Analyzing Utilization of Biomass in Combined Heat and Power and Combined Cooling, Heating, and Power Systems

Abstract

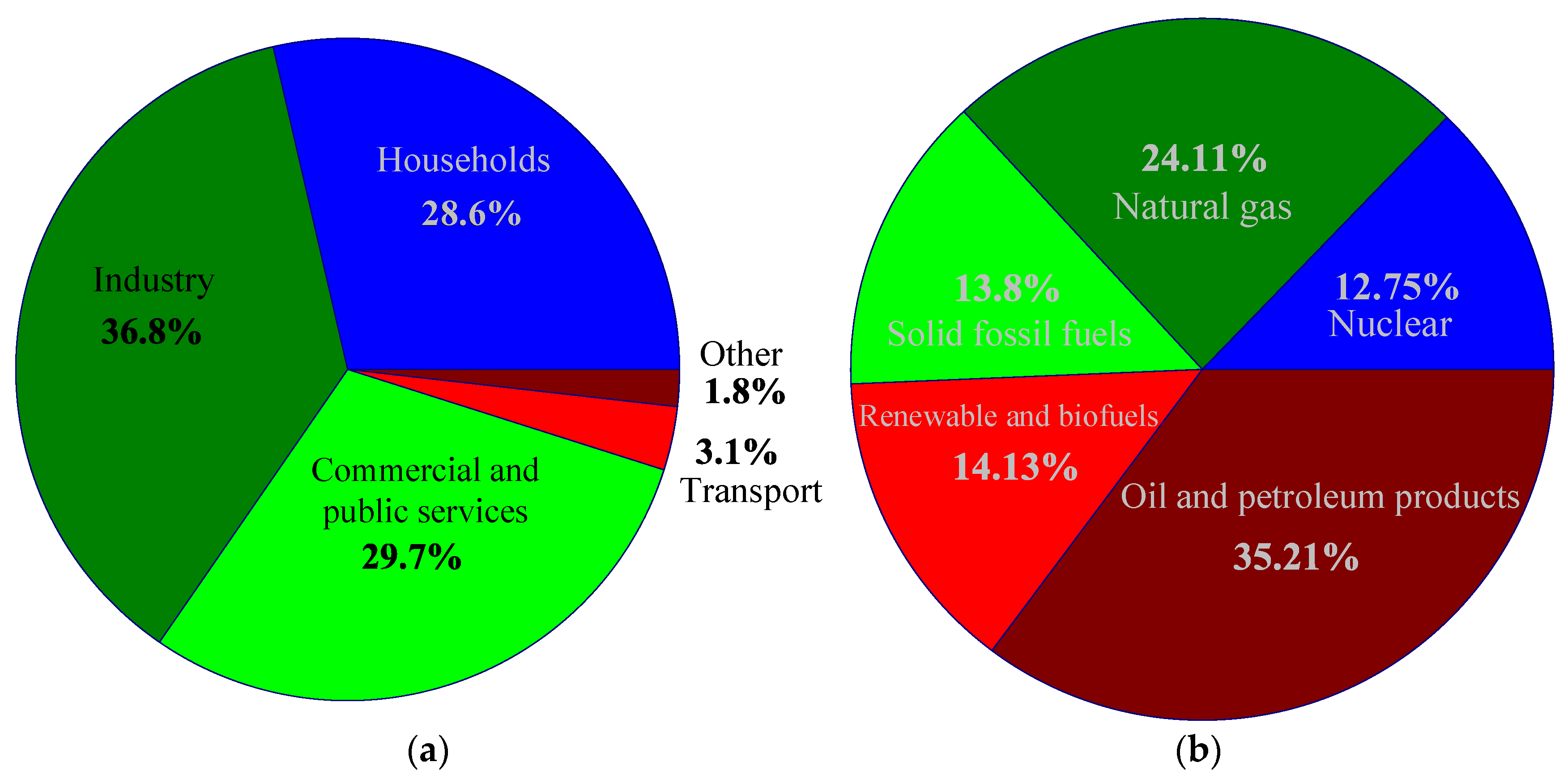

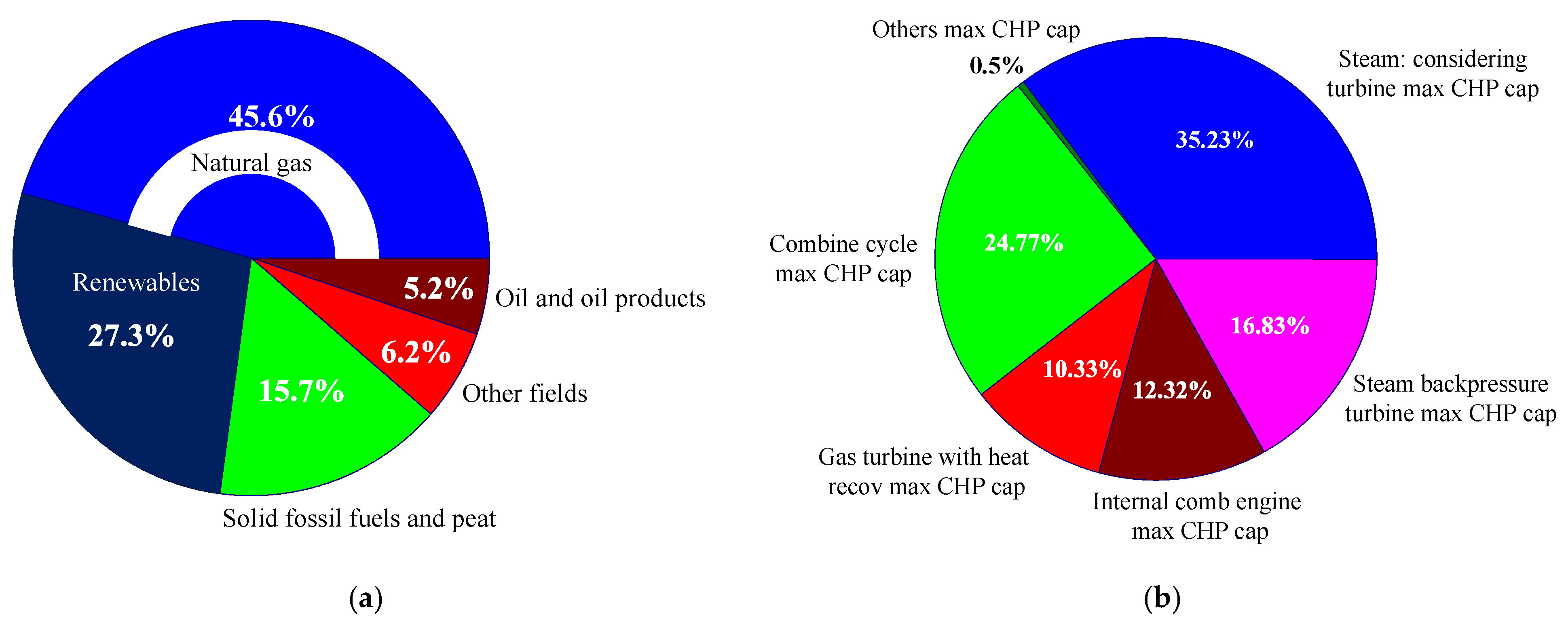

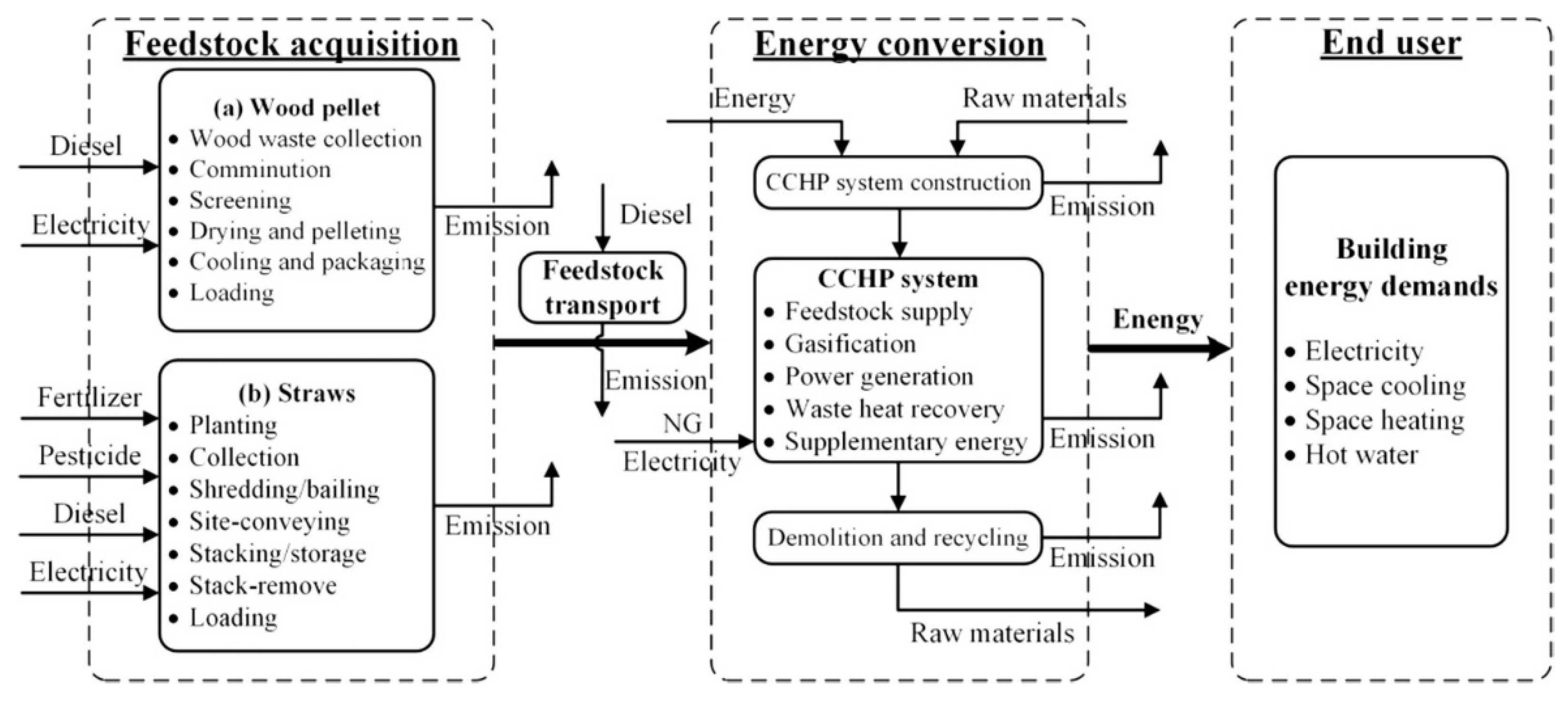

1. Introduction

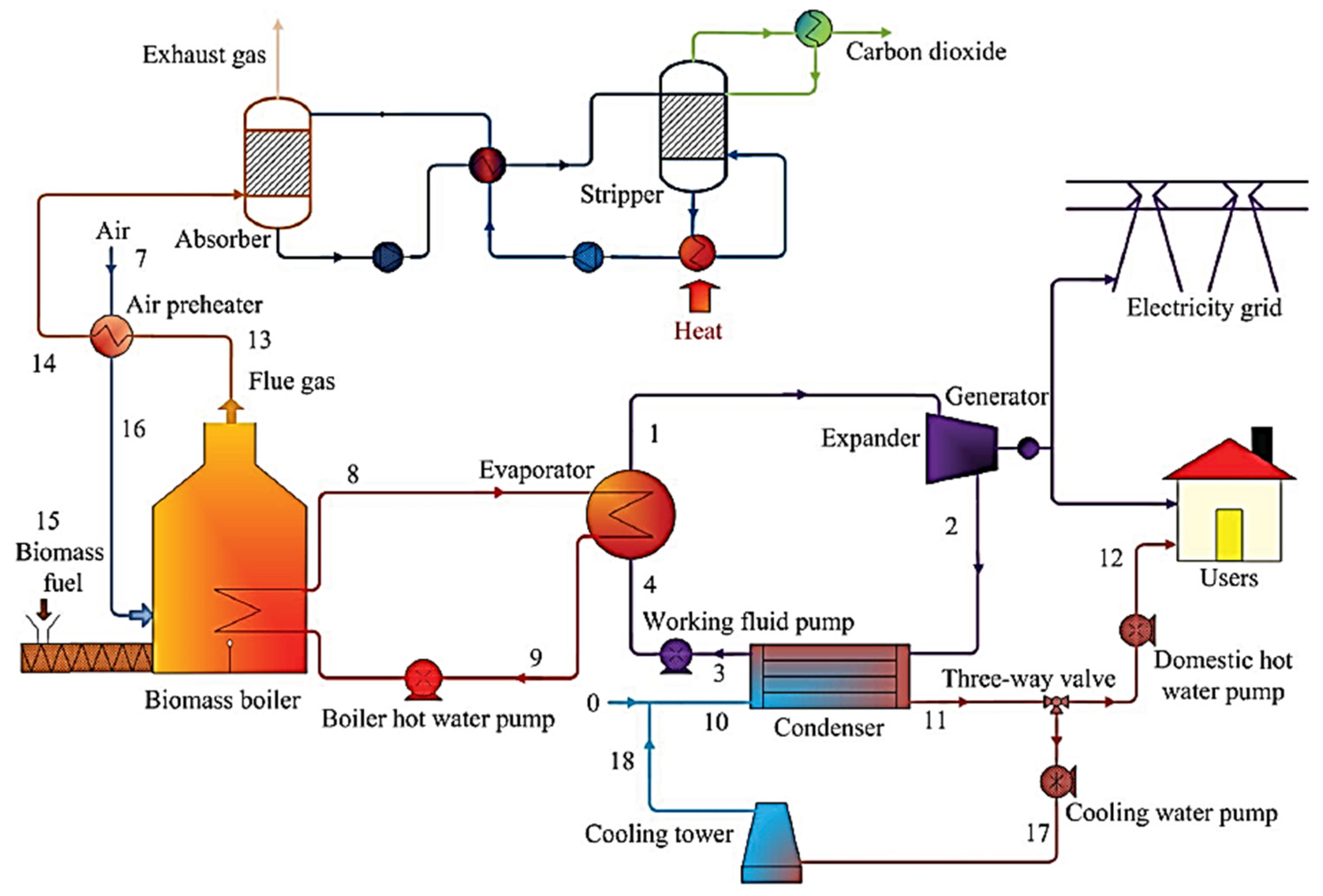

1.1. Utilizing Biomass in Micro-CHP Systems

1.2. Utilizing Biomass in Small- to Large-Scale CHP Plants

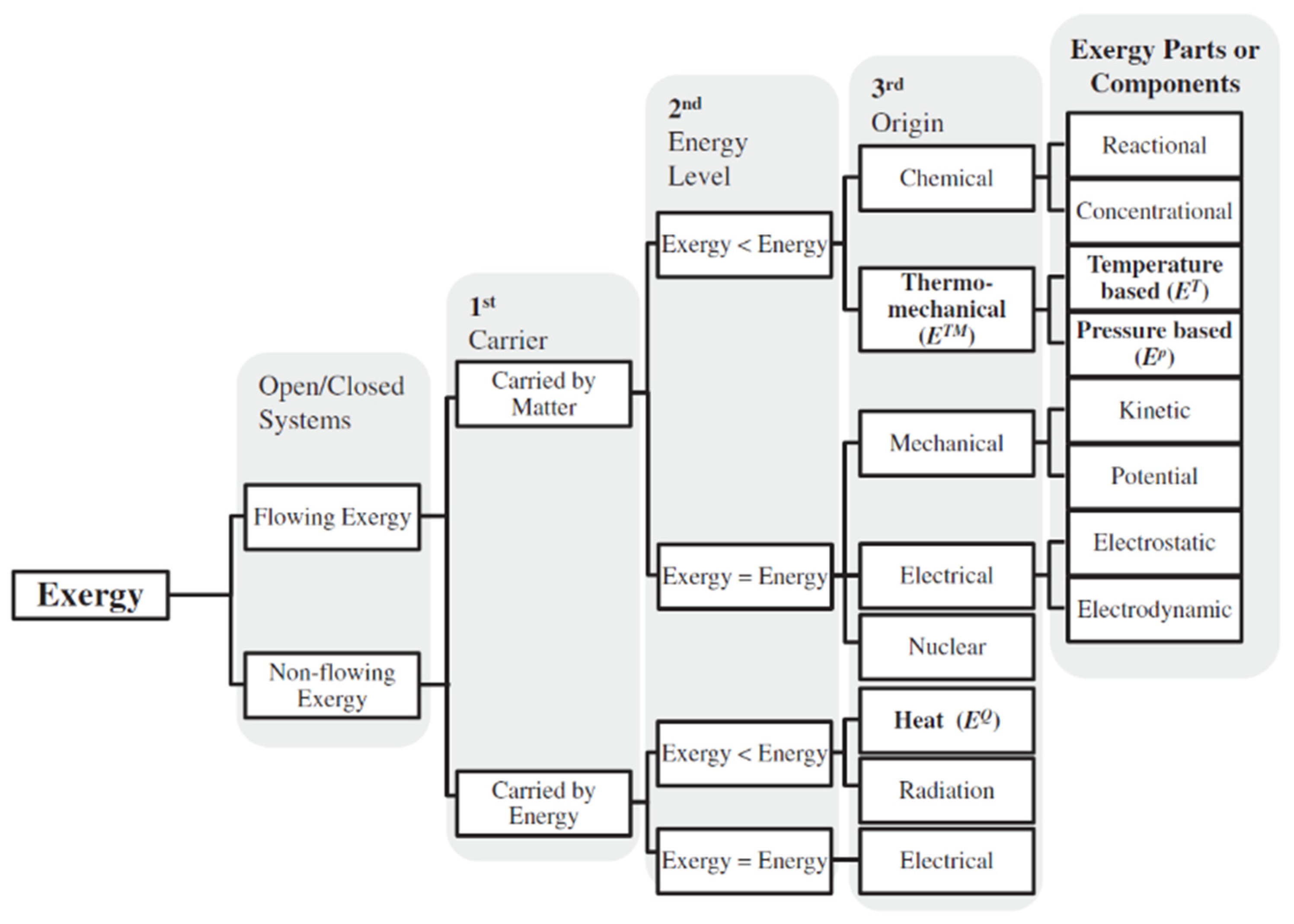

2. Performance Analysis

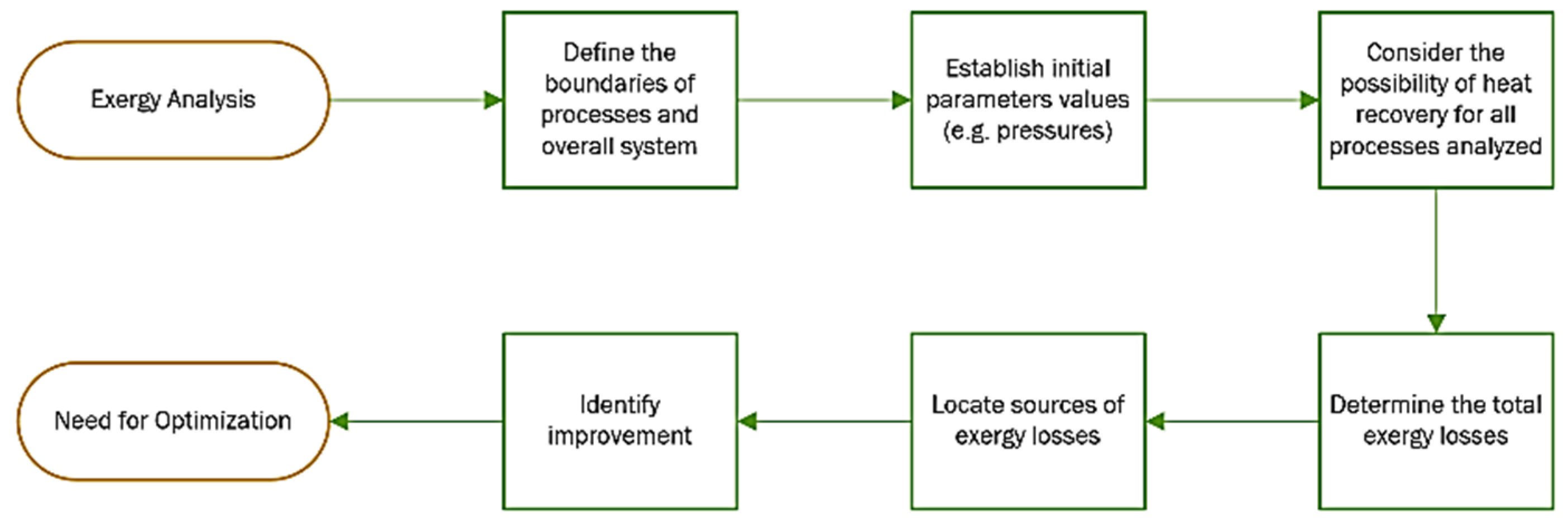

2.1. Energy and Exergy Analysis

- Measuring exergy efficiency and providing information on the performance of the system concerning losses and imperfections in terms of overall and individual components in the system;

- Locating the sources of energy destruction and indicating the need for improvements;

- Ability to consider and link to other assessments, such as economic and environmental;

- It is a key parameter in developing optimization models.

- Relative efficiency (overall exergy efficiency): The ratio of the total output exergy to the total input exergy;

- Consumed–produced efficiency (utilitarian exergy efficiency): The ratio of the exergy of the produced output to the exergy of the consumed input.

2.1.1. Biomass Influencing Factors in Energy and Exergy Analysis

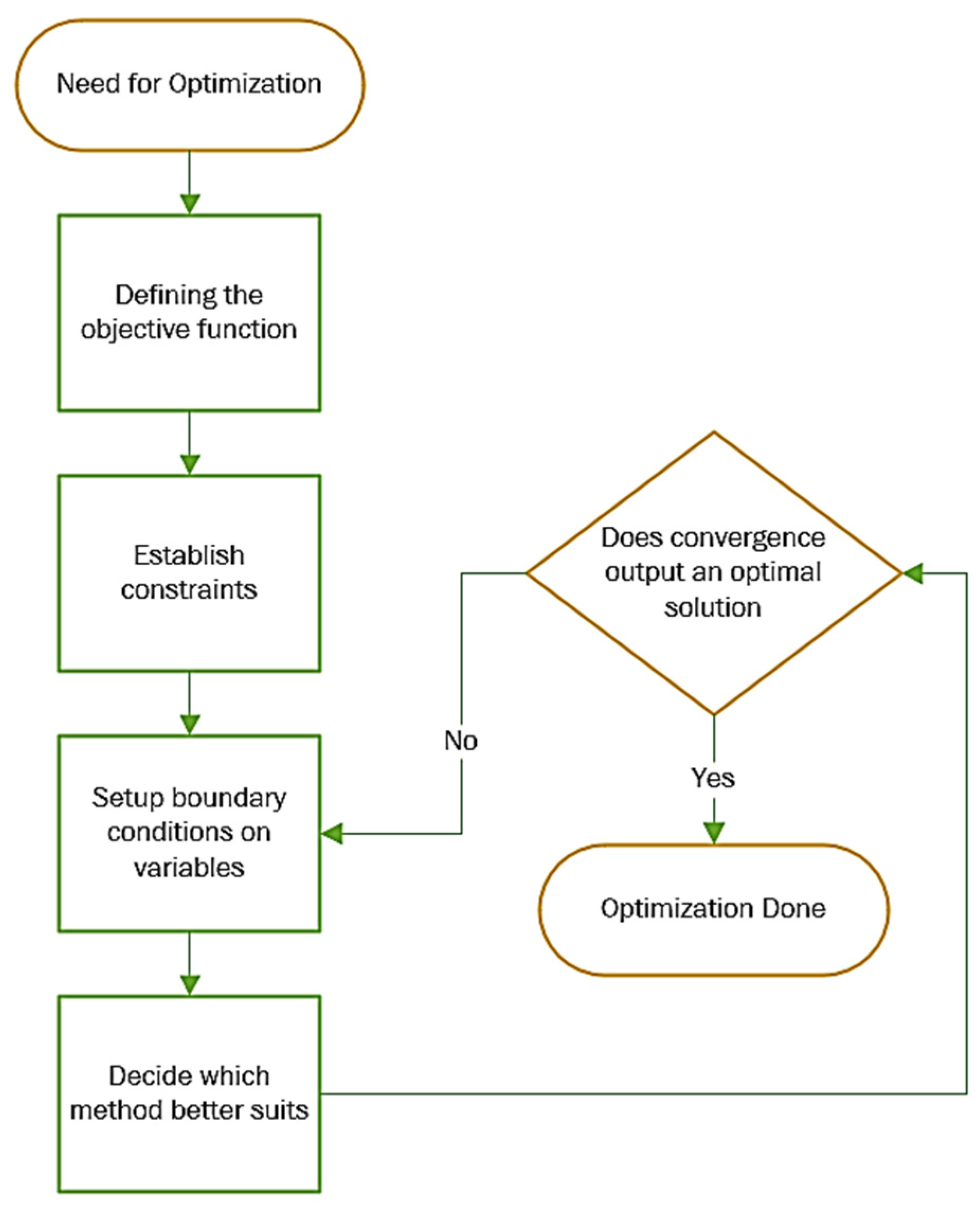

2.2. Thermo-Economic Optimization

2.2.1. Biomass Influencing Factors in Thermo-Economic Analysis

- Average cost: Per unit cost of production (not predictive).

- Marginal cost: Changes in the total production cost by producing an additional unit (predictive).

2.3. Environment Assessment

2.3.1. Biomass Influencing Factors in Environmental Analysis

3. Conclusions and Future Perspective

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RES | Renewable Energy Source |

| GHG | Greenhouse Gases |

| CHP | Combined Heat and Power |

| CCL | Climate Change Levy |

| CCHP | Combined Cooling Heat and Power |

| ppm | Parts Per Million |

| CLC | Chemical Looping Cycle |

| LCOE | Levelized Cost of Electricity |

| ORC | Organic Rankine Cycle |

| SOFC | Solid Oxide Fuel Cell |

| ECA | Enhanced Capital Allowance |

| Mtoe | Million Tonnes of Oil Equivalent |

| ToSIA | Tool for Sustainability Impact Assessment |

| CHP spark spread ($) | |

| Variables | |

| Rate of p, CHP power output (W) | |

| Rate of input heat (kJ/s) | |

| Rate of accumulation of energy | |

| Cost flow | |

| Internal energy (kJ) | |

| Irreversibility | |

| Entropy (kJ/K) | |

| Temperature (K) | |

| Pressure (bar) | |

| Specific exergy (kJ/kg) | |

| Exergy (kJ) | |

| Enthalpy (kJ) | |

| Molar fraction | |

| specific cost | |

| Electrical efficiency (%) | |

| Boiler efficiency (%) | |

| Cost matrix | |

| Thermo-economic cost vector | |

| Maintenance cost rate | |

| Fuel | |

| Emission rate (lb/h) | |

| Exergy efficiency (%) | |

| Initial bagasse moisture (%) | |

| Relative humidity | |

| Universal gas constant (8.3145 kJ/kmol K) | |

| Specific heat capacity (kJ/kg K) | |

| Standard-state Gibbs free energy of reaction (kJ/mol) | |

| Volume (m3) | |

| Subscripts | |

| 0 | Ambient conditions |

| Input stream | |

| Chemical | |

| Heat source | |

| Heat | |

| 00 | Standard partial pressure of component in the environment |

| Output stream | |

| Biomass | |

| Electrical energy | |

| Gen | Entropy generated by system processes |

References

- Delworth, T.L.; Mann, M.E. Observed and Simulated Multidecadal Variability in the Northern Hemisphere. Clim. Dyn. 2000, 16, 661–676. [Google Scholar] [CrossRef]

- Hegerl, G.C.; Zwiers, F.W.; Braconnot, P.; Gillett, N.P.; Luo, Y.; Orsini, J.A.M.; Nicholls, N.; Penner, J.E.; Stott, P.A. Understanding and Attributing Climate Change. In Climate Change 2007: The Physical Science Basis; Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2007; Volume 80, pp. 213–238. [Google Scholar]

- Mora, C.; Frazier, A.G.; Longman, R.J.; Dacks, R.S.; Walton, M.M.; Tong, E.J.; Sanchez, J.J.; Kaiser, L.R.; Stender, Y.O.; Anderson, J.M.; et al. The Projected Timing of Climate Departure from Recent Variability. Nature 2013, 502, 183–187. [Google Scholar] [CrossRef]

- WHO. Greenhouse Gas Concentrations in Atmosphere Reach yet Another High; World Meteorological Organization (WMO): Geneva, Switzerland, 2019; Available online: https://public.wmo.int/en/media/press-release/greenhouse-gas-concentrations-atmosphere-reach-yet-another-high (accessed on 3 June 2021).

- Hannah Ritchie and Max Roser. CO2 and Greenhouse Gas Emissions. Published online at OurWorldInData.org. 2020. Available online: https://ourworldindata.org/co2-and-other-greenhouse-gas-emissions (accessed on 3 June 2021).

- International Energy Agency (IEA). Global Energy and CO2 Status Report; The Latest Trends in Energy and Emissions in 2018; International Energy Agency: Paris, France, 2019; Available online: https://www.iea.org/reports/global-energy-co2-status-report-2019 (accessed on 3 June 2021).

- OECD/IEA. Market Report Series: Renewables 2018; Analysys and Forecasts to 2023; Executive Summary; Market Report Series; IEA Publication: Paris, France, 2018; Available online: https://www.iea.org/reports/renewables-2018 (accessed on 3 June 2021).

- Asafu-Adjaye, J.; Byrne, D.; Alvarez, M. Dataset for Analysing the Relationships among Economic Growth, Fossil Fuel and Non-Fossil Fuel Consumption. Data Brief 2017, 10, 17–19. [Google Scholar] [CrossRef] [PubMed]

- International Energy Agency (IEA). Energy efficiency and renewable energy. In World Energy Outlook 2018: The Future is Electrifying; IEA Publication: Paris, France, 2018; Available online: https://www.iea.org/events/world-energy-outlook-2018-the-future-is-electrifying (accessed on 3 June 2021).

- Bhavanam, A.; Sastry, R.C. Biomass Gasification Processes in Downd Raft Fixed Bed Reactors: A Review. Int. J. Chem. Eng. Appl. 2011, 2, 425–433. [Google Scholar] [CrossRef]

- IRENA—International Renewable Energy Agency Bioenergy. Available online: https://www.irena.org/bioenergy (accessed on 3 June 2021).

- Nabipour Afrouzi, H.; Pamodha Wimalaratna, Y.; Ahmed, J.; Mehranzamir, K.; San, C.L.; Chin-Leong, W.; Bazlul, M.S. A Comprehensive Review on Available/Existing Renewable Energy Systems in Malaysia and Comparison of Their Capability of Electricity Generation in Malaysia. In Entropy and Exergy in Renewable Energy; IntechOpen: London, UK, 2021; Available online: https://www.intechopen.com/online-first/a-comprehensive-review-on-available-existing-renewable-energy-systems-in-malaysia-and-comparison-of- (accessed on 3 June 2021). [CrossRef]

- Banja, M.; Jégard, M. Renewable Technologies in the EU Electricity Sector: Trends and Projections. Analysis in the Framework of the EU 2030 Climate and Energy Strategy; EUR 28897 EN; JRC109254; Publications Office of the European Union: Luxembourg, 2017; ISBN 978-92-79-76903-0. [Google Scholar] [CrossRef]

- Malico, I.; Nepomuceno Pereira, R.; Gonçalves, A.C.; Sousa, A.M.O. Current Status and Future Perspectives for Energy Production from Solid Biomass in the European Industry. Renew. Sustain. Energy Rev. 2019, 112, 960–977. [Google Scholar] [CrossRef]

- Kummamuru, B. WBA Global Bioenergy Statistics 2018. World Bioenergy Assoc. 2018, 43. [Google Scholar] [CrossRef]

- Calderon, C.; Colla, M.; Jossart, J.-M.; Hemeleers, N.; Martin, A.; Aveni, N.; Caferri, C. Statistical Report 2019; Report Biomass Supply; Bioenergy Europe: Brussels, Belgium, 2019; Available online: https://bioenergyeurope.org/index.php?option=com_attachments&task=download&id=737:Bioenergy-Lanscape-2019_FINAL_web (accessed on 3 June 2021).

- Singh, P.; Singh, N. Political Economy of Bioenergy Transitions in Developing Countries: A Case Study of Punjab, India. World Dev. 2019, 124, 104630. [Google Scholar] [CrossRef]

- Thumann, A.; Mehta, D.P. 9.1 Definition of “Cogeneration.” In Handbook of Energy Engineering; Fairmont Press, Inc.: Atlanta, GA, USA, 2013; ISBN 978-0-88173-695-3. [Google Scholar]

- Bagherian, M.A.; Mehranzamir, K. A Comprehensive Review on Renewable Energy Integration for Combined Heat and Power Production. Energy Convers. Manag. 2020, 224, 113454. [Google Scholar] [CrossRef]

- Benam, M.R.; Madani, S.S.; Alavi, S.M.; Ehsan, M. Optimal Configuration of the CHP System Using Stochastic Programming. IEEE Trans. Power Deliv. 2015, 30, 1048–1056. [Google Scholar] [CrossRef]

- Macadam, J.; Cox, J. Combined heat and power. In Chemical Engineer; Elsevier Ltd.: Amsterdam, The Netherlands, 2008; p. 32. [Google Scholar]

- Houwing, M.; Negenborn, R.R.; de Schutter, B. Demand Response with Micro-CHP Systems. Proc. IEEE 2011, 99, 200–213. [Google Scholar] [CrossRef]

- Yang, G.; Zheng, C.Y. Case of CCHP System in Shanghai. In Handbook of Energy Systems in Green Buildings; Wang, R., Zhai, X., Eds.; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Carbon Trust. Introducing Combined Heat and Power; Carbon Trust: London, UK, 2010; p. 59. [Google Scholar]

- Badea, N.; Ion, I.V.; Cazacu, N.; Paraschiv, L.; Paraschiv, S.; Caraman, S. Renewable Energy Sources for the mCCHP-SE-RES Systems. In Design for Micro-Combined Cooling, Heating and Power Systems: Stirling Engines and Renewable Power Systems; Badea, N., Ed.; Springer: London, UK, 2015; pp. 91–131. ISBN 978-1-4471-6254-4. [Google Scholar]

- Janoska, P. Energy Transitions Indicators; IEA: Paris, France, 2019. [Google Scholar]

- Eurostat. Combined Heat and Power (CHP) Data; Eurostat: Luxembourg, 2019. [Google Scholar]

- Eurostat. CHP Data Capacity Generation 2015; Eurostat: Luxembourg, 2015. [Google Scholar]

- Radenahmad, N.; Azad, A.T.; Saghir, M.; Taweekun, J.; Bakar, M.S.A.; Reza, M.S.; Azad, A.K. A Review on Biomass Derived Syngas for SOFC Based Combined Heat and Power Application. Renew. Sustain. Energy Rev. 2019, 119, 109560. [Google Scholar] [CrossRef]

- Arsalis, A. A Comprehensive Review of Fuel Cell-Based Micro-Combined-Heat-and-Power Systems. Renew. Sustain. Energy Rev. 2019, 105, 391–414. [Google Scholar] [CrossRef]

- Martinez, S.; Michaux, G.; Salagnac, P.; Bouvier, J.L. Micro-Combined Heat and Power Systems (Micro-CHP) Based on Renewable Energy Sources. Energy Convers. Manag. 2017, 154, 262–285. [Google Scholar] [CrossRef]

- Murugan, S.; Horák, B. A Review of Micro Combined Heat and Power Systems for Residential Applications. Renew. Sustain. Energy Rev. 2016, 64, 144–162. [Google Scholar] [CrossRef]

- Maghanki, M.M.; Ghobadian, B.; Najafi, G.; Galogah, R.J. Micro Combined Heat and Power (MCHP) Technologies and Applications. Renew. Sustain. Energy Rev. 2013, 28, 510–524. [Google Scholar] [CrossRef]

- Situmorang, Y.A.; Zhao, Z.; Yoshida, A.; Abudula, A.; Guan, G. Small-Scale Biomass Gasification Systems for Power Generation (<200 kW Class): A Review. Renew. Sustain. Energy Rev. 2020, 117, 109486. [Google Scholar] [CrossRef]

- Wegener, M.; Malmquist, A.; Isalgué, A.; Martin, A. Biomass-Fired Combined Cooling, Heating and Power for Small Scale Applications—A Review. Renew. Sustain. Energy Rev. 2018, 96, 392–410. [Google Scholar] [CrossRef]

- Contino, F.; Moret, S.; Limpens, G.; Jeanmart, H. Whole-Energy System Models: The Advisors for the Energy Transition. Prog. Energy Combust. Sci. 2020, 81, 100872. [Google Scholar] [CrossRef]

- Codina Gironès, V.; Moret, S.; Peduzzi, E.; Nasato, M.; Maréchal, F. Optimal Use of Biomass in Large-Scale Energy Systems: Insights for Energy Policy. Energy 2017, 137, 789–797. [Google Scholar] [CrossRef]

- Rajabi, M.; Mehrpooya, M.; Haibo, Z.; Huang, Z. Chemical Looping Technology in CHP (Combined Heat and Power) and CCHP (Combined Cooling Heating and Power) Systems: A Critical Review. Appl. Energy 2019, 253, 113544. [Google Scholar] [CrossRef]

- Segurado, R.; Pereira, S.; Correia, D.; Costa, M. Techno-Economic Analysis of a Trigeneration System Based on Biomass Gasification. Renew. Sustain. Energy Rev. 2019, 103, 501–514. [Google Scholar] [CrossRef]

- Ferreira, S.; Monteiro, E.; Brito, P.; Vilarinho, C. Biomass Resources in Portugal: Current Status and Prospects. Renew. Sustain. Energy Rev. 2017, 78, 1221–1235. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A. Development of Biogas Combustion in Combined Heat and Power Generation. Renew. Sustain. Energy Rev. 2014, 40, 868–875. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; d’Accadia, M.D.; Palombo, A.; Vicidomini, M. Hybrid Solid Oxide Fuel Cells-Gas Turbine Systems for Combined Heat and Power: A Review. Appl. Energy 2015, 156, 32–85. [Google Scholar] [CrossRef]

- Bagherian, M.A.; Mehranzamir, K.; Ahmed, J.; Nafea, M.; Nabipour-Afrouzi, H.; Wooi, C.; Beiranvand Pour, A.; Rezania, S.; Alizadeh, S.M. Techno-Economic Analysis of Direct Combustion and Gasification Systems for off-Grid Energy Supply: A Case for Organic Rankine Cycle and Dual Fluidized-Bed. IET Renew. Power Gener. 2021. [Google Scholar] [CrossRef]

- Giampietro, M.; Mayumi, K.; Şorman, A.H. Energy Analysis for a Sustainable Future: Multi-Scale Integrated Analysis of Societal and Ecosystem Metabolism, 1st ed.; Mayumi, K., Şorman, A.H., ProQuest (Firm), Eds.; Routledge: London, UK; New York, NY, USA, 2013; ISBN 978-020-310-799-7. [Google Scholar]

- Blok, K.; Nieuwlaar, E. Introduction to Energy Analysis; Taylor & Francis: Abingdon, UK, 2016; ISBN 978-131-720-727-6. [Google Scholar]

- Dincer, I.; Rosen, M.A. Chapter 1—Thermodynamic Fundamentals. In Exergy, 2nd ed.; Dincer, I., Rosen, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 1–20. ISBN 978-0-08-097089-9. [Google Scholar]

- Taner, T. Application of Exergy; IntechOpen: London, UK, 2018; ISBN 978-178-923-266-0. [Google Scholar]

- Yang, S.; Yang, Q.; Qian, Y. A Composite Efficiency Metrics for Evaluation of Resource and Energy Utilization. Energy 2013, 61, 455–462. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A. Chapter 10—Exergy Analysis of Renewable Energy Systems. In Exergy; Dincer, I., Rosen, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 163–228. ISBN 978-0-08-044529-8. [Google Scholar]

- Terzi, R. Application of Exergy Analysis to Energy Systems, Application of Exergy, Tolga Taner; IntechOpen: London, UK, 2018; Available online: https://www.intechopen.com/books/application-of-exergy/application-of-exergy-analysis-to-energy-systems (accessed on 3 June 2021). [CrossRef]

- Marmolejo-Correa, D.; Gundersen, T. A Comparison of Exergy Efficiency Definitions with Focus on Low Temperature Processes. Energy 2012, 44, 477–489. [Google Scholar] [CrossRef]

- Caliano, M.; Bianco, N.; Graditi, G.; Mongibello, L. Design Optimization and Sensitivity Analysis of a Biomass-Fired Combined Cooling, Heating and Power System with Thermal Energy Storage Systems. Energy Convers. Manag. 2017, 149, 631–645. [Google Scholar] [CrossRef]

- Damirchi, H.; Najafi, G.; Alizadehnia, S.; Mamat, R.; Nor Azwadi, C.S.; Azmi, W.H.; Noor, M.M. Micro Combined Heat and Power to Provide Heat and Electrical Power Using Biomass and Gamma-Type Stirling Engine. Appl. Therm. Eng. 2016, 103, 1460–1469. [Google Scholar] [CrossRef]

- Camporeale, S.M.; Fortunato, B.; Torresi, M.; Turi, F.; Pantaleo, A.M.; Pellerano, A. Part Load Performance and Operating Strategies of a Natural Gas—Biomass Dual Fueled Microturbine for Combined Heat and Power Generation. J. Eng. Gas Turbines Power 2015, 137. [Google Scholar] [CrossRef]

- Li, C.Y.; Deethayat, T.; Wu, J.Y.; Kiatsiriroat, T.; Wang, R.Z. Simulation and Evaluation of a Biomass Gasification-Based Combined Cooling, Heating, and Power System Integrated with an Organic Rankine Cycle. Energy 2018, 158, 238–255. [Google Scholar] [CrossRef]

- Kotas, T.J. (Ed.) Appendix A—Chemical exergy and enthalpy of devaluation. In The Exergy Method of Thermal Plant Analysis; Butterworth-Heinemann: Oxford, UK, 1985; pp. 236–262. ISBN 978-0-408-01350-5. [Google Scholar]

- Mujumdar, A.S. A Review of: “Exergy Method—Technical and Ecological Applications”. Dry. Technol. 2005, 23, 2523–2524. Available online: https://www.tandfonline.com/doi/abs/10.1080/07373930500341773?journalCode=ldrt20 (accessed on 3 June 2021). [CrossRef]

- Rosen, M.A. Exergy: Analysis. In Encyclopedia of Energy Engineering and Technology, 2nd ed.; Informa UK Limited: London, UK, 2014; pp. 683–691. ISBN 978-047-003-037-0. [Google Scholar]

- Flórez-Orrego, D.; Nascimento Silva, F.; de Oliveira Junior, S. Syngas Production with Thermo-Chemically Recuperated Gas Expansion Systems: An Exergy Analysis and Energy Integration Study. Energy 2019, 178, 293–308. [Google Scholar] [CrossRef]

- Flórez-Orrego, D.; Maréchal, F.; de Oliveira Junior, S. Comparative Exergy and Economic Assessment of Fossil and Biomass-Based Routes for Ammonia Production. Energy Convers. Manag. 2019, 194, 22–36. [Google Scholar] [CrossRef]

- Karellas, S.; Braimakis, K. Energy-Exergy Analysis and Economic Investigation of a Cogeneration and Trigeneration ORC-VCC Hybrid System Utilizing Biomass Fuel and Solar Power. Energy Convers. Manag. 2016, 107, 103–113. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, W.; He, Z. Thermodynamic Analysis and Optimization of a Novel Organic Rankine Cycle-Based Micro-Scale Cogeneration System Using Biomass Fuel. Energy Convers. Manag. 2019, 198, 111803. [Google Scholar] [CrossRef]

- Yang, Y.; Brammer, J.G.; Wright, D.G.; Scott, J.A.; Serrano, C.; Bridgwater, A.V. Combined Heat and Power from the Intermediate Pyrolysis of Biomass Materials: Performance, Economics and Environmental Impact. Appl. Energy 2017, 191, 639–652. [Google Scholar] [CrossRef]

- Najafi, G.; Hoseini, S.S.; de Goey, L.P.H.; Yusaf, T. Optimization of Combustion in Micro Combined Heat and Power (MCHP) System with the Biomass-Stirling Engine Using SiO2 and Al2O3 Nanofluids. Appl. Thermal Eng. 2020, 169. [Google Scholar] [CrossRef]

- Morrone, P.; Algieri, A.; Castiglione, T. Hybridisation of Biomass and Concentrated Solar Power Systems in Transcritical Organic Rankine Cycles: A Micro Combined Heat and Power Application. Energy Convers. Manag. 2019, 180, 757–768. [Google Scholar] [CrossRef]

- Campo, P.; Benitez, T.; Lee, U.; Chung, J.N. Modeling of a Biomass High Temperature Steam Gasifier Integrated with Assisted Solar Energy and a Micro Gas Turbine. Energy Convers. Manag. 2015, 93, 72–83. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, W.; Li, J.; Li, H.; Wang, Y.; Li, S. Thermodynamic Analysis and Economic Assessment of Biomass-Fired Organic Rankine Cycle Combined Heat and Power System Integrated with CO2 Capture. Energy Convers. Manag. 2020, 204, 112310. [Google Scholar] [CrossRef]

- Karimi, M.H.; Chitgar, N.; Emadi, M.A.; Ahmadi, P.; Rosen, M.A. Performance Assessment and Optimization of a Biomass-Based Solid Oxide Fuel Cell and Micro Gas Turbine System Integrated with an Organic Rankine Cycle. Int. J. Hydrogen Energy 2020. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Y. Energy, Exergy and Environmental Analysis of a Hybrid Combined Cooling Heating and Power System Utilizing Biomass and Solar Energy. Energy Convers. Manag. 2016, 124, 566–577. [Google Scholar] [CrossRef]

- Authayanun, S.; Hacker, V. Energy and Exergy Analyses of a Stand-Alone HT-PEMFC Based Trigeneration System for Residential Applications. Energy Convers. Manag. 2018, 160, 230–242. [Google Scholar] [CrossRef]

- Moradi, R.; Marcantonio, V.; Cioccolanti, L.; Bocci, E. Integrating Biomass Gasification with a Steam-Injected Micro Gas Turbine and an Organic Rankine Cycle Unit for Combined Heat and Power Production. Energy Convers. Manag. 2020, 205, 112464. [Google Scholar] [CrossRef]

- Salman, C.A.; Naqvi, M.; Thorin, E.; Yan, J. Impact of Retrofitting Existing Combined Heat and Power Plant with Polygeneration of Biomethane: A Comparative Techno-Economic Analysis of Integrating Different Gasifiers. Energy Convers. Manag. 2017, 152, 250–265. [Google Scholar] [CrossRef]

- Prakash, M.; Sarkar, A.; Sarkar, J.; Mondal, S.S.; Chakraborty, J.P. Proposal and Design of a New Biomass Based Syngas Production System Integrated with Combined Heat and Power Generation. Energy 2017, 133, 986–997. [Google Scholar] [CrossRef]

- Galanti, L.; Franzoni, A.; Traverso, A.; Massardo, A.F. Existing Large Steam Power Plant Upgraded for Hydrogen Production. Appl. Energy 2011, 88, 1510–1518. [Google Scholar] [CrossRef]

- Sharma, A.; Shinde, Y.; Pareek, V.; Zhang, D. Process Modelling of Biomass Conversion to Biofuels with Combined Heat and Power. Bioresour. Technol. 2015, 198, 309–315. [Google Scholar] [CrossRef]

- Beiron, J.; Montañés, R.M.; Normann, F.; Johnsson, F. Dynamic Modeling for Assessment of Steam Cycle Operation in Waste-Fired Combined Heat and Power Plants. Energy Convers. Manag. 2019, 198, 111926. [Google Scholar] [CrossRef]

- Gustavsson, C.; Hulteberg, C. Co-Production of Gasification Based Biofuels in Existing Combined Heat and Power Plants—Analysis of Production Capacity and Integration Potential. Energy 2016, 111, 830–840. [Google Scholar] [CrossRef]

- Balaji, C. Essentials of Thermal System Design and Optimization; Ane Books: New Delhi, India; CRC Press: Boca Raton, FL, USA, 2011; ISBN 978-143-989-154-4. [Google Scholar]

- Bagherian, M.A.; Mehranzamir, K.; Ahmed, J.; Nafea, M.; Nabipour-Afrouzi, H.; Wooi, C.-l. Development of Biomass-Fueled Cogeneration Systems for Off-Grid Electrification. In Proceedings of the 2nd International Conference on Smart Power & Inter-net Energy Systems (SPIES), Bangkok, Thailand, 15–18 September 2020; pp. 566–571. [Google Scholar] [CrossRef]

- Bagherian, M.A.; Mehranzamir, K.; Pour, A.B.; Rezania, S.; Taghavi, E.; Nabipour-Afrouzi, H.; Dalvi-Esfahani, M.; Alizadeh, S.M. Classification and Analysis of Optimization Techniques for Integrated Energy Systems Utilizing Renewable Energy Sources: A Review for CHP and CCHP Systems. Processes 2021, 9, 339. [Google Scholar] [CrossRef]

- Rao, S.S. Engineering Optimization: Theory and Practice; Wiley: Hoboken, NJ, USA, 2019; ISBN 978-111-945-471-7. [Google Scholar]

- Arora, J.S. Chapter 6—Optimum Design: Numerical Solution Process and Excel Solver. In Introduction to Optimum Design, 4th ed.; Arora, J.S., Ed.; Academic Press: Boston, MA, USA, 2017; pp. 237–278. ISBN 978-0-12-800-806-5. [Google Scholar]

- Frangopoulos, C.A. Recent Developments and Trends in Optimization of Energy Systems. Energy 2018, 164, 1011–1020. [Google Scholar] [CrossRef]

- Deb, K. Introduction to Genetic Algorithms for Engineering Optimization. In New Optimization Techniques in Engineering; Springer: Berlin/Heidelberg, Germany, 2004; pp. 13–51. ISBN 978-3-540-39930-8. [Google Scholar]

- Demirel, Y. 5—Thermoeconomics. In Nonequilibrium Thermodynamics, 2nd ed.; Demirel, Y., Ed.; Elsevier Science B.V.: Amsterdam, The Netherlands, 2007; pp. 275–318. ISBN 978-0-444-53079-0. [Google Scholar]

- Demirel, Y. Thermodynamic Analysis. Arab. J. Sci. Eng. 2013, 38, 221–249. [Google Scholar] [CrossRef]

- Demirel, Y.; Gerbaud, V. Thermoeconomics. In Nonequilibrium Thermodynamics; Demirel, Y., Gerbaud, V., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 267–294. ISBN 978-0-444-64112-0. [Google Scholar]

- Zhang, X.; Zeng, R.; Mu, K.; Liu, X.; Sun, X.; Li, H. Exergetic and Exergoeconomic Evaluation of Co-Firing Biomass Gas with Natural Gas in CCHP System Integrated with Ground Source Heat Pump. Energy Convers. Manag. 2019, 180, 622–640. [Google Scholar] [CrossRef]

- Li, C.Y.; Wu, J.Y.; Chavasint, C.; Sampattagul, S.; Kiatsiriroat, T.; Wang, R.Z. Multi-Criteria Optimization for a Biomass Gasification-Integrated Combined Cooling, Heating, and Power System Based on Life-Cycle Assessment. Energy Convers. Manag. 2018, 178, 383–399. [Google Scholar] [CrossRef]

- Baghernejad, A.; Yaghoubi, M.; Jafarpur, K. Exergoeconomic Comparison of Three Novel Trigeneration Systems Using SOFC, Biomass and Solar Energies. Appl. Thermal Eng. 2016, 104, 534–555. [Google Scholar] [CrossRef]

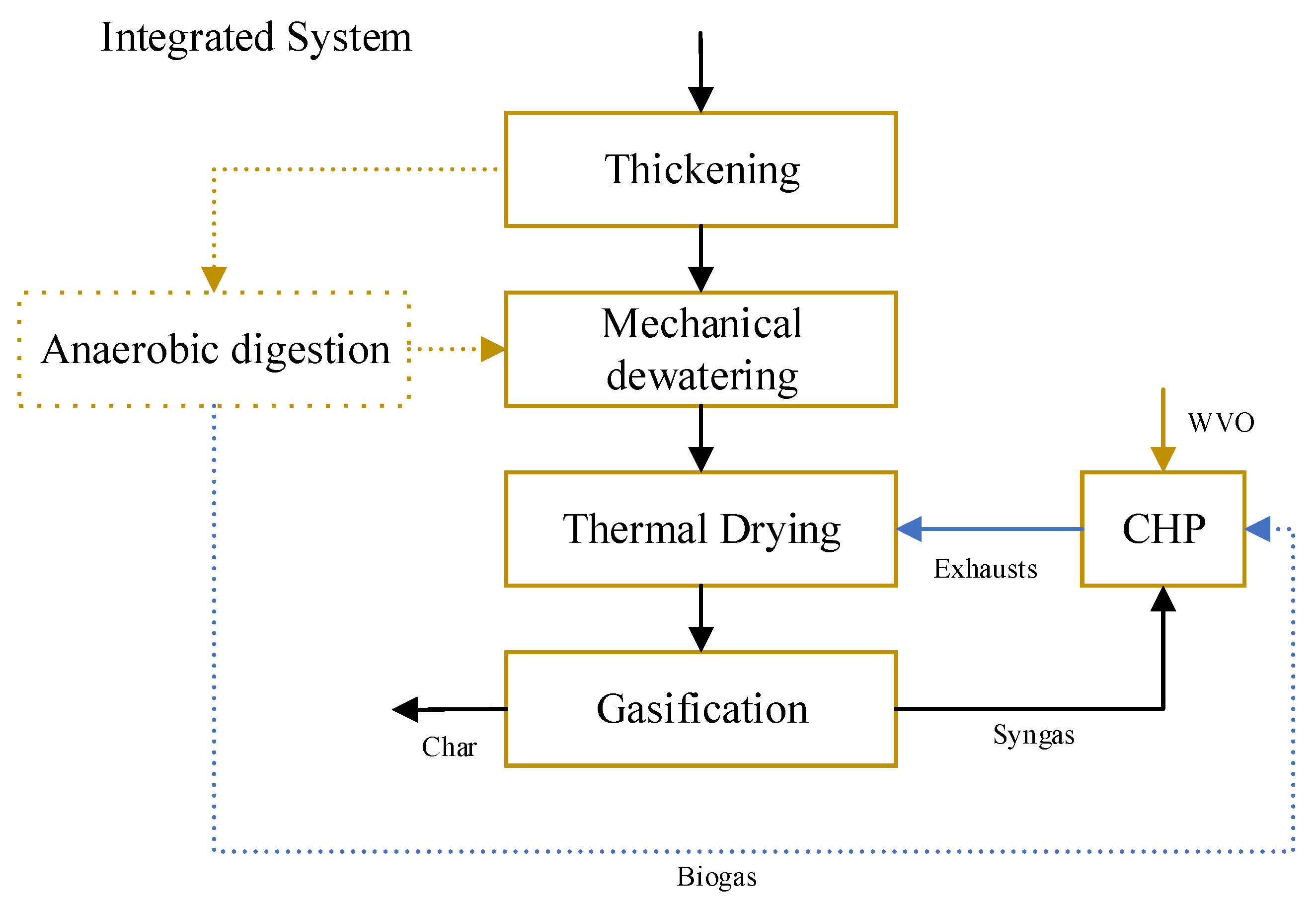

- Di Fraia, S.; Massarotti, N.; Vanoli, L.; Costa, M. Thermo-Economic Analysis of a Novel Cogeneration System for Sewage Sludge Treatment. Energy 2016, 115, 1560–1571. [Google Scholar] [CrossRef]

- Gandiglio, M.; Saberi Mehr, A.; MosayebNezhad, M.; Lanzini, A.; Santarelli, M. Solutions for Improving the Energy Efficiency in Wastewater Treatment Plants Based on Solid Oxide Fuel Cell Technology. J. Clean. Prod. 2020, 247, 119080. [Google Scholar] [CrossRef]

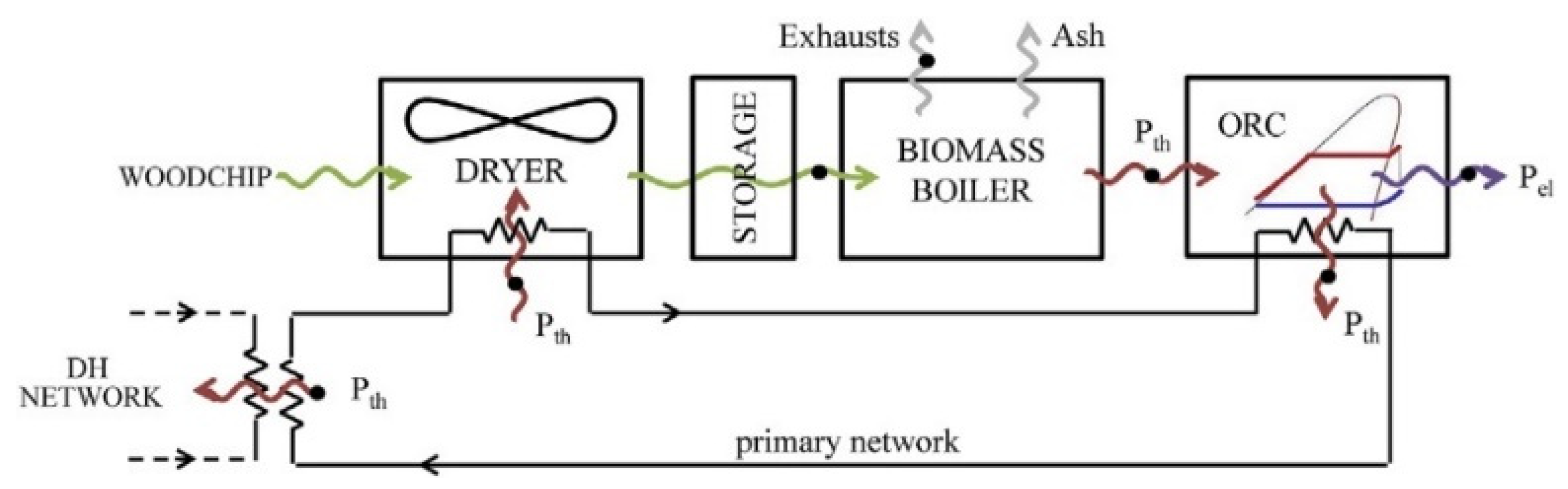

- Prando, D.; Renzi, M.; Gasparella, A.; Baratieri, M. Monitoring of the Energy Performance of a District Heating CHP Plant Based on Biomass Boiler and ORC Generator. Appl. Therm. Eng. 2015, 79, 98–107. [Google Scholar] [CrossRef]

- Díez-Montero, R.; Solimeno, A.; Uggetti, E.; García-Galán, M.J.; García, J. Feasibility Assessment of Energy-Neutral Microalgae-Based Wastewater Treatment Plants under Spanish Climatic Conditions. Process. Saf. Environ. Prot. 2018, 119, 242–252. [Google Scholar] [CrossRef]

- Wang, J.; Mao, T.; Sui, J.; Jin, H. Modeling and Performance Analysis of CCHP (Combined Cooling, Heating and Power) System Based on Co-Firing of Natural Gas and Biomass Gasification Gas. Energy 2015, 93, 801–815. [Google Scholar] [CrossRef]

- Wang, J.; Ma, C.; Wu, J. Thermodynamic Analysis of a Combined Cooling, Heating and Power System Based on Solar Thermal Biomass Gasification☆. Appl. Energy 2019, 247, 102–115. [Google Scholar] [CrossRef]

- Frangopoulos, C.A. Exergy, Energy System Analysis and Optimization—Volume II: Thermoeconomic Analysis Modeling, Simulation and Optimization in Energy Systems; Eolss Publishers Company Limited: Oxford, UK, 2009; Available online: https://play.google.com/store/books/details/Exergy_Energy_System_Analysis_and_Optimization_Vol?id=udGUCwAAQBAJ&hl=en (accessed on 3 June 2021).

- Abusoglu, A.; Kanoglu, M. Exergoeconomic Analysis and Optimization of Combined Heat and Power Production: A Review. Renew. Sustain. Energy Rev. 2009, 13, 2295–2308. [Google Scholar] [CrossRef]

- Lozano, M.A.; Valero, A. Theory of the Exergetic Cost. Energy 1993, 18, 939–960. [Google Scholar] [CrossRef]

- Szargut, J.; Morris, D.R.; Steward, F.R. Exergy Analysis of Thermal, Chemical, and Metallurgical Processes; Hemisphere Publishing: New York, NY, USA, 1987. [Google Scholar]

- Valero, A.; Lozano, M.A. An Introduction to Thermoeconomics; Cambridge, University Press: Cambridge, UK, 1997; Volume 9, ISBN 020-341-872-7. [Google Scholar]

- Tsatsaronis, G.; Moran, M.J. Exergy-Aided Cost Minimization. Energy Convers. Manag. 1997, 38, 1535–1542. [Google Scholar] [CrossRef]

- Darabadi Zareh, A.; Khoshbakhti Saray, R.; Mirmasoumi, S.; Bahlouli, K. Extensive Thermodynamic and Economic Analysis of the Cogeneration of Heat and Power System Fueled by the Blend of Natural Gas and Biogas. Energy Convers. Manag. 2018, 164, 329–343. [Google Scholar] [CrossRef]

- Lythcke-Jørgensen, C.; Haglind, F. Design Optimization of a Polygeneration Plant Producing Power, Heat, and Lignocellulosic Ethanol. Energy Convers. Manag. 2015, 91, 353–366. [Google Scholar] [CrossRef]

- Beith, R. (Ed.) Small and Micro Combined Heat and Power (CHP) Systems: Advanced Design, Performance, Materials and Applications; Woodhead Publishing: Cambridge, UK, 2011; Volume 18, ISBN 978-184-569-795-2. [Google Scholar]

- Frangopoulos, C.A. Optimization Methods for Energy Systems. In Exergy, Energy System Analysis and Optimization; EOLSS Publications: Abu Dhabi, United Arab Emirates, 2017; Volume II, pp. 233–258. ISBN 978-1-84826-165-5. Available online: http://www.eolss.net/sample-chapters/c08/ (accessed on 3 June 2021).

- Al-Sulaiman, F.A.; Dincer, I.; Hamdullahpur, F. Thermoeconomic Optimization of Three Trigeneration Systems Using Organic Rankine Cycles: Part II—Applications. Energy Convers. Manag. 2013, 69, 209–216. [Google Scholar] [CrossRef]

- Al-Sulaiman, F.A.; Dincer, I.; Hamdullahpur, F. Thermoeconomic Optimization of Three Trigeneration Systems Using Organic Rankine Cycles: Part I—Formulations. Energy Convers. Manag. 2013, 69, 199–208. [Google Scholar] [CrossRef]

- Dinçer, I. Exergy: Energy, Environment and Sustainable Development, 2nd ed.; Dincer, I., Rosen, M.A., Eds.; Elsevier: Oxford, UK, 2012; ISBN 978-008-097-090-5. [Google Scholar]

- Naikwadi, K.P.; Karasek, F.W. Chapter 24 Environmental analysis. In Chromatography, 5th ed.; Heftmann, E., Ed.; Journal of Chromatography Library; Elsevier: Amsterdam, The Netherlands, 1992; Volume 51, pp. B555–B582. [Google Scholar]

- Cushion, E.; Whiteman, A.; Dieterle, G. Bioenergy Development: Issues and Impacts for Poverty and Natural Resource Management; Agriculture and Rural Development Series; World Bank Publications: Washington, DC, USA, 2009; ISBN 978-082-138-129-8. [Google Scholar]

- Maroušek, J.; Strunecký, O.; Stehel, V. Biochar Farming: Defining Economically Perspective Applications. Clean Technol. Environ. Policy 2019, 21, 1389–1395. [Google Scholar] [CrossRef]

- House, K.Z.; Baclig, A.C.; Ranjan, M.; van Nierop, E.A.; Wilcox, J.; Herzog, H.J. Economic and Energetic Analysis of Capturing CO2 from Ambient Air. Proc. Natl. Acad. Sci. USA 2011, 108, 20428. [Google Scholar] [CrossRef]

- Brown, R.C. Biorenewable Resources Engineering New Products from Agriculture, 2nd ed.; Brown, R.C., Brown, T.R., Eds.; Wiley Blackwell: Chichester, UK, 2014; ISBN 978-111-852-493-0. [Google Scholar]

- Sacchelli, S. 9—Social, economic, and environmental impacts of biomass and biofuel supply chains. In Biomass Supply Chains for Bioenergy and Biorefining; Holm-Nielsen, J.B., Ehimen, E.A., Eds.; Woodhead Publishing: Cambridge, UK, 2016; pp. 191–213. ISBN 978-1-78242-366-9. [Google Scholar]

- Ashter, S.A. 13—Environmental impact of biomass conversion. In Technology and Applications of Polymers Derived from Biomass; Ashter, S.A., Ed.; Plastics Design Library; William Andrew Publishing: Norwich, NY, USA, 2018; pp. 249–259. ISBN 978-0-323-51115-5. [Google Scholar]

- Jagger, P.; Kittner, N. Deforestation and Biomass Fuel Dynamics in Uganda. Biomass Bioenergy 2017, 105, 1–9. [Google Scholar] [CrossRef]

- Bajpai, P. Chapter 10—Energy-related environmental issues. In Biomass to Energy Conversion Technologies; Bajpai, P., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 205–216. ISBN 978-0-12-818400-4. [Google Scholar]

- Lazarus, M.; von Hippel, D. A Guide to Environmental Analysis for Energy Planners; Stockholm Environment Institute: Boston, MA, USA, 1995. [Google Scholar]

- Balaman, Ş.Y. Chapter 4—Sustainability Issues in Biomass-Based Production Chains. In Decision-Making for Biomass-Based Production Chains; Balaman, Ş.Y., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 77–112. ISBN 978-0-12-814-278-3. [Google Scholar]

- Tojo, S.; Hirasawa, T. Research Approaches to Sustainable Biomass Systems; Elsevier Science: Amsterdam, The Netherlands, 2013; ISBN 978-012-404-683-2. [Google Scholar]

- Maraver, D.; Sin, A.; Sebastián, F.; Royo, J. Environmental Assessment of CCHP (Combined Cooling Heating and Power) Systems Based on Biomass Combustion in Comparison to Conventional Generation. Energy 2013, 57, 17–23. [Google Scholar] [CrossRef]

- ISO. Environmental Managment, Life Cycle Anaysis, Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO. ISO/TS 14072: Environmental Management—Life Cycle Assessment—Requirements and Guidelines for Organizational Life Cycle Assessment; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Havukainen, J.; Nguyen, M.T.; Väisänen, S.; Horttanainen, M. Life Cycle Assessment of Small-Scale Combined Heat and Power Plant: Environmental Impacts of Different Forest Biofuels and Replacing District Heat Produced from Natural Gas. J. Cleaner Prod. 2018, 172, 837–846. [Google Scholar] [CrossRef]

- Tagliaferri, C.; Evangelisti, S.; Clift, R.; Lettieri, P. Life Cycle Assessment of a Biomass CHP Plant in UK: The Heathrow Energy Centre Case. Chem. Eng. Res. Des. 2018, 133, 210–221. [Google Scholar] [CrossRef]

- Muthu, S.S. 6—Estimating the overall environmental impact of textile processing: Life cycle assessment (LCA) of textile products. In Assessing the Environmental Impact of Textiles and the Clothing Supply Chain; Muthu, S.S., Ed.; Woodhead Publishing: Cambridge, UK, 2014; pp. 105–131. ISBN 978-1-78242-104-7. [Google Scholar]

- Maier, J.M.; Sowlati, T.; Salazar, J. Life Cycle Assessment of Forest-Based Biomass for Bioenergy: A Case Study in British Columbia, Canada. Resour. Conserv. Recycl. 2019, 146, 598–609. [Google Scholar] [CrossRef]

- Khasreen, M.M.; Banfill, P.F.G.; Menzies, G.F. Life-Cycle Assessment and the Environmental Impact of Buildings: A Review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- Karvonen, J.; Kunttu, J.; Suominen, T.; Kangas, J.; Leskinen, P.; Judl, J. Integrating Fast Pyrolysis Reactor with Combined Heat and Power Plant Improves Environmental and Energy Efficiency in Bio-Oil Production. J. Cleaner Prod. 2018, 183, 143–152. [Google Scholar] [CrossRef]

- Roy, D.; Samanta, S.; Ghosh, S. Techno-Economic and Environmental Analyses of a Biomass Based System Employing Solid Oxide Fuel Cell, Externally Fired Gas Turbine and Organic Rankine Cycle. J. Cleaner Prod. 2019, 225, 36–57. [Google Scholar] [CrossRef]

- Mortazaei, M.; Rahimi, M. A Comparison between Two Methods of Generating Power, Heat and Refrigeration via Biomass Based Solid Oxide Fuel Cell: A Thermodynamic and Environmental Analysis. Energy Convers. Manag. 2016, 126, 132–141. [Google Scholar] [CrossRef]

- Li, H.; Zhang, X.; Liu, L.; Zeng, R.; Zhang, G. Exergy and Environmental Assessments of a Novel Trigeneration System Taking Biomass and Solar Energy as Co-Feeds. Appl. Thermal Eng. 2016, 104, 697–706. [Google Scholar] [CrossRef]

- Gholamian, E.; Zare, V.; Mousavi, S.M. Integration of Biomass Gasification with a Solid Oxide Fuel Cell in a Combined Cooling, Heating and Power System: A Thermodynamic and Environmental Analysis. Int. J. Hydrogen Energy 2016, 41, 20396–20406. [Google Scholar] [CrossRef]

- Su, B.; Han, W.; Zhang, X.; Chen, Y.; Wang, Z.; Jin, H. Assessment of a Combined Cooling, Heating and Power System by Synthetic Use of Biogas and Solar Energy. Appl. Energy 2018, 229, 922–935. [Google Scholar] [CrossRef]

- Chicco, G.; Mancarella, P. Assessment of the Greenhouse Gas Emissions from Cogeneration and Trigeneration Systems. Part I: Models and Indicators. Energy 2008, 33, 410–417. [Google Scholar] [CrossRef]

- Uris, M.; Linares, J.I.; Arenas, E. Feasibility Assessment of an Organic Rankine Cycle (ORC) Cogeneration Plant (CHP/CCHP) Fueled by Biomass for a District Network in Mainland Spain. Energy 2017, 133, 969–985. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bagherian, M.A.; Mehranzamir, K.; Rezania, S.; Abdul-Malek, Z.; Pour, A.B.; Alizadeh, S.M. Analyzing Utilization of Biomass in Combined Heat and Power and Combined Cooling, Heating, and Power Systems. Processes 2021, 9, 1002. https://doi.org/10.3390/pr9061002

Bagherian MA, Mehranzamir K, Rezania S, Abdul-Malek Z, Pour AB, Alizadeh SM. Analyzing Utilization of Biomass in Combined Heat and Power and Combined Cooling, Heating, and Power Systems. Processes. 2021; 9(6):1002. https://doi.org/10.3390/pr9061002

Chicago/Turabian StyleBagherian, Mohammad Ali, Kamyar Mehranzamir, Shahabaldin Rezania, Zulkurnain Abdul-Malek, Amin Beiranvand Pour, and Seyed Morteza Alizadeh. 2021. "Analyzing Utilization of Biomass in Combined Heat and Power and Combined Cooling, Heating, and Power Systems" Processes 9, no. 6: 1002. https://doi.org/10.3390/pr9061002

APA StyleBagherian, M. A., Mehranzamir, K., Rezania, S., Abdul-Malek, Z., Pour, A. B., & Alizadeh, S. M. (2021). Analyzing Utilization of Biomass in Combined Heat and Power and Combined Cooling, Heating, and Power Systems. Processes, 9(6), 1002. https://doi.org/10.3390/pr9061002