Microwave Radiation Impact on Heavy Oil Upgrading from Carbonate Deposits in the Presence of Nano-Sized Magnetite

Abstract

:1. Introduction

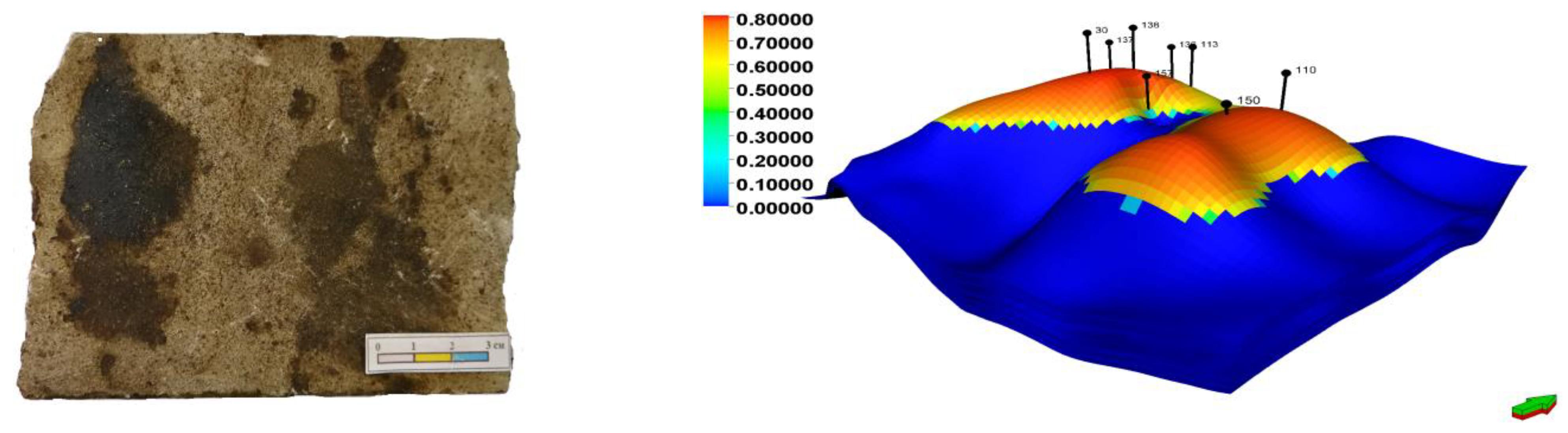

2. Materials and Methods

2.1. Materials

2.2. Experiments

3. Results and discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Muraza, O.; Galadima, A. Aquathermolysis of Heavy Oil: A Review and Perspective on Catalyst Development. Fuel 2015, 157, 219–231. [Google Scholar] [CrossRef]

- Maity, S.K.; Ancheyta, J.; Marroquín, G. Catalytic Aquathermolysis Used for Viscosity Reduction of Heavy Crude Oils: A Review. Energy and Fuels 2010, 24, 2809–2816. [Google Scholar] [CrossRef]

- Vakhin, A.V.; Aliev, F.A.; Mukhamatdinov, I.I.; Sitnov, S.A.; Kudryashov, S.I.; Afanasiev, I.S.; Petrashov, O.V.; Nurgaliev, D.K. Extra-Heavy Oil Aquathermolysis Using Nickel-Based Catalyst: Some Aspects of In-Situ Transformation of Catalyst Precursor. Catalysts 2021, 11, 189. [Google Scholar] [CrossRef]

- Khelkhal, M.A.; Eskin, A.A.; Nurgaliev, D.K.; Vakhin, A.V. Thermal Study on Stabilizing Combustion Front via Bimetallic Mn@Cu Tallates during Heavy Oil Oxidation. Energy Fuels 2019, 34, 5121–5127. [Google Scholar] [CrossRef]

- Khelkhal, M.A.; Eskin, A.A.; Vakhin, A.V. Kinetic Study on Heavy Oil Oxidation by Copper Tallates. Energy Fuels 2019, 33, 12690–12695. [Google Scholar] [CrossRef]

- Vakhin, A.V.; Khelkhal, M.A.; Tajik, A.; Gafurov, M.R.; Morozov, O.G.; Nasybullin, A.R.; Karandashov, S.A.; Ponomarev, A.A.; Krapivnitskaia, T.O.; Glyavin, M.Y. The Role of Nanodispersed Catalysts in Microwave Application during the Development of Unconventional Hydrocarbon Reserves: A Review of Potential Applications. Processes 2021, 9, 420. [Google Scholar] [CrossRef]

- Farhadian, A.; Khelkhal, M.A.; Tajik, A.; Lapuk, S.E.; Rezaeisadat, M.; Eskin, A.A.; Rodionov, N.O.; Vakhin, A.V. Effect of Ligand Structure on the Kinetics of Heavy Oil Oxidation: Toward Biobased Oil-Soluble Catalytic Systems for Enhanced Oil Recovery. Ind. Eng. Chem. Res. 2021, 60, 14713–14727. [Google Scholar] [CrossRef]

- Mukhamatdinov, I.I.; Sitnov, S.A.; Slavkina, O.V.; Bugaev, K.A.; Laikov, A.V.; Vakhin, A.V. The Aquathermolysis of Heavy Oil from Riphean-Vendian Complex with Iron-Based Catalyst: FT-IR Spectroscopy Data. Pet. Sci. Technol. 2019, 37, 1410–1416. [Google Scholar] [CrossRef]

- Minkhanov, I.F.; Bolotov, A.V.; Al-Muntaser, A.A.; Mukhamatdinov, I.I.; Vakhin, A.V.; Varfolomeev, M.A.; Slavkina, O.V.; Shchekoldin, K.A.; Darishchev, V.I. Experimental Study on the Improving the Efficiency of Oil Displacement by Co-Using of the Steam-Solvent Catalyst (Russian). Neft. Khozyaystvo-Oil Ind. 2021, 2021, 54–57. [Google Scholar] [CrossRef]

- Kudryashov, S.I.; Afanasiev, I.S.; Petrashov, O.V.; Vakhin, A.V.; Sitnov, S.A.; Akhmadiayrov, A.A.; Varfolomeev, M.A.; Nurgaliev, D.K. Catalytic Heavy Oil Upgrading by Steam Injection with Using of Transition Metals Catalysts (Russian). Neft. Khozyaystvo-Oil Ind. 2017, 2017, 30–34. [Google Scholar] [CrossRef]

- Li, H.; Gao, H.; Zhao, X.; Xia, Z.; Yu, B.; Sun, D. Experimental Study on Viscosity Reduction of Heavy Oil with Water Content by Synergistic Effect of Microwave and Nano-Catalyst. J. Pet. Sci. Eng. 2022, 208, 109271. [Google Scholar] [CrossRef]

- Muslimov, R.K. On a New Paradigm for the Development of the Oil and Gas Complex in Russia (Russian). Neft. Khozyaystvo-Oil Ind. 2021, 2021, 8–13. [Google Scholar] [CrossRef]

- Yashchenko, I.G.; Polishchuk, Y.M. Classification of Poorly Recoverable Oils and Analyis of Their Quality Characteristics. Chem. Technol. Fuels Oils 2016, 52, 434–444. [Google Scholar] [CrossRef]

- Vernaya, O.I.; Krotova, I.N.; Maksimov, Y.V.; Rostovshchikova, T.N. Effect of the Support Nature on the Catalytic Properties of Iron in Benzene Benzylation. Pet. Chem. 2017, 57, 93–99. [Google Scholar] [CrossRef]

- Tsodikov, M.V.; Rostovshchikova, T.N.; Smirnov, V.V.; Kiseleva, O.I.; Maksimov, Y.V.; Suzdalev, I.P.; Ikorskii, V.N. Structure and Size Effects in Catalysis by Immobilized Nanoclusters of Iron Oxides. Catal. Today 2005, 105, 634–640. [Google Scholar] [CrossRef]

- Maksimov, Y.V.; Rostovshchikova, T.N.; Kiseleva, O.I.; Smirnov, V.V.; Suzdalev, I.P.; Prusakov, V.E.; Tsodikov, M.V.; Ikorsky, V.N. Catalytic Conversions of Chloro-Olefins on Iron Oxide Nanoparticles. 3. Electronic and Magnetic Properties of Fe2O3 Nanoparticles on Silicas of Various Nature. Izv. RAN Phys. Ser. 2010, 74, 328–332. [Google Scholar]

- Rostovshchikova, T.; Smirnov, V.; Kiseleva, O.; Yushcenko, V.; Tzodikov, M.; Maksimov, Y.; Suzdalev, I.; Kustov, L.; Tkachenko, O. Acidic and Catalytic Properties of Silica Modified by Iron Oxide Nanoparticles. Catal. Today 2010, 152, 48–53. [Google Scholar] [CrossRef]

- Hayashi, H.; Chen, L.Z.; Tago, T.; Kishida, M.; Wakabayashi, K. Catalytic Properties of Fe/SiO2 Catalysts Prepared Using Microemulsion for CO Hydrogenation. Appl. Catal. A Gen. 2002, 231, 81–89. [Google Scholar] [CrossRef]

- Kuhrs, C.; Arita, Y.; Weiss, W.; Ranke, W.; Schlögl, R. Understanding Heterogeneous Catalysis on an Atomic Scale: A Combined Surface Science and Reactivity Investigation for the Dehydrogenation of Ethylbenzene over Iron Oxide Catalysts. Top. Catal. 2000, 14, 111–123. [Google Scholar] [CrossRef]

- Rostovshchikova, T.N.; Smirnov, V.V.; Tsodikov, M.V.; Bukhtenko, O.V.; Maksimov, Y.V.; Kiseleva, O.I.; Pankratov, D.A. Catalytic Conversions of Chloro-Olefins on Iron Oxide Nanoparticles. Communication I. Isomerization of Dichlorobutenes in the Presence of Iron Oxide Nanoparticles Immobilized on Silicas of Various Structures. Bull. USSR Acad. Sci. Chem. Ser. 2005, 6, 1376–1382. [Google Scholar]

- Rostovshchikova, T.N.; Kiseleva, O.I.; Yurkov, G.Y.; Gubin, S.P.; Pankratov, D.A.; Perfiliev, Y.D.; Smirnov, V.V.; Chernavsky, P.A.; Pankina, G.V. Catalysis of Reactions of Chlorine Olefins of Allyl Structure by Nanosized Iron Oxides. Mosc. Univ. Bull. Epis. 2 Chem. 2001, 42, 318–324. [Google Scholar]

- Sitnov, S.; Mukhamatdinov, I.; Aliev, F.; Khelkhal, M.A.; Slavkina, O.; Bugaev, K. Heavy Oil Aquathermolysis in the Presence of Rock-Forming Minerals and Iron Oxide (II, III) Nanoparticles. Pet. Sci. Technol. 2020, 38, 574–579. [Google Scholar] [CrossRef]

- Kuznetsov, B.N. Catalysis of Chemical Transformations of Coal and Biomass. Science 1990, 52, 485–492. [Google Scholar]

- Derbyshire, F.; Hager, T. Coal Liquefaction and Catalysis. Fuel 1994, 73, 1087–1092. [Google Scholar] [CrossRef]

- Taheri-Shakib, J.; Kantzas, A. A Comprehensive Review of Microwave Application on the Oil Shale: Prospects for Shale Oil Production. Fuel 2021, 305, 121519. [Google Scholar] [CrossRef]

- Arapova, O.V.; Chistyakov, A.V.; Palankoev, T.A.; Bondarenko, G.N.; Tsodikov, M.V. Microwave-Assisted Lignin Conversion to Liquid Products in the Presence of Iron and Nickel. Pet. Chem. 2020, 60, 1019–1025. [Google Scholar] [CrossRef]

- Shang, H.; Yue, Y.; Zhang, J.; Wang, J.; Shi, Q.; Zhang, W.; Liu, L.; Omar, S. Effect of Microwave Irradiation on the Viscosity of Crude Oil: A View at the Molecular Level. Fuel Process. Technol. 2018, 170, 44–52. [Google Scholar] [CrossRef] [Green Version]

- Goryachikh, D.V.; Kayukova, G.P.; Nigmedzyanova, L.Z.; Kiyamova, A.M.; Yu, M. Ganeeva Influence of Microwave Heating on the Yield and Composition of Natural Bitumen from Sandstones of the Shugurovskoye Field. Enhanced Oil Recovery at the Late Stage of Oil Field Development and Integrated Development of High-Viscosity Oils and Natur. In Proceedings of the International Scientific and Practical Conference, Moscow, Russia, 1–3 November 2007; pp. 178–183. [Google Scholar]

- Leite, L.F.; Borschiver, S.; Canongia, C.; Antunes, A.M.S. Survey of Microwave Technology Potential Application in Heavy Crude Oil Upgrading. In Proceedings of the 2nd Mercosur Congress on Chemical Engineering and 4th Mercosur Congress on Process Systems Engineering, Rio de Janeiro, Brazil, 14–18 August 2005. [Google Scholar]

- Mokhlisse, A.; Chanâa, M.B.; Outzourhit, A. Pyrolysis of the Moroccan (Tarfaya) Oil Shales under Microwave Irradiation. Fuel 2000, 79, 733–742. [Google Scholar]

- Wong, G.K.; Yen, T.F. An Electron Spin Resonance Probe Method for the Understanding of Petroleum Asphaltene Macrostructure. J. Pet. Sci. Eng. 2000, 28, 55–64. [Google Scholar] [CrossRef]

- Li, Y.; Shang, H.; Zhang, Q.; Elabyouki, M.; Zhang, W. Theoretical Study of the Structure and Properties of Ni/V Porphyrins under Microwave Electric Field: A DFT Study. Fuel 2020, 278, 118305. [Google Scholar] [CrossRef]

- Vanetsev, A.S.; Tretyakov, Y.D. Microwave-Assisted Synthesis of Individual and Multicomponent Oxides. Russ. Chem. Rev. 2007, 76, 397. [Google Scholar] [CrossRef]

- Sitnov, S.A.; Mukhamatdinov, I.I.; Vakhin, A.V.; Katnov, V.E.; Nurgaliev, D.K.; Lyabipov, M.R.; Amerkhanov, M.I. A Method of Producing a Nanosized Catalyst Based on Mixed Iron Oxide for Intensification of the Production of Heavy Hydrocarbon Feedstocks and a Catalyst Obtained by This Method. Patent No. 2655391 RU, 3 December 2018. [Google Scholar]

- Ma, W.; Luo, X.; Tao, S.; Liu, J.; Guan, P. Modified Pyrolysis Experiments and Indexes to Re-Evaluate Petroleum Expulsion Efficiency and Productive Potential of the Chang 7 Shale, Ordos Basin, China. J. Pet. Sci. Eng. 2020, 186, 106710. [Google Scholar] [CrossRef]

- Mullins, O.C.; Betancourt, S.S.; Cribbs, M.E.; Dubost, F.X.; Creek, J.L.; Andrews, A.B.; Venkataramanan, L. The Colloidal Structure of Crude Oil and the Structure of Oil Reservoirs. Energy Fuels 2007, 21, 2785–2794. [Google Scholar] [CrossRef]

- Matveenko, V.N.; Kirsanov, E.A. The Viscosity and Structure of Dispersed Systems. Mosc. Univ. Chem. Bull. 2011, 66, 199–228. [Google Scholar] [CrossRef]

- Bera, A.; Babadagli, T. Effect of Native and Injected Nano-Particles on the Efficiency of Heavy Oil Recovery by Radio Frequency Electromagnetic Heating. J. Pet. Sci. Eng. 2017, 153, 244–256. [Google Scholar] [CrossRef]

- Greff, J.; Babadagli, T. Use of Nano-Metal Particles as Catalyst under Electromagnetic Heating for in-Situ Heavy Oil Recovery. J. Pet. Sci. Eng. 2013, 112, 258–265. [Google Scholar] [CrossRef]

| Reservoir and Fluid Characteristics | Parameters |

|---|---|

| Layer depth, m | up to 2000 |

| Effective oil-saturated thickness, m | from 3 and more |

| Permeability, μm2 | any, if less than 0.10, preliminary fracturing is carried out for the injection of catalysts |

| Oil viscosity in reservoir conditions, mPa.s | more than 500 |

| Density of oil, kg/m3 | 850–1100 |

| Sample | SARA Fractions, wt.% | |||

|---|---|---|---|---|

| Saturates | Aromatics | Resins | Asphaltenes | |

| The extracted oil from the Mayorovskoye oil-saturated rock | 17.2 | 31.4 | 31.3 | 20.1 |

| The Presence of a Catalyst | Power, W | Exhaust Gas Temperature, °C | Time, min | |

|---|---|---|---|---|

| Original rock sample | + | 800 | 110 | 36 |

| - | 600 | 100 | 20 | |

| + | 600 | 110 | 28 | |

| Small fraction | + | 600 | 120 | 60 |

| CO2 | Hydrocarbon Gases, wt.% | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Limit Hydrocarbon Gases | Unsaturated Hydrocarbon Gases | Other Gases | |||||||||||||

| Methane | Ethane | Propane | n-Butane | i-Butane | n-Pentane | i-Pentane | Σ Limiting Alkanes | Ethylene | Propene | Butenes | Pentenes | Σ Unsaturated Alkanes | |||

| 1 | 97.4 | 0.46 | 0.04 | 0.08 | 0.16 | 0.04 | 0.15 | 0.12 | 1.05 | 0.01 | 0.05 | 0.15 | 0.12 | 0.34 | 1.26 |

| 2 | 98.1 | 0.10 | 0.16 | 0.27 | 0.08 | 0.05 | 0.03 | 0.02 | 0.72 | 0.18 | 0.19 | 0.17 | 0.06 | 0.60 | 0.55 |

| 3 | 94.2 | 0.22 | 0.30 | 0.12 | 0.07 | 0.06 | 0.04 | 3.75 | 4.56 | 0.25 | 0.19 | 0.17 | 0.07 | 0.69 | 0.58 |

| 4 | 98.5 | 0.07 | 0.27 | 0.11 | 0.06 | 0.01 | 0.03 | 0.01 | 0.58 | 0.17 | 0.20 | 0.18 | 0.08 | 0.63 | 0.31 |

| Sample | SARA Fractions, wt.% | ||||

|---|---|---|---|---|---|

| Saturated HC | Aromatic HC | Resins | Asphaltenes | ||

| Original extract | 17.2 | 31.4 | 31.3 | 20.1 | |

| After microwave processing | No 1 | 19.3 | 20.4 | 39.7 | 20.6 |

| No 2 | 19.0 | 22.3 | 31.3 | 27.4 | |

| No 3 | 20.1 | 19.3 | 43.3 | 17.3 | |

| No 4 | 19.4 | 17.0 | 44.4 | 19.2 | |

| Sample | Temperature Ranges, °C | Total Weight Loss | ||||||

|---|---|---|---|---|---|---|---|---|

| Up to 100 | 100–200 | 200–300 | 300–400 | 400–500 | 500–600 | |||

| Original Extract | 0.33 | 0.30 | 0.44 | 1.17 | 0.65 | 0.86 | 3.75 | |

| After microwave processing | No 1 | 0.40 | 0.29 | 0.40 | 0.66 | 0.80 | 1.45 | 4.00 |

| No 2 | 0.20 | 0.22 | 0.39 | 0.71 | 0.69 | 1.08 | 3.29 | |

| No 3 | 0.12 | 0.56 | 0.69 | 1.52 | 0.72 | 1.79 | 5.40 | |

| No 4 | 0.17 | 0.27 | 0.46 | 0.70 | 0.77 | 1.98 | 4.35 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vakhin, A.V.; Khelkhal, M.A.; Tajik, A.; Ignashev, N.E.; Krapivnitskaya, T.O.; Peskov, N.Y.; Glyavin, M.Y.; Bulanova, S.A.; Slavkina, O.V.; Schekoldin, K.A. Microwave Radiation Impact on Heavy Oil Upgrading from Carbonate Deposits in the Presence of Nano-Sized Magnetite. Processes 2021, 9, 2021. https://doi.org/10.3390/pr9112021

Vakhin AV, Khelkhal MA, Tajik A, Ignashev NE, Krapivnitskaya TO, Peskov NY, Glyavin MY, Bulanova SA, Slavkina OV, Schekoldin KA. Microwave Radiation Impact on Heavy Oil Upgrading from Carbonate Deposits in the Presence of Nano-Sized Magnetite. Processes. 2021; 9(11):2021. https://doi.org/10.3390/pr9112021

Chicago/Turabian StyleVakhin, Alexey V., Mohammed A. Khelkhal, Arash Tajik, Nikita E. Ignashev, Tatiana O. Krapivnitskaya, Nikolay Yu. Peskov, Mikhail Yu. Glyavin, Svetlana A. Bulanova, Olga V. Slavkina, and Konstantin A. Schekoldin. 2021. "Microwave Radiation Impact on Heavy Oil Upgrading from Carbonate Deposits in the Presence of Nano-Sized Magnetite" Processes 9, no. 11: 2021. https://doi.org/10.3390/pr9112021

APA StyleVakhin, A. V., Khelkhal, M. A., Tajik, A., Ignashev, N. E., Krapivnitskaya, T. O., Peskov, N. Y., Glyavin, M. Y., Bulanova, S. A., Slavkina, O. V., & Schekoldin, K. A. (2021). Microwave Radiation Impact on Heavy Oil Upgrading from Carbonate Deposits in the Presence of Nano-Sized Magnetite. Processes, 9(11), 2021. https://doi.org/10.3390/pr9112021