Implementation of Technical and Technological Progress in Dairy Production

Abstract

1. Introduction

2. Materials and Methods

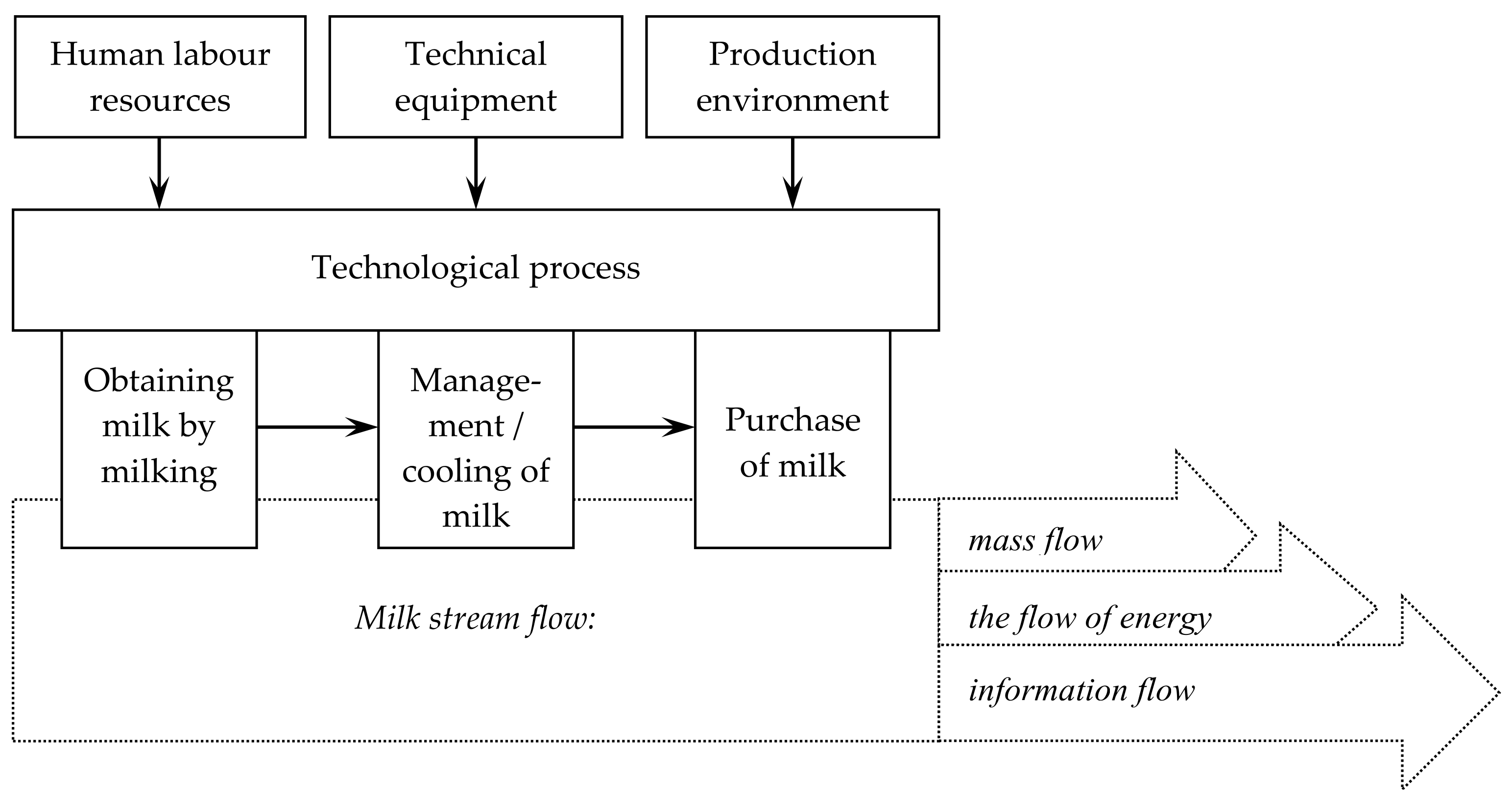

2.1. Identification of the Technological Process in Dairy Production Systems

2.2. The Procedure for Calculating the Technological Index Level

2.3. Using the Technological Index Level to Analyze Technological Processes in the Dairy Production System

2.4. Linking the Technological Level with the Assessment of the Implementation of Various Forms of Progress

- Biological progress is ahead of technical progress;

- Technical progress is ahead of biological progress;

- Biological progress and technological progress converge in terms of specific, measurable features.

2.5. Research Materials in the Area of Dairy Production

3. Results and Discussion

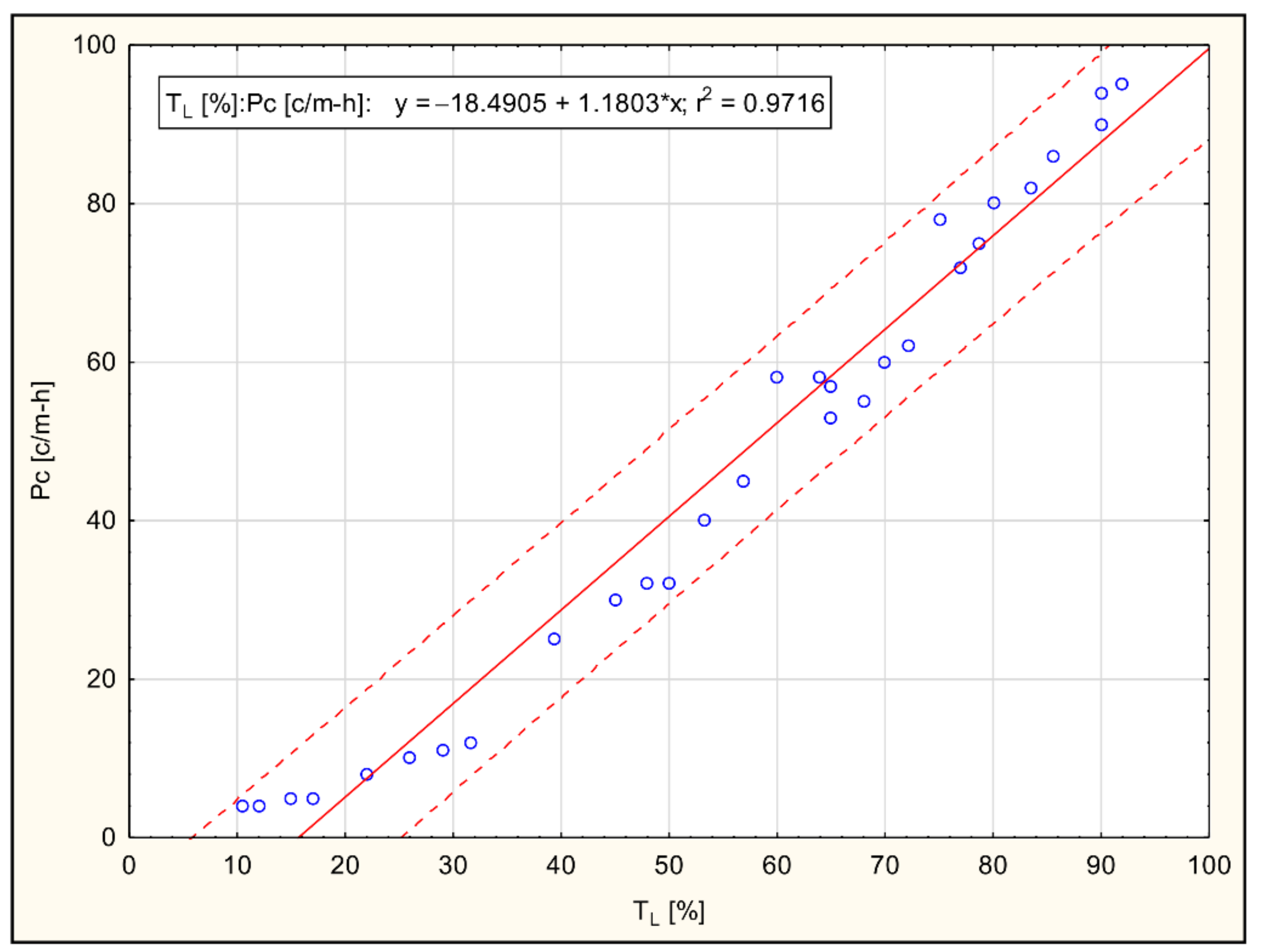

3.1. Milkman’s Work Productivity

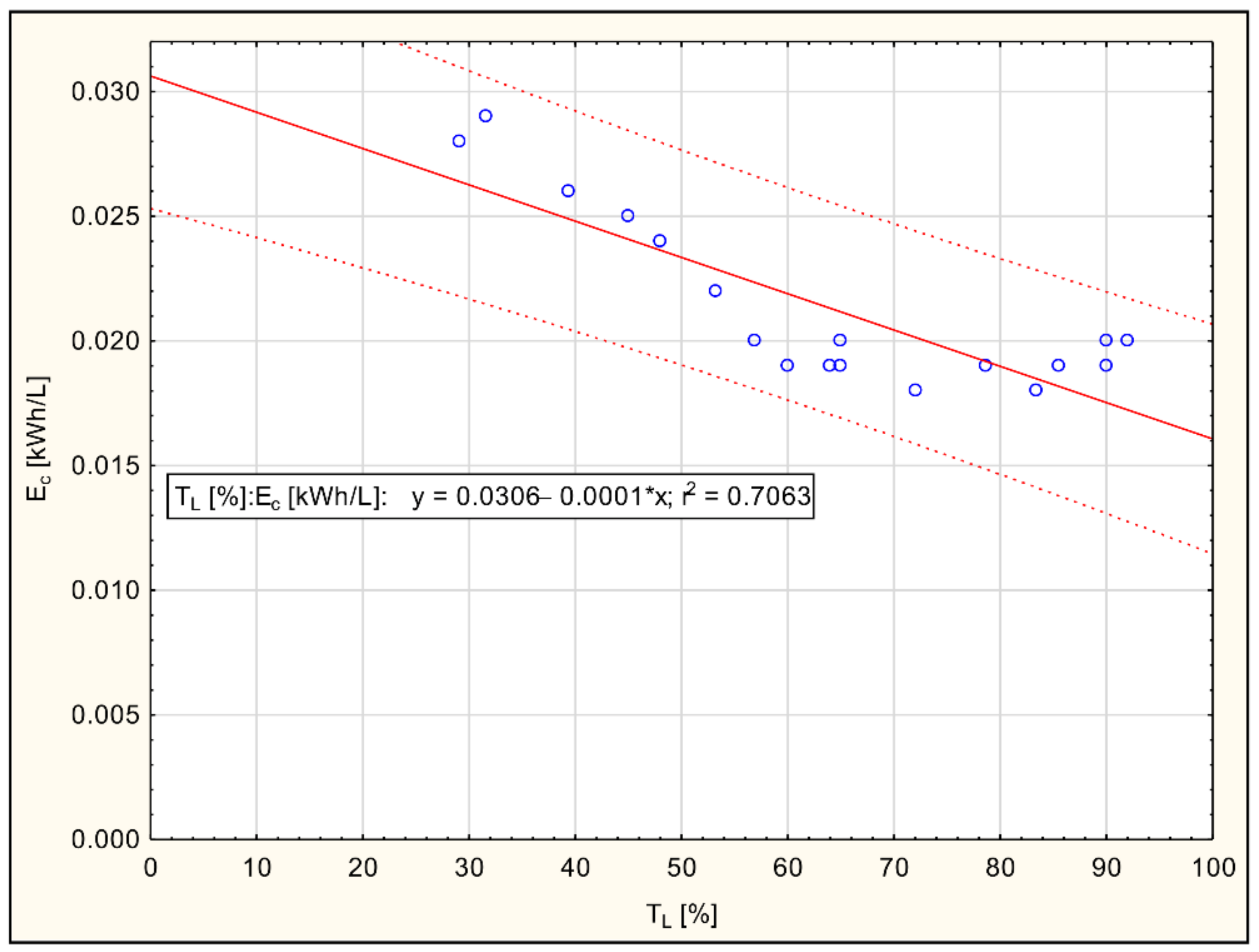

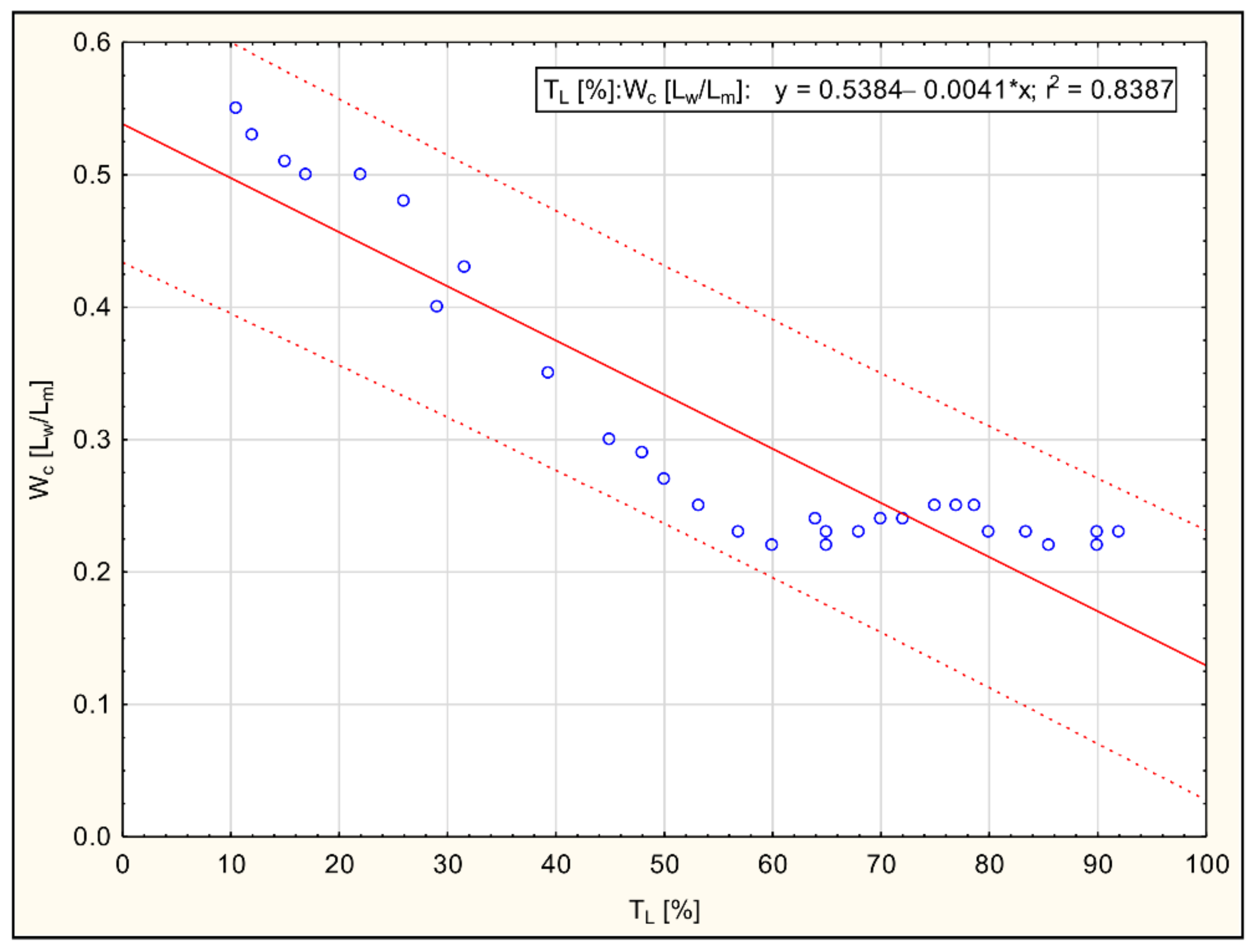

3.2. Simultaneous Implementation of Progress in the Field of Cow Milking

4. General Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pawlak, K.; Kołodziejczak, M. The role of agriculture in ensuring food security in developing countries: Considerations in the context of the problem of sustainable food production. Sustainability 2020, 12, 5488. [Google Scholar] [CrossRef]

- Zegar, J.S. Współczesne Wyzwania Rolnictwa (Contemporary Challenges of Agriculture); Polish Scientific Publishers: Warsaw, Poland, 2012. (In Polish) [Google Scholar]

- Gerosa, S.; Skoet, J. Milk Availability. Trends in Production and Demand and Medium-Term Outlook; ESA Working Paper No 12-01; Agricultural Development Economics Division, FAO: Rome, Italy, 2012; p. 38. [Google Scholar]

- Bakke, A.J.; Shehan, C.V.; Hayes, J.E. Type of milk typically consumed, and stated preference, but not health consciousness affect revealed preferences for fat in milk. Food Qual. Prefer. 2016, 49, 92–99. [Google Scholar] [CrossRef] [PubMed]

- Canavari, M.; Coderoni, S. Consumer stated preferences for dairy products with carbon footprint labels in Italy. Agric. Food Econ. 2020, 8, 4. [Google Scholar] [CrossRef]

- Ertl, P.; Klocker, H.; Hörtenhuber, S.; Knaus, W.; Zollitsch, W. The net contribution of dairy production to human food supply: The case of Austrian dairy farms. Agric. Syst. 2015, 137, 119–125. [Google Scholar] [CrossRef]

- Gloy, B.A.; Hyde, J.; LaDue, E.L. Dairy farm management and long-term farm financial performance. Agric. Res. Econ. Rev. 2002, 31, 233–247. [Google Scholar] [CrossRef]

- Hanson, J.D.; Franzluebbers, A. Principles of integrated agricultural systems. Renew. Agric. Food Syst. 2008, 23, 263–264. [Google Scholar] [CrossRef]

- Walters, J.P.; Archer, D.W.; Sassenrath, G.F.; Hendrickson, J.R.; Hanson, J.D.; Halloran, J.M.; Vadas, P.; Alarcon, V.J. Exploring agricultural production systems and their fundamental components with system dynamics modelling. Ecol. Model. 2016, 333, 51–65. [Google Scholar] [CrossRef]

- Hendrickson, J.R.; Sassenrath, G.F.; Archer, D.W.; Hanson, J.D.; Halloran, J.M. Interactions in integrated agricultural systems: The past, present and future. Renew. Agric. Food Syst. 2008, 23, 314–324. [Google Scholar] [CrossRef]

- Nowacki, T. Paradygmaty Energotechnologicznej Efektywności Transformacji Gospodarki Żywnościowej [Paradigms of Energy Effectiveness Evaluation in Food Economy Transformation]; Institute of Rural and Agricultural Development; Polish Academy of Sciences: Warsaw, Poland, 1999; p. 124. (In Polish) [Google Scholar]

- Von Keyserlingk, M.A.G.; Martin, N.P.; Kebreab, E.; Knowlton, K.F.; Grant, R.J.; Stephenson, M.; Sniffen, C.J.; Harner, J.P.; Wright, A.D.; Smith, S.I. Invited review: Sustainability of the US dairy industry. J. Dairy Sci. 2013, 96, 5405–5425. [Google Scholar] [CrossRef]

- Díaz de Otálora, X.; del Prado, A.; Dragoni, F.; Estellés, F.; Amon, B. Evaluating three-pillar sustainability modelling approaches for dairy cattle production systems. Sustainability 2021, 13, 6332. [Google Scholar] [CrossRef]

- Del Prado, A.; Scholefield, D. Use of SIMSDAIRY modelling framework system to compare the scope on the sustainability of a dairy farm of animal and plant genetic-based improvements with management-based changes. J. Agric. Sci. 2008, 146, 195–211. [Google Scholar] [CrossRef]

- Van Calker, K.J.; Berentsen, P.B.M.; Giesen, G.W.J.; Huirne, R.B.M. Maximising sustainability of Dutch dairy farming systems for different stakeholders: A modelling approach. Ecol. Econ. 2008, 65, 407–419. [Google Scholar] [CrossRef]

- Vayssières, J.; Guerrin, F.; Paillat, J.M.; Lecomte, P. GAMEDE: A global activity model for evaluating the sustainability of dairy enterprises Part I-Whole-farm dynamic model. Agric. Syst. 2009, 101, 128–138. [Google Scholar] [CrossRef]

- Färe, R.; Whittaker, G. An intermediate input model of dairy production using complex survey data. J. Agricult. Econ. 1995, 46, 201–213. [Google Scholar] [CrossRef]

- Reyes, A.A.; Blake, R.W.; Shumway, C.R.; Long, J.T. Multistage optimization model for dairy production. J. Dairy Sci. 1981, 64, 2003–2016. [Google Scholar] [CrossRef]

- Miranda, M.J.; Schnitkey, G.D. An empirical model of asset replacement in dairy production. J. Appl. Econom. 1995, 10, S41–S55. [Google Scholar] [CrossRef]

- Shalloo, L.; Dillon, P.; Rath, M.; Wallace, M. Description and validation of the Moorepark Dairy System Model. J. Dairy Sci. 2004, 87, 1945–1959. [Google Scholar] [CrossRef]

- Schils, R.L.M.; de Haan, M.H.A.; Hemmer, J.G.A.; van den Pol-van Dasselaar, A.; de Boer, J.A.; Evers, A.G.; Holshof, G.; van Middelkoop, J.C.; Zom, R.L.G. DairyWise, A Whole-Farm Dairy Model. J. Dairy Sci. 2007, 90, 5334–5346. [Google Scholar] [CrossRef]

- Doole, G.J.; Romera, A.J.; Adler, A.A. An optimization model of a New Zealand dairy farm. J. Dairy Sci. 2013, 96, 2147–2160. [Google Scholar] [CrossRef]

- Rotz, C.A.; Black, J.R.; Mertens, D.R.; Buckmaster, D.R. DAFOSYM: A Model of the Dairy Forage System. J. Product. Agric. 1989, 2, 83–91. [Google Scholar] [CrossRef]

- Beukes, P.C.; Palliser, C.C.; Macdonald, K.A.; Lancaster, J.A.S.; Levy, G.; Thorrold, B.S.; Wastney, M.E. Evaluation of a Whole-Farm Model for pasture-based dairy systems. J. Dairy Sci. 2008, 91, 2353–2360. [Google Scholar] [CrossRef] [PubMed]

- Rotz, C.A.; Montes, F.; Hafner, S.D.; Heber, A.J.; Grant, R.H. Ammonia emission model for whole farm evaluation of dairy production systems. J. Environ. Qual. 2014, 43, 1143–1158. [Google Scholar] [CrossRef] [PubMed]

- Dou, Z.; Kohn, R.A.; Ferguson, J.D.; Boston, R.C.; Newbold, J.D. Managing nitrogen on dairy farms: An integrated approach I. Model description. J. Dairy Sci. 1996, 79, 2071–2080. [Google Scholar] [CrossRef]

- Ghisellini, P.; Protano, G.; Viglia, S.; Gaworski, M.; Setti, M.; Ulgiati, S. Integrated agricultural and dairy production within a circular economy framework. A comparison of Italian and Polish farming systems. J. Environ. Account. Manag. 2014, 2, 367–384. [Google Scholar] [CrossRef]

- Salinas-Martínez, J.A.; Posadas-Domínguez, R.R.; Morales-Díaz, L.D.; Rebollar-Rebollar, S.; Rojo-Rubio, R. Cost analysis and economic optimization of small-scale dairy production systems in Mexico. Livest. Sci. 2020, 237, 104028. [Google Scholar] [CrossRef]

- Binswanger, H. Agricultural mechanization: A comparative historical perspective. World Bank Res. Obs. 1986, 1, 27–56. [Google Scholar] [CrossRef]

- Olmstead, A.L.; Rhode, P. An overview of California agricultural mechanization, 1870–1930. Agric. Hist. 1988, 62, 86–112. Available online: http://www.jstor.org/stable/3743209 (accessed on 15 July 2021).

- Sims, B.; Kienzle, J. Sustainable agricultural mechanization for smallholders: What is it and how can we implement it? Agriculture 2017, 7, 50. [Google Scholar] [CrossRef]

- Michałek, R.; Kowalski, J. Technical progress in agriculture. Ann. Rev. Agric. Eng. 2000, 2, 67–80. [Google Scholar]

- Michałek, R. (Ed.) Uwarunkowania Technicznej Rekonstrukcji Rolnictwa [Conditions for the Technical Reconstruction of Agriculture]; PTIR: Cracow, Poland, 1998. (In Polish) [Google Scholar]

- Wójcicki, Z. Technological progress and consumption of energy in the agricultural production in Poland. Probl. Rol. Swiat. 2006, 15, 95–103. (In Polish) [Google Scholar]

- Creswell, J.W. Research Design: Qualitative, Quantitative, and Mixed Methods Approaches, 1st ed.; Wyd. UJ: Cracow, Poland, 2013. (In Polish) [Google Scholar]

- Nowacki, T.; Nowacki, J.K. Changes and Trends in the Quality and Balance of Energy Consumption in Agriculture (General Methodology); AGRI/MECH Report No. 105; United Nations: Geneva, Switzerland, 1984. [Google Scholar]

- Šarauskis, E.; Naujokienė, V.; Lekavičienė, K.; Kriaučiūnienė, Z.; Jotautienė, E.; Jasinskas, A.; Zinkevičienė, R. Application of granular and non-granular organic fertilizers in terms of energy, environmental and economic efficiency. Sustainability 2021, 13, 9740. [Google Scholar] [CrossRef]

- Mota-Rojas, D.; Braghieri, A.; Álvarez-Macías, A.; Serrapica, F.; Ramírez-Bribiesca, E.; Cruz-Monterrosa, R.; Masucci, F.; Mora-Medina, P.; Napolitano, F. The use of draught animals in rural labour. Animals 2021, 11, 2683. [Google Scholar] [CrossRef]

- Statistica v.13 Software; StatSoft Polska: Cracow, Poland, 2021; Available online: www.statsoft.pl (accessed on 2 September 2021).

- Gaworski, M.; Kamińska, N.; Kic, P. Evaluation and optimization of milking in some Polish dairy farms differed in milking parlours. Agron. Res. 2017, 15, 112–122. [Google Scholar]

- Calcante, A.; Tangorra, F.M.; Oberti, R. Analysis of electric energy consumption of automatic milking systems in different configurations and operative conditions. J. Dairy Sci. 2016, 99, 4043–4047. [Google Scholar] [CrossRef]

- Shortall, J.; O’Brien, B.; Sleator, R.D.; Upton, J. Daily and seasonal trends of electricity and water use on pasture-based automatic milking dairy farms. J. Dairy Sci. 2018, 101, 1565–1578. [Google Scholar] [CrossRef]

- Rasmussen, J.B.; Pedersen, J. Electricity and Water Consumption at Milking; Farm Test–Cattle nr. 17, 1–42; Danish Agricultural Advisory Service: Aarhus, Denmark, 2004. [Google Scholar]

- FAOstat. Available online: http://www.fao.org/faostat/en/#data/QI (accessed on 20 September 2021).

- Meskens, L.; Vandermersch, M.; Mathijs, E. Implication of the Introduction of Automatic Milking on Dairy Farms. Literature Review on the Determinants and Implications of Technology Adoption; Internal Report; Catholic University: Leuven, Belgium, 2001. [Google Scholar]

- Kaufmann, R.; Ammann, H.; Hilty, R.; Nosal, D.; Schick, M. Automatisches Melken-Systeme, Einsatzgrenzen, Wirtschaftlichkeit; FAT-Berichte Nr. 579; Forschungsanstalt für Agrarwirtschaft und Landtechnik FAT: Tänikon, Switzerland, 2001; p. 579. (In German) [Google Scholar]

- Harms, J.; Wendl, G. Analyze von Kapazitätsreserven bei Automatischen Melksystemen. Landtechnik 2009, 6, 432–435. (In German) [Google Scholar] [CrossRef]

- Bonsels, T.; Schmitz, M. Roboter: Zu viel Leerlauf. Top Agrar. 2013, 1, 22–24. (In German) [Google Scholar]

- Rotz, C.A.; Coiner, C.U.; Soder, K.J. Automatic milking systems, farm size, and milk production. J. Dairy Sci. 2003, 86, 4167–4177. [Google Scholar] [CrossRef]

- Heikkilä, A.M.; Vanninen, L.; Manninen, E. Economics of small-scale dairy farms having robotic milking. In Proceedings of the First North American Conference on Precision Dairy Management, Toronto, ON, Canada, 2–5 March 2010. [Google Scholar]

- Matson, R.D.; King, M.T.M.; Duffield, T.F.; Santschi, D.E.; Orsel, K.; Pajor, E.A.; Penner, G.B.; Mutsvangwa, T.; DeVries, T.J. Benchmarking of farms with automated milking systems in Canada and associations with milk production and quality. J. Dairy Sci. 2021, 104, 7971–7983. [Google Scholar] [CrossRef]

- King, M.T.M.; Pajor, E.A.; LeBlanc, S.J.; DeVries, T.J. Associations of herd-level housing, management, and lameness prevalence with productivity and cow behavior in herds with automated milking systems. J. Dairy Sci. 2016, 99, 9069–9079. [Google Scholar] [CrossRef]

- Tremblay, M.; Hess, J.P.; Christenson, B.M.; McIntyre, K.K.; Smink, B.; van der Kamp, A.J.; de Jong, L.G.; Dopfer, D. Factors associated with increased milk production for automatic milking systems. J. Dairy Sci. 2016, 99, 3824–3837. [Google Scholar] [CrossRef] [PubMed]

- Siewert, J.M.; Salfer, J.A.; Endres, M.I. Factors associated with productivity on automatic milking system dairy farms in the Upper Midwest United States. J. Dairy Sci. 2018, 101, 8327–8334. [Google Scholar] [CrossRef] [PubMed]

- Castro, A.; Pereira, J.M.; Amiama, C.; Bueno, J. Estimating efficiency in automatic milking systems. J. Dairy Sci. 2012, 95, 929–936. [Google Scholar] [CrossRef] [PubMed]

- Gaworski, M.; Leola, A.; Sada, O.; Kic, P.; Priekulis, J. Effect of cow traffic system and herd size on cow performance and automatic milking systems capacity. Agron. Res. 2016, 14, 33–40. [Google Scholar]

- Jacobs, J.A.; Siegford, J.M. Invited review: The impact of automatic milking systems on dairy cow management, behavior, health, and welfare. J. Dairy Sci. 2012, 95, 2227–2247. [Google Scholar] [CrossRef]

- Deming, J.A.; Bergeron, R.; Leslie, K.E.; DeVries, T.J. Associations of housing, management, milking activity, and standing and lying behavior of dairy cows milked in automatic systems. J. Dairy Sci. 2013, 96, 344–351. [Google Scholar] [CrossRef]

- Mehta, C.R.; Chandel, N.S.; Senthilkumar, T. Status, challenges and strategies for farm mechanization in India. Agric. Mech. Asia Afr. Lat. Am. 2014, 45, 43–50. [Google Scholar]

- Priekulis, J.; Laurs, A. Development trends of milk production mechanisation in Latvia. In Proceedings of the Conference on Engineering for Rural Development, Jelgava, Latvia, 20–22 May 2020; Volume 19, pp. 270–275. [Google Scholar] [CrossRef]

- Romaniuk, W.; Mazur, K.; Borek, K.; Borusiewicz, A.; Wardal, W.J.; Tabor, S.; Kuboń, M. Biomass energy technologies from innovative dairy farming systems. Processes 2021, 9, 335. [Google Scholar] [CrossRef]

- Luo, X.; Liao, J.; Hu, L.; Zang, Y.; Zhou, Z. Improving agricultural mechanization level to promote agricultural sustainable development. Trans. Chin. Soc. Agric. Eng. 2016, 32, 1–11. [Google Scholar]

- Luo, X.; Liao, J.; Zou, X.; Zhang, Z.; Zhou, Z.; Zang, Y.; Hu, L. Enhancing agricultural mechanization level through information technology. Trans. Chin. Soc. Agric. Eng. 2016, 32, 1–14. [Google Scholar]

- Li, W.; Wei, X.; Zhu, R.; Guo, K. Study on factors affecting the agricultural mechanization level in China based on structural equation modeling. Sustainability 2019, 11, 51. [Google Scholar] [CrossRef]

- Næss, G.; Bøe, K.E. Labour input in small cubicle dairy barns with different layouts and mechanisation levels. Biosyst. Eng. 2011, 110, 83–89. [Google Scholar] [CrossRef]

- John, A.J.; Clark, C.E.F.; Freeman, M.J.; Kerrisk, K.L.; Garcia, S.C.; Halachmi, I. Review: Milking robot utilization, a successful precision livestock farming evolution. Animal 2016, 10, 1484–1492. [Google Scholar] [CrossRef]

- Gargiulo, J.I.; Eastwood, C.R.; Garcia, S.C.; Lyons, N.A. Dairy farmers with larger herd sizes adopt more precision dairy technologies. J. Dairy Sci. 2018, 101, 5466–5473. [Google Scholar] [CrossRef]

- Borowski, P.F. Innovative processes in managing an enterprise from the energy and food sector in the Era of Industry 4.0. Processes 2021, 9, 381. [Google Scholar] [CrossRef]

- Ramos, M.C.; Campos, A.T.; Júnior, T.Y.; da Silva, K.C.P. Milk production sustainability: Energy balance in intensive dairy livestock farming focused on processes. Eng. Agrícola 2014, 34, 473–484. [Google Scholar] [CrossRef][Green Version]

- Egas, D.; Ponsá, S.; Llenas, L.; Colón, J. Towards energy-efficient small dairy production systems: An environmental and economic assessment. Sustain. Prod. Consump. 2021, 28, 39–51. [Google Scholar] [CrossRef]

- Shine, P.; Upton, J.; Sefeedpari, P.; Murphy, M.D. Energy consumption on dairy farms: A review of monitoring, prediction modelling, and analyses. Energies 2020, 13, 1288. [Google Scholar] [CrossRef]

- Kraatz, S. Energy intensity in livestock operations—Modeling of dairy farming systems in Germany. Agric. Syst. 2012, 110, 90–106. [Google Scholar] [CrossRef]

- Masi, M.; Vecchio, Y.; Pauselli, G.; Di Pasquale, J.; Adinolfi, F. A typological classification for assessing farm sustainability in the Italian bovine dairy sector. Sustainability 2021, 13, 7097. [Google Scholar] [CrossRef]

- Tramontini, R.C.M.; Bánkuti, F.I.; Pozza, M.S.S.; Massuda, E.M.; Damasceno, J.C.; Dias, A.M.; Ítavo, C.C.B.F.; Ítavo, L.C.V.; Santos, G.T. Typology of dairy production systems based on management strategies in Paraná State, Brazil. Trop. Anim. Sci. J. 2021, 44, 123–130. [Google Scholar] [CrossRef]

- Davis, K.L.; Jago, J.G.; Wieliczko, R.; Copeman, P.J.A.; Bright, K.; Woolford, M.W. Factors influencing milk harvesting efficiency in an automatic milking system. Proc. N. Z. Soc. Anim. Prod. 2005, 65, 271–275. [Google Scholar]

- Gaworski, M.; Leola, A.; Kiiman, H.; Sada, O.; Kic, P.; Priekulis, J. Assessment of dairy cow herd indices associated with different milking systems. Agron. Res. 2018, 16, 83–93. [Google Scholar]

- Abhijeet, K.; Prasanna, S.B.; Mahesh, P.S.; Gouri, M.D.; Vivek, M.P.; Bhandekar, S.K.; Ali, S.M.; Masood, K.D.; Karan, P. Comparative study of automation and conventional system on production performance in dairy farms. Asian J. Dairy Food Res. 2021, 40, 25–29. [Google Scholar] [CrossRef]

- Gaworski, M.; Priekulis, J. Analysis of milking system development on example of two Baltic countries. In Proceedings of the Conference on Engineering for Rural Development, Jelgava, Latvia, 29–30 May 2014; Volume 13, pp. 79–84. [Google Scholar]

- Gaworski, M.; Leola, A. Effect of technical and biological potential on dairy production development. Agron. Res. 2014, 12, 215–222. [Google Scholar]

- Chiumenti, A.; da Borso, F.; Chiumenti, R.; Kic, P. Applying a mathematical model to compare, choose, and optimize the management and economics of milking parlors in dairy farms. Agriculture 2020, 10, 472. [Google Scholar] [CrossRef]

- Bonora, F.; Benni, S.; Barbaresi, A.; Tassinari, P.; Torreggiani, D. A cluster-graph model for herd characterisation in dairy farms equipped with an automatic milking system. Biosyst. Eng. 2018, 167, 1–7. [Google Scholar] [CrossRef]

- Gaworski, M.; Leola, A.; Priekulis, J. Comparative analysis on effectiveness of AMS use on an example of three European countries. Agron. Res. 2013, 11, 231–238. [Google Scholar]

- van der Linden, A.; Oosting, S.J.; van de Ven, G.W.J.; Zom, R.; van Ittersum, M.K.; Gerber, P.J.; de Boer, I.J.M. Yield gap analysis in dairy production systems using the mechanistic model LiGAPS-dairy. J. Dairy Sci. 2021, 104, 5689–5704. [Google Scholar] [CrossRef]

- Luik-Lindsaar, H.; Põldaru, R.; Roots, J. Estonian dairy farms’ technical efficiency and factors predicting it. Agron. Res. 2019, 17, 593–607. [Google Scholar] [CrossRef]

- Piwczyński, D.; Sitkowska, B.; Kolenda, M.; Brzozowski, M.; Aerts, J.; Schork, P.M. Forecasting the milk yield of cows on farms equipped with automatic milking system with the use of decision trees. Anim. Sci. J. 2020, 91, e13414. [Google Scholar] [CrossRef]

- Toro-Mujica, P.; Vera, R.; Pinedo, P.; Bas, F.; Enríquez-Hidalgo, D.; Vargas-Bello-Pérez, E. Adaptation strategies based on the historical evolution for dairy production systems in temperate areas: A case study approach. Agric. Syst. 2020, 182, 102841. [Google Scholar] [CrossRef]

- Kuwahara, K.C.; Damasceno, J.C.; Bánkuti, F.I.; Prizon, R.C.; Rossoni, D.F.; Eckstein, I.I. Sustainability and typology of dairy production systems. Ciências Agrárias 2018, 39, 2081–2092. [Google Scholar] [CrossRef]

- Chávez-Pérez, L.M.; Soriano-Robles, R.; Espinosa-Ortiz, V.E.; Miguel-Estrada, M.; Rendón-Rendón, M.C.; Jiménez-Jiménez, R.A. Does small-scale livestock production use a high technological level to survive? Evidence from dairy production in Northeastern Michoacán, Mexico. Animals 2021, 11, 2546. [Google Scholar] [CrossRef]

- Leola, A.; Priekulis, J.; Česna, J.; Gaworski, M. Trend of cow herd size in Baltic states. Agron. Res. 2021, 19, 1052–1059. [Google Scholar] [CrossRef]

- Robbins, J.A.; von Keyserlingk, M.A.G.; Fraser, D.; Weary, D.M. Invited review: Farm size and animal welfare. J. Anim. Sci. 2016, 94, 5439–5455. [Google Scholar] [CrossRef]

- Wagner, A.; Palmer, R.W.; Bewley, J.; Jackson-Smith, D.B. Producer satisfaction, efficiency, and investment cost factors of different milking systems. J. Dairy Sci. 2001, 84, 1890–1898. [Google Scholar] [CrossRef]

- Carreira, X.; Mariño, R.; Perez-Cancio, X.; Fernández, M. Design of algorithms for evaluating the efficiency of labour and variability of some group milking parlour parameters. Livest. Sci. 2013, 151, 252–263. [Google Scholar] [CrossRef]

- Hadley, G.L.; Harsh, S.B.; Wolf, C.A. Managerial and financial implications of major dairy farm expansions in Michigan and Wisconsin. J. Dairy Sci. 2002, 85, 2053–2064. [Google Scholar] [CrossRef]

- Mills, K.E.; Weary, D.M.; von Keyserlingk, M.A.G. Graduate Student Literature Review: Challenges and opportunities for human resource management on dairy farms. J. Dairy Sci. 2021, 104, 1192–1202. [Google Scholar] [CrossRef]

- Gaworski, M. Ethics and transformation of Polish food chain. In Ethics and the Politics of Food: Preprints of the 6th Congress of the European Society for Agricultural and Food Ethics; Kaiser, M., Lien, M.E., Eds.; Wageningen Academic Publisher: Oslo, Norway, 2006; pp. 270–273. [Google Scholar]

| Key Concepts in Analysis | Technological Index Level—TL (%) | |||||

|---|---|---|---|---|---|---|

| Scope → | 0–20 | 21–40 | 41–60 | 61–80 | 81–100 | |

| Average → | 10 | 30 | 50 | 70 | 90 | |

| Farm categories | CI | CII | CIII | CIV | CV | |

| Generations of agricultural machinery (technical infrastructure) | GamI | GamII | GamIII | GamIV | GamV | |

| Key Concepts in Analysis | Selected, Measurable (or Descriptive) Identification Features of Key Concepts |

|---|---|

| Farm categories |

|

| Generations of agricultural machinery and equipment (technical infrastructure) |

|

| Farm Categories (C) | |||||||

|---|---|---|---|---|---|---|---|

| CI | CII | CIII | CIV | CV | |||

| W [%] | 10 | 30 | 50 | 70 | 90 | ||

| Generation of technical equipment (Gam) | GV | 90 | GamV ↔ CI | GamV ↔ CII | GamV ↔ CIII | GamV ↔ CIV | GamV ↔ CV |

| GIV | 70 | GamIV ↔ CI | GamIV ↔ CII | GamIV ↔ CIII | GamIV ↔ CIV | GamIV ↔ CV | |

| GIII | 50 | GamIII ↔ CI | GamIII ↔ CII | GamIII ↔ CIII | GamIII ↔ CIV | GamIII ↔ CV | |

| GII | 30 | GamII ↔ CI | GamII ↔ CII | GamII ↔ CIII | GamII ↔ CIV | GamII ↔ CV | |

| GI | 10 | GamI ↔ CI | GamI ↔ CII | GamI ↔ CIII | GamI ↔ CIV | GamI ↔ CV | |

| Geographic Region | Milk Yield of Cows (kg cow−1 year−1) |

|---|---|

| Africa | 540 |

| Asia | 1956 |

| South America | 2953 |

| Oceania | 4571 |

| Australia and New Zealand | 4596 |

| Europe | 6498 |

| North America | 10,479 |

| World | 2699 |

| Category | CmyI | CmyII | CmyIII | CmyIV | CmyV |

|---|---|---|---|---|---|

| Range | 500–2500 | 2501–4500 | 4501–6500 | 6501–8500 | 8501–10,500 |

| Mean | 1500 | 3500 | 5500 | 7500 | 9500 |

| Link | GamV ↔ CmyI | GamV ↔ CmyII | GamV ↔ CmyIII | GamV ↔ CmyIV | GamV ↔ CmyV |

|---|---|---|---|---|---|

| Country (milk yield of cows) | Bulgaria (3627) Romania (3217) | Lithuania (6424) Slovenia (6178) Ireland (5783) Croatia (4608) | Portugal (8423) United Kingdom (8317) Germany (8246) Belgium (8088) Hungary (8077) Luxembourg (7780) Greece (7667) Austria (7215) Slovakia (7185) France (7153) Latvia (7073) Cyprus (6818) Malta (6744) Poland (6693) Italy (6661) | Denmark (9973) Estonia (9657) Spain (9178) Finland (9170) Netherlands (9154) Sweden (8973) Czech Republic (8731) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaworski, M. Implementation of Technical and Technological Progress in Dairy Production. Processes 2021, 9, 2103. https://doi.org/10.3390/pr9122103

Gaworski M. Implementation of Technical and Technological Progress in Dairy Production. Processes. 2021; 9(12):2103. https://doi.org/10.3390/pr9122103

Chicago/Turabian StyleGaworski, Marek. 2021. "Implementation of Technical and Technological Progress in Dairy Production" Processes 9, no. 12: 2103. https://doi.org/10.3390/pr9122103

APA StyleGaworski, M. (2021). Implementation of Technical and Technological Progress in Dairy Production. Processes, 9(12), 2103. https://doi.org/10.3390/pr9122103