Bibliometric Studies on Emissions from Diesel Engines Running on Alcohol/Diesel Fuel Blends. A Case Study about Noise Emissions

Abstract

1. Introduction

1.1. Alcohols

1.1.1. Methanol

1.1.2. Ethanol

1.1.3. Propanol

1.1.4. Butanol

1.2. Noise Emissions

2. Materials and Methods

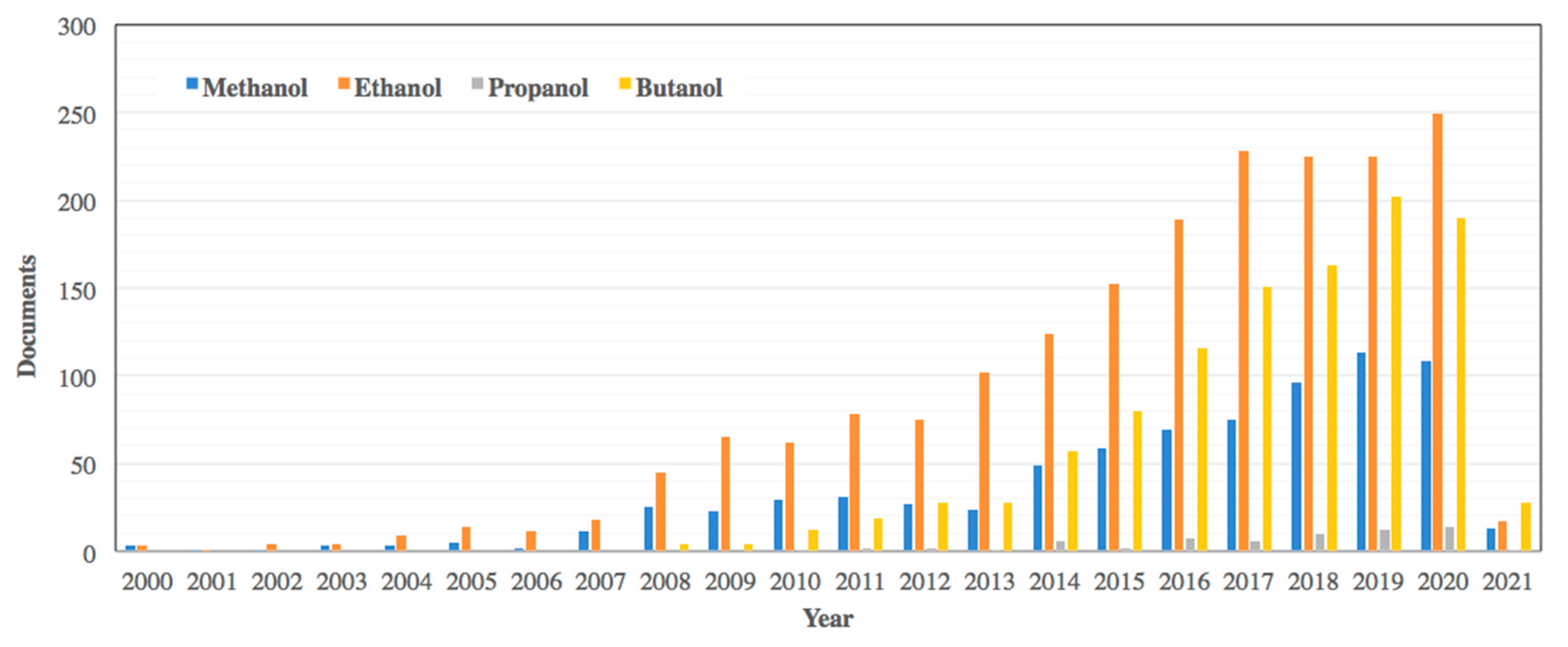

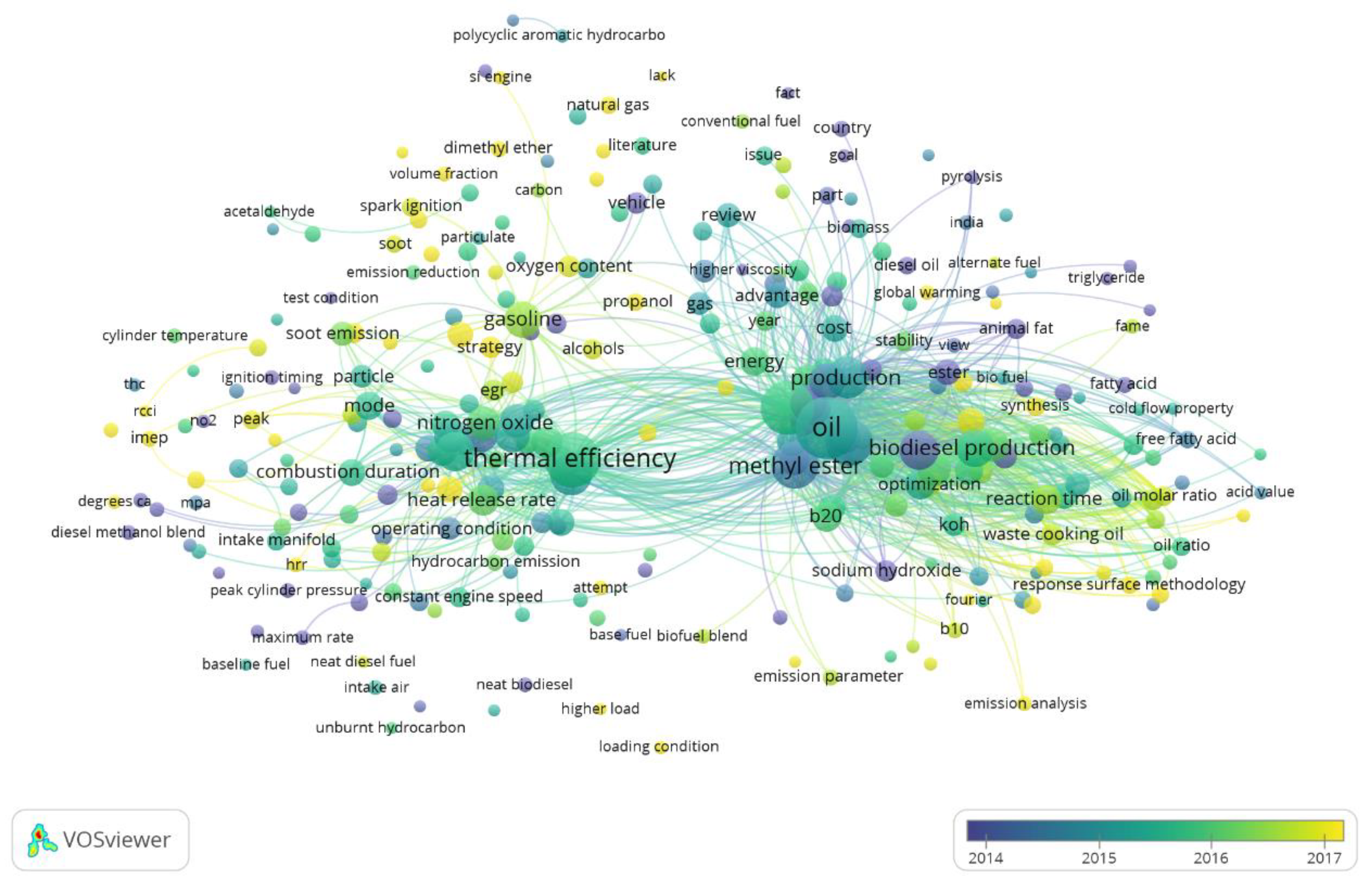

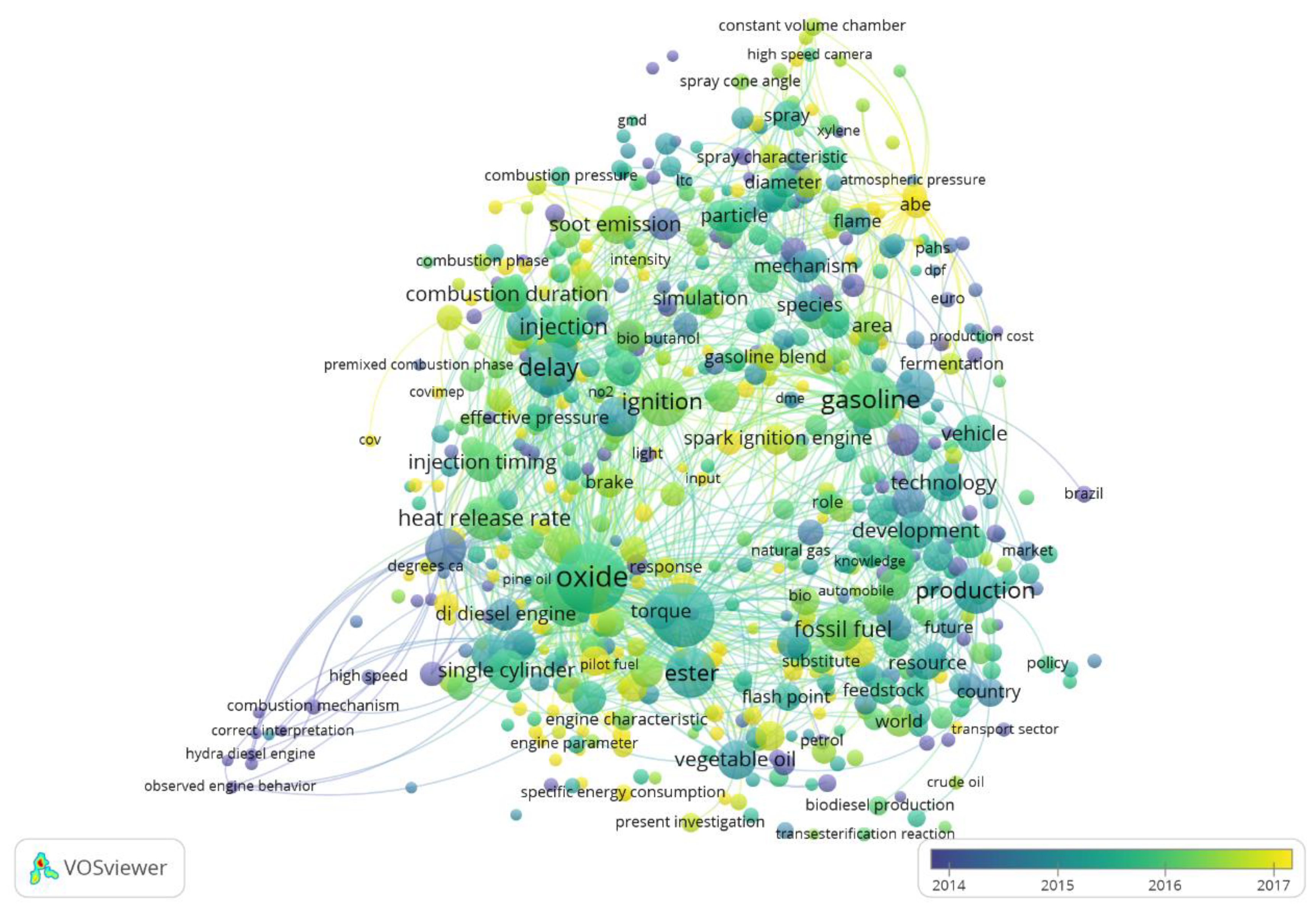

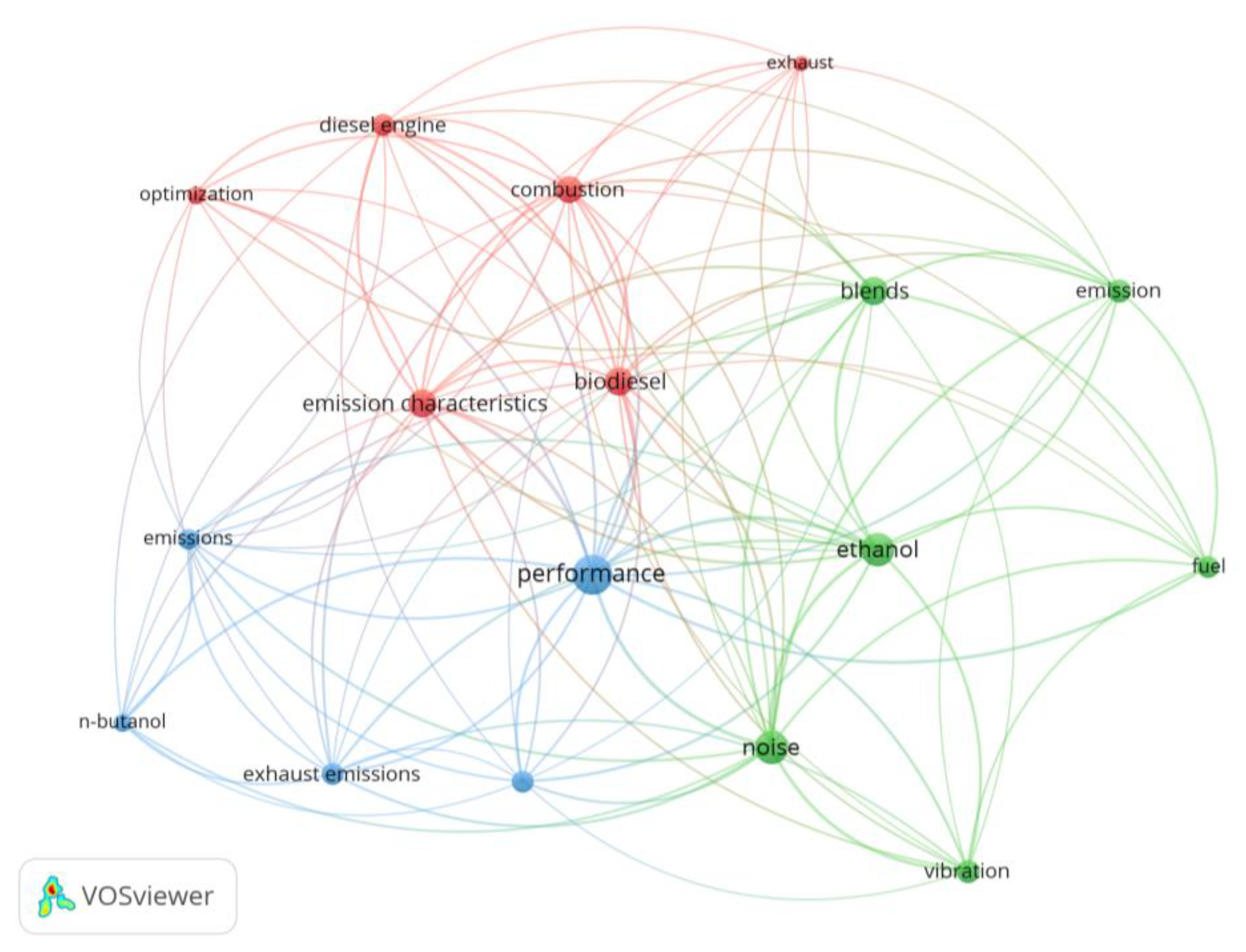

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Agarwal, A.K. Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog. Energy Combust. Sci. 2007, 33, 233–271. [Google Scholar] [CrossRef]

- Armas, O.; Cárdenas, D.; García-Contreras, R.; Mata, C. Bioethanol-Diesel Blends Used in Diesel Engines and Vehicles under Transient Operation. 2020. Available online: https://www.intechopen.com/online-first/bioethanol-diesel-blends-used-in-diesel-engines-and-vehicles-under-transient-operation (accessed on 26 March 2021).

- Gaffney, J.S.; Marley, N.A. The impacts of combustion emissions on air quality and climate—From coal to biofuels and beyond. Atmos. Environ. 2009, 43, 23–36. [Google Scholar] [CrossRef]

- Lapuerta, M.; Armas, O.; Garcia-Contreras, R. Stability of diesel-bioethanol blends for use in diesel engines. Fuel 2007, 86, 1351–1357. [Google Scholar] [CrossRef]

- Ribeiro, N.M.; Pinto, A.C.; Quintella, C.M.; da Rocha, G.O.; Teixeira, L.S.G.; Guarieiro, L.L.N.; Rangel, M.D.; Veloso, M.C.C.; Rezende, M.J.C.; da Cruz, R.S.; et al. The role of additives for diesel and diesel blended (ethanol or biodiesel) fuels: A review. Energy Fuels 2007, 21, 2433–2445. [Google Scholar] [CrossRef]

- Laza, T.; Bereczky, A. Basic fuel properties of rapeseed oil-higher alcohols blends. Fuel 2011, 90, 803–810. [Google Scholar] [CrossRef]

- Abu-Qudais, M.; Haddad, O.; Qudaisat, M. The effect of alcohol fumigation on diesel engine performance and emissions. Energy Convers. Manag. 2000, 41, 389–399. [Google Scholar] [CrossRef]

- Lapuerta, M.; Garcia-Contreras, R.; Campos-Fernandez, J.; Dorado, M.P. Stability, lubricity, viscosity, and cold-flow properties of alcohol-diesel blends. Energy Fuels 2010, 24, 4497–4502. [Google Scholar] [CrossRef]

- Hansen, A.C.; Zhang, Q.; Lyne, P.W.L. Ethanol-diesel fuel blends—A review. Bioresour. Technol. 2005, 96, 277–285. [Google Scholar] [CrossRef]

- Campos-Fernandez, J.; Arnal, J.M.; Gomez, J.; Dorado, M.P. A comparison of performance of higher alcohols/diesel fuel blends in a diesel engine. Appl. Energy 2012, 95, 267–275. [Google Scholar] [CrossRef]

- Directive 2002/49/EC of the European Parliament and of the Council of 25 June 2002 Relating to the Assessment and Management of Environmental Noise—Declaration by the Commission in the Conciliation Ommittee on the Directive Relating to the Assessment and Managament of Enviromental Noise. 2002. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32002L0049 (accessed on 26 March 2021).

- Giakoumis, E.G.; Rakopoulos, D.C.; Rakopoulos, C.D. Combustion noise radiation during dynamic diesel engine operation including effects of various biofuel blends: A review. Renew. Sustain. Energy Rev. 2016, 54, 1099–1113. [Google Scholar] [CrossRef]

- Redel-Macías, M.D.; Leiva-Candia, D.E.; Soriano, J.A.; Herreros, J.M.; Cubero-Atienza, A.J.; Pinzi, S. Influence of short carbon-chain alcohol (ethanol and 1-propanol)/diesel fuel blends over diesel engine emissions. Energies 2021, 14, 1309. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Jiao, W.Z.; Qi, G.S. Preparation and properties of methanol-diesel oil emulsified fuel under high-gravity environment. Renew. Energy 2011, 36, 1463–1468. [Google Scholar] [CrossRef]

- Chao, M.R.; Lin, T.C.; Chao, H.R.; Chang, F.H.; Chen, C.B. Effects of methanol-containing additive on emission characteristics from a heavy-duty diesel engine. Sci. Total Environ. 2001, 279, 167–179. [Google Scholar] [CrossRef]

- Sayin, C.; Ilhan, M.; Canakci, M.; Gumus, M. Effect of injection timing on the exhaust emissions of a diesel engine using diesel-methanol blends. Renew. Energy 2009, 34, 1261–1269. [Google Scholar] [CrossRef]

- Anand, K.; Sharma, R.P.; Mehta, P.S. Experimental investigations on combustion, performance and emissions characteristics of neat karanji biodiesel and its methanol blend in a diesel engine. Biomass Bioenergy 2011, 35, 533–541. [Google Scholar] [CrossRef]

- Bayraktar, H. An experimental study on the performance parameters of an experimental CI engine fueled with diesel-methanol-dodecanol blends. Fuel 2008, 87, 158–164. [Google Scholar] [CrossRef]

- Sayin, C. Engine performance and exhaust gas emissions of methanol and ethanol-diesel blends. Fuel 2010, 89, 3410–3415. [Google Scholar] [CrossRef]

- Sayin, C.; Ozsezen, A.N.; Canakci, M. The influence of operating parameters on the performance and emissions of a DI diesel engine using methanol-blended-diesel fuel. Fuel 2010, 89, 1407–1414. [Google Scholar] [CrossRef]

- Yao, C.D.; Cheung, C.S.; Cheng, C.H.; Wang, Y.S.; Chan, T.L.; Lee, S.C. Effect of diesel/methanol compound combustion on diesel engine combustion and emissions. Energy Convers. Manag. 2008, 49, 1696–1704. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, C.D.; Dimaratos, A.M.; Rakopoulos, D.C. Exhaust emissions with ethanol or n-butanol diesel fuel blends during transient operation: A review. Renew. Sustain. Energy Rev. 2013, 17, 170–190. [Google Scholar] [CrossRef]

- Armas, O.; Lapuerta, M.; Mata, C.; Pérez, D. Online emissions from a vibrating roller using an ethanol− diesel blend during a railway construction. Energy Fuels 2009, 23, 2989–2996. [Google Scholar] [CrossRef]

- Misra, R.D.; Murthy, M.S. Blending of additives with biodiesels to improve the cold flow properties, combustion and emission performance in a compression ignition engine—A review. Renew. Sustain. Energy Rev. 2011, 15, 2413–2422. [Google Scholar] [CrossRef]

- Lu, X.C.; Yang, J.G.; Zhang, W.G.; Huang, Z. Effect of cetane number improver on heat release rate and emissions of high speed diesel engine fueled with ethanol-diesel blend fuel. Fuel 2004, 83, 2013–2020. [Google Scholar]

- Can, O.; Celikten, I.; Usta, N. Effects of ethanol addition on performance and emissions of a turbocharged indirect injection Diesel engine running at different injection pressures. Energy Convers. Manag. 2004, 45, 2429–2440. [Google Scholar] [CrossRef]

- Huang, J.C.; Wang, Y.D.; Li, S.D.; Roskilly, A.P.; Yu, H.D.; Li, H.F. Experimental investigation on the performance and emissions of a diesel engine fuelled with ethanol-diesel blends. Appl. Therm. Eng. 2009, 29, 2484–2490. [Google Scholar] [CrossRef]

- Ajav, E.A.; Singh, B.; Bhattacharya, T.K. Experimental study of some performance parameters of a constant speed stationary diesel engine using ethanol-diesel blends as fuel. Biomass Bioenergy 1999, 17, 357–365. [Google Scholar] [CrossRef]

- Chen, H.; Wang, J.X.; Shuai, S.J.; Chen, W.M. Study of oxygenated biomass fuel blends on a diesel engine. Fuel 2008, 87, 3462–3468. [Google Scholar] [CrossRef]

- Chen, H.; Shual, S.J.; Wang, J.X. Study on combustion characteristics and PM emission of diesel engines using ester-ethanol-diesel blended fuels. Proc. Combust. Inst. 2007, 31, 2981–2989. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Papagiannakis, R.G.; Kyritsis, D.C. Combustion heat release analysis of ethanol or n-butanol diesel fuel blends in heavy-duty DI diesel engine. Fuel 2011, 90, 1855–1867. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Kakaras, E.C.; Giakoumis, E.G. Effects of ethanol-diesel fuel blends on the performance and exhaust emissions of heavy duty DI diesel engine. Energy Convers. Manag. 2008, 49, 3155–3162. [Google Scholar] [CrossRef]

- Park, S.H.; Youn, I.M.; Lee, C.S. Influence of ethanol blends on the combustion performance and exhaust emission characteristics of a four-cylinder diesel engine at various engine loads and injection timings. Fuel 2011, 90, 748–755. [Google Scholar] [CrossRef]

- Kwanchareon, P.; Luengnaruemitchai, A.; Jai-In, S. Solubility of a diesel-biodiesel-ethanol blend, its fuel properties, and its emission characteristics from diesel engine. Fuel 2007, 86, 1053–1061. [Google Scholar] [CrossRef]

- Pidol, L.; Lecointe, B.; Starck, L.; Jeuland, N. Ethanol-biodiesel-diesel fuel blends: Performances and emissions in conventional diesel and advanced low temperature combustions. Fuel 2012, 93, 329–338. [Google Scholar] [CrossRef]

- Lei, J.L.; Bi, Y.H.; Shen, L.Z. Performance and emission characteristics of diesel engine fueled with ethanol-diesel blends in different altitude regions. J. Biomed. Biotechnol. 2011, 2011, 417421. [Google Scholar] [CrossRef]

- Sahin, Z.; Durgun, O. Theoretical investigation of effects of light fuel fumigation on diesel engine performance and emissions. Energy Convers. Manag. 2007, 48, 1952–1964. [Google Scholar] [CrossRef]

- de Caro, P.S.; Mouloungui, Z.; Vaitilingom, G.; Berge, J.C. Interest of combining an additive with diesel-ethanol blends for use in diesel engines. Fuel 2001, 80, 565–574. [Google Scholar] [CrossRef]

- Li, D.; Huang, Z.; Lu, X.C.; Zhang, W.; Yang, J. Physico-chemical properties of ethanol-diesel blend fuel and its effect on performance and emissions of diesel engines. Renew. Energy 2005, 30, 967–976. [Google Scholar] [CrossRef]

- Kim, H.; Choi, B. Effect of ethanol-diesel blend fuels on emission and particle size distribution in a common-rail direct injection diesel engine with warm-up catalytic converter. Renew. Energy 2008, 33, 2222–2228. [Google Scholar] [CrossRef]

- Armas, O.; García-Contreras, R.; Ramos, Á. Pollutant emissions from New European Driving Cycle with ethanol and butanol diesel blends. Fuel Process. Technol. 2014, 122, 64–71. [Google Scholar] [CrossRef]

- Song, C.L.; Zhao, Z.A.; Lv, G.; Song, J.N.; Liu, L.D.; Zhao, R.F. Carbonyl compound emissions from a heavy-duty diesel engine fueled with diesel fuel and ethanol-diesel blend. Chemosphere 2010, 79, 1033–1039. [Google Scholar] [CrossRef]

- Kumar, B.R.; Saravanan, S. Use of higher alcohol biofuels in diesel engines: A review. Renew. Sustain. Energy Rev. 2016, 60, 84–115. [Google Scholar] [CrossRef]

- Karabektas, M.; Hosoz, M. Performance and emission characteristics of a diesel engine using isobutanol-diesel fuel blends. Renew. Energy 2009, 34, 1554–1559. [Google Scholar] [CrossRef]

- Jin, C.; Yao, M.F.; Liu, H.F.; Lee, C.F.F.; Ji, J. Progress in the production and application of n-butanol as a biofuel. Renew. Sustain. Energy Rev. 2011, 15, 4080–4106. [Google Scholar] [CrossRef]

- Yao, M.F.; Wang, H.; Zheng, Z.Q.; Yue, Y. Experimental study of n-butanol additive and multi-injection on HD diesel engine performance and emissions. Fuel 2010, 89, 2191–2201. [Google Scholar] [CrossRef]

- Armas, O.; García-Contreras, R.; Ramos, Á. Pollutant emissions from engine starting with ethanol and butanol diesel blends. Fuel Process. Technol. 2012, 100, 63–72. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G.; Dimaratos, A.M.; Kyritsis, D.C. Effects of butanol-diesel fuel blends on the performance and emissions of a high-speed DI diesel engine. Energy Convers. Manag. 2010, 51, 1989–1997. [Google Scholar] [CrossRef]

- Valentino, G.; Corcione, F.E.; Iannuzzi, S.E.; Serra, S. Experimental study on performance and emissions of a high speed diesel engine fuelled with n-butanol diesel blends under premixed low temperature combustion. Fuel 2012, 92, 295–307. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Dimaratos, A.M.; Giakoumis, E.G.; Rakopoulos, D.C. Investigating the emissions during acceleration of a turbocharged diesel engine operating with bio-diesel or n-butanol diesel fuel blends. Energy 2010, 35, 5173–5184. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Hountalas, D.T.; Kakaras, E.C.; Giakoumis, E.G.; Papagiannakis, R.G. Investigation of the performance and emissions of bus engine operating on butanol/diesel fuel blends. Fuel 2010, 89, 2781–2790. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Dimaratos, A.M.; Giakoumis, E.G.; Rakopoulos, D.C. Study of turbocharged diesel engine operation, pollutant emissions and combustion noise radiation during starting with bio-diesel or n-butanol diesel fuel blends. Appl. Energy 2011, 88, 3905–3916. [Google Scholar] [CrossRef]

- Dogan, O. The influence of n-butanol/diesel fuel blends utilization on a small diesel engine performance and emissions. Fuel 2011, 90, 2467–2472. [Google Scholar] [CrossRef]

- World Health Organization (WHO). Burden of Disease from Environmental Noise. 2011. Available online: https://www.who.int/quantifying_ehimpacts/publications/e94888.pdf?ua=1 (accessed on 10 March 2021).

- Mata, C.; Gómez, A.; Armas, O. The influence of ethanol-diesel blend on pollutant emissions from different bus fleets under acceleration transitions. Fuel 2017, 209, 322–328. [Google Scholar] [CrossRef]

- Li, W.; Ren, Y.; Wang, X.B.; Miao, H.; Jiang, D.M.; Huang, Z.H. Combustion characteristics of a compression ignition engine fuelled with diesel-ethanol blends. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2008, 222, 265–274. [Google Scholar] [CrossRef]

- Magand, S.; Lecointe, B.; Chaudoye, F.; Castagne, M. Optimization of a Euro 5 Vehicle powered by an ethanol based diesel fuel. SAE Int. J. Fuels Lubr. 2010, 3, 260–272. [Google Scholar] [CrossRef]

- Michikawauchi, R.; Tanno, S.; Ito, Y.; Kanda, M. Combustion improvement of diesel engine by alcohol addition—Investigation of port injection method and blended fuel method. SAE Int. J. Fuels Lubr. 2011, 4, 48–57. [Google Scholar] [CrossRef]

- Magand, S.; Pidol, L.; Chaudoye, F.; Sinoquet, D.; Wahl, F.; Castagne, M.; Lecointe, B. Use of ethanol/diesel blend and advanced calibration methods to satisfy Euro 5 emission standards without DPF. Oil Gas Sci. Technol. Rev. D IFP Energ. Nouv. 2011, 66, 855–875. [Google Scholar] [CrossRef][Green Version]

- Zhang, Z.-Q.; Zhao, F.-Q.; Deng, J.; Li, L.-G. A simulated study on the performance of diesel engine with ethanol-diesel blend fuel. Therm. Sci. 2013, 17, 205–216. [Google Scholar] [CrossRef]

- Heuser, B.; Kremer, F.; Pischinger, S.; Rohs, H.; Holderbaum, B.; Koerfer, T. An experimental investigation of dual-fuel combustion in a light duty diesel engine by in-cylinder blending of ethanol and diesel. SAE Int. J. Engines 2016, 9, 11–25. [Google Scholar] [CrossRef]

- Taghizadeh-Alisaraei, A.; Rezaei-Asl, A. The effect of added ethanol to diesel fuel on performance, vibration, combustion and knocking of a CI engine. Fuel 2016, 185, 718–733. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, C.D.; Dimaratos, A.M.; Rakopoulos, D.C. Combustion noise radiation during the acceleration of a turbocharged diesel engine operating with biodiesel or n-butanol diesel fuel blends. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2012, 226, 971–986. [Google Scholar] [CrossRef]

- Satsangi, D.P.; Tiwari, N. Experimental investigation on combustion, noise, vibrations, performance and emissions characteristics of diesel/n-butanol blends driven genset engine. Fuel 2018, 221, 44–60. [Google Scholar] [CrossRef]

- Morgul, O.K. Experimental analysis for assessing noise and vibration of the diesel engine fuelled with a butanol-diesel blend under different injection pressures and engine speeds. Int. J. Environ. Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Fastl, H.; Zwicker, E. Psycho-Acoustics: Facts and Models; Springer: New York, NY, USA, 2007. [Google Scholar]

- Li, J.; Yu, W.; Yang, W. Evaluating performance and emissions of a CI engine fueled with n-octanol/diesel and n-butanol/diesel blends under different injection strategies. Fuel 2021, 284, 119085. [Google Scholar] [CrossRef]

- Li, X.; Guan, C.; Yang, K.; Cheung, C.S.; Huang, Z. Impact of lower and higher alcohol additions to diesel on the combustion and emissions of a direct-injection diesel engine. Environ. Sci. Pollut. Res. 2019, 26, 21001–21012. [Google Scholar] [CrossRef]

| Properties | Method | Diesel Fuel | Methanol | Ethanol | Propanol | Butanol |

|---|---|---|---|---|---|---|

| Chemical formulation | C10H20–C15H28 | CH3OH | C2H5OH | C3H7OH | C4H9OH | |

| Density at 15 °C (kg/m3) | EN * ISO ** 12185 | 835 | 791.3 | 789.4 | 803.7 | 809.7 |

| Kinematic viscosity at 40 °C (cSt) | EN ISO 3104 | 2.72 | 0.58 | 1.13 | 1.74 | 2.22 |

| Lower heating value (MJ/kg) | UNE *** 51123 | 42.49 | 19.58 | 26.83 | 30.63 | 33.09 |

| Gross heating value (MJ/kg) | UNE 51123 | 45.54 | 22.31 | 29.67 | 33.52 | 36.02 |

| Octane number | EN ISO 12156 | 52 | 5 | 8 | 12 | 17 |

| Boiling point (°C) | 150-380 | 64.5 | 78.4 | 97.1 | 117.7 | |

| Stoichiometric air/fuel ratio | 1/14.67 | 1/6.47 | 1/9.01 | 1/10.35 | 1/11.19 | |

| Lubricity (corrected wear scar, μm) | 315 | 1100 | 1057 | 922 | 591 |

| Reference | Engine Type | Noise Meter | Noise Parameters | Test Conditions | Results (Compared to 100% Diesel Fuel) | Tested Blends |

|---|---|---|---|---|---|---|

| [13] | Four-cylinder turbocharged diesel engine (85.22 kW) | GRAS prepolarized free-field microphone using Soundbook multi-channel meter with Samurai v1.7 SINUS MEsstechnik GmbH | Sound pressure level (dBA) | Stationary test | ↑ at high engine load | P30, P10, P20, E10 |

| [56] | Single-cylinder direct-injection diesel engine (11 kW) | No noise meter is used. Noise is estimated from cylinder pressure | Neither noise parameters nor noise quantification are provided | ↓ | E0, E5, E10, E25, E20 + 0.2% CN improver | |

| [57] | Four-cylinder turbocharged common rail injection diesel engine (66 kW) | Noise is simulated | dB | New European Driving Cycle (NEDC) | ↓ | E0, E5, E10, E25, E20 |

| [58] | Four-cylinder common rail injection diesel engine | AVL combustion noise meter 450 based on cylinder pressure | Neither noise parameters nor noise quantification are provided | NEDC | ↓ | B10–B30 |

| [59] | Four-cylinder diesel engine (66 kW) | No noise meter is used. Noise is estimated from cylinder pressure | dB | NEDC | ↑ | E0, E20 |

| [60] | Four-cylinder diesel engine (100 kW) | No noise meter is used. Noise is estimated from ringing intensity | Neither noise parameters nor noise quantification are provided | ↓ | E0, E10, E20, E30 | |

| [61] | Single-cylinder diesel engine (80 kW) | No noise meter is used. Noise is estimated from cylinder pressure | Neither noise parameters nor noise quantification are provided | Stationary test | ↓ | Ethanol/diesel fuel blends |

| [62] | Six-cylinder diesel engine (92 kW) | Three accelerometers are used | Neither noise parameters nor noise quantification are provided | Stationary test | ↑ (for E8) | D100, D98E2, D96E4, D94E6, D92E8, D90E10, D88E12 |

| [52] | Six-cylinder direct injection turbocharged diesel engine (power 177 kW) | AVL combustion noise meter 450 based on cylinder pressure | dB | Stationary test | Minimal noise deviation | D100, D7030BD, D75B25 |

| [63] | Six-cylinder direct injection turbocharged diesel engine (177 kW) | AVL combustion noise meter 450 based on cylinder pressure | dBA | Transient test | ↑ | D100, D70BD30, D75B25 |

| [64] | Single-cylinder direct injection diesel engine (7.4 kW) | LabVIEW software at a sampling frequency of 25.6 kHz. B&K noise acquisition system (microphones) | dBA | Stationary test | ↑ at high engine load | D100, B1, B2, B3, B4 |

| [65] | Single-cylinder direct injection diesel engine (5.5 kW) | Triaxial accelerometer B&K 4535-B, RT Photon and software | LAeq (dBA) | Stationary test | ↑ 1–2 dBA | D100, B10, D90 |

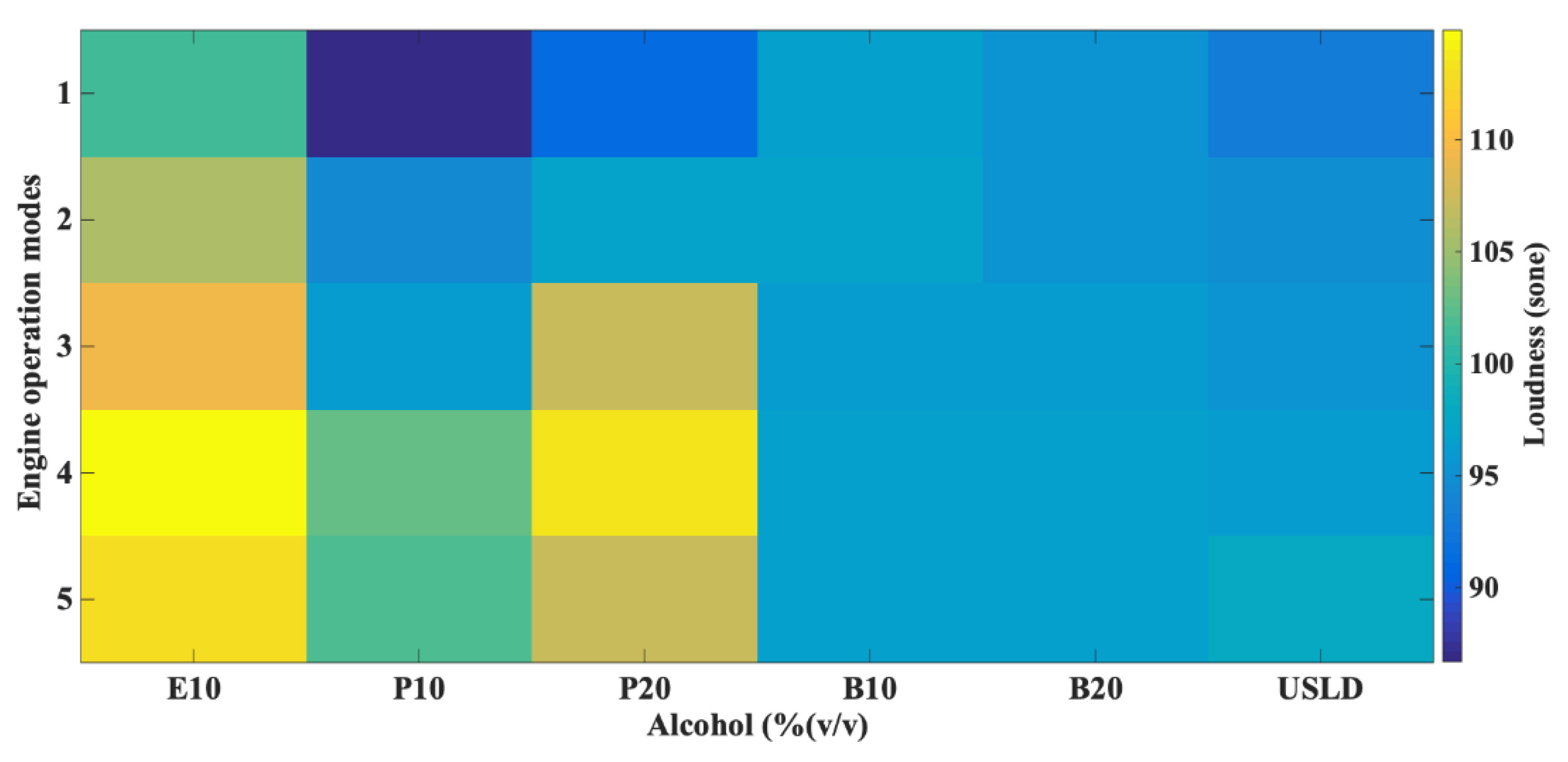

| MODE NO. | ENGINE SPEED (min−1) | TORQUE (Nm) |

|---|---|---|

| 1 | 1500 | 25 |

| 2 | 1700 | 50 |

| 3 | 1900 | 100 |

| 4 | 2100 | 250 |

| 5 | 2500 | 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Redel-Macías, M.D.; Pinzi, S.; Babaie, M.; Zare, A.; Cubero-Atienza, A.; Dorado, M.P. Bibliometric Studies on Emissions from Diesel Engines Running on Alcohol/Diesel Fuel Blends. A Case Study about Noise Emissions. Processes 2021, 9, 623. https://doi.org/10.3390/pr9040623

Redel-Macías MD, Pinzi S, Babaie M, Zare A, Cubero-Atienza A, Dorado MP. Bibliometric Studies on Emissions from Diesel Engines Running on Alcohol/Diesel Fuel Blends. A Case Study about Noise Emissions. Processes. 2021; 9(4):623. https://doi.org/10.3390/pr9040623

Chicago/Turabian StyleRedel-Macías, María Dolores, Sara Pinzi, Meisam Babaie, Ali Zare, Antonio Cubero-Atienza, and M. Pilar Dorado. 2021. "Bibliometric Studies on Emissions from Diesel Engines Running on Alcohol/Diesel Fuel Blends. A Case Study about Noise Emissions" Processes 9, no. 4: 623. https://doi.org/10.3390/pr9040623

APA StyleRedel-Macías, M. D., Pinzi, S., Babaie, M., Zare, A., Cubero-Atienza, A., & Dorado, M. P. (2021). Bibliometric Studies on Emissions from Diesel Engines Running on Alcohol/Diesel Fuel Blends. A Case Study about Noise Emissions. Processes, 9(4), 623. https://doi.org/10.3390/pr9040623