Drying Characteristics and Quality Attributes Affected by a Fluidized-Bed Drying Assisted with Swirling Compressed-Air for Preparing Instant Red Jasmine Rice

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Cooked Red Jasmine Rice Sample

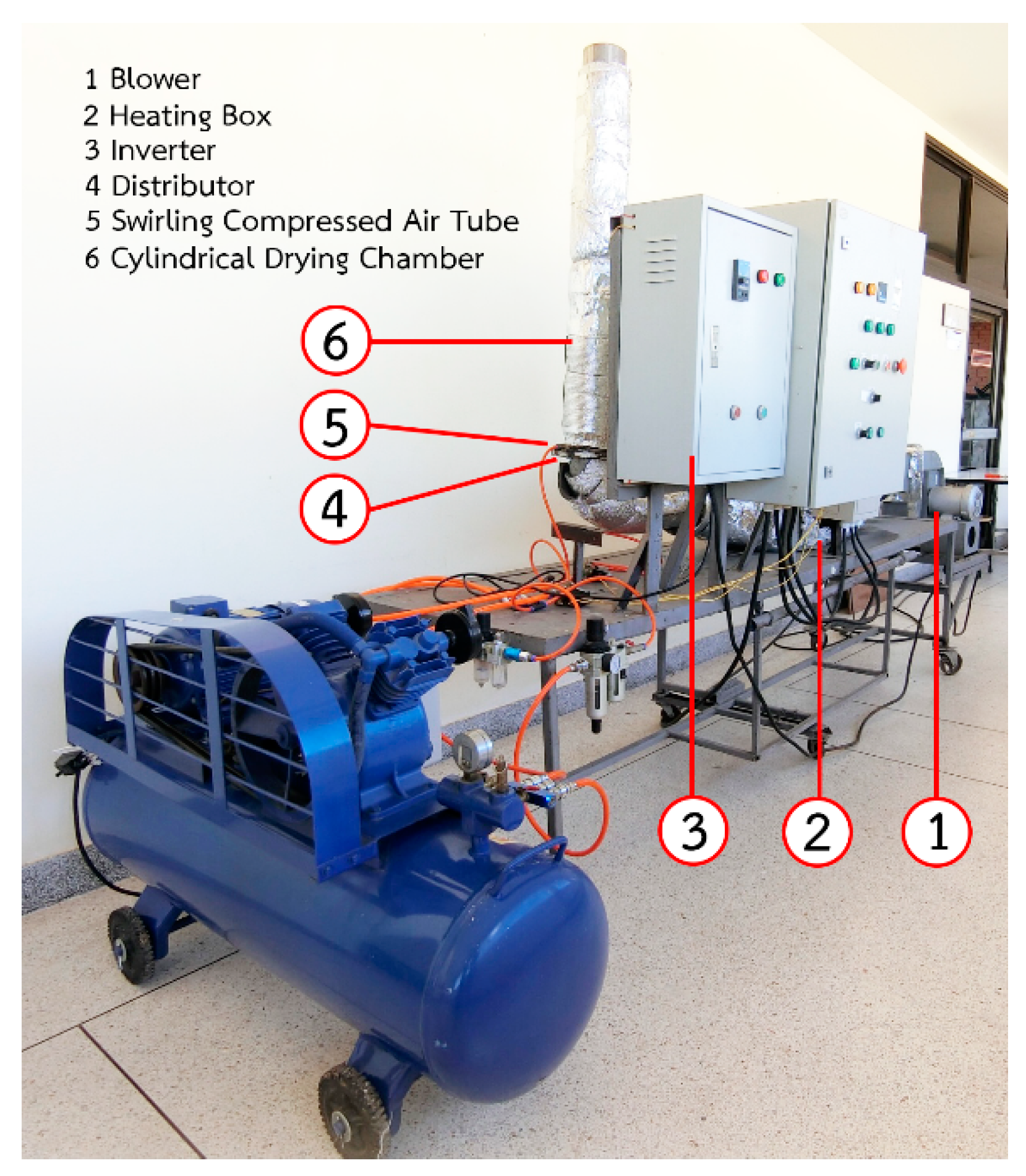

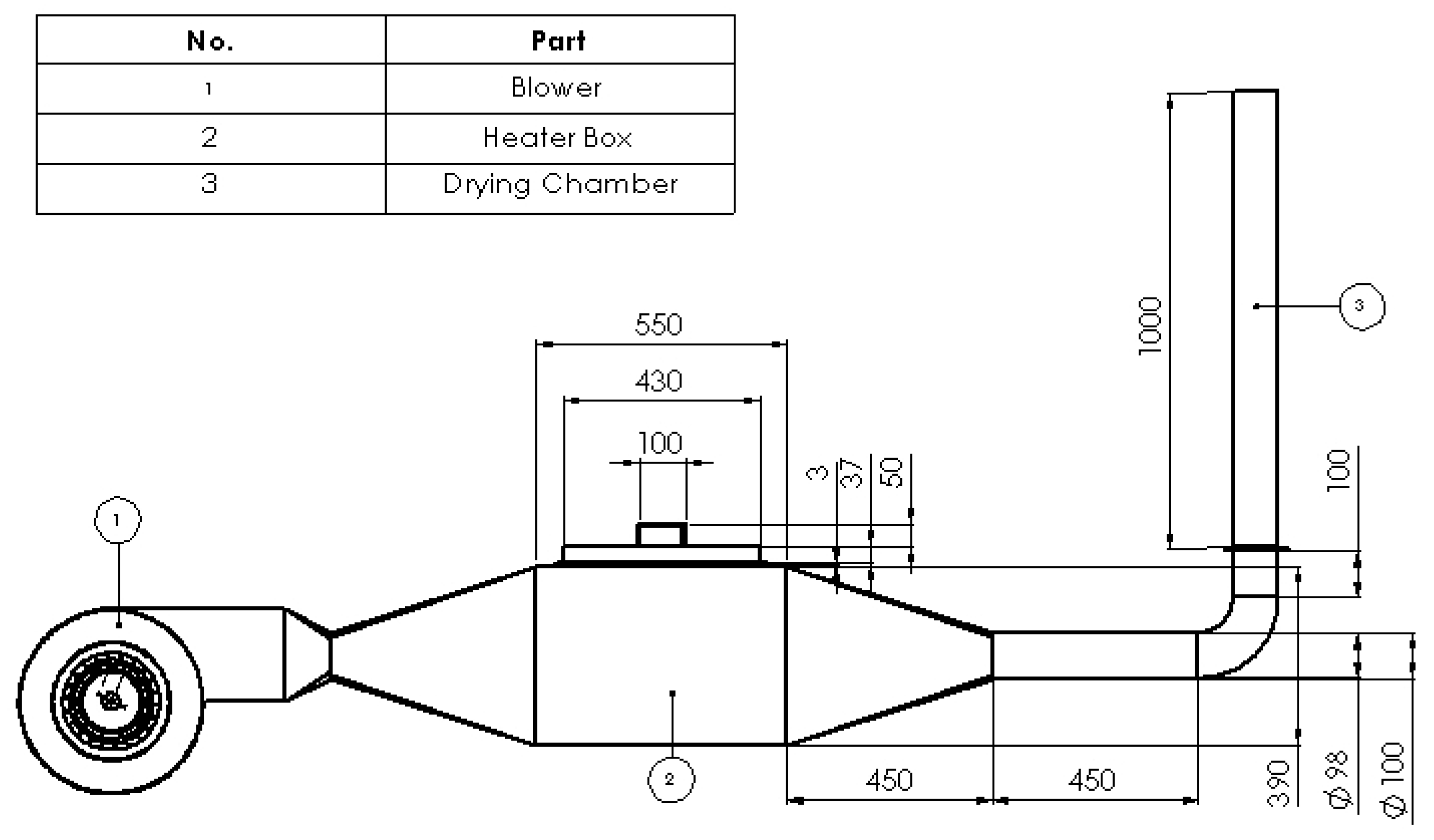

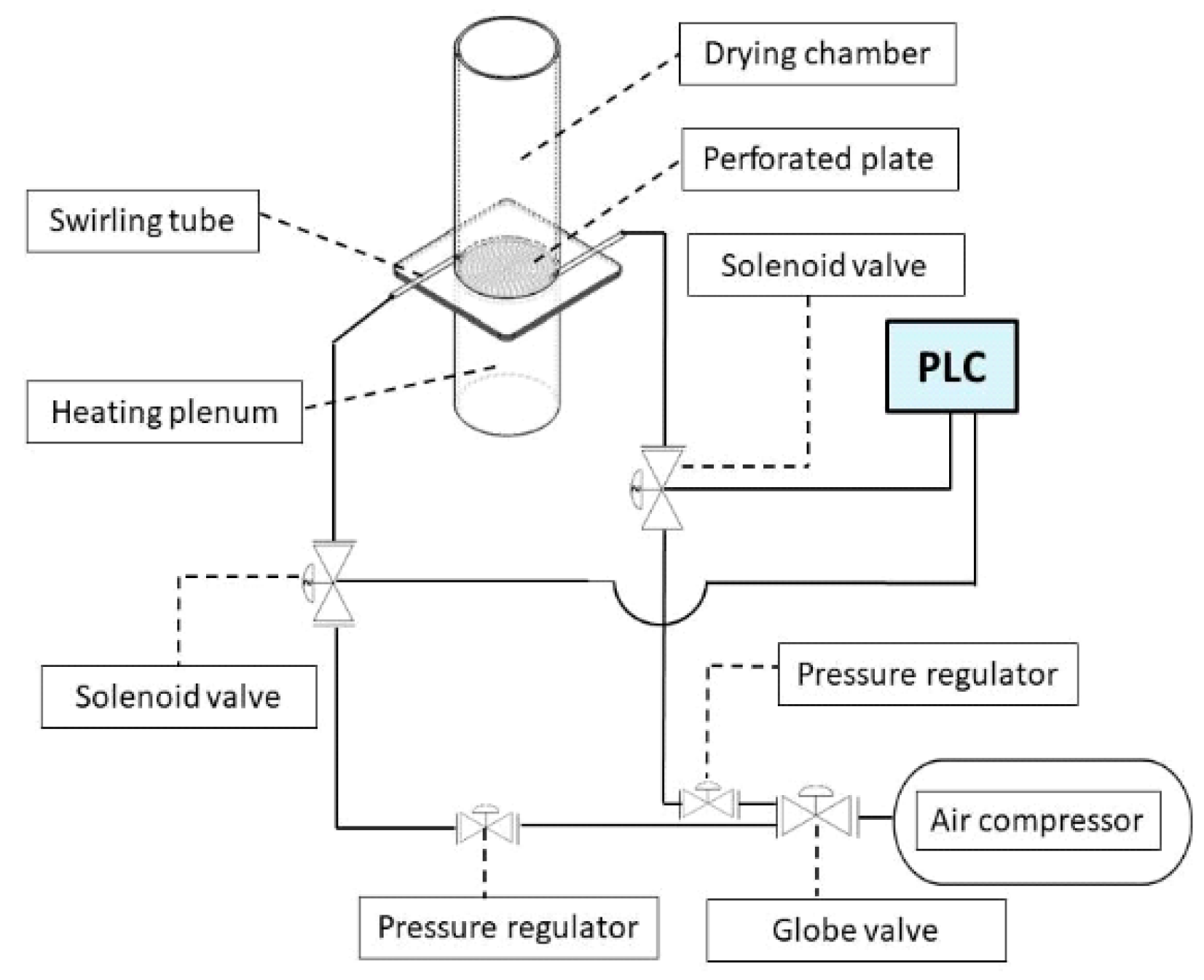

2.2. A Process of Fluidized Bed Drying Assisted with Swirling Compressed Air Stream

2.3. Analysis of Drying Characteristics

2.4. Quality Attributes of Instant and Rehydrated Jasmine Rice

2.4.1. Physical Properties

2.4.2. Color in CIE System

2.4.3. Shrinkage and Rehydration Ratio

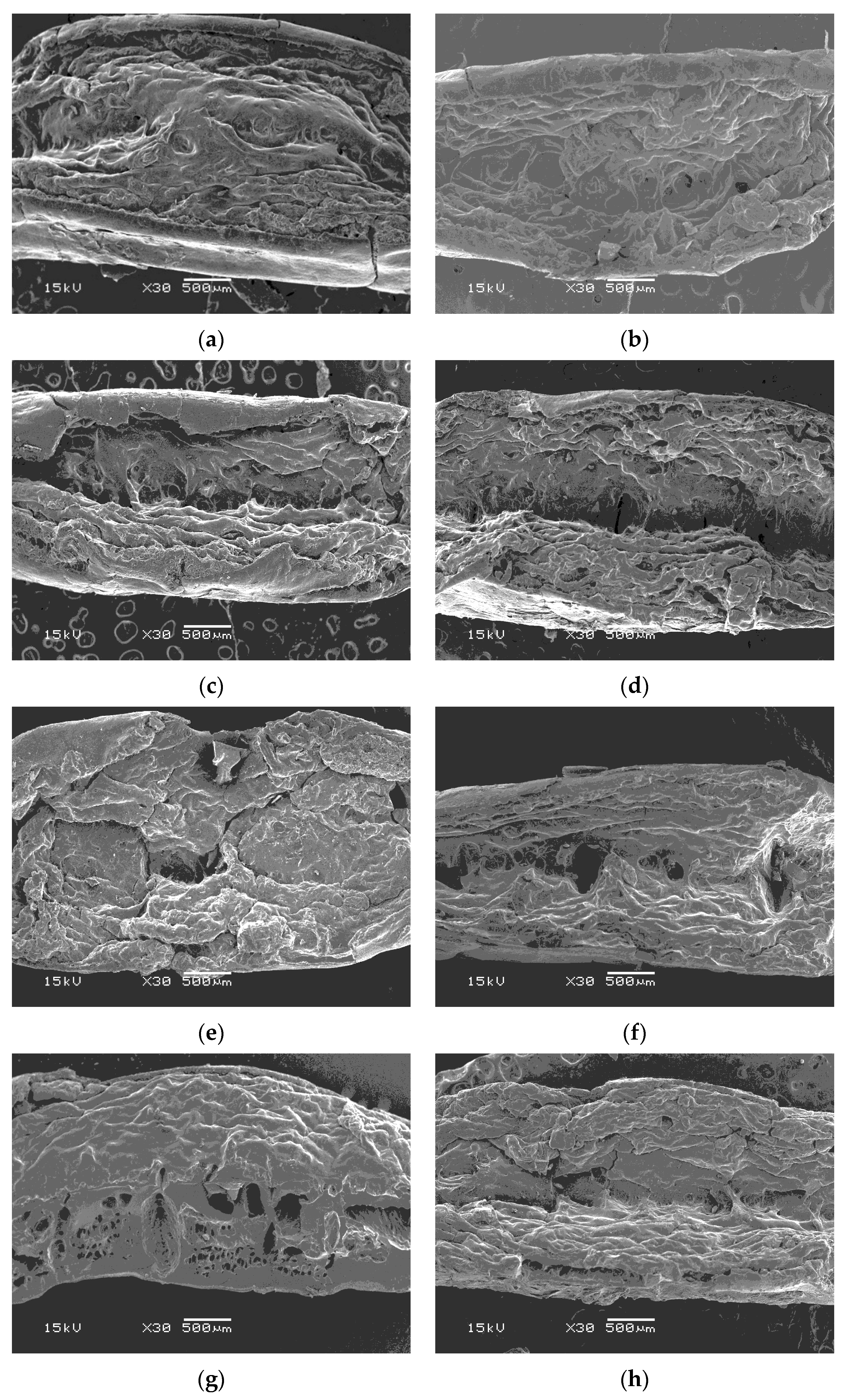

2.4.4. Microstructure of Instant Red Jasmine Rice

2.4.5. Analysis of Textural Properties

2.4.6. Antioxidant Properties

Sample Preparation

Total Anthocyanin Content Analysis

Total Phenolic Content Analysis

Total Flavonoid Content Analysis

Analysis of DPPH Radical Scavenging Activity

2.5. Response Surface Methodology

3. Results and Discussion

3.1. Analysis of Drying Characteristics

3.1.1. Drying Model

3.1.2. Effective Diffusivity

3.1.3. Activation Energy

3.2. Influence of Fluidizing Air Temperature Combined with Supply of Swirling Compressed Air

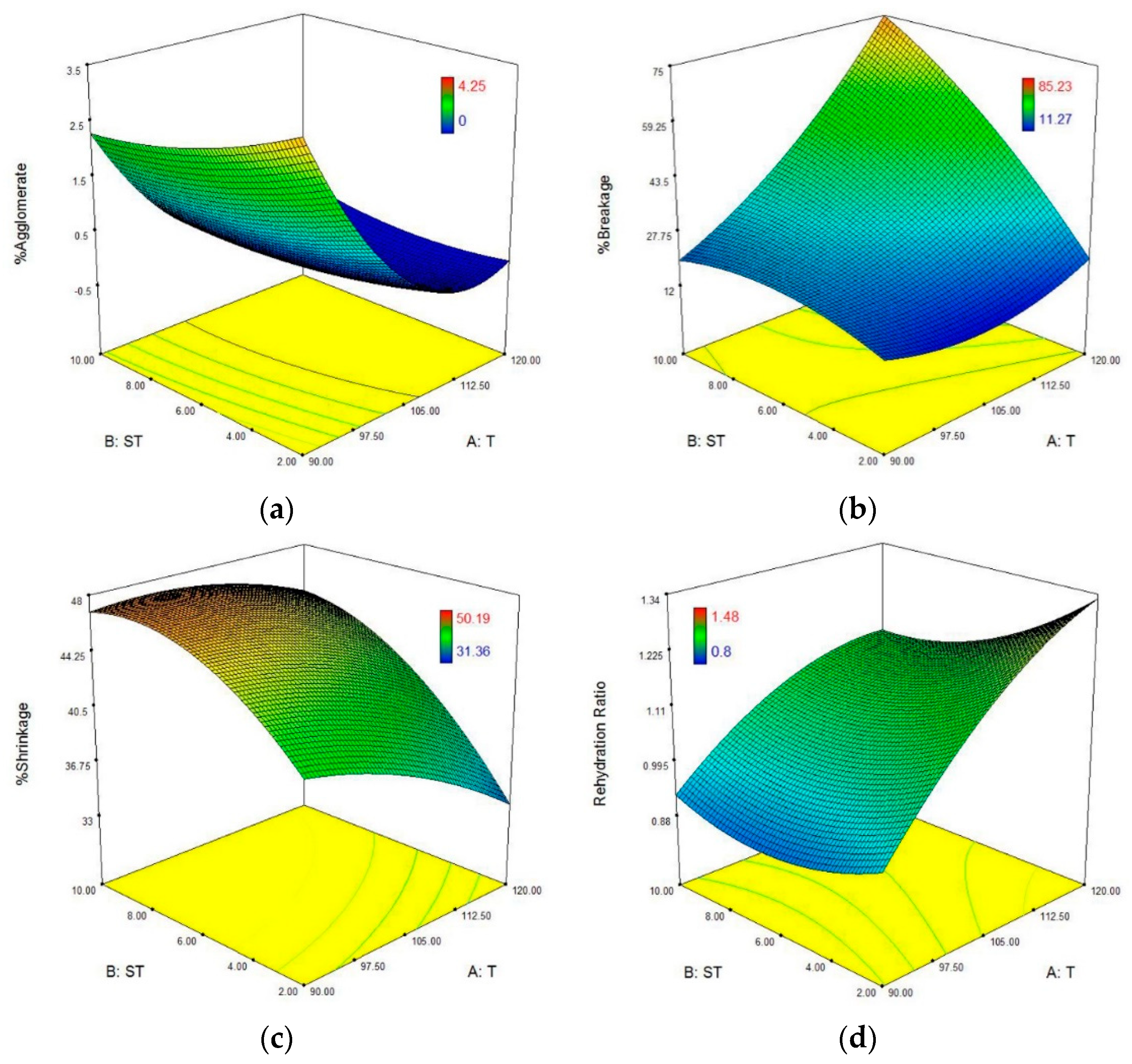

3.2.1. Physical Properties and Rehydration Ratio

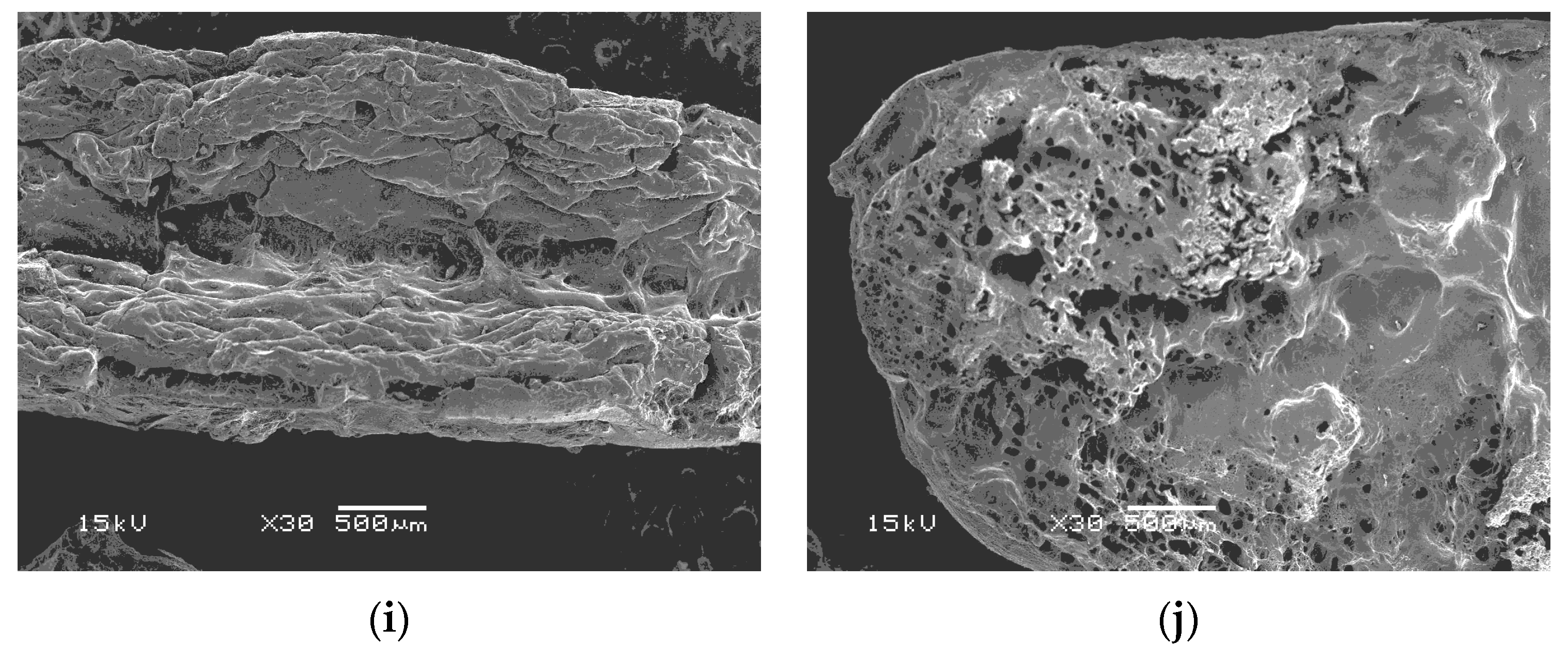

3.2.2. Antioxidant Properties

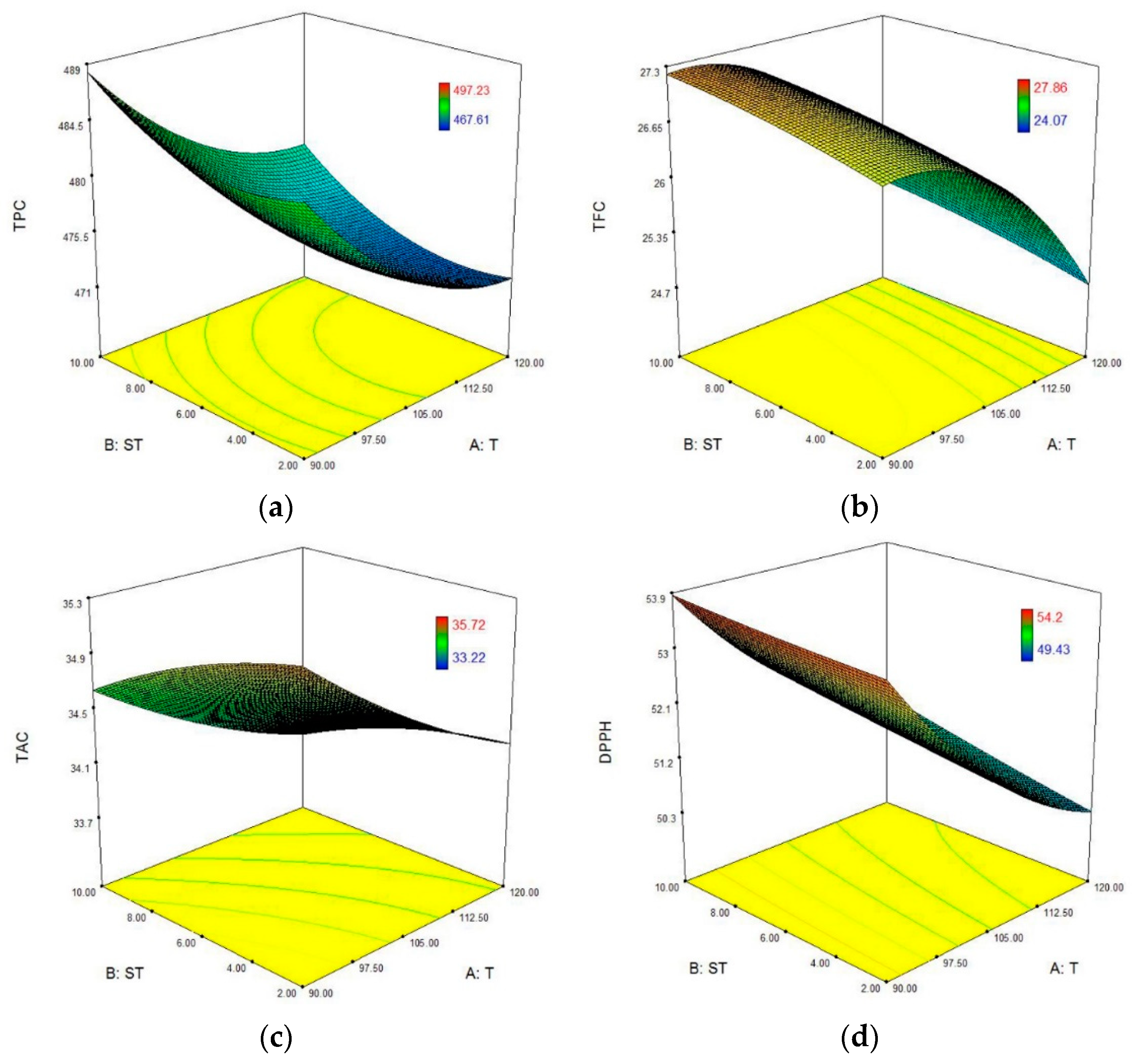

3.3. Optimization

3.4. Suitable Rehydration Condition

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, X.Q.; Nagao, N.; Itani, T.; Irifune, K. Anti-oxidative analysis, and identification and quantification of anthocyanin pigments in different colored rice. Food Chem. 2012, 135, 2783–2788. [Google Scholar] [CrossRef] [PubMed]

- Goufo, P.; Trindade, H. Rice antioxidant: Phenolic acids, flavonoids, anthocyanins, proanthocyanins, tocopherols, tocotrienols, γ-oryzanol, and phytic acid. Food Sci. Nutr. 2014, 2, 75–104. [Google Scholar] [CrossRef] [PubMed]

- Ratseewo, J.; Warren, F.J.; Siriamornpun, S. The influence of starch structure and anthocyanin content on the digestibility of Thai pigmented rice. Food Chem. 2019, 298, 124949. [Google Scholar] [CrossRef] [PubMed]

- Poosri, S.; Thilavech, T.; Pasukamonset, P.; Suparpprom, C.; Adisakwattana, S. Studies on riceberry rice (Oryza sativa L.) extract on the key steps related to carbohydrate and lipid digestion and absorption: A new source of natural bioactive substances. NFS J. 2019, 17, 17–23. [Google Scholar] [CrossRef]

- Chen, H.H. Investigation of properties of long-grain brown rice treated by low-pressure plasma. Food Bioprocess Tech. 2014, 7, 2484–2491. [Google Scholar] [CrossRef]

- Le, T.Q.; Jittanit, W. Optimization of operating process parameters for instant brown rice production with microwave-followed by convective hot air drying. J. Stored Prod. Res. 2015, 61, 1–8. [Google Scholar] [CrossRef]

- Prasert, W.; Suwannaporn, P. Optimization of instant jasmine rice process and its physicochemical properties. J. Food Eng. 2009, 95, 54–61. [Google Scholar] [CrossRef]

- Dutta, H.; Mahanta, C.L. Laboratory process development and physicochemical characterization of a low amylose and hydrothermally treated ready-to-eat rice product requiring no cooking. Food Bioprocess Tech. 2014, 7, 212–223. [Google Scholar] [CrossRef]

- Rewthong, O.; Soponronnarit, S.; Taechapairoj, C.; Tungtrakul, P.; Prachayawarakorn, S. Effects of cooking, drying and pretreatment methods on texture and starch digestibility of instant rice. J. Food Eng. 2011, 103, 258–264. [Google Scholar] [CrossRef]

- Pei, F.; Shi, Y.; Mariga, A.M.; Yang, W.-J.; Tang, X.-Z.; Zhao, L.-Y.; An, X.-X.; Hu, Q.-H. Comparison of freeze-drying and freeze-drying combined with microwave vacuum drying methods on drying kinetics and rehydration characteristics of button mushroom (Agaricus bisporus) slices. Food Bioprocess Tech. 2014, 7, 1629–1639. [Google Scholar] [CrossRef]

- Yu, L.; Turner, M.S.; Fitzgerald, M.; Stokes, J.R.; Witt, T. Review of the effects of different processing technologies on cooked and convenience rice quality. Trends Food Sci. Technol. 2017, 59, 124–138. [Google Scholar] [CrossRef] [Green Version]

- Luangmalawat, P.; Prachayawarakorn, S.; Nathakaranakule, A.; Soponronnarit, S. Effect of temperature on drying characteristics and quality of cooked rice. LWT 2008, 41, 716–723. [Google Scholar] [CrossRef]

- Le, T.Q.; Jittanit, W. Drying characteristics of cooked jasmine brown rice and true densities of dried products. Kasetsart J. (Nat. Sci.) 2012, 46, 256–271. [Google Scholar]

- Jiao, A.; Xu, X.; Jin, Z. Modelling of dehydration-rehydration of instant rice in combined microwave-hot air drying. Food Bioprod. Process. 2014, 92, 259–265. [Google Scholar] [CrossRef]

- Chen, X.; Qian, P.; Zhang, X.J.; Liu, F.N.; Lu, R.R. Improving instant rice quality by novel combined drying. Dry Technol. 2014, 32, 1448–1456. [Google Scholar] [CrossRef]

- Patil, S.B.; Khan, M.K. Germinated brown rice as a value added rice product: A review. J. Food Sci. Technol. 2011, 48, 661–667. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Das, M.; Banerjee, R.; Bal, S. Evaluation of physicochemical properties of enzyme treated brown rice (Part B). LWT 2008, 41, 2092–2096. [Google Scholar] [CrossRef]

- Das, M.; Gupta, S.; Kapoor, V.; Banerjee, R.; Bal, S. Enzymatic polishing of rice—a new processing technology. LWT 2008, 41, 2079–2084. [Google Scholar] [CrossRef]

- Gaewsondee, T.; Duangkhamchan, W. A novel process for preparing instant riceberry using fluidized bed drying assisted with swirling compressed-air: Kinetic aspects. Food Bioprocess Tech. 2019, 12, 1422–1434. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 16th ed.; Association of Official Agricultural Chemists: Washington, DC, USA, 1995. [Google Scholar]

- Zielinska, M.; Michalska, A. Microwave-assisted drying of blueberry (Vaccinium corrymbosum L.) fruit: Drying kinetics, polyphenols, anthocyanins, antioxidant capacity, color and texture. Food Chem. 2016, 212, 671–680. [Google Scholar] [CrossRef] [PubMed]

- Sutharut, J.; Sudarat, J. Total anthocyanin content and antioxidant activity of germinated colored rice. Int. Food Res. J. 2012, 19, 215–221. [Google Scholar]

- Martynenko, A.; Chen, Y. Degradation kinetics of total anthocyanins and formation of polymeric color in blueberry hydrothermodynamic (HTD) processing. J. Food Eng. 2016, 171, 44–51. [Google Scholar] [CrossRef]

- Butsat, S.; Siriamornpun, S. Antioxidant capacities and phenolic compounds of the husk, bran and endosperm of Thai rice. Food Chem. 2010, 119, 606–613. [Google Scholar] [CrossRef]

- Chang, C.C.; Yang, M.H.; Wen, H.M.; Chern, J.C. Estimation of total flavonoid content in propolis by two complementary colorimetric methods. J. Food Drug Anal. 2002, 10, 178–182. [Google Scholar] [CrossRef]

- Loypimai, P.; Moongngarm, A.; Chottanom, P. Effects of ohmic heating on lipase activity, bioactive compounds and antioxidant activity of rice bran. Aust. J. Basic Appl. Sci. 2009, 3, 3642–3652. [Google Scholar]

- Candioti, L.V.; de Zan, M.M.; Cámara, M.S.; Goicoechea, H.C. Experimental design and multiple response optimization. Using the desirability function in analytical methods development. Talanta 2014, 124, 123–138. [Google Scholar] [CrossRef] [PubMed]

- Onwude, D.I.; Hashim, N.; Janius, R.B.; Mat Nawi, N.; Abdan, K. Modeling the thin-layer drying of fruits and vegetables: A review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 599–618. [Google Scholar] [CrossRef]

- Ahn, J.; Sparrow, E.M.; Gorman, J.M. Turbulence intensity effects on heat transfer and fluid-flow for a circular cylinder in crossflow. Int. J. Heat Mass Transf. 2017, 113, 613–621. [Google Scholar] [CrossRef]

- Lee, J.M.; Lim, E.W.C. Heat transfer in a pulsating turbulent fluidized bed. Appl. Therm. Eng. 2020, 174, 115321. [Google Scholar] [CrossRef]

- Stefanova, A.; Bi, H.T.; Lim, C.J.; Grace, J.R. Heat transfer from immersed vertical tube in a fluidized bed of group A particles near the transition to the turbulent fluidization flow regime. Int. J. Heat Mass Transf. 2008, 51, 2020–2028. [Google Scholar] [CrossRef]

- Qiu, G.; Wang, D.; Song, X.; Deng, Y.; Zhao, Y. Degradation kinetics and antioxidant capacity of anthocyanins in air impingement jet dried purple potato slices. Food Res. Int. 2018, 105, 121–128. [Google Scholar] [CrossRef]

- Li, W.; Pang, X.; Xiao, J.; Wang, X.; He, R.; Zhao, X. Degradation kinetics of pelargonidin-3-(p-coumaroyl)diglucoside-5-(malonyl)glucoside and pelargonidin-3-(feruloyl)diglucoside-5-(malonyll)glucoside in red radish during air-impingement jet drying. LWT 2020, 127, 109390. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, G.; Li, X.; Zhao, Y.; Lei, D.; Ding, G.; Ambrose, K.; Liu, Y. Combined medium- and short-wave infrared and hot air impingement drying of sponge gourd (Luffa cylindrical) slices. J. Food Eng. 2020, 284, 110043. [Google Scholar] [CrossRef]

- Babalis, S.J.; Belessiotis, V.G. Influence of the drying conditions on the drying constants and moisture diffusivity during the thin layer drying of figs. J. Food Eng. 2004, 65, 449–458. [Google Scholar] [CrossRef]

- López-Vidaña, E.C.; Figueroa, I.P.; Cortés, F.B.; Rojano, B.A.; Ocaña, A.N. Effect of temperature on antioxidant capacity during drying process of mortiño (Vaccinium meridionale Swartz). Int. J. Food Prop. 2017, 20, 294–305. [Google Scholar] [CrossRef] [Green Version]

- Mirzaee, E.; Rafiee, S.; Keyhani, A.; Eman-Djomeh, Z. Determining of moisture diffusivity and activation energy in drying of apricots. Res. Agric. Eng. 2009, 55, 114–120. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez, Ó.; Santacatalina, J.V.; Simal, S.; Garcia-Perez, J.V.; Femenia, A.; Rosselló, C. Influence of power ultrasound application on drying kinetics of apple and its antioxidant and microstructural properties. J. Food Eng. 2014, 129, 21–29. [Google Scholar] [CrossRef]

- Demarchi, S.M.; Quintero Ruiz, N.A.; Concellón, A.; Ginera, S.A. Effect of temperature on hot-air drying rate and on retention of antioxidant capacity in apple leathers. Food Bioprod. Process. 2010, 91, 310–318. [Google Scholar] [CrossRef]

- Miranda, M.; Maureira, H.; Rodríguez, K.; Vega-Gálvez, A. Influence of temperature on the drying kinetics, physicochemical properties, and antioxidant capacity of Aloe Vera (Aloe Barbadensis Miller) gel. J. Food Eng. 2009, 91, 297–304. [Google Scholar] [CrossRef]

- Katsube, T.; Tsurunaga, Y.; Sugiyama, M.; Furuno, T.; Yamasaki, Y. Effect of air-drying temperature on antioxidant capacity and stability of polyphenolic compounds in mulberry (Morus Alba L.) leaves. Food Chem. 2009, 113, 964–969. [Google Scholar] [CrossRef]

- Kuljarachanan, T.; Devahastin, S.; Chiewchan, N. Evolution of antioxidant compounds in lime residues during drying. Food Chem. 2009, 113, 944–949. [Google Scholar] [CrossRef]

- López-Vidaña, E.C.; Rojano, B.; Pilatowsky, F.I.; Zapata, K.; Cortés, F. Evaluation of the sorption equilibrium and effect of drying temperature on the antioxidant capacity of the Jaboticaba (Myrciaria Cauliflora). Chem. Eng. Commun. 2016, 203, 809–821. [Google Scholar] [CrossRef]

- Piga, A.; Del Caro, A.; Corda, G. From plums to prunes: Influence of drying parameters on polyphenols and antioxidant activity. J. Agric. Food Chem. 2003, 51, 3675–3681. [Google Scholar] [CrossRef]

- Walter, M.; Marchesan, E.; Massoni, P.F.S.; da Silva, L.P.; Sartori, G.M.S.; Ferreira, R.B. Antioxidant properties of rice grains with light brown, red, and black pericarp colors and the effect of processing. Food Res. Int. 2013, 50, 698–703. [Google Scholar] [CrossRef] [Green Version]

- Nowak, D.; Jakubczyk, E. The freeze-drying of foods—The characteristic of the process course and the effect of its parameters on the physical properties of food materials. Foods 2020, 9, 1488. [Google Scholar] [CrossRef]

- Shofian, N.M.; Hamid, A.A.; Osman, A.; Saari, N.; Anwar, F.; Dek, M.S.P.; Hairuddin, M.R. Effect of freeze-drying on the antioxidant compounds and antioxidant activity of selected tropical fruits. Int. J. Mol. Sci. 2011, 12, 4678–4692. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ratseewo, J.; Meeso, N.; Siriamornpun, S. Changes in amino acids and bioactive compounds of pigmented rice as affected by far-infrared radiation and hot air drying. Food Chem. 2020, 306, 125644. [Google Scholar] [CrossRef]

- Wanyo, P.; Meeso, N.; Siriamornpun, S. Effects of different treatments on the antioxidant properties and phenolic compounds of rice bran and rice husk. Food Chem. 2014, 157, 457–463. [Google Scholar] [CrossRef]

- Wanyo, P.; Siriamornpun, S.; Meeso, N. Improvement of quality and antioxidant properties of dried mulberry leaves with combined far-infrared radiation and air convection in Thai tea process. Food Bioprod Process 2011, 89, 22–30. [Google Scholar] [CrossRef]

- Chen, Y.; Martynenko, A. Combination of hydrothermodynamic (HTD) processing and different drying methods for natural blueberry leather. LWT 2018, 87, 470–477. [Google Scholar] [CrossRef]

| Variable | Unit | Coded Values and Ranges | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| x1: fluidizing air temperature | °C | 90 | 105 | 120 |

| x2: swirling air supply time | min | 2 | 6 | 10 |

| SCAP (bar) | FAT (°C) | k | n | Deff (×10−8 m2s−1) | Ea (kJ mol−1) |

|---|---|---|---|---|---|

| 4 | 90 | 0.10248 ± 0.00175 de | 0.83519 ± 0.00812cd | 3.25 ± 0.16 de | 15.45 ± 0.17 ns |

| 105 | 0.11983 ± 0.00651 c | 0.86152 ± 0.01815 bc | 4.22 ± 0.53 bc | ||

| 120 | 0.13104 ± 0.00242 bc | 0.87113 ± 0.00618 ab | 4.79 ± 0.21 bc | ||

| 5 | 90 | 0.09745 ± 0.00246 e | 0.82108 ± 0.00723 d | 2.92 ± 0.16 e | 13.66 ± 2.28 ns |

| 105 | 0.10887 ± 0.00693 d | 0.86671 ± 0.01079 ab | 3.91 ± 0.42 cd | ||

| 120 | 0.12217 ± 0.00639 c | 0.85033 ± 0.01475 bc | 4.11 ± 0.45 bcd | ||

| 6 | 90 | 0.12511 ± 0.00748 bc | 0.84925 ± 0.01741 bc | 4.19 ± 0.54 bc | 13.81 ± 0.17 ns |

| 105 | 0.13544 ± 0.00815 b | 0.87502 ± 0.02087 ab | 5.03 ± 0.72 b | ||

| 120 | 0.15072 ± 0.00784 a | 0.89014 ± 0.02048 a | 5.94 ± 0.79 a |

| Conditions | Model Parameters | Predicted Drying Time (min) | Actual Drying Time (min) | MC (%wb) | %Error | ||

|---|---|---|---|---|---|---|---|

| FAT (°C) | SCAP (bar) | k | n | ||||

| 90 | 4 | 0.10349 | 0.83464 | 28.98 | 29 | 11.21 ± 0.93 | 10.79 |

| 98 | 4.5 | 0.10231 | 0.84541 | 28.51 | 28.5 | 13.11 ± 1.02 | 23.72 |

| 105 | 5 | 0.10889 | 0.85610 | 25.59 | 26 | 12.46 ± 1.32 | 19.74 |

| 113 | 5.5 | 0.12501 | 0.86993 | 20.92 | 21 | 12.75 ± 2.19 | 21.57 |

| 120 | 6 | 0.14893 | 0.88558 | 15.85 | 16 | 11.58 ± 1.22 | 13.64 |

| No. | X1 | X2 | Percentage Agglomerate | Percentage Breakage | Percentage Shrinkage | Rehydration Ratio |

|---|---|---|---|---|---|---|

| 1 | 90 | 2 | 3.67 | 17.33 | 42.00 | 0.92 |

| 2 | 90 | 6 | 2.33 | 18.33 | 44.67 | 0.94 |

| 3 | 90 | 10 | 2.33 | 24.00 | 47.67 | 0.90 |

| 4 | 105 | 2 | 0.00 | 18.67 | 37.67 | 1.21 |

| 5 | 105 | 6 | 0.00 | 26.67 | 46.33 | 1.08 |

| 6 | 105 | 10 | 0.00 | 39.33 | 46.33 | 1.09 |

| 7 | 120 | 2 | 0.00 | 13.00 | 33.67 | 1.35 |

| 8 | 120 | 6 | 0.00 | 62.33 | 42.00 | 1.14 |

| 9 | 120 | 10 | 0.00 | 72.00 | 44.33 | 1.17 |

| Source | Estimated Coefficient | |||

|---|---|---|---|---|

| Percentage Agglomerate | Percentage Breakage | Percentage Shrinkage | Rehydration Ratio | |

| Intercept | ||||

| (a0) | −0.15 | 31.59 | 45.04 | 1.09 |

| Linear terms | ||||

| (a1) X1 | −1.39 a | 14.61 a | −2.39 a | 0.15 a |

| (a2) X2 | −0.22 ns | 14.39 a | 4.17 a | 0.053 b |

| Interaction terms | ||||

| (a12) X1X2 | 0.34 ns | 13.08 a | 1.25 ns | 0.040 ns |

| Quadratic terms | ||||

| (a11) | 1.39 a | 6.27 ns | −1.05 ns | −0.057 ns |

| (a11) | 0.22 ns | −5.05 ns | −2.39 b | 0.053 ns |

| Lack-of-fit (p value) | 0.3976 ns | 0.0026 a | 0.2375 ns | 0.5095 ns |

| Model (p value) | <0.0001 a | <0.0001 a | <0.0001 a | <0.0001 a |

| F value | ||||

| X1 | 102.98 | 54.11 | 20.48 | 42.20 |

| X2 | 2.66 | 52.47 | 62.21 | 5.34 |

| X1X2 | 4.00 | 28.92 | 3.72 | 2.00 |

| 34.33 | 3.33 | 1.33 | 2.01 | |

| 0.89 | 2.16 | 6.82 | 1.78 | |

| R2 | 0.8734 | 0.8704 | 0.8183 | 0.7175 |

| Adj.R2 | 0.8432 | 0.8395 | 0.7750 | 0.6502 |

| Predicted R2 | 0.7725 | 0.7841 | 0.6921 | 0.5417 |

| C.V. (%) | 62.72 | 26.00 | 5.24 | 9.00 |

| Std. Dev. | 0.58 | 8.43 | 2.24 | 0.098 |

| No. | X1 | X2 | TPC | TFC | TAC | DPPH |

|---|---|---|---|---|---|---|

| 1 | 90 | 2 | 483.26 | 26.73 | 35.24 | 53.71 |

| 2 | 90 | 6 | 484.95 | 27.18 | 35.22 | 53.75 |

| 3 | 90 | 10 | 488.07 | 27.11 | 34.52 | 53.73 |

| 4 | 105 | 2 | 475.55 | 26.29 | 34.68 | 51.19 |

| 5 | 105 | 6 | 474.81 | 26.67 | 34.35 | 51.81 |

| 6 | 105 | 10 | 479.60 | 26.86 | 34.29 | 52.21 |

| 7 | 120 | 2 | 471.97 | 24.85 | 34.31 | 50.50 |

| 8 | 120 | 6 | 471.22 | 24.84 | 34.08 | 50.58 |

| 9 | 120 | 10 | 478.06 | 25.22 | 33.76 | 51.09 |

| Cooked sample | 530.30 | 35.10 | 58.23 | 62.58 | ||

| FD sample | 515.82 | 31.75 | 55.16 | 60.50 | ||

| Source | Estimated Coefficient | |||

|---|---|---|---|---|

| TPC | TFC | TAC | DPPH | |

| Intercept | ||||

| (a0) | 475.04 | 26.64 | 34.50 | 51.72 |

| Linear terms | ||||

| (a1) X1 | −5.84 a | −1.02 a | −0.47 a | −1.50 a |

| (a2) X2 | 2.49 ns | 0.22 ns | −0.28 b | 0.27 ns |

| Interaction terms | ||||

| (a12) X1X2 | 0.32 ns | −0.002 ns | 0.043 ns | 0.14 ns |

| Quadratic terms | ||||

| (a11) | 2.94 ns | −0.62 b | 0.082 ns | 0.49 ns |

| (a11) | 2.43 ns | −0.053 ns | −0.083 ns | 0.025 ns |

| Lack-of-fit (p value) | 0.9452 ns | 0.8650 ns | 0.6877 ns | 0.7101 ns |

| Model (p value) | 0.0016 a | 0.0001 a | 0.0012 a | 0.0001 a |

| F value | ||||

| X1 | 21.99 | 61.03 | 22.25 | 98.21 |

| X2 | 4.00 | 2.85 | 7.66 | 3.21 |

| X1X2 | 0.044 | 0.000 | 0.12 | 0.59 |

| 1.85 | 7.50 | 0.22 | 3.48 | |

| 1.26 | 0.056 | 0.23 | 0.009 | |

| R2 | 0.5813 | 0.7728 | 0.5921 | 0.8340 |

| Adj.R2 | 0.4816 | 0.7187 | 0.4950 | 0.7945 |

| Predicted R2 | 0.2928 | 0.6095 | 0.3246 | 0.7177 |

| C.V. (%) | 1.10 | 2.11 | 1.23 | 1.24 |

| Std. Dev. | 5.28 | 0.55 | 0.42 | 0.64 |

| T | ST | %Agglo | %Broke | %Shrink | RR | TPC | TFC | TAC | DPPH | Desirability |

|---|---|---|---|---|---|---|---|---|---|---|

| 98.48 | 2 | 1.31 | 12.67 | 39.86 | 1.10 | 478.20 | 26.69 | 34.93 | 52.28 | 0.603 |

| 98.48 | 2 | 1.36 | 12.74 | 39.91 | 1.10 | 478.35 | 26.70 | 34.94 | 52.31 | 0.603 |

| 98.48 | 2 | 1.18 | 12.51 | 39.74 | 1.11 | 478.83 | 26.67 | 34.90 | 52.19 | 0.603 |

| 102.75 | 2 | 0.59 | 12.06 | 39.00 | 1.17 | 475.96 | 26.51 | 34.77 | 51.73 | 0.593 |

| 94.71 | 10 | 1.23 | 24.88 | 47.10 | 0.99 | 485.12 | 27.22 | 34.47 | 53.18 | 0.532 |

| Temperature (°C) | Rehydration Time (min) | Mean Force (kg) | Mean Extrusion Force (kg cm−2) |

|---|---|---|---|

| 70 | 5 | 22.12 ± 3.25 a | 2.95 ± 0.43 a |

| 10 | 13.18 ± 0.79 c | 1.76 ± 0.10 c | |

| 15 | 9.77 ± 1.28 d | 1.30 ± 0.17 d | |

| 100 | 5 | 12.77 ± 0.22 c | 1.71 ± 0.03 c |

| 10 | 9.11 ± 0.41 de | 1.21 ± 0.06 de | |

| 15 | 7.37 ± 0.45 ef | 0.98 ± 0.06 ef | |

| Control | 16.42 ± 0.36 b | 2.19 ± 0.04 b | |

| Freeze-dried sample | 6.60 ± 0.23 f | 0.88 ± 0.03 f | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chupawa, P.; Gaewsondee, T.; Duangkhamchan, W. Drying Characteristics and Quality Attributes Affected by a Fluidized-Bed Drying Assisted with Swirling Compressed-Air for Preparing Instant Red Jasmine Rice. Processes 2021, 9, 1738. https://doi.org/10.3390/pr9101738

Chupawa P, Gaewsondee T, Duangkhamchan W. Drying Characteristics and Quality Attributes Affected by a Fluidized-Bed Drying Assisted with Swirling Compressed-Air for Preparing Instant Red Jasmine Rice. Processes. 2021; 9(10):1738. https://doi.org/10.3390/pr9101738

Chicago/Turabian StyleChupawa, Prarin, Tiwanat Gaewsondee, and Wasan Duangkhamchan. 2021. "Drying Characteristics and Quality Attributes Affected by a Fluidized-Bed Drying Assisted with Swirling Compressed-Air for Preparing Instant Red Jasmine Rice" Processes 9, no. 10: 1738. https://doi.org/10.3390/pr9101738

APA StyleChupawa, P., Gaewsondee, T., & Duangkhamchan, W. (2021). Drying Characteristics and Quality Attributes Affected by a Fluidized-Bed Drying Assisted with Swirling Compressed-Air for Preparing Instant Red Jasmine Rice. Processes, 9(10), 1738. https://doi.org/10.3390/pr9101738