Techno-Economic Evaluation of Biorefineries Based on Low-Value Feedstocks Using the BioSTEAM Software: A Case Study for Animal Bedding

Abstract

1. Introduction

2. Materials and Methods

2.1. Modelling the Wheat Straw Biorefinery

2.1.1. Pretreatment System

2.1.2. Hydrolysis and Fermentation System

2.1.3. Ethanol Purification System

2.1.4. Anaerobic Digestion System

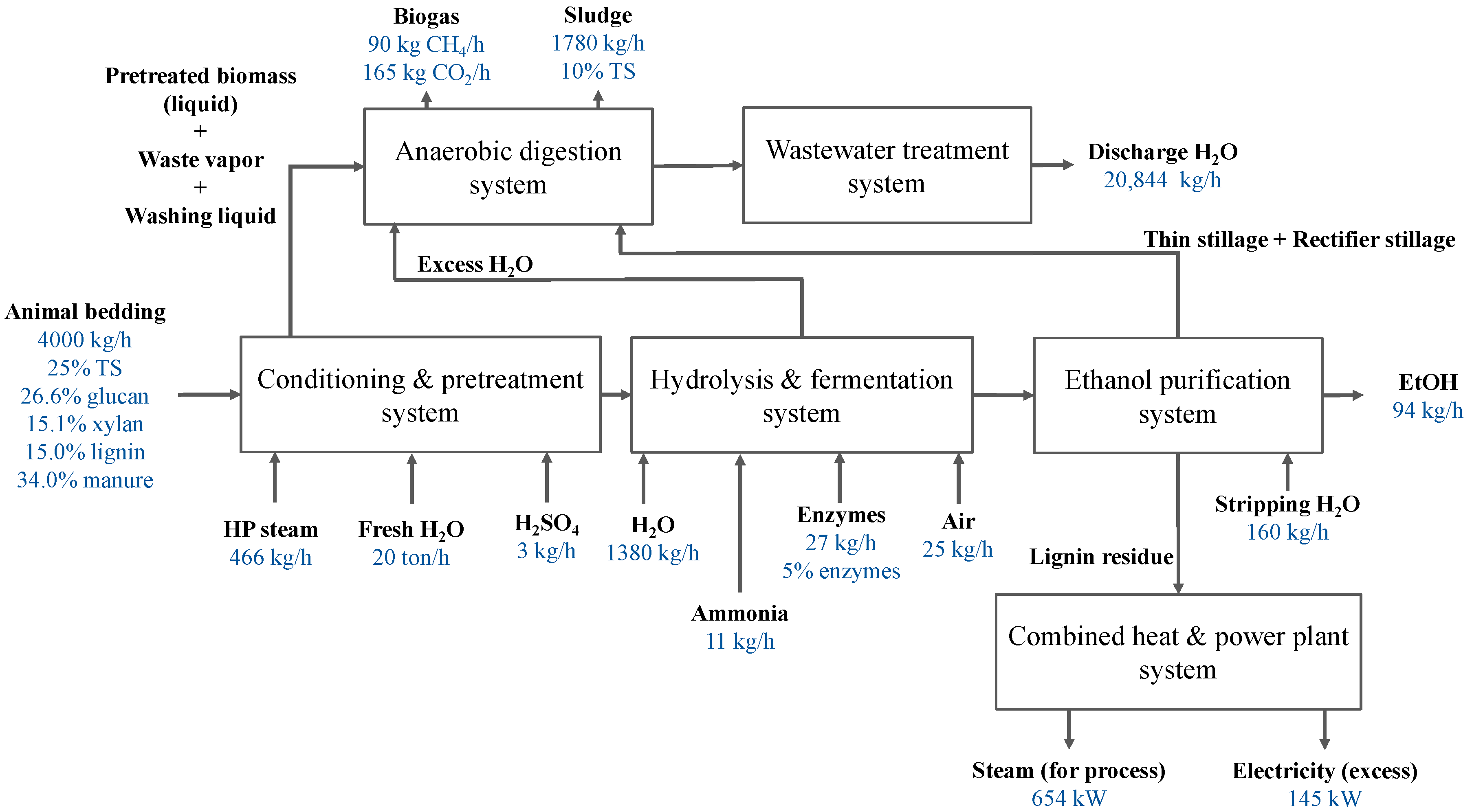

2.2. Modelling the Animal Bedding Biorefinery

Conditioning and Pretreatment System

2.3. Economic Estimations

3. Results and Discussion

3.1. Simulation of the Wheat Straw Biorefinery

3.2. Simulation of the Animal Bedding Biorefinery

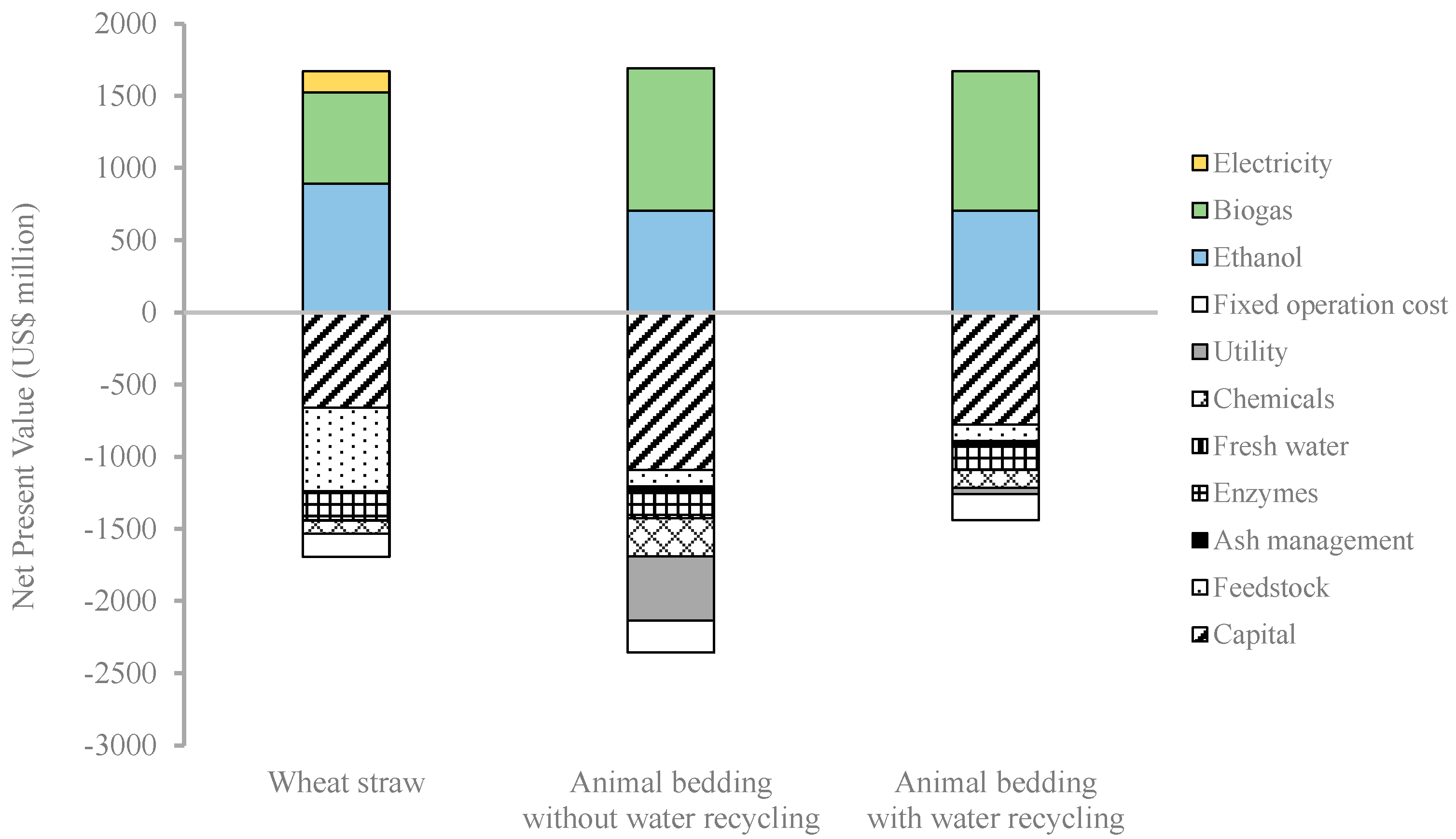

3.3. Techno-Economic Feasibility

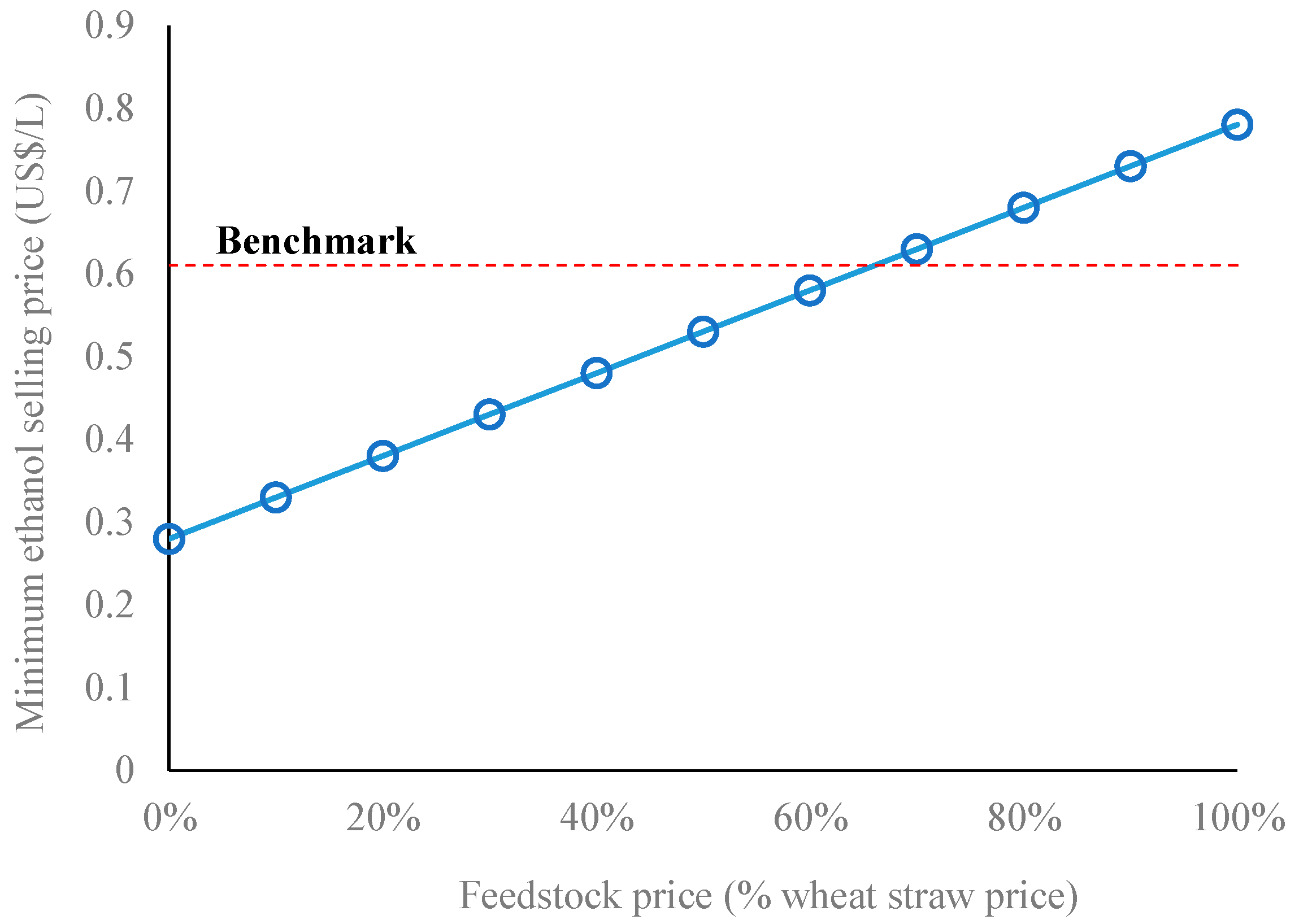

Sensitivity Analyses

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- International Energy Agency (IEA); International Renewable Energy Agency (IRENA). Executive Summary of Perspectives for the Energy Transition—Investment Needs for a Low-Carbon Energy System. 2017. Available online: https://www.irena.org/publications/2017/Mar/Perspectives-for-the-energy-transition-Investment-needs-for-a-low-carbon-energy-system (accessed on 20 April 2017).

- International Energy Agency (IEA). Technology Roadmap—Delivering Sustainable Bioenergy. 2017. Available online: http://www.iea.org/publications/freepublications/publication/Technology_Roadmap_Delivering_Sustainable_Bioenergy.pdf (accessed on 18 January 2018).

- Sub Group on Advanced Biofuels. Building up the Future. The Cost of Biofuels; MI-06-17-107-EN-N. 2017. Available online: https://publications.europa.eu/en/publication-detail/-/publication/13e27082-67a2-11e8-ab9c-01aa75ed71a1/language-en/format-PDF (accessed on 27 June 2018).

- International Energy Agency (IEA). Advanced Biofuels—Potential for Cost Reduction. 2020. Available online: https://www.ieabioenergy.com/wp-content/uploads/2020/02/T41_CostReductionBiofuels-11_02_19-final.pdf (accessed on 13 March 2020).

- Dabe, S.J.; Prasad, P.J.; Vaidya, A.N.; Purohit, H.J. Technological pathways for bioenergy generation from municipal solid waste: Renewable energy option. Environ. Prog. Sustain. Energy 2018, 38, 654–671. [Google Scholar] [CrossRef]

- Uçkun Kiran, E.; Trzcinski, A.P.; Ng, W.J.; Liu, Y. Bioconversion of food waste to energy: A review. Fuel 2014, 134, 389–399. [Google Scholar] [CrossRef]

- Sagastume Gutiérrez, A.; Cabello Eras, J.J.; Hens, L.; Vandecasteele, C. The energy potential of agriculture, agroindustrial, livestock, and slaughterhouse biomass wastes through direct combustion and anaerobic digestion. The case of Colombia. J. Clean. Prod. 2020, 269. [Google Scholar] [CrossRef]

- Bakraoui, M.; Hazzi, M.; Karouach, F.; Ouhammou, B.; El Bari, H. Experimental biogas production from recycled pulp and paper wastewater by biofilm technology. Biotechnol. Lett. 2019, 41, 1299–1307. [Google Scholar] [CrossRef]

- Tomás-Pejó, E.; Fermoso, J.; Herrador, E.; Hernando, H.; Jiménez-Sánchez, S.; Ballesteros, M.; González-Fernández, C.; Serrano, D.P. Valorization of steam-exploded wheat straw through a biorefinery approach: Bioethanol and bio-oil co-production. Fuel 2017, 199, 403–412. [Google Scholar] [CrossRef]

- Larsen, J.; Østergaard Petersen, M.; Thirup, L.; Wen Li, H.; Krogh Iversen, F. The IBUS Process—Lignocellulosic Bioethanol Close to a Commercial Reality. Chem. Eng. Technol. 2008, 31, 765–772. [Google Scholar] [CrossRef]

- Vancov, T.; Schneider, R.C.; Palmer, J.; McIntosh, S.; Stuetz, R. Potential use of feedlot cattle manure for bioethanol production. Bioresour. Technol. 2015, 183, 120–128. [Google Scholar] [CrossRef] [PubMed]

- Yue, Z.; Teater, C.; Liu, Y.; Maclellan, J.; Liao, W. A sustainable pathway of cellulosic ethanol production integrating anaerobic digestion with biorefining. Biotechnol. Bioeng. 2010, 105, 1031–1039. [Google Scholar] [CrossRef] [PubMed]

- You, Y.; Liu, S.; Wu, B.; Wang, Y.-W.; Zhu, Q.-L.; Qin, H.; Tan, F.-R.; Ruan, Z.-Y.; Ma, K.-D.; Dai, L.-C.; et al. Bio-ethanol production by Zymomonas mobilis using pretreated dairy manure as a carbon and nitrogen source. RSC Adv. 2017, 7, 3768–3779. [Google Scholar] [CrossRef]

- Sanchis-Sebastiá, M.; Erdei, B.; Kovacs, K.; Galbe, M.; Wallberg, O. Introducing low-quality feedstocks in bioethanol production: Efficient conversion of the lignocellulose fraction of animal bedding through steam pretreatment. Biotechnol. Biofuels 2019, 12, 215. [Google Scholar] [CrossRef]

- Ballesteros, M.; Sáez, F.; Ballesteros, I.; Manzanares, P.; Negro, M.J.; Martínez, J.M.; Castañeda, R.; Oliva Dominguez, J.M. Ethanol Production from the Organic Fraction Obtained After Thermal Pretreatment of Municipal Solid Waste. Appl. Biochem. Biotechnol. 2010, 161, 423–431. [Google Scholar] [CrossRef] [PubMed]

- Hasanzadeh, E.; Mirmohamadsadeghi, S.; Karimi, K. Enhancing energy production from waste textile by hydrolysis of synthetic parts. Fuel 2018, 218, 41–48. [Google Scholar] [CrossRef]

- Cortes-Peña, Y. BioSTEAM: The Biorefinery Simulation and Techno-Economic Analysis Modules. Available online: https://github.com/yoelcortes/biosteam (accessed on 17 January 2020).

- Cortes-Peña, Y.; Guest, J.S. Documentation for BioSTEAM: The Biorefinery Simulation and Techno-Economic Analysis Modules. Available online: https://biosteam.readthedocs.io/en/latest (accessed on 17 January 2020).

- Cortes-Peña, Y. Bioindustrial-Park: BioSTEAM’s Premier Repository for Biorefinery Models and Results. Available online: https://github.com/yoelcortes/Bioindustrial-Park (accessed on 17 January 2020).

- Erdei, B.; Hancz, D.; Galbe, M.; Zacchi, G. SSF of steam-pretreated wheat straw with the addition of saccharified or fermented wheat meal in integrated bioethanol production. Biotechnol. Biofuels 2013, 6, 169. [Google Scholar] [CrossRef] [PubMed]

- Joelsson, E.; Dienes, D.; Kovacs, K.; Galbe, M.; Wallberg, O. Combined production of biogas and ethanol at high solids loading from wheat straw impregnated with acetic acid: Experimental study and techno-economic evaluation. Sustain. Chem. Process. 2016, 4, 14. [Google Scholar] [CrossRef]

- Ballesteros, I.; Negro, M.J.; Oliva, J.M.; Cabanas, A.; Manzanares, P.; Ballesteros, M. Ethanol production from steam-explosion pretreated wheat straw. Appl. Biochem. Biotechnol. 2006, 130, 496–508. [Google Scholar] [CrossRef]

- Bauer, A.; Bosch, P.; Friedl, A.; Amon, T. Analysis of methane potentials of steam-exploded wheat straw and estimation of energy yields of combined ethanol and methane production. J. Biotechnol. 2009, 142, 50–55. [Google Scholar] [CrossRef]

- Victorin, M.; Sanchis-Sebastiá, M.; Davidsson, Å.; Wallberg, O. Production of Biofuels from Animal Bedding: Biogas or Bioethanol? Influence of Feedstock Composition on the Process Layout. Ind. Eng. Chem. Res. 2019, 58, 21927–21935. [Google Scholar] [CrossRef]

- Seider, W.D.; Lewin, D.R.; Seader, J.D.; Widagdo, S.; Gani, R.; Ng, K.M. Product and Process Design Principles: Synthesis, Analysis, and Evaluation, 4th ed.; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar]

- Humbird, D.; Davis, R.; Tao, L.; Kinchin, C.; Hsu, D.; Aden, A.; Schoen, P.; Lukas, J.; Olthof, B.; Worley, M.; et al. Process Design and Economics for Biochemical Conversion of Lignocellulosic Biomass to Ethanol; NREL/TP-5100-47764; National Renewable Energy Laboratory: Golden, CO, USA, 2011. [Google Scholar]

- Smith, R. Chemical Process: Design and Integration, 2nd ed.; Wiley: Chichester, UK, 2005. [Google Scholar]

- Bauer, F.; Hulteberg, C.; Persson, T.; Daniel, T. Biogas Upgrading—Review of Commercial Technologies; SGC Rapport 2013:270; SGC Rapport: Malmö, Sweden, 2013. [Google Scholar]

- Cortes-Peña, Y.; Kumar, D.; Singh, V.; Guest, J.S. BioSTEAM: A Fast and Flexible Platform for the Design, Simulation, and Techno-Economic Analysis of Biorefineries under Uncertainty. ACS Sustain. Chem. Eng. 2020, 8, 3302–3310. [Google Scholar] [CrossRef]

- Balan, V. Current Challenges in Commercially Producing Biofuels from Lignocellulosic Biomass. ISRN Biotechnol. 2014, 2014, 463074. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. All biomass is local: The cost, volume produced, and global warming impact of cellulosic biofuels depend strongly on logistics and local conditions. Biofuels Bioprod. Biorefin. 2015, 9, 422–434. [Google Scholar] [CrossRef]

- Liao, W.; Liu, Y.; Liu, C.; Chen, S. Optimizing dilute acid hydrolysis of hemicellulose in a nitrogen-rich cellulosic material—Dairy manure. Bioresour. Technol. 2004, 94, 33–41. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanchis-Sebastiá, M.; Gomis-Fons, J.; Galbe, M.; Wallberg, O. Techno-Economic Evaluation of Biorefineries Based on Low-Value Feedstocks Using the BioSTEAM Software: A Case Study for Animal Bedding. Processes 2020, 8, 904. https://doi.org/10.3390/pr8080904

Sanchis-Sebastiá M, Gomis-Fons J, Galbe M, Wallberg O. Techno-Economic Evaluation of Biorefineries Based on Low-Value Feedstocks Using the BioSTEAM Software: A Case Study for Animal Bedding. Processes. 2020; 8(8):904. https://doi.org/10.3390/pr8080904

Chicago/Turabian StyleSanchis-Sebastiá, Miguel, Joaquín Gomis-Fons, Mats Galbe, and Ola Wallberg. 2020. "Techno-Economic Evaluation of Biorefineries Based on Low-Value Feedstocks Using the BioSTEAM Software: A Case Study for Animal Bedding" Processes 8, no. 8: 904. https://doi.org/10.3390/pr8080904

APA StyleSanchis-Sebastiá, M., Gomis-Fons, J., Galbe, M., & Wallberg, O. (2020). Techno-Economic Evaluation of Biorefineries Based on Low-Value Feedstocks Using the BioSTEAM Software: A Case Study for Animal Bedding. Processes, 8(8), 904. https://doi.org/10.3390/pr8080904