A Comparative Study on Extraction and Physicochemical Properties of Soluble Dietary Fiber from Glutinous Rice Bran Using Different Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Hot Water Extraction

2.4. Ultrasound-Assisted Enzymatic Extraction

2.5. Characterization of Purity and Yield of Soluble Dietary Fiber

2.6. Fourier Transform Infrared Spectroscopy (FTIR)

2.7. Physicochemical Properties of Soluble Dietary Fiber from Glutinous Rice Bran

2.7.1. Color Difference

2.7.2. Solubility (S)

2.7.3. Water-Holding Capacity (WHC)

2.7.4. Swelling Capacity (SC)

2.8. Statistical Analysis

3. Results and Discussion

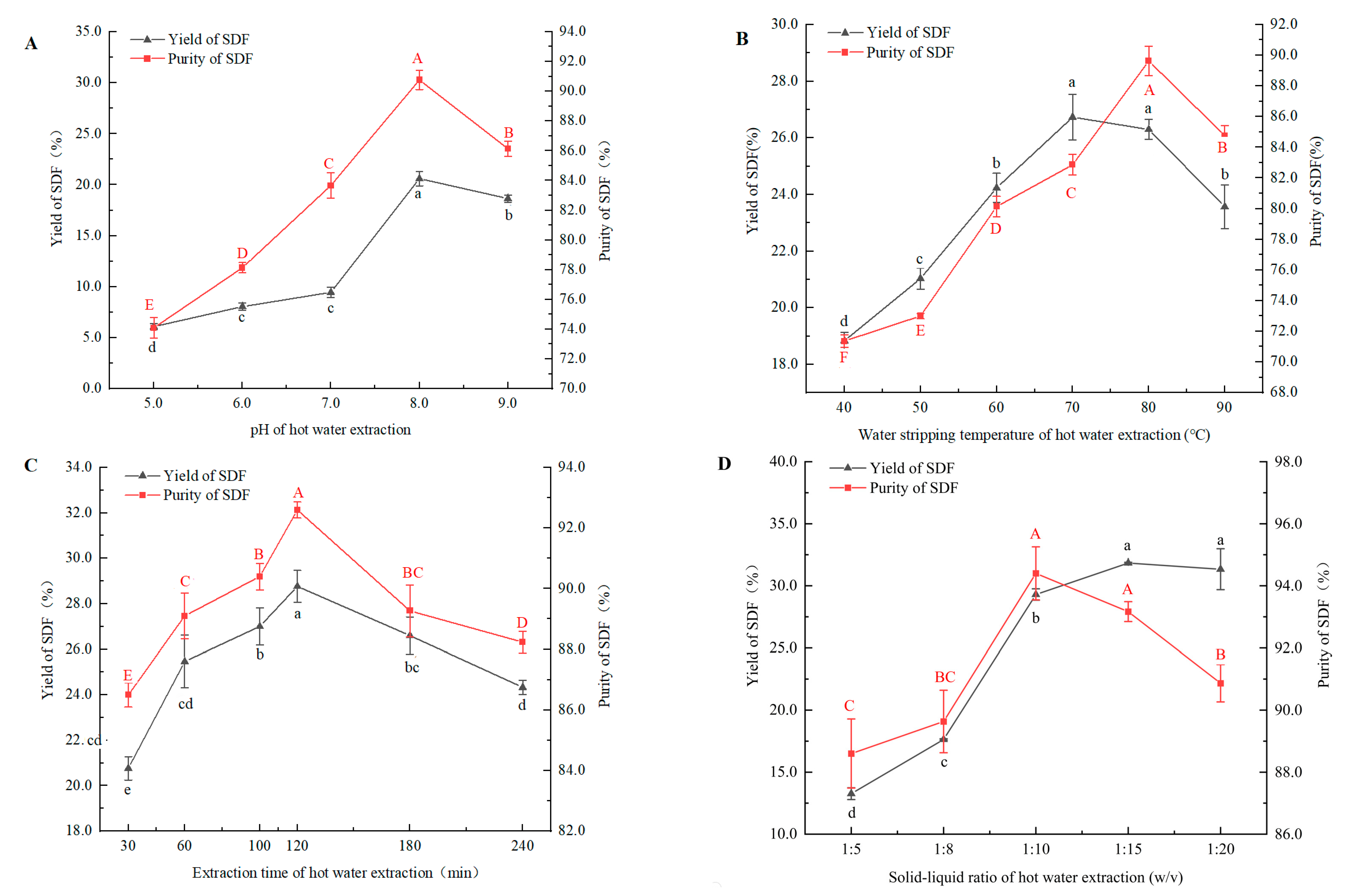

3.1. Hot Water Extraction

3.1.1. Effect of pH on SDF Yield and Purity

3.1.2. Effect of Extraction Temperature on SDF Yield and Purity

3.1.3. Effect of Extraction Time on SDF Yield and Purity

3.1.4. Effect of Solid-Liquid Ratio on SDF Yield and Purity

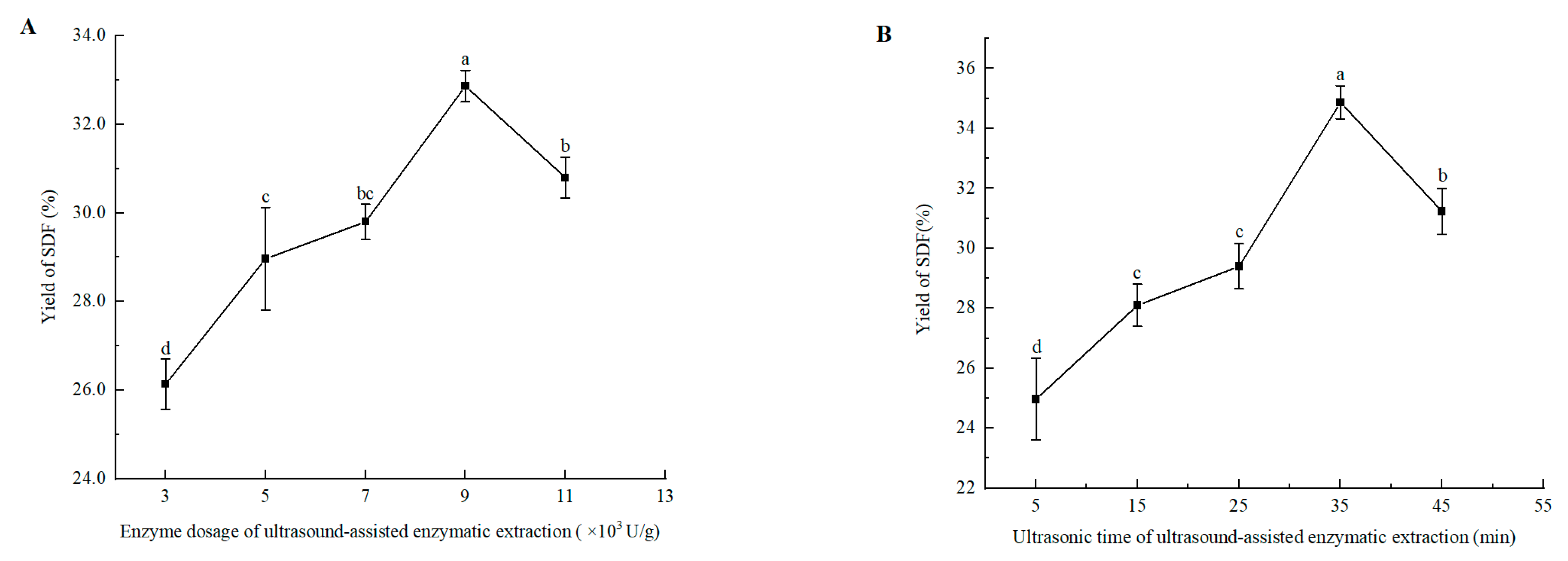

3.2. Ultrasound-Assisted Enzymatic Extraction

3.2.1. Effect of Cellulase Dosage on SDF Yield

3.2.2. Effect of Ultrasonic Time on SDF Yield

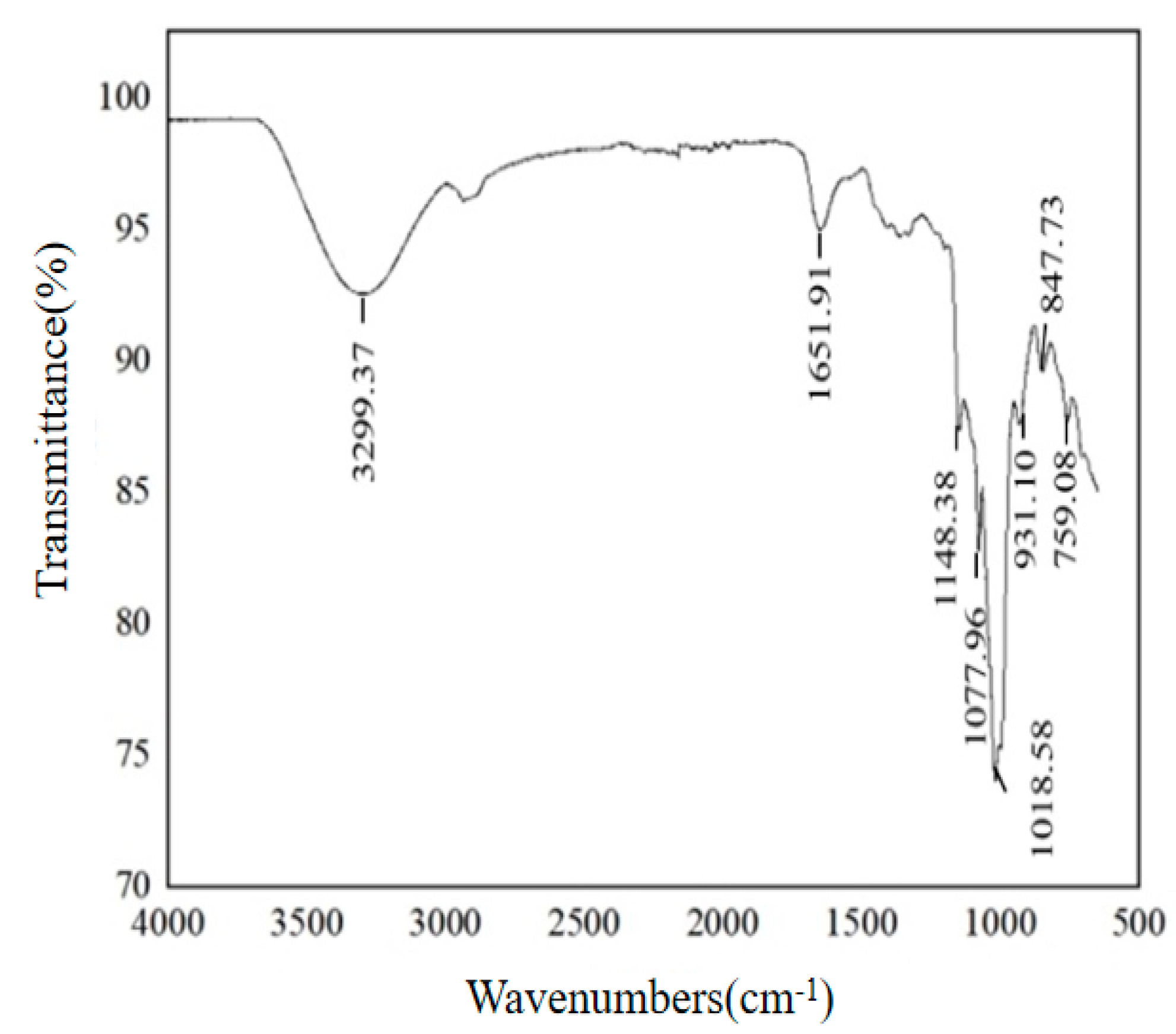

3.3. FTIR

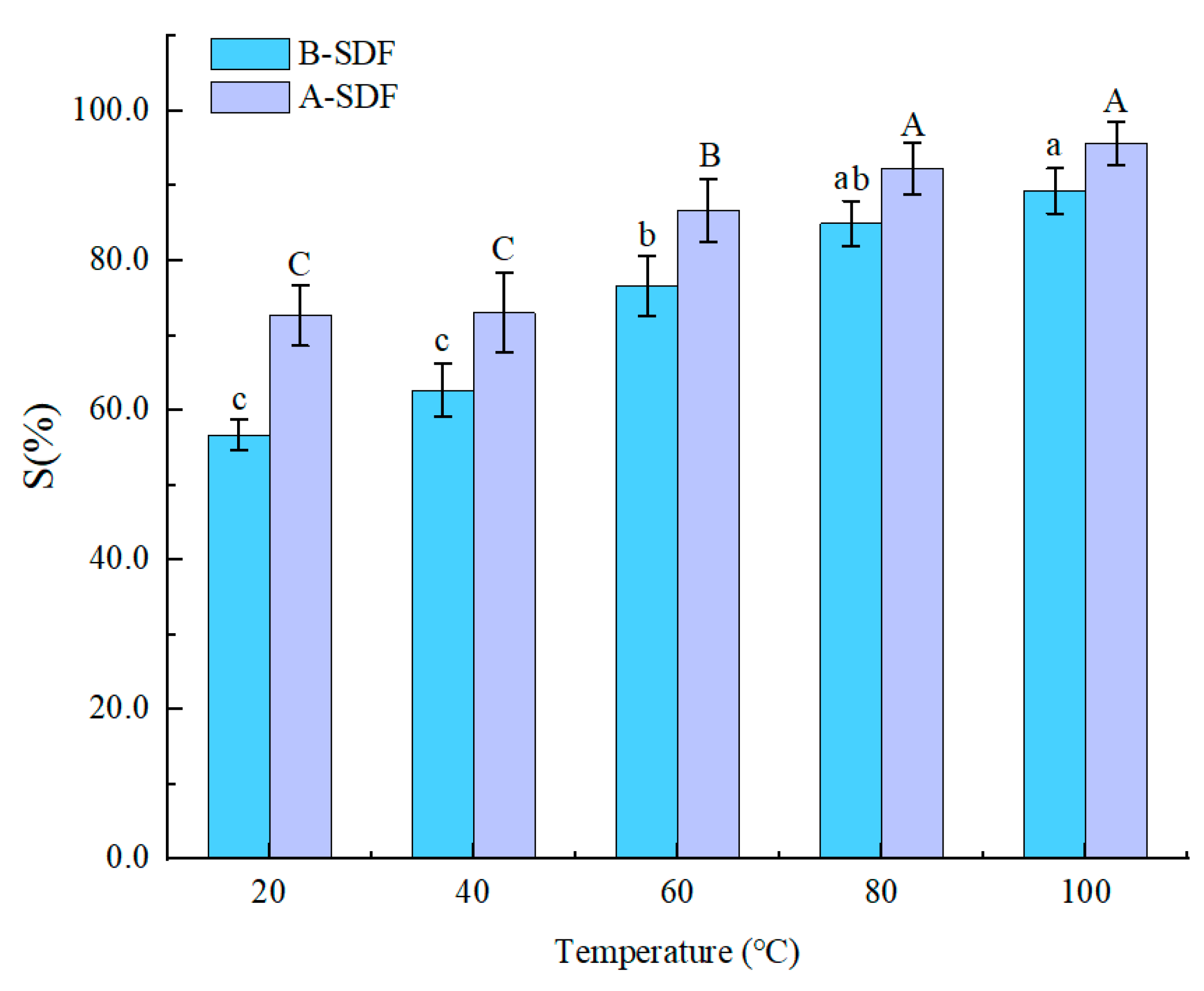

3.4. Physicochemical Properties

3.4.1. Color Difference

3.4.2. Solubility (S)

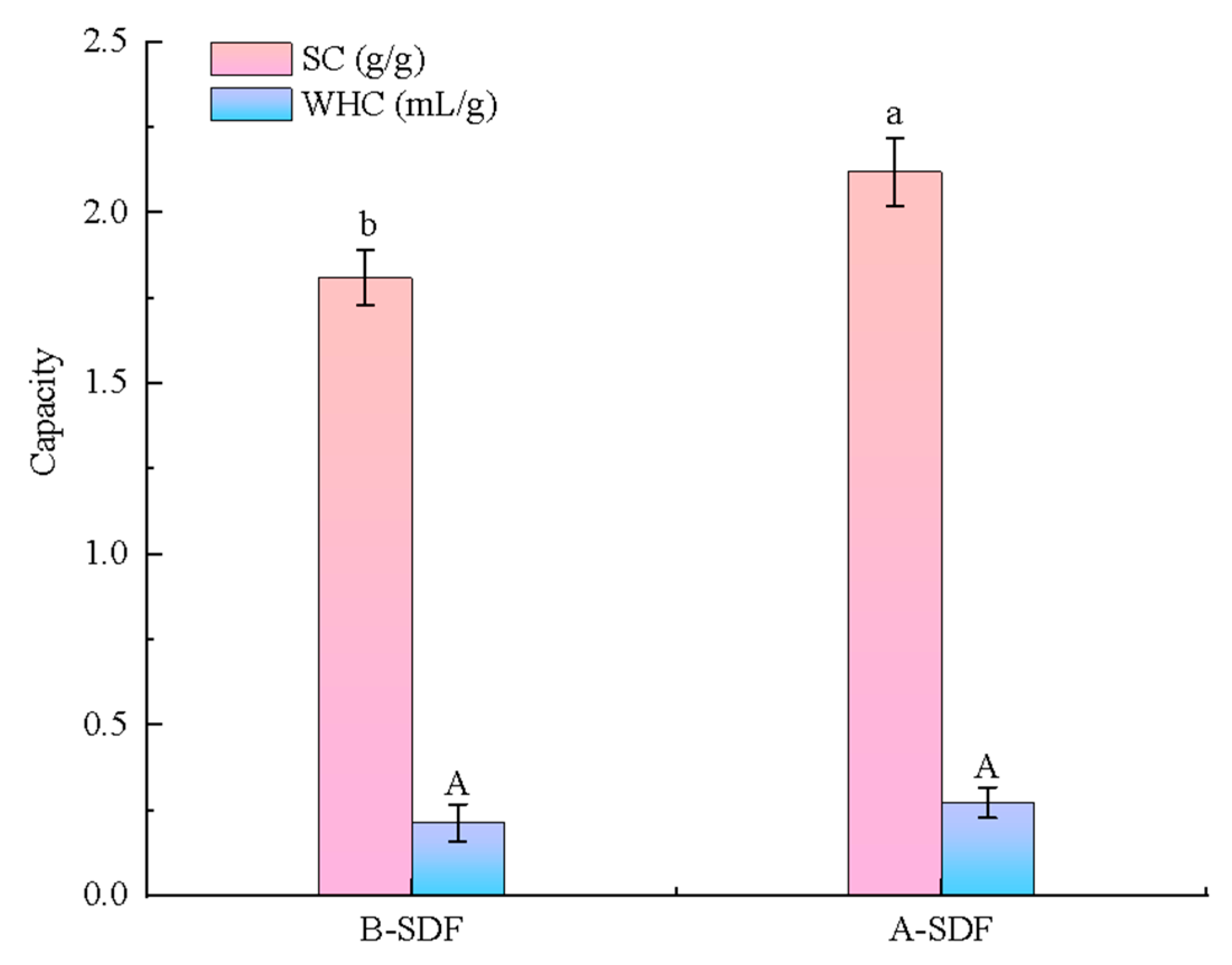

3.4.3. WHC and SC

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Man, L.; Xuezhi, L.; Shengmin, Z.; Wang, T.T.Y.; Sihan, Z.; Kunlong, Y.; Yongxin, L.; Jun, T.; Jing, W. Dietary fiber isolated from sweet potato residues promotes a healthy gut microbiome profile. Food Funct. 2020, 11, 689–699. [Google Scholar] [CrossRef]

- Dong, W.; Wang, D.; Hu, R.; Long, Y.; Lv, L. Chemical composition, structural and functional properties of soluble dietary fiber obtained from coffee peel using different extraction methods. Food Res. Int. 2020, 136, 109497. [Google Scholar] [CrossRef]

- Gidley, M.J.; Yakubov, G.E. Functional categorisation of dietary fibre in foods: Beyond ‘soluble’ vs ‘insoluble’. Trends Food Sci. Technol. 2019, 86, 563–568. [Google Scholar] [CrossRef]

- Elleuch, M.; Bedigian, D.; Roiseux, O.; Besbes, S.; Blecker, C.; Attia, H. Dietary fibre and fibre-rich by-products of food processing: Characterisation, technological functionality and commercial applications: A review. Food Chem. 2010, 124, 411–421. [Google Scholar] [CrossRef]

- Du, X.; Wang, L.; Huang, X.; Jing, H.; Wang, H. Effects of different extraction methods on structure and properties of soluble dietary fiber from defatted coconut flour. LWT-Food Sci. Technol. 2021, 143, 111031. [Google Scholar] [CrossRef]

- Sattaka, P. Geographical distribution of glutinous rice in the Greater Mekong sub-region. J. Mekong Soc. 2016, 12, 27–48. [Google Scholar]

- Kamran, S.M.; Sadiq, B.M.; Muhammad, A.F.; Hafiz, K.S. Rice bran: A novel functional ingredient. Crit. Rev. Food Sci. Nutr. 2014, 54, 807–816. [Google Scholar] [CrossRef]

- Lloyd, B.J.; Siebenmorgen, T.J.; Beers, K.W. Effects of Commercial Processing on Antioxidants in Rice Bran. Cereal Chem. 2000, 77, 551–555. [Google Scholar] [CrossRef]

- Lamberts, L.; Delcour, J.A. Carotenoids in Raw and Parboiled Brown and Milled Rice. J. Agric. Food Chem. 2008, 56, 11914. [Google Scholar] [CrossRef]

- Bhunia, R.K.; Sinha, K.; Kaur, R.; Kaur, S.; Chawala, K. A Holistic View of the Genetic Factors Involved in Triggering Hydrolytic and Oxidative Rancidity of Rice Bran Lipids. Food Rev. Int. 2021. [Google Scholar] [CrossRef]

- Daou, C.; Zhang, H. Functional and physiological properties of total, soluble, and insoluble dietary fibres derived from defatted rice bran. J. Food Sci. Technol. 2014, 51, 3878–3885. [Google Scholar] [CrossRef] [PubMed]

- Hu, K.; Chen, D.; Sun, Z. Structures, physicochemical properties, and hypoglycemic activities of soluble dietary fibers from white and black glutinous rice bran: A comparative study. Food Res. Int. 2022, 159, 111423. [Google Scholar] [CrossRef] [PubMed]

- Xiaojuan, W.; Fang, L.; Wei, W. Effect of rice bran rancidity on the structure and antioxidant properties of rice bran soluble dietary fiber. J. Cereal Sci. 2022, 105, 103469. [Google Scholar] [CrossRef]

- Daiva, Z.; Ruta, V.; Rimgaile, D.; Joana, B.; Zaneta, R.; Darius, C.; Mantas, S.; Grazina, J. A comparative study on the structural and functional properties of water-soluble and alkali-soluble dietary fibres from rice bran after hot-water, ultrasound, hydrolysis by cellulase, and combined pre-treatments. Int. J. Food Sci. Technol. 2021, 57, 1137–1149. [Google Scholar] [CrossRef]

- Dong, H.; Lin, S.; Zhang, Q.; Chen, H.; Lan, W.; Li, H.; He, J.; Qin, W. Effect of extraction methods on the properties and antioxidant activities of Chuanminshen violaceum polysaccharides. Int. J. Biol. Macromol. 2016, 93, 179–185. [Google Scholar] [CrossRef] [PubMed]

- Cheng, L.; Zhang, X.; Hong, Y.; Li, Z.; Li, C.; Gu, Z. Characterisation of physicochemical and functional properties of soluble dietary fibre from potato pulp obtained by enzyme-assisted extraction. Int. J. Biol. Macromol. 2017, 101, 1004–1011. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Zeng, G.; Pan, Y.; Chen, W.; Huang, W.; Chen, H.; Li, Y. Properties of soluble dietary fiber-polysaccharide from papaya peel obtained through alkaline or ultrasound-assisted alkaline extraction. Carbohydr. Polym. 2017, 172, 102–112. [Google Scholar] [CrossRef]

- Yan, F.; Zhu, L.; Zhu, D.; Miao, X.; Niu, G.; Wei, W. Analysis of Ultrasonic-Microwave Synergistic Enzyme Extraction of Soluble Dietary Fiber from Millet Bran and Its Antioxidant Activity. Sci. Technol. Food Ind. 2022, 43, 163–172. [Google Scholar] [CrossRef]

- Neto, O.S.; Batista, E.; Meirelles, A. The employment of ethanol as solvent to extract Brazil nut oil. J. Clean. Prod. 2018, 180, 866–875. [Google Scholar] [CrossRef]

- Wang, C.; Li, L.; Sun, X.; Qin, W.; Zhang, Q. High-speed shearing of soybean flour suspension disintegrates the component cell layers and modifies the hydration properties of okara fibers. LWT-Food Sci. Technol. 2019, 116, 108505. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, H.; Yi, C.; Quan, K.; Lin, B. Chemical composition, structure, physicochemical and functional properties of rice bran dietary fiber modified by cellulase treatment. Food Chem. 2020, 342, 128352. [Google Scholar] [CrossRef] [PubMed]

- Shao, J.; Fu, J.; Zhang, G. Study on Quality of Soluble Dietary Fiber from Jujube (Z. vulgaris Lam) with Different Treatments. E3S Web Conf. 2020, 185, 04017. [Google Scholar] [CrossRef]

- Yan, J.K.; Wu, L.X.; Cai, W.D.; Xiao, G.S.; Duan, Y.Q.; Zhang, H.H. Subcritical water extraction-based methods affect the physicochemical and functional properties of soluble dietary fibers from wheat bran. Food Chem. 2019, 298, 124987. [Google Scholar] [CrossRef] [PubMed]

- Ye, J.; Hua, X.; Zhao, Q.; Dong, Z.; Li, Z.; Zhang, W.; Yang, R. Characteristics of alkali-extracted peanut polysaccharide-protein complexes and their ability as Pickering emulsifiers. Int. J. Biol. Macromol. 2020, 162, 1178–1186. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Lai, P.; Shen, H.; Zhen, H.; Fang, R. Effect of Extraction Methods on Polysaccharide of Clitocybe maxima Stipe. Adv. J. Food Sci. Technol. 2013, 5, 370–373. [Google Scholar] [CrossRef]

- Yun, L.; Li, D.; Yang, L.; Zhang, M. Hot water extraction and artificial simulated gastrointestinal digestion of wheat germ polysaccharide. Int. J. Biol. Macromol. 2018, 123, 174–181. [Google Scholar] [CrossRef]

- Shen, D.K.; Gu, S.; Bridgwater, A.V. The thermal performance of the polysaccharides extracted from hardwood: Cellulose and hemicellulose. Carbohydr. Polym. 2010, 82, 39–45. [Google Scholar] [CrossRef]

- Al-Farsi, M.A.; Lee, C.Y. Optimization of phenolics and dietary fibre extraction from date seeds. Food Chem. 2008, 108, 977–985. [Google Scholar] [CrossRef]

- Bouaziz, A.; Masmoudi, M.; Kamoun, A.; Besbes, S.; Blecker, C. Optimization of Insoluble and Soluble Fibres Extraction from Agave americana L. Using Response Surface Methodology. J. Chem. 2014, 2014, 627103. [Google Scholar] [CrossRef]

- Wu, H.; Li, M.; Yang, X.; Wei, Q.; Shang, H. Extraction optimization, physicochemical properties and antioxidant and hypoglycemic activities of polysaccharides from roxburgh rose (Rosa roxburghii Tratt.) leaves. Int. J. Biol. Macromol. 2020, 165, 517–529. [Google Scholar] [CrossRef]

- Loretta, B.; Oliviero, M.; Vittorio, M.; Bojórquez-Quintal, E.; Franca, P.; Silvia, P.; Fabio, Z. Quality by design approach to optimize cladodes soluble fiber processing extraction in Opuntia ficus indica (L. ) Miller. J. Food Sci. Technol. 2019, 56, 3627–3634. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Chen, H.; Tian, J.; Wang, J.; Wang, Y.; Xing, L. Enzymolysis-ultrasonic assisted extraction, chemical characteristics and bioactivities of polysaccharides from corn silk. Carbohydr. Polym. 2014, 101, 332–341. [Google Scholar] [CrossRef] [PubMed]

- Gu, M.; Fang, H.; Gao, Y.; Su, T.; Yu, L.L. Characterization of enzymatic modified soluble dietary fiber from tomato peels with high release of lycopene. Food Hydrocoll. 2019, 99, 105321. [Google Scholar] [CrossRef]

- Chen, S.; Jiang, L.; Yang, L.; Sui, X. Ultrasound-Assisted Enzymatic Extraction of Dietary Fiber from Pods. Procedia Eng. 2011, 15, 5056–5061. [Google Scholar] [CrossRef]

- Yuliarti, O.; Goh, K.; Matia-Merino, L.; Mawson, J.; Drummond, L.; Brennan, C.S. Effect of extraction techniques and conditions on the physicochemical properties of the water soluble polysaccharides from gold kiwifruit (Actinidia chinensis). Int. J. Food Sci. Technol. 2010, 43, 2268–2277. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, Y. Physicochemical and functional properties of coconut (Cocos nucifera L) cake dietary fibres: Effects of cellulase hydrolysis, acid treatment and particle size distribution. Food Chem. 2018, 257, 135–142. [Google Scholar] [CrossRef]

- Marwa, C.R.; Souhir, A.; Sabu, T.; Hamadi, A.; Dorra, G. Use of green chemistry methods in the extraction of dietary fibers from cactus rackets (Opuntia ficus indica): Structural and microstructural studies. Int. J. Biol. Macromol. 2018, 116, 901–910. [Google Scholar] [CrossRef]

- Zhang, R.; Guo, J.; Liu, Y.; Chen, S.; Zhang, S.; Yu, Y. Effects of sodium salt types on the intermolecular interaction of sodium alginate/antarctic krill protein composite fibers. Carbohydr. Polym. 2018, 189, 72–78. [Google Scholar] [CrossRef]

- Yan, X.; Ye, R.; Chen, Y. Blasting extrusion processing: The increase of soluble dietary fiber content and extraction of soluble-fiber polysaccharides from wheat bran. Food Chem. 2015, 180, 106–115. [Google Scholar] [CrossRef]

- Yu, L.; Gong, Q.; Yang, Q.; Sun, J.; Bi, J.; Zhang, C. Technology Optimization for Microwave-assisted Extraction of Water Soluble Dietary Fiber from Peanut Hull and Its Antioxidant Activity. Food Sci. Technol. Res. 2011, 17, 401–408. [Google Scholar] [CrossRef]

- Mir, N.A.; Riar, C.S.; Singh, S. Effect of pH and holding time on the characteristics of protein isolates from Chenopodium seeds and study of their amino acid profile and scoring. Food Chem. 2018, 272, 165–173. [Google Scholar] [CrossRef] [PubMed]

- Steingoetter, A.; Buetikofer, S.; Curcic, J.; Menne, D.; Rehfeld, J.F.; Fried, M.; Schwizer, W.; Wooster, T.J. The Dynamics of Gastric Emptying and Self-Reported Feelings of Satiation Are Better Predictors Than Gastrointestinal Hormones of the Effects of Lipid Emulsion Structure on Fat Digestion in Healthy Adults-A Bayesian Inference Approach. J. Nutr. 2017, 147, 706–714. [Google Scholar] [CrossRef] [PubMed]

- Ullah, I.; Yin, T.; Xiong, S.; Huang, Q.; Zia-ud-Din; Zhang, J.; Javaid, A.B. Effects of thermal pre-treatment on physicochemical properties of nano-sized okara (soybean residue) insoluble dietary fiber prepared by wet media milling. J. Food Eng. 2018, 237, 18–26. [Google Scholar] [CrossRef]

- Maphosa, Y.; Jideani, V.A. Dietary fiber extraction for human nutrition-A review. Food Rev. Int. 2016, 32, 98–115. [Google Scholar] [CrossRef]

- Gan, J.; Huang, Z.; Yu, Q.; Peng, G.; Xie, M. Microwave assisted extraction with three modifications on structural and functional properties of soluble dietary fibers from grapefruit peel. Food Hydrocoll. 2019, 101, 105549. [Google Scholar] [CrossRef]

| SDF | L | a | b | ΔE |

|---|---|---|---|---|

| B-SDF | 58.36 ± 0.02 | 0.33 ± 0.03 | −0.23 ± 0.02 | 2.91 |

| A-SDF | 60.42 ± 0.04 | 2.30 ± 0.03 | 1.27 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; He, S.; Sun, H.; Li, Q.; Gao, K.; Miao, X.; Xiang, J.; Wu, X.; Gao, L.; Zhang, Y. A Comparative Study on Extraction and Physicochemical Properties of Soluble Dietary Fiber from Glutinous Rice Bran Using Different Methods. Separations 2023, 10, 90. https://doi.org/10.3390/separations10020090

Chen H, He S, Sun H, Li Q, Gao K, Miao X, Xiang J, Wu X, Gao L, Zhang Y. A Comparative Study on Extraction and Physicochemical Properties of Soluble Dietary Fiber from Glutinous Rice Bran Using Different Methods. Separations. 2023; 10(2):90. https://doi.org/10.3390/separations10020090

Chicago/Turabian StyleChen, Haoshuang, Shudong He, Hanju Sun, Qiuyang Li, Kuan Gao, Xinya Miao, Jie Xiang, Xiongjie Wu, Longmei Gao, and Yi Zhang. 2023. "A Comparative Study on Extraction and Physicochemical Properties of Soluble Dietary Fiber from Glutinous Rice Bran Using Different Methods" Separations 10, no. 2: 90. https://doi.org/10.3390/separations10020090

APA StyleChen, H., He, S., Sun, H., Li, Q., Gao, K., Miao, X., Xiang, J., Wu, X., Gao, L., & Zhang, Y. (2023). A Comparative Study on Extraction and Physicochemical Properties of Soluble Dietary Fiber from Glutinous Rice Bran Using Different Methods. Separations, 10(2), 90. https://doi.org/10.3390/separations10020090