Stability of a Viscous Liquid Jet in a Coaxial Twisting Compressible Airflow

Abstract

1. Introduction

2. Mathematical Model

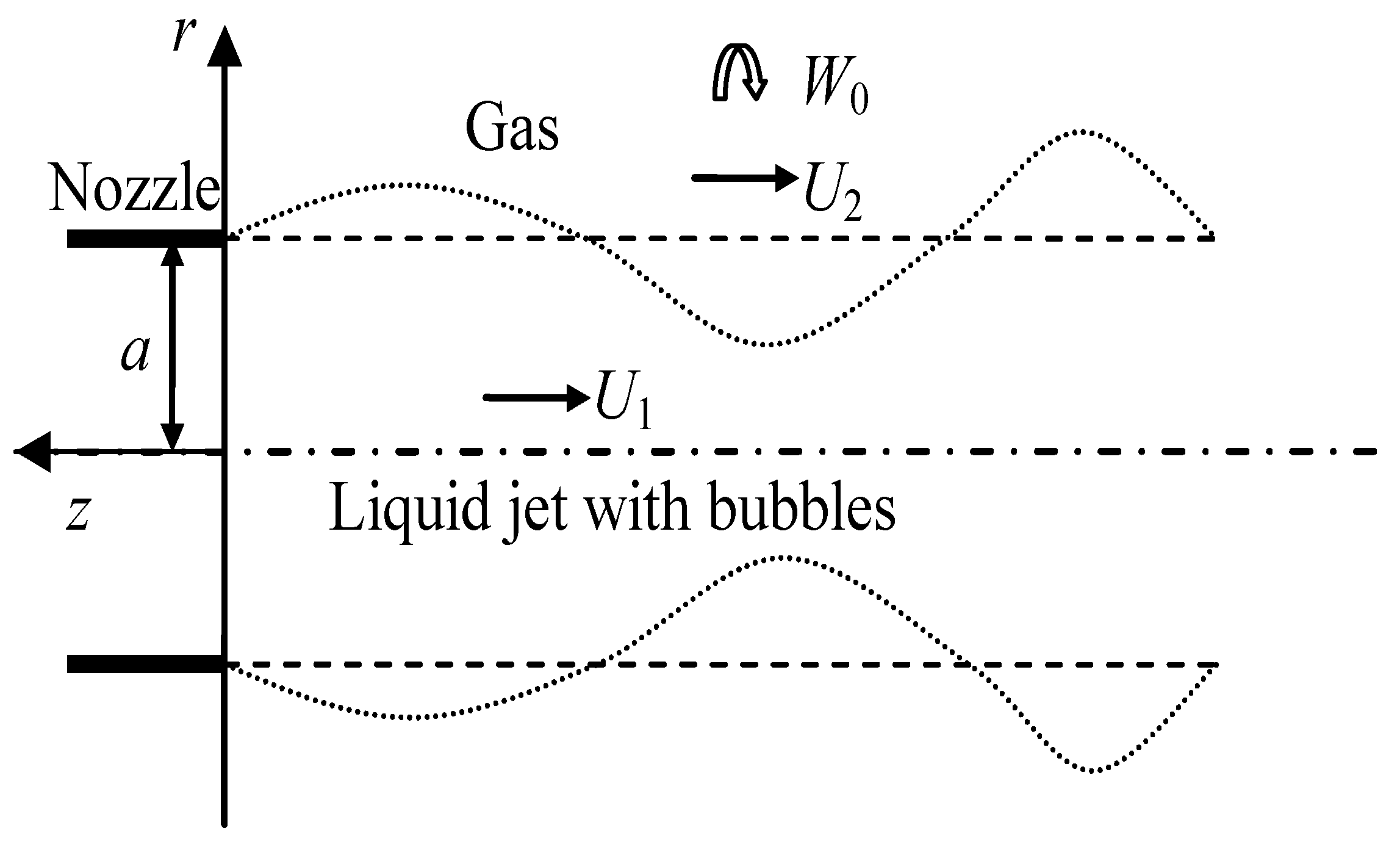

2.1. Physical Model and Initial Flow Field

- (1)

- The surrounding gas is a compressible Newtonian fluid;

- (2)

- Ignore the influence of the viscosity, gravity, and temperature of the surrounding gas;

- (3)

- The liquid jet does not swirl, and the surrounding gas has a coaxial twisting velocity;

- (4)

- There is no slippage between the cavitation bubbles and the liquid jet, and there is no interaction between the cavitation bubbles;

- (5)

- The mixed phase consisting of uniformly distributed cavitation bubbles and liquid jet is a continuous medium.

2.2. Establishment and Solution of Mathematical Model

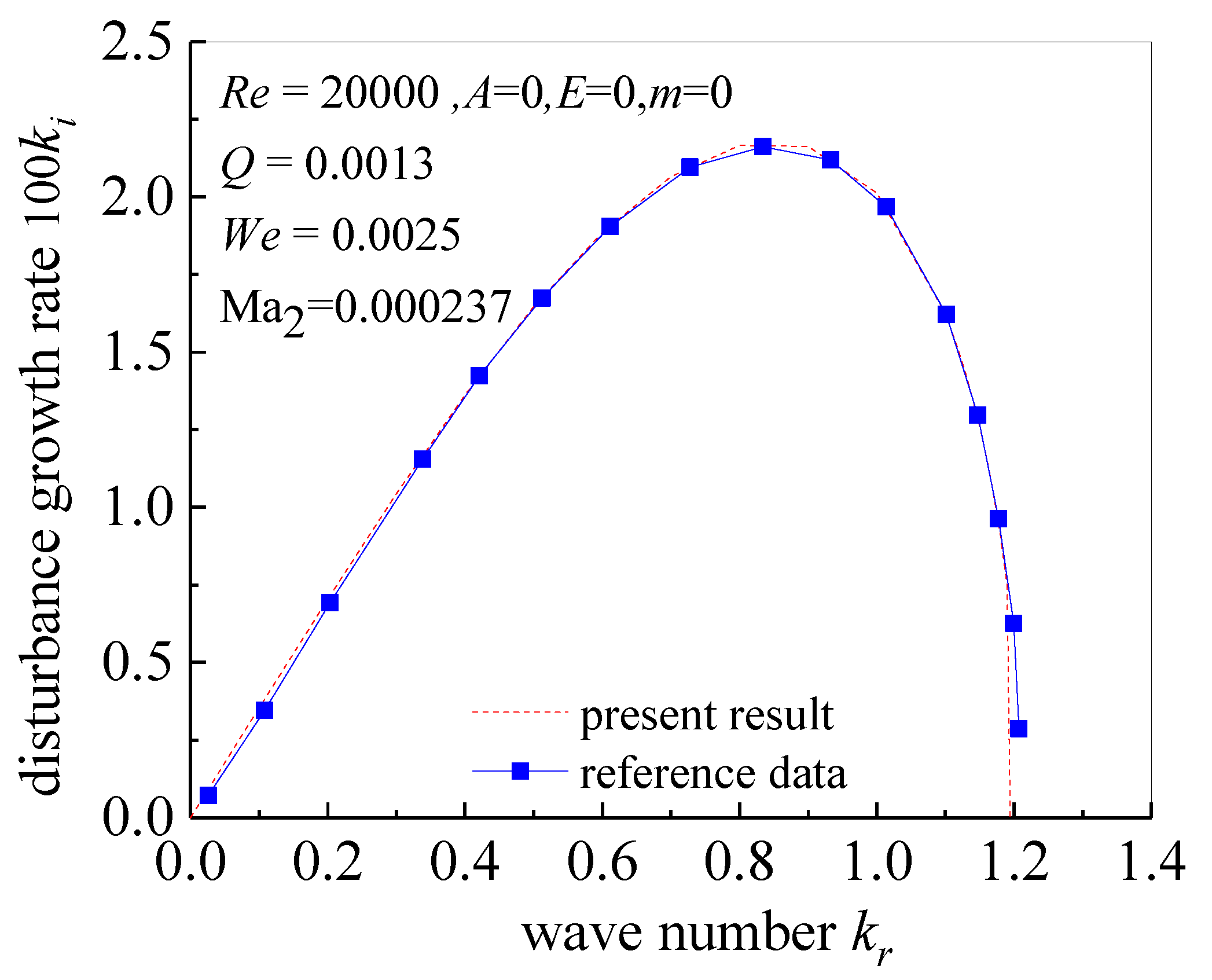

2.3. Verification and Solution

3. Results and Discussions

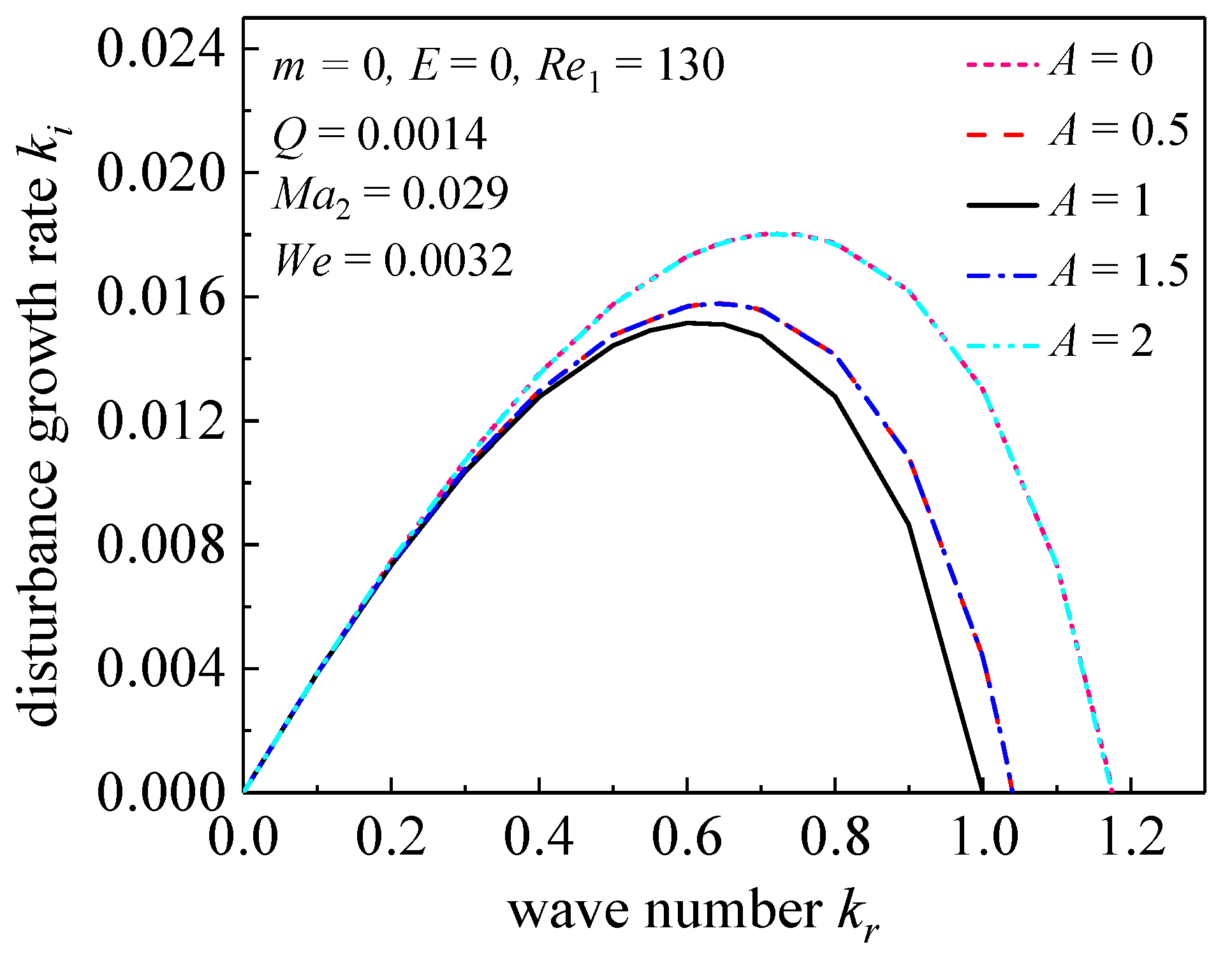

3.1. Effect of Ejecting Airflow on the Stability of Viscous Liquid Jet

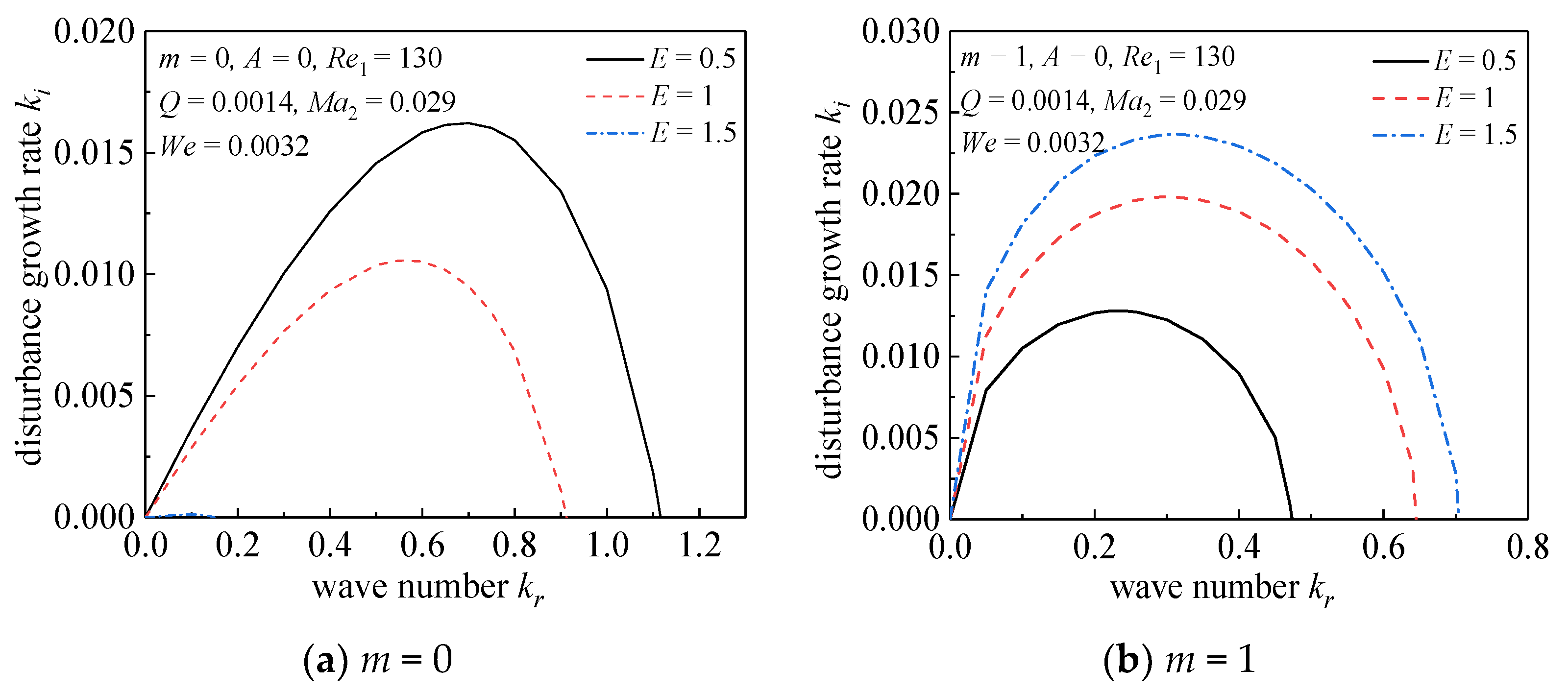

3.2. Effect of Swirling Airflow on the Stability of Viscous Liquid Jet

3.3. Effect of Twisting Airflow on the Stability of Viscous Liquid Jet

4. Conclusions

- (1)

- Take into account the twist and compressibility of the surrounding airflow, the viscosity of the liquid jet and the cavitation bubbles within the liquid jet, a mathematical model for describing the stability of the liquid jet in a coaxial twisting compressible gas flow was established, the model and its solving method were verified.

- (2)

- The ejection of surrounding airflow is divided into weak ejection (A 2) and strong ejection (A > 2). Under the weak ejection of the surrounding airflow, the maximum perturbation growth rate of the jet decreases first and then increases with the increase of the axial velocity of the airflow. When the gas–liquid axial velocity is the same (A = 1), the maximum perturbation growth rate of the liquid jet is the smallest. When the absolute value of (A − 1) is the same, the resulting aerodynamic effect on the liquid jet stability is basically the same. Under the strong ejection of the surrounding airflow, the maximum perturbation growth rate of the liquid jet increases sharply with the increase in the air ejection velocity. It is concluded that the greater the gas–liquid velocity, the more unstable the liquid jet becomes.

- (3)

- When the surrounding airflow swirls, the swirling airflow plays a stable role on the liquid jet in the axisymmetric mode, as opposed to the asymmetry mode. The dominant mode changes from axisymmetric to asymmetry as the airflow rotation strength increases. For a cylindrical liquid jet, when the airflow rotation strength is increased, the maximum growth rate of the liquid jet decreases first and then increases. The liquid jet is the most stable when E = 0.65, and the liquid jet begins to become easier to breakup when E = 0.8425 compared with E = 0 (no swirling air). The increase in the airflow rotation strength from 0.8425 is beneficial to the breakup of the liquid jet, and the airflow rotation strength has a significant effect on the stability of the liquid jet.

- (4)

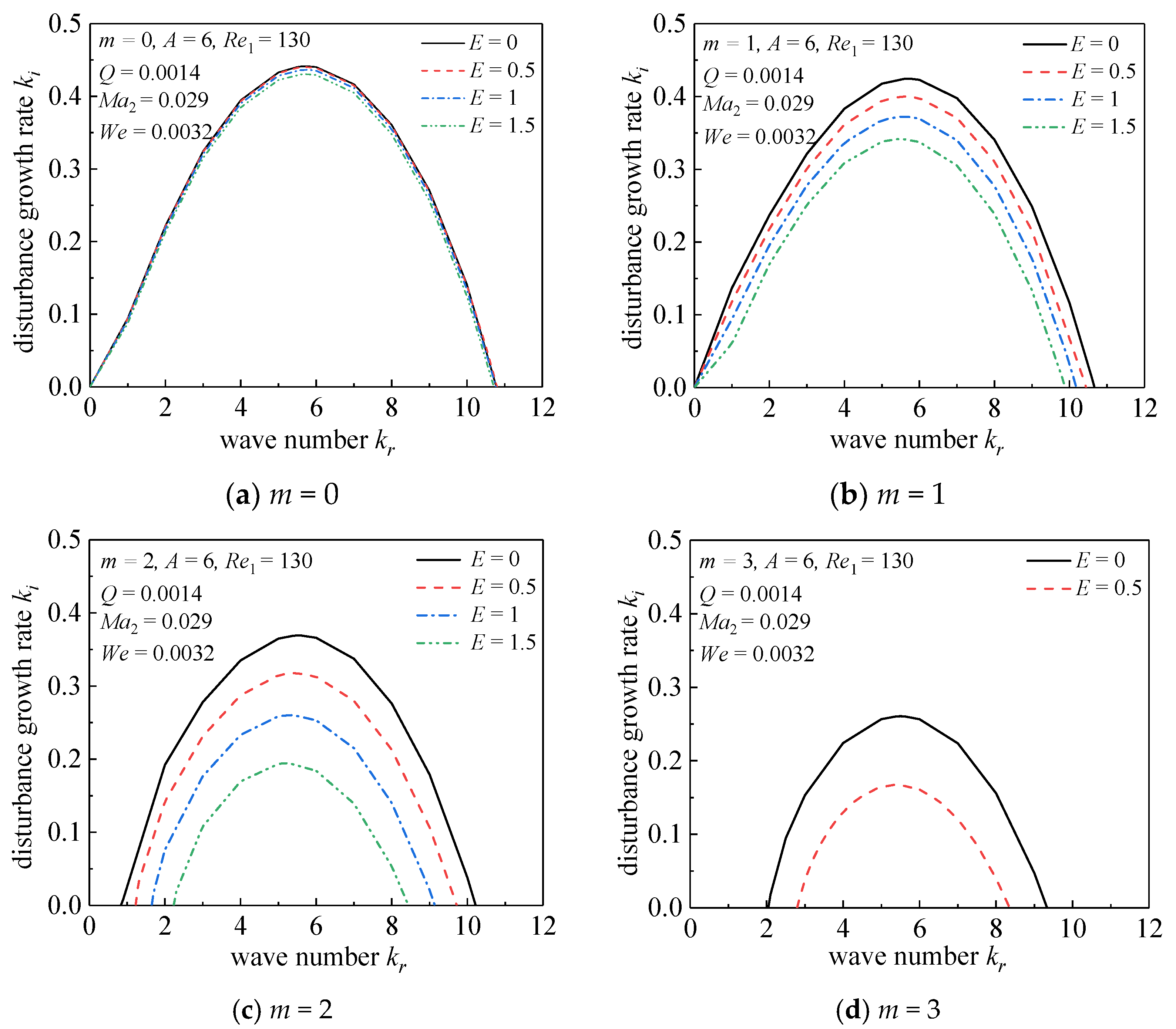

- When the surrounding airflow twists, the stability of the liquid jet is enhanced with the increase of the airflow rotation strength, both in the axisymmetric mode and in the asymmetry mode. According to the calculation conditions of this paper, the twist of the surrounding airflow is not conducive to the breakup of the liquid jet.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| a | cylindrical nozzle radius, m |

| A | the gas-liquid axial velocity ratio |

| E | the non-dimensional rotational strength |

| ki | a the disturbance spatial growth rate |

| kr | the wave number in the z direction |

| kv | the bubble adiabatic index |

| m | the wave number in the θ direction |

| Ma2 | the surrounding gas Mach number |

| N | the number of cavitation per unit volume |

| the liquid jet pressure, N/m2 | |

| the surrounding gas pressure, N/m2 | |

| pin | the gas phase inertia, N/m2 |

| the surface tension, N/m2 | |

| Q | the gas-liquid density ratio |

| rv | the cavity average radius, m |

| R | the gas constant |

| Re1 | the liquid jet Reynolds number |

| Tl | the liquid jet temperature, K |

| U1 | the liquid jet velocity, m/s |

| U2 | the surrounding gas velocity in the z-axis direction, m/s |

| radial velocities, m/s | |

| circumferential velocities, m/s | |

| axial velocities, m/s | |

| W0 | the surrounding gas rotation strength, m2/s |

| We | the ratio of the surface tension to the inertial force |

| zv | the bubble compressibility factor |

| α | bubble volume fraction |

| η | the perturbation on the liquid jet at the interface, m |

| μl | liquid viscosity, Pa·s |

| μv | cavitation bubble viscosity, Pa·s |

| the liquid jet density, kg/m3 | |

| the gas density, kg/m3 | |

| ρl | the liquid density, kg/m3 |

| ρv | the cavitation bubble density, kg/m3 |

| σ | the surface tension factor at the interface, N/m |

| ωr | the disturbance temporal growth rate |

| ωi | the wave frequency |

| Subscripts | |

| 1 | liquid jet parameters |

| 2 | airflow parameters |

Appendix A

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

| ; |

References

- Li, H.S.; Kelly, R.E. The instability of a liquid jet in a compressible air stream. Phys. Fluids 1992, 4, 2162–2168. [Google Scholar] [CrossRef]

- Zhou, Z.W.; Lin, S.P. Effects of compressibility on the atomization of liquid jets. J. Propuls. Power 1992, 8, 736–740. [Google Scholar] [CrossRef]

- Lasheras, J.C.; Hopfinger, E.J. Liquid jet instability and atomization in a coaxial gas stream. Ann. Rev. Fluid Mech. 2000, 32, 275–308. [Google Scholar] [CrossRef]

- Gordillo, J.M.; Perez-Saborid, M.; Ganan-Calvo, A.M. Linear stability of co-flowing liquid-gas jets. J. Fluid Mech. 2001, 448, 23–51. [Google Scholar] [CrossRef]

- Solórzano-López, J.; Zenit, R.; Ramírez-Argáez, M.A. Mathematical and physical simulation of the interaction between a gas jet and a liquid free surface. Appl. Math. Model. 2011, 35, 4991–5005. [Google Scholar] [CrossRef]

- Zarei, M.; Davarpanah, A.; Mokhtarian, N.; Farahbod, F. Integrated feasibility experimental investigation of hydrodynamic, geometrical and, operational characterization of methanol conversion to formaldehyde. Energy Sources Part A-Recover. Util. Environ. Eff. 2020, 42, 89–103. [Google Scholar] [CrossRef]

- Davarpanah, A.; Zarei, M.; Valizadeh, K.; Mirshekari, B. CFD design and simulation of ethylene dichloride (EDC) thermal cracking reactor. Energy Sources Part A: Recover. Util. Environ. Eff. 2019, 41, 1573–1587. [Google Scholar] [CrossRef]

- Daryayehsalameh, B.; Nabavi, M.; Vaferi, B. Modeling of CO2 capture ability of [Bmim][BF4] ionic liquid using connectionist smart paradigms. Environ. Technol. Innov. 2021, 22, 101484. [Google Scholar] [CrossRef]

- Liao, Y.; Jeng, S.M.; Jog, M.A. Instability of an annular liquid sheet surrounded by swirling airstreams. AIAA J. 2000, 38, 453–460. [Google Scholar] [CrossRef]

- Ibrahim, A.A.; Jog, M.A. Effect of liquid and air swirl strength and relative rotational direction on the instability of an annular liquid sheet. Acta Mech. 2006, 186, 113–133. [Google Scholar] [CrossRef]

- Jog, M.A.; Ibrahim, A.A. Nonlinear breakup of a coaxial liquid jet in a swirling gas stream. Phys. Fluids 2006, 18, 14101. [Google Scholar]

- Lin, Y.J.; Yang, Y.X.; Xi, D.G.; Qing, D. A study on the instability of an annular swirling liquid jet. J. Eng. Thermophys. 2001, 22, 519–522. [Google Scholar]

- Kumar, A.; Sahu, S. Large scale instabilities in coaxial air-water jets with annular air swirl. Phys. Fluids 2019, 31, 124103. [Google Scholar] [CrossRef]

- Du, Q.; Li, X.G.; Liu, N. Effect of gas swirl on breakup scale of annular liquid jet for Para-Sinuous disturbances. J. Tianjin Univ. 2008, 41, 569–575. [Google Scholar]

- Guo, J.P.; Bai, F.Q.; Chang, Q.; Du, Q. Investigation on Asymmetric Instability of Cylindrical Power-Law Liquid Jets. Energies 2019, 12, 2785. [Google Scholar] [CrossRef]

- Strasser, W.; Battaglia, F. Identification of Pulsation Mechanism in a Transonic Three-Stream Airblast Injector. J. Fluids Eng. 2016, 138, 111303. [Google Scholar] [CrossRef]

- Lü, M.; Ning, Z.; Lu, M.; Sun, C. On the spatial stability of a liquid jet in the presence of vapor cavities. Phys. Fluids 2013, 25, 114107. [Google Scholar] [CrossRef]

- Lü, M.; Ning, Z.; Yan, K.; Sun, C. Temporal and spatial stability of liquid jet containing cavitation bubbles in coaxial swirling compressible flow. Meccanica 2016, 51, 2121–2133. [Google Scholar] [CrossRef]

- Wang, X.T.; Ning, Z.; Lü, M.; Sun, C.H. Temporal analysis of breakup for a power law liquid jet in a swirling gas. Meccanica 2018, 53, 2067–2078. [Google Scholar] [CrossRef]

- Wang, X.T.; Ning, Z.; Lü, M. Temporal instability for a charged power-law liquid jet in a coaxial swirling air. AIAA J. 2018, 56, 3515–3523. [Google Scholar] [CrossRef]

- Liang, X.; Deng, D.S.; Nave, J.C.; Johnson, S.G. Linear stability analysis of capillary instabilities for concentric cylindrical shells. J. Fluid Mech. 2011, 683, 235–262. [Google Scholar] [CrossRef]

- Valizadeh, K.; Farahbakhsh, S.; Bateni, A.; Zargarian, A.; Davarpanah, A.; Alizadeh, A.; Zarei, M. A parametric study to simulate the non-Newtonian turbulent flow in spiral tubes. Energy Sci. Eng. 2020, 8, 134–149. [Google Scholar] [CrossRef]

- Chandrasekhar, S. Hydrodynamic and Hydromagnetic Stability; Oxford University Press: Oxford, UK, 1961. [Google Scholar]

- Decent, S.P.; King, A.C.; Simmons, M.J.H.; Părău, E.I.; Wallwork, I.M.; Gurney, C.J.; Uddin, J. The trajectory and stability of a spiralling liquid jet: Viscous theory. Appl. Math. Model. 2009, 33, 4283–4302. [Google Scholar] [CrossRef]

- Lin, S.P.; Lian, Z.W. Mechanisms of the breakup of liquid jets. AIAA J. 1990, 28, 120–126. [Google Scholar] [CrossRef]

- Yan, C.J. Atomization Mechanisms of 3-D viscous Liquid jets in a compressible gas. Trans. CSICE 2007, 25, 346–351. [Google Scholar]

- Yan, C.J.; Xie, M.Z. Boundary conditions and Instability analysis for disturbance governing equation of liquid jets. Chin. J. Eng. Math. 2008, 25, 563–566. [Google Scholar]

- Potter, M.C.; Wiggert, D.C. Mechanics of Fluids, 3rd ed.; Cengage Learning: Stamford, CT, USA, 2009. [Google Scholar]

- Lin, S.P. Breakup of Liquid Sheets and Jets; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Lü, M.; Ning, Z.; Sun, C. Study on the stability of liquid jet in coaxial swirling compressible gas and cavitation bubble within a single droplet. CSTAM J. 2016, 48, 857–866. [Google Scholar]

| Parameters | Units | Values |

|---|---|---|

| Liquid density | kg/m3 | 848 |

| Surface tension | N/m | 2.689 × 10−2 |

| Gas density | kg/m3 | 1.193 |

| Kinematic viscosity | m2/s | 7.6658 × 10−6 |

| Jet speed | m/s | 10 |

| Nozzle radius | m | 1 × 10−4 |

| Temperature | K | 300 |

| Sound speed in gas | m/s | 348 |

| E | 0 | 0.5 | 1 | 3 | 5 | 7 |

| m | 0 | 0 | 1 | 2 | 6 | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, L.-M.; Lü, M.; Ning, Z. Stability of a Viscous Liquid Jet in a Coaxial Twisting Compressible Airflow. Processes 2021, 9, 918. https://doi.org/10.3390/pr9060918

Guo L-M, Lü M, Ning Z. Stability of a Viscous Liquid Jet in a Coaxial Twisting Compressible Airflow. Processes. 2021; 9(6):918. https://doi.org/10.3390/pr9060918

Chicago/Turabian StyleGuo, Li-Mei, Ming Lü, and Zhi Ning. 2021. "Stability of a Viscous Liquid Jet in a Coaxial Twisting Compressible Airflow" Processes 9, no. 6: 918. https://doi.org/10.3390/pr9060918

APA StyleGuo, L.-M., Lü, M., & Ning, Z. (2021). Stability of a Viscous Liquid Jet in a Coaxial Twisting Compressible Airflow. Processes, 9(6), 918. https://doi.org/10.3390/pr9060918