Evaluation of CO2 Adsorption Parameters in Fluidised Zeolite 13X Beds Using Non-Linear Multivariate Optimisation

Abstract

:1. Introduction

- Absorption processes;

- Micro-algal ciofixation processes (photosynthetic fixation);

- Cryogenic processes;

- Cold methanol (Rectisol process);

- Polyethylene glycol diethylene ether (Selexol process);

- Propylene carbonate (Fluor process).

- Pressure swing: The pressure of the adsorption chamber is lowered to very low values.

- Temperature swing: The temperature is increased.

- Electrical swing: The electric current that runs through the adsorbent bed is changed.

- n gas phase mass balances;

- n mass balances in the adsorbed phase;

- 1 energy balance related to intra-system exchange;

- 1 energy balance related to external exchange;

- 1 momentum balance;

- n equilibrium relations.

2. Materials and Methods

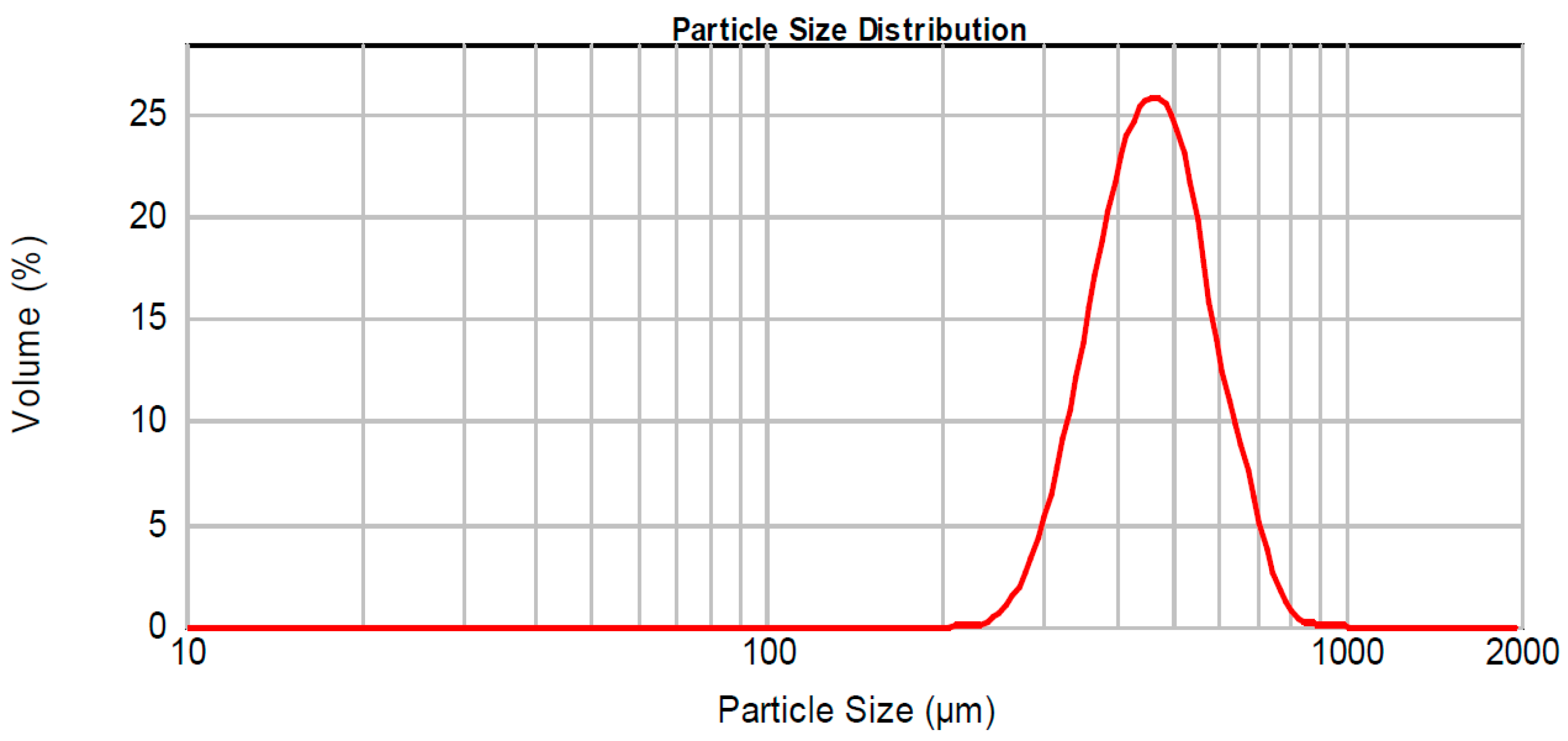

- Particle size distribution;

- Sauter diameter;

- Volume diameter.

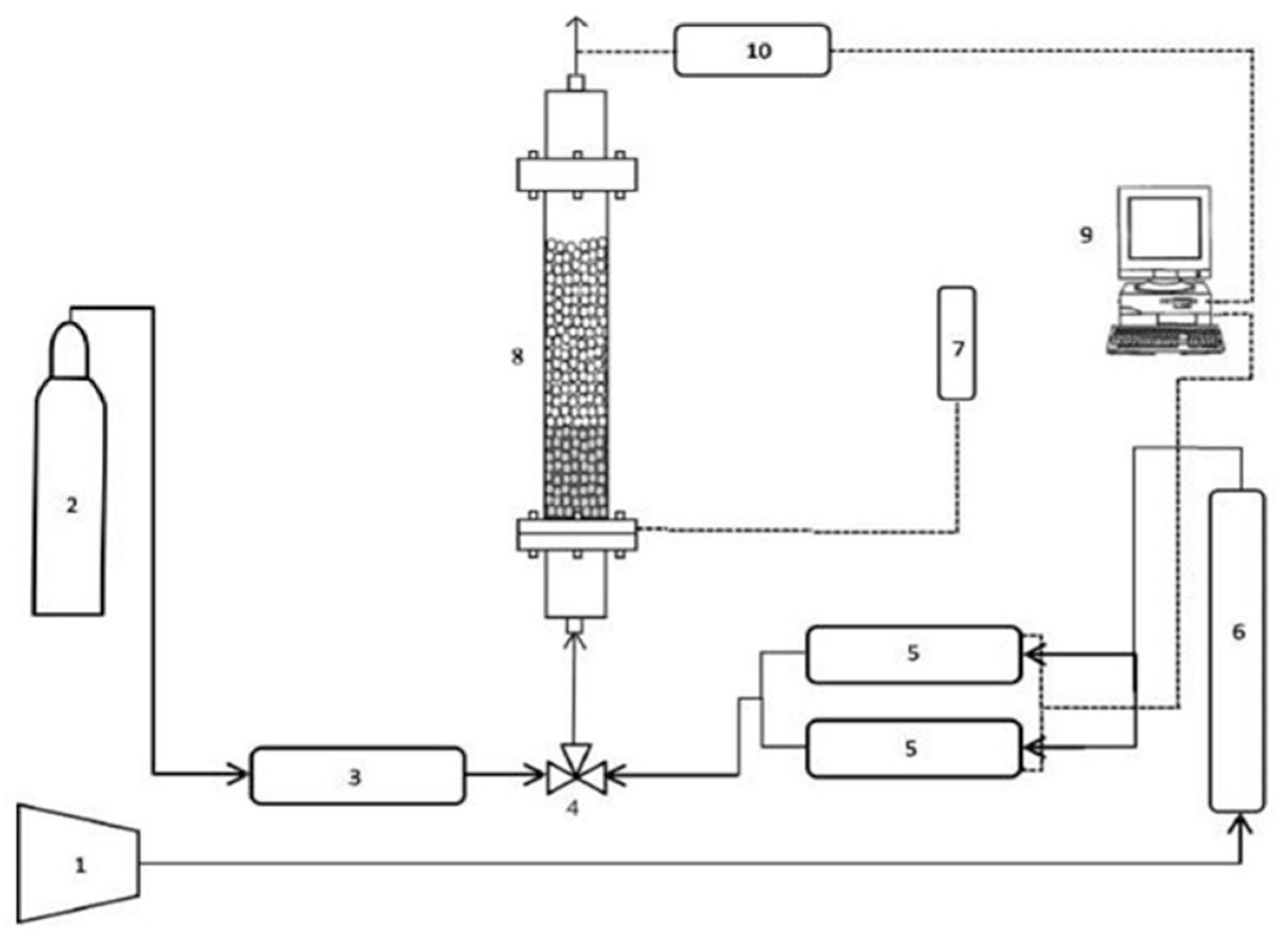

- The upper one has the function of conveying the gas coming out of the bed to the composition analyser.

- The lower one is connected to the distribution chamber through a porous septum that has the task of evenly distributing the gas entering the bed. Glass marbles with a diameter of 11 mm and a density of 2.48 g/cm3 are used to pack the columns.

- Gas sampling probe: This allows samples of gas to be examined. It consists of a handle and a tube, inside of which there is a thermocouple.

- Gas pump: It is located inside the analyser and has the function of sucking the sample.

- Gas chamber: Located inside it are electrochemical cells. The cells measure the oxygen content and send an electrical signal directly proportional to the volumetric concentration of the species.

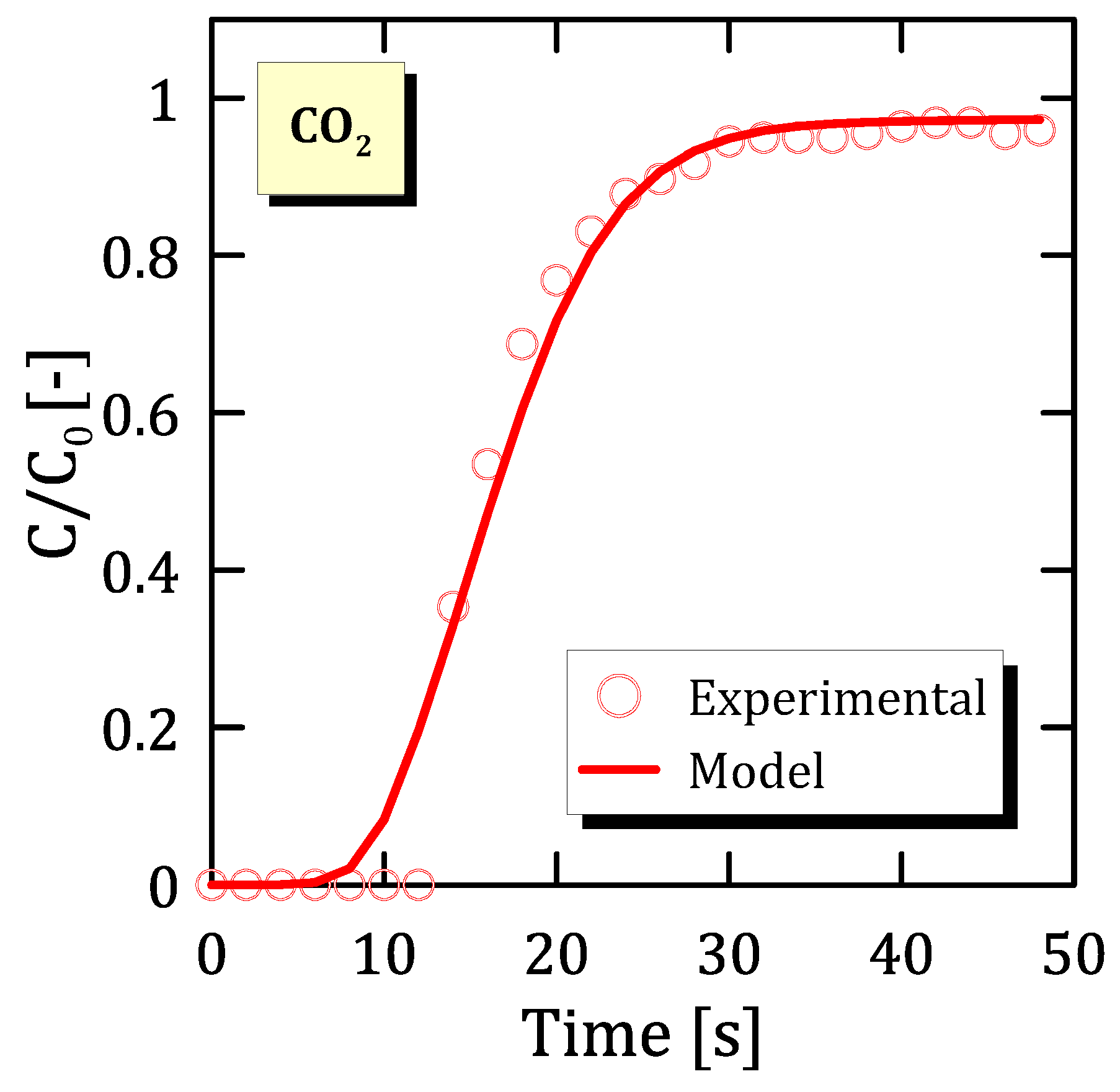

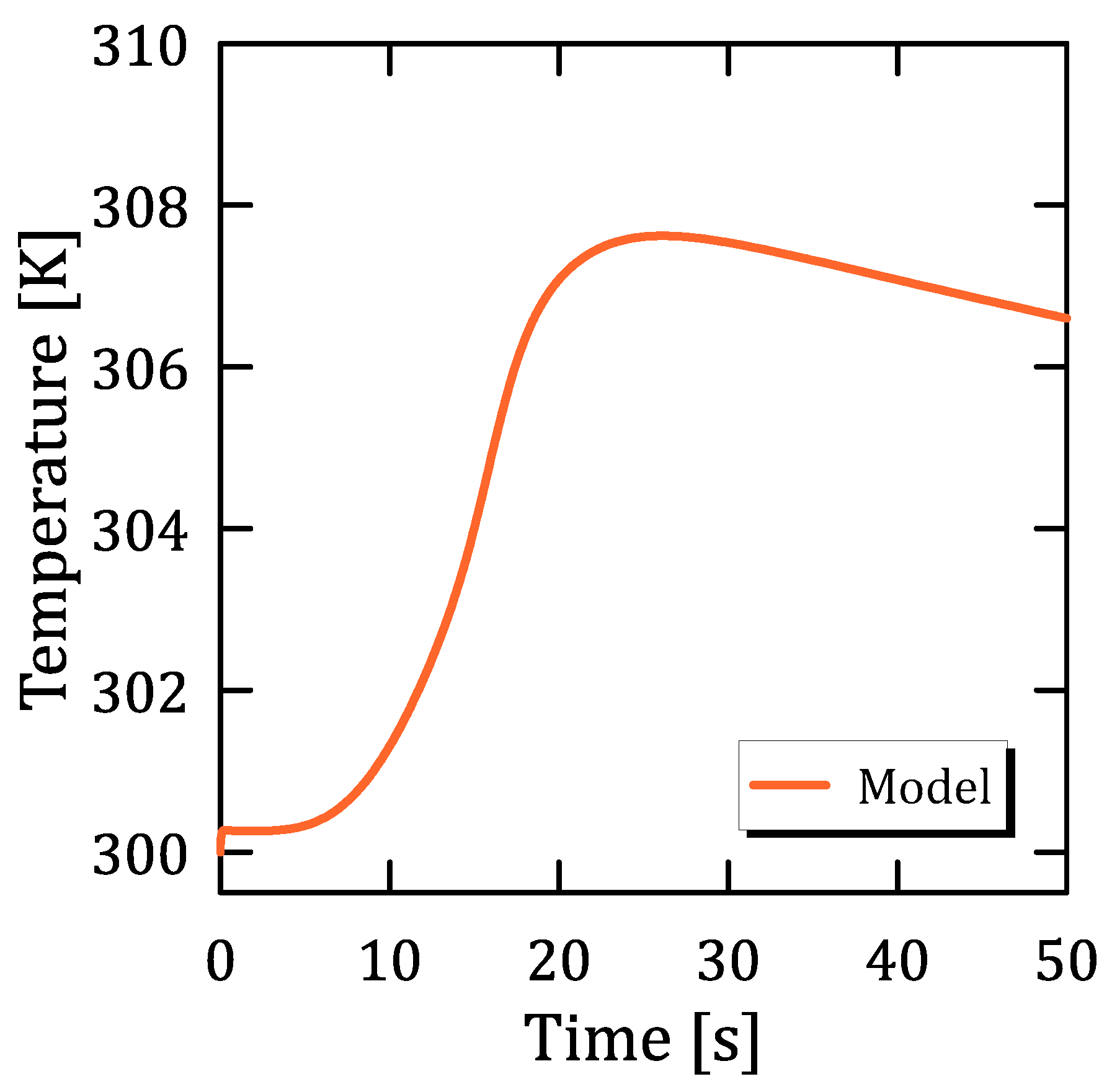

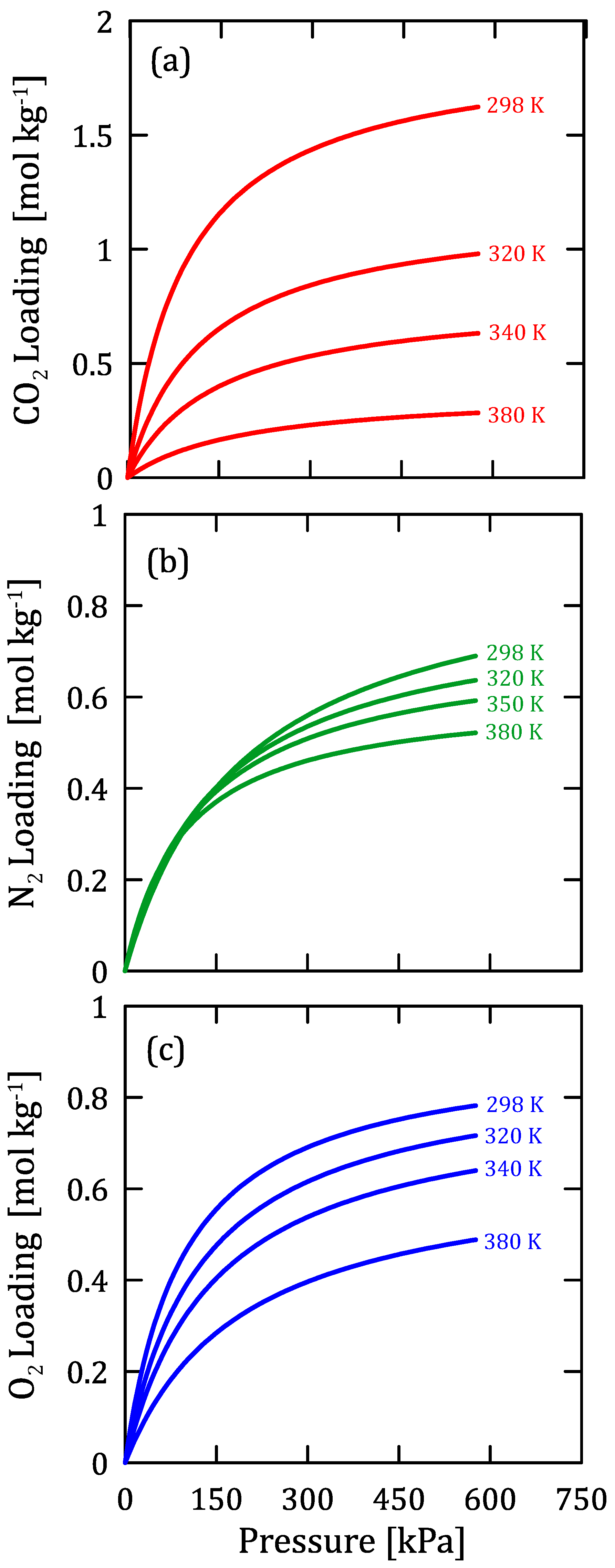

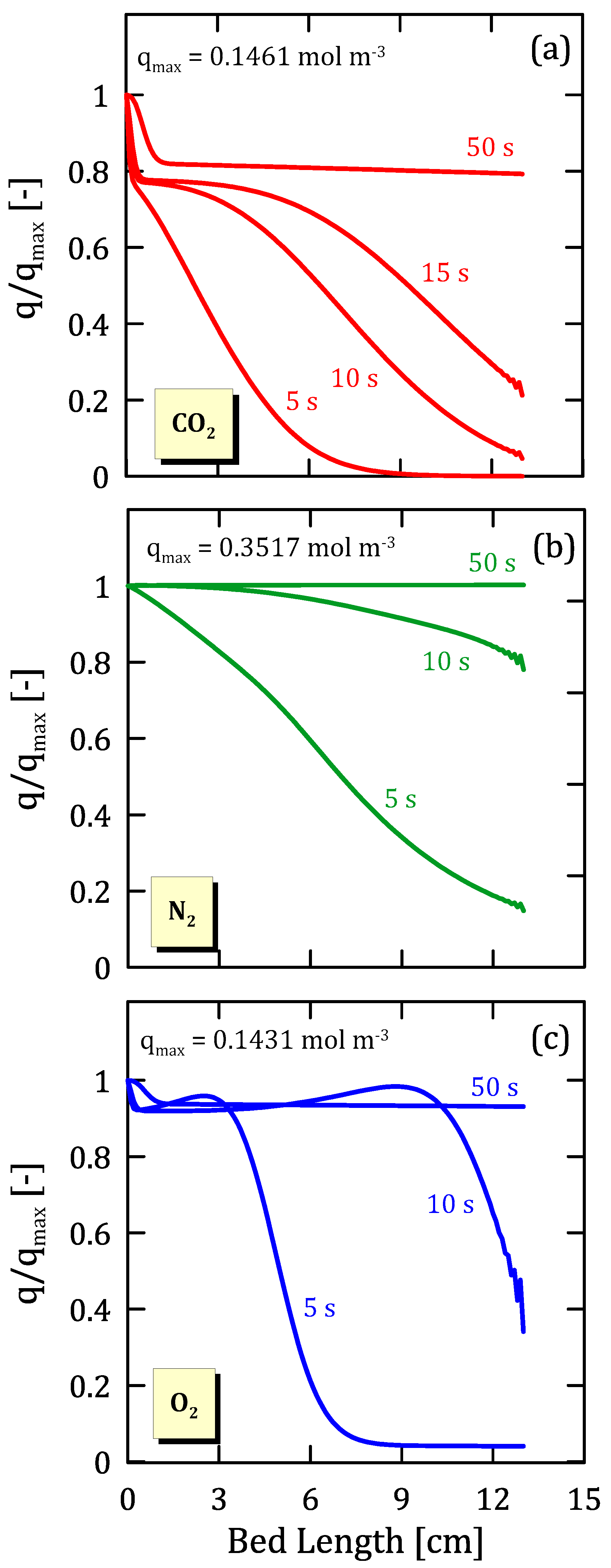

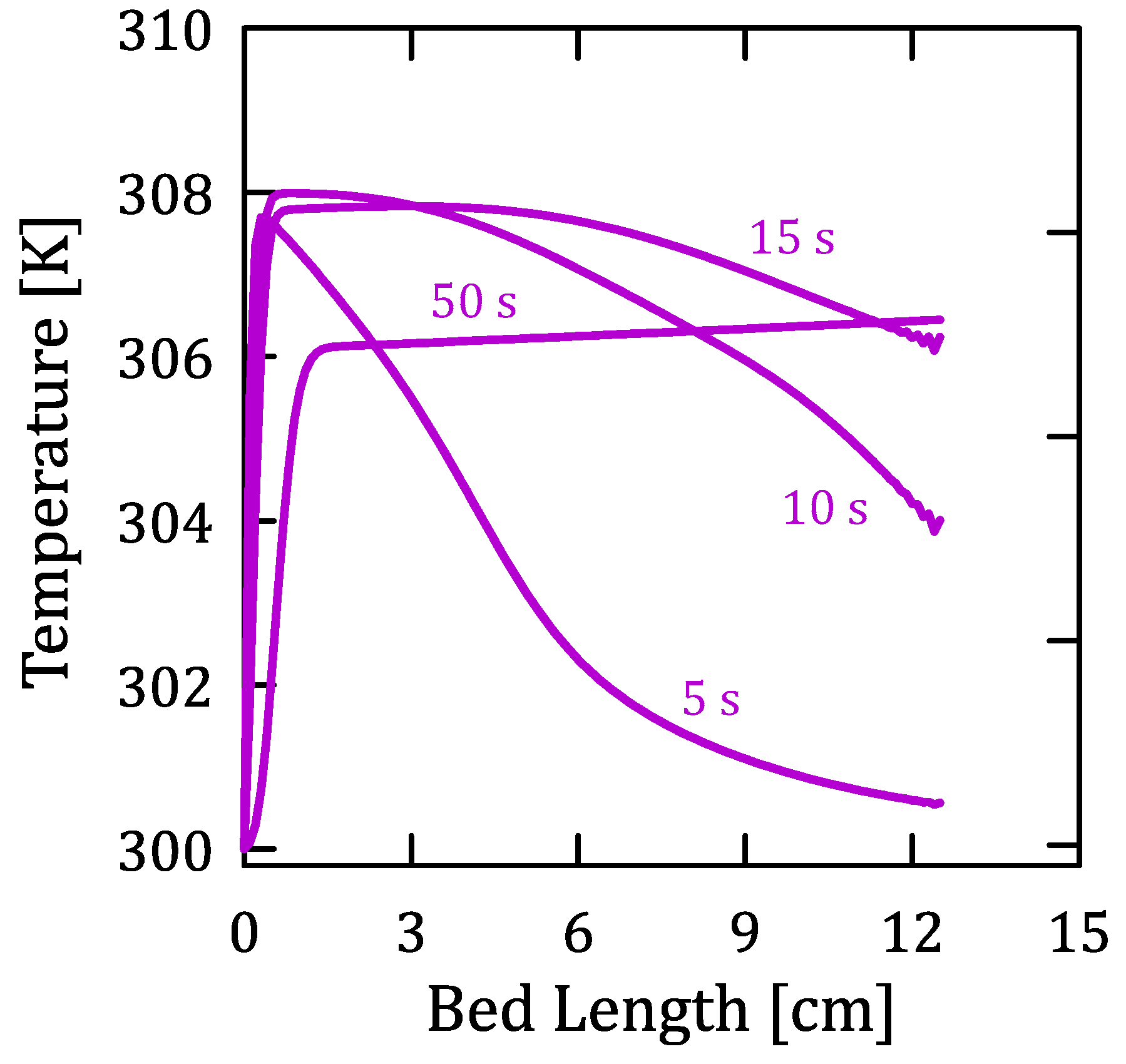

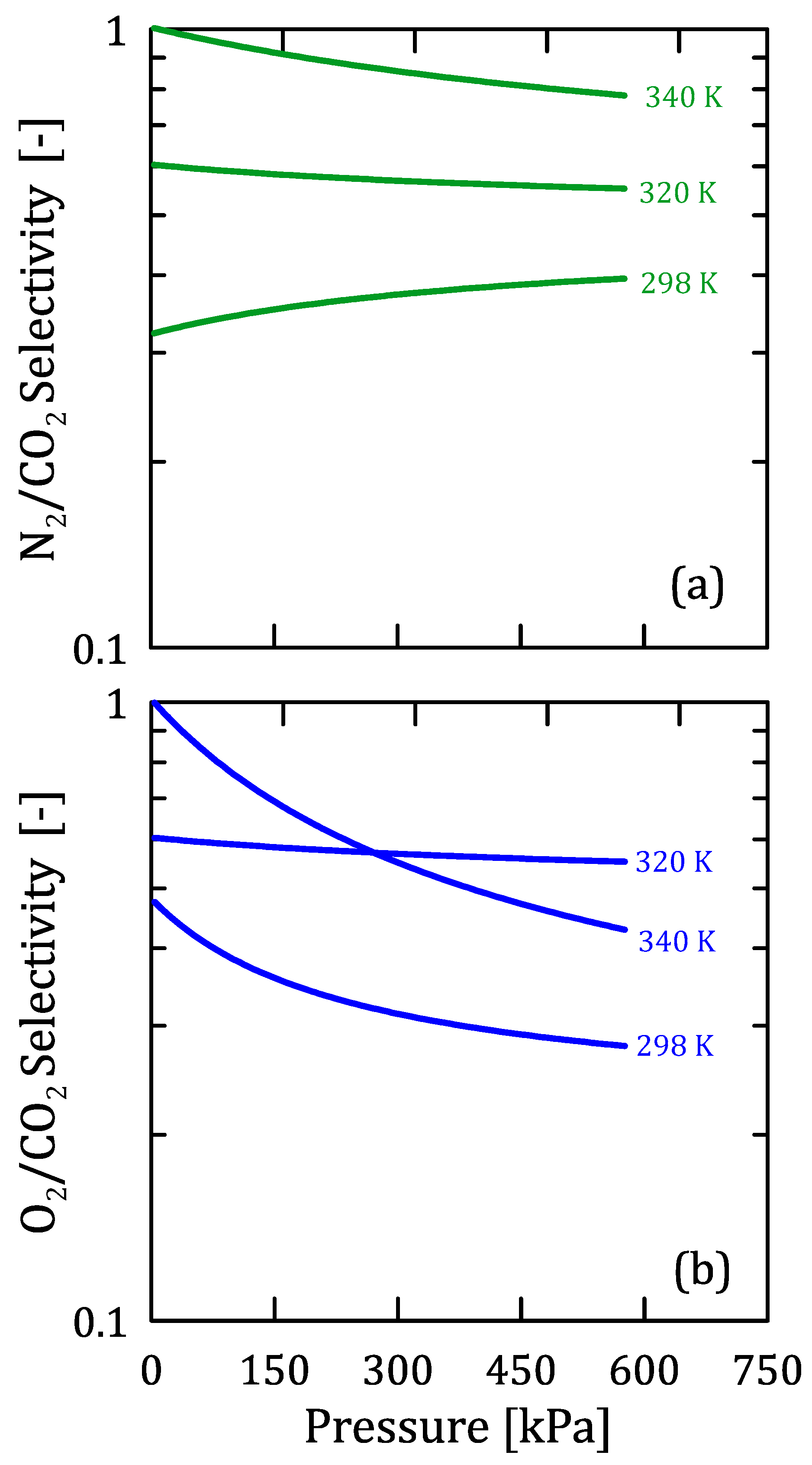

3. Results and Discussion

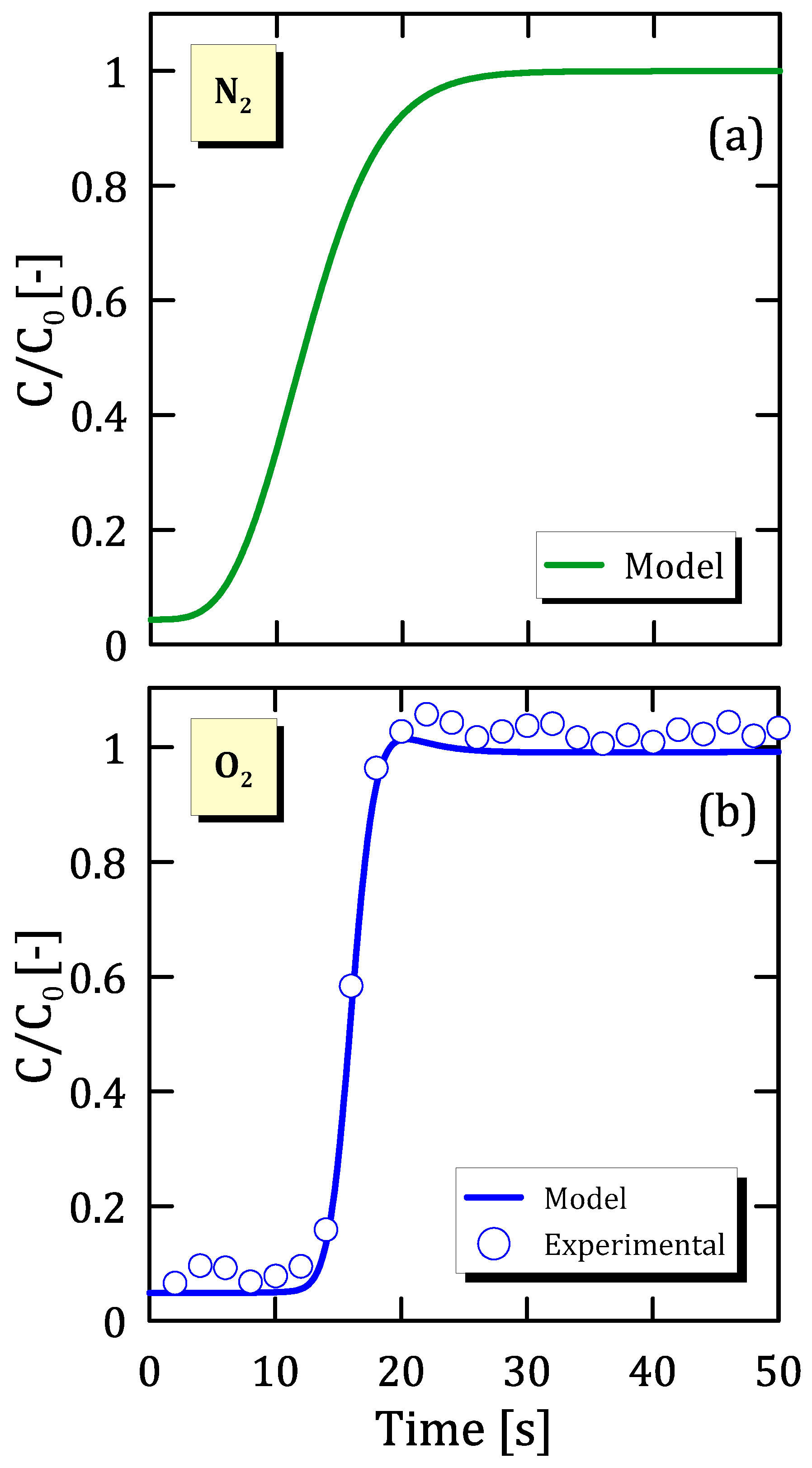

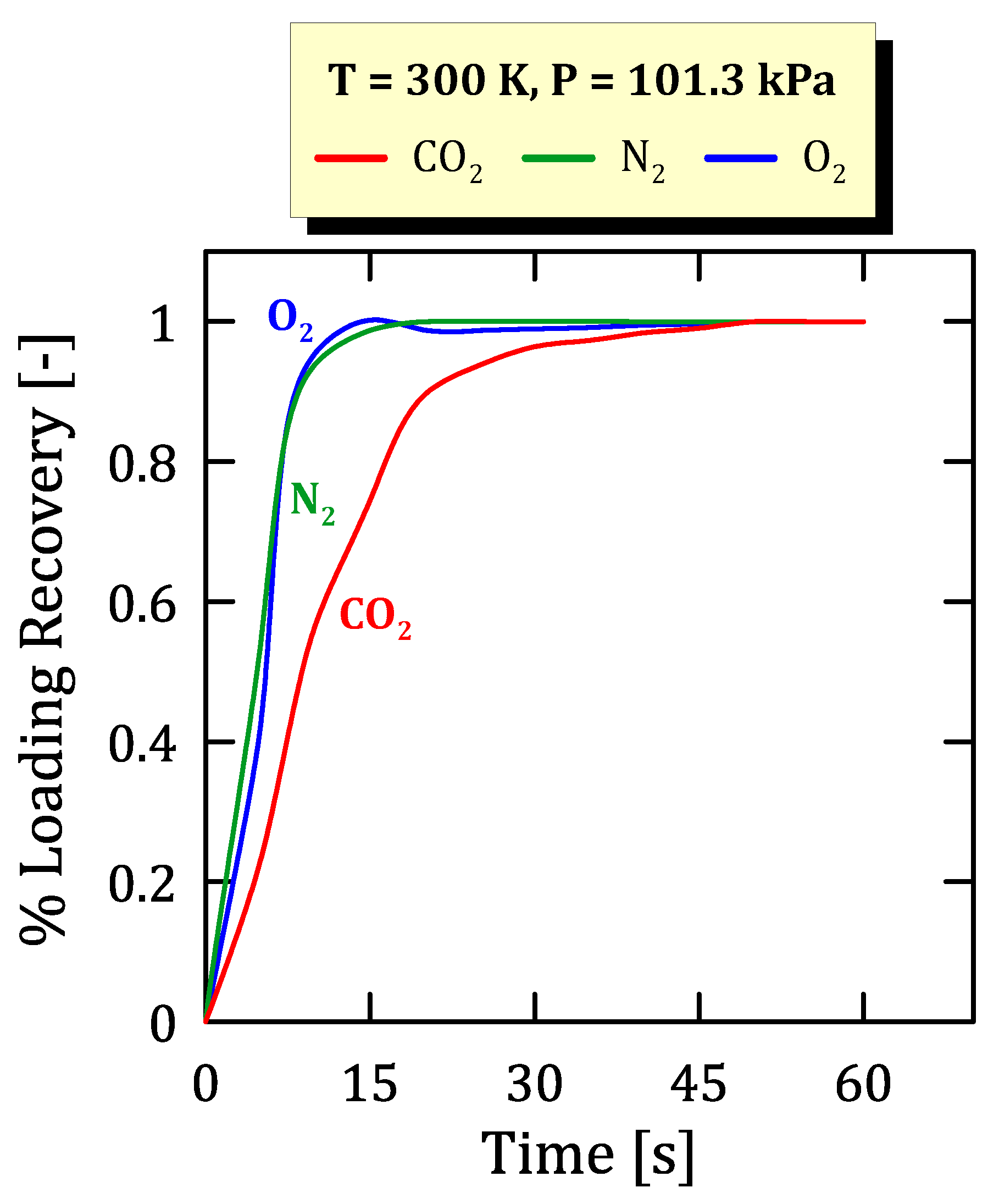

- If is high, the adsorption is rapid, and therefore, the breakthrough curve grows very quickly.

- If is low, the adsorption is slow, and therefore, the breakthrough curve grows very slowly.

- The adsorption of nitrogen is much more rapid than that of oxygen.

- The curve value comes above the unit value because the driving force changes the sign.

- At the outlet, there is a flux given by the sum of the incoming flux and the flux desorbed by the solid.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| List of Symbols | |

| Symbols | Description |

| am | Specific area, m−1 |

| Am | Exchange area, m2 |

| b0 | Affinity pre-exponential factor, Pa−1 |

| b | Affinity, Pa−1 |

| cP | Specific heat, K·mol−1·K−1 |

| C | Concentration in the fluid phase, mol m−3 |

| dP | Particle diameter, m |

| D | Diffusion coefficient, m2·s−1 |

| fobj | Objective function, - |

| F | Flux exchanged with the adsorbed face, mol·m−2·s−1 |

| h | Heat transport coefficient, W·m−2·K−1 |

| kLDF | Mass transport coefficient, s−1 |

| L | Column length, m |

| n | Number of species, - |

| ni | Number of moles of i species, mol |

| N | Total flux, mol·m−2·s−1 |

| P | Pressure, Pa |

| q | Loading in the adsorbed phase, mol·kg−1 |

| qs0 | Saturation loading, mol·kg−1 |

| QAds | Heat of adsorption, J·mol−1 |

| R | Ideal gas constant, J·mol−1·K−1 |

| R2 | Determination coefficient, - |

| Re | Reynolds number, - |

| t | Time, s |

| T | Temperature, K |

| u, v | Velocity, m·s−1 |

| vf | Superficial velocity, m·s−1 |

| V | Volume m3 |

| x | Mole fraction, - |

| y | Gas mole fraction, - |

| Greek symbols | |

| α | Generic coefficient |

| ΔH | Enthalpy variation, J·mol−1 |

| Δx | Space variation, m |

| ε | Voidage degree, - |

| θ | Generic variable |

| μ | Viscosity, Pa·s−1 |

| ρ | Density, kg·m−3 |

| ϕ | Sphericity, - |

| Adsorption parameter, - | |

| Subscripts and Superscripts | |

| ads | Adsorption |

| atm | Atmospheric pressure |

| e | Equilibrium |

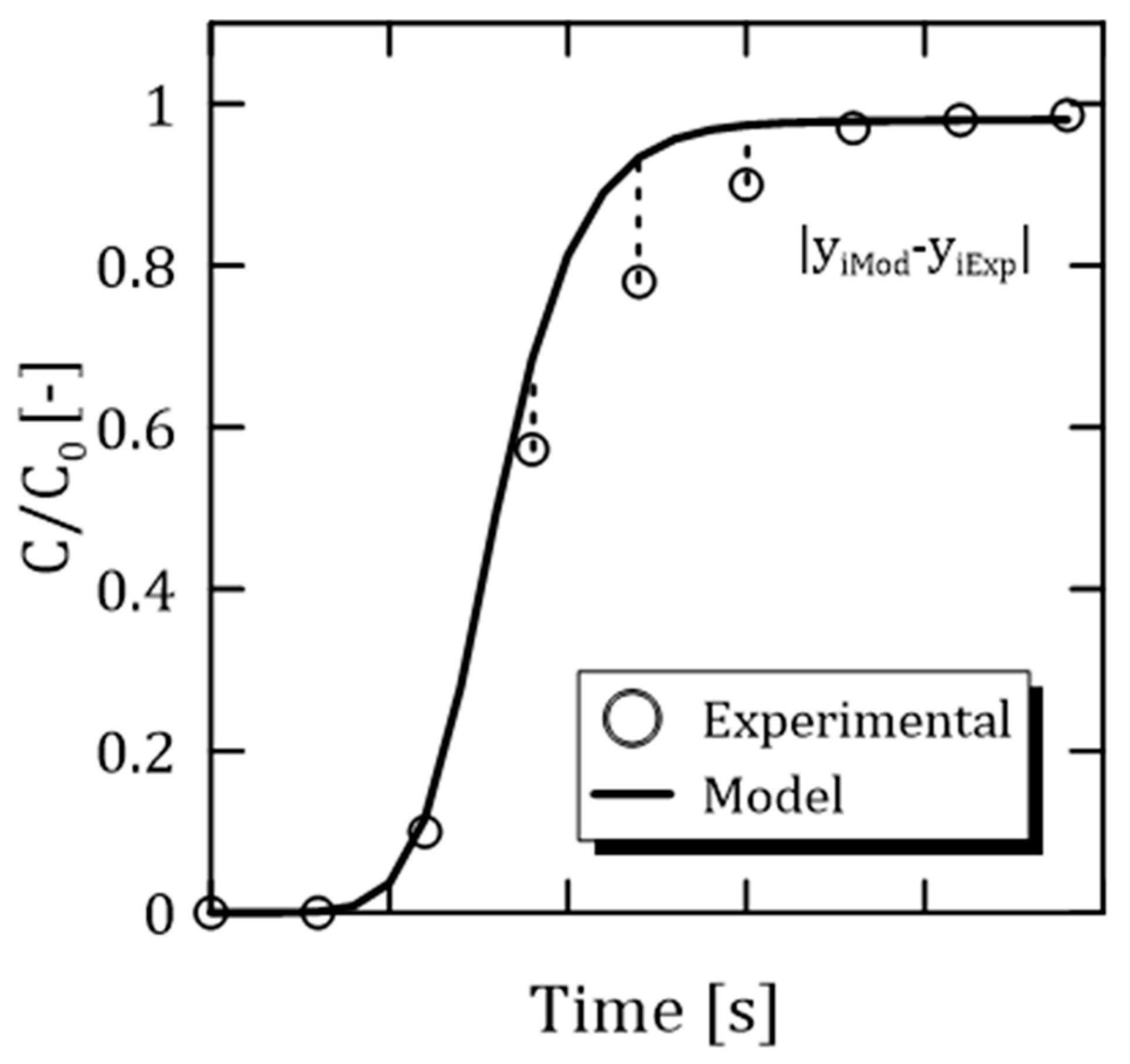

| Exp | Experimental |

| g | Gas |

| i | Generic species |

| j | Index for spatial discretisation |

| Lang | Langmuir |

| LDF | Linear driving force |

| Mod | Model |

| n | Index for time discretisation |

| p | Particle |

| s | Solid |

| sat | Saturation |

| w | Wall |

Appendix A. Modelling of Carbon Dioxide–Air Adsorption

Appendix A.1. Gas-Phase Balance

Appendix A.2. Mass Balance in the Adsorbed Phase

Appendix A.3. Energy Balance

Appendix A.4. Pressure Loss Equation

Appendix A.5. Simulation System

- The first derivative can be written as Forward, Backward or Centred. The Forward and Backward formulations are less accurate than the Centred formulation, so a method that uses the latter formulation is more accurate.

- The second derivative can only be expressed through a Centred formulation.

Appendix A.6. Initial and Boundary Conditions

- The concentration inside the bed is the same as that in air (Equation (A37));

- The concentration of the adsorbed phase is zero, as the adsorbent material is considered to be completely regenerated from the previous operations (Equation (A38));

- The temperature is equal to the ambient temperature (Equations (A41)–(A45)).

Appendix A.7. Method of Line

Appendix A.8. Parametric Optimisation

References

- Sreedhara, I.; Vaidhiswarana, R.; Kamania, M.B.; Venugopalb, A. Process and engineering trends in membrane based carbon capture. Renew. Sustain. Energy Rev. 2017, 68, 659–684. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Z.; Zhao, S.; Wang, J.; Wang, S. Recent advances on mixed matrix membranes for CO2 separation. Chin. J. Chem. Eng. 2017, 25, 1581–1597. [Google Scholar] [CrossRef]

- Kim, S.; Lee, M.Y. High performance polymer membranes for CO2 separation. Curr. Opin. Chem. Eng. 2013, 2, 238–244. [Google Scholar] [CrossRef]

- Abd, A.A.; Naji, S.Z.; Hashim, A.S.; Othman, R.M. Carbon dioxide removal through physical adsorption using carbonaceous and non-carbonaceous adsorbents: A review. J. Environ. Chem. Eng. 2020, 8, 104142. [Google Scholar]

- Yu, H.C.; Huang, H.C.; Tan, S.C. A Review of CO2 Capture by Absorption and Adsorption. Aerosol Air Qual. Res. 2012, 12, 745–769. [Google Scholar] [CrossRef]

- Feng, J.; Guo, H.; Wang, S.; Zhao, Y.; Ma, X. Fabrication of multi-shelled hollow Mg-modified CaCO3 microspheres and their improved CO2 adsorption performance. Chem. Eng. J. 2017, 321, 401–441. [Google Scholar] [CrossRef]

- García, S.; Pis, J.J.; Rubiera, F.; Pevida, C. Predicting mixed-gas adsorption equilibria on activated carbon for Precombustion CO2 capture. Langmuir 2013, 29, 6042–6052. [Google Scholar] [CrossRef]

- Gao, H.; Zhou, L.; Luo, X.; Liang, Z. Optimised process configuration for CO2 recovery from crude synthesis gas via a rectisol wash process. Int. J. Greenh. Gas Control 2018, 79, 83–90. [Google Scholar] [CrossRef]

- Duong, D.D. Adsorption Analysis: Equilibia and Kinetics. Series on Chemical Engineering; Imperial College Press: London, UK, 1998. [Google Scholar]

- Girimonte, R.; Formisani, B.; Testa, F. Adsorption of CO2 on a confined fluidized bed of pelletized 13X zeolite. Powder Technol. 2017, 311, 9–17. [Google Scholar] [CrossRef]

- Girimonte, R.; Formisani, B.; Testa, F. CO2 adsorption in a confined fluidized bed of zeolite pellets: Influence of operating velocity. Particuology 2018, 46, 67–74. [Google Scholar] [CrossRef]

- Ghurabi, E.H.A.; Ajbar, A.; Asif, M. Enhancement of CO2 Removal Efficacy of Fluidized Bed Using Particle Mixing. Appl. Sci. 2018, 8, 1467. [Google Scholar] [CrossRef]

- Poursaeidesfahani, A.; Andres-Garcia, E.; de Lange, M.; Torres-Knoop, A.; Rigutto, M.; Nair, N.; Kapteijn, F.; Gascon, J.; Dubbeldam, D.; Vlugt, T.J. Prediction of adsorption isotherms from breakthrough curves. Predict. Adsorpt. Isotherms Breakthr. Curves 2019, 277, 237–244. [Google Scholar] [CrossRef]

- Ünveren, E.E.; Monkul, Ö.B.; Sarıoğlan, Ş.; Karademir, N.; Alper, E. Solid amine sorbents for CO2 capture by chemical adsorption: A Review. Petroleum 2016, 3, 37–50. [Google Scholar] [CrossRef]

- Mansour, B.M.; Habib, M.A.; Bamidele, O.E.; Basha, M.; Qasem, N.A.A.; Peedikakkal, A.; Laoui, T.; Ali, M. Carbon capture by physical adsorption: Materials, experimental investigations and numerical modeling and simulations—A review. Appl. Energy 2016, 161, 225–255. [Google Scholar] [CrossRef]

- Motsi, T.; Rowson, N.A.; Simmons, M.J.H. Adsorption of heavy metals from acid mine drainage by natural zeolite. Int. J. Miner. Process 2009, 92, 42–48. [Google Scholar] [CrossRef]

- Boonchuay, A.; Worathanakul, P. The Diffusion Behavior of CO2 Adsorption from a CO2/N2 Gas Mixture on Zeolite 5A in a Fixed-Bed Column. Atmosphere 2022, 13, 513. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, W.; Chen, X.; Xia, Q.; Li, Z. Adsorption of CO2 on Zeolite 13X and Activated Carbon with Higher Surface Area. Sep. Sci. Technol. 2010, 45, 710–719. [Google Scholar] [CrossRef]

- Dantas, T.L.P.; Luna, F.M.T.; Silva, I.J., Jr.; Torres, A.E.B.; Azevedo, D.C.S.; Rodrigues, A.E.; Moreira, R.F.P.M. Modeling of the fixed-bed adsorption of carbon dioxide and a carbon dioxide nitrogen mixture on Zeolite 13X. Braz. J. Chem. Eng. 2011, 28, 533–544. [Google Scholar] [CrossRef]

- Morales, O.R.; Santiago, G.R.; Siqueira, R.M.; Azevedo, S.C.D.; Neto, B.M. Assessment of CO2 Desorption from 13X Zeolite for a Prospective TSA Process; Springer Science+Business Media: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Moura, P.A.S.; Bezerra, D.P.; Vilarrasa-Garcia, E.; Bastos-Neto, M.; Azevedo, D.C.S. 2016 Adsorption Equilibria of CO2 and CH4 in Cation-Exchanged Zeolites 13X; Springer Science+Business Media: New York, NY, USA, 2015. [Google Scholar]

- Garshasbi, V.; Jahangiri, M.; Anbia, M. Equilibrium CO2 adsorption on zeolite 13X prepared from natural clays. Appl. Surf. Sci. 2017, 393, 225–233. [Google Scholar] [CrossRef]

- Pereira, A.; Ferreira, A.F.P.; Rodrigues, A.; Ribeiro, A.M.; Regufe, M.J. Evaluation of the potential of a 3D-printed hybrid zeolite 13X/activated carbon material for CO2/N2 separation using electric swing adsorption. Chem. Eng. J. 2022, 450, 138197. [Google Scholar] [CrossRef]

- Kareem, F.A.; Shariff, A.M.; Ullaha, S.; Dreisbachb, F.; Keonga, L.K.; Mellona, N.; Garga, S. Experimental measurements and modeling of supercritical CO2 adsorption on 13X and 5A zeolites. J. Nat. Gas Sci. Eng. 2018, 50, 115–127. [Google Scholar] [CrossRef]

- Majchrzak-Kucęba, I.; Wawrzynczak, D.; Sciubidlo, A. Experimental investigation into CO2 capture from the cement plant by VPSA technology using zeolite 13X and activated carbon. J. CO2 Util. 2022, 61, 102027. [Google Scholar] [CrossRef]

- Won, W.; Lee, S.; Lee, K.S. Modeling and parameter estimation for a fixed-bed adsorption process for CO2 capture using zeolite 13X. Sep. Purif. Technol. 2012, 85, 120–129. [Google Scholar] [CrossRef]

- Najafi, A.M.; Soltanali, S.; Khorashe, F.; Ghassabzadeh, H. Effect of binder on CO2, CH4, and N2 adsorption behavior, structural properties, and diffusion coefficients on extruded zeolite 13X. Chemosphere 2023, 324, 138275. [Google Scholar] [CrossRef] [PubMed]

- Ghaemi, A.; Dehnavi, M.K.; Khoshraftar, Z. Exploring artificial neural network approach and RSM modeling in the prediction of CO2 capture using carbon molecular sieves. Case Stud. Chem. Environ. Eng. 2023, 7, 100310. [Google Scholar] [CrossRef]

- Beleli, Y.S.; de Paiva, J.L.; Seckler, M.M.; Carrillo Le Roux, G.A. Optimization of a continuous multi-stage fluidized bed system for CO2 capture utilizing temperature swing adsorption. Comput. Aided Chem. Eng. 2023, 52, 3233–3238. [Google Scholar]

- Hamdi, S.; Schiesser, W.E.; Griffiths, G.W. Method of Lines, Part I: Basic Concepts. Scholarpedia 2007, 2, 2859. [Google Scholar] [CrossRef]

- Scott, D.M. Effects of bed pressure drop on adsorption and desorption with Langmuir Isotherms. Chem. Eng. Sci. 1993, 17, 3001–3006. [Google Scholar] [CrossRef]

|

|

|

|

|

| 1 | Compressor | 6 | Moisture Abatement System |

| 2 | CO2 cylinder (Pyrossigeno®) | 7 | U-shaped manhole |

| 3 | CO2 rotameter (ASA S.p.A.®) | 8 | Fluidisation column |

| 4 | 3-way valve (Plasson®) | 9 | Computer |

| 5 | MFC Air (Brooks Instruments®) | 10 | Composition Analyser (Madur®) |

| Parameter | Value |

|---|---|

| fobj | 0.22 |

| R2 | 0.9985 |

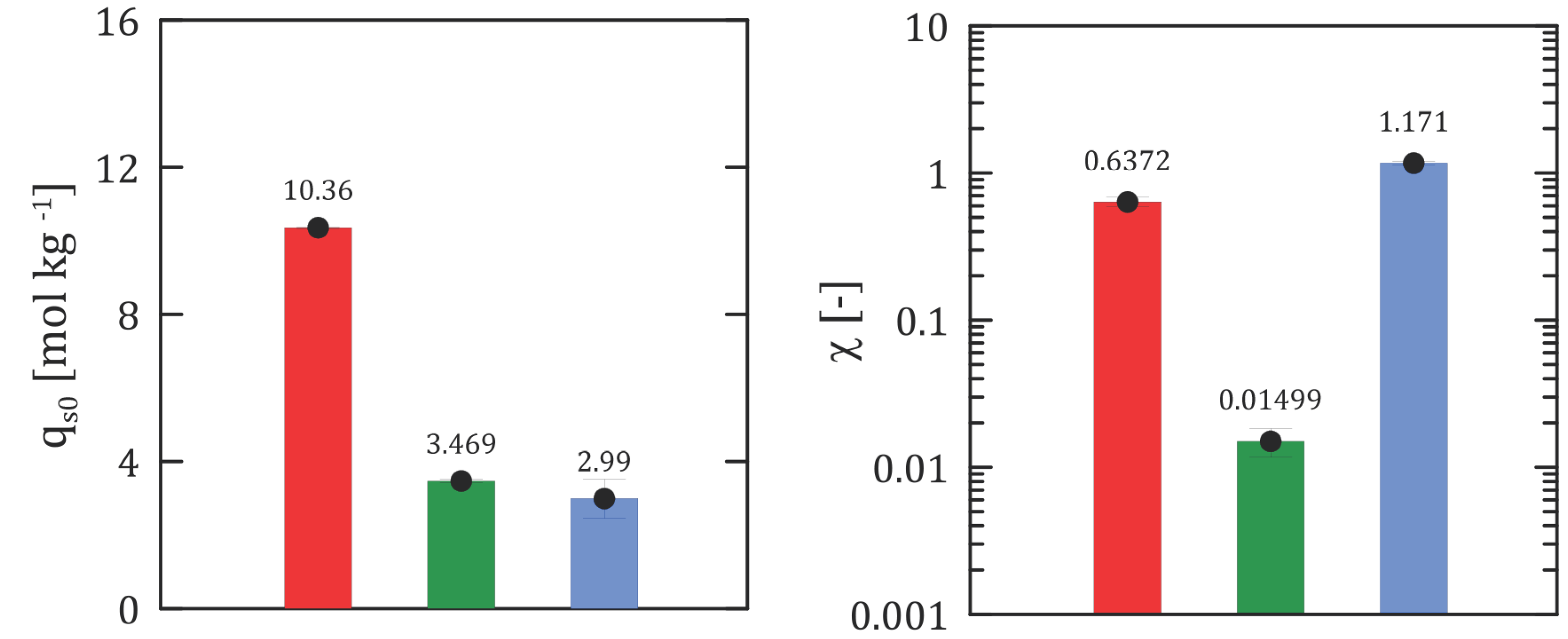

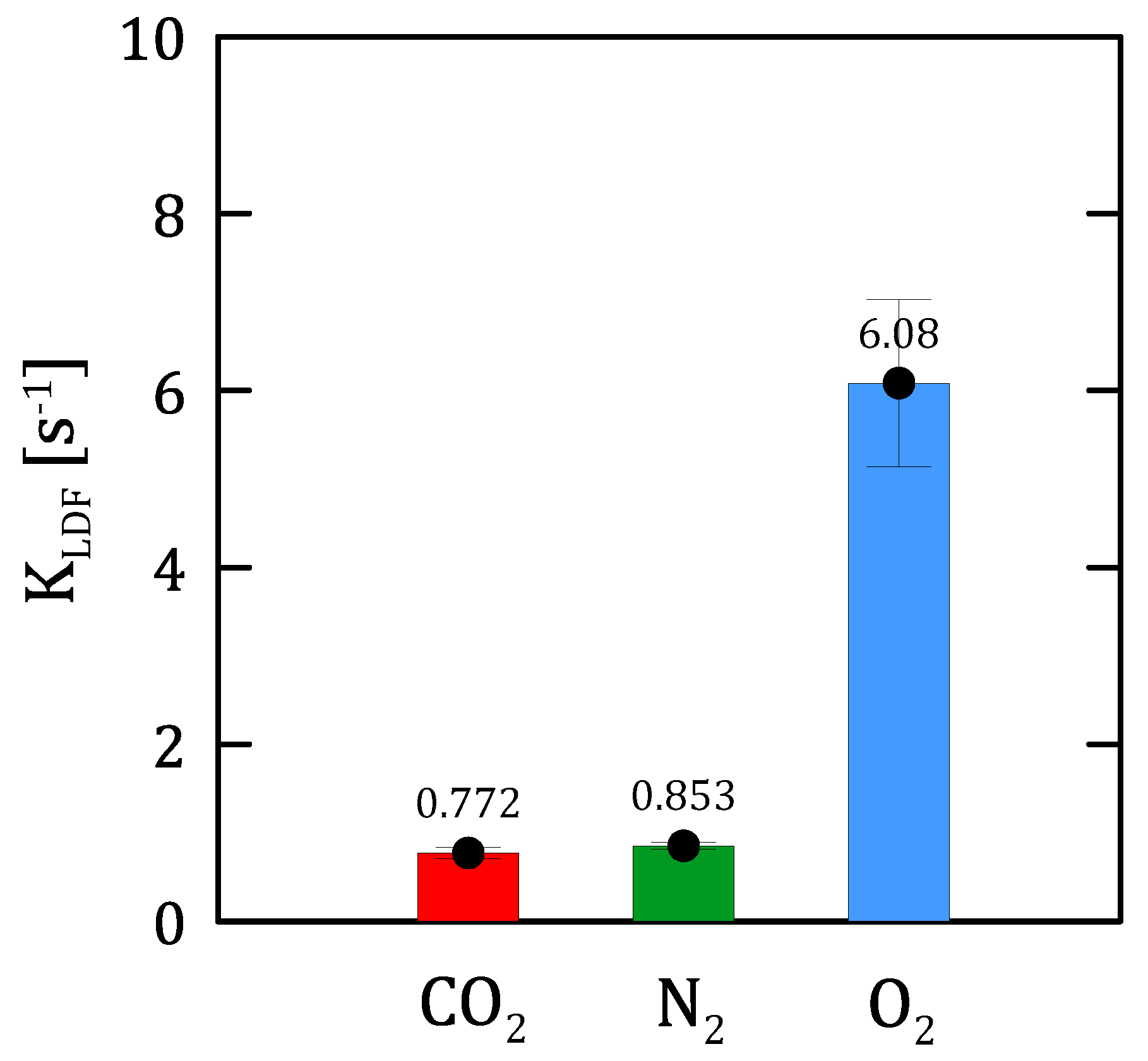

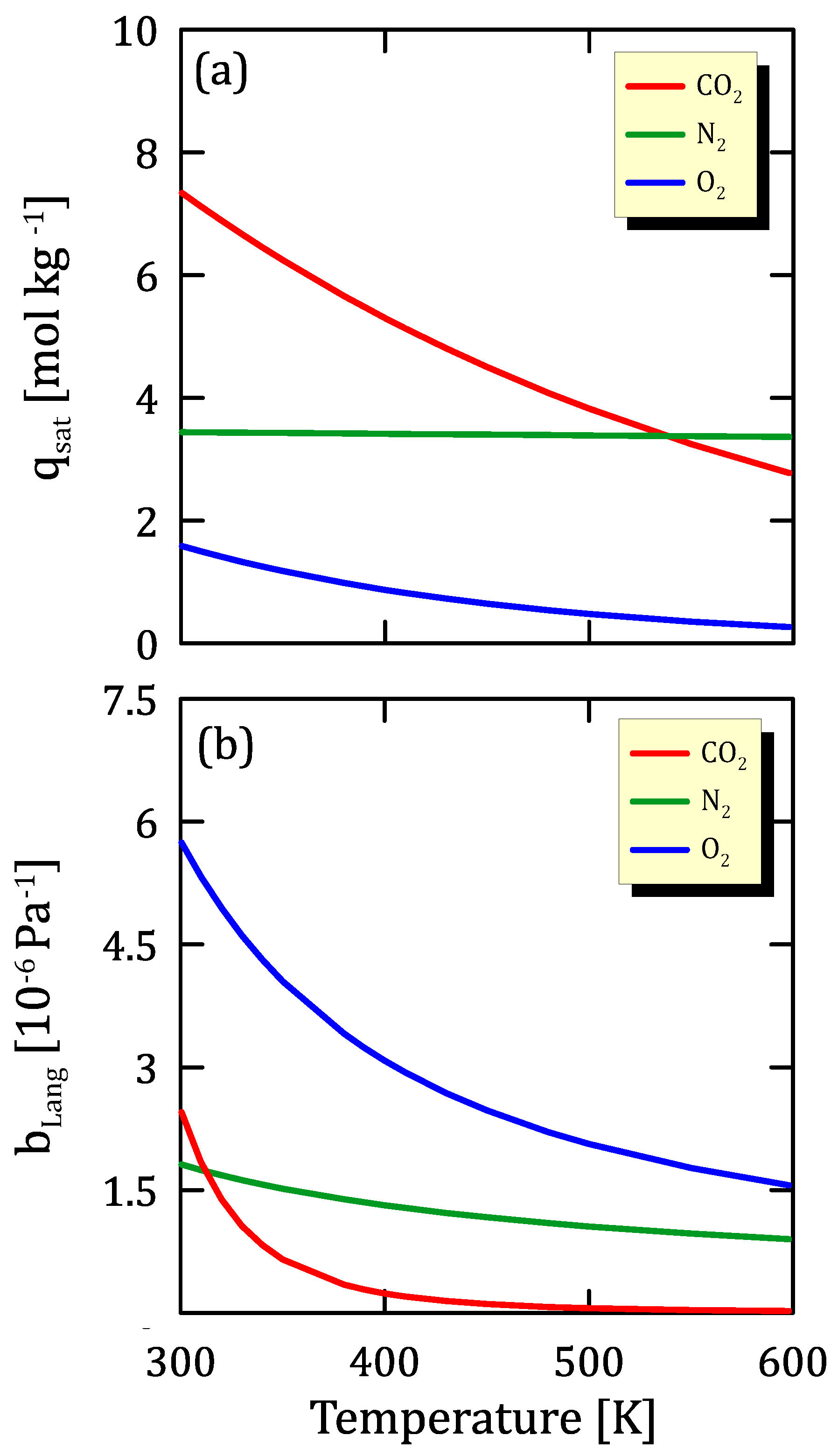

| Species | Parameters | Optimal Value | Confidence Intervals | Units |

|---|---|---|---|---|

| CO2 | KLDF | 0.7722 | ±0.0641 | s−1 |

| 10.358 | ±0.0268 | mol·kg−1 | ||

| 0.6372 | ±0.0475 | - | ||

| b0 | 6.328 × 10−9 | ±0.216 × 10−9 | Pa−1 | |

| Qads | 22017 | ±65 | J·mol−1 | |

| N2 | KLDF | 0.8534 | ±0.0424 | s−1 |

| 3.4695 | ±0.0419 | mol·kg−1 | ||

| 0.01499 | ±0.0033 | - | ||

| b0 | 1.535 × 10−5 | ±0.236 × 10−5 | Pa−1 | |

| Qads | 1788 | ±48 | J·mol−1 | |

| O2 | KLDF | 6.0846 | ±0.9426 | s−1 |

| 2.9904 | ±0.5273 | mol·kg−1 | ||

| 1.1707 | ±0.0337 | - | ||

| b0 | 1.447 × 10−5 | ±0.119 × 10−5 | Pa−1 | |

| Qads | 4819 | ±21 | J·mol−1 |

| Species | Parameter | Conditions | This Work | The Literature | Ref. |

|---|---|---|---|---|---|

| CO2 | qsat, mol·kg−1 | 298 K | 7.4 | 7.5 | [22] |

| 298 K | 7.4 | 7.1 | [23] | ||

| 308 K | 7.2 | 6.6 | [23] | ||

| 318 K | 6.9 | 6.2 | [23] | ||

| 328 K | 6.7 | 5.7 | [23] | ||

| 273 K | 8.0 | 7.4 | [24] | ||

| 323 K | 6.8 | 7.3 | [25] | ||

| 343 K | 6.4 | 6.8 | [25] | ||

| N2 | q, mol·kg−1 | (303 K, 1 bar) | 0.91 | 0.63 | [26] |

| (298 K, 1 bar) | 0.53 | 0.40 | [27] | ||

| (323 K, 1 bar) | 0.49 | 0.23 | [27] | ||

| (323 K, 1 bar) | 0.42 | 0.11 | [27] | ||

| (298 K, 1 bar) | 0.53 | 0.38 | [28] | ||

| O2 | q, mol·kg−1 | (303 K, 1 bar) | 0.83 | 0.31 | [26] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caravella, A.; Prenesti, G.; De Luca, S.; Turano, M.; Testa, F.; Girimonte, R. Evaluation of CO2 Adsorption Parameters in Fluidised Zeolite 13X Beds Using Non-Linear Multivariate Optimisation. Separations 2023, 10, 558. https://doi.org/10.3390/separations10110558

Caravella A, Prenesti G, De Luca S, Turano M, Testa F, Girimonte R. Evaluation of CO2 Adsorption Parameters in Fluidised Zeolite 13X Beds Using Non-Linear Multivariate Optimisation. Separations. 2023; 10(11):558. https://doi.org/10.3390/separations10110558

Chicago/Turabian StyleCaravella, Alessio, Giuseppe Prenesti, Salvatore De Luca, Maria Turano, Flaviano Testa, and Rossella Girimonte. 2023. "Evaluation of CO2 Adsorption Parameters in Fluidised Zeolite 13X Beds Using Non-Linear Multivariate Optimisation" Separations 10, no. 11: 558. https://doi.org/10.3390/separations10110558

APA StyleCaravella, A., Prenesti, G., De Luca, S., Turano, M., Testa, F., & Girimonte, R. (2023). Evaluation of CO2 Adsorption Parameters in Fluidised Zeolite 13X Beds Using Non-Linear Multivariate Optimisation. Separations, 10(11), 558. https://doi.org/10.3390/separations10110558