1. Introduction

Wet flue gas desulfurization (WFGD) is used to treat most of the flue gas produced by the power and heat production and supply industries in China [

1]. Through the countercurrent contact between acidic flue gas and alkaline slurry, the acidic gas is absorbed by the slurry, thus achieving the purpose of removing sulfur dioxide [

2,

3]. The operating cost of WFGD is mainly composed of electricity consumption, alkali consumption, water consumption, labor cost and equipment maintenance. The desulfurization efficiency can be effectively improved by increasing the amount of slurry circulation, but the amount of power required by the slurry circulation pump is greatly increased, thus increasing the electricity consumption. The increase in the operating resistance of the desulfurization spray tower will cause the induced draft fan to use more power, so the electricity consumption will also increase. Since the desulfurization spray tower is the main equipment of WFGD [

4], the operating parameters, structure design and hydrodynamic performance analysis of the desulfurization spray tower are particularly important.

In the desulfurization spray tower, the non-uniformity of the flue gas flow field is common, due to the radial flow direction of the flue gas [

5]. It is a common method to optimize the uniformity of the flue gas flow field by adjusting the operating parameters in the tower. Deng [

6] optimized the flow field through the flow rate of the flue gas inlet and continued through the uniformity index to evaluate the uniformity of the flow field. Wang [

7] proposed a detailed design scheme by studying the flow field uniformity of the desulfurization spray tower with different spray layers. Wang [

8] simulated the gas-liquid flow field of the desulfurization spray tower in full size by ANSYS CFX software and concluded that the combined flow field of 2nd and 3rd spray level is the most uniform. In addition to adjusting operating parameters, changing the tower structure is also an optimization method. Xiao [

9] simulated PCF (a wet flue gas desulfurization absorber) with different inlet structure forms, and chose the best PCF inlet structure to reduce design time and economic cost.

However, the adjustment of operating parameters may increase the operating costs. In addition, changing the structure of the tower is not viable in the existing equipment. With the improvement of environmental protection requirements and the harsh requirements of engineering reconstruction, installing special structures has become an important and feasible flow field optimization method. Chou [

10] added perforated sieve trays into the desulfurization spray tower with the consideration of chemical effects and concluded that the perforated sieve trays can increase the desulfurization efficiency. Zhen [

11] optimized the flow field by adding a FPC (flow pattern controlling) device to the desulfurization spray tower. Compared with the common spray tower without a perforated plate, the desulfurization performance of the FPC device is significantly improved. Both the deflector [

12] and the rod bank [

13] are important structures for the development of the flow field of the desulfurization spray tower, which are used to optimize the flow field uniformity and strengthen the mass transfer. Research on the flow field distribution of these two structures has mainly focused on the distribution of flue gas, while the liquid distribution has not been analyzed in detail. Although Wang [

14] proposed the droplet self-adjustment to explain the gas-liquid interaction, it is not clear how the two structures regulate the gas-liquid contact.

The disadvantage of high energy consumption of WFGD in traditional coal-fired power plants is increasingly prominent [

15]. Therefore, the recovery of flue gas residual heat has become the focus of energy-saving transformation. In WFGD, most of the residual heat of flue gas is transferred to the slurry. The study of two kinds of heat transfer is beneficial to provide ideas for the subsequent recovery of flue gas residual heat. However, the analysis of special structures in previous studies is not comprehensive, especially the analysis of the gas-liquid two-phaseheat transfer law in a desulfurization spray tower.

Computational fluid dynamics (CFD) is an ideal method for the optimal design of the desulfurization spray tower and for the prediction of flow field distribution. Gas-liquid two-phase flow can be simulated by Euler–Euler [

16,

17,

18] and Euler–Lagrange [

19,

20] methods. It is believed that in some studies liquid exists in the form of liquid film, formed on the surface of the structures with its local volume concentration much higher than 10%, which contributes to the application of the Euler–Euler method [

10,

14]. However, according to experimental studies, the liquid volume fraction in a large area of the spray tower is less than 5–8% [

21]. Comparing with the Euler–Euler method, particles and injection types are modeled strictly and accurately by the Euler–Lagrange method [

22]. The Euler–Lagrange method is adopted in this paper to model the two-phase flow in WFGD due to the requirements of accurate analysis of the liquid phase and the gas-liquid phase interaction.

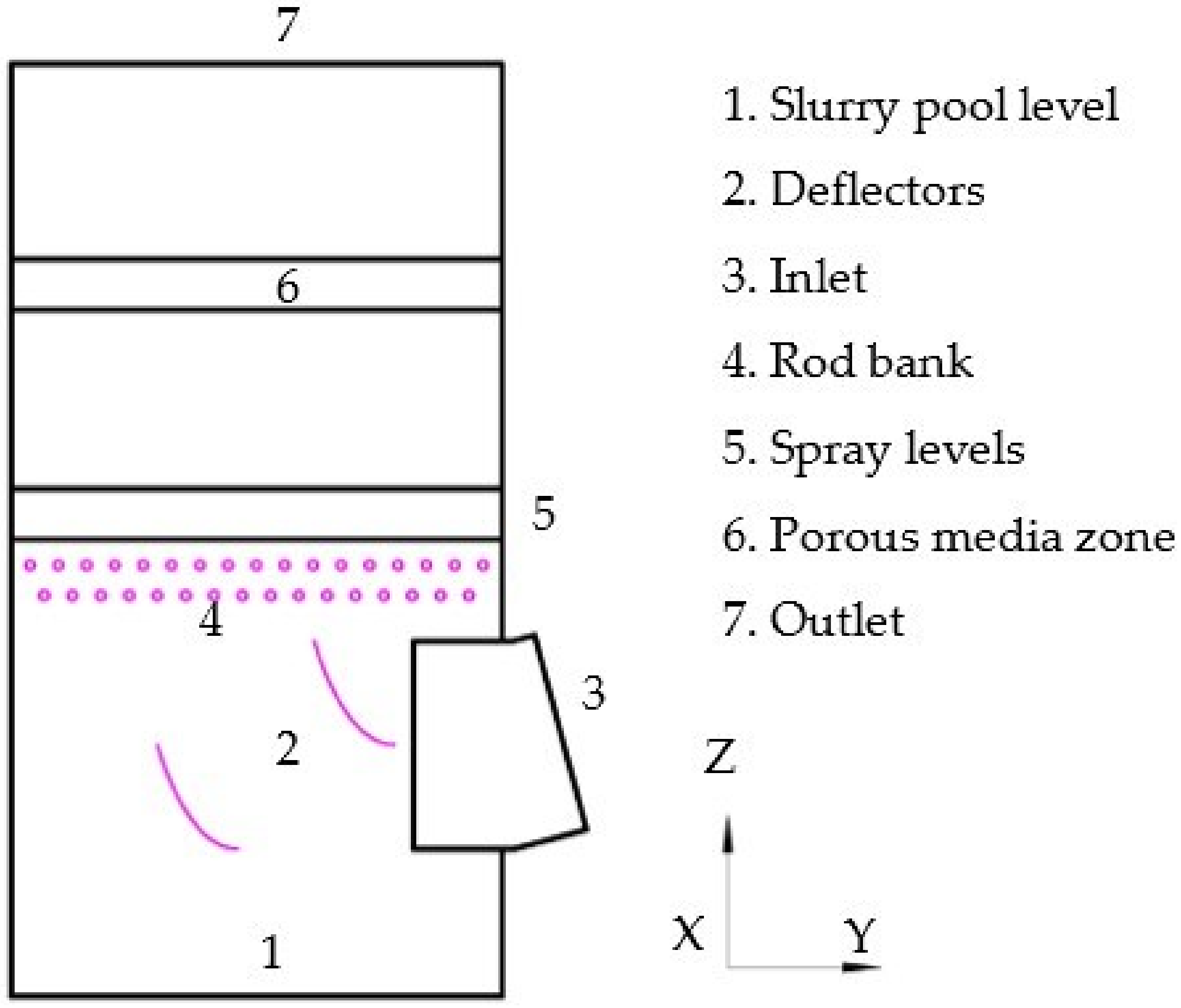

In this paper, a CFD numerical simulation method is used to study the original desulfurization spray tower (OST) of a 330 MW coal-fired unit WFGD system, the deflector desulfurization spray tower (original desulfurization spray tower + deflector) (DST) and the rod bank desulfurization spray tower (original desulfurization spray tower + rod bank), respectively. The flow field under three working conditions is analyzed, the gas-liquid contact intensification in DST and RBST is revealed, and the influence of gas-liquid contact strengthening on heat and mass transfer is discussed. Finally, the operating resistance in each desulfurization spray tower is analyzed.

4. Simulation Results and Discussion

4.1. Contact Condition of Gas-Liquid

Figure 6 shows the velocity and streamline distributions for the three operating conditions on the X = 0 plane.

Figure 7 shows the liquid mass concentration distribution on the X = 0 plane. In the OST, the flue gas enters the tower and flows to the left (the negative direction of the Y axis) and upward (the positive direction of the Z axis) at a relatively high velocity near the inlet. The flue gas stream can be divided into two types according to its flow path, one is the stream S

OST,A with a short path in the liquid distribution area, and the other is the flow S

OST,B with a long path. Obviously, stream S

OST,B has better contact with the liquid. However, the running resistance of S

OST,B is larger, making the flue gas flow of stream S

OST,A stronger than S

OST,B. After the flue gas flows into the liquid distribution area, the flue gas with a high velocity is subject to greater resistance, while that of the flue gas with a low velocity is just the opposite. This is a rectifier phenomenon between gas and liquid phases. Even if there is rectification phenomenon, the flue gas velocity distribution tends to be obviously uniform when the flue gas reaches a height of more than 5 m. In DST, the flue gas passes through the diversion of the first deflector to form two streams, one stream (S

DST,A) flow upward, and the other forms two streams (S

DST,B and S

DST,C) by the second deflector. Streams S

DST, B and S

DST, C have better contact with the liquid and are stronger than S

DST,A. In RBST, the flue gas flow is similar to OST, and the component of the flow velocity on the Y axis is larger, which makes the flue gas flow in the negative direction (left) of the Y axis toward the tower. Thus, the flue gas flow of stream S

RBST,B is stronger than stream S

OST,B.

In the three working conditions, the spray liquid near the flue gas inlet is affected by the movement of the flue gas and moves to the left, causing the liquid aggregation and high concentration liquid interface formation. And at the same time, an area with zero liquid concentration is formed near the inlet, namely the “Liquid Void Area”, causing uneven distribution of liquid. The deflectors cause the liquid to be blocked and concentrated above the deflectors. As a result, two “Liquid Void Areas” are formed below deflectors.

In the OST, the gas velocity is high and the liquid concentration is low in the inlet area. The liquid is concentrated in the left side of the tower and almost no gas flows through, resulting in poor gas-liquid contact conditions. However, for streams SDST,B and SDST,C in DST as well as stream SRBST,B in RBST, the velocity component of flue gas in the Y axis direction is relatively high, so the flue gas can flow smoothly to the left side of the tower, thus improving the contact conditions between the two phases, which is the gas-liquid contact intensification effect.

Figure 8 shows the distribution of flue gas velocity and liquid mass concentration on the curve of height Z = 3 m on the plane X = 0. In OST, the liquid mass concentration is evenly distributed at about 4 kg/m

3. However, within the range of Y = 4–6 m, the velocity of flue gas is higher than 6 m/s and the maximum reaches 8.8 m/s, forming a wide range of “flue gas channel”, resulting in a short gas-liquid contact time, and insufficient heat and mass transfer. In DST, the existence of the diversion of the deflectors makes the occurrence of two peaks in the flue gas velocity curve, and the maximum velocity is up to 6.3 m/s. At the position of the left peak, the liquid mass concentration distribution is also at the peak, and the gas-liquid contact has been intensified. At the same time, at the position of the right peak, the flue gas velocity is far less than that of OST, and the liquid mass concentration is also around 4 kg/m

3. Therefore, the gas-liquid contact is also strengthened. In RBST, the maximum peak velocity of flue gas is 8.4 m/s, which is lower than OST. Flue gas velocity and liquid mass concentration fluctuate, obviously. High-speed flue gas and high mass concentration liquid do not continuously gather, which avoids the formation of a wide range of “flue gas channel”, which also strengthens the gas-liquid contact.

4.2. The Heat Transfer of Gas-Liquid

Figure 9 displays the average temperature distribution curve of flue gas at different height Z of the desulfurization spray tower.

Figure 10 displays the distribution of flue gas temperature at different planes. In OST and RBST, the average temperature of flue gas reaches its maximum at Z = 0 (inlet center level height). The maximum average temperature of RBST is greater than OST for the reason that the flue gas of RBST is more widely distributed on the plane Z = 0. Then, as the heat transfer process continues, the flue gas temperature gradually decreases. When the flue gas moves upward to Z = 2 m, the average temperature of flue gas in RBST is already less than OST, and the temperature difference between them becomes larger with the increase in height. Due to the gas-liquid contact intensification caused by the rod bank, the heat transfer efficiency between the two phases in RBST is increased. In DST, due to the action of the first deflector, part of the flue gas flows downward for a certain distance, so the maximum average temperature is at the height Z = −2 m. When the flue gas moves towards Z = 1 m, the gas-liquid contact strengthening effect of DST makes the average temperature of DST flue gas lower than OST. Finally, when the flue gas moves to a position above Z = 7 m, the two phases are out of contact; the average temperature of flue reaches a stable state.

Figure 11 is the distribution of flue gas temperature at Z = 8 m plane. In OST, two-phase heat transfer is insufficient while there is higher temperature in part of the flue gas. In DST and RBST, the two-phase heat transfer effect is better, which further verifies the promoting effect of gas-liquid contact intensification on heat transfer.

Table 5 shows the temperature difference between inlet and outlet of the three working conditions. The temperature difference between inlet and outlet of DST is 3.3 K, which is higher than that of OST. In RBST, the gas-liquid heat transfer effect is the best, and the temperature difference between inlet and outlet flue gas is 5.3 K higher than that of OST.

4.3. The Mass Transfer of Gas-Liquid

Figure 12 displays the concentration distribution of sulfur dioxide. When the flue gas enters the tower, SO

2 reacts quickly with the slurry and its concentration decreases gradually. In OST, Stream S

OST,A is still diffused for high concentration of SO

2 due to its poor contact condition with liquid and incomplete reaction. In DST, the distribution of high concentration of SO

2 in the Y axis is more extensive, which is more conducive to the reaction. In RBST, the high concentration of SO

2 is more widely distributed in the Y-axis direction, while the SO

2 concentration drops sharply and the reaction is violent when the flue gas moves to the position of the rod bank. In DST and RBST, although SO

2 is not completely absorbed due to contact intensification, the concentration of escaped SO

2 was significantly lower than that of OST.

In

Table 6, the desulfurization efficiency under three working conditions is listed. The desulfurization efficiency of DST and RBST increase by 1.8% and 3.6%, respectively, when compared with OST.

4.4. Pressure Drop of Tower

The pressure drop in the desulfurization spray towerhas a significant impact on operating costs. Installing deflectors and rod bank in the desulfurization spray tower will cause an obvious effect on flue gas operation. Therefore, the running resistance of the tower must be optimized.

In

Figure 13, the pressure changes mainly occurred in two areas. First, the pressure decreases under the spray layer area. Second, pressure mutations occur in the porous media zone. In

Figure 14, the pressure distribution curve along the central axis of the tower is shown. The difference of pressure variation in the three working conditions is mainly in the area below the spray levels. Here, the reason for the pressure drop is the change of tower structure, rectifying components (deflectors and rod bank) and resistance from liquid phase. In DST, the flue gas flows from both sides of the deflectors, which causes less resistance. Meanwhile, the deflectors cause the “liquid void areas”, which indirectly reduces the resistance from liquid phase. Therefore, overall, the pressure required by the DST inlet is reduced relative to the OST. In RBST, the rod bank has a direct obstruction effect on the flow of flue gas. Meanwhile, its liquid phase distribution is similar to OST, and the resistance from liquid phase does not decrease. Therefore, the pressure required by RBST inlet is increased relative to OST.

Table 7 lists inlet and outlet pressure drop data under three working conditions. The pressure drop of DST is 37 Pa lower than that of OST. In RBST, the rods are distributed across the entire cross section of the tower, which impedes the flow of the flue gas. As a result, the pressure drop is 33 Pa higher than the OST.