Enhanced Elution of Residual Ammonium from Weathered Crust Elution-Deposited Rare Earth Ore Tailings by Ferric Chloride

Abstract

1. Introduction

2. Materials and Methods

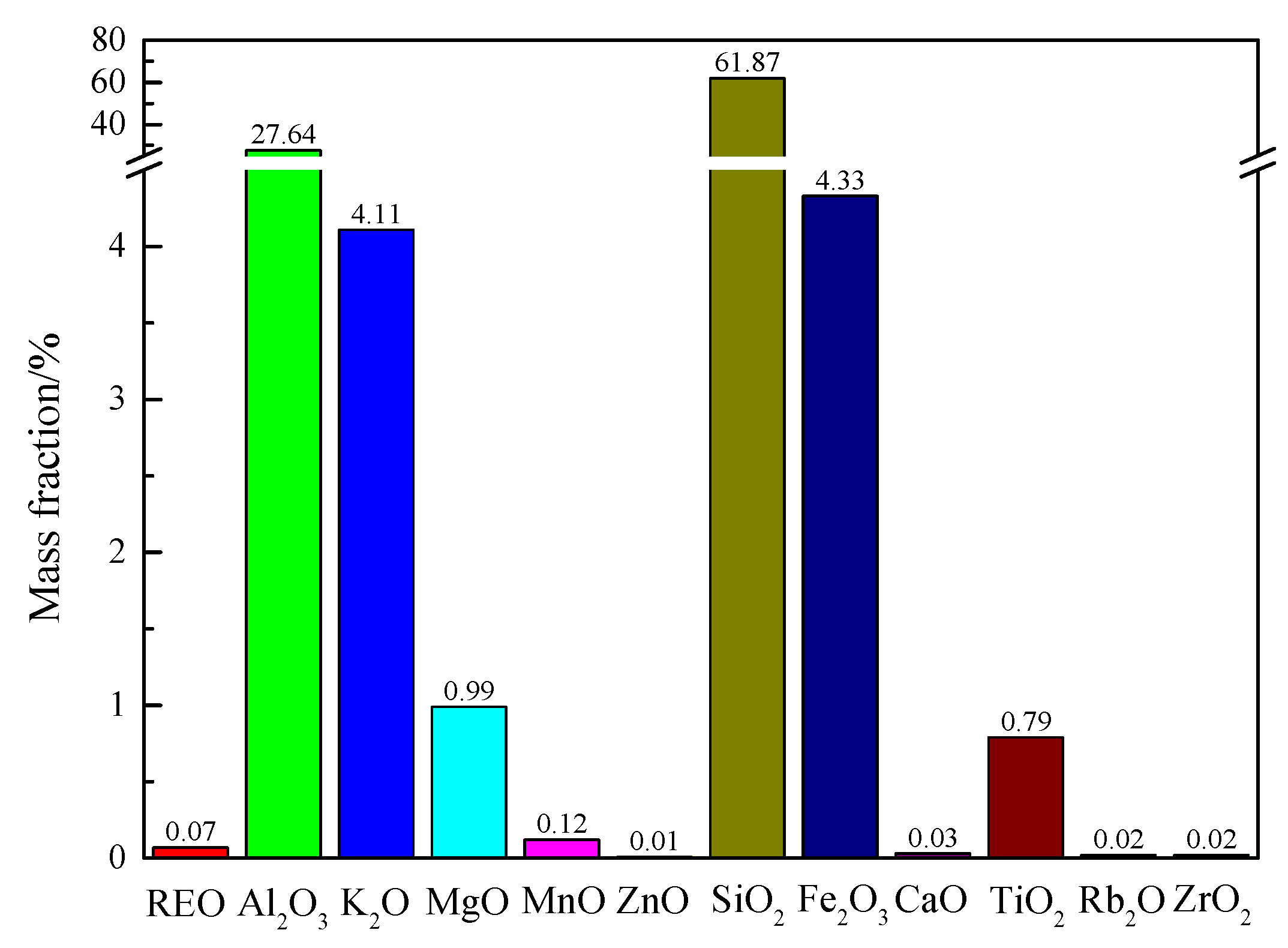

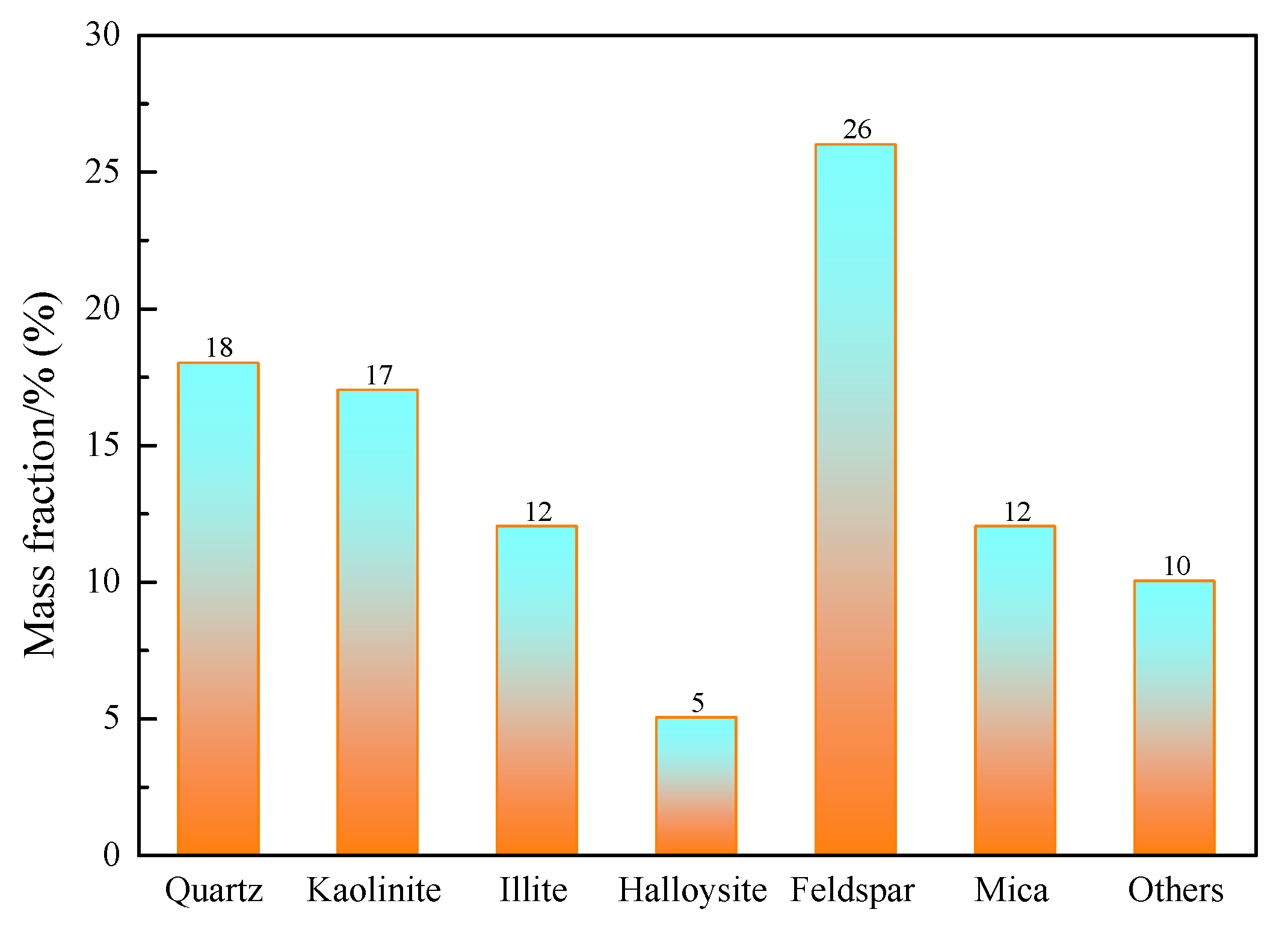

2.1. Materials

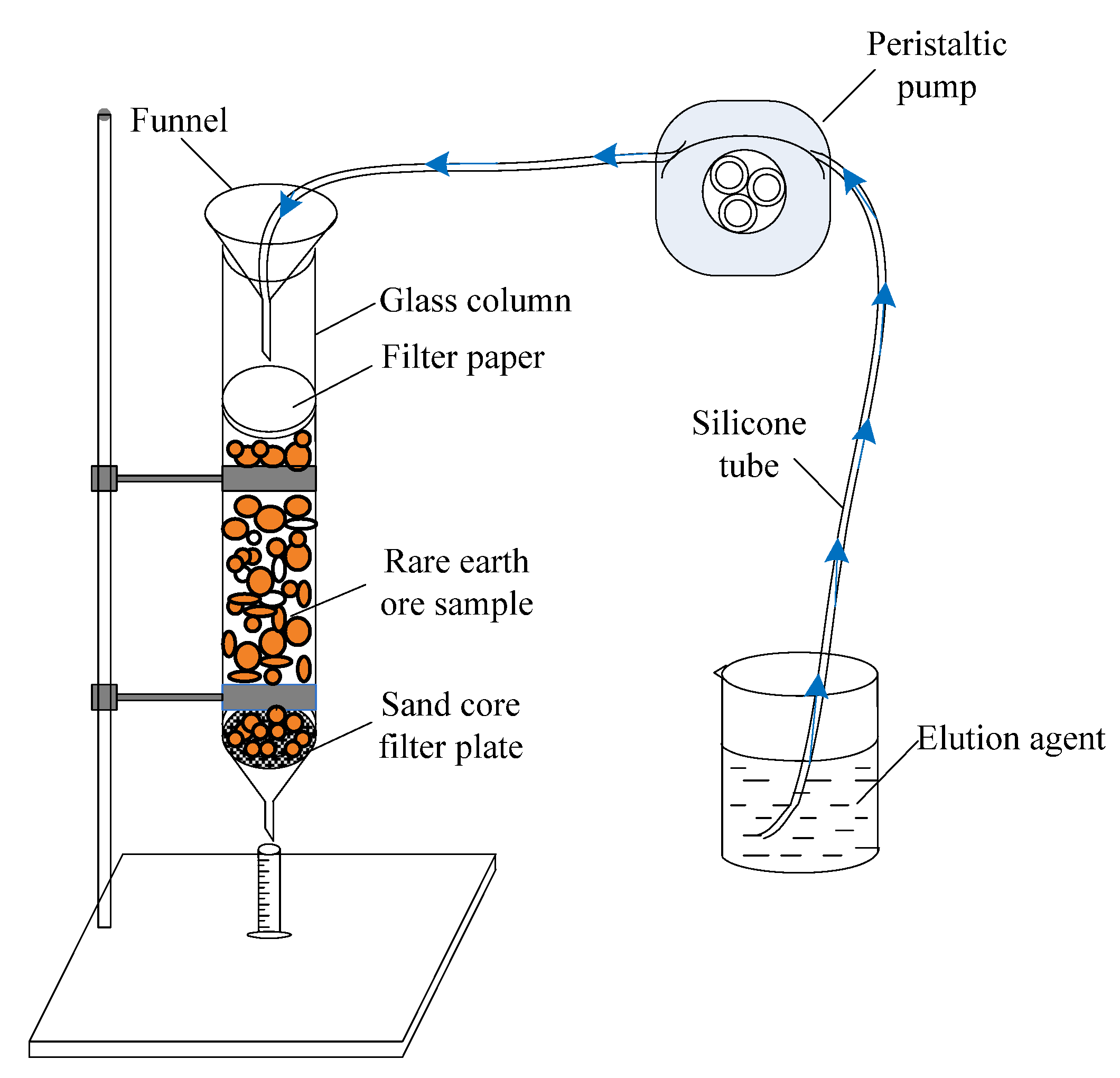

2.2. Column Leaching Experiment

2.3. Analytical Methods

3. Results

3.1. Effect of Different Factors on Ammonium Elution Process

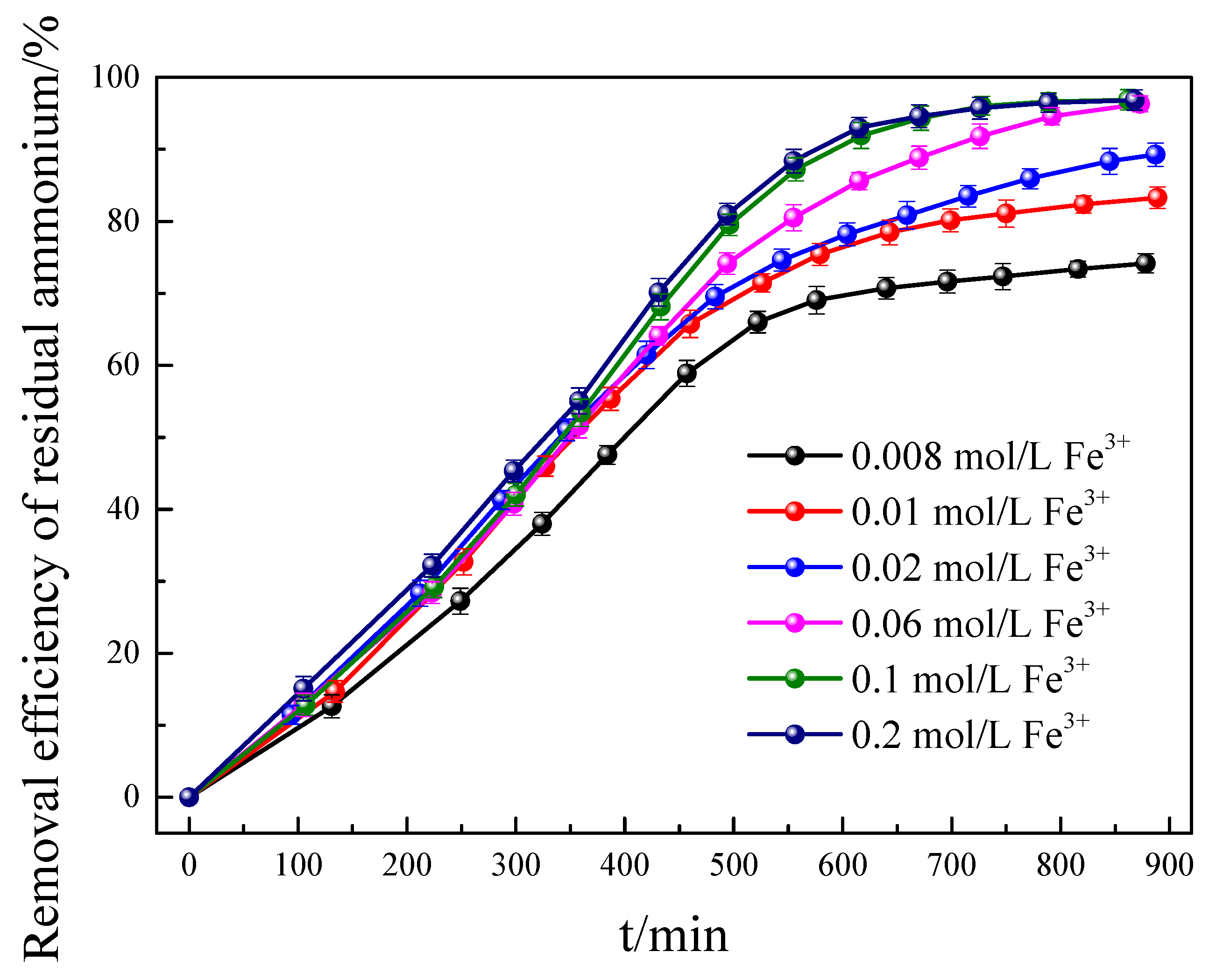

3.1.1. Effect of the Ferric Salt Concentration on Ammonium Removal Efficiency

3.1.2. Effect of Liquid/Solid Ratio on Ammonium Removal Process

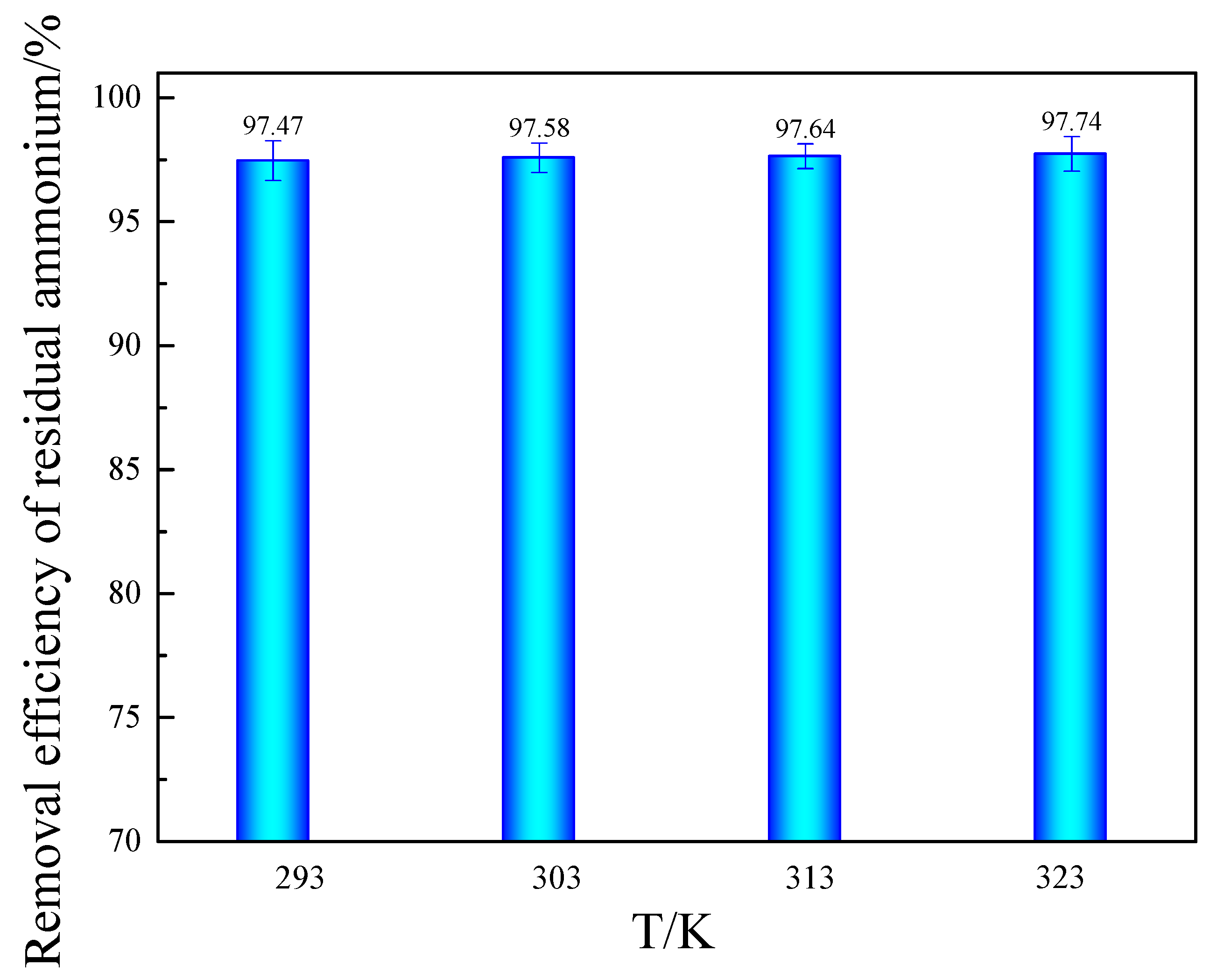

3.1.3. Effect of Temperature on Ammonium Removal Process

3.2. Kinetic Analysis

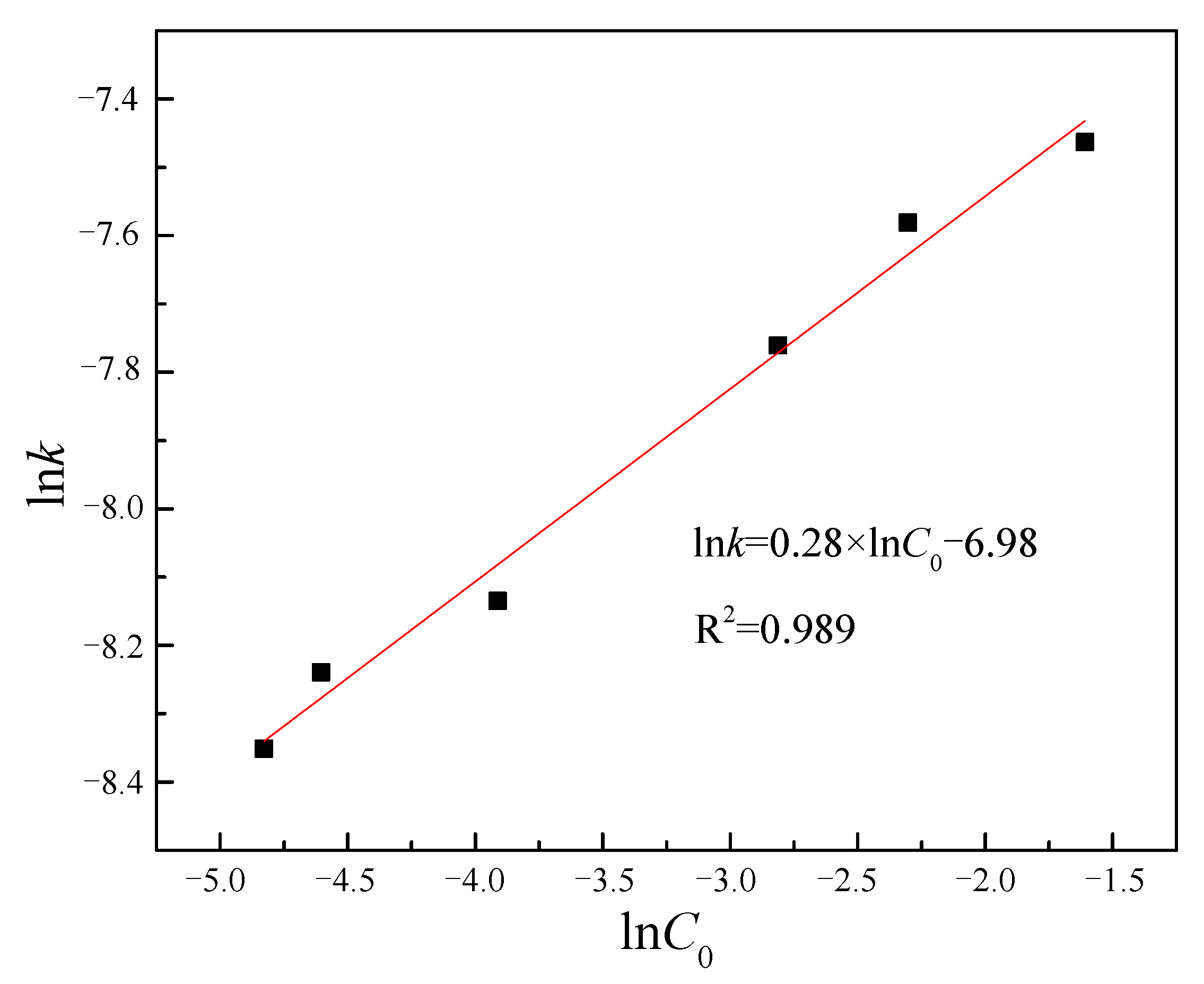

3.2.1. Effect of the Ferric Salt Concentration on Elution Kinetics

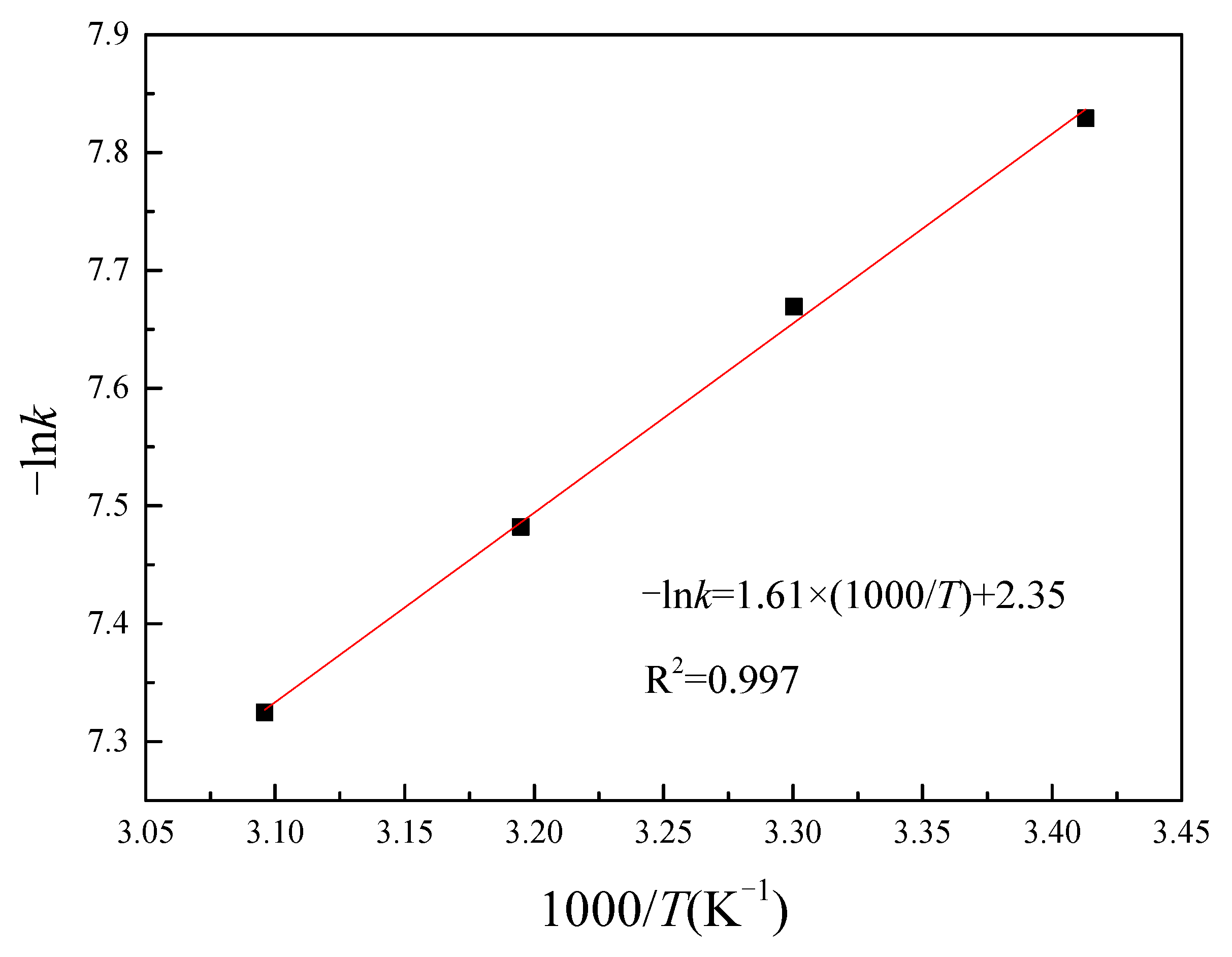

3.2.2. Effect of Temperature on Elution Kinetics

3.3. Mass Transfer Analysis

3.3.1. Effect of the Ferric Salt Concentration on Mass Transfer Process

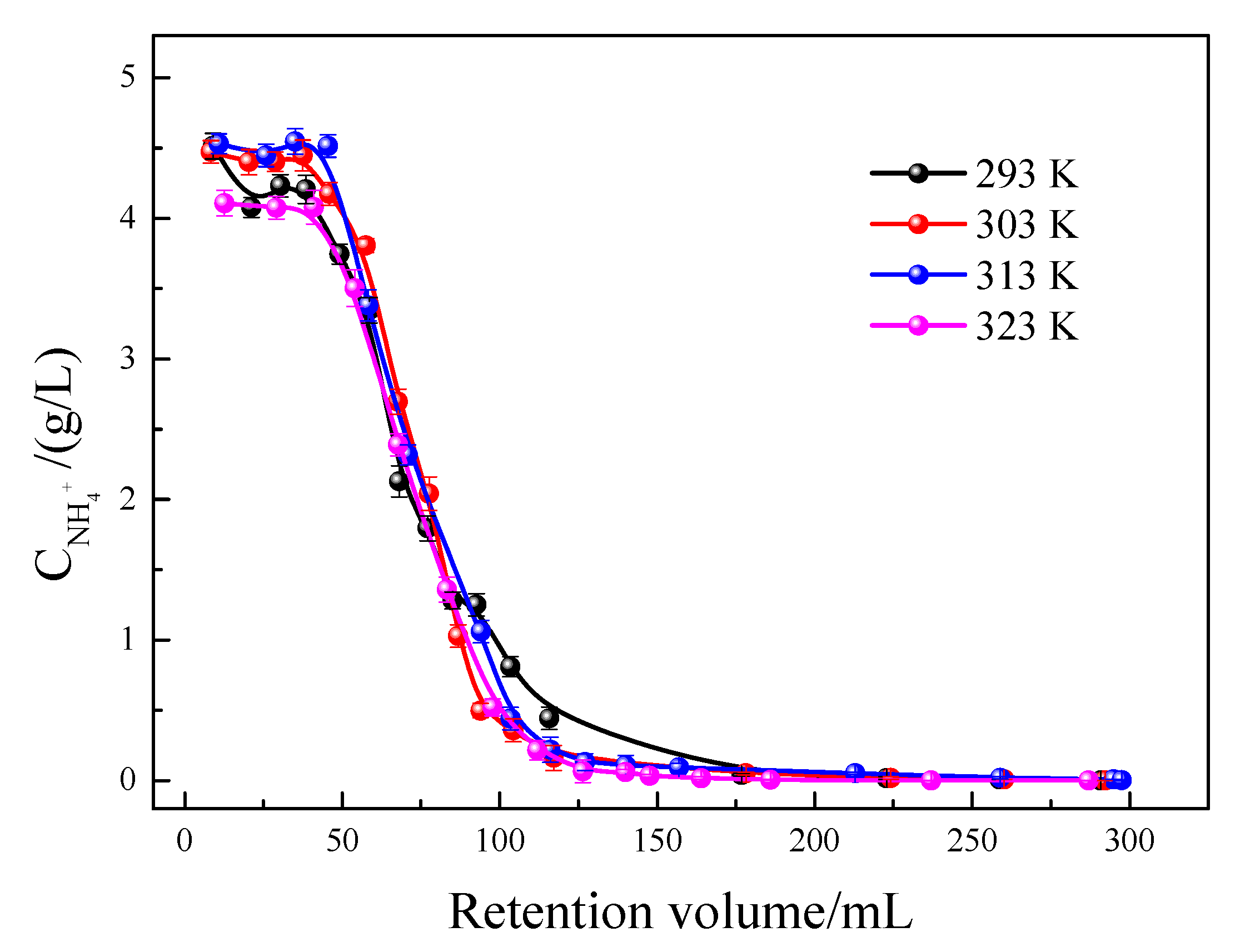

3.3.2. Effect of Temperature on Mass Transfer Process

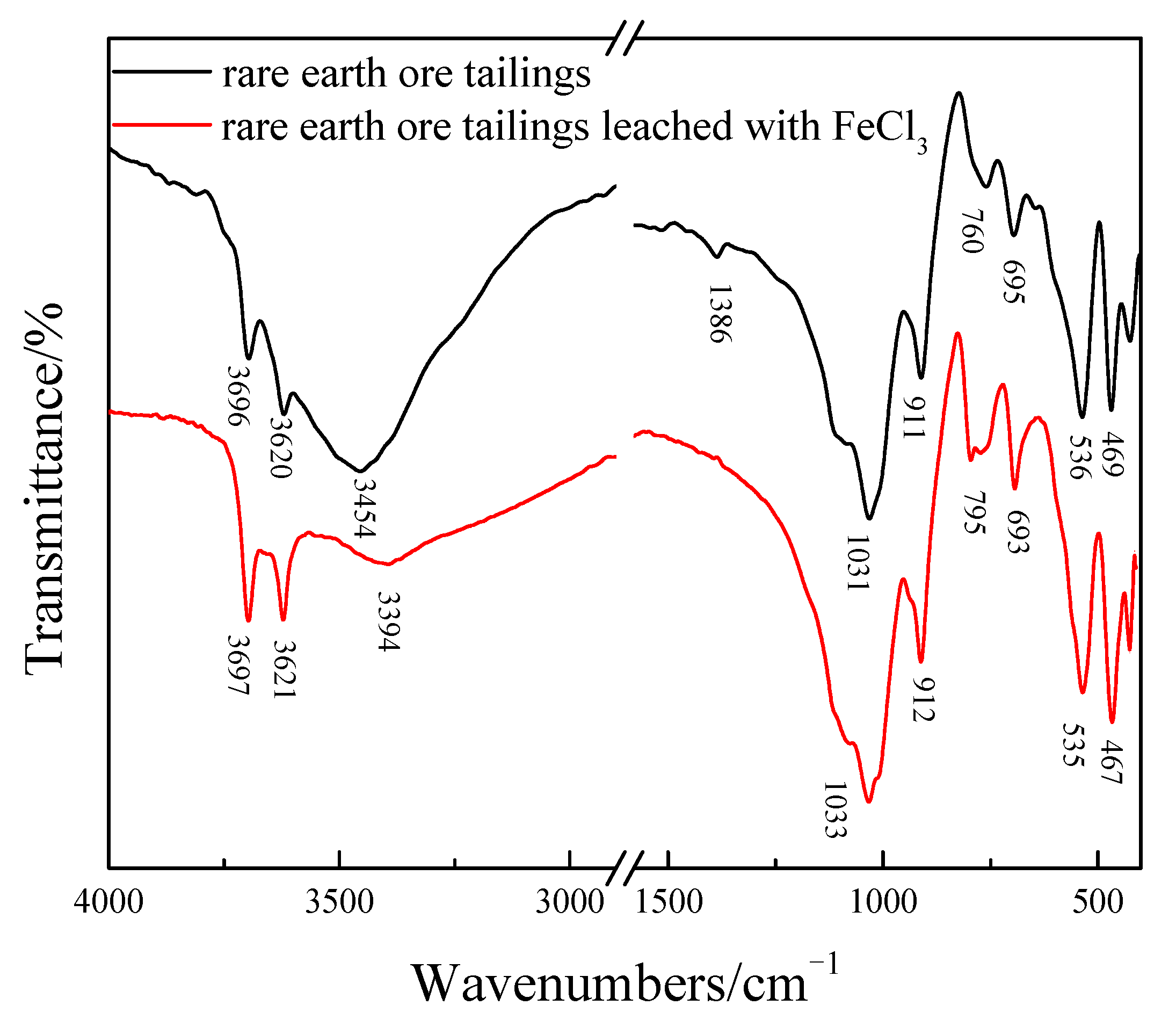

3.4. FT-IR Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| WREO | Weathered crust elution-deposited rare earth ore |

| RA | Residual ammonium |

| RE | Rare earth |

References

- Balaram, V. Rare earth elements: A review of applications, occurrence, exploration, analysis, recycling, and environmental impact. Geosci. Front. 2019, 10, 1285–1303. [Google Scholar] [CrossRef]

- Moldoveanu, G.A.; Papangelakis, V.G. An overview of rare-earth recovery by ion-exchange leaching from ion-adsorption clays of various origins. Mineral. Mag. 2016, 80, 63–76. [Google Scholar] [CrossRef]

- Ju, W.; Yang, J.; Yao, C.; Zhang, X.; Ye, Z.; Liu, D. Experimental Study on the Permeability of Rare Earths with Different Particle Composition for a Novel Heap Leaching Technology. Appl. Sci. 2022, 12, 11368. [Google Scholar] [CrossRef]

- Wang, G.; Xu, J.; Ran, L.; Zhu, R.; Ling, B.; Liang, X.; Kang, S.; Wang, Y.; Wei, J.; Ma, L. A Green and Efficient Technology to Recover Rare Earth Elements from Weathering Crusts. Nat. Sustain. 2023, 6, 81–92. [Google Scholar] [CrossRef]

- Shi, Q.; Zhao, Y.; Meng, X.; Shen, L.; Qiu, G.; Zhang, X.; Yu, H.; He, X.; He, H.; Zhao, H. Column Leaching of Ion Adsorption Rare Earth Ore at Low Ammonium Concentration. J. Mater. Res. Technol. 2022, 19, 2135–2145. [Google Scholar] [CrossRef]

- Yang, L.; Wang, D.; Li, C.; Sun, Y.; Zhou, X. Searching for a high efficiency and environmental benign reagent to leach ion-adsorption rare earths based on the zeta potential of clay particles. Green Chem. 2018, 20, 4528–4536. [Google Scholar] [CrossRef]

- Meng, X.; Zhao, H.; Zhang, Y.; Shen, L.; Gu, G.; Qiu, G.; Zhang, X.; Yu, H.; He, X.; Liu, C. Simulated Bioleaching of Ion-Adsorption Rare Earth Ore Using Metabolites of Biosynthetic Citrate: An Alternative to Cation Exchange Leaching. Miner. Eng. 2022, 189, 107900. [Google Scholar] [CrossRef]

- Wu, S.; Wang, L.; Zhao, L.; Zhang, P.; El-Shall, H.; Moudgil, B.; Huang, X.; Zhang, L. Recovery of rare earth elements from phosphate rock by hydrometallurgical processes-a critical review. Chem. Eng. J. 2018, 335, 774–800. [Google Scholar] [CrossRef]

- Ju, W.; Yang, J.; Wang, Z.; Yao, C.; Zhang, X. Formation Mechanism of Preferential Flow Paths and Seepage Characteristics of a Novel Growable Pile for Heap Leaching of Rare Earth. Adv. Mater. Sci. Eng. 2021, 2021, 3010859. [Google Scholar] [CrossRef]

- Deng, G.; Yang, Y. A Review of The Mining Technologies of Ion-absorbed Rare Earth Mineral. Chin. Rare Earths 2016, 37, 129–133. [Google Scholar]

- Zhou, L.B.; Yang, J.; Kang, S.J.; Wang, X.J.; Yu, H.D.; Wan, Y.H. Enhancing Leaching Efficiency of Ion Adsorption Rare Earths by Ameliorating Mass Transfer Effect of Rare Earth Ions by Applying an Electric Field. J. Rare Earth 2023, in press. [Google Scholar] [CrossRef]

- Xia, H.; Deng, P.; Wu, X.; Liu, D.; Qiu, S.; Liu, Y.; Yu, Y. Simulation Research on Pilot Experimental of In-situ Leaching Ion-adsorption Rare Earth Ores with Plant Leaching Agent. Nonferrous Met. Eng. 2020, 10, 52–59. [Google Scholar]

- Zhou, F.; Zhang, L.; Wang, Z.; Zhang, Y.; Chi, R.; Wu, X. Application of surfactant for improving leaching process of weathered crust elution-deposited rare earth ores. J. Rare Earths 2024, 42, 181–190. [Google Scholar] [CrossRef]

- Feng, J.; Zhou, F.; Chi, R.; Liu, X.; Xu, Y.; Liu, Q. Effect of a novel compound on leaching process of weathered crust elution-deposited rare earth ore. Miner. Eng. 2018, 129, 63–70. [Google Scholar] [CrossRef]

- Zou, H.; Zhang, Z.; Chen, Z.; Liu, D.; Chai, X.; Zhang, H.; Chi, R. Seepage process on weathered crust elution-deposited rare earth ores with ammonium carboxylate solution. Phys. Probl. Miner. Process. 2020, 56, 89–101. [Google Scholar]

- Zhu, D.; Qiu, T.; Zhong, J.; Zeng, Q.; Fang, X. Molecular dynamics simulation of aluminum inhibited leaching during ion-adsorbed type rare earth ore leaching process. J. Rare Earths 2019, 37, 1334–1340. [Google Scholar] [CrossRef]

- Qiu, T.; Fang, X.; Wu, H.; Zeng, Q.; Zhu, D. Leaching behaviors of iron and aluminum elements of ion-absorbed-rare-earth ore with a new impurity depressant. Trans. Nonferrous Met. Soc. China 2014, 24, 2986–2990. [Google Scholar] [CrossRef]

- Qiu, T.; Zhu, D.; Fang, X.; Zeng, Q.; Gao, G.; Zhu, H. Leaching kinetics of ionic rare-earth in ammonia-nitrogen wastewater system added with impurity inhibitor. J. Rare Earths 2014, 32, 1175–1183. [Google Scholar] [CrossRef]

- Yan, H.; Liang, T.; Liu, Q.; Qiu, T.; Ai, G. Compound leaching behavior and regularity of ionic rare earth ore. Powder Technol. 2018, 333, 106–114. [Google Scholar] [CrossRef]

- Chen, J.; Qiu, J.; Chen, X.; Peng, B.; Yang, Y.; Xiao, Y. The coordination-reduction leaching process of ion-adsorption type rare earth ore with ascorbic acid. J. Rare Earths 2023, 41, 1225–1233. [Google Scholar] [CrossRef]

- Guo, Q.; Li, Z.; Pan, J.; Li, B.; Zhao, L.; Liu, D.; Zheng, X.; Wang, C. Leaching Mechanism of Aluminum during Column Leaching of Ion-Adsorption Rare Earth Ore Using Magnesium Sulfate. Minerals 2023, 13, 401. [Google Scholar] [CrossRef]

- HJ 535-2009; Water Quality-Determination of Ammonia Nitrogen-Nessler’s Reagent Spectrophotometry. China Standards Press: Beijing, China, 2009.

- Sohn, H.; Wadsworth, M. Rate Processes in Extractive Metallurgy; Plenum: New York, NY, USA, 1979. [Google Scholar]

- Li, M.; Zhang, X.; Liu, Z.; Hu, Y.; Wang, M.; Liu, J.; Yang, J. Kinetics of leaching fluoride from mixed rare earth concentrate with hydrochloric acid and aluminum chloride. Hydrometallurgy 2013, 140, 71–76. [Google Scholar] [CrossRef]

- Zhu, P.; Zhang, X.; Li, K.; Qian, G.; Zhou, M. Kinetics of leaching refractory gold ores by ultrasonic-assisted electro-chlorination. J. Int. Min. Metall. Mater. 2012, 19, 473–477. [Google Scholar] [CrossRef]

- Ashraf, M.; Zafar, Z.; Ansari, T. Selective leaching kinetics and upgrading of low-grade calcareous phosphate rock in succinic acid. Hydrometallurgy 2005, 80, 286–292. [Google Scholar] [CrossRef]

- Li, Y. Ion Adsorption Rare Earth Resources and Their Green Extraction; Chemical Industry Press: Beijing, China, 2014. [Google Scholar]

| Concentration/(mol/L) | k (min−1) | R2 |

|---|---|---|

| 0.008 | 0.000236 | 0.983 |

| 0.01 | 0.000264 | 0.989 |

| 0.02 | 0.000293 | 0.995 |

| 0.06 | 0.000426 | 0.995 |

| 0.10 | 0.000510 | 0.978 |

| 0.20 | 0.000574 | 0.986 |

| Temperature/(K) | k (min−1) | R2 |

|---|---|---|

| 293 | 0.000398 | 0.986 |

| 303 | 0.000467 | 0.980 |

| 313 | 0.000563 | 0.990 |

| 323 | 0.000659 | 0.978 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Feng, J.; Luo, X.; Zhou, F.; Chi, R. Enhanced Elution of Residual Ammonium from Weathered Crust Elution-Deposited Rare Earth Ore Tailings by Ferric Chloride. Separations 2025, 12, 301. https://doi.org/10.3390/separations12110301

Wu X, Feng J, Luo X, Zhou F, Chi R. Enhanced Elution of Residual Ammonium from Weathered Crust Elution-Deposited Rare Earth Ore Tailings by Ferric Chloride. Separations. 2025; 12(11):301. https://doi.org/10.3390/separations12110301

Chicago/Turabian StyleWu, Xiaoyan, Jian Feng, Xianping Luo, Fang Zhou, and Ruan Chi. 2025. "Enhanced Elution of Residual Ammonium from Weathered Crust Elution-Deposited Rare Earth Ore Tailings by Ferric Chloride" Separations 12, no. 11: 301. https://doi.org/10.3390/separations12110301

APA StyleWu, X., Feng, J., Luo, X., Zhou, F., & Chi, R. (2025). Enhanced Elution of Residual Ammonium from Weathered Crust Elution-Deposited Rare Earth Ore Tailings by Ferric Chloride. Separations, 12(11), 301. https://doi.org/10.3390/separations12110301