Simulation of Glass Fiber Reinforced Polypropylene Nanocomposites for Small Wind Turbine Blades

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Characterization

2.1.1. Glass Fiber

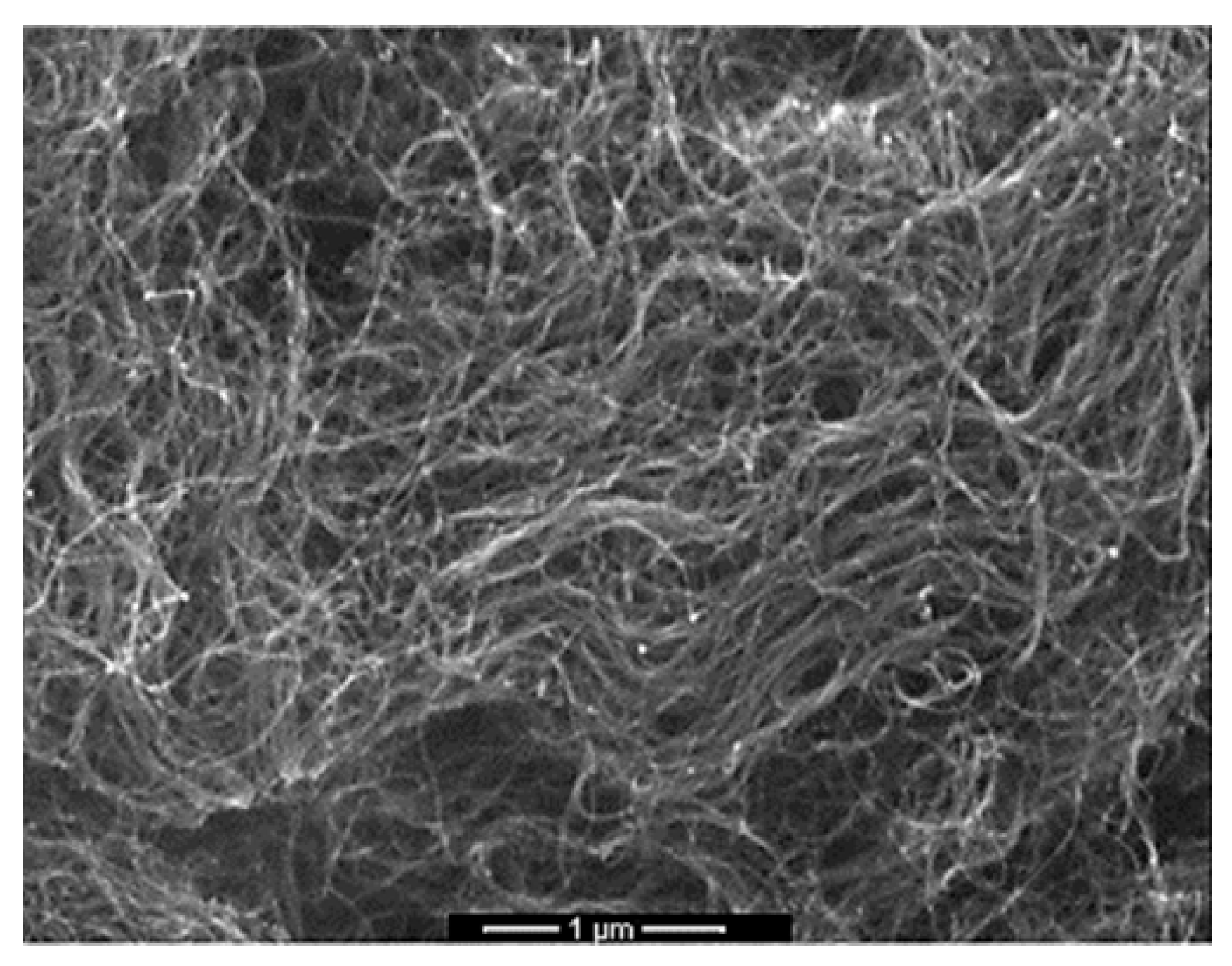

2.1.2. Multi-Walled Carbon Nanotubes (MWCNTs)

2.1.3. Synthesis of Glass Fiber-Reinforced Polypropylene-Carbon Nanotube Composites

2.1.4. PP-Nanocomposite Processing

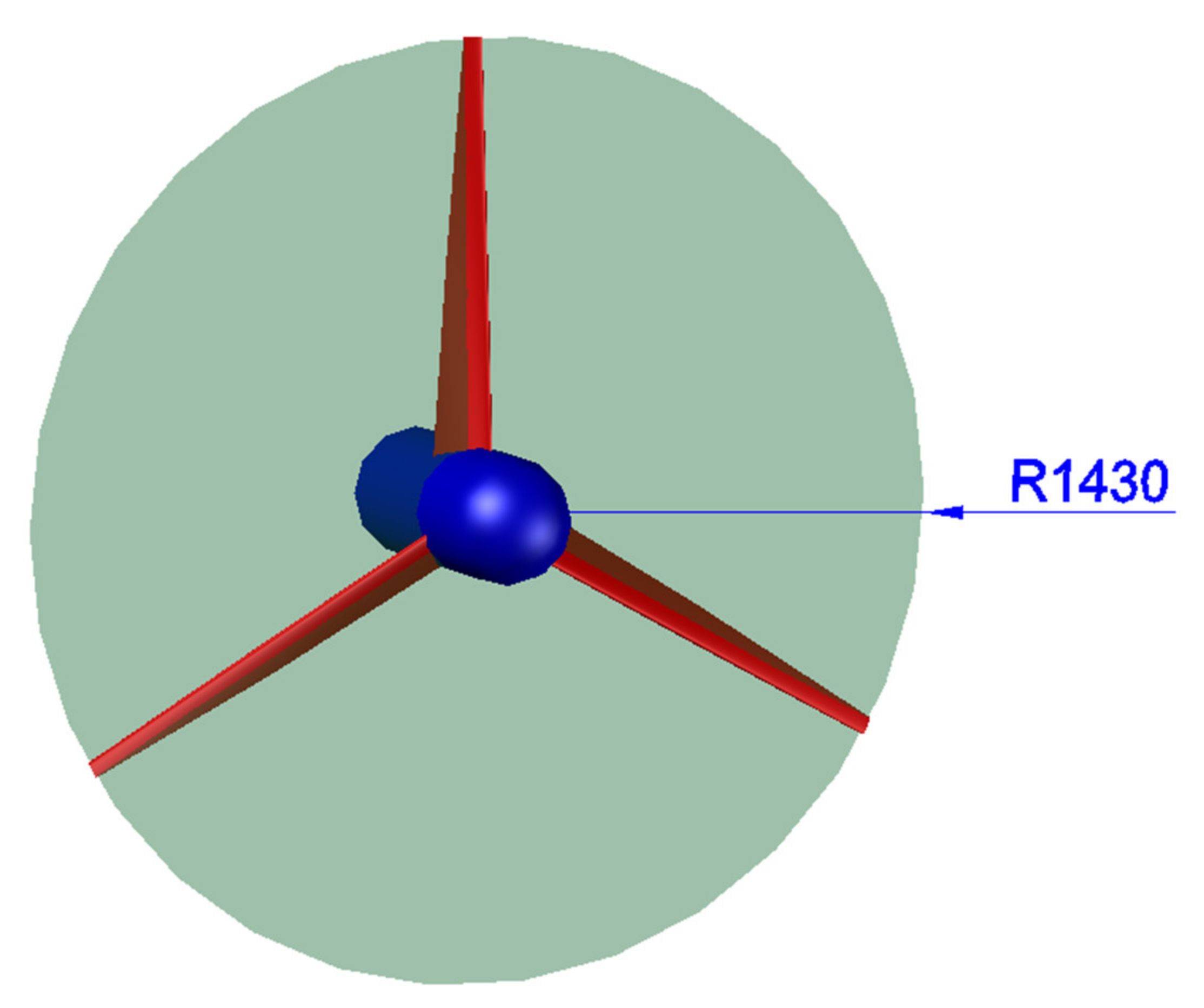

2.2. Model Wind Turbine

3. Results and Discussion

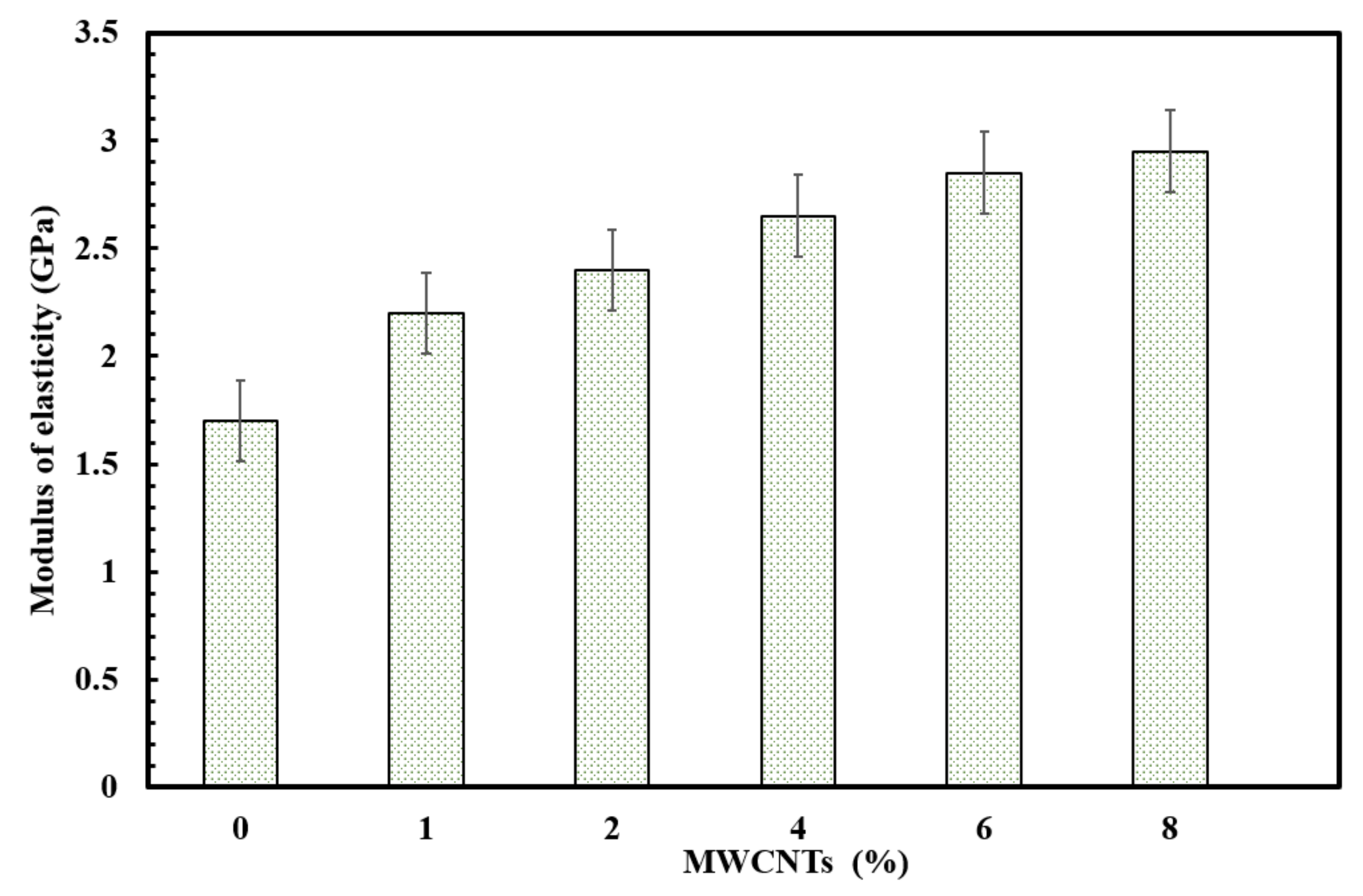

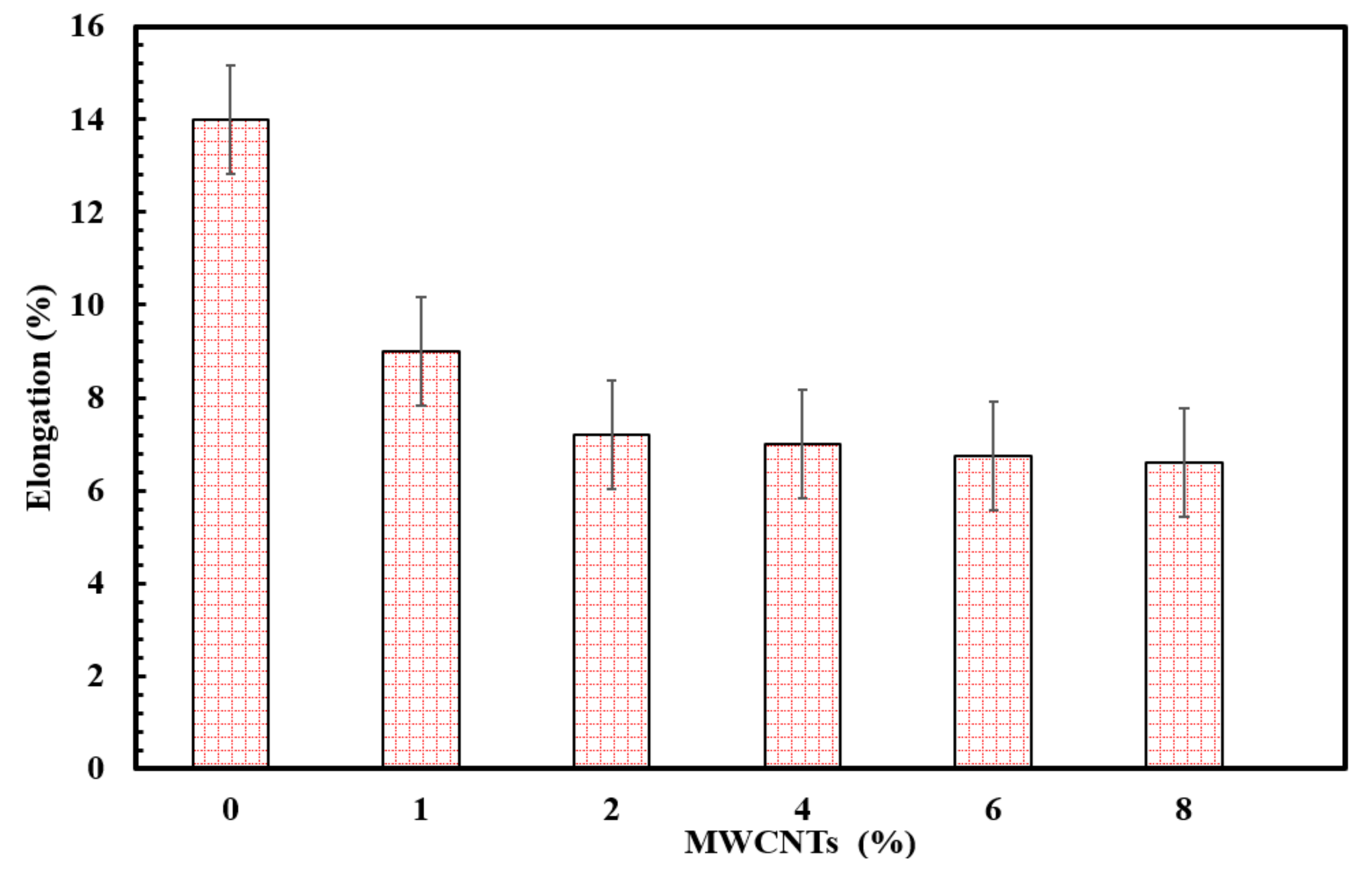

3.1. Tensile Properties of GF-PP-MWCNT Composites

3.2. Melt Flow Index of PP-Chopped E-Glass Fiber Composites

3.3. Surface Analysis of PP-Glass Fiber Composites

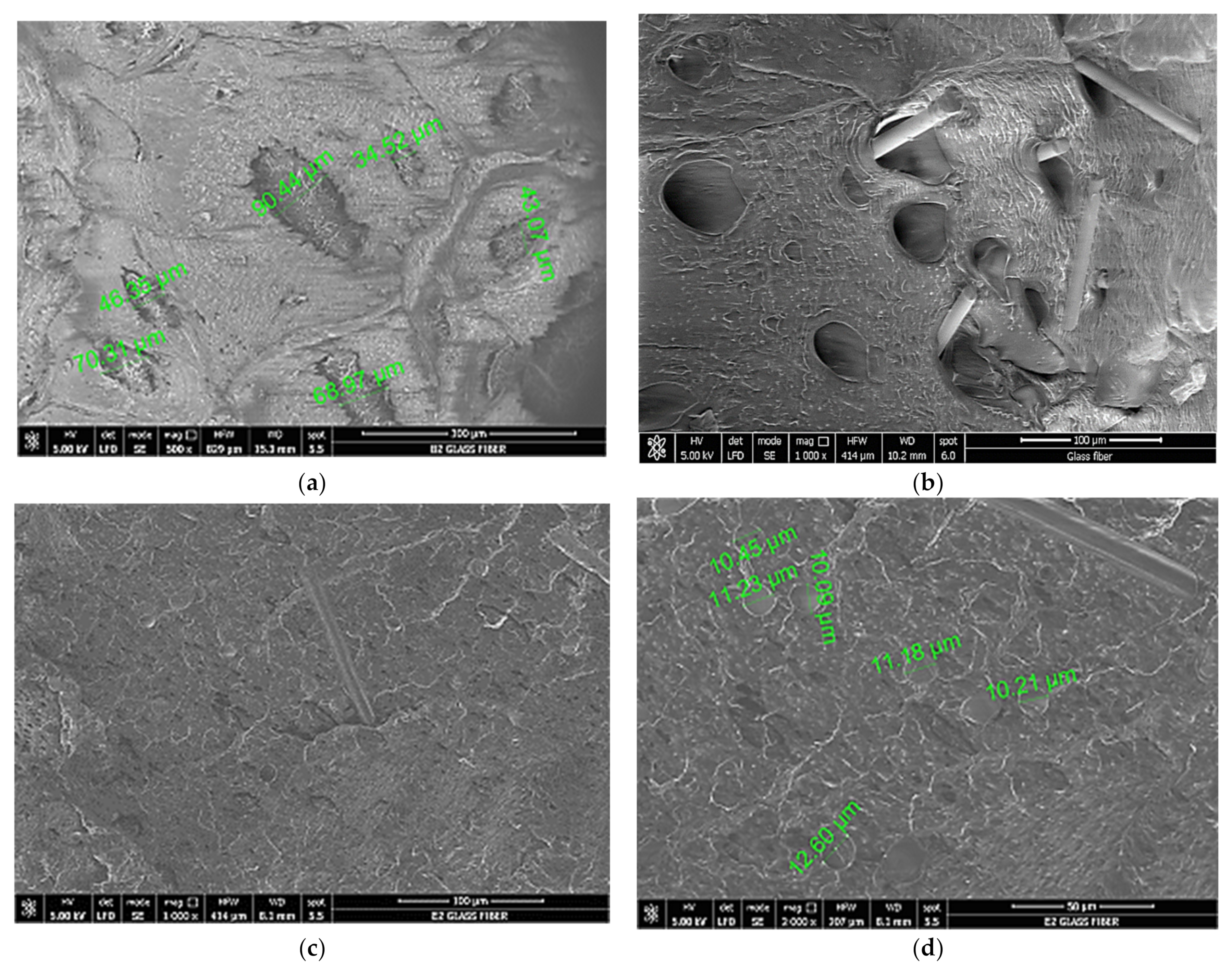

3.4. Surface Morphology

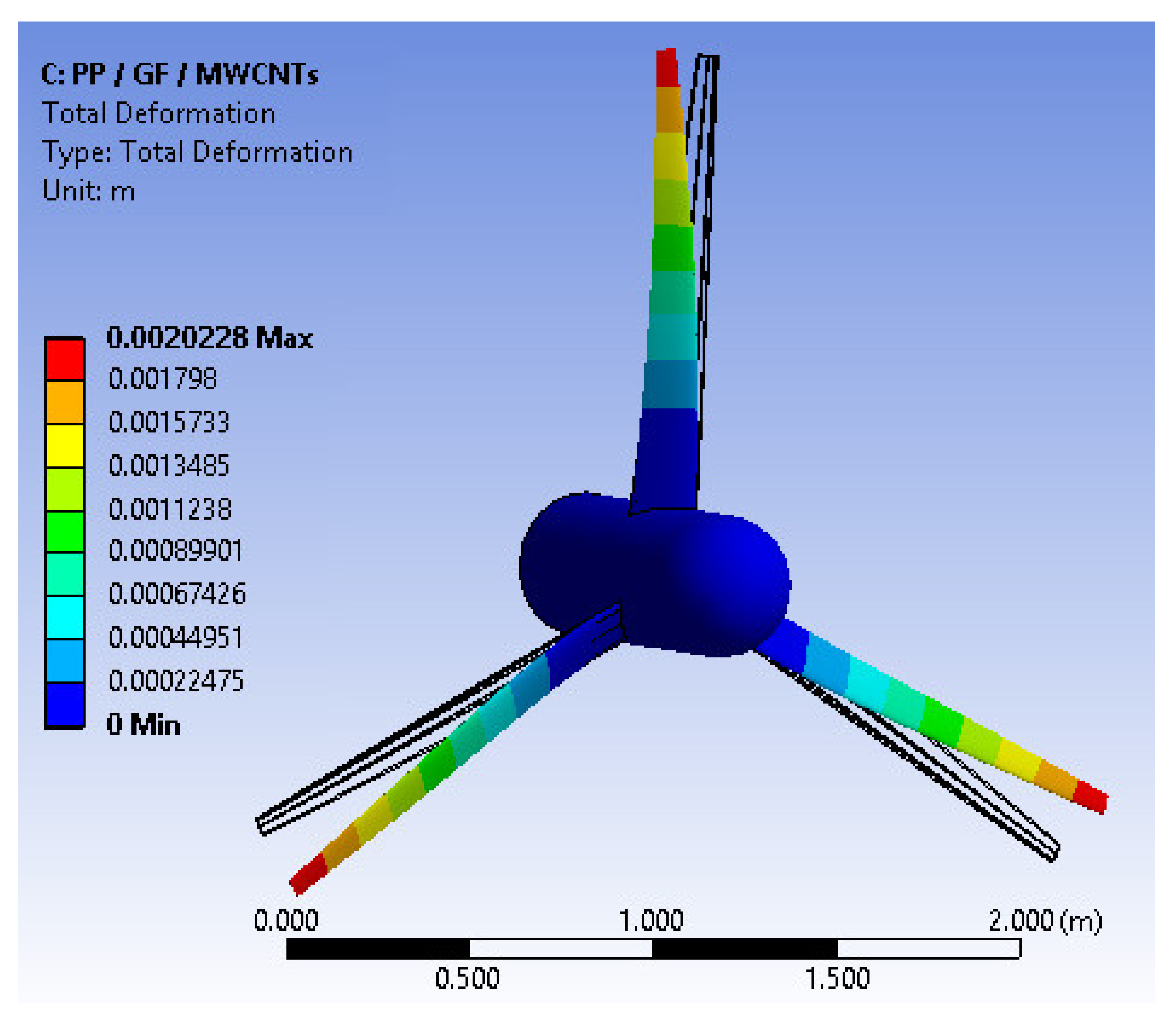

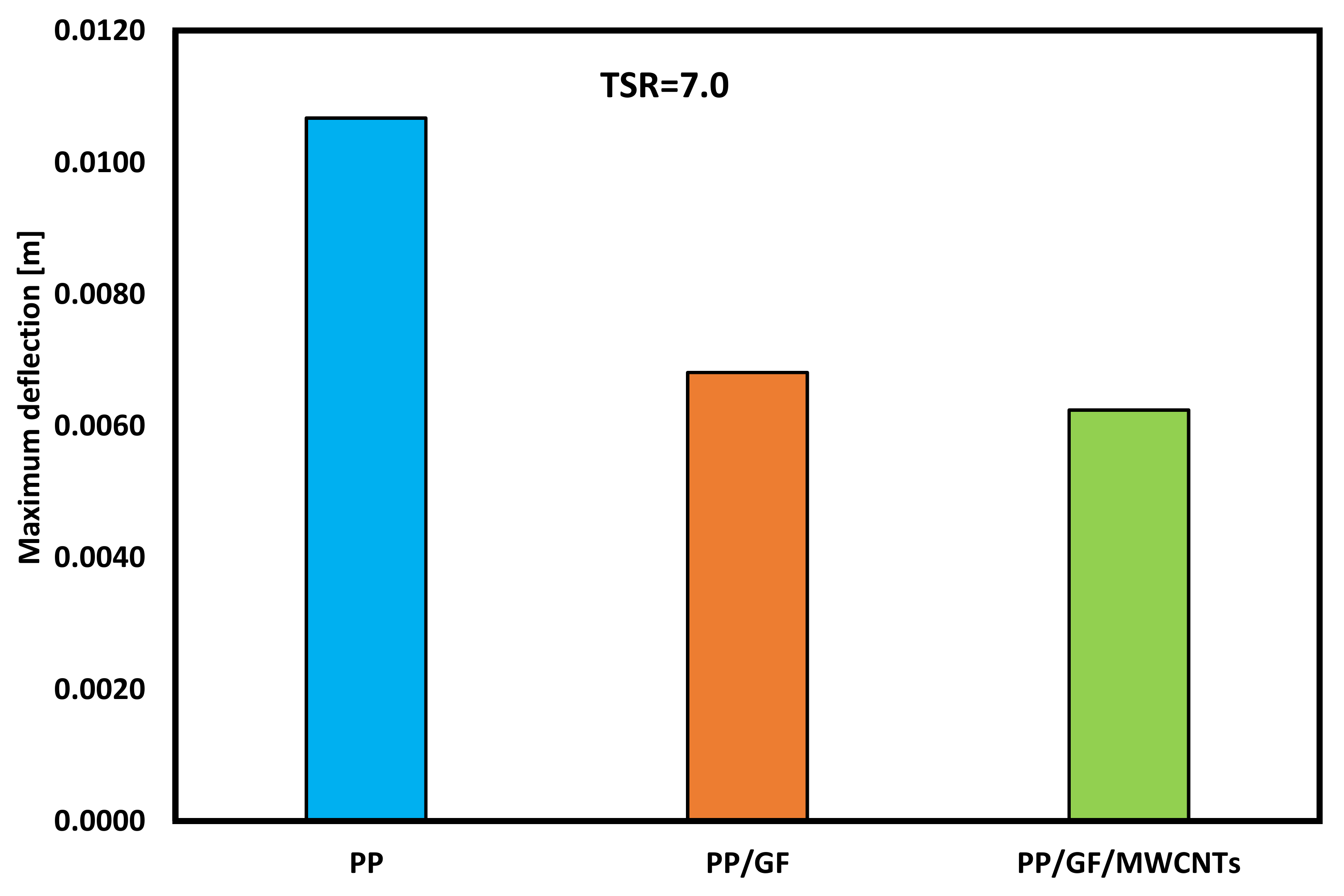

3.5. Finite Element Method Modelling

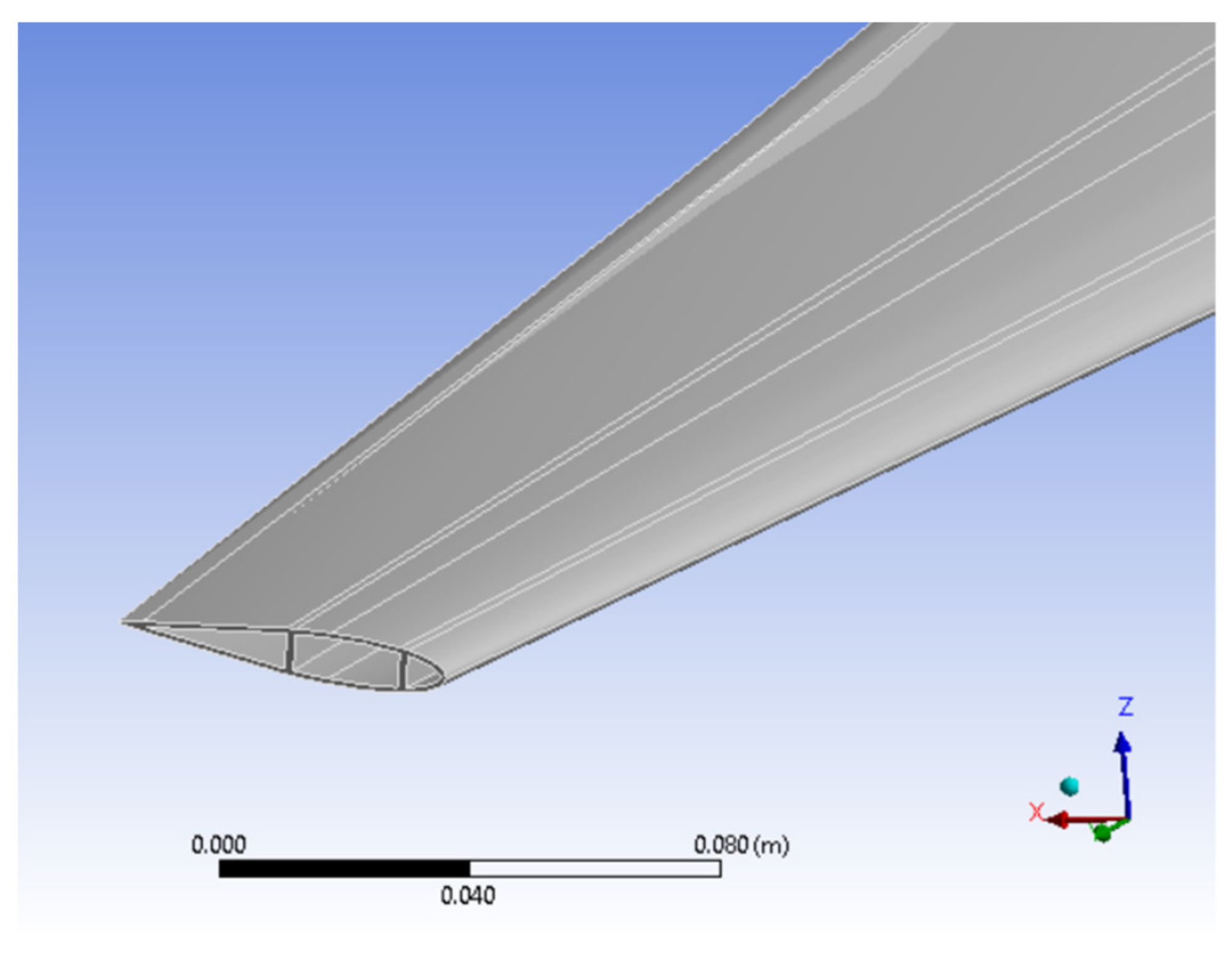

3.5.1. Geometry

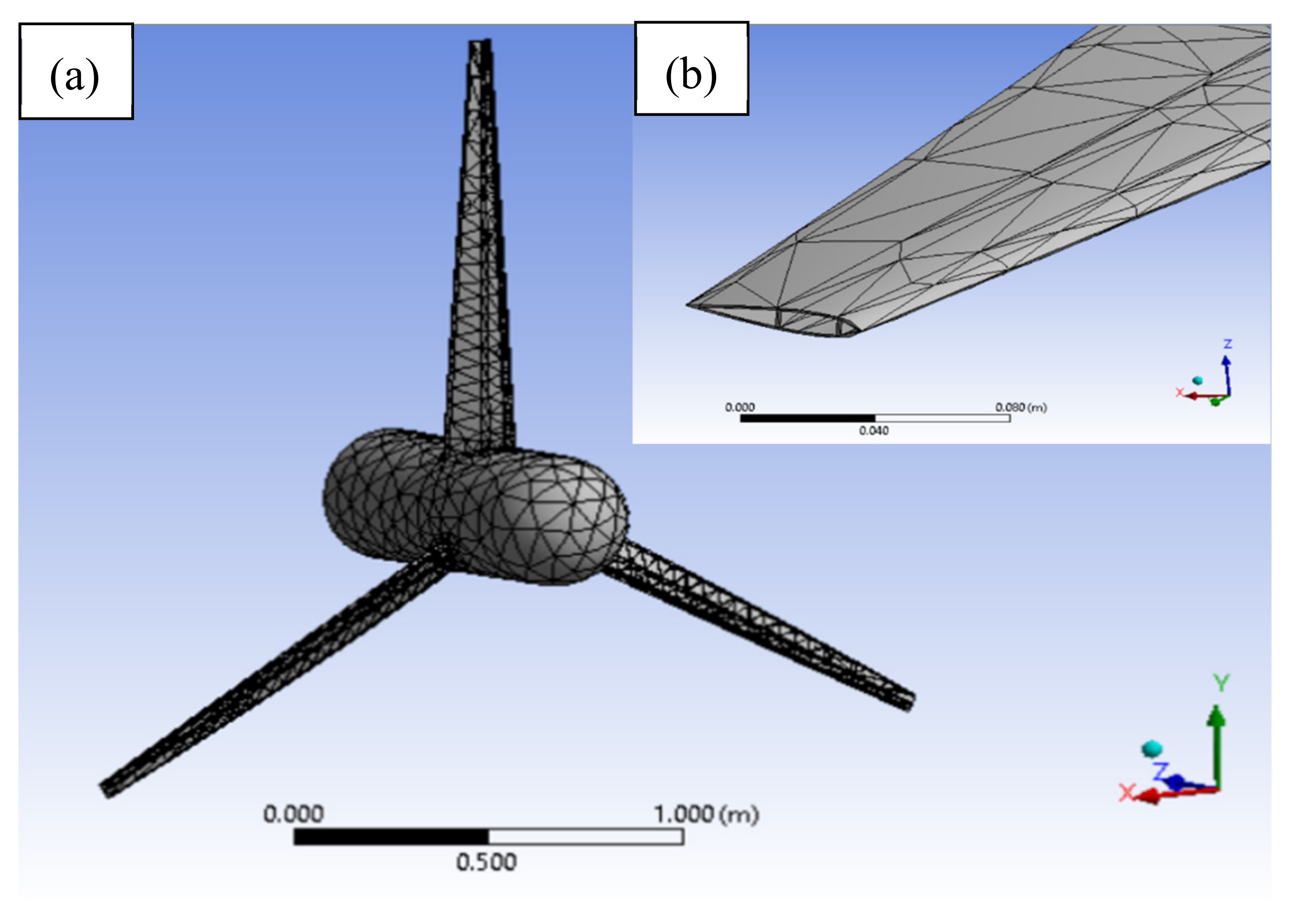

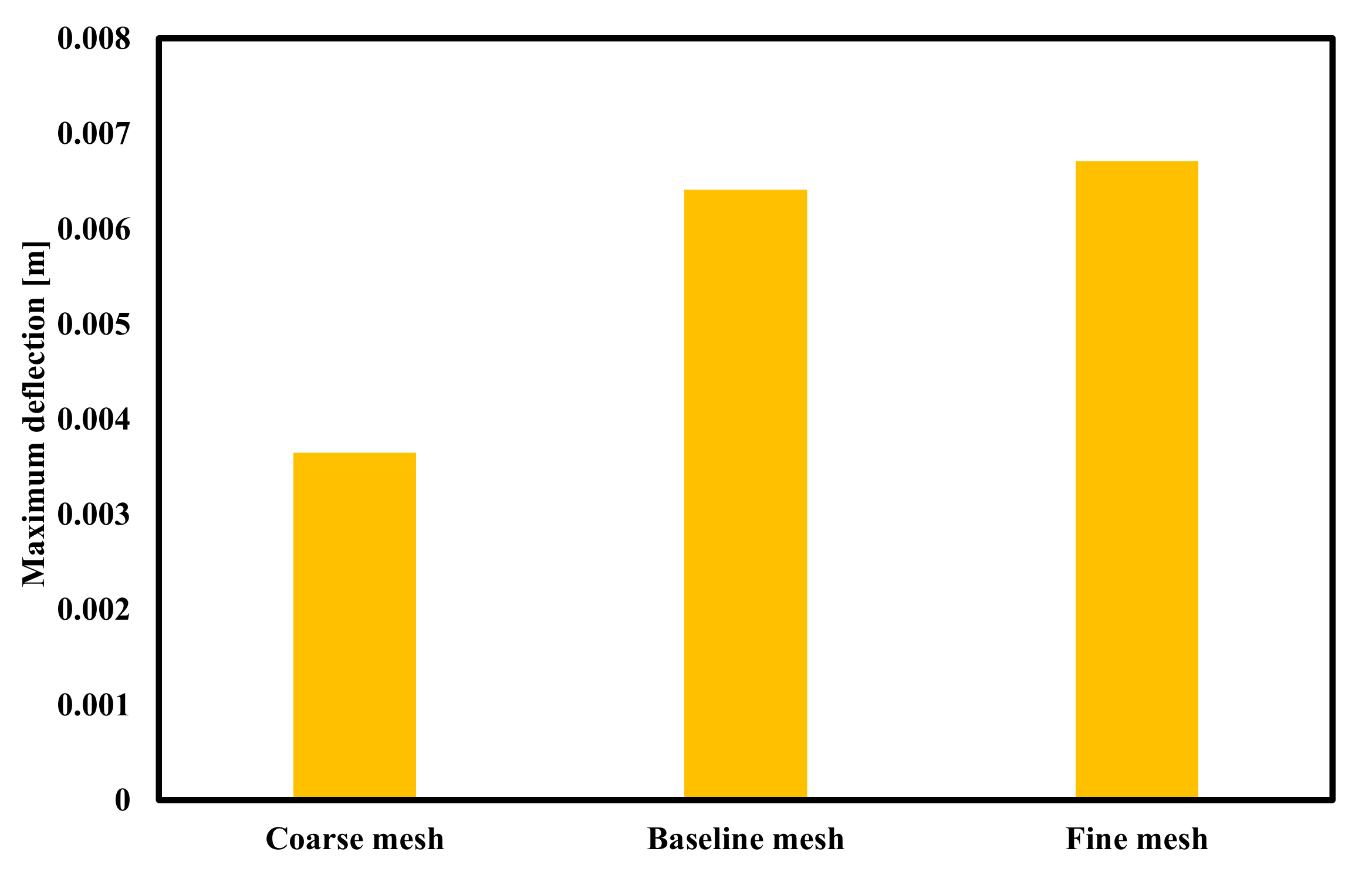

3.5.2. FEA Mesh

3.5.3. Boundary Conditions

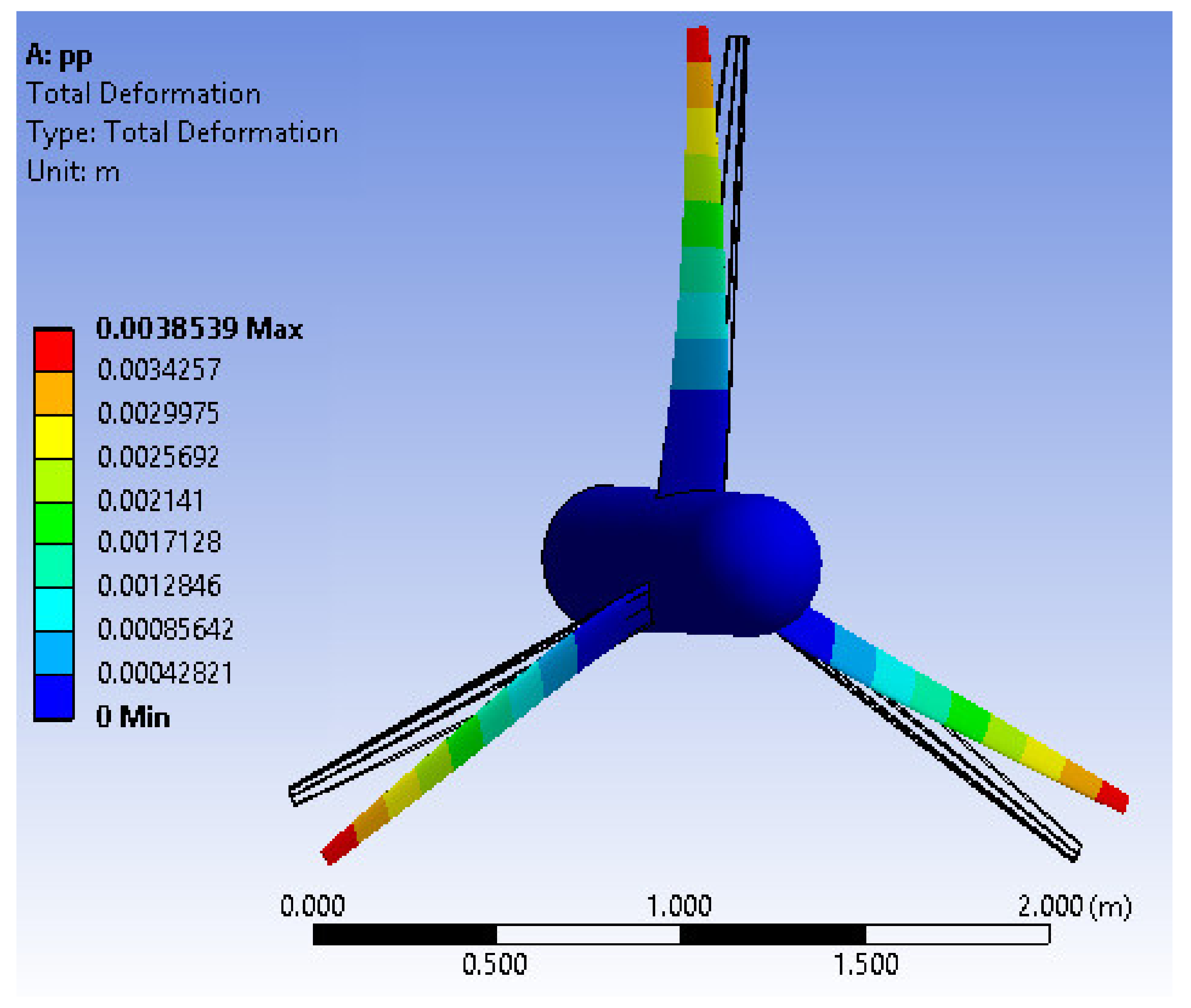

3.5.4. Solution and Post-Process Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zoromba, M.S.; Tashkandi, M.; Alshehri, A.; Abdel-Aziz, M.; Bassyouni, M.; Mahmoud, S.; Ben Slimane, A.; Al-Hossainy, A. Polymer solar cell based on doped o-anthranilic acid and o-aminophenol copolymer. Opt. Mater. 2020, 104, 109947. [Google Scholar] [CrossRef]

- Ashby, M.; Bréchet, Y.; Cebon, D.; Salvo, L. Selection strategies for materials and processes. Mater. Des. 2004, 25, 51–67. [Google Scholar] [CrossRef]

- Elhenawy, Y.; Hafez, G.; Abdel-Hamid, S.; Elbany, M. Prediction and assessment of automated lifting system per-formance for multi-storey parking lots powered by solar energy. J. Clean. Prod. 2020, 266, 121859. [Google Scholar] [CrossRef]

- Marsh, G. Reinforced plastics transform ‘small wind’ market. Reinf. Plast. 2004, 48, 22–26. [Google Scholar] [CrossRef]

- Bassyouni, M.; Gutub, S. Materials selection strategy and surface treatment of polymer composites for wind turbine baldes fabrication. Polym. Polym. Compos. 2013, 21, 463–471. [Google Scholar]

- Park, H. A study on structural design and analysis of small wind turbine blade with natural fibre (flax) composite. Adv. Compos. Mater. 2015, 25, 1–18. [Google Scholar] [CrossRef]

- Habali, S.; Saleh, I. Local design, testing and manufacturing of small mixed airfoil wind turbine blades of glass fibre reinforced plastics: Part I: Design of the blade and root. Energy Convers. Manag. 2000, 41, 249–280. [Google Scholar] [CrossRef]

- Sharma, K.; Shukla, M. Three-phase carbon fiber amine functionalized carbon nanotubes epoxy composite: Pro-cessing, characterisation, and multiscale modeling. J. Nanomater. 2014, 2014. [Google Scholar] [CrossRef]

- Da Costa, M.S.P.; Clausen, P.D. Structural Analysis of a Small Wind Turbine Blade Subjected to Gyro-scopic Load. J. Phys. Conf. Ser. 2020, 1618, 042006. [Google Scholar] [CrossRef]

- Ullah, H.; Ullah, B.; Silberschmidt, V.V. Structural integrity analysis and damage assessment of a long composite wind turbine blade under extreme loading. Compos. Struct. 2020, 246, 112426. [Google Scholar] [CrossRef]

- Junaedi, H.; Baig, M.; Dawood, A.; Albahkali, E.; Almajid, A. Mechanical and Physical Properties of Short Carbon Fiber and Nanofiller-Reinforced Polypropylene Hybrid Nanocomposites. Polymers 2020, 12, 2851. [Google Scholar] [CrossRef] [PubMed]

- Fanaradelli, T.D.; Rousakis, T.C. 3D Finite Element Pseudodynamic Analysis of Deficient RC Rectan-gular Columns Confined with Fiber Reinforced Polymers under Axial Compression. Polymers 2020, 12, 2546. [Google Scholar] [CrossRef] [PubMed]

- Sherif, G.; Chukov, D.I.; Tcherdyntsev, V.V.; Torokhov, V.G.; Zherebtsov, D.D. Effect of Glass Fi-bers Thermal Treatment on the Mechanical and Thermal Behavior of Polysulfone Based Composites. Polymers 2020, 12, 902. [Google Scholar] [CrossRef] [PubMed]

- Sommer, V.; Stockschläder, J.; Walther, G. Estimation of glass and carbon fiber reinforced plastic waste from end-of-life rotor blades of wind power plants within the European Union. Waste Manag. 2020, 115, 83–94. [Google Scholar] [CrossRef] [PubMed]

- Joustra, J.; Flipsen, B.; Balkenende, R. Structural reuse of high end composite products: A design case study on wind turbine blades. Resour. Conserv. Recycl. 2021, 167, 105393. [Google Scholar] [CrossRef]

- Boyano, A.; Lopez-Guede, J.; Torre-Tojal, L.; Fernandez-Gamiz, U.; Zulueta, E.; Mujika, F. Delamination Fracture Behavior of Unidirectional Carbon Reinforced Composites Applied to Wind Turbine Blades. Materials 2021, 14, 593. [Google Scholar] [CrossRef]

- Rizk, P.; Al Saleh, N.; Younes, R.; Ilinca, A.; Khoder, J. Hyperspectral imaging applied for the detection of wind turbine blade damage and icing. Remote. Sens. Appl. Soc. Environ. 2020, 18, 100291. [Google Scholar] [CrossRef]

- Elhenawy, Y.; Fouad, Y.; Marouani, H.; Bassyouni, M. Performance Analysis of Reinforced Epoxy Functionalized Carbon Nanotubes Composites for Vertical Axis Wind Turbine Blade. Polymers 2021, 13, 422. [Google Scholar] [CrossRef]

- Rodrigues, S.; Marta, A. On addressing wind turbine noise with after-market shape blade add-ons. Renew. Energy 2019, 140, 602–614. [Google Scholar] [CrossRef]

- Bassyouni, M.; Taha, I.; Abdel-Hamid, S.M.-S.; Steuernagel, L. Physico-mechanical properties of chemically treated polypropylene rice straw bio-composites. J. Reinf. Plast. Compos. 2012, 31, 303–312. [Google Scholar] [CrossRef]

- Bassyouni, M.; Sherif, S.A.; Sadek, M.; Ashour, F. Synthesis and characterization of polyurethane–Treated waste milled light bulbs composites. Compos. Part B Eng. 2012, 43, 1439–1444. [Google Scholar] [CrossRef]

- Cosco, F.; Serratore, G.; Gagliardi, F.; Filice, L.; Mundo, D. Experimental Characteri-zation of the Torsional Damping in CFRP Disks by Impact Hammer Modal Testing. Polymers 2020, 12, 493. [Google Scholar] [CrossRef] [PubMed]

- Feih, S.; Wei, J.; Kingshott, P.; Sørensen, B.F. The influence of fibre sizing on the strength and fracture toughness of glass fibre composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 245–255. [Google Scholar] [CrossRef]

- Thomason, J.; Jenkins, P.; Yang, L. Glass Fibre Strength—A Review with Relation to Composite Recycling. Fibers 2016, 4, 18. [Google Scholar] [CrossRef]

- Rehman, S. Wind energy resources assessment for Yanbo, Saudi Arabia. Energy Convers. Manag. 2004, 45, 2019–2032. [Google Scholar] [CrossRef]

- Biron, M. Future Prospects for Thermoplastics and Thermoplastic Composites Technical Information for Plastic Users; Elsevier: Oxford, UK, 2007. [Google Scholar]

- Chandler, H. Wind Energy, the Facts an Analysis of Wind Energy in the EU-25; European Wind Energy Association: Brussels, Belgium, 2007. [Google Scholar]

- Theodore, M.; Hosur, M.; Thomas, J.; Jeelani, S. Influence of functionalization on properties of MWCNT–epoxy nanocomposites. Mater. Sci. Eng. A 2011, 528, 1192–1200. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Satheeshkumar, S.; Naveen, J. Glass fiber-reinforced polymer composites–A review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Jarukumjorn, K.; Suppakarn, N. Effect of glass fiber hybridization on properties of sisal fiber–polypropylene composites. Compos. Part B Eng. 2009, 40, 623–627. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Fernández, B.; Cantero, G.; Llano-Ponte, R.; Valea, A.; Mondragon, I. Mechanical properties of flax fibre/polypropylene composites. Influence of fibre/matrix modification and glass fibre hybridization. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1637–1644. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Chopped glass and recycled newspaper as reinforcement fibers in injection molded poly(lactic acid) (PLA) composites: A comparative study. Compos. Sci. Technol. 2006, 66, 1813–1824. [Google Scholar] [CrossRef]

- Wharton, S.; Lundquis, J. Atmospheric stability affects wind turbine power collection. Environmental Res. Lett. 2012, 7, 1–9. [Google Scholar] [CrossRef]

- Crowson, R.; Folkes, M.; Bright, P. Rheology of short glass fibre-reinforced thermoplastics and its application to injec-tion moulding I. Fibre motion and viscosity measurement. Polym. Eng. Sci. 2004, 20, 925–933. [Google Scholar] [CrossRef]

- Thomason, J. The influence of fibre length and concentration on the properties of glass fibre reinforced polypropylene. 6. The properties of injection moulded long fibre PP at high fibre content. Compos. Part A Appl. Sci. Manuf. 2005, 36, 995–1003. [Google Scholar] [CrossRef]

- Kam, T.; Jiang, J.; Yang, H.; Chang, R.; Lai, F.; Tseng, Y. Fabrication and Testing of Composite Sandwich Blades for a Small Wind Power System. In Proceedings of the PEA-AIT International Conference on Energy and Sustainable Development: Issues and Strategies. Asian Institute of Technology, Klong Luang, Thailand, 2–4 June 2010. [Google Scholar]

- Wang, X.-D.; Vinodgopal, K.; Dai, G.-P. Synthesis of Carbon Nanotubes by Catalytic Chemical Vapor Deposition. Perspect. Carbon Nanotub. 2019. [Google Scholar] [CrossRef]

- Nurul, M.; Mariatti, M. Effect of thermal conductive fillers on the properties of polypropylene composites. J. Thermoplast. Compos. Mater. 2011, 26, 627–639. [Google Scholar] [CrossRef]

- Thomason, J. The influence of fibre length and concentration on the properties of glass fibre reinforced polypropylene: 5. Injection moulded long and short fibre PP. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1641–1652. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Tensile strength at break (MPa) | Warp: 1555; weft: 1387 |

| Moisture content | 0.11% |

| Density (kg/m3) | 2.55 × 103 |

| Thermal conductivity (W/m °C) | 1.3 |

| Electrical resistivity (Ω⋅m) | 1.0 × 1014 |

| Length (mm) | 2.5 |

| Diameter (µm) | 13 |

| Density (kg/m3) | 2600 |

| Coupling agent | Polyvinyl acetate with silane |

| Multi-Walled Carbon Nanotubes | SEM _MWCNTs | |

|---|---|---|

| Surface area | 275 m2/g |  |

| Carbon purity | > 90% | |

| Diameter | ~10 nm | |

| Length | ~1.7 μm | |

| Metal oxides | 9% | |

| Parameters | Values | Unit |

|---|---|---|

| No. of blades | 3 | |

| Radius of rotor (R) | r + L | m |

| Radius of hub (r) | 0.13 | m |

| Length of blade (L) | 0.5, 0.7, 0.9, 1.1, 1.3 | m |

| Rated speed of wind ) | 7 | m/s |

| Rated speed of the rotor ) | 34.26 | rad/s |

| Airfoil | NACA0015 |

| MWCNTs wt.% | 0 | 1 | 2 | 4 | 6 | 8 |

|---|---|---|---|---|---|---|

| MFI | 11.0 | 8.4 | 6.20 | 3.30 | 0.47 | 0.03 |

| Property | PP | PP/GF (Short Fiber Composite) at 10% wt./wt. | PP/GF/MWCNTs |

|---|---|---|---|

| Density (kg/m3) | 900 | 1020 | 1030 |

| Thermal expansion coefficient (µstrain/°C) | 27.1 | 10.4 | 9.7 |

| Thermal conductivity (Wm−1k−1) | 0.88 | 0.267 | 0.307 |

| Specific heat capacity (JKg−1k−1) | 1932 | 1650 | 1700 |

| Tensile strength (MPa) | 32 | 34.5 | 42 |

| Poisson’s ratio | 0.43 | 0.32 | 0.30 |

| Young’s modulus (GPa) | 1.34 | 1.72 | 2.5 |

| Coarse Mesh | Baseline Mesh | Fine Mesh | |

|---|---|---|---|

| Nodes | 33,489 | 96,700 | 137,467 |

| Elements | 7210 | 20,100 | 27,523 |

| Maximum deflection (mm) | 3.652 | 6.322 | 6.721 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elhenawy, Y.; Fouad, Y.; Marouani, H.; Bassyouni, M. Simulation of Glass Fiber Reinforced Polypropylene Nanocomposites for Small Wind Turbine Blades. Processes 2021, 9, 622. https://doi.org/10.3390/pr9040622

Elhenawy Y, Fouad Y, Marouani H, Bassyouni M. Simulation of Glass Fiber Reinforced Polypropylene Nanocomposites for Small Wind Turbine Blades. Processes. 2021; 9(4):622. https://doi.org/10.3390/pr9040622

Chicago/Turabian StyleElhenawy, Yasser, Yasser Fouad, Haykel Marouani, and Mohamed Bassyouni. 2021. "Simulation of Glass Fiber Reinforced Polypropylene Nanocomposites for Small Wind Turbine Blades" Processes 9, no. 4: 622. https://doi.org/10.3390/pr9040622

APA StyleElhenawy, Y., Fouad, Y., Marouani, H., & Bassyouni, M. (2021). Simulation of Glass Fiber Reinforced Polypropylene Nanocomposites for Small Wind Turbine Blades. Processes, 9(4), 622. https://doi.org/10.3390/pr9040622