Abstract

To implement sustainable water resource management, the industries that produce a huge amount of wastewater are aiming to recycle wastewater. Reverse osmosis (RO) is an advanced membrane process that can produce potable water from wastewater. However, the presence of diverse pollutants in the wastewater necessitates effective pretreatment to ensure successful RO implementation. This study evaluated the efficiency of microfiltration (MF) and ultrafiltration (UF) as two pretreatment methods prior to RO, i.e., MF-RO and UF-RO, for recycling poultry slaughterhouse wastewater (PSWW). The direct treatment of PSWW with RO (direct RO) was also considered for comparison. In this study, membrane technology serves as a post treatment for PSWW, which was conventionally treated at Sanderson Farm. The results demonstrated that all of the processes, including MF-RO, UF-RO, and direct RO treatment of PSWW, rejected 100% of total phosphorus (TP), over 91.2% of chemical oxygen demand (COD), and 87% of total solids (TSs). Total nitrogen (TN) levels were reduced to 5 mg/L for MF-RO, 4 mg/L for UF-RO, and 9 mg/L for direct RO. In addition, the pretreatment of PSWW with MF and UF increased RO flux from 46.8 L/m2 h to 51 L/m2 h, an increase of approximately 9%. The product water obtained after MF-RO, UF-RO, and direct RO meets the required potable water quality standards for recycling PSWW in the poultry industry. A cost analysis demonstrated that MF-RO was the most economical option among membrane processes, primarily due to MF operating at a lower pressure and having a high water recovery ratio. In contrast, the cost of using RO without MF and UF pretreatments was approximately 2.6 times higher because of cleaning and maintenance expenses related to fouling. This study concluded that MF-RO is a preferable option for recycling PSWW. This pretreatment method would significantly contribute to environmental sustainability by reusing well-treated PSWW for industrial poultry purposes while maintaining cost efficiency.

1. Introduction

Water is a basic human need and critical to global social and economic growth. However, the distribution of water is not uniform worldwide and is at risk from many sources of pollution. This water resource challenge can only be resolved by sustainable water resource management which is extremely important to ensure safety and promote social, ecological, and economic progress. The goal of sustainable management of water resources is to fulfill the growing demands without compromising the ability of future generations to do so. To implement this approach, the industrial sectors, which use excessive water, are keenly interested in conserving water resources by recycling wastewater [1].

The food industry is among the top-ranked industries that are highly concerned about water consumption [2]. In the food industry, in particular, poultry consumes 24% of freshwater, which is the highest proportion compared to other food sectors. The largest portion of this water is utilized in the operations of slaughtering, processing, and cleaning within poultry slaughterhouse plants [3]. Typically, a bird consumes approximately 24.4 L of water on average [4]. The water consumed is saturated with proteins, fats, quills, paunch, feces, urine, blood, and other organic matter. If this poultry slaughterhouse wastewater (PSWW) is released into local water bodies untreated, the biodegradable organic matter will almost eliminate the dissolved oxygen (DO) of the surface water and may cause the death of marine life and increase algae growth and water-borne diseases [5,6,7]. Therefore, it is necessary to treat PSWW before releasing it into the environment.

In the poultry industry, PSWW typically undergoes preliminary treatments, such as screening, sieving, and retention, followed by primary treatments like dissolved air flotation (DAF), electrocoagulation, and sedimentation. Subsequently, secondary treatments, which include anaerobic and aerobic processes, are employed. However, these methods primarily focus on meeting discharging standards and do not involve recycling the wastewater. To conserve water resources, it is crucial to implement recycling measures [8]. Implementing wastewater recycling in the poultry industry is challenging due to the requirement of meeting potable water quality to be able to reuse PSWW [9]. However, membrane technology has become a favorable option for wastewater recycling due to its high efficiency in separating contaminants, avoidance of chemical usage, and numerous advantages over traditional methods. The initial use of a membrane for treating PSWW was conducted by Jason et al. [10]. Their research employed a 50 KDa tubular UF membrane. The results showed that the UF membrane effectively purified PSWW, making it suitable for discharge and potential reuse while reclaiming valuable nutrients. Following this milestone, numerous researchers have studied the treatment of PSWW with membrane technologies [7].

Among various types of filtration membranes, reverse osmosis (RO) membrane technology provides the highest-quality water permeate and has already proven useful for treating wastewater in various industries, including poultry, municipal, seawater, petroleum, dairy, dyeing, and others [11,12,13,14,15,16]. RO is a high-pressure membrane filtration process that rejects dissolved solids from the water by generating hydrostatic pressure that exceeds the natural osmotic pressure of feed. This results in the absorption of water molecules on the membrane surface, which then permeate from the feed side of the membrane to the filtrate side [17]. This rejection of solids by the RO occurs due to the size exclusion and physical–chemical interactions between the solute, solvent, and membrane. RO offers several advantages, such as a low cost per liter of purified water, a compact and modular design, and the potential for fully automated process control [18].

However, a major drawback of RO is membrane fouling, in which particles are deposited on the membrane surface or in the membrane pores due to the presence of several pollutants in wastewater, encompassing colloidal or particulate matter, dissolved organics, chemical reactants, and microorganisms. The foulants are categorized into organic and inorganic compounds [19,20]. The fouling dramatically decreases productivity and permeate quality, leading to high operational costs, frequent cleaning, and limited membrane lifetime. The decrease in the permeate rate and quality directly impacts the sustainable use of RO, mainly its efficiency and economic aspects. Unconventional membrane-based techniques, specifically microfiltration (MF) and ultrafiltration (UF), have recently gained popularity as pretreatment methods prior to RO [21].

To treat PSWW, UF has been utilized as a pretreatment method for RO in some research studies to improve RO performance. For example, in a study conducted by Coskun et al. [22], where membrane technology was utilized for PSWW recycling, their results indicated that RO without UF pretreatment led to a significant decline in the long-term RO membrane fluxes due to extensive fouling. Consequently, operational expenses for the RO process increased. Coskun et al. [22] concluded that RO without UF pretreatment is inefficient for treating PSWW. Similarly, another study revealed that the treatment of PSWW with an integrated membrane system of UF and RO achieved a removal efficiency of up to 100% of turbidity, color, and total suspended solids (TSSs) and 99.6% of biochemical oxygen demand (BOD) and chemical oxygen demand (COD), meeting drinking water standards [23].

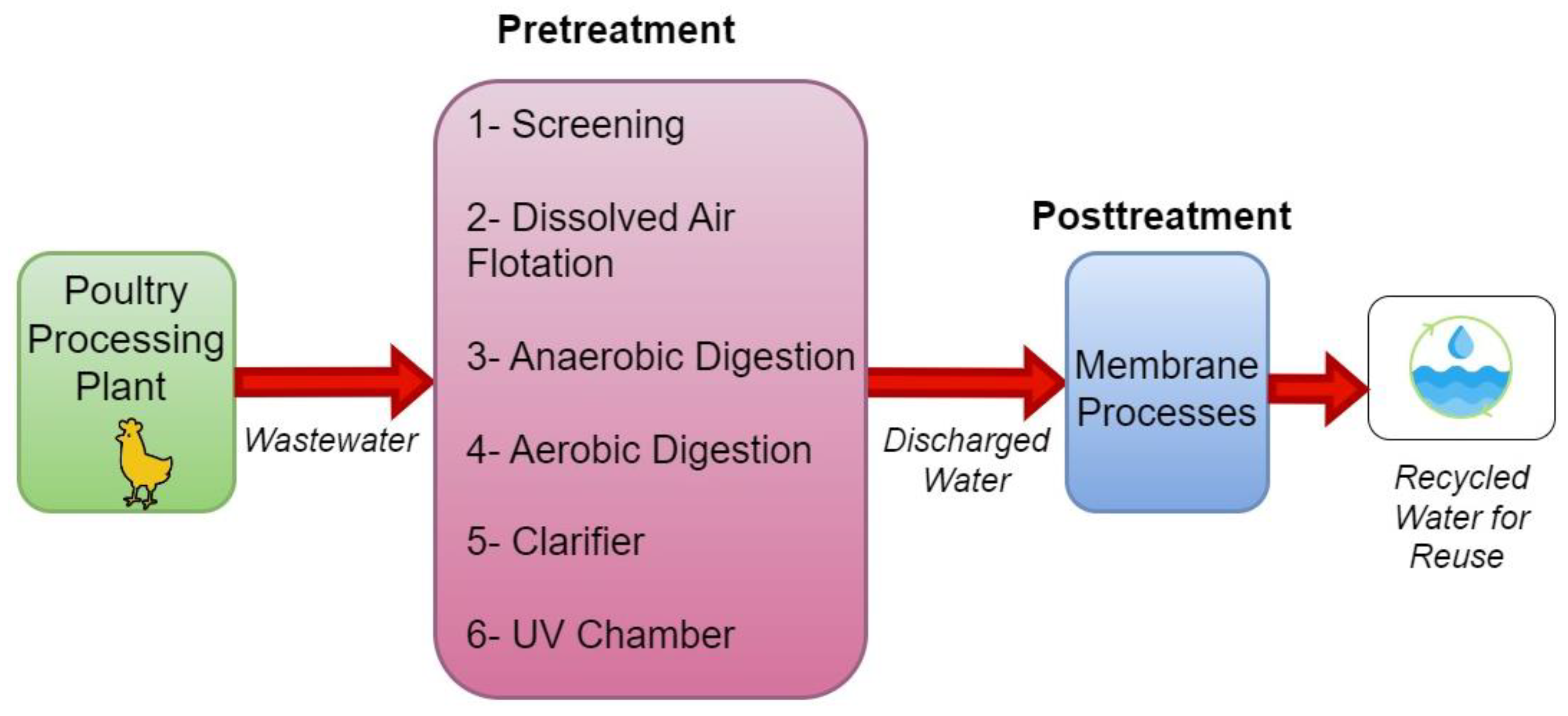

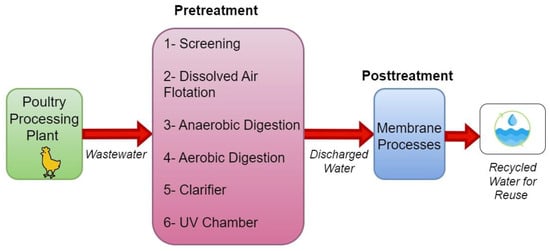

Previous studies [23,24,25,26,27,28,29,30] have been conducted on MF as a standalone or UF as a standalone membrane system and as pretreatment processes prior to RO for purifying PSWW, showing promising outcomes. However, a noticeable research gap exists in directly comparing MF and UF techniques for RO pretreatment technologies for PSWW. This study evaluates MF and UF pretreatment methods for RO to recycle PSWW. Also, the direct treatment of PSWW with RO is conducted for comparison. The aim is to identify the best approach to improve RO efficiency while maintaining cost-effectiveness. Moreover, the result of this study serves as a significant step toward a sustainable environment as it addresses water scarcity issues by recycling PSWW back into the poultry industry with membrane technology post treatment, as shown in Figure 1. This approach reduces the burden on freshwater resources while conserving them. Additionally, advanced membrane technology ensures high water quality, thereby reducing environmental impacts through complete on-site PSWW treatment. Moreover, enhancing the cost efficiency of membrane technology enables economical water recycling for poultry industries. Thus, the innovation of this work lies in its comprehensive and comparative evaluation of membrane pretreatment techniques for RO in recycling PSWW to advance cost-effective and sustainable wastewater treatment processes in the poultry industry.

Figure 1.

Comprehensive process flow diagram of PSWW treatment.

2. Materials and Methods

2.1. Poultry Slaughterhouse Wastewater Characterization

The PSWW was obtained at the discharging unit of the Sanderson poultry processing plant located in Bryan, TX, USA. The PSWW was transported to the research lab within 2 h. The PSWW was stored in 5-gallon plastic jugs inside a cooler with 10 pounds of ice to maintain its temperature. Once the samples reached the research lab, the PSWW was immediately characterized for COD, total solids (TSs), total dissolved solids (TDSs), TSSs, total volatile solids (TVSs), total fixed solids (TFSs), total nitrogen (TN), and total phosphorous (TP). These analyses were performed following the Hach version of Standard Methods for the Examination of Water and Wastewater, as listed in Table 1. The analysis of TSSs involved the use of a Watman microfiber filter with a pore size of 1.5 μm (Little Chalfont, Buckinghamshire, UK). Hach instruments, reagents, and vials were utilized for conducting COD, TP, and TN tests. To validate the results, each characterization test was repeated three times. Blanks and standards were employed to calibrate the instruments used in the COD, TP, and TN measurements.

Table 1.

Standard Method for Examination of Water and Wastewater.

2.2. Pretreatment of Poultry Slaughterhouse Wastewater with Ultrafiltration and Microfiltration

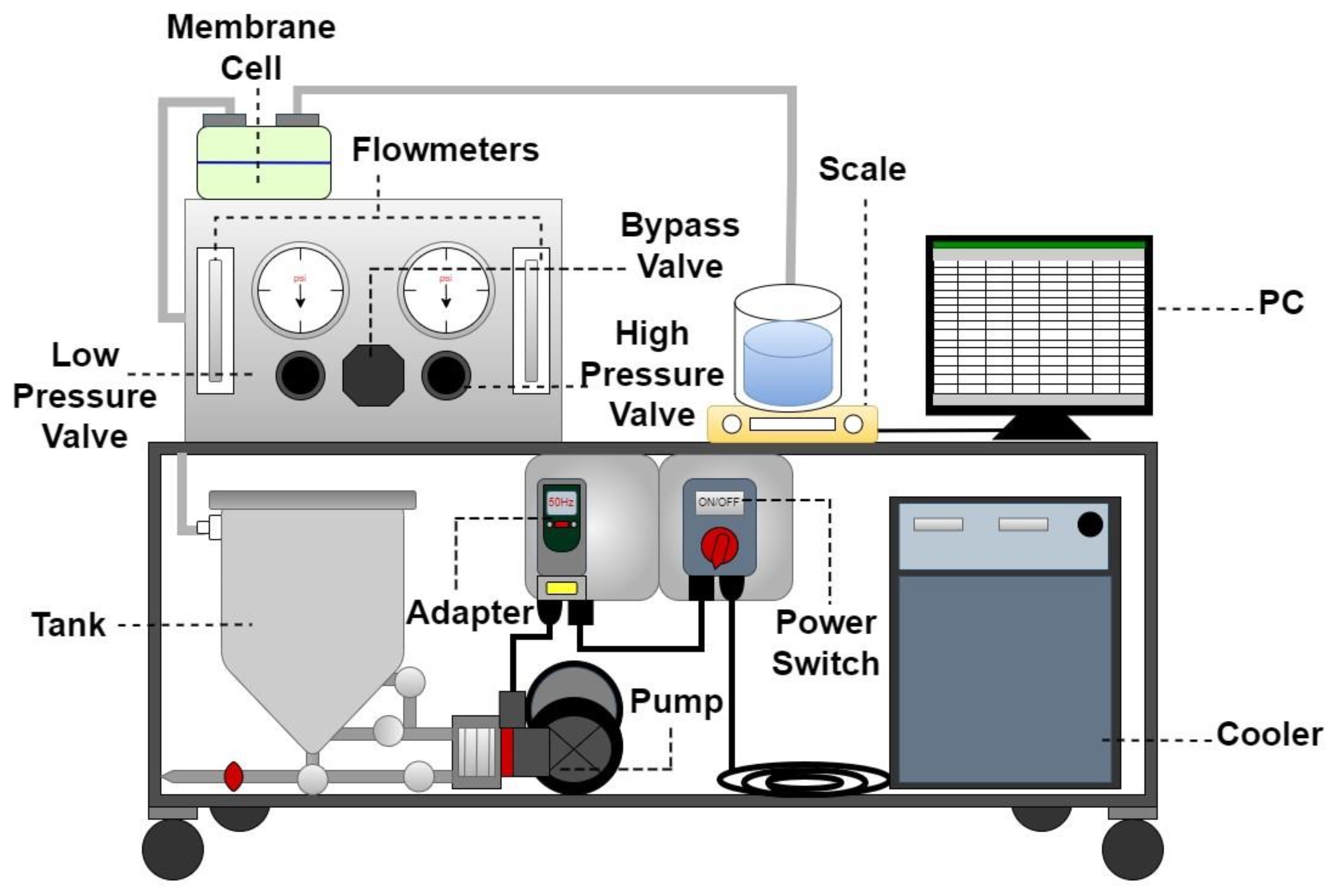

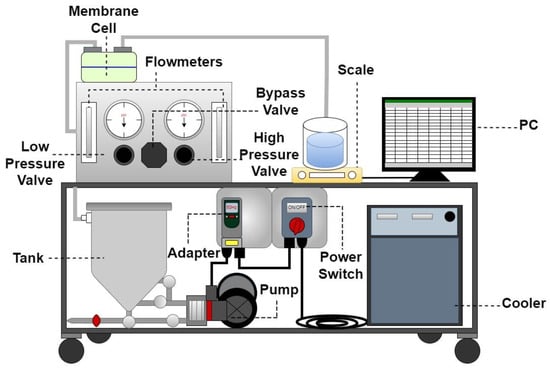

The pretreatment of PSWW was conducted with MF and UF membranes. Both MF and UF membranes were procured from Sterlitech Corporation (Auburn, WA, USA). The MF membrane was made up of polyvinylidene fluoride (PVDF), while the UF membrane was composed of polyether sulfone (PES), as listed in Table 2. The MF and UF membranes were used in a Sterlitech customized membrane system, as illustrated in Figure 2. The membrane filtration system consisted of two flowmeters, a power-on switch, an adapter, a high-pressure valve, a low-pressure valve, a bypass valve, a pump, a tank, and a cooling unit. The membrane cell was made up of Delrin material. The dimensions of the cell were 0.127 m in length, 0.1 m in width, and 0.083 m in height, and the effective membrane area of the cell was 0.0042 m2. The tank was made of stainless steel and could hold up to about 20 L of wastewater. The operating pressure and flow rate of the MF membrane were 413 kPa and 6.0 L/min, respectively. UF was run at the same flow rate as MF; however, the pressure was twice as high as that in MF. The performance of MF and UF was evaluated based on pollutant removal efficiency and average flux.

Table 2.

UF, MF, and RO membrane specifications [31,32,33].

Figure 2.

Schematic of Sterlitech customized membrane system.

2.3. Characterization of Microfiltration and Ultrafiltration Foulants

The fouling cake on the MF and UF membrane surfaces was removed by splashing the water on their surfaces, collecting the foulant particles in a Petri glass dish, and then allowing them to air dry. The MF and UF foulants were examined under a Smith Detection Fourier Transform Infrared spectrometer and PerkinElmer thermogravimetric analyzer. The thermogravimetric analyzer (TGA) was employed to quantify the percentage of organic and inorganic compounds present in the foulants. The temperature range for the TGA analysis began at room temperature and increased gradually at a rate of 10 °C per minute until it reached a maximum temperature of 800 °C. The Fourier Transform Infrared Spectroscopy (FTIR) spectrometer was employed to detect the organically functional groups present in the foulant particles. The surface characteristics and elemental composition of virgin and fouled MF and UF membranes were analyzed using scanning electron microscopy–energy dispersive X-ray spectroscopy (SEM-EDS).

2.4. Treatment of Poultry Slaughterhouse Wastewater with Reverse Osmosis

The MF and UF permeate underwent RO treatment, referred to as (MF-RO) and (UF-RO) processes, respectively. The PSWW was also directly treated with the RO process, referred to as (direct RO), for comparison. The RO membrane, made of polyamide material as shown in Table 2, was procured from Sterlitech Corporation (Auburn, WA, USA). The operating pressure of RO was 1516 kPa and it was operated at the same flow rate as for MF and UF. The customized membrane system, shown in Figure 2, was also employed for the RO processes. The performance of all processes, including MF-RO, UF-RO, and direct RO, was assessed based on various factors, including real-time flux (Jw), average flux (Jaw), rejection coefficient (R), and permeate quality. For flux measurement during the pretreatment and treatment of PSWW, a single piece of membrane was employed without chemical cleaning or backwashing. For permeate quality, the results were validated using the permeates from two sets of experiments.

The Jw was calculated by taking the difference in weight of the permeate collected every minute (ΔW) and dividing it by the water density (), effective membrane area (A), and time interval (Δt), as indicated in Equation (1). The Jaw was calculated by dividing the cumulative flux over the total time.

The value of R was determined using Equation (2), where represents the concentration of the permeate and represents the concentration of the retentate.

2.5. Economic Analysis

The preliminary economic analysis was performed by evaluating the total cost per year for the processes, including conventional treatment, MF-RO, UF-RO, and direct RO for the treatment of PSWW in (College Station, TX), (Arlington, VA), and (Goodyear, AZ), USA.

The total cost per year was calculated by summing the freshwater consumption and wastewater treatment costs per year, as shown in Equation (3).

Total Cost (USD/year) = Freshwater consumption cost (USD/year) + Wastewater treatment cost (USD/year)

The wastewater treatment cost per year was calculated by multiplying the wastewater treatment unit cost, as listed in Table 3, by the wastewater generated per day at Sanderson Farm, which is 6098 m3, and then by 365 days. The wastewater treatment unit cost for conventional treatment was obtained from the research conducted by Coskun et al. [22], which listed a cost of 0.36 USD/m3, as shown in Table 3. The wastewater treatment unit cost of 1.02 USD/m3 for UF-RO was determined from a study by Prez et al. [34]. For MF-RO, the wastewater treatment unit cost was adjusted using the data obtained from Prez et al. [34], where the energy consumption cost of MF was halved since the pressure used for MF in this study was half of the pressure of UF in pretreating PSWW, resulting in a total wastewater treatment cost of 1.01 USD/m3.

Table 3.

Wastewater treatment unit cost [22,34].

The economic analysis is not intended to be exhaustive but supplemental to our experimental work; therefore, the treatment cost for MF-RO, UF-RO, and RO were sourced directly from the literature and only energy consumption cost adjustments were made for MF-RO and UF-RO. The treatment cost for RO was 2.8 times higher than that of UF-RO, as indicated by Coskun et al. [22].

The freshwater consumption cost per year for each method was calculated by multiplying water consumption per day for each process by the freshwater consumption unit cost for the commercial water customers in (College Station, TX, USA), (Goodyear, AZ, USA), and (Arlington, VA, USA) and then by 365 days. The freshwater consumption unit cost for each region is listed in Table 4.

Table 4.

Freshwater consumption unit cost [35,36,37].

3. Results

3.1. Characterization of Poultry Slaughterhouse Wastewater

TSs are the sum of TDSs and TSSs for the stable water samples. Given that 4 ± 0.4 mg/L of TSSs was found in the PSWW, most of the solids present were TDSs, with a measured level of 2012 ± 82.3 mg/L. The primary reason for minimal TSSs in the PSWW is the operation of serial physical and biological treatments of PSWW at the Sanderson wastewater treatment plant. The TVSs and TFSs were quantified as 403 ± 27.6 mg/L and 1613 ± 55.1 mg/L, respectively. Furthermore, the PSWW exhibited a TP content of 54 ± 0.4 mg/L and a COD level of 34 ± 0.7 mg/L. The TN content was measured as 252 ± 2.1 mg/L. The TN content is high in PSWW due to the application of the anaerobic and aerobic digestion processes in the biological treatment of PSWW at the Sanderson wastewater treatment plant. The sequential treatment decomposes organic nitrogen into ammonia and other inorganic forms of nitrogen products. The samples of PSWW were randomly collected and analyzed in triplicate, and the results are consistent among the triplicates.

3.2. Pretreatment of Poultry Slaughterhouse Wastewater with Ultrafiltration and Microfiltration

3.2.1. Characterization of Microfiltration and Ultrafiltration Permeate

The PSWW pretreated with MF and UF retained some pollutants. MF achieved a removal efficiency of 15.4% of TSs, 68.2% of TVSs, 2.2% of TFSs, 5.6% of TP, and 32.1% of TN. MF outperformed UF regarding COD rejection, achieving a removal efficiency of 26.5% compared to 8.8% for UF, as reported in Table 5. However, UF resulted in a higher removal efficacy of 18.5%, 70.0%, 5.7%, 16.7%, and 37.3% for TSs, TVSs, TFSs, TP, and TN, respectively. In our study, the feed water of MF and UF is the slightly yellow water discharged to the environment after a series of conventional wastewater treatment steps, including dissolved air floatation, anaerobic digestion, aerobic digestion, sedimentation, and clarification. The water would primarily contain several inert soluble organic species for COD, such as flavines, polycarboxylates humic acids, etc., along with a small amount of big particles of biosolids, colloids, and algae. Although the UF membrane has a smaller MWCO than the MF membrane, the relatively higher pressure of UF caused a slightly higher COD in the UF permeate than that of the MF permeate in our experiments. The results obtained in this study for COD removal efficiency are comparable to the findings of Marchesi et al. [27]. They utilized membrane technology for the treatment and reuse of wastewater from the precooling system of chicken carcasses. Their findings showed that MF demonstrated a higher elimination efficiency of 62.5% of COD compared to UF, which reduced COD by 47.8%. Goswami and Pugazhenthi [38] studied the treatment of PSWW using a tubular ceramic MF membrane with fly ash as the key precursor. Their investigation yielded notable results, with MF achieving a 100% reduction in COD, highlighting its exceptional performance in the field of wastewater treatment.

Table 5.

Characterization of PSWW, UF, and MF permeate.

3.2.2. Average Flux and Rejection Coefficient of Microfiltration and Ultrafiltration

The average flux of MF was 152.2 L/m2-h, which was 2.8 times higher than the UF average flux of 55.1 L/m2-h, as presented in Table 6. The flux value obtained in this study for MF is very close to the results of a study conducted by Abboah and Kiepper [25] in which they used membrane filtration as a substitute process for pretreating poultry processing wastewater. Their study utilized an MF process with the same pore size and membrane material specification as ours and achieved an average flux of 124 L/m2-h. In addition, in their research, MF demonstrated the highest average flux compared to UF. The higher average flux of MF is due to the larger pores of the MF membrane compared to UF, which allows a higher volume of water to pass through the MF membrane every minute. The rejection coefficient for MF was 0.2. This value was determined based on the measurement of TDSs in the permeate and retentate, which was 1706 mg/L and 2120 mg/L, respectively. Moreover, the rejection coefficient of UF was 0.4 as the concentration of TDSs in the permeate was 1643 mg/L and the concentration of retentate was 2730 mg/L. These results align with the data in Table 5, demonstrating that UF resulted in an overall higher rejection efficiency compared to MF.

Table 6.

Average flux and rejection coefficient (referring to TDSs) of MF and UF pretreatments.

3.3. Foulants’ Characterization

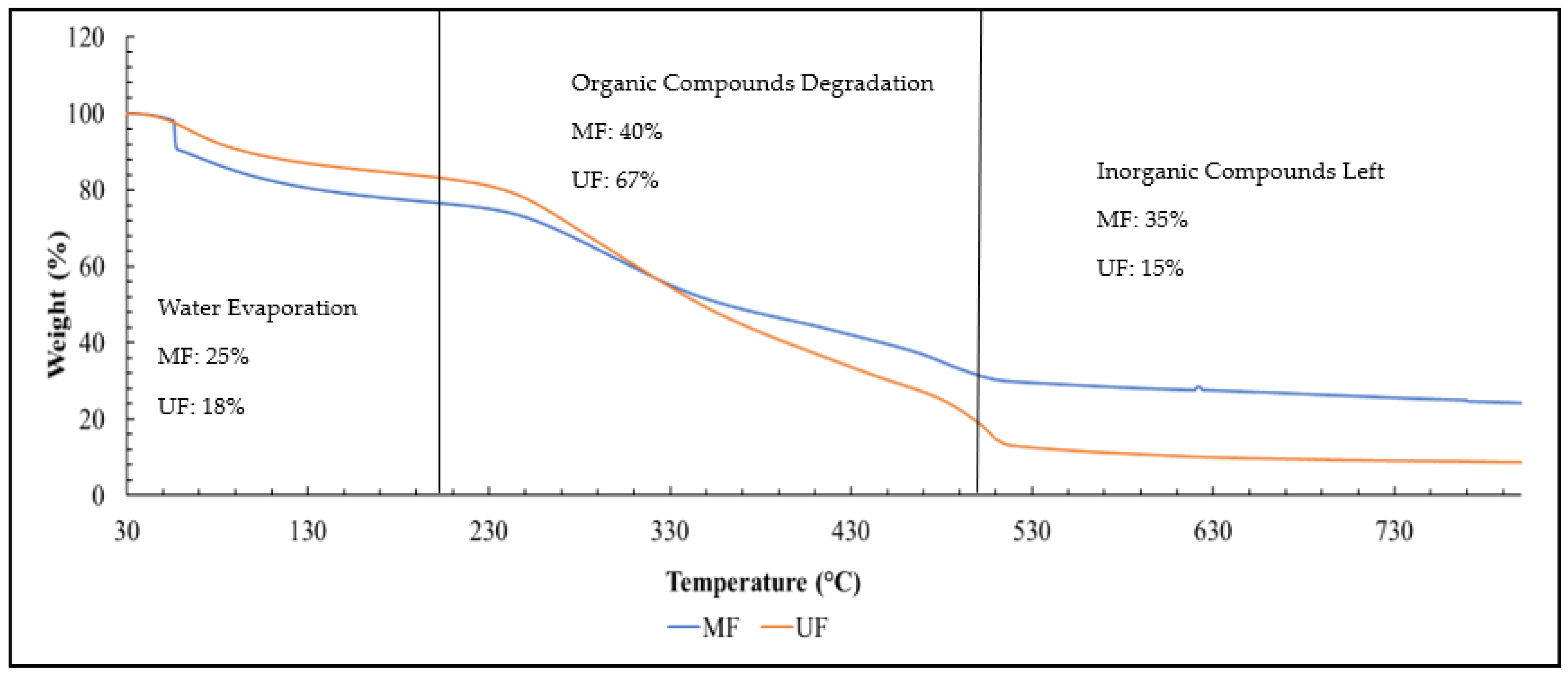

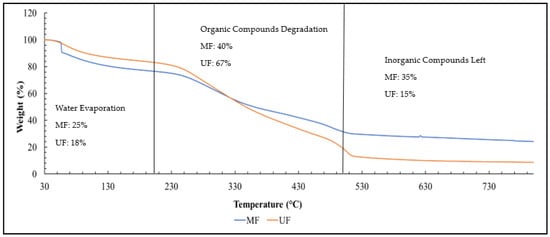

3.3.1. Thermogravimetric Analyzer

Weight loss analysis at different stages was used to quantify the proportion of organic and inorganic compounds in the MF and UF foulants. As displayed in Figure 3, up to 200 °C, the TGA curve showed a weight loss of around 25% for MF and about 18% for UF. This initial weight loss was caused by the evaporation of water molecules from the foulants, a characteristic seen in both MF and UF foulants. The degradation of organic compounds for MF and UF foulants occurred within the temperature range from 200 °C to 500 °C, accounting for approximately 40% of organics in MF foulants and 67% in UF foulants. The remaining weight percentage represents the quantity of inorganic compounds found in MF and UF, which were 35% and 15%, respectively. The TGA results corroborate the TVSs measurements, indicating that the UF achieved high removal efficiency of TVSs compared to that of MF. Consequently, UF fouling exhibited a higher concentration of organic compounds than MF fouling.

Figure 3.

TGA of UF and MF foulants.

The TGA graphs for both MF and UF foulants were very similar to one another, thus indicating that the MF and UF foulants have common organic components that break down at similar temperatures during TGA analysis.

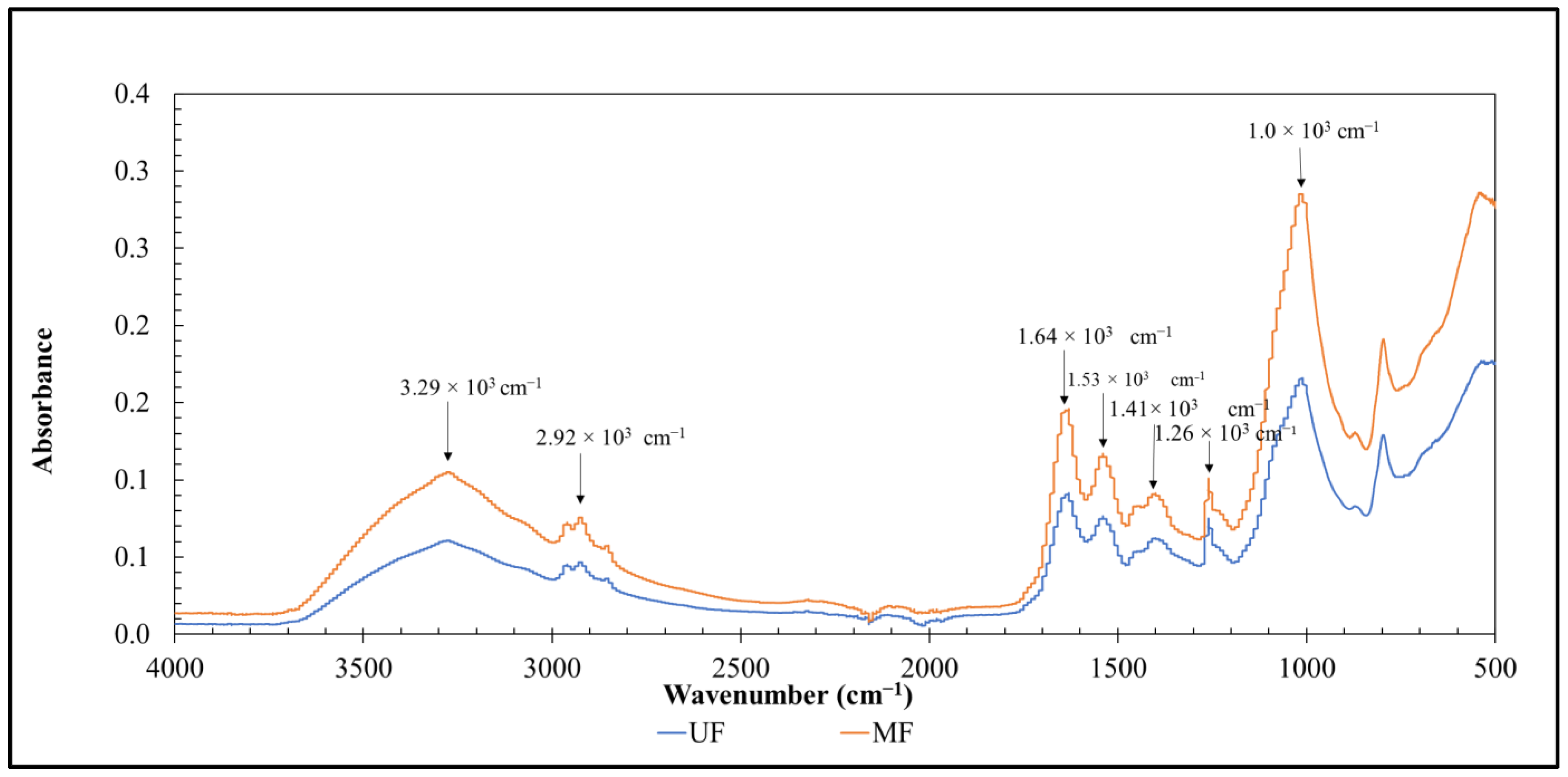

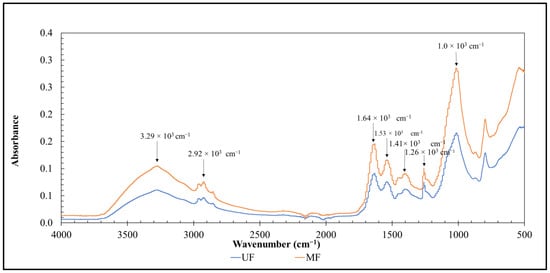

3.3.2. Fourier Transform Infrared Spectroscopy

FTIR is a rapid and accurate method for identifying functional groups, providing valuable information about the composition of foulants [39]. The FTIR analysis revealed that the MF and UF foulants contain very similar organic compounds, as similar bands were identified. For instance, the peak at 1000 cm−1 and 1260 cm−1 is associated with the C-O group in polysaccharides, and 1410 cm−1 represents the C-O group in hydroxy acid lipids, as shown in Figure 4. The 1530 cm−1 and 1640 cm−1 specify an amino group in proteins. The 2920 cm−1 shows the C-H group in fats and 3290 cm−1 exhibits the protein hydroxyl group.

Figure 4.

FTIR spectroscopy of MF and UF foulants.

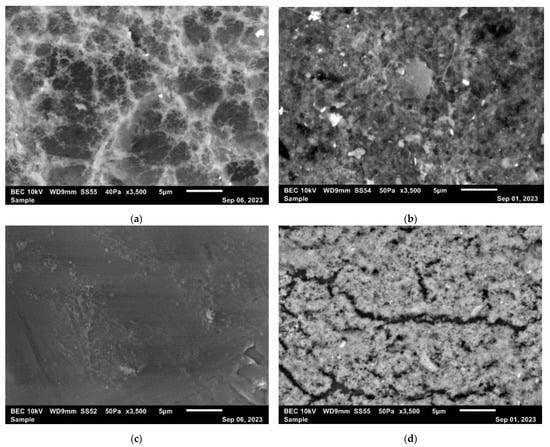

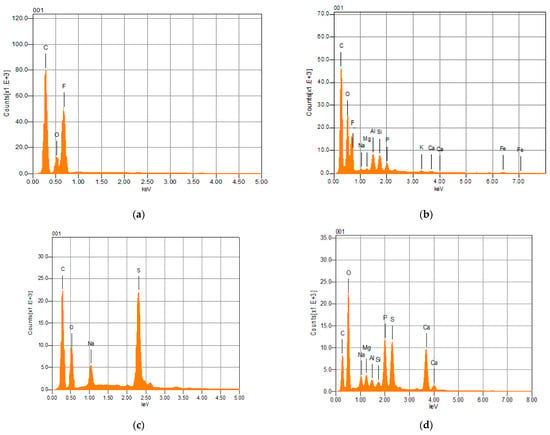

3.3.3. Scanning Electron Microscopy–Energy Dispersive X-ray Spectroscopy

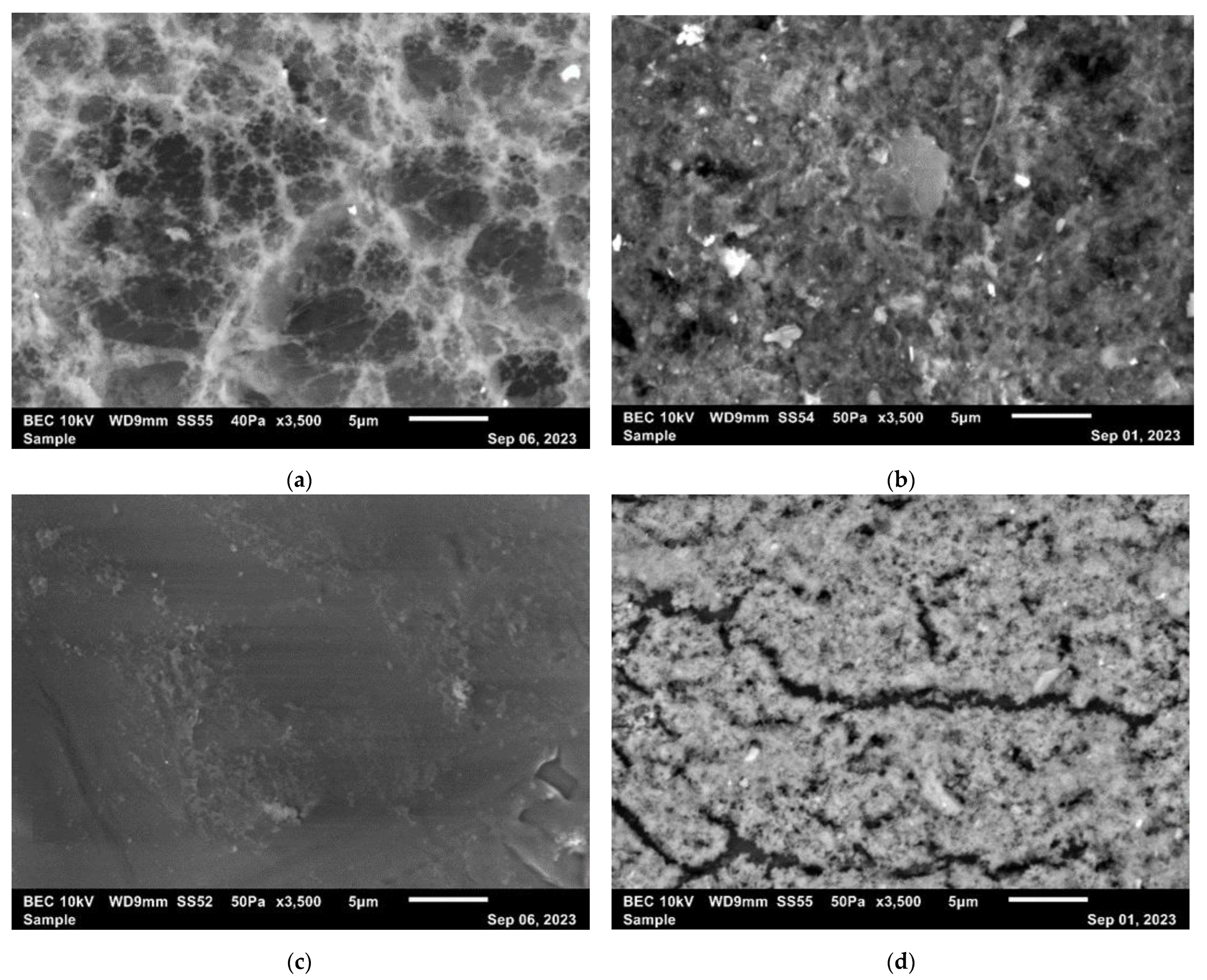

The MF and UF fouled and virgin membranes were analyzed using SEM-EDS. The SEM results showed a significant difference in the morphology between the virgin and fouled membranes in both the MF and UF categories. As illustrated in Figure 5a,c, the MF and UF virgin membranes displayed a smooth surface compared to the MF and UF fouled membranes in Figure 5b,d, in which a ridge structure is apparent. In the fouled membranes, the deposition of particles resulted in the amorphous matrix. This fouling layer introduced additional resistance to the MF and UF membranes, significantly reducing their filtration performance.

Figure 5.

SEM analysis of virgin and fouled membranes: (a) virgin MF membrane; (b) foulants on MF membrane; (c) virgin UF membrane; (d) foulants on UF membrane.

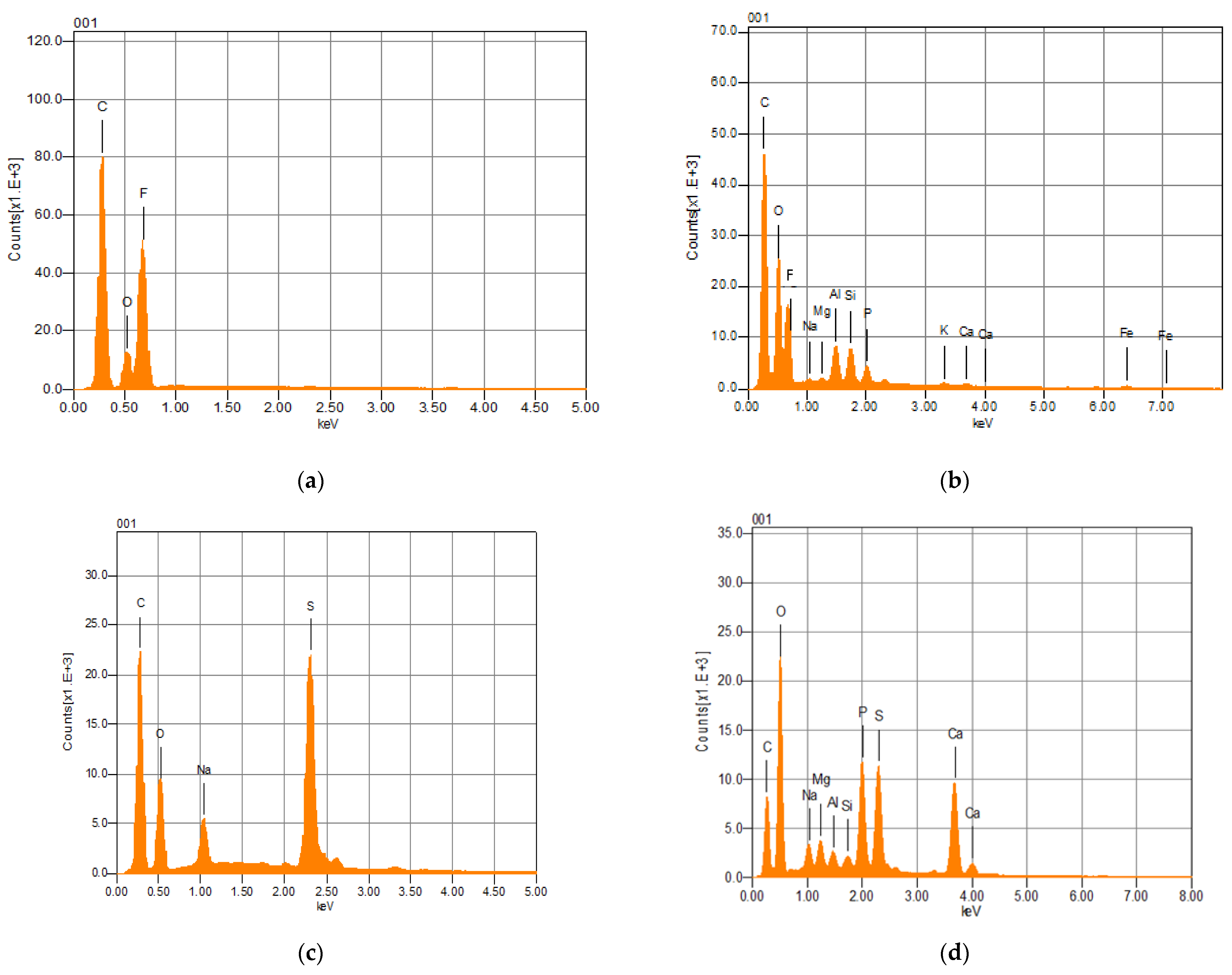

The EDS tool was used to analyze the elemental composition of the fouling layer on the membrane surface. In the case of the MF virgin membrane, the EDS showed the presence of carbon (C), oxygen (O), and fluorine (F), as shown in Figure 6a. However, the EDS for the fouled MF membrane presented significant peaks for elements such as sodium (Na), magnesium (Mg), aluminum (Al), silicon (Si), phosphorus (P), potassium (K), calcium (Ca), and iron (Fe), as displayed in Figure 6b. For the UF virgin membrane, the EDS revealed elemental peaks for C, O, Na, and sulfur (S), as shown in Figure 6c. However, the results for the fouled UF membrane indicated the presence of various inorganic elements, including Mg, Al, Si, P, and Ca, as presented in Figure 6d.

Figure 6.

EDS elemental analysis of fouled and virgin membranes. (a) MF virgin membrane; (b) MF fouled membrane; (c) UF virgin membrane; (d) UF fouled membrane.

These findings indicate that the foulants on both the MF and UF membrane surfaces consist of inorganic compounds containing elements such as Na, Mg, Al, Si, Ca, P, K, and Fe. Additionally, a significant rise in O in both the MF and UF membranes indicates the existence of organic compounds, like humic substances, proteins, or polysaccharides [40].

3.4. Treatment of Poultry Slaughterhouse Wastewater with Microfiltration–Reverse Osmosis, Ultrafiltration–Reverse Osmosis, and Direct Reverse Osmosis

3.4.1. Characterization of Microfiltration–Reverse Osmosis, Ultrafiltration–Reverse Osmosis, and Reverse Osmosis Permeate

The PSWW treatment with MF-RO, UF-RO, and RO achieved a 100% removal efficiency for TP and greater than a 91.2% removal efficacy for COD, as shown in Table 7. Furthermore, they removed over 87% of TSs from the PSWW. The TN level was reduced to 5 mg/L for MF-RO, 4 mg/L for UF-RO, and 9 mg/L for direct RO treatment. Meiramkulova et al. [30] studied the purification of PSWW by integrating membrane filtration with electrochemical pretreatment. Their research achieved comparable removal efficiencies of 99.76% for COD, and 96.77% and above 93.05% for phosphorus and nitrogen parameters, respectively.

Table 7.

Characterization of MF-RO, UF-RO, and direct RO permeate.

Among all three processes, UF-RO showed the highest pollutant removal efficiency, followed by MF-RO, with the second highest, and direct RO, with the lowest removal efficiency. Nevertheless, the parameters measured in the product water achieved through all of these processes meet the required U.S. standards, including TN levels less than 10 mg/L and TDS levels below 500 mg/L, suitable for wastewater in the poultry industry for poultry processing [41,42,43]. In our previous study, Fatima et al. [44], we used membrane technologies, including UF, forward osmosis, and RO to treat and recycle PSWW. The UF-FO-RO membrane process completely removed the TSs, TVSs, TFSs, and TP from PSWW. However, the level of TN was decreased to 22 mg/L, which exceeds the required limit of 10 mg/L for reusing PSWW. This research study explored a maximum of two membrane sequential processes, specifically MF-RO and UF-RO, and direct RO treatment for PSWW. Although the removal efficacy for the TSs, TVSs, and TFSs was less than that achieved with UF-FO-RO, these processes produced a permeate that meets potable water standards across all parameters.

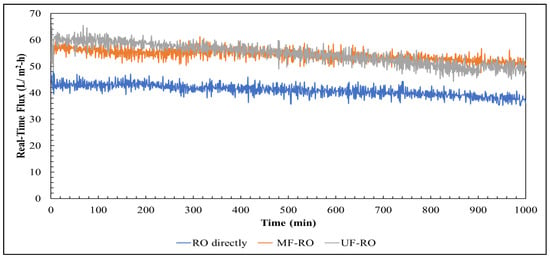

3.4.2. Real-Time Flux, Average Flux, and Rejection Coefficient of Microfiltration–Reverse Osmosis, Ultrafiltration–Reverse Osmosis, and Direct Reverse Osmosis

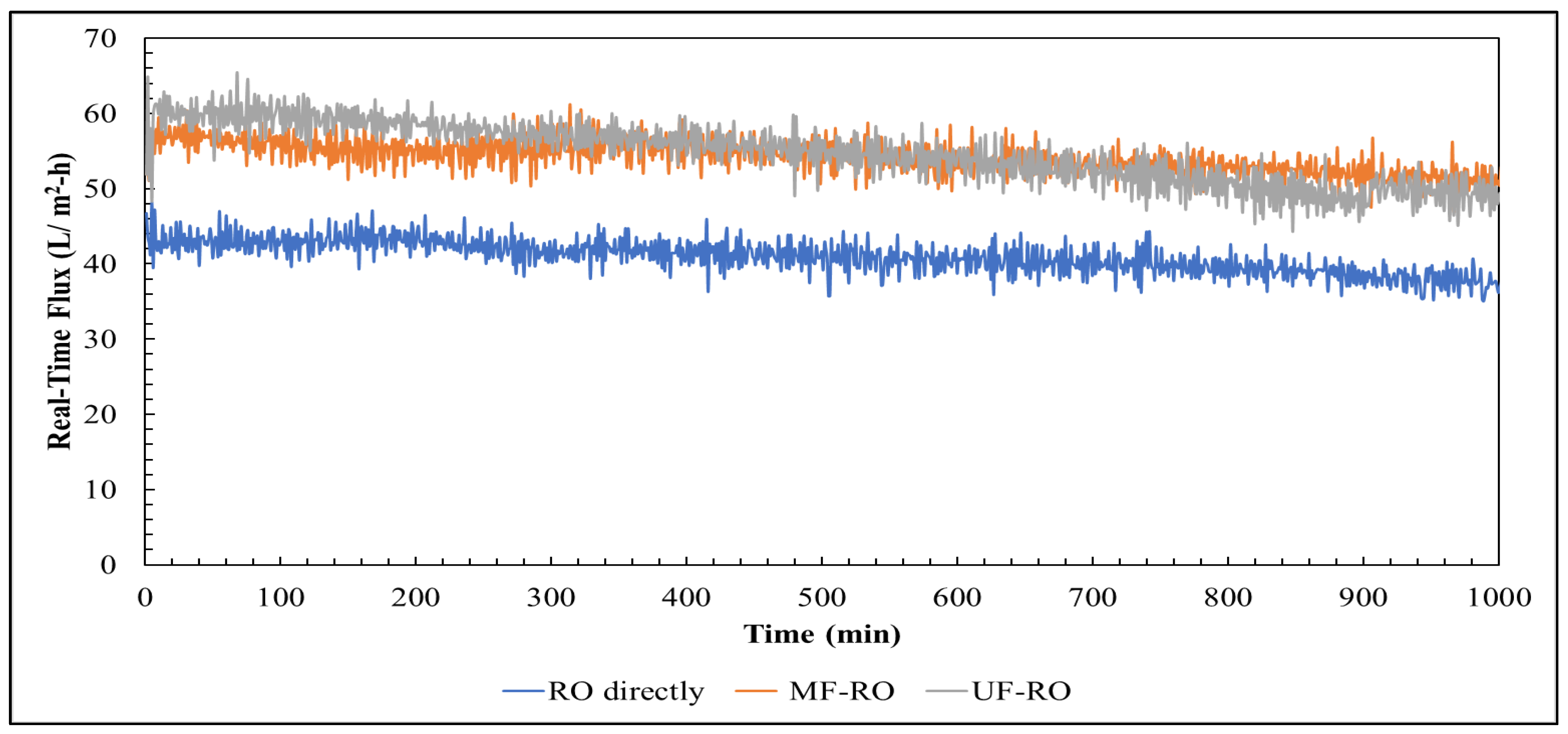

The real-time fluxes of MF-RO and UF-RO were very similar to one another. Both processes started at a flux of around 51 L/m2-h and maintained stability for 18 h. However, RO showed a lower initial flux of 46.8 L/m2-h, as shown in Figure 7. This observation highlights that employing MF or UF as a pretreatment for RO leads to a significant increase in water flux of approximately 9%, in accordance with the results of Coskun et al. [22]. In their research, UF as a pretreatment for RO increased membrane flux by 5.7 times.

Figure 7.

Real-time flux of MF-RO, UF-RO, and direct RO.

The average flux was 54.5 L/m2-h for MF-RO, 54.1 L/m2-h for UF-RO, and 40.8 L/m2-h for direct RO, as listed in Table 8. The rejection coefficient of the UF-RO process was the highest (0.96), resulting from a TDS concentration of 166 mg/L in the permeate and 5070 mg/L in the retentate. The rejection coefficient for the MF-RO process was the second highest (0.94), as the TDS concentration in the permeate was 250 mg/L, and 4800 mg/L in the retentate. The rejection coefficient for the direct RO process was the lowest (0.91) because the TDS concentration in the permeate was 325 mg/L and it was 3714 mg/L in the retentate. These results are justified by the data in Table 7, where UF-RO exhibited the highest removal efficiency, MF-RO is in the second position, and RO has the lowest removal efficiency.

Table 8.

Average flux and rejection coefficient (referring to TDSs) of MF-RO, UF-RO, and direct RO processes.

3.5. Economic Analysis

In poultry slaughterhouses, it is reported that 24.4 L of water per bird is used for poultry processing operations. Given that an average of 250,000 birds are processed daily at the Sanderson poultry processing plant, the total freshwater consumption will amount to 6098 m3/day.

3.5.1. Wastewater Treatment Cost

Considering the wastewater treatment unit cost for each process, which is 0.36 USD/m3 for conventional, 1.37 USD/m3 for MF-RO, 1.38 USD/m3 for UF-RO, and 3.8 USD/m3 for direct RO treatment as stated in Table 3, this results in a wastewater treatment cost of 823,535 USD/year for the conventional process, 3,049,305 USD/year for MF-RO, 3,071,563 USD/year for UF-RO, and 8,591,472 USD/year for RO, as listed in Table 9.

Table 9.

Economic analysis of MF-RO, UF-RO, and direct RO processes for PSWW treatment.

3.5.2. Freshwater Consumption Cost

For the RO process, 75% of water was recovered, as listed in Table 9. In the MF-RO process, 73.5% of wastewater was effectively recovered, calculated by considering the recovery rates of 98% for MF and 75% for RO. In the UF-RO process, a water recovery rate of 67.5% was achieved, calculated based on 90% UF water recovery and 75% RO water recovery. Considering the water recovery rates of 73.5%, 67%, and 75% in the MF-RO, UF-RO, and RO processes, the total freshwater consumption for MF-RO accounts for 1616 m3/day, 2012 m3/day for UF-RO, and 1524 m3/day for RO.

Considering the current local price of city freshwater, which is 0.8 USD/m3 in College Station, Texas [35], 1.36 USD/m3 in Arlington, Virginia [37], and 1.46 USD/m3 in Goodyear, Arizona [36], as listed in Table 4, the conventional method results in a freshwater consumption cost of 1,780,616 USD/year, 3,027,047 USD/year, and 3,249,624 USD/year for College Station, Texas, Arlington, Virginia, and Goodyear, Arizona, respectively. Using the same approach, the freshwater consumption costs for MF-RO, UF-RO, and RO have been calculated for specific regions, as shown in Table 9.

3.5.3. Total Cost

The total cost combines the freshwater consumption cost and wastewater treatment cost. In Texas, this results in costs of 2,604,151 USD/year for conventional, 3,521,177 USD/year for MF-RO, 3,659,067 USD/year for UF-RO, and 9,036,480 USD/year for RO treatment. In Virginia, the total cost amounts to 3,850,582 USD/year for conventional, 3,851,487 USD/year for MF-RO, 4,070,320 USD/year for UF-RO, and 9,347,986 USD/year for RO treatment. In Arizona, the total cost for conventional treatment is calculated as 4,073,159 USD/year, for MF-RO, it is 3,910,471 USD/year, for UF-RO, it is 4,143,758 USD/year, and for RO, it is 9,403,612 USD/year.

Table 9 shows that the total cost of MF-RO and UF-RO is very close across all of the regions. This similarity can be attributed to the fact that wastewater treatment costs were very close, with the unit costs of 1.37 USD/m3 and 1.38 USD/m3, respectively. Additionally, the water recovery for both processes varies by only 6%, resulting in a slight difference in freshwater consumption costs. Consequently, the total cost for MF-RO and UF-RO is comparable. However, given that this analysis was preliminary, we recommend conducting a detailed economic analysis of the MF-RO and UF-RO processes. This will provide a more comprehensive understanding of their respective costs and benefits.

Among all of the membrane processes under consideration, MF-RO emerges as the most economically efficient solution for recycling PSWW. The cost-effectiveness of the MF-RO process can be attributed to two key factors: a lower pressure and high flux, which enable high water recovery. The combination of these factors positions MF-RO as the most economical choice for PSWW treatment. The second most cost-effective option is UF-RO, with costs closely approaching those of MF-RO. However, direct PSWW treatment with RO proves to be expensive, approximately 2.6 times higher compared to the cost of treating PSWW with MF-RO due to its substantial fouling-related maintenance expenses. This highlights the significant cost-saving impact of pretreatment, reducing RO expenses by a considerable percentage.

Furthermore, two states of the USA, Virginia and Arizona, are facing water scarcity issues, resulting in elevated water prices. The current water price in Arlington, Virginia, is 1.36 USD/m3 [37], and in Goodyear, Arizona, it is 1.46 USD/m3 [36]. The high water prices in these regions can be attributed to various factors, including the impacts of climate change such as increased temperatures and prolonged droughts, along with insufficient management of freshwater resources and inadequate water infrastructure [45,46]. The high freshwater consumption cost in Virginia and Arizona has shown that the cost of recycling wastewater using advanced membrane technologies is somewhat comparable to the total cost of conventional water use and wastewater management. This suggests that over time, membrane technology will become economically viable, while also making a significant contribution to water conservation for human consumption and addressing water scarcity issues.

Despite the increasing viability of membrane technology over time, it will still encounter limitations such as the end of life (EOL) of membranes due to irreversible fouling, and the disposal of EOL membranes will negatively impact the environment. Therefore, research has been conducted on recycling EOL membranes to improve their sustainability, which has shown promising results [47]. Sielbal et al. [48] explored transforming the spent RO membrane into another useful membrane through oxidation of the active layer. Their results showed that the RO membrane was successfully recycled to have characteristics similar to the NF membrane, effectively treating brackish and surface water. The study conducted by Chen et al. [47] showed that the closed-loop cycle reduced membrane production and disposal, thereby reducing CO2 emissions by 24% along with 27% of environmental and economic impacts compared to membranes without recycling. All of these studies indicate that the limitations of membrane technology are being addressed, which would make membrane technology more economical in use.

4. Conclusions

It is concluded that PSWW treatment using MF-RO, UF-RO, and direct RO meets the standards for potable water quality required for reusing wastewater in the poultry industry. However, using MF and UF pretreatment methods before RO yields remarkable performance improvements. It results in a 9% increase in membrane flux, higher pollutant removal efficiencies from wastewater, and substantial reductions in RO membrane costs. The cost of RO without pretreatment is high due to expenses associated with fouling and maintenance. The foulants in the pretreatment primarily consist of organic compounds such as proteins and carbohydrates found in algae and colloids, along with some inorganic matter. Considering the economic analysis and removal efficiency, MF-RO emerges as the most cost-efficient option, followed by UF-RO and RO alone. These results suggest that a combination of the MF-RO membrane process holds excellent promise for PSWW treatment, specifically in areas where freshwater prices are high due to water scarcity issues. Overall, MF-RO demonstrates outstanding performance by delivering high efficiency in pollutant removal and recovering valuable products, all while maintaining economic efficiency. This study proposes that the MF-RO process is a sustainable approach to addressing the potable water shortage crisis, demonstrating excellence in treating PSWW. To broaden its impact on additional sustainable uses, future directions should involve evaluating the MF-RO combination for various wastewater types. Furthermore, there should be a concerted focus on implementing strategies to not only enhance the overall cost efficiency of this process but also to incorporate measures that strengthen its sustainability.

Author Contributions

Conceptualization, F.F., H.D. and R.R.K.; methodology, F.F. and S.F.; resources, R.R.K.; data curation, F.F. and S.F.; writing—original draft preparation, F.F.; writing—review and editing, S.F., H.D. and R.R.K.; supervision, R.R.K.; project administration, R.R.K.; funding acquisition, R.R.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was mainly funded by the USDA-National Institute of Food and Agriculture, grant number 2020-38821-31091, and partial support was received from the National Science Foundation CREST Center for Energy & Environmental Sustainability, NSF grant number 1914692.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study, in the collection, analyses, or interpretation of data, in the writing of the manuscript, or in the decision to publish the results.

Abbreviation

| COD | Chemical oxygen demand |

| EDS | Energy dispersive X-ray spectroscopy |

| FTIR | Fourier-transform infrared spectroscopy |

| Jav | Average flux |

| Jw | Real-time flux |

| MF | Microfiltration |

| MWCO | Molecular weight cut-off |

| PES | Polyether sulfone |

| PVDF | Polyvinylidene fluoride |

| PSWW | Poultry slaughterhouse wastewater |

| R | Rejection coefficient |

| RO | Reverse osmosis |

| SEM | Scanning electron microscopy |

| TGA | Thermogravimetric analysis |

| TDSs | Total dissolved solids |

| TFSs | Total fixed solids |

| TN | Total nitrogen |

| TP | Total phosphorous |

| TSs | Total solids |

| TSSs | Total suspended solids |

| TVSs | Total volatile solids |

| UF | Ultrafiltration |

References

- Issaoui, M.; Jellali, S.; Zorpas, A.A.; Dutournie, P. Membrane Technology for Sustainable Water Resources Management: Challenges and Future Projections. Sustain. Chem. Pharm. 2022, 25, 100590. [Google Scholar] [CrossRef]

- Garnier, C.; Guiga, W.; Lameloise, M.L.; Degrand, L.; Fargues, C. Treatment of Cauliflower Processing Wastewater by Nanofiltration and Reverse Osmosis in View of Recycling. J. Food Eng. 2022, 317, 110863. [Google Scholar] [CrossRef]

- Baker, B.R.; Mohamed, R.; Al-Gheethi, A.; Aziz, H.A. Advanced Technologies for Poultry Slaughterhouse Wastewater Treatment: A Systematic Review. J. Dispers. Sci. Technol. 2020, 42, 880–899. [Google Scholar] [CrossRef]

- Optimizing Water Reuse in Meat and Poultry Processing. Available online: https://www.watertechonline.com/water-reuse/article/14223701/optimizing-water-reuse-in-meat-and-poultry-processing (accessed on 25 September 2023).

- Maggie, N.; Bingoa, M.B.; Ntwampea, S.K.O. Poultry Slaughterhouse Wastewater Treatment Plant Design Advancements. In Proceedings of the 16th SOUTH AFRICA Int’l Conference on Agricultural, Chemical, Biological & Environmental Sciences, Johannesburg, South Africa, 18–19 November 2019. [Google Scholar]

- Njoya, M.; Basitere, M.; Ntwampe, S.K.O. Analysis of the Characteristics of Poultry Slaughterhouse Wastewater (PSW) and Its Treatability. Water Pract. Technol. 2019, 14, 959–970. [Google Scholar] [CrossRef]

- Ng, M.; Dalhatou, S.; Wilson, J.; Kamdem, B.P.; Temitope, M.B.; Paumo, H.K.; Djelal, H.; Assadi, A.A.; Nguyen-tri, P.; Kane, A. Characterization of Slaughterhouse Wastewater and Development of Treatment Techniques: A Review. Processes 2022, 10, 1300. [Google Scholar] [CrossRef]

- Fatima, F.; Du, H.; Kommalapati, R.R. Treatment of Poultry Slaughterhouse Wastewater with Membrane Technologies: A Review. Water 2021, 13, 1905. [Google Scholar] [CrossRef]

- Matsumura, E.M.; Mierzwa, J.C. Water Conservation and Reuse in Poultry Processing Plant-A Case Study. Resour. Conserv. Recycl. 2008, 52, 835–842. [Google Scholar] [CrossRef]

- Shih, J.C.H.; Kozink, M.B. Ultrafiltration Treatment of Poultry Processing Wastewater and Recovery of a Nutritional By-Product. Poult. Sci. 1980, 59, 247–252. [Google Scholar] [CrossRef]

- Brião, V.B.; Vieira Salla, A.C.; Miorando, T.; Hemkemeier, M.; Cadore Favaretto, D.P. Water Recovery from Dairy Rinse Water by Reverse Osmosis: Giving Value to Water and Milk Solids. Resour. Conserv. Recycl. 2019, 140, 313–323. [Google Scholar] [CrossRef]

- Zheng, L.; Wang, X.; Wang, X. Reuse of Reverse Osmosis Concentrate in Textile and Dyeing Industry by Combined Process of Persulfate Oxidation and Lime-Soda Softening. J. Clean. Prod. 2015, 108, 525–533. [Google Scholar] [CrossRef]

- Egea-Corbacho Lopera, A.; Gutiérrez Ruiz, S.; Quiroga Alonso, J.M. Removal of Emerging Contaminants from Wastewater Using Reverse Osmosis for Its Subsequent Reuse: Pilot Plant. J. Water Process Eng. 2019, 29, 100800. [Google Scholar] [CrossRef]

- Yildirim, O.; Tunay, D.; Ozkaya, B. Reuse of Sea Water Reverse Osmosis Brine to Produce Dunaliella Salina Based β-Carotene as a Valuable Bioproduct: A Circular Bioeconomy Perspective. J. Environ. Manag. 2022, 302, 114024. [Google Scholar] [CrossRef]

- Hernández, K.; Muro, C.; Ortega, R.E.; Velazquez, S.; Riera, F. Water Recovery by Treatment of Food Industry Wastewater Using Membrane Processes. Environ. Technol. 2021, 42, 775–788. [Google Scholar] [CrossRef]

- Jafarinejad, S.; Jafarinejad, S. A Comprehensive Study on the Application of Reverse Osmosis (RO) Technology for the Petroleum Industry Wastewater Treatment. J. Water Environ. Nanotechnol. 2017, 2, 243–264. [Google Scholar] [CrossRef]

- Ezugbe, E.O.; Rathilal, S. Membrane Technologies in Wastewater Treatment: A Review. Membranes 2020, 10, 89. [Google Scholar] [CrossRef]

- Zubair, M.M.; Saleem, H.; Zaidi, S.J. Recent Progress in Reverse Osmosis Modeling: An Overview. Desalination 2023, 564, 116705. [Google Scholar] [CrossRef]

- Ahmed, M.A.; Amin, S.; Mohamed, A.A. Fouling in Reverse Osmosis Membranes: Monitoring, Characterization, Mitigation Strategies and Future Directions. Heliyon 2023, 9, e14908. [Google Scholar] [CrossRef]

- Malaeb, L.; Ayoub, G.M. Reverse Osmosis Technology for Water Treatment: State of the Art Review. Desalination 2011, 267, 1–8. [Google Scholar] [CrossRef]

- Jamaly, S.; Darwish, N.N.; Ahmed, I.; Hasan, S.W. A Short Review on Reverse Osmosis Pretreatment Technologies. Desalination 2014, 354, 30–38. [Google Scholar] [CrossRef]

- Coskun, T.; Debik, E.; Kabuk, H.A.; Manav Demir, N.; Basturk, I.; Yildirim, B.; Temizel, D.; Kucuk, S. Treatment of Poultry Slaughterhouse Wastewater Using a Membrane Process, Water Reuse, and Economic Analysis. Desalin. Water Treat. 2016, 57, 4944–4951. [Google Scholar] [CrossRef]

- Meiramkulova, K.; Zorpas, A.A.; Orynbekov, D.; Zhumagulov, M.; Saspugayeva, G.; Kydyrbekova, A.; Mkilima, T.; Inglezakis, V.J. The Effect of Scale on the Performance of an Integrated Poultry Slaughterhouse Wastewater Treatment Process. Sustainability 2020, 12, 4679. [Google Scholar] [CrossRef]

- Abboah-afari, E.; Kiepper, B.H. Membrane Filtration of Poultry Processing Wastewater: I. Pre-DAF (Dissolved Air Flotation). Appl. Eng. Agric. 2012, 28, 231–236. [Google Scholar] [CrossRef]

- Abboah-afari, E.; Kiepper, B.H. The Use of Membrane Filtration as an Alternative Pretreatment Method For Poultry Processing Wastewater. In Proceedings of the 2011 Georgia Water Resources Conference, Athens, GA, USA, 11–13 April 2011. [Google Scholar]

- Yordanov, D. Preliminary Study of the Efficiency of Ultrafiltration Treatment of Poultry Slaughterhouse Wastewater. Bulg. J. Agric. Sci. 2010, 16, 700–704. [Google Scholar]

- Marchesi, C.M.; Paliga, M.; Oro, C.E.D.; Dallago, R.M.; Zin, G.; Di Luccio, M.; Oliveira, J.V.; Tres, M.V. Use of Membranes for the Treatment and Reuse of Water from the Pre-Cooling System of Chicken Carcasses. Environ. Technol. 2019, 42, 126–133. [Google Scholar] [CrossRef]

- Mannapperuma, J.D.; Santos, M.R. Reconditioning of Poultry Chiller Overflow by Ultrafiltration. J. Food Process Eng. 2004, 27, 497–516. [Google Scholar] [CrossRef]

- Basitere, M.; Rinquest, Z.; Njoya, M.; Sheldon, M.S.; Ntwampe, S.K.O. Treatment of Poultry Slaughterhouse Wastewater Using a Static Granular Bed Reactor (SGBR) Coupled with Ultrafiltration (UF) Membrane System. Water Sci. Technol. 2017, 76, 106–114. [Google Scholar] [CrossRef]

- Meiramkulova, K.; Devrishov, D.; Zhumagulov, M.; Arystanova, S.; Karagoishin, Z.; Marzanova, S.; Kydyrbekova, A.; Mkilima, T.; Li, J. Performance of an Integrated Membrane Process with Electrochemical Pre-Treatment on Poultry Slaughterhouse Wastewater Purification. Membranes 2020, 10, 256. [Google Scholar] [CrossRef]

- UF Flat-Sheet Performance Comparison by Manufacturer. Available online: https://www.sterlitech.com/sy-mk-ultrafiltration-uf-membrane-cf042-size.html (accessed on 25 September 2023).

- RO Flat-Sheet Performance Comparison by Manufacturer. Available online: https://www.sterlitech.com/dow-sw30xfr-reverse-osmosis-ro-membrane-305-x-305-mm-size.html (accessed on 25 September 2023).

- MF Flat-Sheet Performance Comparison by Manufacturer. Available online: https://www.sterlitech.com/synder-membrane-filters-v0-2-pvdf-mf-150mm-5-pk.html (accessed on 25 September 2023).

- Pérez, G.; Gómez, P.; Ortiz, I.; Urtiaga, A. Techno-Economic Assessment of a Membrane-Based Wastewater Reclamation Process. Desalination 2022, 522, 115409. [Google Scholar] [CrossRef]

- College Station Water Rates. Available online: https://opendoc.cstx.gov/DocArc/Browse.aspx?id=1444875&dbid=0&repo=DOCUMENT-SERVER&cr=1 (accessed on 7 February 2024).

- Arizona Water Rates. Available online: https://www.goodyearaz.gov/government/departments/finance/utilities-customer-service/service-rates (accessed on 7 February 2024).

- Virginia Water Rates. Available online: https://www.arlingtonva.us/Government/Programs/Water-Utilities/Customer-Service/Rates (accessed on 7 February 2024).

- Goswami, K.P.; Pugazhenthi, G. Treatment of Poultry Slaughterhouse Wastewater Using Tubular Microfiltration Membrane with Fly Ash as Key Precursor. J. Water Process Eng. 2020, 37, 101361. [Google Scholar] [CrossRef]

- Amir, R.M.; Anjum, F.M.; Khan, M.I.; Khan, M.R.; Pasha, I.; Nadeem, M. Application of Fourier Transform Infrared (FTIR) Spectroscopy for the Identification of Wheat Varieties. J. Food Sci. Technol. 2013, 50, 1018–1023. [Google Scholar] [CrossRef]

- Phukan, R.; Guttierez, L.; De Schepper, W.; Vanoppen, M.; Verbeken, K.; Raes, K.; Verliefde, A.; Cornelissen, E. Short Term Fouling Tests on Homogeneous and Heterogeneous Anion-Exchange Membranes from Food and Bio-Based Industrial Streams: Foulant Identification and Characterization. Sep. Purif. Technol. 2023, 322, 124247. [Google Scholar] [CrossRef]

- Total Nitrogen. Available online: https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=P10070OQ.TXT (accessed on 7 February 2024).

- Drinking Water Regulations and Contaminants. Available online: https://www.epa.gov/sdwa/drinking-water-regulations-and-contaminants (accessed on 7 February 2024).

- Summary Table for Evaluation of Drinking Water Quality Goals. Available online: https://www.waterboards.ca.gov/rwqcb5/water_issues/drinking_water_policy/summary_table.pdf (accessed on 7 February 2024).

- Fatima, F.; Du, H.; Kommalapati, R.R. A Sequential Membrane Process of Ultrafiltration Forward Osmosis and Reverse Osmosis for Poultry Slaughterhouse Wastewater Treatment and Reuse. Membranes 2023, 13, 296. [Google Scholar] [CrossRef] [PubMed]

- Perceptions of Water Scarcity in Charlottesville, Virginia. Available online: https://libraetd.lib.virginia.edu/public_view/v118rg170 (accessed on 7 February 2024).

- Drought. Available online: https://www.azwater.gov/drought/drought-status (accessed on 7 February 2024).

- Chen, J.; Dai, R.; Wang, Z. Closing the Loop of Membranes by Recycling End-of-Life Membranes: Comparative Life Cycle Assessment and Economic Analysis. Resour. Conserv. Recycl. 2023, 198, 107153. [Google Scholar] [CrossRef]

- Seibel, F.I.; Brião, V.B.; Maxime, P.; Seibel, F.I.; Otávio, G.; Giubel, M.; Barbosa Brião, V.; Shabani, M.; Pontié, M. End-of-Life Reverse Osmosis Membranes: Recycle Procedure and Its Applications for the Treatment of Brackish. J. Appl. Res. Water Wastewater 2021, 8, 77–87. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).