Numerical Study of Effect of Sawtooth Riblets on Low-Reynolds-Number Airfoil Flow Characteristic and Aerodynamic Performance

Abstract

:1. Introduction

2. Computational Method

2.1. Problem Definition

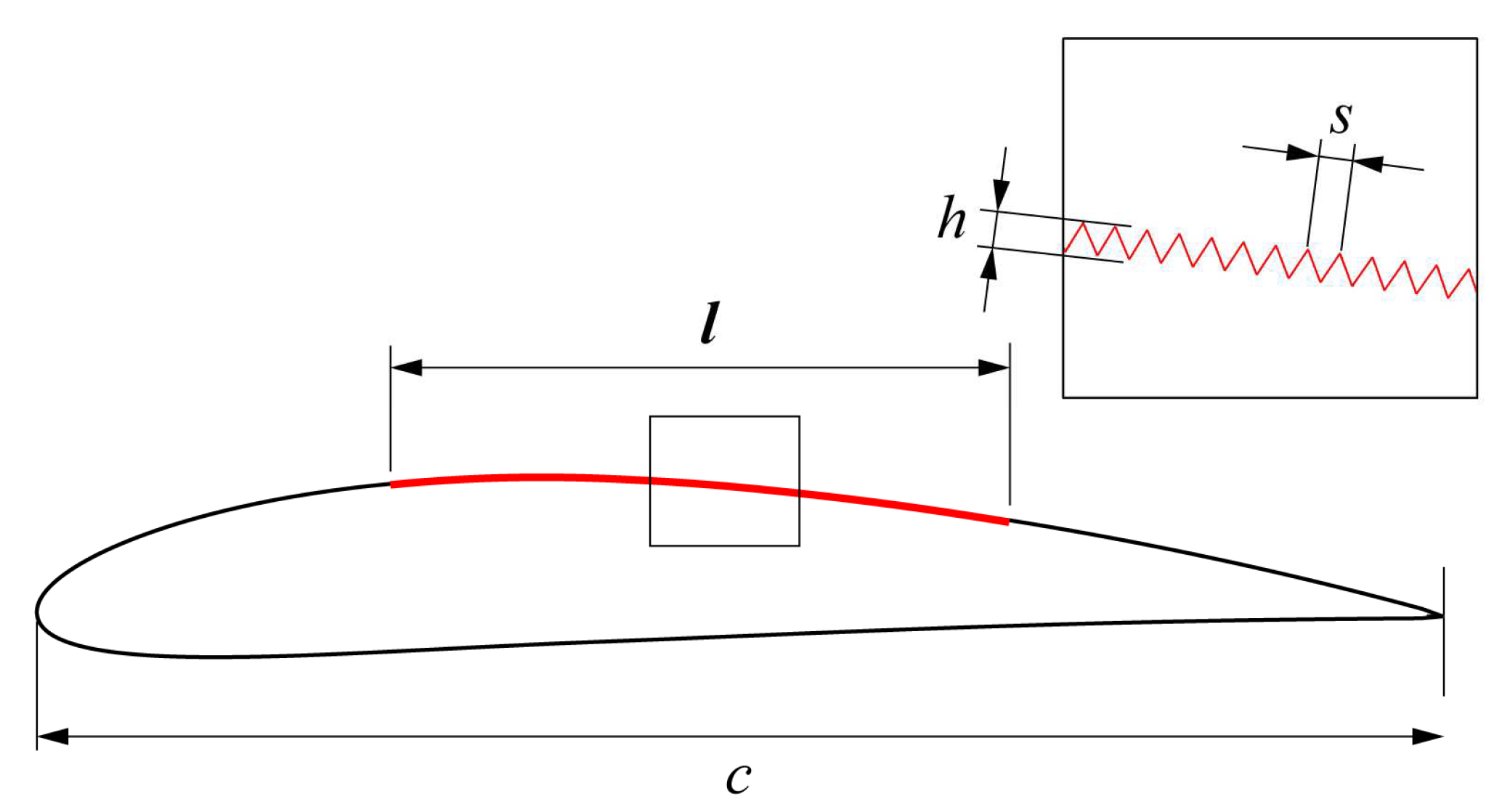

2.2. Riblet Design

2.3. CFD Governing Equations

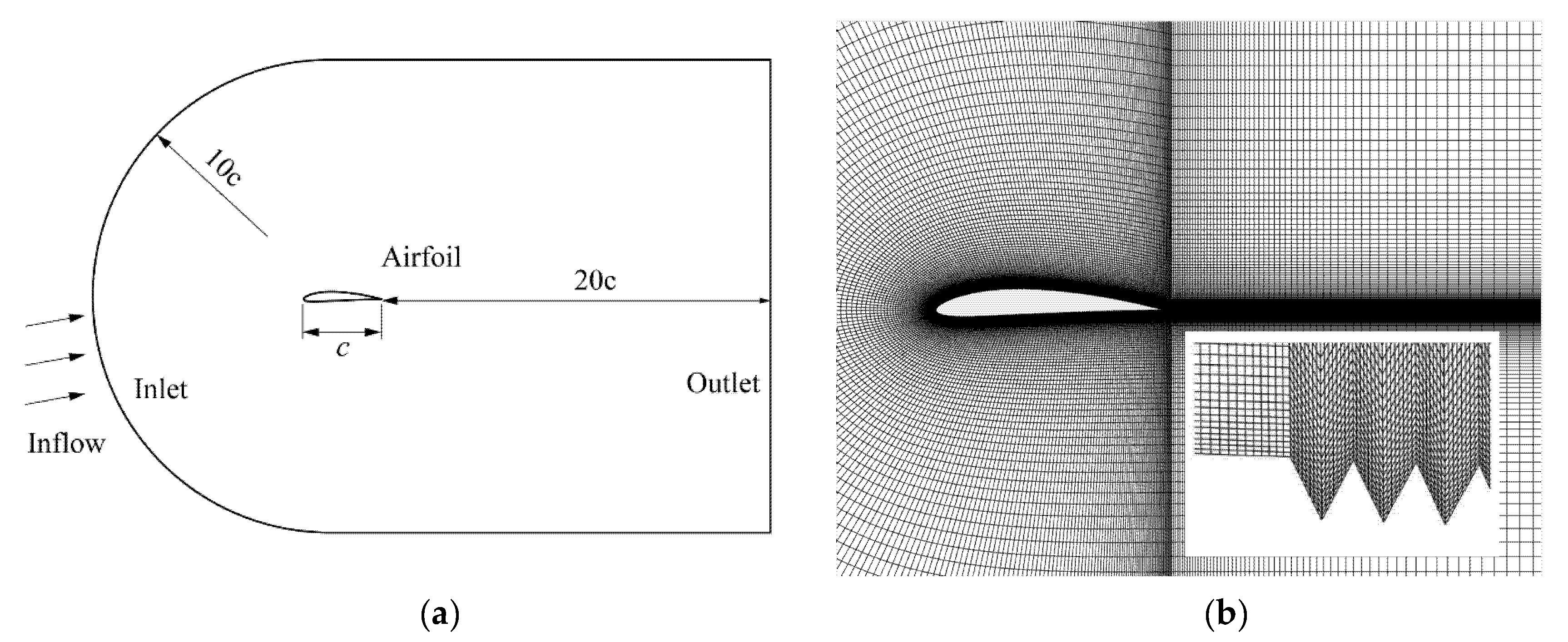

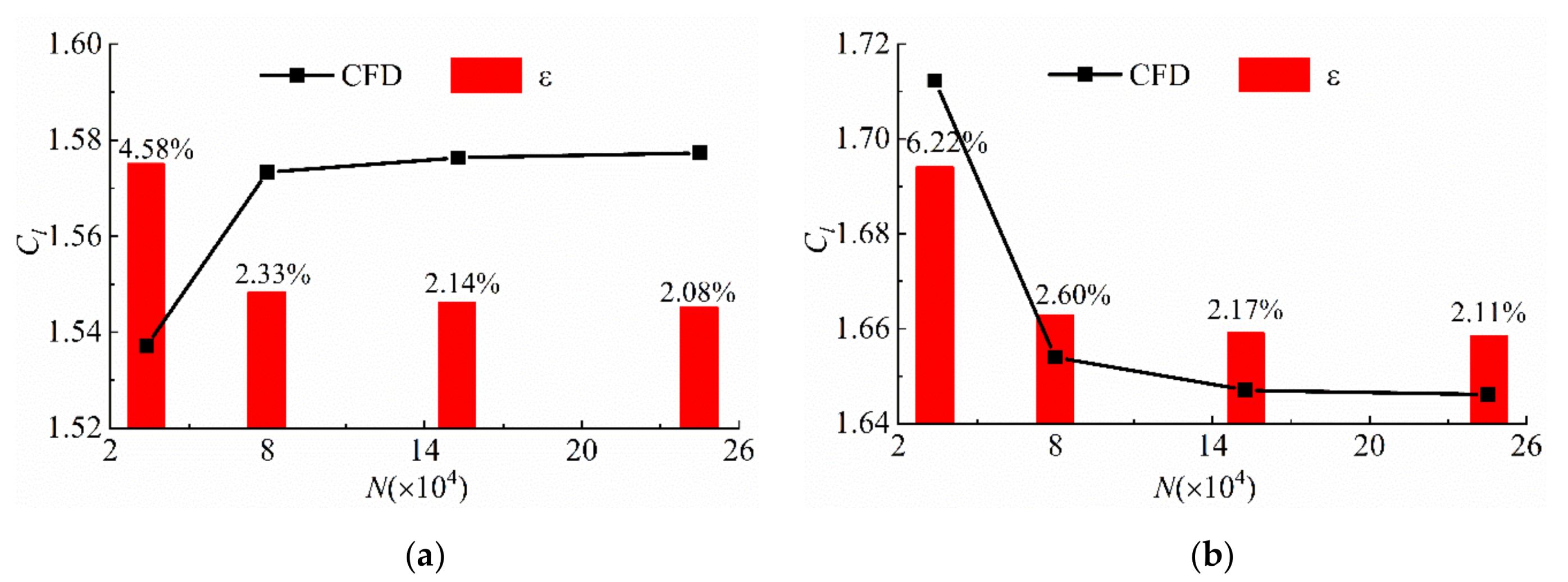

2.4. Mesh Model and Validation

3. Result, Analysis, and Discussion

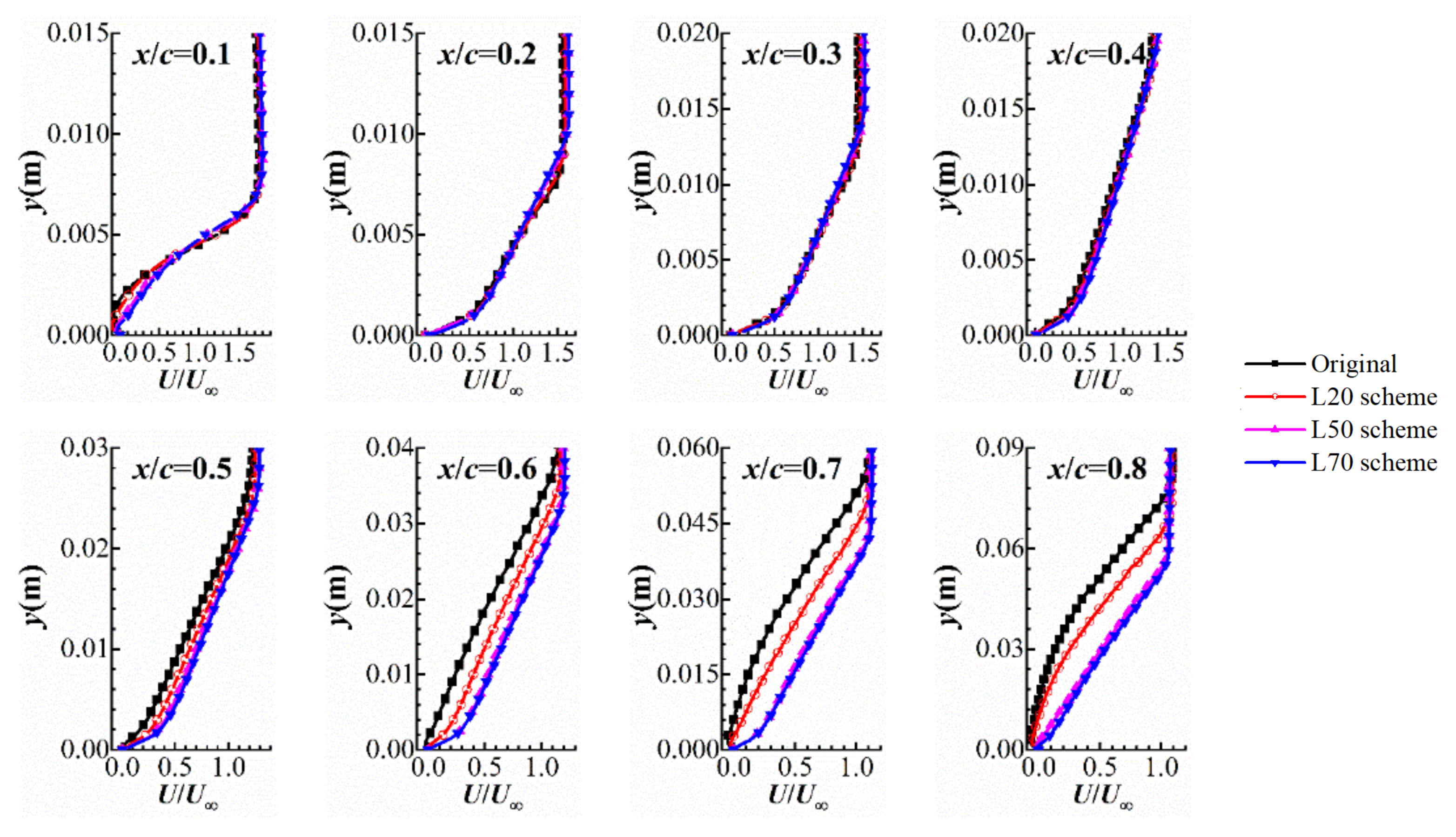

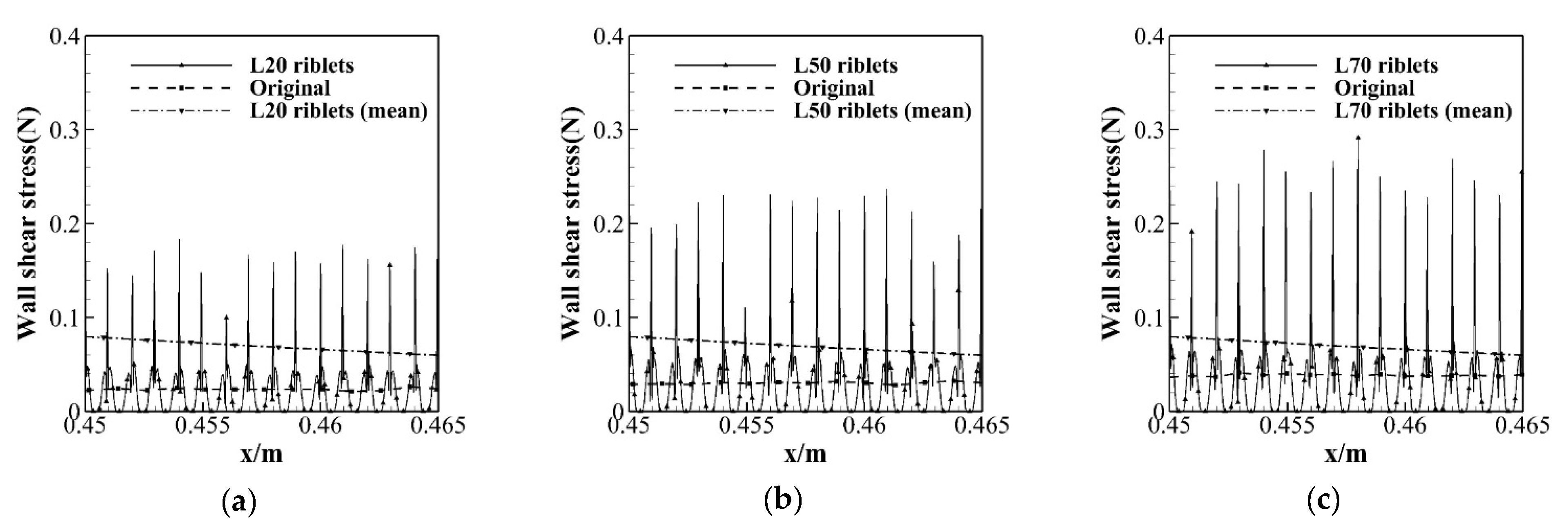

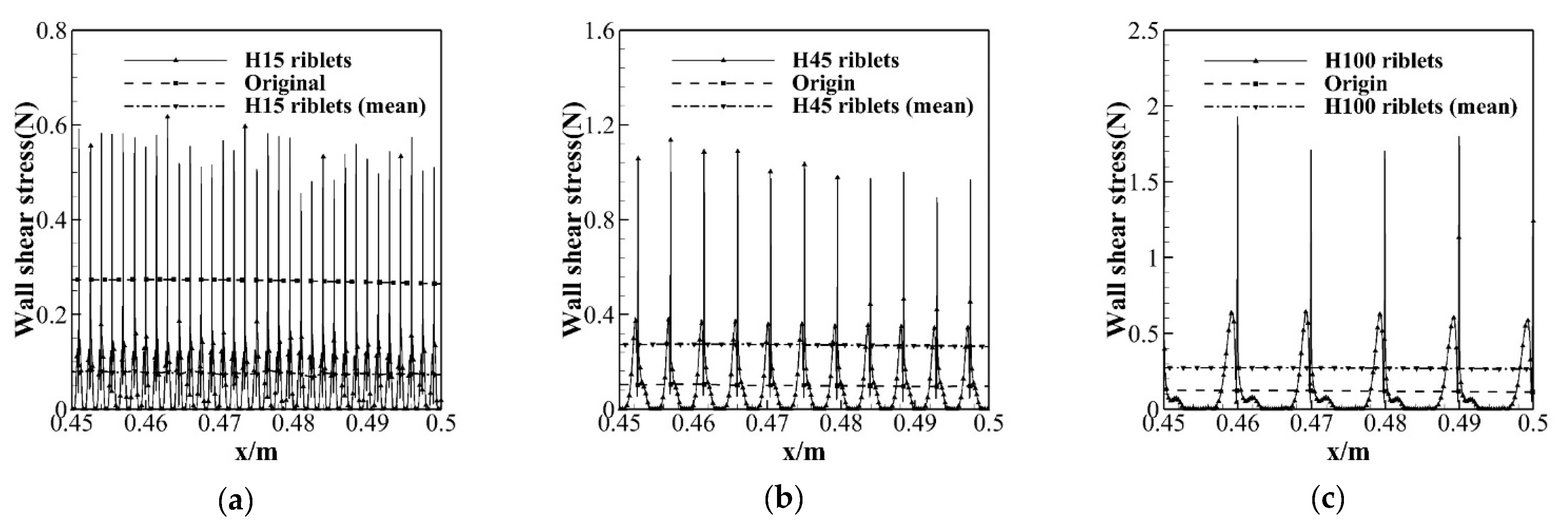

3.1. Flow Characteristics of the Riblets Inside the Boundary Layer

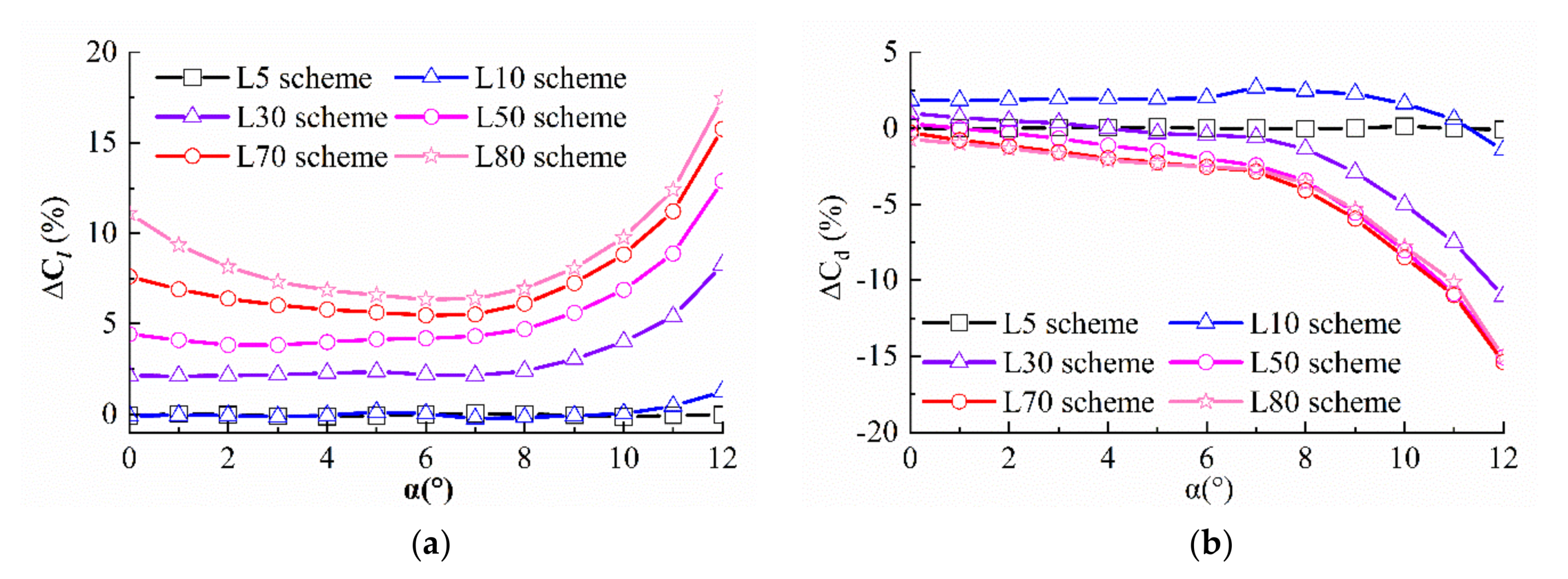

3.2. Effect of the Riblets with Different Lengths

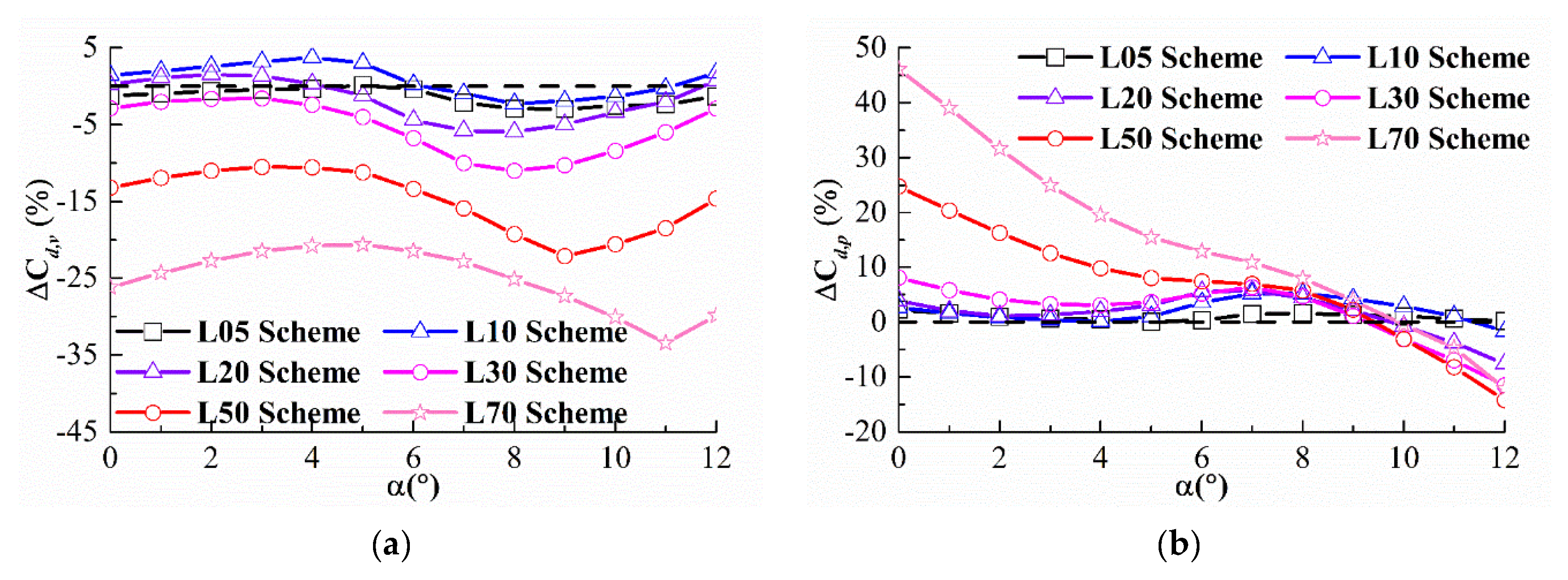

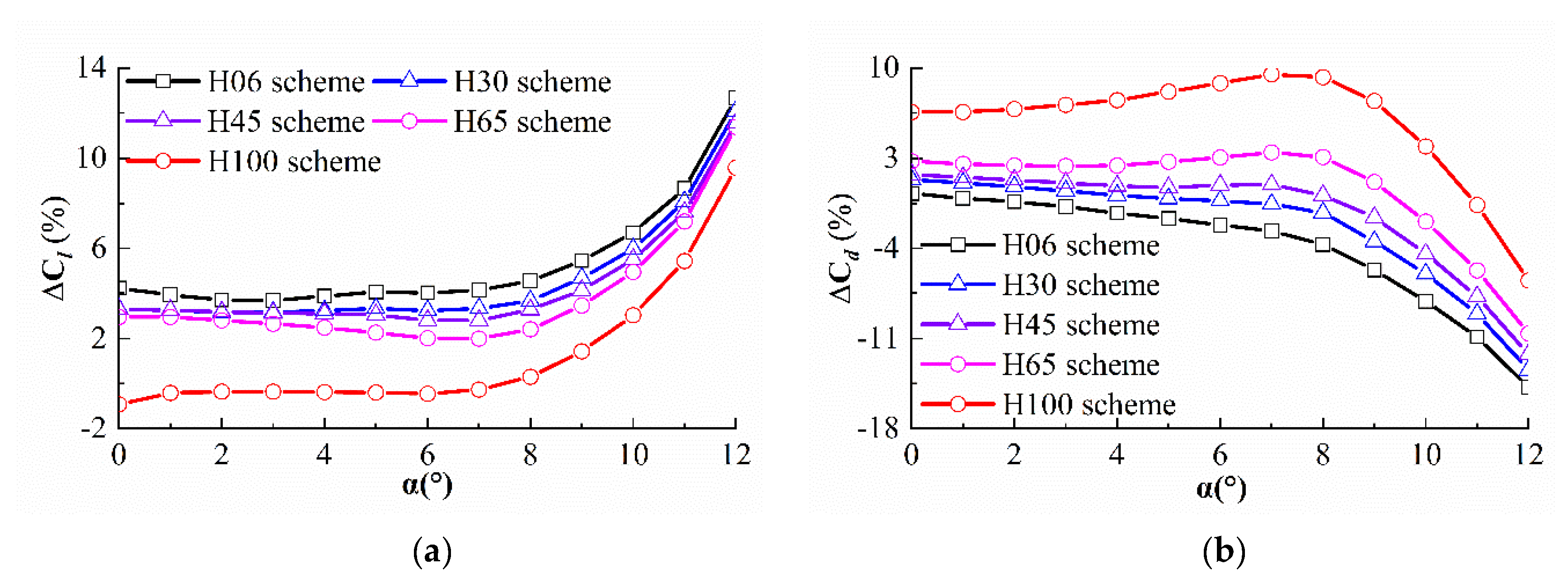

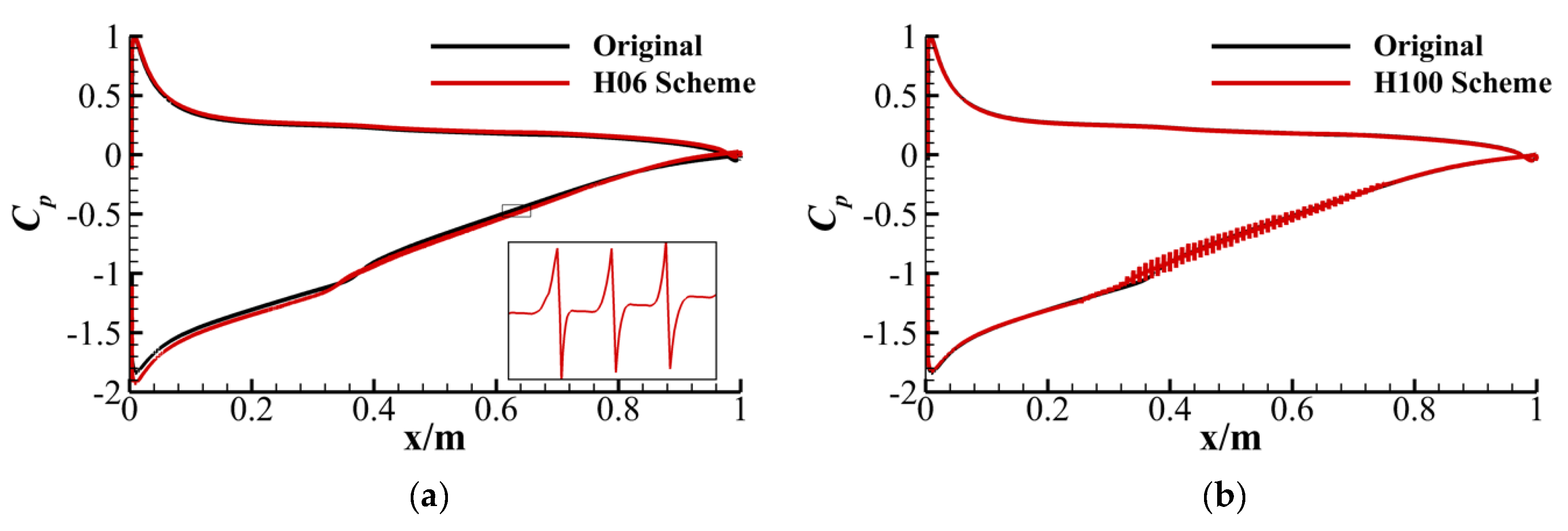

3.3. Effect of Riblets with Different Heights

4. Conclusions

- (1)

- The amount of drag reduction considerably varies with the length and height of the riblet and the AOA of the airfoil flow. When the length exceeds 0.2c, the improvement in the aerodynamic performance is nearly proportional to the riblet length. The most efficient riblet length is found to be 0.8c, which increases the lift and reduces the drag by 17.46% and 15.04% at a 12° AOA, respectively. On the contrary, the riblets with a length of 0.05c and 0.1c are unfavorable to the airfoil.

- (2)

- The drag reduction effect is in inverse proportion to the riblet height. The riblets with larger heights the airfoil drag at most of the designed AOAs. The most efficient riblet height in this study is 0.6 mm, as it produces an increase in lift and reduction in drag of 12.67% and 14.8%, respectively. Moreover, the riblets with different sizes perform better at a large AOA than at a small AOA, especially when considering riblet height. The drag coefficients of the riblets whose heights exceed 0.6 mm are significantly increased at a 0~7° AOA.

- (3)

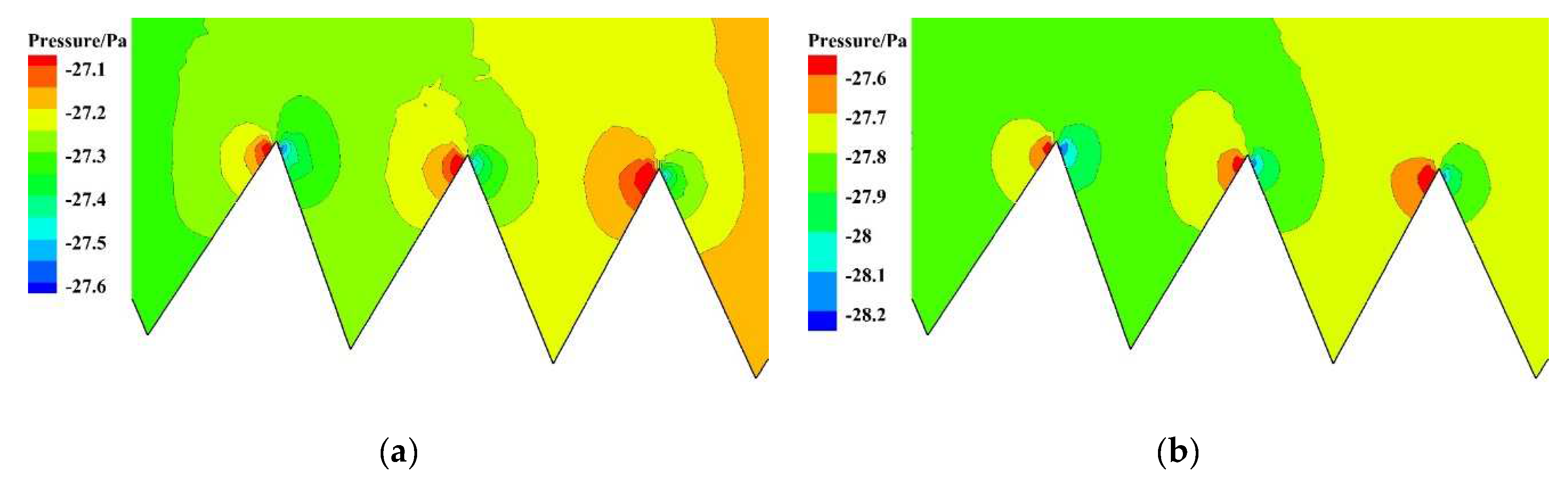

- When the flow separation occurs at the airfoil surface, the presence of riblets effectively restrains the trailing edge separation (TSV) compared with the original profile. Nevertheless, no flow separation appears at the small AOA, while the riblets increase the pressure difference at the tip of the structure. The significantly diminished TSV at a large AOA is the main reason for the reduction in the pressure drag, and it explains why the riblets perform better under these conditions.

- (4)

- The reason why the riblets decrease the airfoil viscous drag is that the vortex of riblet formed in it plays the role of the rolling bearing. The boundary layer’s thickness, energy loss, and momentum loss are also reduced due to the increase in the velocity gradient at the bottom of the boundary layer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Walsh, M.J. Drag Characteristics of V Groove and Transverse Curvature Riblets. In Viscous Flow Drag Reduction; Hough, G.R., Ed.; American Institute of Aeronautics and Astronautics: Dallas, TX, USA, 1980; Volume 72, pp. 168–184. [Google Scholar]

- Fu, Y.F.; Yuan, C.Q.; Bai, X.Q. Marine drag reduction of shark skin inspired riblet surfaces. Biosurf. Biotribol. 2017, 3, 11–24. [Google Scholar] [CrossRef]

- Jung, Y.C.; Bhushan, B. Biomimetic Structures for Fluid Drag Reduction in Laminar and Turbulent Flows. J. Phys. Condens. Matter 2010, 22, 35104–35112. [Google Scholar] [CrossRef]

- Bechert, D.W.; Bruse, M.; Hage, W. Experiments on Drag-Reducing Surfaces and Their Optimization with an Adjustable Geometry. J. Fluid Mech. 1997, 338, 59–87. [Google Scholar] [CrossRef]

- Bai, X.; Zhang, X.; Yuan, C. Numerical Analysis of Drag Reduction Performance of Different Shaped Riblet Surfaces. Mar. Technol. Soc. J. 2016, 50, 62–72. [Google Scholar] [CrossRef]

- Bixler, G.D.; Bhushan, B. Fluid Drag Reduction with Shark-Skin Riblet Inspired Microstructured Surfaces. Adv. Funct. Mater. 2013, 23, 4507–4528. [Google Scholar] [CrossRef]

- Bechert, D.W.; Bruce, M.; Hage, W. Experiments with three-dimensional riblets as an idealized model of shark skin. Exp. Fluids 2000, 28, 403–412. [Google Scholar] [CrossRef]

- Hou, J.; Vajdi Hokmabad, B.; Ghaemi, S. Three-dimensional measurement of turbulent flow over a riblet surface. Exp. Therm. Fluid Sci. 2017, 85, 229–239. [Google Scholar] [CrossRef]

- Ng, J.H.; Jaiman, R.K.; Lim, T.T. Direct Numerical Simulations of Riblets in a Fully-Developed Turbulent Channel Flow: Effects of Geometry. In Advances in Computation, Modeling and Control of Transitional and Turbulent Flows; World Scientific: Singapore, 2016. [Google Scholar]

- El-Samni, O.A.; Chun, H.H.; Yoon, H.S. Drag reduction of turbulent flow over thin rectangular riblets. Int. J. Eng. Sci. 2007, 45, 436–454. [Google Scholar] [CrossRef]

- Suzuki, Y.; Kasagi, N. Turbulent drag reduction mechanism above a riblet surface. AIAA J. 1994, 32, 1781–1790. [Google Scholar] [CrossRef]

- Yulia, P.; Pierre, S.; Yves, C. Turbulent Drag Reduction using Sinusoidal Riblets with Triangular Cross-Section. In Proceedings of the 38th AIAA Fluid Dynamics Conference and Exhibit, Seattle, WA, USA, 23–26 June 2008; pp. 2008–3745. [Google Scholar]

- Sasamori, M.; Mamori, H.; Iwamoto, K. Experimental study on drag-reduction effect due to sinusoidal riblets in turbulent channel flow. Exp. Fluids 2014, 55, 1828. [Google Scholar] [CrossRef]

- Sasamori, M.; Iihama, O.; Mamori, H. Parametric Study on a Sinusoidal Riblet for Drag Reduction by Direct Numerical Simulation. Flow Turbul. Combust. 2017, 99, 47–69. [Google Scholar] [CrossRef]

- Goldstein, D.; Handler, R.; Sirovich, L. Direct numerical simulation of turbulent flow over a modeled riblet covered surface. J. Fluid Mech. 1995, 302, 333–376. [Google Scholar] [CrossRef]

- Choi, H.; Moin, P.; Kim, J. Direct Numerical Simulation of Turbulent Flow Over Riblets. J. Fluid Mech. 1993, 255, 503–509. [Google Scholar] [CrossRef]

- Caram, J.M.; Ahmed, A. Effect of riblets on turbulence in the wake of an airfoil. AIAA J. 1991, 29, 1769–1770. [Google Scholar] [CrossRef]

- Han, M.; Lim, H.C.; Jang, Y.G. Fabrication of a Micro-Riblet Film and Drag Reduction Effects on Curved Objects. In Proceedings of the TRANSDUCERS, Solid-State Sensors, Actuators and Microsystems, 12th International Conference on Solid State Sensors, Boston, MA, USA, 8–12 June 2003. [Google Scholar]

- Chamorro, L.P.; Arndt, R.E.A.; Sotiropoulos, F. Drag reduction of large wind turbine blades through riblets: Evaluation of riblet geometry and application strategies. Renew. Energy 2013, 50, 1095–1105. [Google Scholar] [CrossRef]

- Sareen, A.; Deters, R.W.; Henry, S.P. Drag Reduction Using Riblet Film Applied to Airfoils for Wind Turbines. J. Sol. Energy Eng. 2013, 136, 021007. [Google Scholar] [CrossRef]

- Viswanath, P.R. Aircraft viscous drag reduction using riblets. Prog. Aerosp. Sci. 2002, 38, 571–600. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y. Numerical study of an airfoil with riblets installed based on large eddy simulation. Aerosp. Sci. Technol. 2018, 78, 661–670. [Google Scholar] [CrossRef]

- Wang, S.; Rong, R.; Zhengren, W.U. Research on Drag-reduction Characteristic of Non-smooth Surface Riblet Structure on Aerofoil Blade of Centrifugal Fan. Proc. CSEE 2013, 33, 112–118. [Google Scholar]

- Zhengren, W.U.; Hao, X.; Rong, R. Three-dimensional Numerical Analysis on Drag Reduction Characteristics of the Riblet Structure for Centrifugal Fan Blades. Proc. CSEE 2014, 34, 1815–1821. [Google Scholar]

- Neumann, D.; Dinkelacker, A. Drag measurements on V-grooved surfaces on a body of revolution in axial flow. Appl. Sci. Res. 1991, 48, 105–114. [Google Scholar] [CrossRef]

- Walsh, M.J. Riblets as a Viscous Drag Reduction Technique. AIAA J. 1983, 21, 485–486. [Google Scholar] [CrossRef]

- Li, X.; Li, Z.; Zhu, B.; Wang, W. Effect of Tip Clearance Size on Tubular Turbine Leakage Characteristics. Processes 2021, 9, 1481. [Google Scholar] [CrossRef]

- Huang, Z.; Shi, G.; Liu, X. Effect of Flow Rate on Turbulence Dissipation Rate Distribution in a Multiphase Pump. Processes 2021, 9, 886. [Google Scholar] [CrossRef]

- Coles, D.; Wadcock, A.J. Flying-Hot-Wire Study of 2-Dimensional Mean Flow Past an NACA 4412 Airfoil at Maximum Lift. In Proceedings of the 11th Fluid and Plasma Dynamics Conference, Seattle, WA, USA, 10–12 July 1978. [Google Scholar]

| Turbulence Model | Grid Number | 0° | 4.5° | 8° | 12° | 16° |

|---|---|---|---|---|---|---|

| 0.3998 | 0.8772 | 1.2003 | 1.5245 | 1.7064 | ||

| 0.4024 | 0.8813 | 1.2294 | 1.5379 | 1.6731 | ||

| 0.4080 | 0.8855 | 1.2356 | 1.5467 | 1.6617 | ||

| 0.4091 | 0.8886 | 1.2398 | 1.5549 | 1.6584 | ||

| 0.4009 | 0.8793 | 1.2053 | 1.5347 | 1.7099 | ||

| 0.4079 | 0.8826 | 1.2327 | 1.5648 | 1.6648 | ||

| 0.4126 | 0.8877 | 1.2400 | 1.5690 | 1.6561 | ||

| 0.4142 | 0.8905 | 1.2436 | 1.5731 | 1.6519 | ||

| 0.4169 | 0.8834 | 1.2115 | 1.5372 | 1.7123 | ||

| 0.4213 | 0.8994 | 1.2499 | 1.5733 | 1.6540 | ||

| 0.4261 | 0.9036 | 1.2450 | 1.5763 | 1.6470 | ||

| 0.4272 | 0.9006 | 1.2435 | 1.5774 | 1.6461 | ||

| Experiment | - | 0.4299 | 0.8959 | 1.2896 | 1.6109 | 1.6120 |

| AOA | |||

|---|---|---|---|

| 0 | 7.610 | −0.293 | 7.926 |

| 2 | 6.383 | −1.160 | 7.632 |

| 4 | 5.798 | −1.953 | 7.906 |

| 6 | 5.478 | −2.537 | 8.224 |

| 8 | 6.121 | −4.081 | 10.636 |

| 10 | 8.852 | −8.466 | 18.920 |

| 12 | 15.778 | −15.369 | 36.803 |

| Scheme | Pressure Drag (%) | Viscous Drag (%) | Total Drag (%) |

|---|---|---|---|

| H06 | 6.45 | −15.68 | −2.37 |

| H15 | 8.47 | −16.70 | −1.56 |

| H45 | 15.35 | −20.08 | 1.23 |

| H65 | 20.43 | −21.42 | 3.76 |

| H75 | 23.85 | −21.99 | 5.58 |

| H100 | 31.17 | −22.46 | 9.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Wang, J.; Jiang, B.; Li, Z.; Xiao, Q. Numerical Study of Effect of Sawtooth Riblets on Low-Reynolds-Number Airfoil Flow Characteristic and Aerodynamic Performance. Processes 2021, 9, 2102. https://doi.org/10.3390/pr9122102

Yang X, Wang J, Jiang B, Li Z, Xiao Q. Numerical Study of Effect of Sawtooth Riblets on Low-Reynolds-Number Airfoil Flow Characteristic and Aerodynamic Performance. Processes. 2021; 9(12):2102. https://doi.org/10.3390/pr9122102

Chicago/Turabian StyleYang, Xiaopei, Jun Wang, Boyan Jiang, Zhi’ang Li, and Qianhao Xiao. 2021. "Numerical Study of Effect of Sawtooth Riblets on Low-Reynolds-Number Airfoil Flow Characteristic and Aerodynamic Performance" Processes 9, no. 12: 2102. https://doi.org/10.3390/pr9122102

APA StyleYang, X., Wang, J., Jiang, B., Li, Z., & Xiao, Q. (2021). Numerical Study of Effect of Sawtooth Riblets on Low-Reynolds-Number Airfoil Flow Characteristic and Aerodynamic Performance. Processes, 9(12), 2102. https://doi.org/10.3390/pr9122102