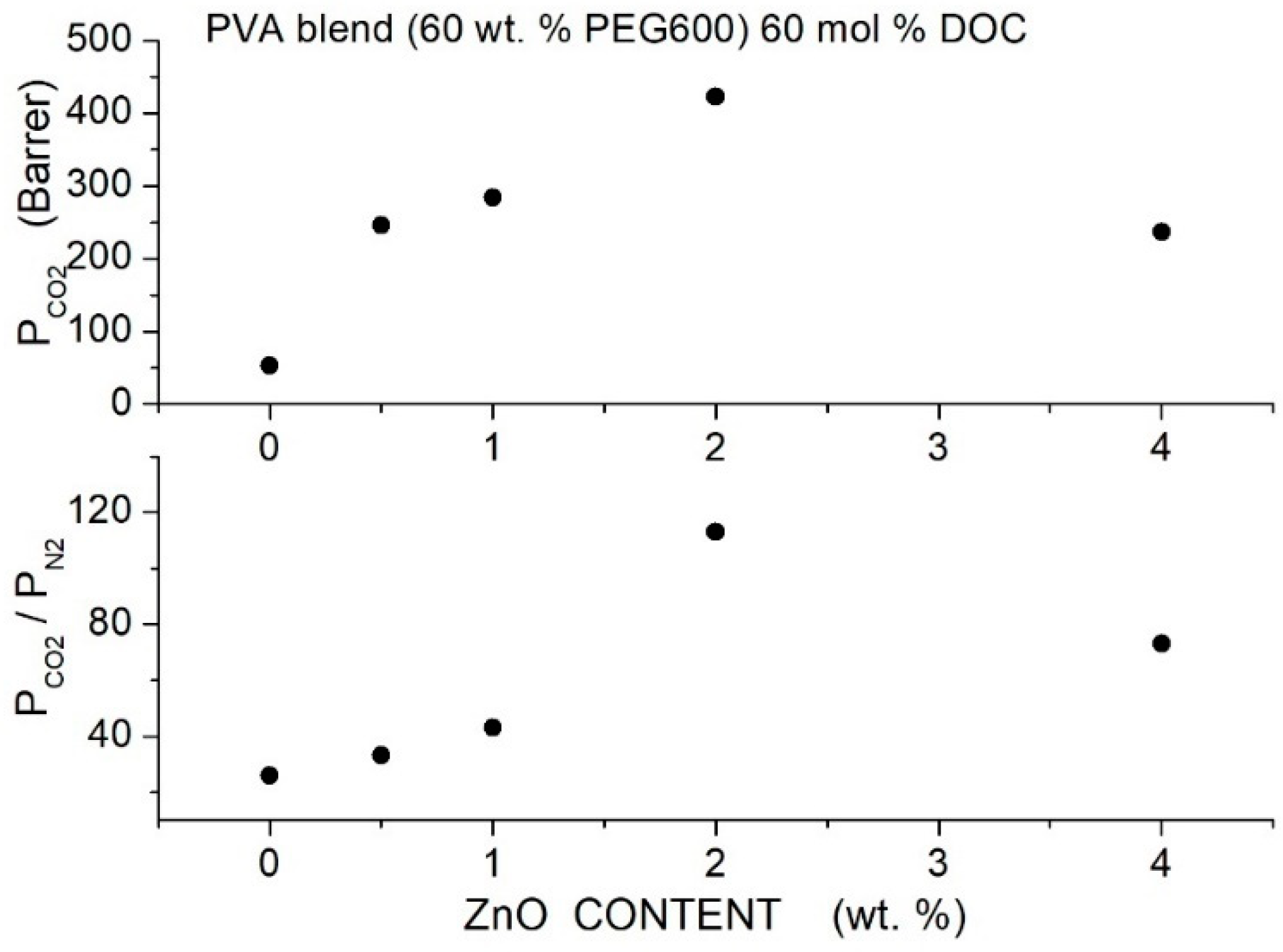

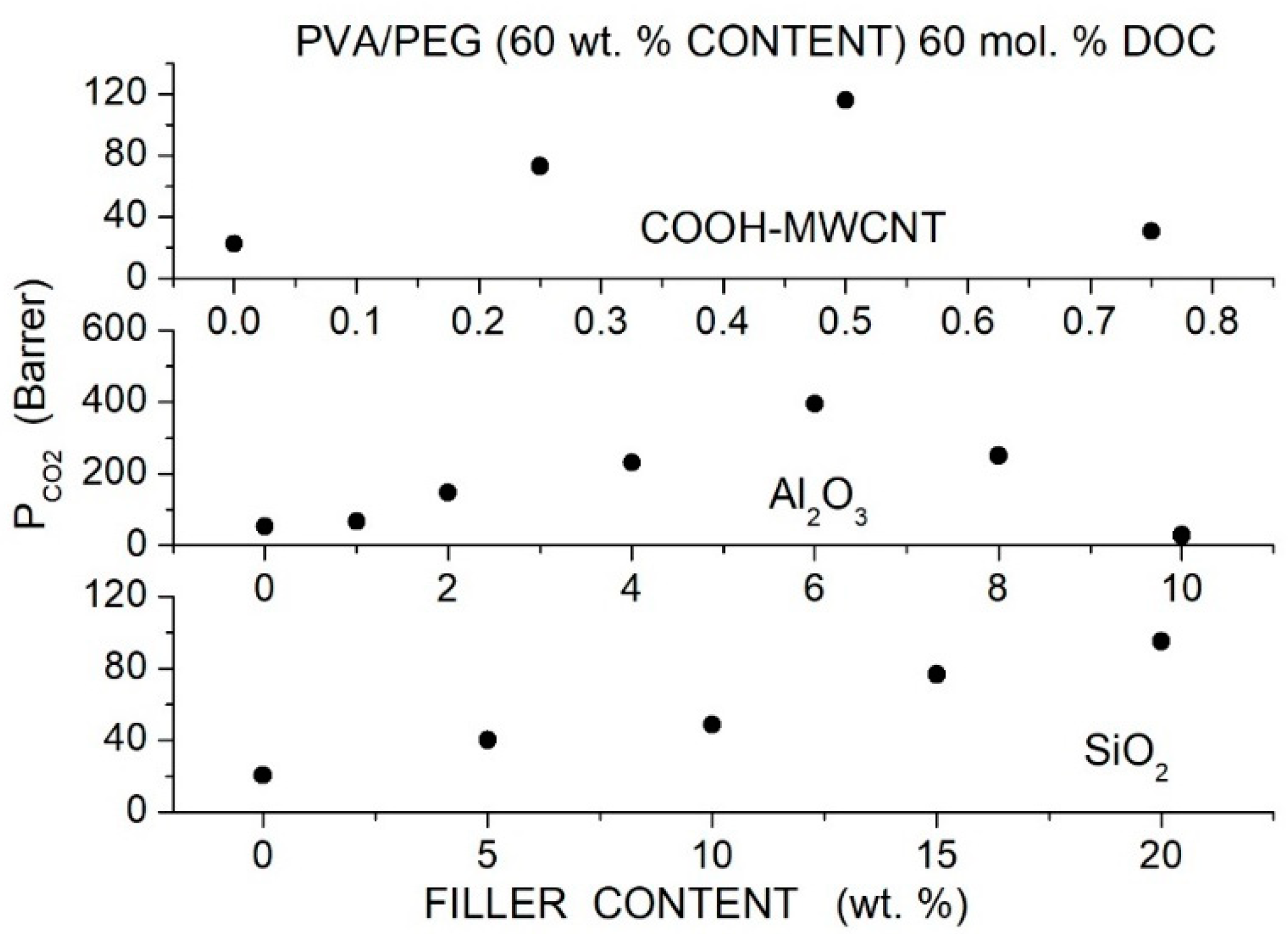

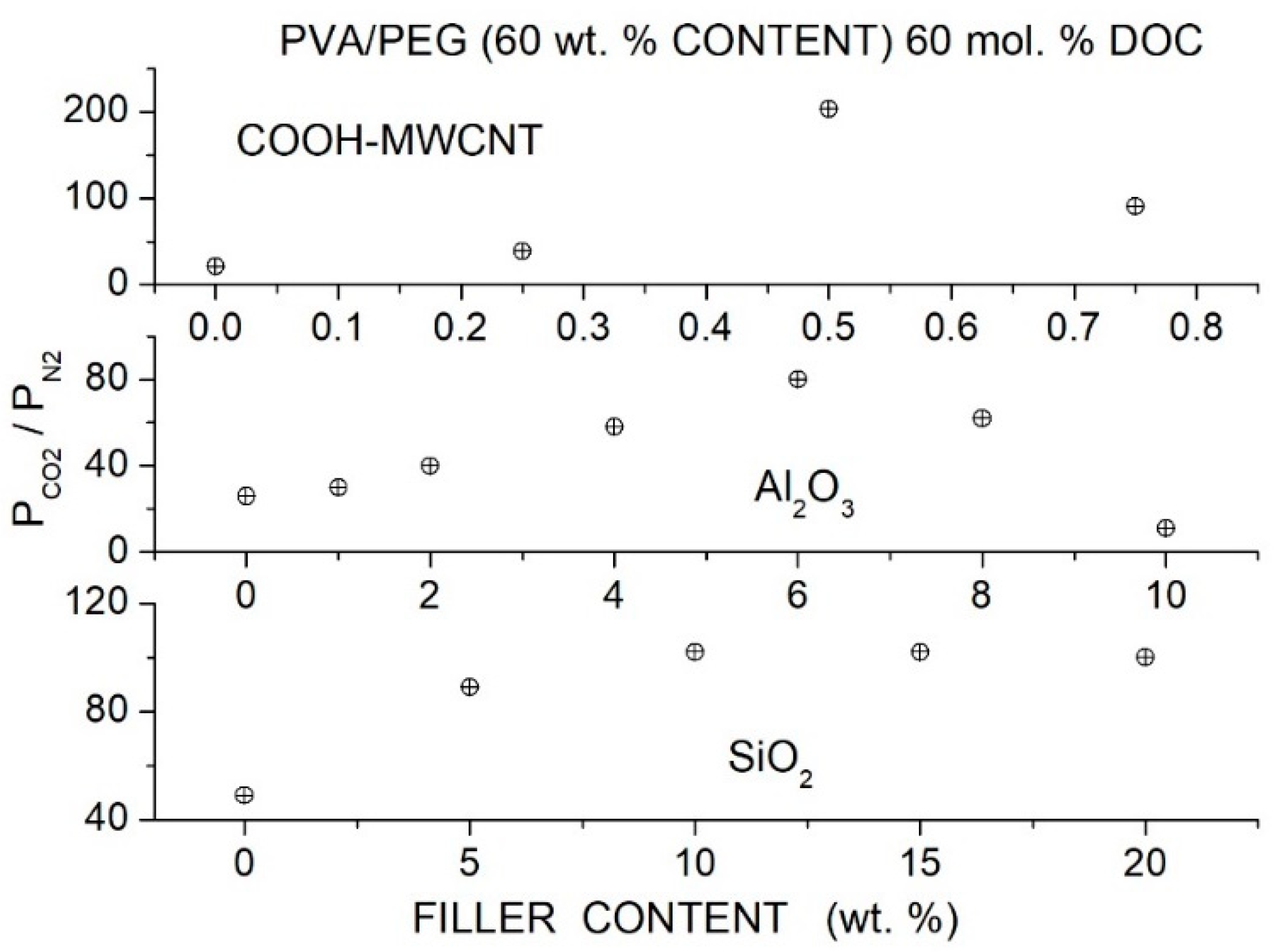

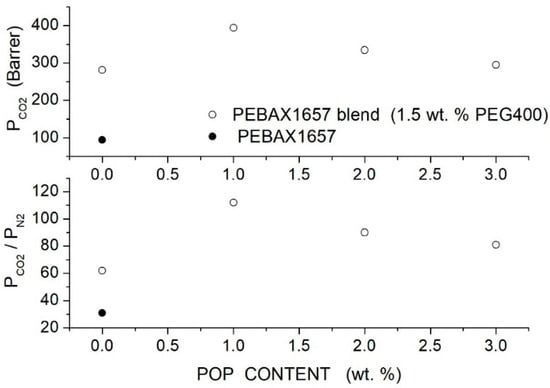

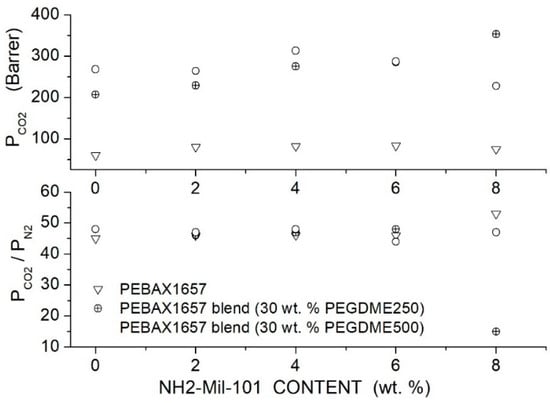

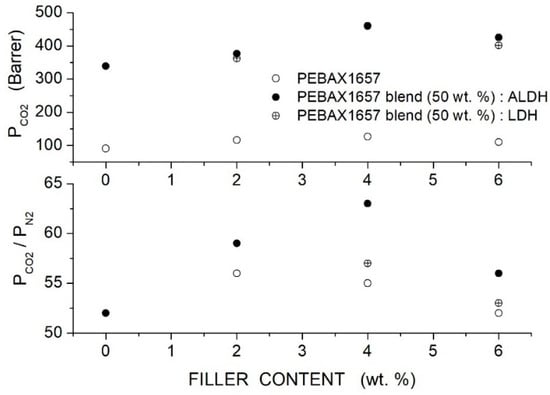

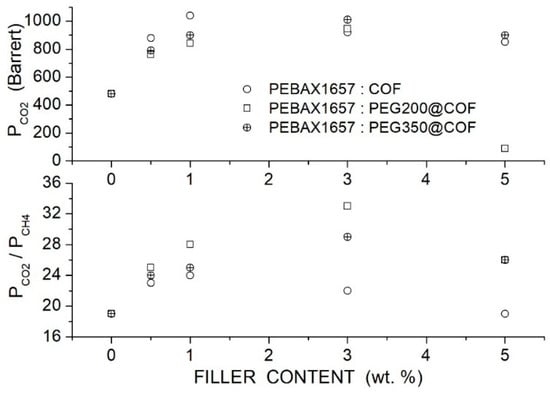

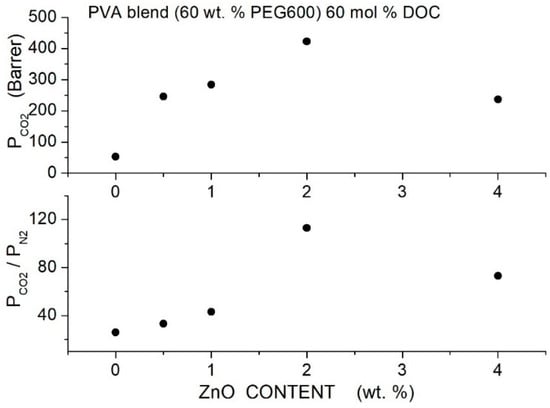

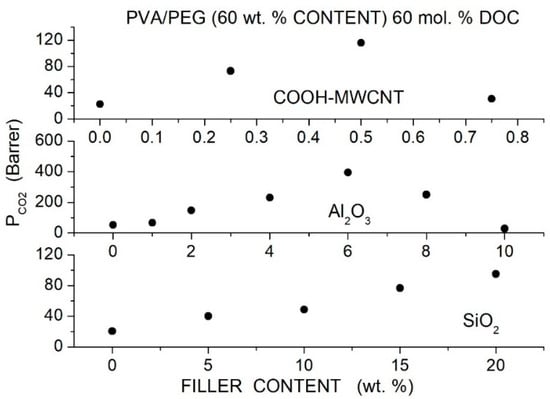

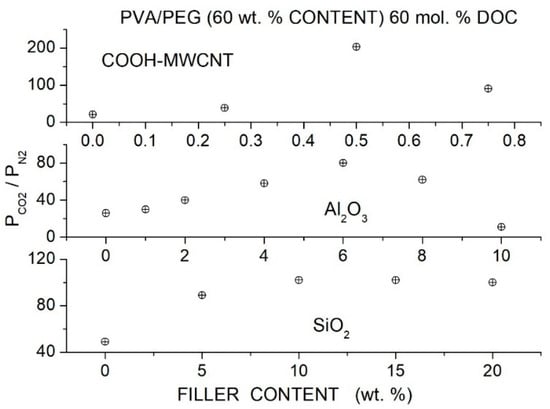

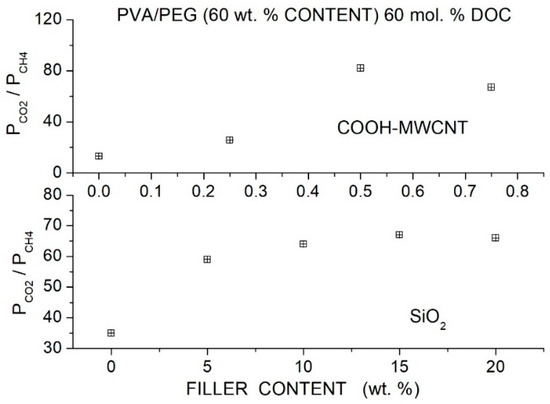

permeability and diffusivity values of neat and hybrid PIM_1 membranes with different f-MWCNT contents. The /N2 and permeability-selectivity and diffusivity-selectivity values are also reported. Data were obtained in single gas tests at 30 °C and 2 bar feed pressure [90].