Mode-Based Analysis and Optimal Operation of MSF Desalination System

Abstract

1. Introduction

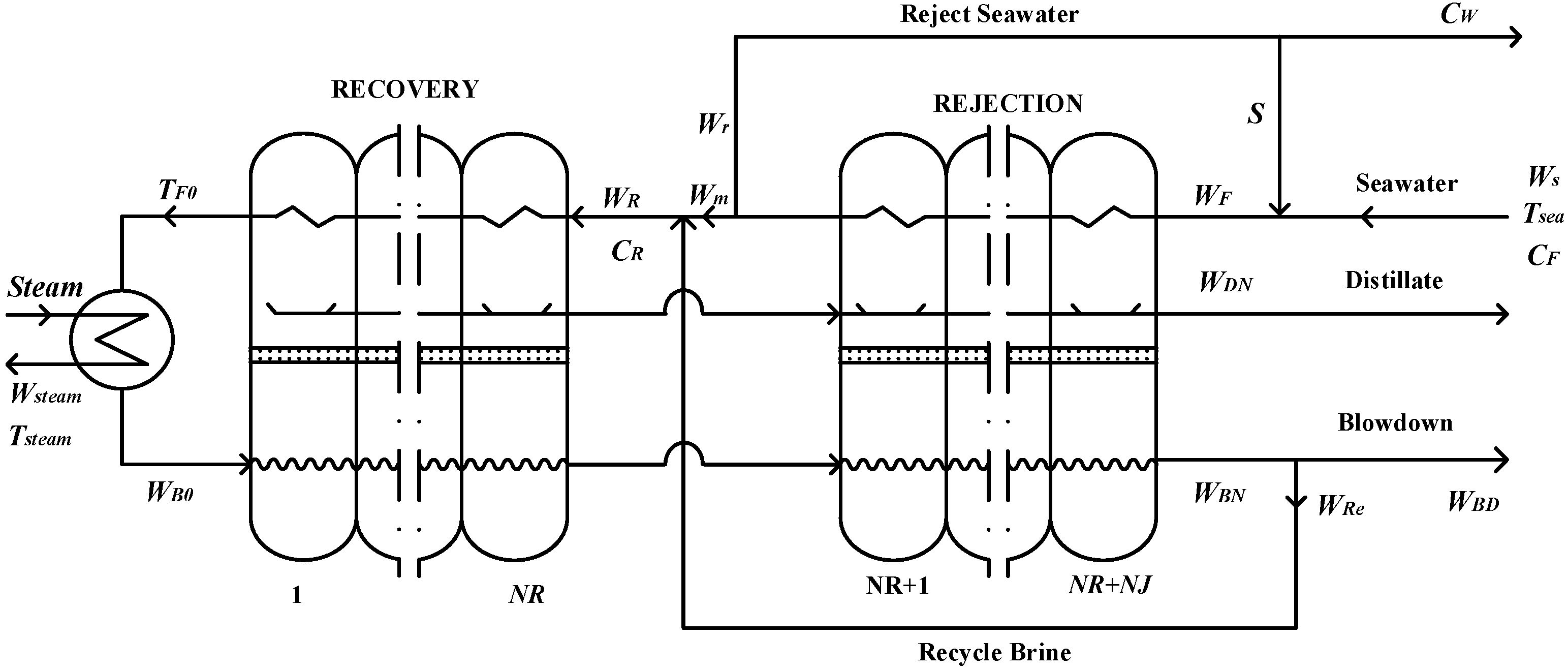

2. Flowsheet of Multi-Stage Flash (MSF) Process

3. Mathematical Model of MSF Process

- (1)

- The distillate from whatever stage is salt free;

- (2)

- Non-condensable gases are ignored;

- (3)

- The system is adiabatic.

3.1. Flash Chamber Module

3.2. Brine Heater

3.3. Splitters and Mixers Module

3.4. Physical Parameter Equations

4. Simulation and Analysis

4.1. Steady-State Simulation of MSF Desalination System

4.2. Analysis of MSF Desalination System

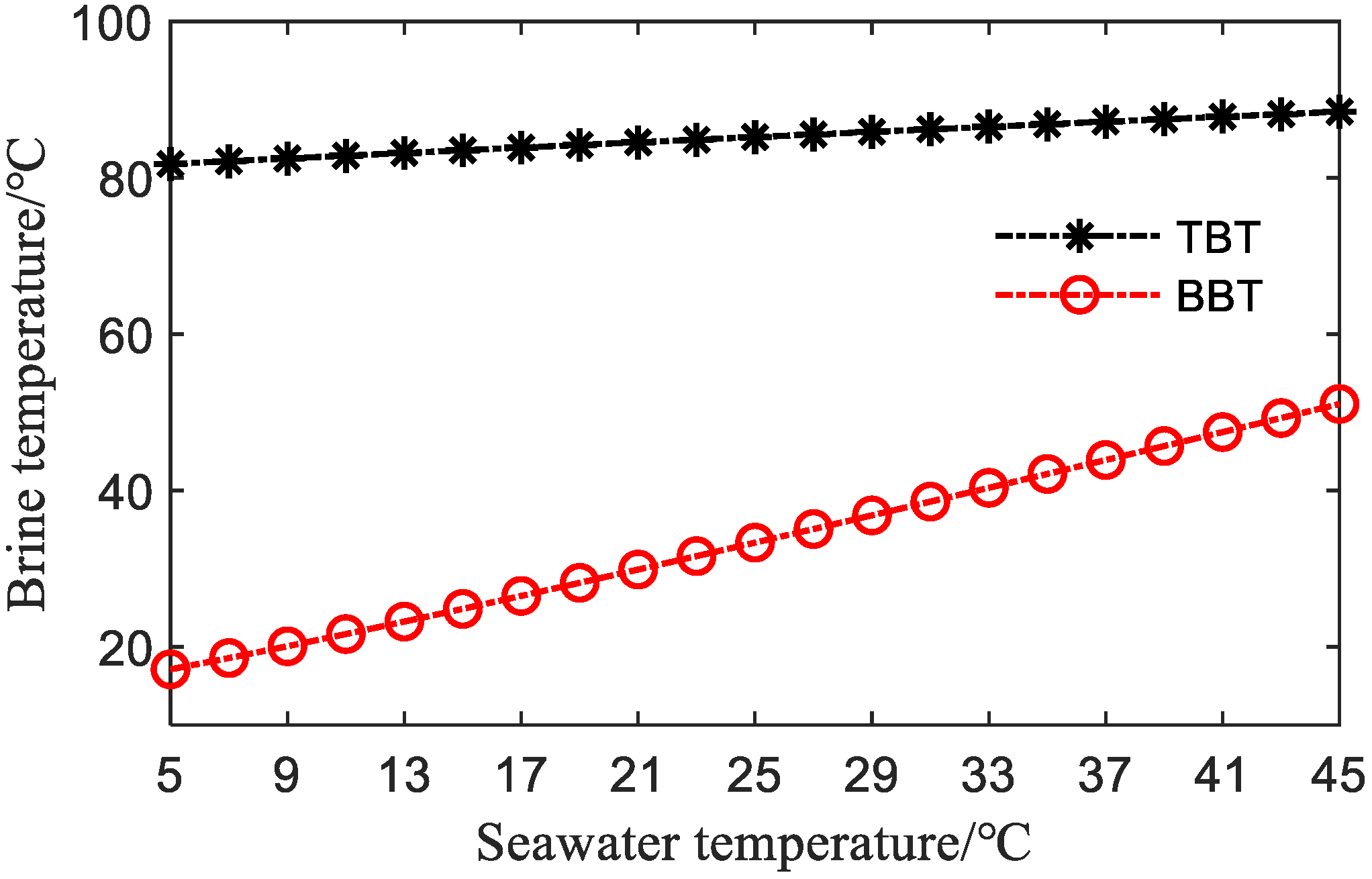

4.2.1. Effect of Seawater Temperature on System Performance

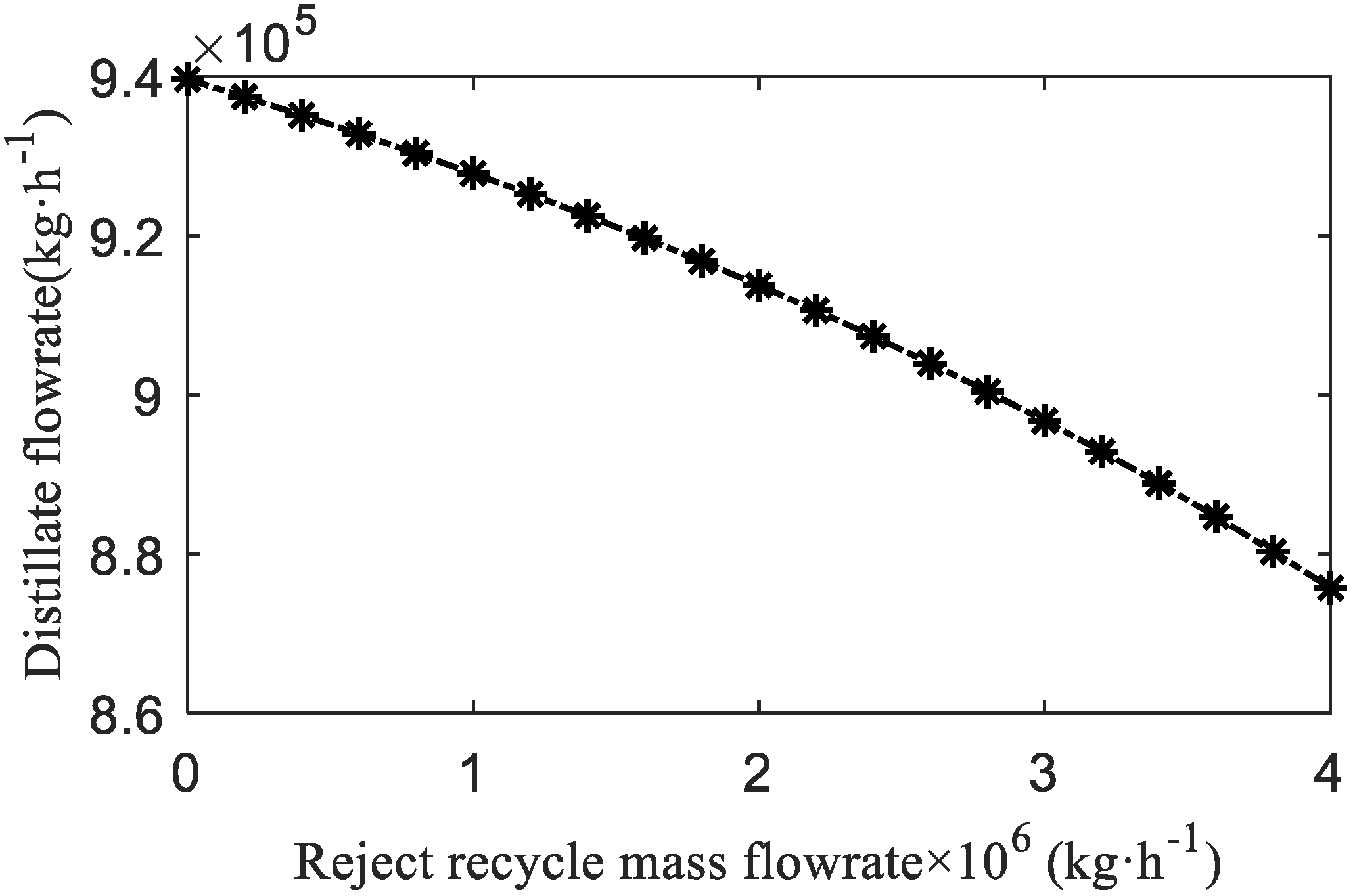

4.2.2. Effect of Reject Recycle Mass Flowrate () on System Performance

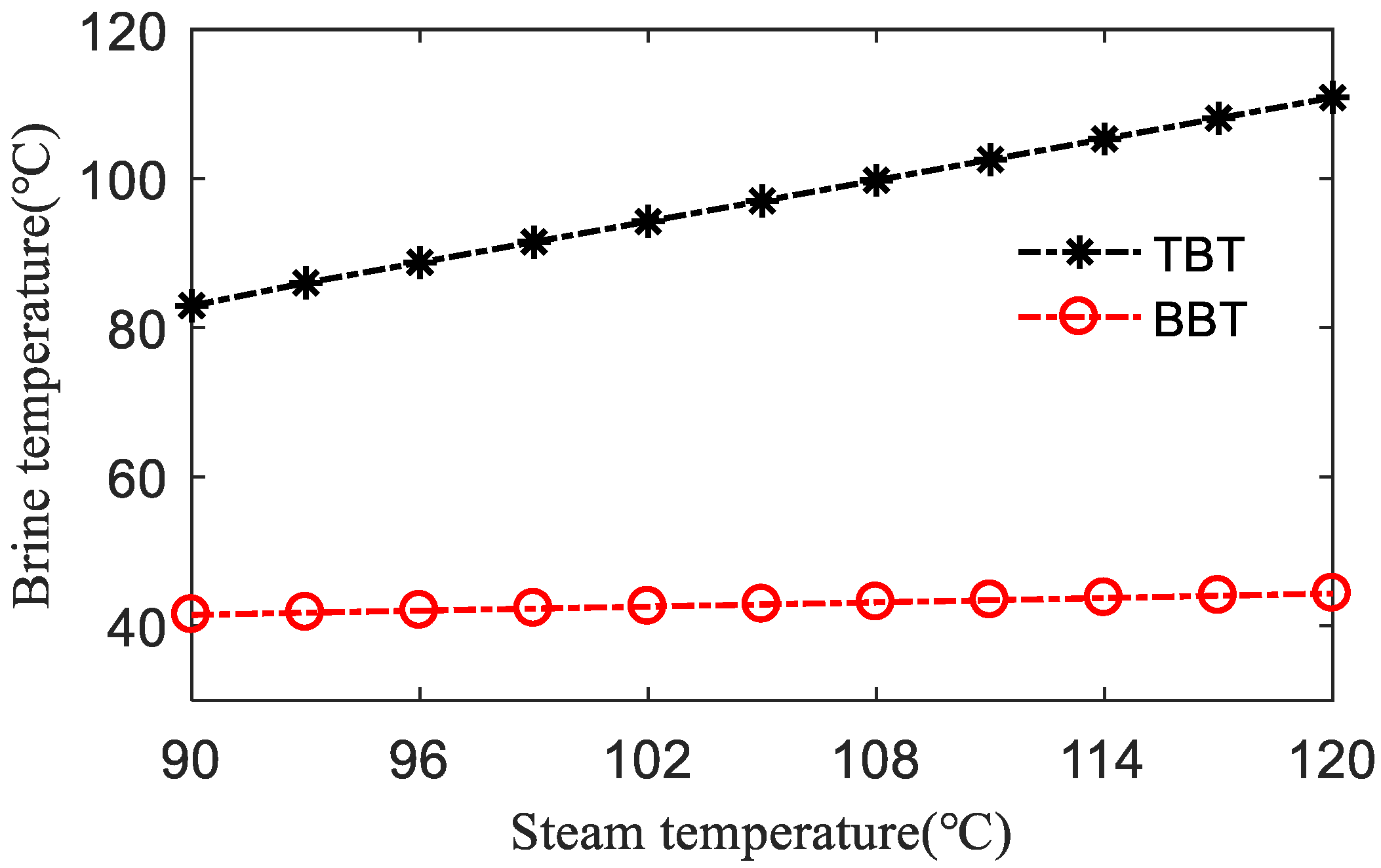

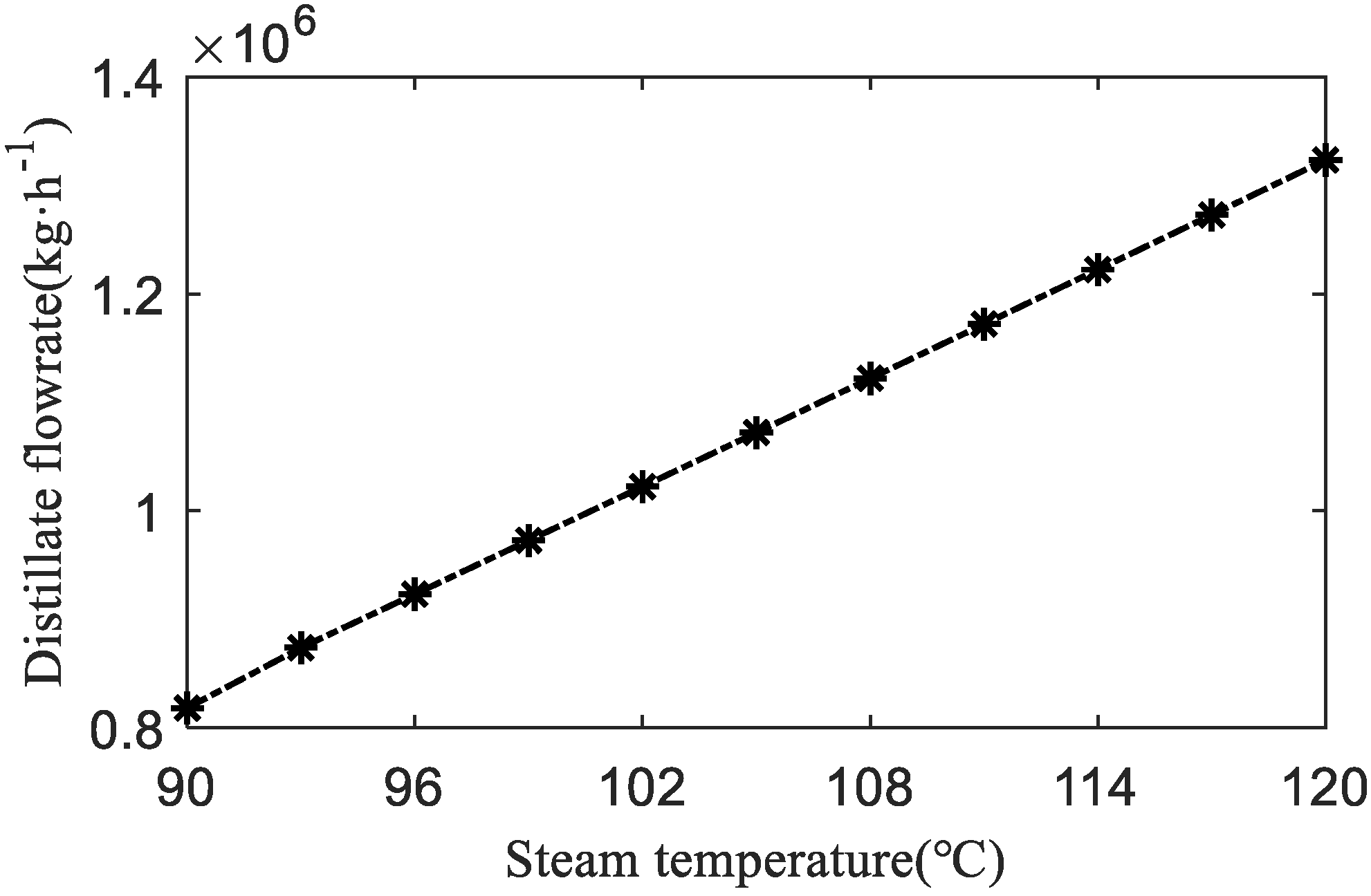

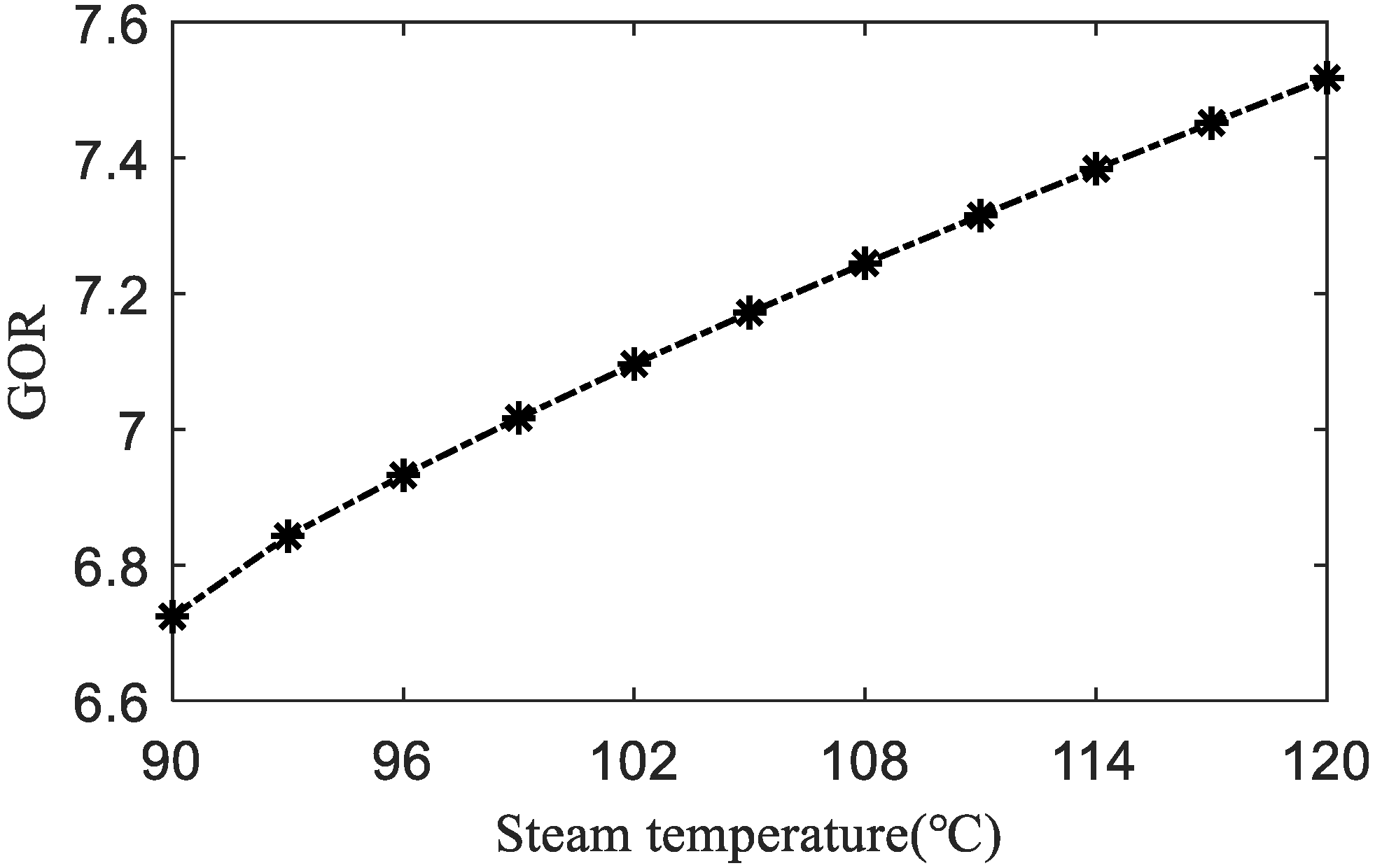

4.2.3. Effect of Steam Temperature () on System Performance

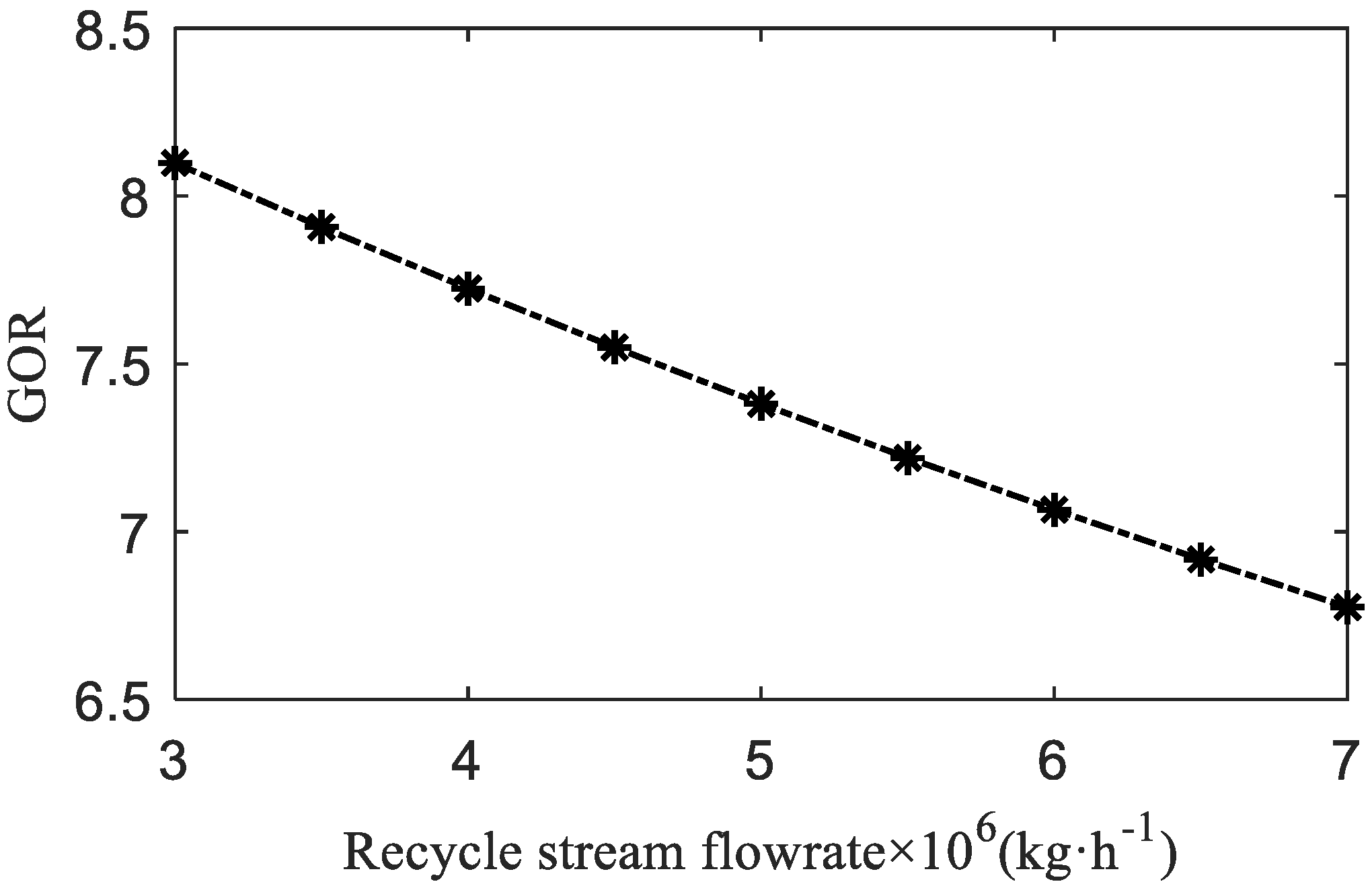

4.2.4. Effect of Recycle Stream Flowrate () on System Performance

5. Operational Optimization of MSF System

5.1. Optimal Operation Problem to Maximize Gained Output Ratio (GOR)

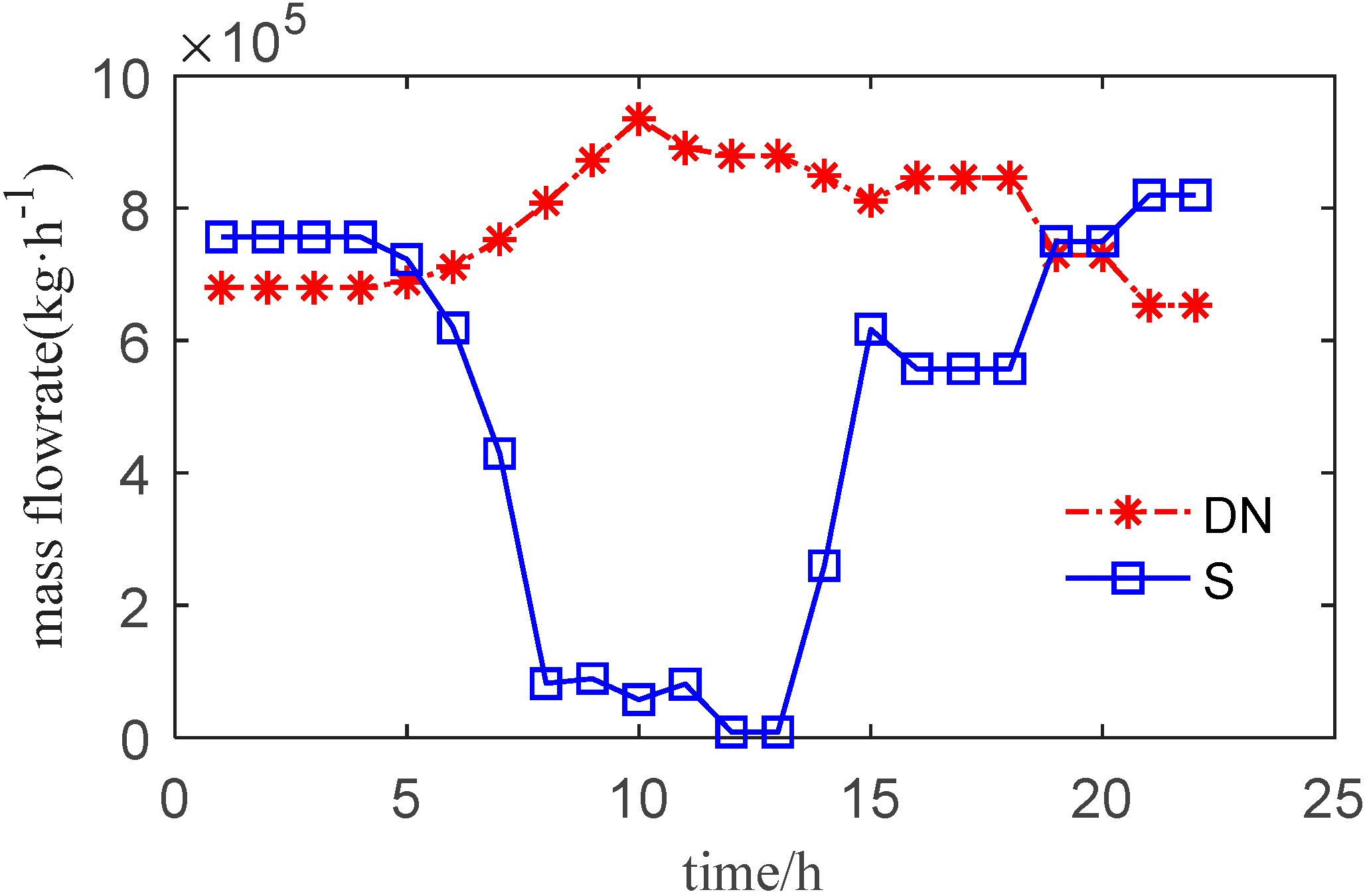

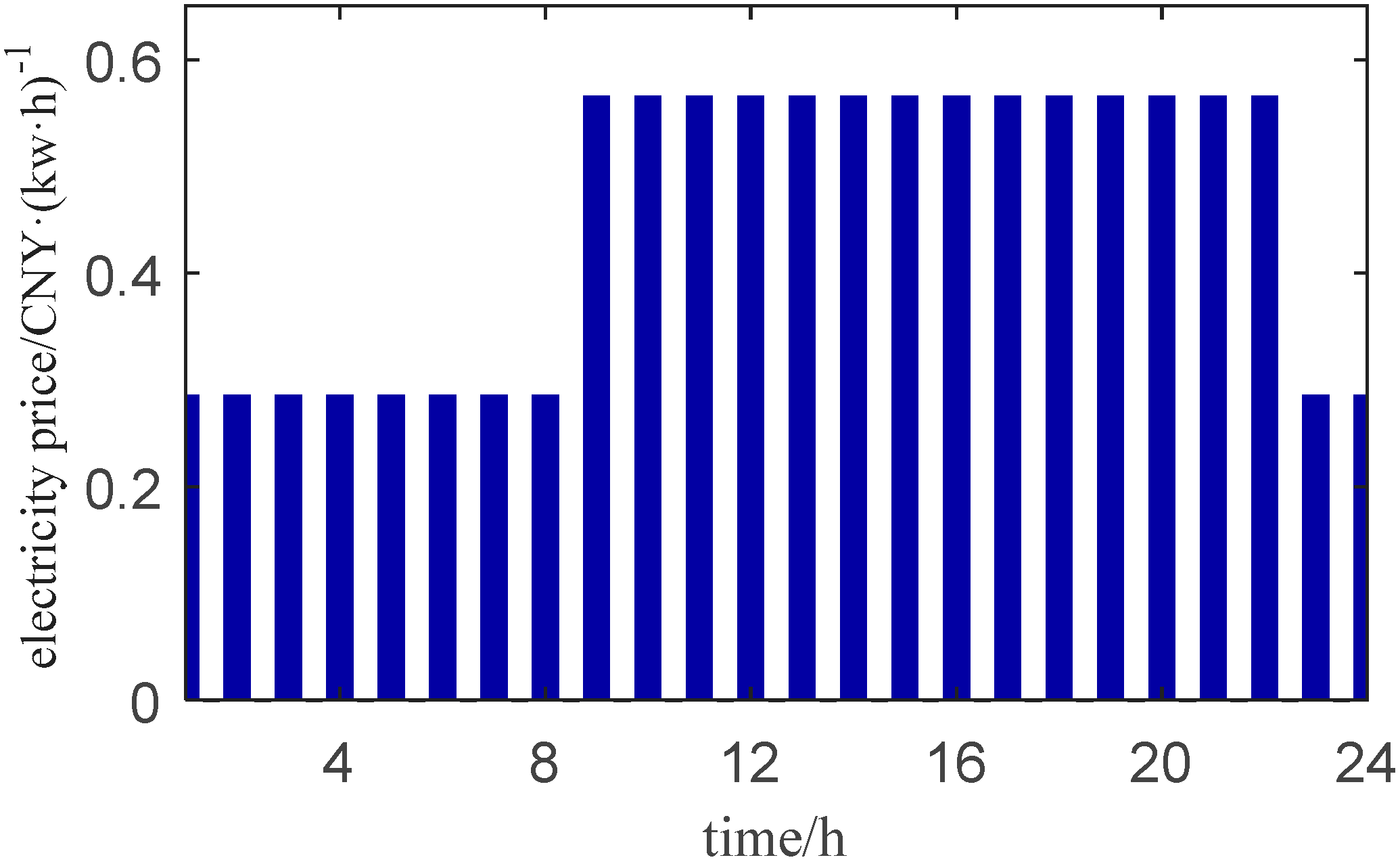

5.2. Optimal Operation Problem to Minimize Daily Operational Cost

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| Heat transfer area of the brine heater, m2 | |

| Heat transfer area of stage j, m2 | |

| Boiling point elevation of stage j | |

| Rejected seawater mass flowrate, kg∙h−1 | |

| Feed seawater salt concentration, wt% | |

| Salt concentration in the flashing leaving the brine heater, wt% | |

| Salt concentration in the flashing brine leaving stage j, wt% | |

| Heat capacity of brine leaving stage j, kcal∙(kg∙°C)−1 | |

| Heat capacity of distillate leaving stage j, kcal∙(kg∙°C)−1 | |

| Salt concentration in make-up water, wt% | |

| Heat capacity of cooling brine leaving stage j, kcal∙(kg∙°C)−1 | |

| Heat capacity of cooling brine leaving brine heater, kcal∙(kg∙°C)−1 | |

| Salt concentration in the cooling brine to the recovery section, wt% | |

| Recycle brine concentration, wt% | |

| Internal diameter of condenser tube, m | |

| External diameter of condenser tube, m | |

| Internal diameter of condenser tube at stage j, m | |

| External diameter of condenser tube at stage j, m | |

| Electricity price, CNY/h | |

| Brine heater fouling factor, h∙m2∙°C∙kcal−1 | |

| Fouling factor at stage j, h∙m2∙°C∙kcal−1 | |

| Gained output ratio | |

| Pump stroke, m | |

| Specific enthalpy of flashing brine at stage j, kcal∙kg−1 | |

| Specific enthalpy of distillate at stage j, kcal∙kg−1 | |

| Specific enthalpy of recycle stream at stage j, kcal∙kg−1 | |

| Specific enthalpy of make-up brine at stage j, kcal∙kg−1 | |

| Specific enthalpy of stream to recovery section, kcal∙kg−1 | |

| Specific enthalpy of recycle brine at rejection stage, kcal∙kg−1 | |

| Specific enthalpy of steam at stage j, kcal∙kg−1 | |

| Specific enthalpy of brine at the entrance of rejection section, kcal∙kg−1 | |

| Specific enthalpy of feed seawater, kcal∙kg−1 | |

| Height of condenser tube at stage j, m | |

| Length of brine heater condenser tube, m | |

| Length of condenser tube at stage j, m | |

| Total number of stages, N = NR + NJ | |

| Non-equilibrium allowance, °C | |

| Number of stages in the heat rejection section | |

| Number of stages in the heat recovery section | |

| Steam price, CNY/MkJ | |

| Mass flow, kg/h | |

| Reject recycle mass flowrate, kg∙h−1 | |

| Temperature of flashing brine leaving stage j, °C | |

| Temperature of flashing brine leaving the brine heater, °C | |

| Temperature of distillate leaving stage j, °C | |

| Temperature of cooling brine leaving stage j, °C | |

| Temperature of cooling brine to brine heater, °C | |

| Temperature loss due to demister and condenser, °C | |

| Temperature of flashed vapor at stage j, °C | |

| Seawater temperature, °C | |

| Steam temperature, °C | |

| Overall heat transfer coefficient at the brine heater, kcal∙(m2∙h∙°C)−1 | |

| Overall heat transfer coefficient at stage j, kcal∙(m2∙h∙°C)−1 | |

| Evaporation capacity of brine at stage j, kg∙h−1 | |

| Flashing brine mass flowrate leaving brine heater, kg∙h−1 | |

| Blowdown mass flowrate, kg∙h−1 | |

| Flashing Brine mass flowrate leaving stage j, kg∙h−1 | |

| Flashing Brine mass flowrate leaving stage N, kg∙h−1 | |

| Distillate mass flowrate leaving stage j, kg∙h−1 | |

| Distillate mass flowrate leaving stage N, kg∙h−1 | |

| Flashing seawater mass flowrate to rejection section, kg∙h−1 | |

| Width of condenser tube at stage j, m | |

| Make-up brine mass flowrate, kg∙h−1 | |

| Cooling brine mass flowrate to recovery section, kg∙h−1 | |

| Mass flowrate to the reject seawater splitter, kg∙h−1 | |

| Recycle stream mass flowrate, kg∙h−1 | |

| Seawater mass flowrate, kg∙h−1 | |

| Steam mass flowrate, kg∙h−1 | |

| Latent heat of steam, kcal∙kg−1 |

References

- Liu, D.-B.; Su, Y.-Y. Challenges in global water resource management. Express Water Resour. Hydropower Inf. 2007, 2, 3–8. [Google Scholar]

- Gao, C.-J.; Chen, G.-H. World Water Resources. In Manual of Desalination Technology and Engineering, 1st ed.; Ye, L., Ding, J.-H., Eds.; Chemical Industry Press: Beijing, China, 2007; pp. 1–2. [Google Scholar]

- Zhang, B.-Z. Multistage flash seawater desalination technology. Cfhi Technol. 2008, 4, 48–49. [Google Scholar]

- Bremere, I.; Kennedy, M.; Stikker, A.; Schippers, J. How water scarcity will affect the growth in the desalination market in the coming 25 years. Desalination 2001, 138, 7–15. [Google Scholar] [CrossRef]

- Caldera, U.; Breyer, C. Learning curve for seawater reverse osmosis desalination plants: Capital cost trend of the past, present, and future. Water Resour. Res. 2017, 53, 10523–10538. [Google Scholar]

- Jones, E.; Qadira, M. The state of desalination and brine production: A global outlook. Sci. Total Environ. 2019, 657, 1343–1356. [Google Scholar] [CrossRef]

- Xie, L.-X.; Li, P.-L.; Wang, S.-C. Status of desalination technology and review of various desalination methods. Chem. Ind. Eng. Prog. 2003, 10, 55–58. [Google Scholar]

- Zhao, Z.-H.; Yuan, Y.-C.; Chen, Y. Analysis of multi-stage flash seawater desalination technology. Sci. Mosaic 2017, 8, 46–49. [Google Scholar]

- Wang, H.-T.; Li, B.-A.; Liu, B. The current situation of seawater desalination technology and new technology review. J. Salt Sci. Chem. Ind. 2014, 6, 1–5. [Google Scholar]

- Alsadaie, S.M.; Mujtaba, I.M. Dynamic modelling of Heat Exchanger fouling in multistage flash (MSF) desalination. Desalination 2017, 409, 47–65. [Google Scholar] [CrossRef]

- Hawaidi, E.A.M.; Mujtaba, I.M. Impact of Fouling on Flexible Design and Operation of MSF Desalination Process with Variable Freshwater Demand. Comput. Aided Chem. Eng. 2012, 30, 502–506. [Google Scholar]

- Helal, A.M.; Medani, M.S.; Soliman, M.A.; Flower, J.R. A tridiagonal matrix model for multi-stage flash desalination plants. Pergamon 1986, 10, 327–342. [Google Scholar]

- Marina, R.; Angelo, B.; Marco, M.; Massimo, M. Modeling multi-stage flash desalination plants. Desalination 1997, 108, 365–374. [Google Scholar]

- Eldessouky, H.T.; Ettouney, H.M. Fundamentals of Salt Water Desalination, 1st ed.; Elsevier: Kuwait City, Kuwait, 2002; pp. 272–409. [Google Scholar]

- Wu, L.-Y.; Xiao, S.-N.; Sun, S.-N. Optimization design of multi-stage flash seawater desalination system. J. East. China Univ. Sci. Technol. 2009, 4, 535–538. [Google Scholar]

- Tanvir, M.S.; Mujtaba, I.M. Neural network based correlations for estimating temperature elevation for seawater in MSF desalination process. Desalination 2005, 195, 251–272. [Google Scholar] [CrossRef]

- Tanvir, M.S.; Mujtaba, I.M. Modelling and simulation of MSF desalination process using gPROMS and neural network based physical property correlation. Comput. Aided Chem. Eng. 2006, 21, 315–320. [Google Scholar]

- Al-Rawajfeh, A.E.; Al-Garalleh, M. Understanding CaCO3-Mg(OH)2 scale formation: A semi-empirical min- do-forces study of CO2-H2O system. Chem. Eng. Commun. 2008, 195, 998–1010. [Google Scholar] [CrossRef]

- Al-Rawajfeh, A.E.; Ihm, S.; Varshney, H.; Mabrouk, A.N. Scale formation model for high top brine temperature multi-stage flash (MSF) desalination plants. Desalination 2014, 350, 53–60. [Google Scholar] [CrossRef]

- Hawaidi, E.A.M.; Mujtaba, I.M. Simulation and optimization of MSF desalination process for fixed freshwater demand: Impact of brine heater fouling. Chem. Eng. J. 2010, 165, 545–553. [Google Scholar] [CrossRef]

- Alsadaie, S.; Mujtaba, I.M. Crystallization of calcium carbonate and magnesium hydroxide in the heat exchangers of once-through Multistage Flash (MSF-OT) desalination process. Comput. Chem. Eng. 2019, 12, 293–305. [Google Scholar] [CrossRef]

- Hu, S.-G.; Zhou, S.-X.; Liang, S.-Y. Thermoeconomic optimization analysis of MSF seawater desalination system. Technol. Water Treat. 2000, 26, 13–17. [Google Scholar]

- Mussati, S.F.; Aguirre, P.; Nicolás, J.S. Optimal MSF plant design. Desalination 2001, 138, 341–347. [Google Scholar] [CrossRef]

- Said, S.; Mansour, E.; Iqbal, M. Flexible Design and Operation of Multi-Stage Flash (MSF) Desalination Process Subject to Variable Fouling and Variable Freshwater Demand. Processes 2013, 1, 279–295. [Google Scholar] [CrossRef]

- Mazzotti, M.; Rosso, M.; Beltramini, A.; Morbidelli, M. Dynamic modeling of multistage flash desalination plants. Desalination 2000, 127, 207–218. [Google Scholar] [CrossRef]

- Gambier, A.; Badreddin, E. Dynamic modelling of MSF plants for automatic control and simulation purposes: A survey. Desalination 2004, 166, 191–204. [Google Scholar] [CrossRef]

- Al-Fulaij, H.F. Dynamic Modeling of Multi Stage Flash (MSF) Desalination Plant. Ph.D. Thesis, University College London, London, UK, 2011. [Google Scholar]

- Bodalal, A.S.; Mounem, S.A.; Abdul Salama, H.S. Dynamic Modeling and Simulation of MSF Desalination Plants. Jordan J. Mech. Ind. Eng. 2010, 4, 394–403. [Google Scholar]

- Lappalainen, J.; Korvola, T.; Alopaeus, V. Modelling and dynamic simulation of a large MSF plant using local phase equilibrium and simultaneous mass, momentum, and energy solver. Comput. Chem. Eng. 2017, 97, 242–258. [Google Scholar] [CrossRef]

- Alsadaie, S.M.; Mujtaba, I.M. Generic Model Control (GMC) in Multistage Flash (MSF) Desalination. J. Process. Control. 2016, 44, 92–105. [Google Scholar] [CrossRef]

- Helal, A.M.; EI-Nashar, A.M.; AI-Katheeri, E. Optimal design of hybrid RO/MSF desalination plants Part I: Modeling and algorithms. Desalination 2003, 154, 43–66. [Google Scholar] [CrossRef]

- Helal, A.M.; EI-Nashar, A.M.; AI-Katheeri, E. Optimal design of hybrid RO/MSF desalination plants part II: Results and discussion. Desalination 2004, 160, 13–27. [Google Scholar] [CrossRef]

- Helal, A.M.; EI-Nashar, A.M.; AI-Katheeri, E. Optimal design of hybrid RO/MSF desalination plants part III: Sensitivity analysis. Desalination 2004, 169, 43–60. [Google Scholar] [CrossRef]

- Woldai, A. Multi-Stage Flash Desalination: Modeling, Simulation, and Adaptive Control; CRC Press: Boca Raton, FL, USA, 2015; Volume 1. [Google Scholar]

- El-Dessouky, H.; Shaban, H.I.; Al-Ramadan, H. Steady-state analysis of multi-stage flash desalination process. Desalination 1995, 103, 271–287. [Google Scholar] [CrossRef]

- Mussati, S.F.; Aguirre, P.A.; Nicolás, J. Improving the efficiency of the MSF once through (MSF-OT) and MSF-mixer (MSF-M) evaporators. Desalination 2004, 166, 141–151. [Google Scholar] [CrossRef]

| Parameters | Unit | Numerical Value |

|---|---|---|

| Internal diameter of condenser () | m | 0.0220 |

| External diameter of condenser () | m | 0.0244 |

| Length of condenser () | m | 12.2 |

| Heat transfer area () | m2 | 3530 |

| Fouling factor () | (h·m2·K)/kcal | 1.86 × 10−4 |

| Parameters | Unit | Heat Recovery Section | Heat Rejection Section |

|---|---|---|---|

| Internal diameter of condenser () | m | 0.0220 | 0.0239 |

| Length of condenser () | m | 12.2 | 10.7 |

| Heat transfer area () | m2 | 3995 | 3530 |

| Width of flash chamber () | m | 12.2 | 10.7 |

| Fouling factor () | (h·m2·K)/kcal | 1.4 × 104 | 2.33 × 105 |

| Stage j | WBj (kg/h) | WDj (kg/h) | CBj (wt%) | TFj (°C) | TDj (°C) | TBj (°C) | VBj (kg/h) | Tvj (°C) |

|---|---|---|---|---|---|---|---|---|

| 0 | 1.2030 × 107 | 6.2964 | 83.2410 | 89.6610 | ||||

| 1.203 × 107 | 6.2922 | 83.33 | 89.74 | |||||

| 1 | 1.1969 × 107 | 6.0530 × 104 | 6.3282 | 80.3232 | 85.6664 | 86.8504 | 60,530.13 | 85.7450 |

| 1.197 × 107 | 5.940 × 104 | 6.3234 | 80.41 | 85.75 | 86.89 | |||

| 2 | 1.1909 × 107 | 1.2148 × 105 | 6.3606 | 77.3566 | 82.7921 | 83.9859 | 60,952.13 | 82.8795 |

| 1.191 × 107 | 1.187 × 105 | 6.3549 | 77.44 | 82.87 | 84.01 | |||

| 3 | 1.1847 × 107 | 1.8275 × 105 | 6.3935 | 74.3456 | 79.8655 | 81.0715 | 61,269.87 | 79.9629 |

| 1.185 × 107 | 1.784 × 105 | 6.3869 | 74.43 | 79.95 | 81.08 | |||

| 4 | 1.1786 × 107 | 2.4423 × 105 | 6.4269 | 71.2944 | 76.8904 | 78.1116 | 61,481.50 | 76.9992 |

| 1.179 × 107 | 2.385 × 105 | 6.4195 | 71.37 | 76.97 | 78.11 | |||

| 5 | 1.1724 × 107 | 3.0582 × 105 | 6.4606 | 68.2080 | 73.8712 | 75.1111 | 61,584.98 | 73.9929 |

| 1.173 × 107 | 2.989 × 105 | 6.4525 | 68.28 | 73.94 | 75.09 | |||

| 6 | 1.1663 × 107 | 3.6740 × 105 | 6.4948 | 65.0914 | 70.8124 | 72.0749 | 61,577.98 | 70.9487 |

| 1.167 × 107 | 3.595 × 105 | 6.4860 | 65.16 | 70.88 | 72.04 | |||

| 7 | 1.1601 × 107 | 4.2885 × 105 | 6.5292 | 61.9501 | 67.7189 | 69.0088 | 61,457.69 | 67.8718 |

| 1.161 × 107 | 4.201 × 105 | 6.5198 | 62.01 | 67.78 | 68.95 | |||

| 8 | 1.1540 × 107 | 4.9007 × 105 | 6.5638 | 58.7898 | 64.5959 | 65.9185 | 61,220.58 | 64.7677 |

| 1.155 × 107 | 4.806 × 105 | 6.5540 | 58.84 | 64.65 | 65.84 | |||

| 9 | 1.1479 × 107 | 5.5094 × 105 | 6.5986 | 55.6168 | 61.4491 | 62.8108 | 60,862.28 | 61.6421 |

| 1.149 × 107 | 5.410 × 105 | 6.5885 | 55.65 | 61.49 | 62.70 | |||

| 10 | 1.1419 × 107 | 6.1131 × 105 | 6.6335 | 52.4379 | 58.2844 | 59.6925 | 60,377.35 | 58.5015 |

| 1.143 × 107 | 6.010 × 105 | 6.6231 | 52.46 | 58.32 | 59.55 | |||

| 11 | 1.1359 × 107 | 6.7107 × 105 | 6.6684 | 49.2603 | 55.1084 | 56.5715 | 59,759.11 | 55.3527 |

| 1.137 × 107 | 6.606 × 105 | 6.6578 | 49.27 | 55.13 | 56.39 | |||

| 12 | 1.1300 × 107 | 7.3007 × 105 | 6.7032 | 46.0923 | 51.9280 | 53.4562 | 58,999.50 | 52.2029 |

| 1.131 × 107 | 7.197 × 105 | 6.6925 | 46.09 | 51.93 | 53.24 | |||

| 13 | 1.1242 × 107 | 7.8816 × 105 | 6.7378 | 43.8680 | 48.7509 | 50.3560 | 58,088.83 | 49.0603 |

| 1.125 × 107 | 7.780 × 105 | 6.7272 | 44.06 | 48.74 | 50.09 | |||

| 14 | 1.1192 × 107 | 8.3822 × 105 | 6.7680 | 40.9495 | 45.9537 | 47.6574 | 50,060.89 | 46.2969 |

| 1.120 × 107 | 8.296 × 105 | 6.7582 | 41.10 | 45.87 | 47.28 | |||

| 15 | 1.1141 × 107 | 8.8884 × 105 | 6.7987 | 37.9936 | 43.1039 | 44.9038 | 50,620.84 | 43.4855 |

| 1.115 × 107 | 8.816 × 105 | 6.7897 | 38.07 | 42.95 | 44.42 | |||

| 16 | 1.1090 × 107 | 9.3966 × 105 | 6.8299 | 35.0000 | 40.2000 | 42.1145 | 50,814.02 | 40.6250 |

| 1.110 × 107 | 9.341 × 105 | 6.8219 | 35.00 | 39.98 | 41.51 | |||

| Wsteam: | 1.3499 × 105 kg/h 1.3489 × 105 kg/h | GOR: | 6.96 6.92 | |||||

| Time | Temperature/°C | Time | Temperature/°C |

|---|---|---|---|

| 2:00–6:00 | 8 | 12:00–13:00 | 14 |

| 6:00–7:00 | 10 | 13:00–15:00 | 12 |

| 7:00–8:00 | 12 | 15:00–16:00 | 10 |

| 8:00–9:00 | 14 | 16:00–17:00 | 9 |

| 9:00–10:00 | 15 | 17:00–20:00 | 8 |

| 10:00–11:00 | 16 | 20:00–22:00 | 6 |

| 11:00–12:00 | 15 | 22:00–0:00 | 5 |

| Time | Distillate Demand (×105 kg/h) | Time | Distillate Demand (×105 kg/h) |

|---|---|---|---|

| 2:00–6:00 | 6.8 | 12:00–13:00 | 8.91 |

| 6:00–7:00 | 6.88 | 13:00–15:00 | 8.79 |

| 7:00–8:00 | 7.11 | 15:00–16:00 | 8.49 |

| 8:00–9:00 | 7.53 | 16:00–17:00 | 8.11 |

| 9:00–10:00 | 8.08 | 17:00–20:00 | 8.46 |

| 10:00–11:00 | 8.72 | 20:00–22:00 | 7.29 |

| 11:00–12:00 | 9.35 | 22:00–0:00 | 6.53 |

| Time | Tsea (°C) | WDN × 105 (kg/h) | WRe × 106 (kg/h) | Wr × 106 (kg/h) | S × 105 (kg/h) | Tsteam (°C) | GOR |

|---|---|---|---|---|---|---|---|

| 2:00–6:00 | 8 | 6.8 | 2.1972 | 7.5647 | 7.5647 | 97 | 8.9302 |

| 6:00–7:00 | 10 | 6.88 | 2.0 | 7.2253 | 7.2253 | 97 | 8.8998 |

| 7:00–8:00 | 12 | 7.11 | 2.0 | 7.0199 | 6.1930 | 97 | 8.8047 |

| 8:00–9:00 | 14 | 7.53 | 2.0 | 6.6484 | 4.2948 | 97 | 8.6357 |

| 9:00–10:00 | 15 | 8.08 | 2.0 | 6.2293 | 0.8170 | 97 | 8.4205 |

| 10:00–11:00 | 16 | 8.72 | 2.0 | 5.4808 | 0.8898 | 97 | 8.1816 |

| 11:00–12:00 | 15 | 9.35 | 2.0778 | 4.9956 | 0.5726 | 97 | 7.9565 |

| 12:00–13:00 | 14 | 8.91 | 2.0 | 5.4636 | 0.8087 | 97 | 8.1138 |

| 13:00–15:00 | 12 | 8.79 | 3.3279 | 7.0736 | 0.0829 | 97 | 8.1415 |

| 15:00–16:00 | 10 | 8.49 | 3.6552 | 7.6955 | 2.5972 | 97 | 8.2444 |

| 16:00–17:00 | 9 | 8.11 | 2.0 | 6.1698 | 6.1698 | 97 | 8.4100 |

| 17:00–20:00 | 8 | 8.46 | 3.0193 | 6.9668 | 5.5723 | 97 | 8.2683 |

| 20:00–22:00 | 6 | 7.29 | 2.5214 | 7.4993 | 7.4993 | 97 | 8.7250 |

| 22:00–0:00 | 5 | 6.53 | 2.5307 | 8.1957 | 8.1957 | 97 | 9.0367 |

| Time | Tsea (°C) | WDN × 105 (kg/h) | WRe × 106 (kg/h) | Wr × 106 (kg/h) | Tsteam (°C) | Wsteam × 104 (kg/h) | TOC (CNY/h) |

|---|---|---|---|---|---|---|---|

| 2:00–6:00 | 8 | 6.8 | 4.0271 | 9.4133 | 92.5587 | 7.9868 | 6669 |

| 6:00–7:00 | 10 | 6.88 | 4.0740 | 9.3036 | 92.6141 | 8.0848 | 6754 |

| 7:00–8:00 | 12 | 7.11 | 4.2170 | 9.1338 | 92.7676 | 8.4213 | 7024 |

| 8:00–9:00 | 14 | 7.53 | 4.4895 | 8.8870 | 93.0528 | 9.0742 | 7540 |

| 9:00–10:00 | 15 | 8.08 | 4.3540 | 8.1832 | 93.4182 | 9.9298 | 8580 |

| 10:00–11:00 | 16 | 8.72 | 4.6610 | 7.7720 | 93.8824 | 11.0101 | 9424 |

| 11:00–12:00 | 15 | 9.35 | 4.8472 | 7.4242 | 94.3241 | 12.0852 | 10257 |

| 12:00–13:00 | 14 | 8.91 | 4.7363 | 7.8370 | 93.9868 | 11.3113 | 9647 |

| 13:00–15:00 | 12 | 8.79 | 4.7571 | 8.1304 | 93.8761 | 11.0991 | 9469 |

| 15:00–16:00 | 10 | 8.49 | 4.6603 | 8.4505 | 93.6492 | 10.6028 | 9072 |

| 16:00–17:00 | 9 | 8.11 | 4.5134 | 8.7067 | 93.3862 | 9.9916 | 8592 |

| 17:00–20:00 | 8 | 8.46 | 4.7148 | 8.6449 | 93.6173 | 10.573 | 9036 |

| 20:00–22:00 | 6 | 7.29 | 4.1718 | 9.2186 | 92.8529 | 8.7493 | 7614 |

| 22:00–0:00 | 5 | 6.53 | 3.9008 | 9.6128 | 92.3985 | 7.6395 | 6385 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, H.; Jiang, A.; Huang, Q.; Xia, Y.; Gao, F.; Wang, J. Mode-Based Analysis and Optimal Operation of MSF Desalination System. Processes 2020, 8, 794. https://doi.org/10.3390/pr8070794

Gao H, Jiang A, Huang Q, Xia Y, Gao F, Wang J. Mode-Based Analysis and Optimal Operation of MSF Desalination System. Processes. 2020; 8(7):794. https://doi.org/10.3390/pr8070794

Chicago/Turabian StyleGao, Hanhan, Aipeng Jiang, Qiuyun Huang, Yudong Xia, Farong Gao, and Jian Wang. 2020. "Mode-Based Analysis and Optimal Operation of MSF Desalination System" Processes 8, no. 7: 794. https://doi.org/10.3390/pr8070794

APA StyleGao, H., Jiang, A., Huang, Q., Xia, Y., Gao, F., & Wang, J. (2020). Mode-Based Analysis and Optimal Operation of MSF Desalination System. Processes, 8(7), 794. https://doi.org/10.3390/pr8070794