Possibilities of Using Organic Waste after Biological and Physical Processing—An Overview

Abstract

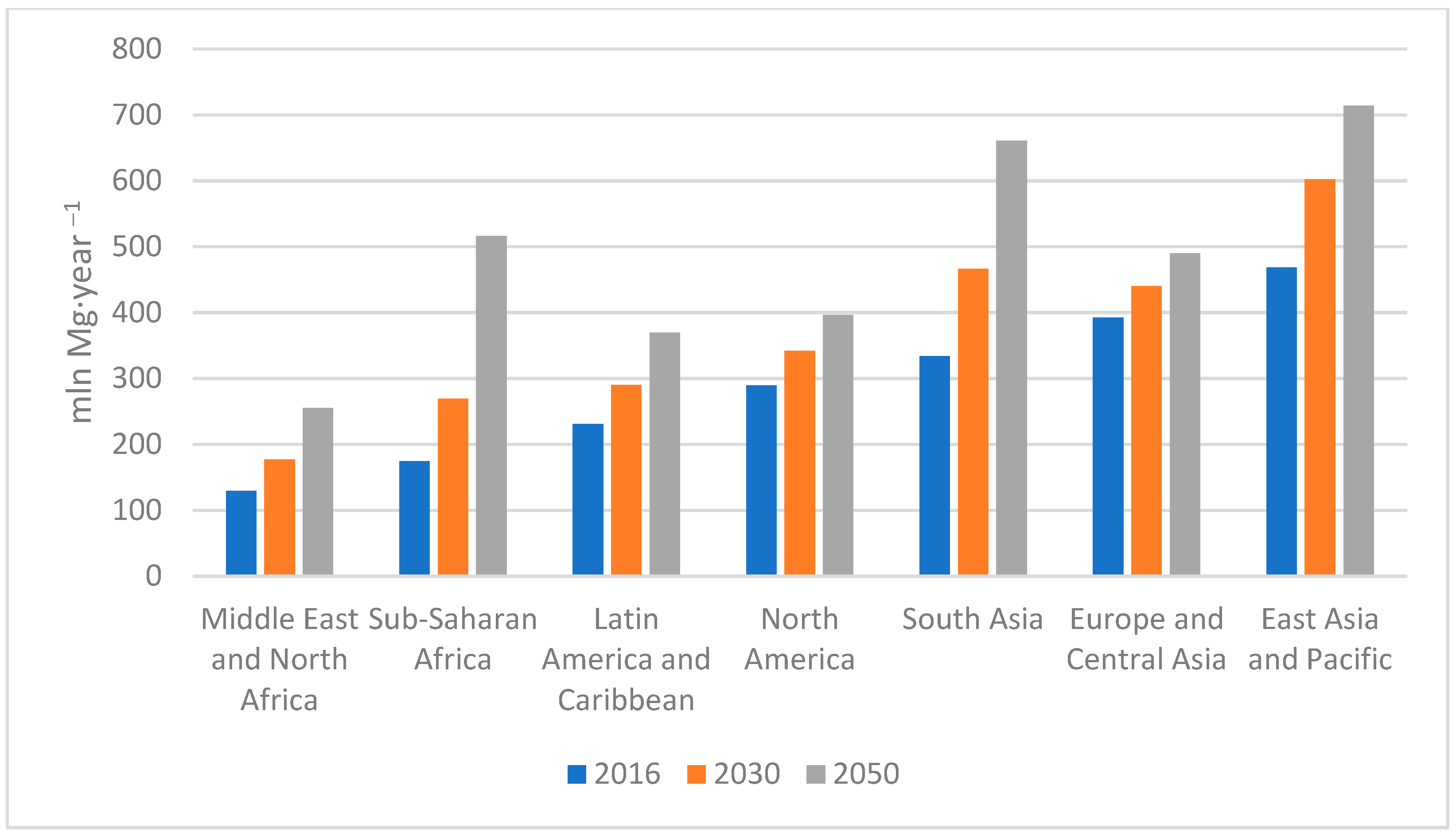

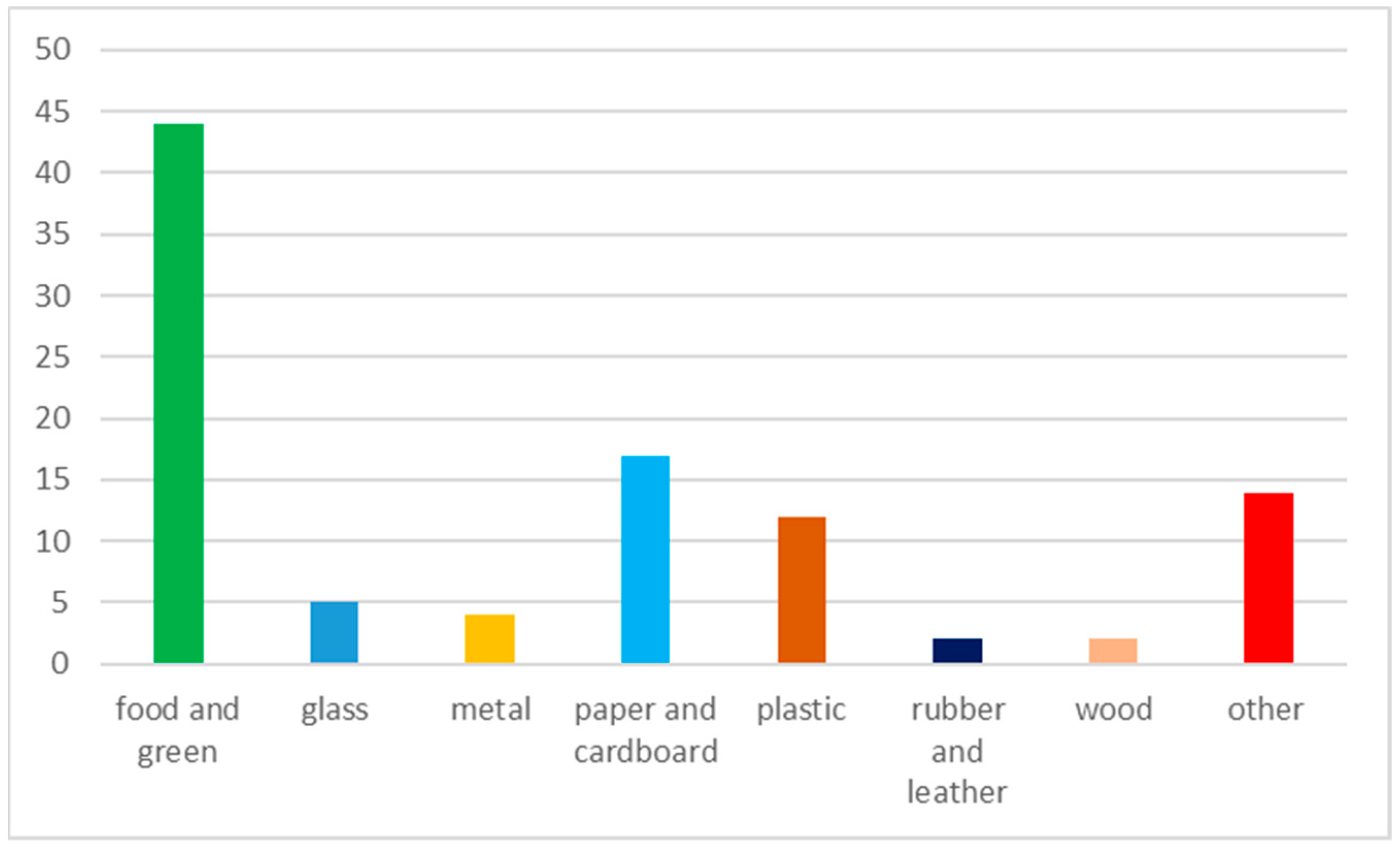

:1. Introduction

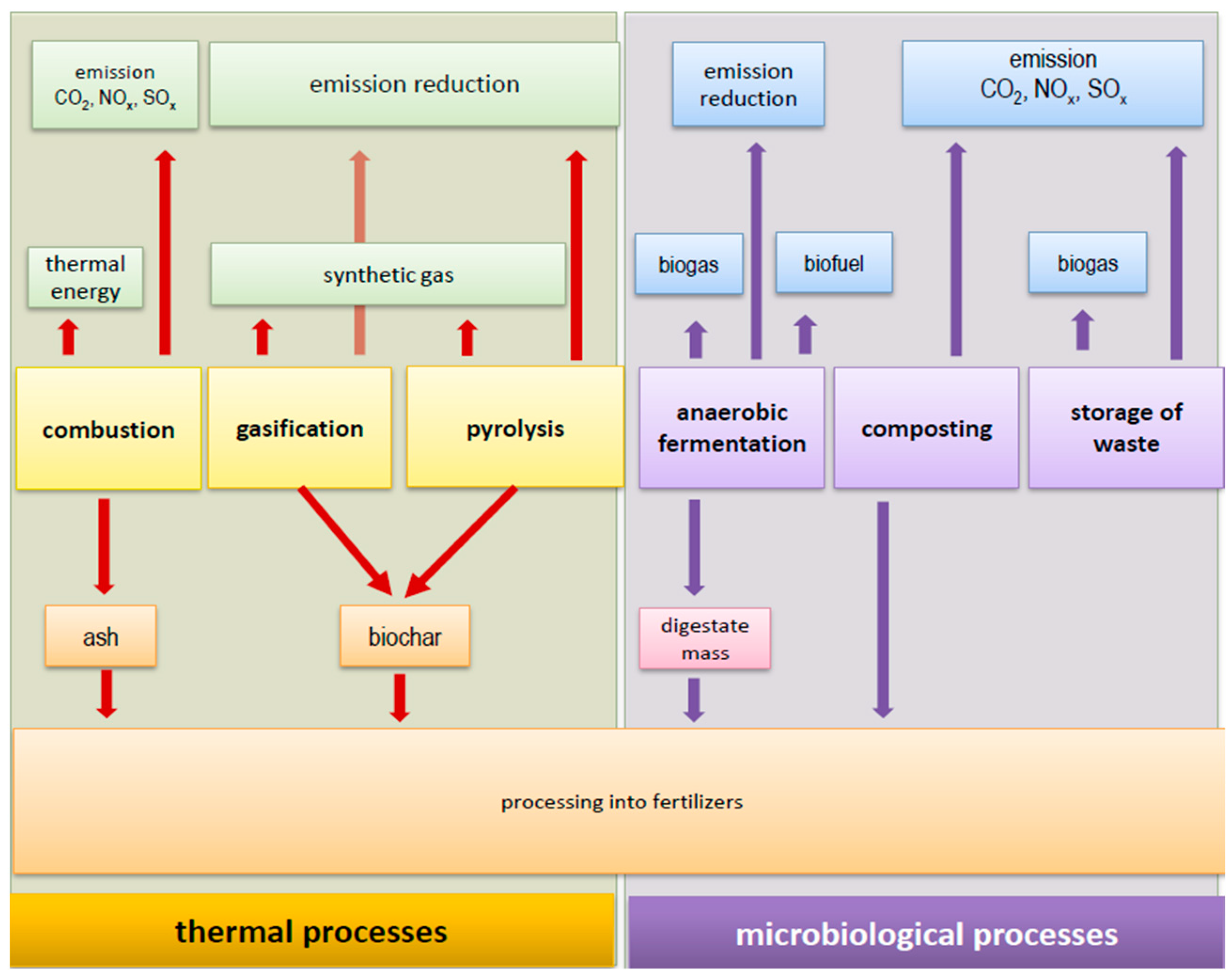

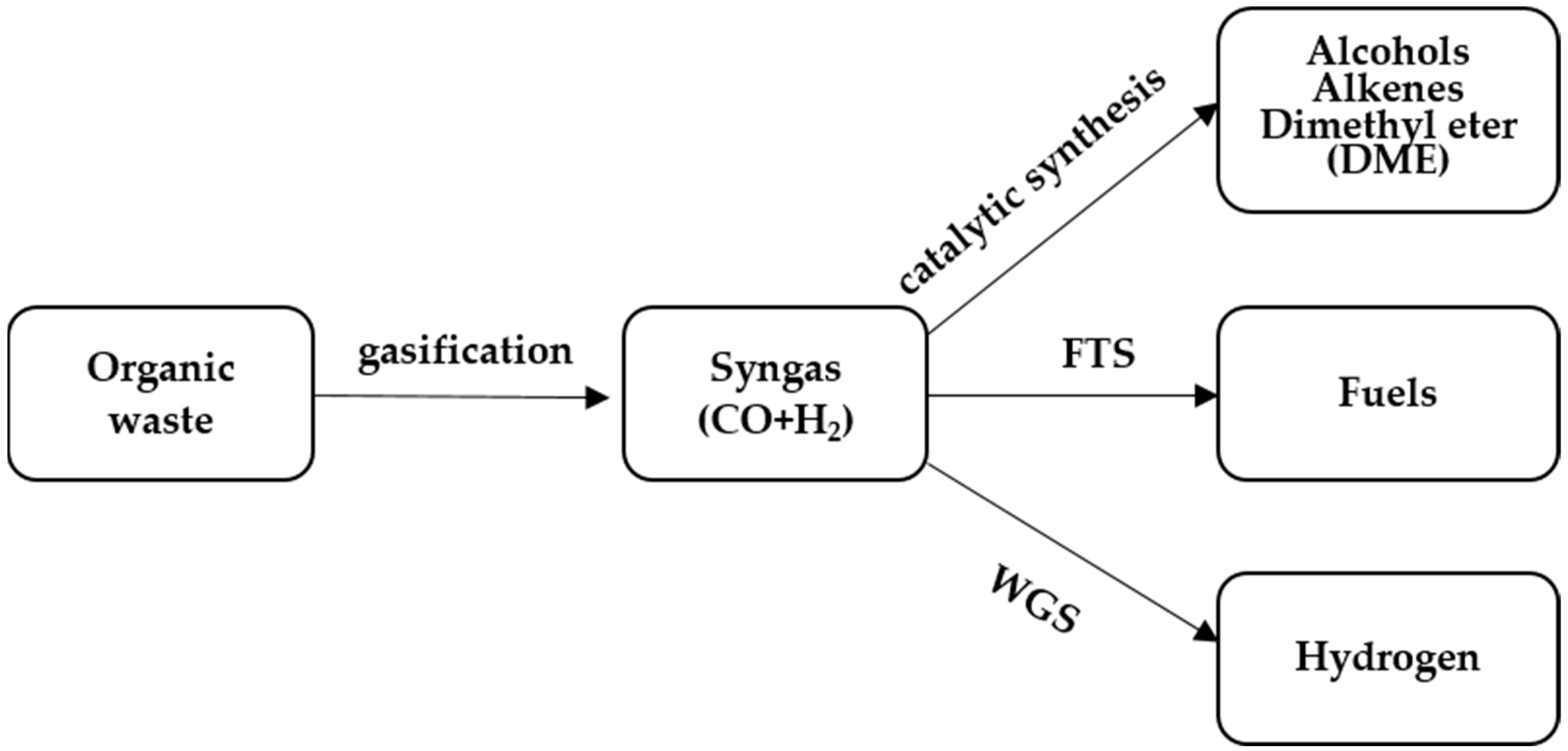

2. Thermal Processes

- (i)

- drying—aims at evaporating excess moisture and preparation of organic material for further incineration stages,

- (ii)

- degassing—usually occurs at low temperatures between 100 and 300 ºC. At this stage, hydrocarbons are released. The rate of drying and degassing processes depends exclusively on the supplied heat.

- (iii)

- incineration—destruction of organic bonds with heat release

3. Microbiological Processes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; Urban Development Series; World Bank: Washington, DC, USA, 2018; Available online: https://openknowledge.worldbank.org/handle/10986/30317 (accessed on 19 May 2021). [CrossRef]

- A European Green Deal. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal/actions-being-taken-eu_en (accessed on 11 May 2021).

- Schröder, P.; Sauvêtre, A.; Gnädinger, F.; Pesaresi, P.; Chmeliková, L.; Doğan, N.; Gerl, G.; Gökçe, A.; Hamel, C.; Millan, R.; et al. Discussion paper: Sustainable increase of crop production through improved technical strategies, breeding and adapted management—A European perspective. Total Environ. 2019, 678, 146–161. [Google Scholar] [CrossRef]

- Schroder, P.; Beckers, B.; Daniels, S.; Gnadinger, F.; Maestri, E.; Marmiroli, N.; Mench, M.; Millan, R.; Obermeier, M.M.; Oustriere, N.; et al. Intensify production, transform biomass to energy and novel goods and protect soils in Europe-A vision how to mobilize marginal lands. Sci. Total Environ. 2018, 616, 1101–1123. [Google Scholar] [CrossRef] [PubMed]

- Regulation (EU) 2019/1009 of the European Parliament and of the Council of 5 June 2019 laying down rules on the making available on the market of EU fertilising products and amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009 and repealing Regulation (EC) No 2003/2003. Off. J. Eur. Union 2019, 19.

- Khan, A.A.; de Jong, W.; Jansens, P.J.; Spliethoff, H. Biomass combustion in fluidized bed boilers: Potential problems and remedies. Fuel Process Technol. 2009, 90, 21–50. [Google Scholar] [CrossRef]

- Melotti, R.; Santagata, E.; Bassani, M.; Salvo, M.; Rizzo, S.A. Preliminary investigation into the physical and chemical properties of biomass ashes used as aggregate fillers for bituminous mixtures. Waste Manag. 2013, 33, 1906–1917. [Google Scholar] [CrossRef]

- Tarelho, L.A.C.; Teixeira, E.R.; Silva, D.F.R.; Modolo, R.C.; Labrincha, J.A.; Rocha, F.J.F.T. Characteristics of distinct ash flows in a biomass thermal power plant with bubbling fluidised bed combustor. Energy 2015, 90, 387–402. [Google Scholar] [CrossRef]

- Lanzerstorfer, C. Chemical composition and physical properties of filter fly ashes from eight grate-fired biomass combustion plants. J. Environ. Sci. 2015, 30, 191–197. [Google Scholar] [CrossRef] [PubMed]

- Park, N.D.; Rutherford, P.M.; Thring, R.W.; Helle, S.S. Wood pellet fly ash and bottom ash as an effective liming agent and nutrient source for rye grass (Lolium perenne L.) and oats (Avena sativa). Chemosphere 2012, 86, 427–432. [Google Scholar] [CrossRef]

- Koivula, N.; Räikkönen, T.; Urpilainen, S.; Ranta, J.; Hänninen, K. Ash in composting of source-separated catering waste. Bioresour. Technol. 2004, 93, 291–299. [Google Scholar] [CrossRef]

- Rosenfeld, P.; Grey, M.; Suffet, M. Composts odor control using high carbon wood ash. Water Sci. Technol. 2004, 49, 171–178. [Google Scholar] [CrossRef]

- Kurola, J.M.; Arnold, M.; Kontro, M.H.; Talves, M.; Romantschu, M. Wood ash for application in municipal biowaste composting. Bioresour. Technol. 2011, 102, 5214–5220. [Google Scholar] [CrossRef] [PubMed]

- Tlustoš, P.; Ochecová, P.; Száková, J.; Perná, I.; Hanzlíček, T.; Habart, J.; Straka, P. Monitoring the quality of ashes from biomass combustion. In Certified Methodology; Czech University of Life Sciences Prague: Prague, Czechia, 2012; Volume 26, ISBN 978-80-213-2327-8. [Google Scholar]

- Zemanová, V.; Trakal, L.; Ochecová, P.; Száková, J.; Pavlíková, D. A model experiment: Competitive sorption of Cd, Cu, Pb and Zn by three different soils. Soil Water Res. 2014, 9, 97–103. [Google Scholar] [CrossRef] [Green Version]

- Bradna, J.; Malaák, J.; Hájek, D. The properties of wheat straw combustion and use of fly ash as a soil amendment. Agron. Res. 2016, 14, 1257–1265. [Google Scholar]

- Ribeiro, J.P.; Vicente, E.D.; Gomes, A.P.; Nunes, M.I.; Alves, C.; Tarelho, L.A.C. Effect of industrial and domestic ash from biomass combustion, and spent coffee grounds, on soil fertility and plant growth: Experiments at field conditions. Environ. Sci. Pollut. Res. 2017, 24, 15270–15277. [Google Scholar] [CrossRef] [PubMed]

- Obernberger, I.; Supancic, K. Possibilities of ash utilisation from biomass combustion plants, ETA-Renewable Energies Ed. In Proceedings of the 17th European Biomass Conference and Exhibition, Hamburg, Germany, 29 June–3 July 2009; pp. 1–12. [Google Scholar]

- Konovalov, V.; Fedorov, A.; Goncharov, A. Use of Slags in the Production of Portland Cement Clinker. In 14th International Congress for Applied Mineralogy (ICAM2019); Glagolev, S., Ed.; Springer Proceedings in Earth and Environmental Sciences; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef] [Green Version]

- Krayushkina, K.; Khimerik, T.; Pershakov, V.; Bieliatynskyi, A. Use of slag materials in road construction. Proc. Natl. Aviat. Univ. 2018, 4, 88–93. [Google Scholar] [CrossRef]

- Díaz, R.O.; Farfán, M.R.; Cardenas, J.; Forero, J. Use of steel slagas a new material for roads. J. Phys. 2017, 935, 012006. [Google Scholar] [CrossRef] [Green Version]

- Kambole, C.; Paige-Green, P.; Kupolati, W.K.; Ndambuki, J.M.; Adeboje, A.O. Basic oxygen furnace slag for road pavements: A review of material characteristics and performance for effective utilisation in southern Africa. Constr. Build. Mater. 2017, 148, 618–631. [Google Scholar] [CrossRef]

- Rouabah, K.; Zergua, A.; Beroual, A.; Guetteche, M. Recovery and Use of Blast Furnace Slag in the Field of Road Construction in Algeria. Open J. Civ. Eng. 2013, 3, 113–118. [Google Scholar] [CrossRef] [Green Version]

- Duong, T.L.; Nguyen, D.T.; Nguyen, H.H.M. Fast pyrolysis of Vietnamese waste biomass: Relationship between biomass composition, reaction conditions, and pyrolysis products, and a strategy to use a biomass mixture as feedstock for bio-oil production. J. Mater. Cycles Waste Manag. 2019, 21, 624–632. [Google Scholar] [CrossRef]

- Budianto, A.; Kusdarini, E.; Effendi, S.S.W.; Aziz, M. The Production of Activated Carbon from Indonesian Mangrove Charcoal. In Proceedings of the 1st International Conference on Advanced Engineering and Technology, Surabaya, Indonesia, 19 September 2018. [Google Scholar] [CrossRef]

- Mansour, F.; Al-Hindi, M.; Yahfoufi, R. The use of activated carbon for the removal of pharmaceuticals from aqueous solutions: A review. Rev. Environ. Sci. Biotechnol. 2018, 17, 109–145. [Google Scholar] [CrossRef]

- Wyrwa, J.; Barska, A. Innovations in the food packaging market: Active packaging. Eur. Food Res. Technol. 2017, 243, 1681–1692. [Google Scholar] [CrossRef]

- Huang, X.; Cao, J.P.; Shi, P.; Zhao, X.Y.; Feng, X.B.; Zhao, Y.P.; Fan, X.; Wei, X.Y.; Takarada, T. Influences of pyrolysis conditions in the production and chemical composition of the bio-oils from fast pyrolysis of sewage sludge. J. Anal. Appl. Pyrolysis 2014, 110, 353–362. [Google Scholar] [CrossRef]

- Bai, B.; Liu, Y.; Wang, Q.; Zou, J.; Zhang, H.; Jin, H.; Li, X. Experimental investigation on gasification characteristics of plastic wastes in supercritical water. Renew. Energy 2019, 135, 32–40. [Google Scholar] [CrossRef]

- Messerle, V.E.; Mosse, A.L.; Ustimenko, A.B. Processing of biomedical waste in plasma gasifier. Waste Manag. 2018, 79, 791–799. [Google Scholar] [CrossRef] [PubMed]

- Purkarová, E.; Ciahotný, K.; Šváb, M.; Skoblia, S.; Beňo, Z. Supercritical water gasification of wastes from the paper industry. J. Supercrit. Fluids 2018, 135, 130–136. [Google Scholar] [CrossRef]

- Arregi, A.; Amutio, M.; Lopez, G.; Bilbao, J.; Olazar, M. Evaluation of thermochemical routes for hydrogen production from biomass: A review. Energy Convers. Manag. 2018, 165, 696–719. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Y.; Riley, J.T.; Pan, W.P. A novel biomass air gasification process for producing tar-free higher heating value fuel gas. Fuel Process. Technol. 2005, 87, 343–353. [Google Scholar] [CrossRef]

- Chinweoke, O.U.; Ogechukwu, C.C.; Onu, A.V.; Kenneth, O.E.; Chinedozi, E.E. Gasification of organic waste for renewable gas production systems. In Transactions on Engineering Technologies; Ao, S.I., Kim, H.K., Amouzegar, M.A., Eds.; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Su, W.; Cai, C.; Liu, P.; Lin, W.; Liang, B.; Zhang, H.; Ma, Z.; Ma, H.; Xing, Y.; Liu, W. Supercritical water gasification of food waste: Effect of parameters on hydrogen production. Int. J. Hydrogen Energy 2020, 45, 14744–14755. Available online: https://www.cheric.org/research/tech/periodicals/doi.php?art_seq=1817908 (accessed on 25 April 2021). [CrossRef]

- Antoniou, N.; Monlau, F.; Sambusiti, C.; Ficara, E.; Barakat, A.; Zabaniotou, A. Contribution to Circular Economy options of mixed agricultural wastes management: Coupling anaerobic digestion with gasification for enhanced energy and material recovery. J. Clean. Prod. 2019, 209, 505–514. [Google Scholar] [CrossRef]

- Lopes, E.J.; Okamura, L.A.; Maruyama, S.A.; Yamamoto, C.I. Evaluation of energy gain from the segregation of organic materials from municipal solid waste in gasification processes. Renew. Energy 2018, 116, 623–629. [Google Scholar] [CrossRef]

- Gorazda, K.; Tarko, B.; Werle, S.; Wzorek, Z. Sewage sludge as a fuel and raw material for phosphorus recovery: Combined process of gasification and P extraction. Waste Manag. 2018, 73, 404–415. [Google Scholar] [CrossRef] [PubMed]

- Thomsen, T.P.; Hauggaard-Nielsen, H.; Gøbel, B.; Stoholm, P.; Ahrenfeldt, J.; Henriksen, U.B.; Müller-Stöver, D.S. Low temperature circulating fluidized bed gasification and co-gasification of municipal sewage sludge. Part 2: Evaluation of ash materials as phosphorus fertilizer. Waste Manag. 2017, 66, 145–154. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Thomsen, T.P.; Sárossy, Z.; Ahrenfeldt, J.; Henriksen, U.B.; Frandsen, F.J.; Müller-Stöver, D.S. Changes imposed by pyrolysis, thermal gasification and incineration on composition and phosphorus fertilizer quality of municipal sewage sludge. J. Environ. Manag. 2017, 198, 308–318. [Google Scholar] [CrossRef] [Green Version]

- Zhu, D.; Xue, B.; Jiang, Y. Using chemical experiments and plant uptake to prove the feasibility and stability of coal gasification fine slag as silicon fertilizer. Environ. Sci. Pollut. Res. 2019, 26, 5925–5933. [Google Scholar] [CrossRef] [PubMed]

- Baniasadi, M.; Santunione, G.; Moradi, A.; Tartarini, P. Zero-waste approach for combined energy and fertilizer production: The case of Ravenna, Italy. AIP Conf. Proc. 2019, 2191, 020013. [Google Scholar] [CrossRef]

- Patel, H.; Müller, F.; Maiti, P.; Maiti, S. Economic evaluation of solar-driven thermochemical conversion of empty cotton boll biomass to syngas and potassic fertilizer. Energy Convers. Manag. 2020, 209, 112631. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Böhm, K.; Tintner, J.; Smidt, E. Modelled on nature—Biological processes in waste. In Management, Integrated Waste Management; Kumar, S., Ed.; InTech: London, UK, 2011; Volume I, ISBN 978-953-307-469-6. Available online: http://www.intechopen.com/books/integrated-waste-management-volumei/modelled-on-nature-biological-processes-in-waste-management (accessed on 12 April 2021).

- Lohri, C.R.; Diener, S.; Zabaleta, I.; Mertenat, A.; Zurbrügg, C. Treatment technologies for urban solid biowaste to create value products: A review with focus on low and middle-income settings. Rev. Environ. Sci. Biotechnol. 2017, 16, 81–130. [Google Scholar] [CrossRef] [Green Version]

- Ayilara, M.S.; Olanrewaju, O.; Babalola, O.O.; Odeyemi, O. Waste Management through Composting: Challenges and Potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

- Sayara, T.; Basheer-Salimia, R.; Hawamde, F.; Sánchez, A. Recycling of Organic Wastes through Composting: Process Performance and Compost Application in Agriculture. Agronomy 2020, 10, 1838. [Google Scholar] [CrossRef]

- Awasthi, S.K.; Sarsaiya, S.; Awasthi, M.K.; Liu, T.; Zhao, J.; Kumar, S.; Zhang, Z. Changes in global trends in food waste composting: Research challenges and opportunities. Bioresour. Technol. 2020, 299, 122555. [Google Scholar] [CrossRef]

- Van der Wurff, A.W.G.; Fuchs, J.G.; Raviv, M.; Termorshuizen, A.J. (Eds.) Handbook for Composting and Compost Use in Organic Horticulture; BioGreenhouse COST Action FA 1105; BioGreenhouse: Wageningen, The Netherlands, 2016. [Google Scholar] [CrossRef] [Green Version]

- Aziz, S.Q.; Omar, I.A.; Mustafa, J.S. Design and study for composting process site. Int. J. Eng. Invent. 2018, 7, 9–18. [Google Scholar]

- Iqbal, M.K.; Nadeem, A.; Sherazi, F.; Khan, R.A. Optimization of process parameters for kitchen waste composting by response surface methodology. Int. J. Environ. Sci. Technol. 2015, 12, 1759–1768. [Google Scholar] [CrossRef] [Green Version]

- Onwosi, C.O.; Igbokwe, V.C.; Odimba, J.N.; Eke, I.E.; Nwankwoala, M.O.; Iroh, I.N.; Ezeogu, L.I. Composting technology in waste stabilization: On the methods, challenges and future prospects. J. Environ. Manage. 2017, 190, 140–157. [Google Scholar] [CrossRef] [PubMed]

- Cerda, A.; Artola, A.; Font, X.; Barrena, R.; Gea, T.; Sánchez, A. Composting of food wastes: Status and challenges. Bioresour. Technol. 2018, 248, 57–67. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Azim, K.; Soudi, B.; Boukhari, S.; Perissol, C.; Roussos, S.; Thami Alami, I. Composting parameters and compost quality: A literature review. Org. Agr. 2018, 8, 141–158. [Google Scholar] [CrossRef]

- Petric, I.; Helic, A.; Avdic, E.A. Evolution of process parameters and determination of kinetics for co-composting of organic fraction of municipal solid waste with poultry manure. Bioresour. Technol. 2012, 117, 107–116. [Google Scholar] [CrossRef] [PubMed]

- Yeh, C.K.; Lin, C.; Shen, H.C.; Cheruiyot, N.K.; Camarillo, M.L.; Wang, C.L. Optimizing Food Waste Composting Parameters and Evaluating Heat Generation. Appl. Sci. 2020, 10, 2284. [Google Scholar] [CrossRef] [Green Version]

- Jain, M.S.; Daga, M.; Kalamdhad, A.S. Variation in the key indicators during composting of municipal solid organic wastes. Sustain. Environ. Res. 2019, 29, 9. [Google Scholar] [CrossRef] [Green Version]

- Shah, Z.; Jani, Y.M.; Khan, F. Evaluation of Organic Wastes for Composting. Commun. Soil Sci. Plant Anal. 2014, 45, 309–320. [Google Scholar] [CrossRef]

- Zarabi, M.; Jalai, M. Rate of Nitrate and Ammonium Release from Organic Residues. Compos. Sci. Util. 2012, 20, 222–229. [Google Scholar] [CrossRef]

- Wang, S.-P.; Zhong, X.-Z.; Wang, T.-T.; Sun, Z.-Y.; Tang, Y.-Q.; Kida, K. Aerobic composting of distilled grain waste eluted from a Chinese spirit making process: The effects of initial pH adjustment. Bioresour. Technol. 2017, 245, 778–785. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Sun, X. Improving green waste composting by addition of sugarcane bagasse and exhausted grape marc. Bioresour. Technol. 2016, 218, 335–343. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, X. Influence of bulking agents on physical, chemical, and microbiological properties during the two-stage composting of green waste. Waste Manag. 2016, 48, 115–126. [Google Scholar] [CrossRef]

- Zhang, H.; Li, G.; Gu, J.; Wang, G.; Li, Y.; Zhang, D. Influence of aeration on volatile sulfur compounds (VSCs) and NH3 emissions during aerobic composting of kitchen waste. Waste Manag. 2016, 58, 369–375. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Muscolo, A.; Papalia, T.; Settineri, G.; Mallamaci, C.; Jeske-Kaczanowska, A. Are raw materials or composting conditions and time that most influence the maturity and/or quality of composts? Comparison of obtained composts on soil properties. J. Clean. Prod. 2018, 195, 93–101. [Google Scholar] [CrossRef]

- Sahu, A.; Manna, M.C.; Bhattacharjya, S.; Rahman, M.M.; Mandal, A.; Thakur, J.K.; Sahu, K.; Bhargav, V.K.; Singh, U.B.; Sahu, K.P.; et al. Dynamics of maturity and stability indices during decomposition of biodegradable city waste using rapo-compost technology. App. Soil Ecol. 2020, 155, 103670. [Google Scholar] [CrossRef]

- Rashwan, M.A.; Alkoaik, F.N.; Saleh, H.A.-R.; Fulleros, R.B.; Ibrahim, M.N. Maturity and stability assessment of composted tomato residues and chicken manure using a rotary drum bioreactor. J. Air Waste Manag. Assoc. 2021, 71, 529–539. [Google Scholar] [CrossRef]

- Oviedo-Ocana, E.R.; Torres, P.; Marmolejo, L.F.; Hoyos, L.V.; Gonzales, S.; Barrena, R.; Komilis, D.; Sanchez, A. Stability and maturity of biowaste composts derived by small municipalities: Correlation among physical, chemical and biological indices. Waste Manag. 2015, 44, 63–71. [Google Scholar] [CrossRef] [Green Version]

- Cesaro, A.; Conte, A.; Belgiorno, V.; Siciliano, A.; Guida, M. The evolution of compost stability and maturity during the full-scale treatment of the organic fraction of municipal solid waste. J. Environ. Manag. 2019, 232, 264–270. [Google Scholar] [CrossRef]

- Mengqi, Z.; Shi, A.; Ajmal, M.; Ye, L.; Awais, M. Comprehensive review on agricultural waste utilization and high-temperature fermentation and composting. Biomass Convers. Biorefin. 2021. [Google Scholar] [CrossRef]

- Cesaro, A.; Belgiorno, V.; Guida, M. Compost from organic solid waste: Quality assessment and European regulations for its sustainable use. Resour. Conserv. Recycl. 2015, 94, 72–79. [Google Scholar] [CrossRef]

- Jodar, J.R.; Ramos, N.; Carreira, J.A.; Pacheco, P.; Fernández-Hernández, A. Quality assessment of compost prepared with municipal solid waste. Open Eng. 2017, 7, 221–227. [Google Scholar] [CrossRef]

- Puyuelo, B.; Arizmendiarrieta, J.S.; Irigoyen, I.; Plana, R. Quality assessment of composts officially registered as organic fertilisers in Spain. Span. J. Agric. Res. 2019, 17, e1101. [Google Scholar] [CrossRef] [Green Version]

- Domínguez, M.; Núñez, R.P.; Piñeiro, J.; Barral, M.T. Physicochemical and biochemical properties of an acid soil under potato culture amended with municipal solid waste compost. Int. J. Recycl. Org. Waste Agric. 2019, 8, 171–178. [Google Scholar] [CrossRef] [Green Version]

- Aranyos, J.T.; Tomócsik, A.; Makádi, M.; Mészáros, J.; Blaskó, L. Changes in physical properties of sandy soil after long-term compost treatment. Int. Agrophys. 2016, 30, 269–274. [Google Scholar] [CrossRef] [Green Version]

- Paradelo, R.; Eden, M.; Martínez, I.; Keller, T.; Houot, S. Soil physical properties of a Luvisol developed on loess after 15 years of amendment with compost. Soil Till. Res. 2019, 191, 207–2015. [Google Scholar] [CrossRef]

- Araujo, A.S.F.; de Melo, W.J.; Araujo, F.F.; Van den Brink, P.J. Long-term effect of composted tannery sludge on soil chemical and biological parameters. Environ. Sci. Pollut. Res. 2020, 27, 41885–41892. [Google Scholar] [CrossRef] [PubMed]

- Slorah, P.C.; Jeswani, H.K.; Cuéllar-Franca, R.; Azapagic, A. Environmental sustainability of anaerobic digestion of household food waste. J. Environ. Manag. 2019, 236, 798–814. [Google Scholar] [CrossRef] [PubMed]

- Morales-Polo, C.; del Mar Cledera-Castro, M.; Moratilla Soria, Y. Reviewing the Anaerobic Digestion of Food Waste: From Waste Generation and Anaerobic Process to Its Perspectives. Appl. Sci. 2018, 8, 1804. [Google Scholar] [CrossRef] [Green Version]

- Xu, F.; Li, Y.; Ge, X.; Yang, L.; Li, Y. Anaerobic digestion of food waste—Challenges and opportunities. Bioresour. Technol. 2018, 247, 1047–1058. [Google Scholar] [CrossRef]

- Ren, Y.; Yu, M.; Wu, C.; Wang, Q.; Gao, M.; Huang, Q.; Liu, Y. A comprehensive review on food waste anaerobic digestion: Research updates and tendencies. Bioresour. Technol. 2018, 247, 1069–1076. [Google Scholar] [CrossRef]

- Czekała, W. Agricultural Biogas Plants as a Chance for the Development of the Agri-Food Sector. J. Ecol. Eng. 2018, 19, 179–183. [Google Scholar] [CrossRef]

- Náthia-Neves, G.; Berni, M.; Dragone, G.; Mussatto, S.I.; Forster-Carneiro, T. Anaerobic digestion process: Technological aspects and recent developments. Int. J. Environ. Sci. Technol. 2018, 15, 2033–2046. [Google Scholar] [CrossRef]

- Tampio, E.; Marttinen, S.; Rintala, J. Liquid fertilizer products from anaerobic digestion of food waste: Mass, nutrient and energy balance of four digestate liquid treatment systems. J. Clean. Prod. 2016, 125, 22–32. [Google Scholar] [CrossRef] [Green Version]

- Monlau, F.; Sambusti, C.; Ficara, E.; Aboulkas, A.; Barakt, A.; Carrère, H. New opportunities for agricultural digestate valorization: Current situation and perspectives. Energy Environ. Sci. 2015, 8, 2600–2621. [Google Scholar] [CrossRef]

- Baştabak, B.; Koçar, G. A review of the biogas digestate in agricultural framework. J. Mater. Cycles Waste Manag. 2020, 22, 1318–1327. [Google Scholar] [CrossRef]

- Nkoa, R. Agricultural benefits and environmental risks of soil fertilization with anaerobic digestates: A review. Agron. Sustain. Dev. 2014, 34, 473–492. [Google Scholar] [CrossRef] [Green Version]

- Cesaro, A. The valorization of the anaerobic digestate from the organic fractions of municipal solid waste: Challenges and perspectives. J. Environ. Manag. 2021, 280, 111742. [Google Scholar] [CrossRef] [PubMed]

- Głowacka, A.; Szostak, B.; Klebaniuk, R. Effect of Biogas Digestate and Mineral Fertilisation on the Soil Properties and Yield and Nutritional Value of Switchgrass Forage. Agronomy 2020, 10, 490. [Google Scholar] [CrossRef] [Green Version]

- Skic, K.; Sokołowska, Z.; Bogutal, P.; Skic, A. The effect of application of digestate and agro-food industry sludges on Dystric Cambisol porosity. PLoS ONE 2020, 15, e0238469. [Google Scholar] [CrossRef]

- Baryga, A.; Połeć, B.; Klasa, A.; Olejnik, T.P. Application of Sugar Beet Pulp Digestate as a Soil Amendment in the Production of Energy Maize. Processes 2021, 9, 765. [Google Scholar] [CrossRef]

- Barłóg, P.; Hlisnikovský, L.; Kunzová, E. Effect of Digestate on Soil Organic Carbon and Plant-Available Nutrient Content Compared to Cattle Slurry and Mineral Fertilization. Agronomy 2020, 10, 379. [Google Scholar] [CrossRef] [Green Version]

- Calamai, A.; Palchetti, E.; Masoni, A.; Marini, L.; Chiaramonti, D.; Dibari, C.; Brilli, L. The Influence of Biochar and Solid Digestate on Rose-Scented Geranium (Pelargonium graveolens L’Hér.) Productivity and Essential Oil Quality. Agronomy 2019, 9, 260. [Google Scholar] [CrossRef] [Green Version]

- Badagaliacca, G.; Petrovičovà, B.; Pathan, S.I.; Roccotelli, A.; Romeo, M.; Monti, M.; Gelsomino, A. Use of solid anaerobic digestate and no-tillage practice for restoring the fertility status of two Mediterranean orchard soils with contrasting properties. Agric. Ecosyst. Environ. 2020, 300, 107010. [Google Scholar] [CrossRef]

- Calamai, A.; Chiaramonti, D.; Casini, D.; Masoni, A.; Palchetti, E. Short-term effects of organic amendments on soil properties and maize (Zea maize L.) growth. Agriculture 2020, 10, 158. [Google Scholar] [CrossRef]

- Marin-Batista, J.D.; Mohedano, A.F.; Rodriguez, J.J.; de la Rubia, M.A. Energy and phosphorous recovery through hydrothermal carbonization of digested sewage sludge. Waste Manag. 2020, 105, 566–574. [Google Scholar] [CrossRef] [PubMed]

- Parmar, K.R.; Ross, A.B. Integration of hydrothermal carbonisation with anaerobic digestion: Opportunities for valorisation of digestate. Energy 2019, 12, 1586. [Google Scholar] [CrossRef] [Green Version]

- Garg, R.N.; Pathak, H.; Das, D.K.; Tomar, R.K. Use of fly ash and biogas slurry for improving wheat yield and physical properties of the soil. Environ. Monit. Assess. 2005, 107, 1–9. [Google Scholar] [CrossRef]

- Pastorelli, R.; Valboa, G.; Lagomarsino, A.; Fabiani, A.; Simoncini, S.; Zaghi, M.; Vignozzi, N. Recycling Biogas Digestate from Energy Crops: Effects on Soil Properties and Crop Productivity. Appl. Sci. 2021, 11, 750. [Google Scholar] [CrossRef]

- Jaša, S.; Badalíková, B.; Červinka, J. Influence of Digestate on Physical Properties of Soil in Zd Budišov. Acta Univ. Agric. Silvic. Mendel. Brun. 2019, 67, 75–83. [Google Scholar] [CrossRef] [Green Version]

- Yu, F.-B.; Luo, X.-P.; Song, C.-F.; Zhang, M.-X.; Shan, S.-D. Concentrated biogas slurry enhanced soil fertility and tomato quality. Acta Agric. Scand. B Soil Plant Sci. 2010, 260, 262–268. [Google Scholar] [CrossRef]

- Ronga, D.; Caradonia, F.; Parisi, M.; Bezzi, G.; Parisi, B.; Allesina, G.; Pedrazzi, S.; Francia, E. Using Digestate and Biochar as Fertilizers to Improve Processing Tomato Production Sustainability. Agronomy 2020, 10, 138. [Google Scholar] [CrossRef] [Green Version]

- Šimon, T.; Kunzová, E.; Friedlová, M. The effect of digestate, cattle slurry and mineral fertilization on the winter wheat yield and soil quality parameters. Plant Soil Environ. 2015, 61, 522–527. [Google Scholar] [CrossRef] [Green Version]

- Przygocka-Cyna, K.; Grzebisz, W. The Multifactorial Effect of Digestate on the Availability of Soil Elements and Grain Yield and Its Mineral Profile—The Case of Maize. Agronomy 2020, 10, 275. [Google Scholar] [CrossRef] [Green Version]

- Tan, F.; Zhu, Q.; Guo, X.; He, L. Effects of digestate on biomass of a selected energy crop and soil properties. J. Sci. Food Agric. 2021, 101, 927–936. [Google Scholar] [CrossRef] [PubMed]

- Nabel, M.; Schrey, S.D.; Poorter, H.; Koller, R.; Jablonowski, N.D. Effects of digestate fertilization on Sida hermaphrodita: Boosting biomass yields on marginal soils by increasing soil fertility. Biomass Bioenerg. 2017, 107, 2007–2013. [Google Scholar] [CrossRef]

- Walsh, J.J.; Jones, D.L.; Chadwick, D.R.; Williams, A.P. Repeated application of anaerobic digestate, undigested cattle slurry and inorganic fertilizer N: Impacts on pasture yield and quality. Grass Forage Sci. 2018, 73, 758–763. [Google Scholar] [CrossRef]

- Persson, T.; Szulc, W.; Rutkowska, B.; Höglind, M.; Hanslin, H.M.; Sæbø, A. Impacts of organic soil amendments on forage grass production under different soil conditions. Agric. Food Sci. 2020, 29, 482–493. [Google Scholar] [CrossRef]

| Raw MIX Components | CaO | Al2O3 | Fe2O3 | SiO2 | MgO |

|---|---|---|---|---|---|

| Blast furnace slag | 39.70 | 8.80 | 2.09 | 39.08 | 4.08 |

| Open-hearth slag | 32.36 | 3.96 | 21.20 | 19.76 | 11.18 |

| Limestone | 52.12 | 0.24 | 0.18 | 1.53 | 0.48 |

| Clay | 7.57 | 12.8 | 6.32 | 50.45 | 3.97 |

| Material | C/N |

|---|---|

| Sewage sludge | 10–30 |

| Municipal solid waste | 49–105 |

| Food waste | 14–17 |

| Fruit wastes | 20–49 |

| Vegetable wastes | 10–17 |

| Green waste | 10–30 |

| Tree leaves | 40–70 |

| Cattle manure | 13–18 |

| Poultry manure | 10–17 |

| Maize residues | 80–90 |

| Wheat straw | 100–150 |

| Sawdust | 150–500 |

| Parameters | Values for Mature Compost | Reference |

|---|---|---|

| C/N ratio | <20:1 | [70] |

| pH | 8.0–9.0 | [70] |

| EC | <9.0 ms cm−1 | [70] |

| Organic matter | <50% | [71] |

| Humification index (HI) | ≤2.4 | [70] |

| Nitrification index (NI) | <3.0 | [54] |

| Germination index (GI) | >80% | [69] |

| Compost Feedstock | Experimental Conditions | Effect on Soil Properties |

|---|---|---|

| Separately collected organic fraction of municipal solid waste [74] | Compost applied annually in doses: 0, 30, 60 Mg FW per ha. Soil silty-loam, pH 5.6, soil rich in organic matter and available forms of P, K | Increasing doses of compost improved (decreased) soil density from 1.31 to 1.16 g cm−3, increased total soil porosity from 49 to 54% and soil stability against water erosion (increase aggregate stability from 29 to 31%). Under applied doses and compared with the control treatment, soil pH increased to 6.5, TOC content reached more than 22 g·kg−1. Soil total nitrogen, soil available phosphorus and soil available potassium increased by about 77%, 55–68% and 65–70%, respectively. CEC increased 63–74% compared with the control. The highest dose of compost significantly increased soil microbial biomass (by 300%) and dehydrogenase activity (by 77%) in relation to control object. |

| Sewage sludge (40%), straw (25%), bentonite (5%), rhyolite (30%) [75] | Compost applied from 2003 every 3 years in doses: 0, 9, 18, 27 Mg DM per ha. Soil—Arenosol, pH 5.3, SOM 0.9%, available phosphorus 240.1 mg P2O5 kg−1, available potassium 183.3 mg K2O kg−1 | Compost application positively affected the soil organic matter content in the 0–30 cm soil layer. The organic matter content of soil increased with increasing compost dose. The SOM content increased in each compost treatment by up to 1.0%. However, significantly higher values of SOM as compared with the control were observed only in the plots where the 18 Mg ha−1 compost dose was applied. The addition of compost significantly reduced the soil bulk density to 1.40–1.35 g cm−3 in compost treatments from 1.5 g cm−3 measured in control plots. |

| MSW—municipal solid waste compost obtained from mechanically separated organic fractions from residual waste; BIO—biowaste compost obtained from co-composting of green wastes and source separated organic fractions of municipal solid wastes; GWS—compost obtained from green waste collected from private and public gardens (70%) and sewage sludge (30%) [76] | Composts applied every second year starting 1998 in an amount of 4 Mg of organic carbon per ha. Soil—Haplic Luvisol | All composts reduced bulk density and increased organic carbon concentrations, which improved apparent air permeability and gas diffusivity, but only a green waste-sewage sludge compost increased water-holding capacity |

| tannery sludge sugarcane bagasse, and manure mixed 1:3:1 v:v:v [77] | Long-term experiment (2009–2019), compost applied every year in doses: 0, 2.5, 5, 10 Mg per ha. Soil—“fluvent” soil (USDA Soil Taxonomy) presenting 100 g kg−1 clay, 282 g kg−1 silt, and 618 g kg−1 sand | Soil pH, K, Ca, TOC, P, and EC increased about 0.5, 2.5, 3, 4, 5, and 9 times after the application of 20 Mg ha−1, respectively. Soil microbial biomass C (MBC) and N (MBN) decreased after the application of compost. In the 10th year, the highest values of MBC and MBN were found in unamended soils, while the lowest values were found in the treatments with application of 10 and 20 Mg ha−1 compost |

| Criterion | Type of Technology | Characteristics |

|---|---|---|

| Proces temperature | Mesophilic | 30–40 °C (optimum 35–37 °C) |

| Termophilic | 50–65 °C (optimum 55 °C) | |

| Dry matter content | Wet | The feedstock is slurried with a large amount of water to provide a dilute feedstock of <15% dry solids (usually 10–15%) |

| Dry | The feedstock used has a dry solids content of 20–40% | |

| number of steps in the process | Single Step | All digestion occurs in one vessel |

| Multi Step | Process consists of several digestion vessels. Usually, the rate limiting hydrolysis step of the anaerobic digestion process is separated from the methanogenesis (in a two-stage system). This results in increased efficiency as the two bacterial groups have different optimal conditions | |

| Method of dosing substrates | Batch | The digester is loaded with raw feedstock and inoculated with digestate from another tank. It is then closed and left until thorough degradation has occurred. The digester is then emptied, and a new batch of organic mixture is added |

| Continuous | The digester is fed continuously with waste material. Fully degraded material is continuously removed from the digester |

| Digestate Substrates | DM | pH | Corg. | Ntot. | P | K | Ca | Mg | Zn | Cu | Cd | Pb |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| % | g/kg DM | mg/kg DM | ||||||||||

| corn silage, sugar bagasse beet, pomace of fruit, waste from dairy, manure [89] | 6.56 | 8.50 | 357.0 | 3.10 | 1.04 | 1.22 | 1.90 | 0.27 | 93.9 | 12.5 | 0.18 | <0.1 |

| silage from corn and rye, apple pomace, and distillery decoction [90] | 5.20 | 7.29 | 372.0 | 49.3 | 14.4 | 11.6 | 19.3 | 7.17 | 1450.0 | 134.0 | 2.47 | 39.7 |

| sugar pulp from sugar beet processing plants [91] | 2.5 | 7.50 | 229.0 | 23.0 | 1.59 | 11.9 | 112.0 | 8.40 | 295.0 | 88.0 | 2.20 | 42.4 |

| cattle slurry, maize silage, haylage [92] | 5.83 | 8.53 | N/A | 31.4 | 11.7 | 55.9 | 29.6 | 8.24 | 295.0 | 90.1 | N/A | N/A |

| corn silage, manure, and vegetable waste [93] | 25.3 | 7.1 | 398.0 | 12.3 | 7.9 | 14.1 | 20.0 | 4.7 | 170.7 | 30.4 | 0.05 | 1.9 |

| animal manures (cow and poultry), solid wastes from citrus and olive processing plants, pruning materials, maize silage, crop residues, milk serum [94] | 18.0 | 8.77 | 389.6 | 16.0 | 1.24 | 2.25 | 0.97 | 0.79 | 25.2 | 1.92 | <0.01 | 0.07 |

| agro-industrial residues, herbaceous biomass [95] | N/A | N/A | 385.0 | 12.1 | 18.2 | 28.3 | 39.2 | 8.53 | N/A | N/A | N/A | N/A |

| sewage sludge [96] | 16.5 | N/A | 327.0 | 51.0 | 45.8 | 2.8 | 30.2 | 3.2 | N/A | N/A | N/A | N/A |

| segetable, garden, fruit [97] | N/A | N/A | 295.0 | 20.0 | 26.0 | 7.0 | 43.0 | 8.0 | N/A | N/A | N/A | N/A |

| municipal solid waste [97] | N/A | N/A | 241.0 | 15.0 | 7.0 | 16.0 | 104.0 | 14.0 | N/A | N/A | N/A | N/A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szulc, W.; Rutkowska, B.; Gawroński, S.; Wszelaczyńska, E. Possibilities of Using Organic Waste after Biological and Physical Processing—An Overview. Processes 2021, 9, 1501. https://doi.org/10.3390/pr9091501

Szulc W, Rutkowska B, Gawroński S, Wszelaczyńska E. Possibilities of Using Organic Waste after Biological and Physical Processing—An Overview. Processes. 2021; 9(9):1501. https://doi.org/10.3390/pr9091501

Chicago/Turabian StyleSzulc, Wiesław, Beata Rutkowska, Stanisław Gawroński, and Elżbieta Wszelaczyńska. 2021. "Possibilities of Using Organic Waste after Biological and Physical Processing—An Overview" Processes 9, no. 9: 1501. https://doi.org/10.3390/pr9091501

APA StyleSzulc, W., Rutkowska, B., Gawroński, S., & Wszelaczyńska, E. (2021). Possibilities of Using Organic Waste after Biological and Physical Processing—An Overview. Processes, 9(9), 1501. https://doi.org/10.3390/pr9091501