Overview of the Benefits and Challenges Associated with Pelletizing Biochar

Abstract

:1. Introduction

2. Biochar Feedstock

3. Overview of the Benefits of Biochar Pellets

- -

- Easy handling and transport to nursery and forest sites

- -

- Improved total porosity and aeration porosity in containers (highly desired attributes and their proper balance are essential for optimum seedling growth)

- -

- Reduced nuisance dust and its non-uniform distribution in small-volume containers

- -

- Less nutrient and heavy metal leaching from the pellets.

4. The Principle of the Densification Process

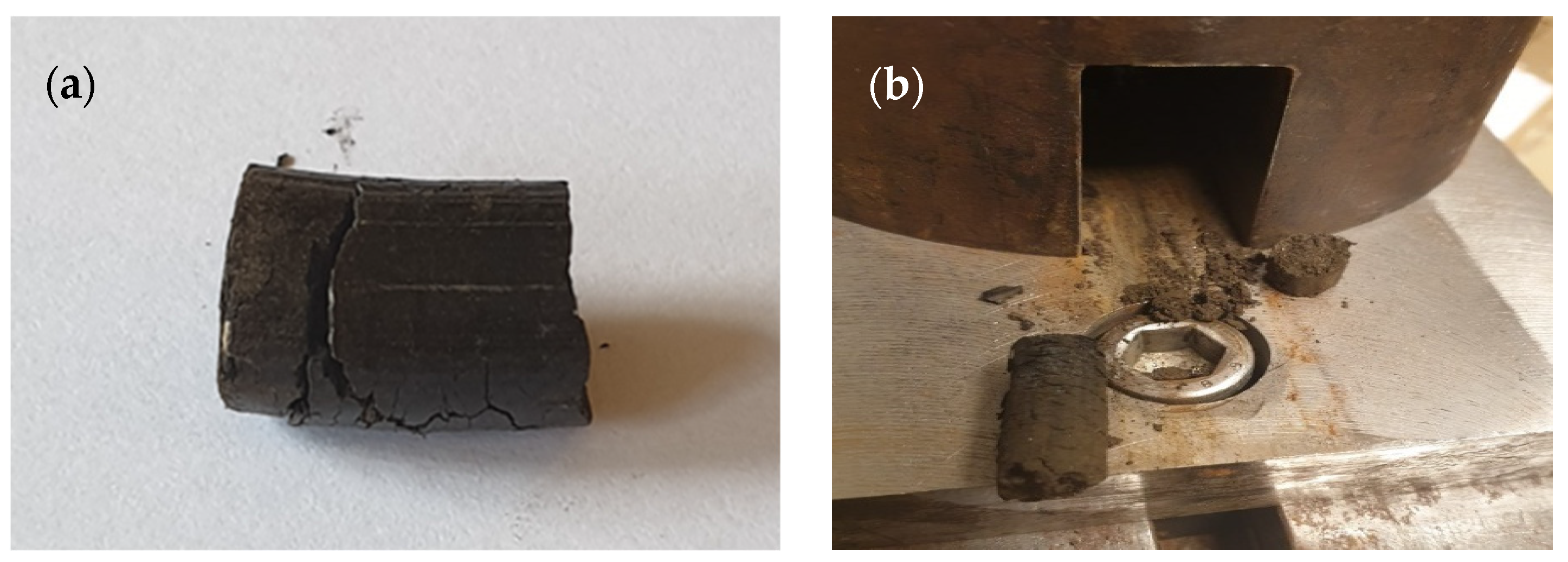

5. Challenges of Pelletizing Biochars Derived from Highly Recalcitrant Materials

6. The Role of Functional Groups in Biochar Densification

7. Pelletizing Pyrochar Derived from Pulp and Paper Mill Sludge

8. Pelletizing Pyrochar Derived from Lignocellulosic Biomass

9. Biochar Pelletizing Methods

- -

- For biochar produced under pyrolysis process conditions (pyrochar), a binder is required for the pelletization of the biochar. A few studies [16,27] used pyrolysis oil as binder and moisture in densification process and reported the mechanical properties of biochar pellets blended with pyrolysis oil enhanced considerably.

- -

- For biochar produced from a HTC process (hydrochar), the use of an external binder may not be required as lignin in hydrochar act as a viable natural binder during pelletization. The nature of lignin at temperatures below 260 °C is not influenced during HTC process [31].

- -

- Moisture plays a very important role in pelletization since moisture can simultaneously act as a binder and lubricant [14]. However, depending on the type of biochar feedstock and carbonization technology, some quantities of water may be added to the mixtures at different mass ratios and homogenized by a magnetic stirrer prior to pelletization.

- -

- Practical biochar pelleting steps using appropriate pellet press involve drying, grinding, addition of binders and water, stirring, compression, cooling, and storage.

10. Conclusions and Research Priorities

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Intergovernmental Panel on Climate Change. Global Warming of 1.5 °C Report; Intergovernmental Panel on climate change: Geneva, Switzerland, 2019. [Google Scholar]

- Sakhiya, A.K.; Anand, A.; Kaushal, P. Production, activation, and applications of biochar in recent times. Biochar 2020, 2, 253–285. [Google Scholar] [CrossRef]

- Wang, D.; Jiang, P.; Zhang, H.; Yuan, W. Biochar production and applications in agro and forestry systems: A review. Sci. Total Environ. 2020, 723, 137775. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, A.; Khoshnevisan, B.; Venkatesh, G.; Eskandari, S. A critical review on advancement and challenges of biochar application in paddy fields: Environmental and life cycle cost analysis. Processes 2020, 8, 1275. [Google Scholar] [CrossRef]

- Sahoo, K.; Upadhyay, A.; Runge, T.; Bergman, R.; Puettmann, M.; Bilek, E. Life-Cycle Assessment and Techno-Economic Analysis of Biochar Produced from Forest Residues Using Portable Systems. Int. J. Life Cycle Assess. 2021, 26, 189–213. [Google Scholar] [CrossRef]

- Mohammadi, A.; Cowie, A.; Cacho, O.; Kristiansen, P.; Anh Mai, T.L.; Joseph, S. Biochar addition in rice farming systems: Economic and energy benefits. Energy 2017, 140, 415–425. [Google Scholar] [CrossRef]

- Major, J.; Lehmann, J.; Rondon, M.; Goodale, C. Fate of soil-applied black carbon: Downward migration, leaching and soil respiration. Glob. Chang. Biol. 2010, 16, 1366–1379. [Google Scholar] [CrossRef]

- Husk, B.; Major, J. Commercial Scale Agricultural Biochar Field Trial in Quebec, Canada, Over Two Years: Effects of Biochar on Soil Fertility, Biology, Crop Productivity and Quality; Blue Leaf Incorporated: Drummondville, QC, Canada, 2008. [Google Scholar]

- Kataki, R.; Chutia, S.R.; Mishra, M.; Bordoloi, N.; Saikia, R.; Bhaskar, T. Feedstock suitability for thermochemical processes. In Recent Advances in Thermo-Chemical Conversion of Biomass, 1st ed.; Pandey, A., Bhaskar, T., Stöcker, M., Sukumaran, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 31–74. [Google Scholar]

- Hu, Q.; Shao, J.; Yang, H.; Yao, D.; Wang, X.; Chen, H. Effects of binders on the properties of bio-char pellets. Appl. Energy 2015, 157, 508–516. [Google Scholar] [CrossRef]

- Xing, X.; Fan, F.; Jiang, W. Characteristics of biochar pellets from corn straw under different pyrolysis temperatures. R. Soc. Open Sci. 2018, 5, 172346. [Google Scholar] [CrossRef] [Green Version]

- Roy, M.M.; Corscadden, K.W. An experimental study of combustion and emissions of biomass briquettes in a domestic wood stove. Appl. Energy 2012, 99, 206–212. [Google Scholar] [CrossRef]

- Li, H.; Jiang, L.-B.; Li, C.-Z.; Liang, J.; Yuan, X.-Z.; Xiao, Z.-H.; Xiao, Z.-H.; Wang, H. Co-pelletization of sewage sludge and biomass: The energy input and properties of pellets. Fuel Process. Technol. 2015, 132, 55–61. [Google Scholar] [CrossRef]

- Riva, L.; Wang, L.; Ravenni, G.; Bartocci, P.; Buø, T.V.; Skreiberg, Ø.; Fantozzi, F.; Nielsen, H.K. Considerations on factors affecting biochar densification behaviour based on a multiparameter model. Energy 2021, 221, 119893. [Google Scholar] [CrossRef]

- Riva, L.; Surup, G.R.; Buø, T.V.; Nielsen, H.K. A study of densified biochar as carbon source in the silicon and ferrosilicon production. Energy 2019, 181, 985–996. [Google Scholar] [CrossRef]

- Riva, L.; Nielsen, H.K.; Skreiberg, Ø.; Wang, L.; Bartocci, P.; Barbanera, M.; Bidini, G.; Fantozzi, F. Analysis of optimal temperature, pressure and binder quantity for the production of biocarbon pellet to be used as a substitute for coke. Appl. Energy 2019, 256, 113933. [Google Scholar] [CrossRef]

- Wang, L.; Buvarp, F.; Skreiberg, Ø.; Bartocci, P. A study on densification and CO2 gasification of biocarbon. Chem. Eng. Trans. 2018, 65, 145–150. [Google Scholar]

- Kang, K.; Zhu, M.; Sun, G.; Qiu, L.; Guo, X.; Meda, V.; Sun, R. Codensification of Eucommia ulmoides Oliver stem with pyrolysis oil and char for solid biofuel: An optimization and characterization study. Appl. Energy 2018, 223, 347–357. [Google Scholar] [CrossRef]

- Bartocci, P.; Barbanera, M.; Skreiberg, Ø.; Wang, L.; Bidini, G.; Fantozzi, F. Biocarbon pellet production: Optimization of pelletizing process. Chem. Eng. Trans. 2018, 65, 355–360. [Google Scholar]

- Hu, Q.; Yang, H.; Yao, D.; Zhu, D.; Wang, X.; Shao, J.; Chen, H. The densification of bio-char: Effect of pyrolysis temperature on the qualities of pellets. Bioresour. Technol. 2016, 200, 521–527. [Google Scholar] [CrossRef]

- Colantoni, A.; Evic, N.; Lord, R.; Retschitzegger, S.; Proto, A.R.; Gallucci, F.; Monarca, D. Characterization of biochars produced from pyrolysis of pelletized agricultural residues. Renew. Sustain. Energy Rev. 2016, 64, 187–194. [Google Scholar] [CrossRef] [Green Version]

- Sun, K.; Jin, M.; Keiluweit, M.; Kleber, Z.; Wang, Z.; Pan, B.; Xing, B. Polar and aliphatic domains regulate sorption of phthalic acid esters (PAEs) to biochar. Bioresour. Technol. 2012, 118, 120–127. [Google Scholar] [CrossRef]

- Sohi, S.; Wade, S.C.; Kern, J. Consistency of biochar properties over time and production scales: A characterisation of standard materials. J. Anal. Appl. Pyrolysis 2017, 132, 200–210. [Google Scholar]

- Ok, Y.S.; Chang, S.X.; Gao, B.; Chung, H.-J. SMART biochar technology—A shifting paradigm towards advanced materials and healthcare research. Environ. Technol. Innov. 2015, 4, 206–209. [Google Scholar] [CrossRef]

- Singh, B.P.; Cowie, A.L.; Smernik, R.J. Biochar carbon stability in a clayey soil as a function of feedstock and pyrolysis temperature. Environ. Sci. Technol. 2012, 46, 11770–11778. [Google Scholar] [CrossRef] [PubMed]

- Hameed, A.; Hussain, S.A.; Yang, J.; Ijaz, M.U.; Liu, Q.; Suleria, H.A.R.; Song, Y. Antioxidants potential of the filamentous fungi (Mucor circinelloides). Nutrients 2017, 9, 1101. [Google Scholar] [CrossRef] [Green Version]

- Riva, L.; Cardarelli, A.; Andersen, G.J.; Buø, T.V.; Barbanera, M.; Bartocci, P.; Fantozzi, F.; Nielsen, H.K. On the self-heating behavior of upgraded biochar pellets blended with pyrolysis oil: Effects of process parameters. Fuel 2020, 278, 118395. [Google Scholar] [CrossRef]

- Mohammadi, A. Biochar Pellets, a Soil Nutritional and Liming Agent or a Source of Energy: Effects of Ash and Lignin on the Physical and Chemical Properties; ÅForsk Foundation: Stockholm, Sweden, 2021. [Google Scholar]

- Abdullah, H.; Wu, H. Biochar as a fuel: Properties and grindability of biochars produced from the pyrolysis of mallee wood under slow-heating conditions. Energy Fuels 2009, 23, 4174–4181. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass palletization—A review. BioResources 2012, 7, 4451–4490. [Google Scholar] [CrossRef]

- Reza, T.M.; Lynam, J.G.; Vasquez, V.R.; Coronella, C.J. Pelletization of biochar from hydrothermally carbonized wood. Environ. Prog. Sustain. Energy 2012, 31, 225–234. [Google Scholar] [CrossRef]

- Mohammadi, A.; Venkatesh, G.; Sandberg, M.; Eskandari, S.; Joseph, S.; Granström, K. A Comprehensive Environmental Life Cycle Assessment of the Use of Hydrochar Pellets in Combined Heat and Power Plants. Sustainability 2020, 12, 9026. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, Z.; Shen, B.; Liu, L. Insights into biochar and hydrochar production and applications: A review. Energy 2019, 171, 581–598. [Google Scholar] [CrossRef]

- Eskandari, S.; Mohammadi, A.; Sandberg, M.; Eckstein, R.L.; Hedberg, K.; Granström, K. HydrocharAmended Substrates for Production of Containerized Pine Tree Seedlings under Different Fertilization Regimes. Agronomy 2019, 9, 350. [Google Scholar] [CrossRef] [Green Version]

- Mladenovic, M.; Paprika, M.; Marinkovic, A. Denitrification techniques for biomass combustion. Renew. Sustain. Energy Rev. 2018, 82, 3350–3364. [Google Scholar] [CrossRef]

- Yin, C.Y. Prediction of higher heating values of biomass from proximate and ultimate analyses. Fuel 2011, 90, 1128–1132. [Google Scholar] [CrossRef] [Green Version]

- Zhu, G.; Yang, L.; Gao, Y.; Xu, J.; Chen, H.; Zhu, Y.; Wang, Y.; Liao, C.; Lu, C.; Zhu, C. Characterization and pelletization of cotton stalk hydrochar from HTC and combustion kinetics of hydrochar pellets by TGA. Fuel 2019, 244, 479–491. [Google Scholar] [CrossRef]

- Liu, Z.; Quek, A.; Balasubramanian, R. Preparation and characterization of fuel pellets from woody biomass, agro-residues and their corresponding hydrochars. Appl. Energy 2014, 113, 1315–1322. [Google Scholar] [CrossRef]

- Chen, H.; Zhou, Y.; Zhao, H.; Li, Q. A comparative study on behavior of heavy metals in pyrochar and hydrochar from sewage sludge. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 565–571. [Google Scholar] [CrossRef]

- Mohammadi, A.; Sandberg, M.; Venkatesh, G.; Eskandari, S.; Dalgaard, T.; Joseph, S.; Granström, K. Environmental performance of end-of-life handling alternatives for paper-and-pulp-mill sludge: Using digestate as a source of energy or for biochar production. Energy 2019, 182, 594–605. [Google Scholar] [CrossRef]

- Mohammadi, A.; Sandberg, M.; Venkatesh, G.; Eskandari, S.; Dalgaard, T.; Joseph, S.; Granström, K. Environmental analysis of producing biochar and energy recovery from pulp and paper mill biosludge. J. Ind. Ecol. 2019, 23, 1039–1051. [Google Scholar] [CrossRef]

- Holm, J.K.; Stelte, W.; Posselt, D.; Ahrenfeldt, J.; Henriksen, U.B. Optimization of a multiparameter model for biomass pelletization to investigate temperature dependence and to facilitate fast testing of pelletization behavior. Energy Fuels 2011, 25, 3706–3711. [Google Scholar] [CrossRef]

- Tabil, L.G. Binding and Pelleting Characteristics of Alfalfa. Ph.D. Thesis, University of Saskatchewan, Saskatchewan, SK, Canada, 1996. [Google Scholar]

- Tabil, L.G.; Sokhansanj, S. Compression and compaction behavior of alfalfa grinds, Part 1: Compression behavior. Powder Hand. Process. 1996, 8, 17–23. [Google Scholar]

- Tabil, L.G.; Sokhansanj, S. Compression and compaction behavior of alfalfa grinds, Part 2: Compaction behavior. Powder Hand. Process. 1996, 8, 117–122. [Google Scholar]

- Holm, J.K.; Henriksen, U.B.; Hustad, J.E.; Sørensen, L.H. Toward an understanding of controlling parameters in softwood and hardwood pellets production. Energy Fuels 2006, 20, 2686–2694. [Google Scholar] [CrossRef]

- Hovey, G.; Allen, D.G.; Tran, H. The sticky behaviour of pulp and paper mill biosludge during drying. Biofuel 2019, 18, 353–359. [Google Scholar]

- Lekha, P.; Andrew, J.; Gibril, M.; Sithole, B. Pulp and paper mill sludge: A potential resource for producing high-value products. TAPPSA 2017, 1, 16–19. [Google Scholar]

- Li, S.; Barreto, V.; Li, R.; Chen, G.; Hsieh, Y.P. Nitrogen retention of biochar derived from different feedstocks at variable pyrolysis temperatures. J. Anal. Appl. Pyrolysis 2018, 133, 136–146. [Google Scholar] [CrossRef]

- Dai, Z.; Zhang, X.; Tang, C.; Muhammad, N.; Wu, J.; Brookes, P.C.; Xu, J. Potential role of biochars in decreasing soil acidification—A critical review. Sci. Total Environ. 2017, 581–582, 601–611. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, A.; Venkatesh, G.; Sandberg, M.; Eskandari, S.; Granström, K. Life cycle assessment of combination of anaerobic digestion and pyrolysis: Focusing on different options for biogas use. Adv. Geosci. 2019, 49, 57–66. [Google Scholar] [CrossRef] [Green Version]

- Anukam, A.I.; Berghel, J.; Famewo, E.B.; Frodeson, S. Improving the understanding of the bonding mechanism of primary components of biomass pellets through the use of advanced analytical instruments. J. Wood Chem. Technol. 2020, 40, 15–32. [Google Scholar] [CrossRef]

- Nielsen, N.P.K.; Gardner, D.J.; Felby, C. Effect of extractives and storage on the pelletizing process of sawdust. Fuel 2010, 89, 94–98. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, F.S. Effects of various solvents on the liquefaction of biomass to produce fuels and chemical feedstocks. Energy Convers. Manag. 2008, 49, 3498–3504. [Google Scholar] [CrossRef]

- Yan, W.; Acharjee, T.C.; Coronella, C.J.; Vasquez, V.R. Thermal pretreatment of lignocellulosic biomass. Environ. Prog. Sustain. Energy 2009, 28, 435–440. [Google Scholar] [CrossRef]

- Gai, C.; Chen, M.; Liu, T.; Peng, N.; Liu, Z. Gasification characteristics of hydrochar and pyrochar derived from sewage sludge. Energy 2016, 113, 957–965. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, H.; Wang, X.; Zhang, S.; Chen, H. Biomass-based pyrolytic polygeneration system on cotton stalk pyrolysis: Influence of temperature. Bioresour. Technol. 2012, 7, 411–418. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A study of bonding and failure mechanisms in fuel pellets from different biomass resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef] [Green Version]

- Olsson, A.M.; Salmen, L. Viscoelasticity of in situ lignin as affected by structure: Softwood vs. hardwood. In Viscoelasticity of Biomaterials; Glasser, W., Ed.; American Chemical Society: Washington, DC, USA, 1992; pp. 133–143. [Google Scholar]

- Bazargan, A.; Rough, S.L.; McKay, G. Compaction of palm kernel shell biochars for application as solid fuel. Biomass Bioenergy 2014, 70, 489–497. [Google Scholar] [CrossRef]

- Kong, L.; Tian, S.; Li, Z.; Luo, R.; Chen, D.; Tu, Y.; Xiong, Y. Conversion of recycled sawdust into high HHV and low NOx emission bio-char pellets using lignin and calcium hydroxide blended binders. Renew. Energy 2013, 60, 559–565. [Google Scholar] [CrossRef]

- Chatterjee, R.; Sajjadi, B.; Chen, W.-Y.; Mattern, D.L.; Hammer, N.; Raman, V.; Dorris, A. Effect of pyrolysis temperature on physicochemical properties and acoustic-based amination of biochar for efficient CO2 adsorption. Front. Energy Res. 2020, 8, 85. [Google Scholar] [CrossRef]

- Mohammadi, A.; Cowie, A.L.; Anh Mai, T.L.; Brandão, M.; de la Rosa, R.A.; Kristiansen, P.; Joseph, S. Climate-change and health effects of using rice husk for biochar-compost: Comparing three pyrolysis systems. J. Clean. Prod. 2017, 162, 260–272. [Google Scholar] [CrossRef]

- Ulusal, A.; Varol, E.A.; Bruckman, V.J.; Uzun, B.B. Opportunity for sustainable biomass valorization to produce biochar for improving soil characteristics. Biomass Convers. Biorefin. 2021, 11, 1041–1051. [Google Scholar] [CrossRef]

| Reference | Country (Region) | Feedstock for Biochar | Carbonization Technology | Binder | Water Added | Pellet Technology |

|---|---|---|---|---|---|---|

| [10] | China | Rice husk | Pyrolysis | Lignin, starch, Ca(OH)2, NaOH | 5–20% | Universal material testing machine (CMT5205, MTS, China) |

| [11] | China | Corn straw | Pyrolysis | - | - | - |

| [16] | Norway-Italy | Pine wood | Pyrolysis | Pyrolysis oil | 33.9 | Compact hot pellet press (MTI, USA) |

| [20] | China | Woody shavings | Pyrolysis | Lignin | 35% | Universal material testing machine (CMT5205, MTS, China) |

| [31] | USA | Pine wood | HTC | - | - | Single pellet machine |

| [37] | China | Cotton stalk | HTC | - | 20% | Single pellet machine |

| [38] | Singapore | Pinewood sawdust, rice husk coconut residues | HTC | - | - | Single pellet machine |

| [61] | China | Spruce wood sawdust | Pyrolysis | Lignin, Ca(OH)2, NaOH, CaCl2, CaO | 0–20% | Hydraulic press powder pelletizer (HuaiYu Tianjin, China) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammadi, A. Overview of the Benefits and Challenges Associated with Pelletizing Biochar. Processes 2021, 9, 1591. https://doi.org/10.3390/pr9091591

Mohammadi A. Overview of the Benefits and Challenges Associated with Pelletizing Biochar. Processes. 2021; 9(9):1591. https://doi.org/10.3390/pr9091591

Chicago/Turabian StyleMohammadi, Ali. 2021. "Overview of the Benefits and Challenges Associated with Pelletizing Biochar" Processes 9, no. 9: 1591. https://doi.org/10.3390/pr9091591

APA StyleMohammadi, A. (2021). Overview of the Benefits and Challenges Associated with Pelletizing Biochar. Processes, 9(9), 1591. https://doi.org/10.3390/pr9091591