Abstract

The need for miniaturised reaction systems has led to the development of various microreactor platforms, such as droplet-based microreactors. However, these microreactors possess inherent drawbacks, such as rapid evaporation and difficult handling, that limit their use in practical applications. Liquid marbles are droplets covered with hydrophobic particles and are a potential platform that can overcome the weaknesses of bare droplets. The coating particles completely isolate the interior liquids from the surrounding environment, thus conveniently encapsulating the reactions. Great efforts have been made over the past decade to demonstrate the feasibility of liquid marble-based microreactors for chemical and biological applications. This review systemically summarises state-of-the-art implementations of liquid marbles as microreactors. This paper also discusses the various aspects of liquid marble-based microreactors, such as the formation, manipulation, and future perspectives.

1. Introduction

The miniaturisation of reaction systems is an attractive approach that dates back to the 1930s when the idea of microscale chemical handling systems was introduced and discussed [1]. Advancements in microelectronics technology have enabled the fabrication of early microreactors in the 1990s, laying the foundation for the rapid development of various types of microreactors in recent decades [2]. Compared to conventional reactors, microreactors offer advantages such as a remarkably high surface area to volume ratio, which enhances the mass and heat transfer, thus increasing the reaction kinetics, as well as improving the yield. The small volume of microreactors also reduces the reagent and energy consumption. A miniaturised reactor also allows for more precise control over reaction parameters, as well as the safer handling of hazardous or exothermic reactions [3,4,5,6]. Owing to these advantages and the development of microfluidic devices [7,8,9], microreactors—particularly, microfluidic reactors—have attracted enormous research interests [10,11,12,13,14]. Nevertheless, these microreactors face difficulties in handling minute amounts of reactants. For instance, liquids tend to wet the reactor walls, leading to cross-contamination and a loss of mass. Furthermore, when reactions involve solid particles or precipitation, microfluidic devices can be clogged. In order to overcome this problem, the contact between the liquid and the surrounding environment should be limited. A significant number of research works have been performed with reactions in droplets on superhydrophobic surfaces. However, the rapid evaporation of solvents remains a challenge.

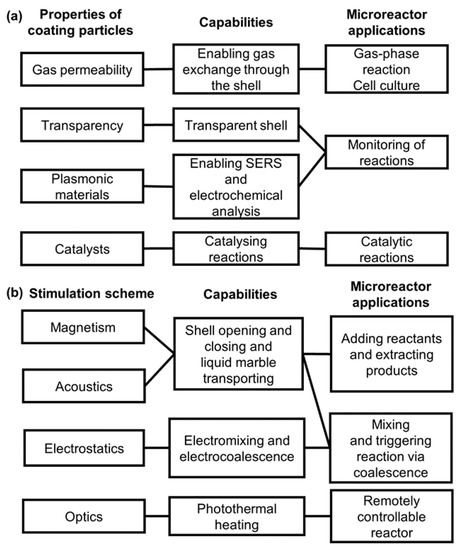

The idea of encapsulating liquid with hydrophobic powder to eliminate the contact between the liquid and external environment can be found in the case of gall-dwelling aphids [15]. The honeydew waste secreted from the aphid is quickly covered with a powdery wax before being rolled away, preventing it from drowning the insects. The covered honeydew can be considered similar to the first liquid marble reported in a study by Aussillous et al., where the authors encapsulated a water droplet with hydrophobic microparticles [16]. Coating particles prevent direct contact between the interior liquid and the surrounding environment, allowing liquid marbles to move around without wetting the surface and to avoid contamination. Owing to these characteristics, liquid marbles have practical applications in the field of microfluidics, such as storage, transportation, or even mechanical computation [17,18,19,20]. Most importantly, their unique properties enable liquid marbles to serve as microreactors for chemical and biological applications. The ability to be manipulated like a soft solid also enhances the feasibility of liquid marbles as microreactors [21]. Therefore, the last decade has witnessed major advances in the development and application of liquid marble-based microreactors. Figure 1 illustrates the feasibility of using liquid marbles for various applications by utilising coating particles with different properties or introducing external stimulations. This paper aims to systematically review the use of liquid marbles as microreactors for chemical and biological applications, including their advantages and drawbacks. Various aspects of liquid marble-based microreactors, including the formation, manipulation, and future perspectives, will also be discussed.

Figure 1.

Applications of liquid marble-based microreactors. (a) Properties of coating particles and microreactor applications. (b) Stimulation schemes and microreactor applications. SERS: by surface-enhanced Raman scattering spectroscopy.

2. Liquid Marble-Based Microreactors

2.1. Formation of Liquid Marbles

A liquid marble can be created simply by rolling a liquid droplet on the surface of a hydrophobic powder bed. The particles assemble on the liquid-air interface of the droplet and form an encapsulating layer, which separates the interior liquid from the supporting substrate. This newly formed liquid marble can function effectively as a microreactor. Using this method, liquid marble-based microreactors can be generated almost instantly in an extremely facile manner. The flexibility in the fabrication options of liquid marbles is also highly advantageous. The combination of the vast range of interior liquids and coating particles can provide liquid marbles with unique characteristics, such as enhanced robustness [22,23], transparency [24], or stimulus-responsiveness [25]. These features allow for the implementation of tailor-made microreactor platforms.

While liquid marble production is easy to perform, the arduousness and the lack of consistency in the volume of liquid marbles remain challenging. Efforts have been made to develop new methods to generate liquid marbles to overcome the many drawbacks associated with the manual method. Castro et al. successfully developed a simple strategy based on gravitational force for the continuous production of liquid marbles [26]. By placing liquid droplets on a ramp with an appropriate inclination angle, the droplets can gain velocity and roll through a hydrophobic particle bed, thus forming liquid marbles. This method allowed the authors to synthesise Janus liquid marbles easily by coalescing the newly formed liquid marbles. Sreejith et al. utilised electrohydrodynamic pulling to assemble an on-demand liquid marble generator that can create submicrolitre to microlitre-sized liquid marbles with high reproducibility [27]. Wang et al. made use of centrifugal force to induce a motion of liquid droplets on a hydrophobic particle bed, effectively generating liquid marbles with a high volume consistency [28]. These platforms are able to produce a large number of liquid marbles with a consistent volume, significantly promoting the use of liquid marbles in many applications.

2.2. Manipulation of Liquid Marbles for Microreactions

One of the largest advantages of liquid marbles is that they can be easily manipulated through a variety of schemes, such as electromagnetism, mechanical means, and pH change. These manipulation schemes can induce motion, deformation, or changes of effective surface tensions. This paper only reports schemes that allow liquid marbles to perform functions such as coalescence and mixing, as well as opening and closing, which are necessary for their operation as microreactors.

2.2.1. Manipulation for Coalescence

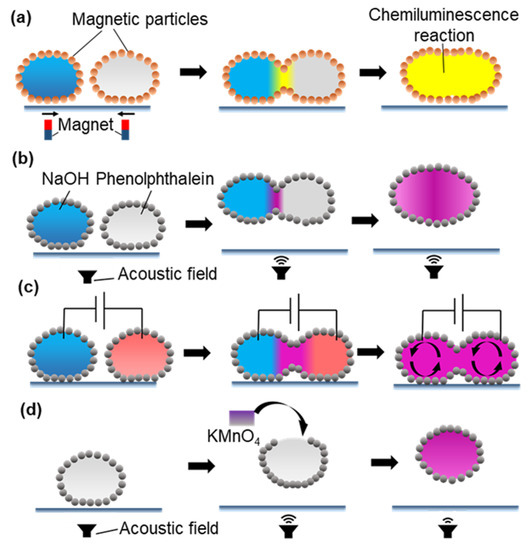

To date, most studies on the applications of liquid marbles as microreactors were carried out by premixing and encapsulating all the reagents in a single liquid marble, owing to the convenience of this method [29]. Nevertheless, performing reactions in a system with multiple liquid marbles has gained more interest. By containing different reactants in separate liquid marbles and triggering the reaction via coalescence, this strategy can provide a safer noncontact initiation for hazardous or highly exothermic reactions and better monitoring for rapid reactions [30]. These advantages drive the development of a remotely controllable initiation for reactions via coalescence. Numerous manipulation schemes were investigated for the coalescence of liquid marbles by introducing external actuation forces, such as electromagnetic and gravitational forces [31,32,33]. Xue et al. first reported the introduction of a magnetic field to move and coalesce magnetic liquid marbles containing different reagents into a larger liquid marble, where chemiluminescence reaction took place (Figure 2a) [34]. However, this manipulation strategy lacks versatility, as it is applicable to magnetic liquid marbles only. The possibility of coalescing nonmagnetic liquid marbles via acoustic levitation was investigated by Chen et al. [35]. The authors observed that, by introducing the acoustic field, two adjacent liquid marbles were able to move and coalesced into a larger liquid marble before being levitated. The reaction between phenolphthalein and the NaOH solution was successfully demonstrated using this strategy (Figure 2b). This method benefitted from the oscillation during the coalescence due to a greatly enhanced mixing of reactants. Luo et al. added carbon dioxide-sensitive particles into the patch-to-patch contacts of different liquid marbles to provide them with the ability to change from being hydrophobic to hydrophilic with the presence of carbon dioxide [30]. These liquid marbles could then be merged effectively when carbon dioxide was introduced to the environment. The authors utilised this mechanism to conduct a range of reactions, including redox, complexation, substitution, and chemiluminescence reactions. Electrocoalescence is another promising approach that has been reported in recent studies [36]. Zhang et al. reported the use of electrode plates embedded beneath a dielectric layer to perform electrocoalescence [37]. The authors also measured cell metabolic activities, further driving liquid marble applications in chemical and biological fields.

Figure 2.

Manipulation of liquid marble-based microreactors. (a) Coalescence-driven chemiluminescence reaction of magnetic liquid marbles [34]. (b) Coalescence of liquid marbles containing NaOH and an indicator via acoustic levitation [35]. (c) Electrocoalescence and electromixing of liquid marbles [36]. (d) Opening, closing, and adding KMnO4 into a liquid marble via acoustic levitation [38].

2.2.2. Manipulation for Mixing

Mixing plays a vital role in reactions, because it ensures homogeneity within the system. Good mixing can significantly increase mass and heat transfers. Furthermore, mixing can enhance dispersion if the reaction involves multiple-phase reactants. However, mixing in liquid marbles remains a challenge, and the lack of an effective mixing method can considerably limit the potential of liquid marble-based microreactors. Moving a liquid marble could induce mixing [39]. This manipulation scheme is easy to conduct, as there are numerous strategies to move the marbles, such as electromagnetic, optical, or acoustic actuations [40]. Xue et al. placed two droplets containing reagents into a single magnetic liquid marble and moved it under a magnetic field to mix its contents and trigger a chemiluminescence reaction [34]. The same method was employed by Zhao et al. to mix the reagents of the glucose assay [41]. However, this method requires manual control of the liquid marble, leading to noncontinuous and inefficient mixing. Li et al. observed that the continuous flow of solutions under an electric field in a Daniell cell can lead to mixing in a liquid marble [42]. The idea of applying an electric field to induce mixing was further developed by Liu et al. [36]. The authors reported that, by introducing an adequately large electrical field, the liquid marbles could be rapidly mixed (Figure 2c). The reaction of 2-methylindole and aldehydes in a highly viscous glycerol solution was demonstrated, proving that electromixing can deliver higher reaction yields. In addition, this manipulation scheme is applicable to many types of coating particles.

2.2.3. Manipulation for Opening and Closing the Liquid Marbles

The capability of introducing reagents and withdrawing products is crucial for liquid marbles to operate effectively as microreactors. Previous studies have reported the use of micropipettes to add and extract interior liquids without damaging liquid marbles [43,44,45,46]. However, this method requires the micropipette tips to penetrate the coating shell of liquid marbles, making the interior liquids susceptible to contamination. Several manipulation schemes of liquid marbles allow the coating shell to be opened and closed for the addition of reactants and the collection of products. Many studies have reported the use of magnetic force to open and close magnetic liquid marbles for chromatographic [34], optical, and electrochemical analyses [41]. Acoustic levitation was also demonstrated as a feasible manipulation scheme for opening and closing the liquid marbles, as the acoustic field can create a hole at the top of the marble [38]. The authors then inserted KMnO4 into the liquid marble via the opening and decreased the sound intensity to close the hole without tampering the liquid marble (Figure 2d). These results paved the way for a method of opening and closing liquid marbles that can be applied to a wide range of nonmagnetic coating particles.

2.3. Lifetime of Liquid Marbles

One of the most important concerns of liquid marbles is to ensure an adequate lifetime for liquid marble-based microreactors. Many biological and chemical reactions require high temperatures and extended lifetimes, thus the need for a stable platform. The evaporation of the interior liquid significantly impacts the shape and eventually leads to the collapse of the liquid marble. Efforts have been made to minimise the evaporation of liquid marbles. For example, the evaporation effect of water droplets and liquid marbles coated with 5–9-µm polytetrafluoroethylene (PTFE) particles was investigated, demonstrating that PTFE can function as an effective barrier, as it can reduce the evaporation rate of water up to 45% [47]. Furthermore, the relative humidity showed a remarkable influence, as the evaporation resistance of the PTFE particles increased from 0.365 to 0.627 sm−1 when the relative humidity increased from 5% to 74%. Dandan et al. investigated the evaporation rate of water droplets and graphite liquid marbles, concluding that the graphite coating particles remarkably enhanced the evaporation resistance [48]. However, under high temperature conditions, relative humidity did not play an important role as at room temperature, because the high vapour saturation concentration at the liquid-gas interface was the main driving force for the gradient of the vapour concentration [49]. Aberle et al. investigated the evaporation of liquid marbles coated with graphite particles at high temperatures, up to 465 °C, where the liquid marbles exhibited strong thermal robustness, as they took a long time, of around 100 s, to evaporate [49]. This could be explained by the Leidenfrost effect—a vapour film produced between the hot surface and liquid marbles hindered the heat transfer, which reduced the evaporation rate. To summarise, by modifying the coating layer and surrounding environment, the lifetime of liquid marbles could be extended up to a desired duration. Chu et al. reported a reaction at the elevated temperature of 80 °C that led to the collapse of the liquid marbles as the water inside rapidly evaporated. Therefore, the authors developed a robust coating layer from superhydrophobic Fe3O4/C microsheets and conducted the reaction in a high-humidity environment to protect the liquid marbles for a period of 50 min [50].

3. Liquid Marbles as Microreactors for Chemical Applications

3.1. Advantages of Liquid Marble-Based Chemical Reactors

Continuous-flow reactors have outstanding advantages that make them widely used in industries. However, batch reactors are preferable for small-scale operations, owing to their flexibility and versatility. Various reactions with a broad range of reaction times and reaction phases can be performed conveniently in batch reactors. While there are many attempts to miniaturise continuous-flow reactors, only a few studies about miniaturised batch reactors have been investigated to date [51,52,53]. These reactors still require volumes in the order of millilitres, as well as sophisticated manufacturing processes. The emergence of liquid marbles has provided an ideal platform for microscale batch reactors. Liquid marbles have small volumes from hundreds of nanolitres to hundreds of microlitres and can be easily adjusted depending on the demand. The coating layer of a liquid marble can function as a barrier to mitigate the effect of evaporation and avert contamination. When handling corrosive or highly exothermic reactions, the lack of contact with the interior liquid can protect the external environment from being damaged, thus reducing the hazards. Liquid marble-based microreactors can avoid problems such as clogging or the inefficient mixing of solvents with viscosity higher than 40 MPa·s [54]. The high surface-to-volume ratio of liquid marbles also provides a suitable platform to accommodate catalytic microreactions. The gas permeability of the shell allows reactions involving gas-phase reactants. To summarise, the numerous advantages of liquid marble-based reactors make them strong candidates as a microscale batch reactor platform.

3.2. Practical Applications of Liquid Marble-Based Chemical Reactors

The feasibility of liquid marbles to serve as microreactors was demonstrated in early studies [34]. The reported reactions mainly took place in the liquid phase and in mild conditions. To date, tremendous efforts have been made to develop a wide range of reactions in liquid marbles, including multiphase, catalytic, or electrochemical reactions. These studies demonstrate the feasibility of liquid marbles as universal microreactors for chemical applications.

3.2.1. Microreactors for Gas-Phase Reactions

The outer coating layers of liquid marbles are generally permeable to gaseous substances, enabling the liquid inside to absorb and react with the gas. This feature allows liquid marbles to function as miniature reactors involving liquid-gas phase reactions. Many studies have utilised this ability to use liquid marbles as gas sensors. Tian et al. introduced different approaches with liquid marbles as gas sensors for the detection of ammonia and hydrochloric acid based on colourimetry and fluorescence methods [55]. Phenolphthalein, CoCl2·2H2O, and CuCl2·2H2O solutions were used as indicators for the detection of NH3 vapours. The colour change due to NH3 vapours of the above solutions was observed (Figure 3a). Liquid marbles derived from 8-hydroxypyrene-1,3,6-trisulfonic acid trisodium salt were also used as fluorescent pH indicators, as their colour changed from green to blue under UV light after being exposed to HCl vapours. The authors also developed a quantitative method for NH3 gas sensing with liquid marbles using a NH3 solution with different concentrations to construct a calibration curve of the colourimetric measurements. This method was further validated by the same authors using ultraviolet–visible spectrophotometry (UV–VIS) [56]. The colourimetric measurements were confirmed to be more suitable for detecting NH3 at low concentrations. Recently, Li et al. developed a rod-shaped liquid plasticine-based gas sensor that indicated gas distribution along its length [57]. The phenolphthalein solution was coated with a superhydrophobic sol-gel film to form liquid plasticine, which could easily be shaped into a rod. A droplet of NH3 solution placed at one end of the rod-shaped sensor evaporated and diffused into the sensor along its length. Therefore, the colour of the sensor would change, and the diffusion rate of NH3 could be observed. While inorganic gases only took a short time to react, their organic counterparts required a longer duration to have any visible effect. Bormashenko et al. demonstrated the feasibility of liquid marbles as microreactors for the Hantzsch reaction to detect organic contamination via colourimetric measurements [58]. A small liquid marble constructed from a solution of ammonia acetate, acetic acid, acetylacetone, and polyvinylidene fluoride powder was used to detect formaldehyde vapours. The emergence of a yellow colour due to the formation of diacetyl-dihydro-lutidine effectively indicated the existence of formaldehyde. In summary, liquid marbles can serve as an effective sensing platform that is extremely cost-effective and easy to perform for the detection of inorganic and organic gases.

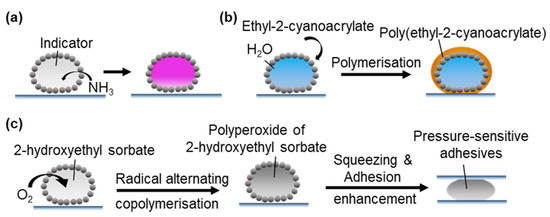

Figure 3.

Gas-phase reaction in liquid marbles. (a) Colour change of liquid marbles containing an indicator when interacting with a NH3 vapour [55]. (b) Polymerisation of ethyl-2-cryanoacrylate on the surface of coating particles [59]. (c) Copolymerisation of 2-hydroxyethyl sorbate (HES) and oxygen to produce pressure-sensitive adhesive using liquid marble-based microreactors [60,61].

The potential of liquid marble-based microreactors was also extended to organic synthesis involving gas-phase reactions. Chin et al. introduced a simple method to synthesise the liquid marble encapsulating layer by exposing a water liquid marble coated with NH2-MIL-53(Al)–Al2O3 composite microparticles to an ethyl-2-cyanoacrylate vapour in a closed container [59]. The vapour condensed on the outer layer of the liquid marble and polymerised into poly(ethyl-2-cyanoacrylate) (Figure 3b). Sato et al. investigated the copolymerisation of a 1,3-dienemonomer with a gaseous monomer in liquid marbles [60]. The author used 2-hydroxyethyl sorbate (HES) and oxygen as comonomers to demonstrate the copolymerisation reaction to synthesise a polyperoxide of HES (PP-HES) (Figure 3c). The conversion of HES to PP-HES in liquid marbles was significantly higher when compared to the one conducted in a test tube, reaching 47.7% and 1.8%, respectively. The authors argued that the remarkably high liquid-gas interfacial area of the liquid marble-based microreactors plays an important role in the improvement of the absorbance and diffusion of oxygen, which, in turn, leads to a higher copolymerisation efficiency. Interestingly, a good yield was obtained without oxygen bubbling and stirring, which are commonly used in a conventional reactor, suggesting that the liquid marble reactor can be more efficient and require less energy. The liquid marbles containing PP-HES could then be utilised as pressure-sensitive adhesives by squeezing to release the contained polyperoxide and subjecting it to UV irradiation or high temperatures [61]. The obtained adhesives possessed an approximate 180° peel strength of commercial pressure-sensitive tape and could be further fine-tuned. In summary, a high interfacial surface area and good gas permeability are the main advantages that make liquid marbles a good reactor platform involving gases. Future studies on the gas absorption efficiency of liquid marbles and its reaction parameters, such as temperature and pressure, are essential to have precise control over reactant and product concentrations.

3.2.2. Microreactors for Solid Material Synthesis

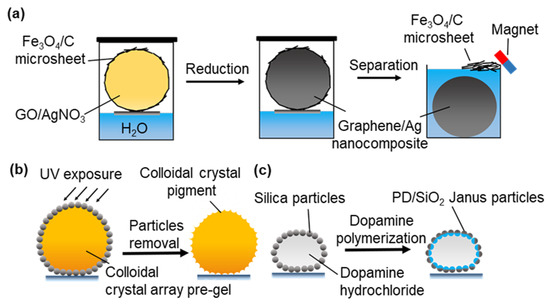

Solid-phase reactions are conveniently performed in liquid marbles, because this platform can avoid clogging, which usually occurs in microchannels. Solid-phase products can also be easily separated from liquid marbles and collected through different material-release mechanisms. Chu et al. demonstrated the use of liquid marbles as miniature reactors for the synthesis of a graphene/Ag nanocomposite (Figure 4a) [50]. The dispersion of graphite oxide and silver nitrate was coated with Fe3O4/C microsheets to form a liquid marble and reduced into graphene/Ag at 80 °C. After the reaction, the synthesised solid was separated from the coating layer simply by placing it in water. The obtained graphene/Ag nanocomposite was used as a catalyst for the reduction of 4-nitroaniline and exhibited good catalytic characteristics. Gu et al. studied the synthesis of colour pigments in liquid marbles (Figure 4b) [62]. Colloidal crystal solutions of silica nanoparticles in poly(ethylene glycol) diacrylates were encapsulated by hydrophobic microparticles. These silica nanoparticles self-assembled into a loose colloidal crystal array, which enabled them to deliver iridescent colours. The marbles were then exposed to UV light to polymerise the liquid inside. Next, the outer layer was removed to obtain noniridescent structural colour pigments. The possibility of using liquid marbles for solid material synthesis also extends to the coating particles. Sheng et al. successfully developed a method to fabricate Janus particles by asymmetrically depositing polydopamine on the surfaces of coating silica particles (Figure 4c) [63]. In these studies, the authors reported that it was easy to separate the synthesised solid material simply by placing them in water or solvent, followed by collecting and drying the solid. Although only a few studies have been performed, these works demonstrated the potential of liquid marbles for solid synthesis.

Figure 4.

Solid material synthesis in liquid marble-based microreactors. (a) Synthesis of graphene/Ag nanocomposite [50]. (b) Synthesis of colour pigment [62]. (c) Synthesis of polydopamine/silica Janus particles in liquid marble reactors [63].

3.2.3. Microreactors for Heterogeneous Catalytic Reactions

Catalysts are used extensively in the chemical industry, owing to their ability to significantly increase reaction kinetics. Catalysts are commonly divided into homogeneous or heterogeneous categories. Heterogeneous catalysts can be easily separated from reaction products and reused through regeneration processes. However, heterogeneous catalytic reactions take place in different stages, including the diffusion, adsorption, and desorption of reactants in and out of the catalyst surfaces, thus requiring a large surface area to achieve a high reaction efficiency. For reactions in an aqueous environment, hydrophobicity directly affects the catalytic activity, as it leads to poor dispersibility in water, which, in turn, limits the surface area. Numerous studies have attempted to overcome this challenge by adding hydrophilic ligands [64] or encapsulating the catalyst with micelles, dendrimers, polymeric capsules, and nanoparticles [65]. Recent studies have suggested that improvements in the dispersibility of hydrophobic catalysts can be achieved by growing a hydrophilic nanoporous shell [66]. Nevertheless, these methods require additional chemicals and complex procedures for the treatment of catalysts, which limit their potential to be widely used. Therefore, liquid marbles are attracting substantial interest, since they can provide a simple and effective platform for catalytic reactions. Recent studies have shown that, by coating liquid marbles with hydrophobic catalyst particles, it is possible to create a microreactor with a large catalyst surface area in a simple manner without additional modifications.

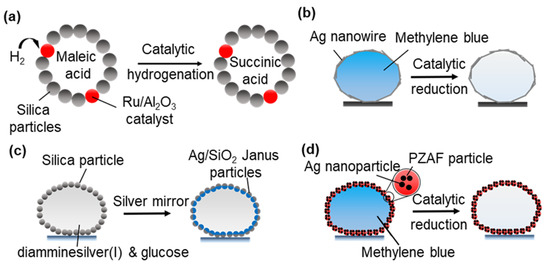

In previous studies, the coating layer is usually made of inert hydrophobic particles. Carter et al. first utilised Ru/Al2O3 as coating particles that effectively catalysed the hydrogenation of maleic acid to succinic acid on a dry water platform (Figure 5a) [67]. The dry water-based microreactors delivered a substantially higher conversion in comparison to a bulk mixture of maleic acid and coating particles. Interestingly, the dry water droplets still maintained their size and flow properties, despite the high pressure and the elevated temperature, indicating that this platform is applicable for reactions under harsh conditions. However, a much longer heating duration is required for the conversion in a dry water droplet to approach the conversion rate of a stirred reactor, suggesting that dry water or liquid marble platforms could be more suitable when applied to reactions conducted at lower temperatures. Miao et al. investigated the feasibility of using large surface area silver nanowires to form catalytic liquid marbles for the reduction of methylene blue in the presence of sodium borohydride (NaBH4) (Figure 5b) [68]. The catalytic activity of silver nanowires remained almost stable after five cycles of reduction. These results clearly indicate that the silver nanowires can catalyse the reduction of methylene blue. The authors also found that larger liquid marbles led to a reduction in the reaction rate because of the decrease in the area of the liquid-air interface, where the catalyst resides. It is worth mentioning that the treatment with 1H,1H,2H,2H-perfluorodecanethiol is necessary to make the silver nanowire hydrophobic.

Figure 5.

Reactions in catalytic liquid marble-based microreactors. (a) Hydrogenation of maleic acid in dry water with a Ru/Al2O3 catalyst [67]. (b) Reduction of methylene blue in catalytic liquid marbles covered by silver nanowires [68]. (c) Silver mirror reaction and Janus particles synthesised with silica-based liquid marbles [69]. (d) Catalytic reduction of methylene blue in liquid marbles covered by silver nanoparticle-decorated poly(cyclotriphosphazene-co-4,4′-(hexafluoroisopropylidene)-diphenol) particles (Ag/PZAF) [71].

Sheng et al. investigated hydrophobic silica particles as the coating layer, which directly participates in the silver mirror reaction [69]. A diamminesilver(I) solution was added to liquid marbles constructed from a glucose solution and fumed silica with different concentrations of silanol to investigate the silver mirror reaction on the surfaces of coating particles (Figure 5c). Bare droplets and partially coated droplets made from the same solution were also studied as references. A colour change was seen in all the liquid marbles, but reflective silver mirrors only appeared on fully coated marbles, proving that the silica coating layer plays an essential role in the formation of the silver mirror. The authors suggested that the H30 silica particles provided a reactive surface for the free silver ions to bind and convert into elemental silver atoms, which function as nucleating sites for the formation of silver mirrors [70]. The authors also utilised the deposition of silver only on one face of the silica particles at the liquid-gas interface to fabricate Janus particles, proving the potential use of liquid marbles as microreactors for the fabrication of nanoparticles. In a recent study, Wei et al. combined synthetic polymer particles from cyclomatrix polyphosphazene and silver to obtain Ag/PZAF composite particles, which exhibited high hydrophobicity and catalytic activity (Figure 5d) [71]. The reduction rate of methylene blue by NaBH4 was significantly higher in liquid marbles coated with the Ag/PZAF composite particles when compared to conventional bulk solutions with a catalyst or bare droplets. Moreover, silver nanoparticles can be dispersed onto PZAF particles and immobilised there, effectively preventing the aggregation that potentially reduces the catalyst surface area. In conclusion, high versatility and the ability to increase the surface area of a hydrophobic catalyst are the characteristics that make liquid marbles a promising platform for heterogeneous catalytic reactions. However, the need to hydrophobise catalysts remains the main drawback of this platform.

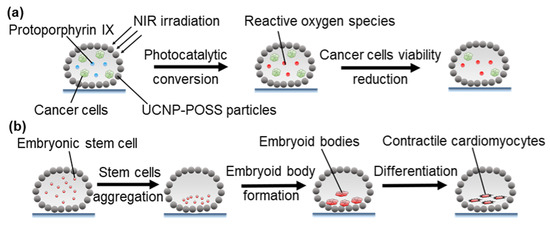

The study on catalytic liquid marbles also extended to photocatalysis. Yb3+/Er3+/Gd3+-doped NaYF4 is a promising material for photocatalytic applications, as it is capable of converting two or more photons into one photon with a higher frequency. This material is also magnetically susceptible, owing to the doping of Gd3+. By bonding the surface of the aforementioned upconversion nanoparticles (UCNPs) with hydrophobic polyhedral oligomeric silsesquioxane (POSS), Wang et al. successfully developed a bifunctional coating material for photocatalytic liquid marbles [72]. Liquid marbles constructed from this material were responsive to magnetic forces and capable of performing upconversion luminescence. These liquid marbles functioned effectively to induce near-infrared irradiation to excite protoporphyrin IX (PpIX) into a reactive oxygen species (ROS). This application has great potential in the photodynamic therapy of cancer cells, which will be reported in the microbioreactors section.

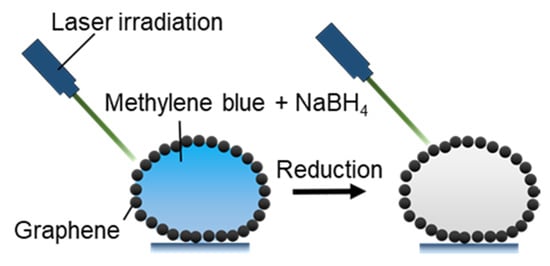

3.2.4. Photothermal Microreactors

Gao et al. introduced a mechanism for heating liquid marbles based on the photothermal effect using laser irradiation (Figure 6) [73]. The authors utilised graphene as the coating layer for liquid marbles, because it can deliver the highest surface temperature under irradiation compared to other materials. The degradation of methylene blue by NaBH4 using photothermal heating was reported, showing that remarkably higher reaction kinetics can be achieved. Compared to reactions conducted at room temperature, heating can enhance the reaction rate constant up to 12 times and the reaction efficiency up to seven times. Based on this mechanism, it is possible to engineer a remotely heatable microreactor that can precisely control the temperature for a wide range of reactions.

Figure 6.

Photothermal heating of a liquid marble for the reduction of methylene blue [73].

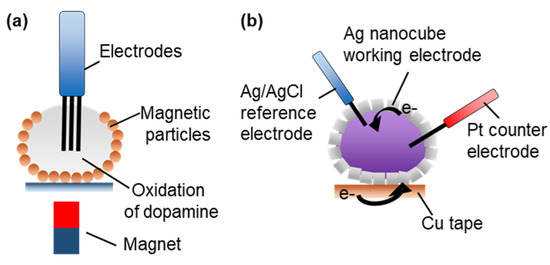

3.2.5. Electrochemical Microreactors

The idea of combining liquid marbles and electrochemistry is attractive, because it opens up a broad range of applications for this platform, such as analytical chemistry, as well as the production of chemicals, batteries, and fuel cells. Zhao et al. conducted the electrochemical detection of dopamine in a magnetic liquid marble that can be opened for the three-microelectrode probe to penetrate the liquid (Figure 7a) [41]. Koh et al. reported the use of the liquid marble itself as the working electrode for electrochemical reactions and spectroelectrochemical analysis (Figure 7b) [74]. The authors utilised the HCl-treated silver nanocube shells of plasmonic liquid marbles as a working electrode for a one-electron redox reaction of Ru3+ to Ru2+ and a heterogeneous electroreduction of methylene blue. Cyclic voltammetry results confirmed the electroreduction of Ru3+ to Ru2+ in plasmonic liquid marbles, whereas no significant responses were observed with the reaction conducted in silica liquid marbles. Furthermore, the three-dimensional metallic plasmonic shell was considerably robust and could deliver a higher peak current of up to 1.5 times as compared to the planar working electrodes. The electroreduction of methylene blue was also investigated. The results demonstrated the formation of leucomethylene blue in the final reduced product through a multistep reduction and oxidation process. Interestingly, this platform is reported to be the first working electrode that is miniaturised, three-dimensional, and is also the smallest spectroelectrochemical microreactor. These results prove that liquid marble-based microreactors are a promising candidate for microscale reactions and analyses.

Figure 7.

Electrochemical microreactor based on a liquid marble platform. (a) Liquid marble opened by magnetic force for the electrochemical detection of the oxidation of dopamine [41]. (b) The shell of plasmonic liquid marbles was used as a working electrode for the redox reaction of Ru3+ and electroreduction of methylene blue [74].

3.2.6. Other Applications

Plasmonic liquid marbles are promising microreactors, because they not only provide suitable platforms for electrochemical reactions but, also, enable real-time and in situ monitoring by surface-enhanced Raman scattering spectroscopy (SERS) [74,75]. Han et al. implemented the concept of performing multistep reactions via coalescing different liquid marbles and monitoring azo-dye synthesis using SERS [76]. The synthesis consists of two reactions, which are the diazotisation of aromatic amine and azo coupling. The first reaction was performed by coalescing liquid marbles containing a solution of nitroaniline and HCl with another liquid marble containing NaNO2. The second reaction was initiated by coalescing another liquid marble encapsulating a bisphenol A (BPA) solution with the previous marble. Interestingly, this plasmonic liquid marble platform allows the SERS detection of BPA to be very sensitive, as the detection limit can be 50,000 times lower than the safety limit of BPA.

In addition to gas sensing and electrochemical analysis, which have been discussed in previous sections, other applications of liquid marbles in quantitative analyses were also demonstrated. Zhao et al. performed a glucose assay in liquid marbles using a colourimetric enzyme-kinetic method [41]. The formation rate of the violet colour from the reaction of glucose and its detection reagent was measured to determine the correlation coefficient between the reaction rate and glucose concentration. By using liquid marbles containing test reagents, Tyowua et al. were able to identify cations and anions, as well as conduct acid-base and redox titrations without introducing any external actuation fields [77]. These tests were done simply by merging droplets of test reagents with liquid marbles and observing the colour change of the indicators. The authors were able to reduce the amounts of reagents and waste, owing to the small volumes of the liquid marbles.

Belousov–Zhabotinsky (BZ)-type reactions are oscillatory chemical reactions that can generate patterns of oxidation wavefronts and be applied in many unconventional computing devices. Fullarton et al. attempted to perform BZ reactions in liquid marble-based microreactors by encapsulating a BZ reaction mixture consisting of malonic acid, bromate ions, and an acid catalyst with polyethylene (PE) or PTFE hydrophobic powders [78]. Oxidation waves through the coating layer and between contiguous liquid marbles could be observed to study the reaction. It is also feasible to control the wave transfer by modifying the BZ liquid marbles system. These results make provisions for the further development of BZ liquid marbles in robot control [79] and photosensors [80].

4. Liquid Marbles as Microreactors for Biological Applications

4.1. Advantages of Liquid Marble-Based Microbioreactors

Numerous inherent characteristics of liquid marbles make them promising candidates for a novel microbioreactor platform. First, liquid marbles can provide a three-dimensional medium that is more similar to the actual environment, thus delivering a better understanding of how biological phenomena take place in reality. The volume of the interior liquid, which spans multiple orders of magnitude, suits applications such as a microscale biological assay or cell culture. The porous shell also permits the exchange of essential gases such as oxygen and carbon dioxide between the liquid marble and its surroundings, which is necessary for aerobic cell culture applications. Furthermore, the hydrophobic shells of liquid marbles can eliminate any contact with surrounding substrates, reducing the risk of biohazard exposures and cross-contaminations. The small volumes of liquid marbles allow for better control of reaction conditions and promote better aggregation for cell cultures. Finally, this platform allows experimental handling to be conducted in a facile manner that is cost-effective and disposable. Therefore, liquid marble-based microbioreactors are a promising platform for diagnostic assays, cell cultures, drug screenings, and polymerase chain reactions [81,82].

4.2. Practical Application of Liquid Marble-Based Microbioreactors

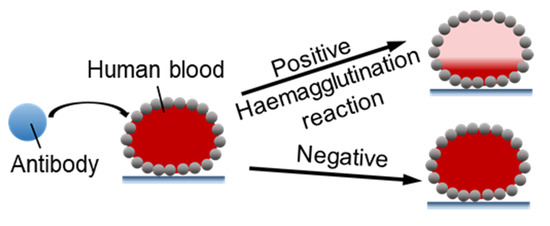

4.2.1. Microbioreactors for Blood Typing

The first use of liquid marbles as a microbioreactor was reported in a study of Arbatan et al. The authors utilised liquid marbles for blood typing (Figure 8) [83]. Blood liquid marbles coated with hydrophobic precipitated calcium carbonate power were injected with antibody solutions to test for haemagglutination. The positive results could be observed immediately, as the red colour of the liquid marbles was separated into light and dark-red colours. Otherwise, a uniformly dark-red colour would be exhibited. Subsequent tests with other antibody solutions were conducted to determine the ABO and Rh blood groups. The liquid marble could also be safely disposed by burning. Therefore, liquid marble-based microbioreactors have the potential to be a safe and cost-effective platform for rapid medical tests.

Figure 8.

Blood typing using liquid marble-based microbioreactors [83].

4.2.2. Microbioreactors for Cell Culture and Treatment

Liquid marbles provide an ideal platform for cell and microorganism cultures, which are essential for biomedical applications. Arbatan et al. first reported the use of liquid marbles to culture Hep G2 hepatocellular cancer cell spheroids in vitro to study how cancer cells aggregate to form tumour spheroids [43]. The authors coated the liquid marbles with inert PTFE particles to have a nonadhesive encapsulating layer that can promote the suspension of the cells. The aggregation of the cancer cells could be observed after one day, whereas three-dimensional cell aggregation appeared after 10 days of incubation, proving that a liquid marble-based microbioreactor could provide a three-dimensional environment for the formation of cell spheroids. These results paved the way for future developments in cancer therapy, as Wang et al. investigated the use of a liquid marble-based microbioreactor as a model for photodynamic therapy (Figure 9a) [72]. Liquid marbles coated with UCNP-POSS can significantly reduce the viability of cancer cells in the presence of PpIX, as these coating particles can catalyse the excitation of PpIX under NIR laser irradiation into ROS, which can lead to cancer cell apoptosis and necrosis [84]. However, liquid marbles covered with microparticles such as PTFE and UCNP-POSS are generally opaque, which hinders the optical analysis of interior liquids [24,85]. The emergence of transparent liquid marbles coated with fumed silica nanoparticles provides a valuable tool for the real-time monitoring of cell growths in this platform. Li et al. investigated the growth of lung cancer stem cells in transparent liquid marbles and conveniently recorded the growing process of spheroids [86]. The authors also studied the effects of various anticancer drugs and RNA on tumour spheroids, reporting that the spheroids cultured in liquid marbles were more resistant to those treatments compared to cells and spheroids cultured in a multiwell plate. These results proved that the liquid marble is a promising platform for the study of cancer treatments.

Figure 9.

Cell cultures and treatments in liquid marble-based microbioreactors. (a) Photodynamic therapy treatment of a cancer cell in liquid marbles [72]. (b) Formation of embryoid bodies and differentiation into cardiac cells in liquid marbles [45]. NIR: near infrared. UCNP-POSS: upconversion nanoparticles-polyhedral oligomeric silsesquioxane.

The study of liquid marbles as a culture media for embryoid bodies is also attracting many research interests, owing to their importance in tissue regeneration therapy. Embryonic stem cells are characterised by continuous proliferation and their capability to differentiate into various cell types. Sarvi et al. first reported the use of a liquid marble-based microbioreactor for the formation of three-dimensional embryoid bodies from murine-derived embryonic stem cell lines (Oct4b2) [87]. The formation of embryoid bodies in liquid marbles could be observed on the third day, proving that liquid marble-based microbioreactors can function effectively for this application. A large liquid marble size and high density of cell seeding were shown to promote aggregation. The authors then further studied the feasibility of differentiating the formed embryoid bodies in liquid marbles into cardiac lineages [44]. Murine embryonic stem cell (ESC) (Oct4B2-ESC) suspension was first cultured in liquid marbles coated with PTFE. After five days, the formed embryoid bodies were then plated in gelatine-coated plates for further differentiation. The embryoid bodies differentiated into contractile cardiomyocytes, which can be used in cell replacement therapy. Lin et al. utilised transparent liquid marbles covered with silica nanoparticles for the growth of embryoid bodies from Oct4B2-ESC and their differentiation into cardiomyocytes without transferring the embryoid bodies into another culture platform (Figure 9b) [45]. The transparency of liquid marbles allows for continuous and real-time monitoring of the formation of embryoid bodies and, eventually, the differentiation into contractile cardiac cells. Ledda et al. also extended the use of liquid marbles for the in vitro maturation of an oocyte, which is an important technique in the livestock field [88]. Cumulus-oocyte complexes were reported to mature well in liquid marbles, showing the potential of liquid marble-based microbioreactors for this application.

The floating liquid marble was investigated as a potential cell culture platform for olfactory ensheathing cells (OECs), as it exhibits various advantages when compared to sessile liquid marbles [89]. The results indicated that OECs in floating liquid marbles were able to form more and larger spheroids than in sessile liquid marbles, owing to the buoyancy that can induce internal flow and mitigate gravitational effects, thus preventing the OECs from sedimenting and aggregating at the bottom, as in sessile liquid marbles. Novel behaviours of OECs were also observed in this study using floating liquid marbles and further reported in a later study [90] The authors demonstrated the interactions of different cell types by the fusion of spheroids and coalescence of liquid marbles, suggesting that liquid marbles can be a suitable platform for the study of cellular behaviours in three-dimensional environments.

The porous shell allows the exchange of oxygen and carbon dioxide between the liquid marble and its surroundings, thus promoting an aerobic respiration process. Tian et al. studied the growth of Lactococcus lactis ssp. Cremoris, which is an aerotolerant anaerobe, and Saccharomyces cerevisiae, which is a facultative aerobe [91]. The results showed that, while the oxygen absorbed by the liquid marble can hinder the growth of L. cremoris, it encourages the proliferation of aerobic S. cerevisiae. Interestingly, there were more viable cells of S. cerevisiae in liquid marble-based microbioreactors than in shaken McCartney bottles, owing to the better diffusion of essential gases for the respiration process into the liquid phase. These results indicated that, while the oxygen absorbed through the porous shell of liquid marbles promoted aerobic processes, it inhibited the viability of anaerobic microorganisms.

Drug screening is also an important application of a liquid marble-based microbioreactor, as reported by Oliveira et al. [46]. The authors introduced surface-modified microparticles into the liquid marble interior to provide adhesion sites for anchorage-dependent cells. Cytotoxic screening tests on these cells were performed and monitored using a digital imaging-based colourimetric method, showing the feasibility of nondestructive tests for monitoring reactions in liquid marbles.

4.2.3. Microbioreactors for Polymerase Chain Reaction

Polymerase chain reaction (PCR) is the quintessential technique for the amplification of DNA [92]. In order to overcome problems associated with conventional methods, including contamination and a large amount of plastic waste, Sreejith et al. attempted to use a liquid marble-based microbioreactor as a platform for this application [85]. First, a PCR mixture was prepared by extracting DNA from human faecal samples and conducting a primary amplification. This mixture was then coated with PTFE powder to form liquid marbles and put in a thermal cycler to perform PCR. Although the results showed that liquid marbles provided a suitable platform for the PCR, the evaporation of the liquid marbles significantly limited the number of thermal cycles that could be performed. In a recent study, the same authors successfully developed a core-shell bead synthesised from a photopolymer liquid that can effectively mitigate the effects of evaporation [93]. This core-shell bead microbioreactor allows the authors to perform up to 30 thermal cycles of PCR, obtaining good DNA amplification results that are comparable to conventional methods. However, this method suffers from a difficulty in retrieving samples due to the hardened polymerised shell, suggesting that materials with a tuneable degradation such as reversible polymers can be a potential solution to overcome this drawback.

5. Future Perspectives

Liquid marbles have found applications in many different fields, as reported in previous sections. However, these studies only used aqueous solutions to construct liquid marbles, which limited the ability of liquid marbles to be used in chemical and biological applications. The introduction of new liquids for this platform can expand the range of applications of liquid marble-based microreactors. This remains a challenge, as liquids with low surface tensions such as organic solvents tend to wet the coating powder. Until now, studies have focused on overcoming this challenge by using modified hydrophobic particles that are able to confine low surface tension liquids. Most studies use magnetic nanoparticles to act as coating powders for liquids marbles, because these particles are easily modified to have low surface energies and can be used for later magnetic manipulations. For instance, Xue et al. developed a coating powder from fluorinated decyl polyhedral oligomeric silsesquioxane (FD-POSS) that effectively formed a series of robust liquid marbles from water and numerous organic solvents, ranging from dimethyl sulfoxide (DMSO) to heptane [34]. Other modifications on Fe3O4 nanoparticles enabled the authors to encapsulate a wide range of organic solvents, including toluene, dichloroethane, ethanol, or even high-viscosity solvents like polydimethylsiloxane, to form liquid marbles [94,95]. These results can provide future applications of liquid marble-based microreactors in organic synthesis.

A new approach for this reactor platform is constructing liquid marbles from novel liquids, such as ionic liquids, which are room-temperature liquid organic salts [96]. Owing to their outstanding properties, such as very low vapour pressure and thermal stability, ionic liquids have attracted significant research interests in the field of green chemistry, as they are considered safe and environmentally benign [97]. Ionic liquids can dissolve numerous types of inorganic, organic, and polymeric compounds [98], enabling their uses as extractions and reaction media [99,100,101,102,103,104]. Ionic liquids also exhibit a tremendous potential to serve as microreactors. For instance, Zhang et al. demonstrated the use of an ionic liquid droplet microreactor for the enzymatic enantioselective transesterification of alcohols and the catalytic cycloaddition reactions [105]. Higher catalysis efficiencies and reaction kinetics were observed with the ionic liquid microreactor, achieving more than a 25-times increase compared to the conventional batch reactors. These results prove that ionic liquids could be promising microreactor platforms. Gao et al. reported the feasibility of constructing liquid marbles containing various kinds of ionic liquids by coating them with oligomerictetrafluoroethylene (OTFE) particles [96]. These findings could allow the use of ionic liquid marbles as microreactors for organic reactions. However, there has been no research on the reactions using ionic liquid marble platforms thus far.

Liquid metals such as Galinstan, eGaIn, and Field’s alloy show great potential as microreactor platforms. Owing to special characteristics such as low viscosity and high electrical and thermal conductivity, liquid metals have found their place in applications such as soft electronics [106], stretchable devices [107], and microswitches [108]. To date, liquid metals have also been extensively investigated in chemistry, mostly for syntheses within bulk liquids and on liquid metal interfaces, as well as catalysts [109,110,111]. Liquid metals can also be used in the synthesis of nanostructures [112,113] or hydrogen production [114,115]. Despite the tremendous advantages, liquid metals have many drawbacks, as they tend to corrode metal substrate surfaces very quickly. Therefore, it is necessary to eliminate the contact between the liquid metals and external substrates. Sivan et al. proposed an effective solution by forming liquid metal marbles by coating liquid metal with different hydrophobic powders, resulting in robust liquid metal marbles [116]. These promising results showed that liquid metal marbles can be used as microreactors for the synthesis of nanostructures. However, the ability to perform reactions on liquid metal marble platforms has not yet been explored. The use of novel liquids such as ionic liquid marbles and liquid metal marbles is attractive, because it can considerably expand the temperature range and extend the applications of liquid marble-based microreactors into different fields.

6. Conclusions

This review systematically summarises the current studies on the use of liquid marbles as microreactors. Liquid marbles are reported to function effectively as microreactor platforms for both chemical and biological applications. The highly flexible combination between core liquids and coating particles enable us to tailor a suitable liquid marble-based microreactor for different applications. The studies reported in this review presented encouraging results that can be further developed. New liquids and particle coatings can further extend the working window of liquid marble-based microreactors.

Author Contributions

Writing—original draft preparation, N.-K.N.; writing—review and editing, C.H.O., P.S., J.J., K.R.S., H.-P.P., and N.-T.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Australian Research Council (ARC) Discovery Early Career Research Award (DECRA) DE200100119 and the ARC Discovery Project DP170100277.

Acknowledgments

C.H.O. acknowledges funding support from the Australian Research Council (ARC) Discovery Early Career Research Award (DECRA) DE200100119. N.T.N. acknowledges funding support from the ARC Discovery Project DP170100277. N.K.N. acknowledges funding support from the Griffith University International Postgraduate Research Scholarship and the ARC DECRA Postgraduate Research Scholarship.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kothare, M.V. Dynamics and control of integrated microchemical systems with application to micro-scale fuel processing. Comput. Chem. Eng. 2006, 30, 1725–1734. [Google Scholar] [CrossRef]

- Mills, P.L.; Quiram, D.J.; Ryley, J.F. Microreactor technology and process miniaturization for catalytic reactions—A perspective on recent developments and emerging technologies. Chem. Eng. Sci. 2007, 62, 6992–7010. [Google Scholar] [CrossRef]

- Tanimu, A.; Jaenicke, S.; Alhooshani, K. Heterogeneous catalysis in continuous flow microreactors: A review of methods and applications. Chem. Eng. J. 2017, 327, 792–821. [Google Scholar] [CrossRef]

- Watts, P.; Haswell, S.J. The application of micro reactors for organic synthesis. Chem. Soc. Rev. 2005, 34, 235–246. [Google Scholar] [CrossRef]

- Yoshida, J.-I.; Nagaki, A.; Yamada, T. Flash Chemistry: Fast Chemical Synthesis by Using Microreactors. Chem. A Eur. J. 2008, 14, 7450–7459. [Google Scholar] [CrossRef]

- Jiao, Z.; Huang, X.; Nguyen, N.T.; Abgrall, P. Thermocapillary actuation of droplet in a planar microchannel. Microfluid. Nanofluid. 2007, 5, 205–214. [Google Scholar] [CrossRef]

- Luong, T.D.; Nguyen, N.T. Surface Acoustic Wave Driven Microfluidics—A Review. Micro Nanosyst. 2010, 2, 217–225. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Tan, S.H.; Nguyen, N.T.; Wong, T.N.; Yobas, L. Microdroplet formation of water and nanofluids in heat-induced microfluidic T-junction. Microfluid. Nanofluid. 2008, 6, 253–259. [Google Scholar] [CrossRef]

- Song, C.; Nguyen, N.T.; Tan, S.H.; Asundi, A. Modelling and optimization of micro optofluidic lenses. Lab Chip 2009, 9, 1178–1184. [Google Scholar] [CrossRef]

- Demello, A.J. Control and detection of chemical reactions in microfluidic systems. Nature 2006, 442, 394–402. [Google Scholar] [CrossRef]

- Su, B.; Wang, S.; Song, Y.; Jiang, L. A miniature droplet reactor built on nanoparticle-derived superhydrophobic pedestals. Nano Res. 2010, 4, 266–273. [Google Scholar] [CrossRef]

- Haswell, S.; Watts, P. Green chemistry: Synthesis in micro reactors. Green Chem. 2003, 5, 240–249. [Google Scholar] [CrossRef]

- Baraldi, P.T.; Hessel, V. Micro reactor and flow chemistry for industrial applications in drug discovery and development. Green Process. Synth. 2012, 1, 149–167. [Google Scholar] [CrossRef]

- Watts, P.; Wiles, C. Micro reactors, flow reactors and continuous flow synthesis. J. Chem. Res. 2012, 36, 181–193. [Google Scholar] [CrossRef]

- Pike, N.; Richard, D.; Foster, W.; Mahadevan, L. How aphids lose their marbles. Proc. R. Soc. Lond. Ser. B Biol. Sci. 2002, 269, 1211–1215. [Google Scholar] [CrossRef]

- Aussillous, P.; Quéré, D. Liquid marbles. Nature 2001, 411, 924–927. [Google Scholar] [CrossRef]

- Draper, T.C.; Fullarton, C.; Phillips, N.; de Lacy Costello, B.P.; Adamatzky, A. Mechanical Sequential Counting with Liquid Marbles. In Proceedings of the International Conference on Unconventional Computation and Natural Computation, Fontainebleau, France, 25–29 June 2018; pp. 59–71. [Google Scholar]

- Nguyen, N.T.; Hejazian, M.; Ooi, C.H.; Kashaninejad, N. Recent Advances and Future Perspectives on Microfluidic Liquid Handling. Micromachines 2017, 8, 186. [Google Scholar] [CrossRef]

- Draper, T.C.; Fullarton, C.; Phillips, N.; de Lacy Costello, B.P.; Adamatzky, A. Liquid marble interaction gate for collision-based computing. Mater. Today 2017, 20, 561–568. [Google Scholar] [CrossRef]

- McHale, G.; Newton, M.I. Liquid marbles: Principles and applications. Soft Matter 2011, 7, 5473–5481. [Google Scholar] [CrossRef]

- Ooi, C.H.; Nguyen, N.T. Manipulation of liquid marbles. Microfluid. Nanofluid. 2015, 19, 483–495. [Google Scholar] [CrossRef]

- Wu, H.; Watanabe, H.; Ma, W.; Fujimoto, A.; Higuchi, T.; Uesugi, K.; Takeuchi, A.; Suzuki, Y.; Jinnai, H.; Takahara, A. Robust Liquid Marbles Stabilized with Surface-Modified Halloysite Nanotubes. Langmuir 2013, 29, 14971–14975. [Google Scholar] [CrossRef]

- Matsukuma, D.; Watanabe, H.; Minn, M.; Fujimoto, A.; Shinohara, T.; Jinnai, H.; Takahara, A. Preparation of poly(lactic-acid)-particle stabilized liquid marble and the improvement of its stability by uniform shell formation through solvent vapor exposure. RSC Adv. 2013, 3, 7862–7866. [Google Scholar] [CrossRef]

- Bhosale, P.S.; Stretz, H.A.; Panchagnula, M.V. Mechanically robust nanoparticle stabilized transparent liquid marbles. Appl. Phys. Lett. 2008, 93, 034109. [Google Scholar] [CrossRef]

- Dupin, D.; Thompson, K.L.; Armes, S.P. Preparation of stimulus-responsive liquid marbles using a polyacid-stabilised polystyrene latex. Soft Matter 2011, 7, 6797–6800. [Google Scholar] [CrossRef]

- Castro, J.O.; Neves, B.M.; Rezk, A.R.; Eshtiaghi, N.; Yeo, L.Y. Continuous Production of Janus and Composite Liquid Marbles with Tunable Coverage. ACS Appl. Mater. Interfaces 2016, 8, 17751–17756. [Google Scholar] [CrossRef] [PubMed]

- Sreejith, K.R.; Ooi, C.H.; Jin, J.; Dao, D.V.; Nguyen, N.T. An automated on-demand liquid marble generator based on electrohydrodynamic pulling. Rev. Sci. Instrum. 2019, 90, 055102. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Chan, K.F.; Ji, F.; Wang, Q.; Chiu, P.W.Y.; Guo, Z.; Zhang, L. On-Demand Coalescence and Splitting of Liquid Marbles and Their Bioapplications. Adv. Sci. 2019, 6, 1802033. [Google Scholar] [CrossRef]

- Xin, Z.; Skrydstrup, T. Liquid Marbles: A Promising and Versatile Platform for Miniaturized Chemical Reactions. Angew. Chem. Int. Ed. 2019, 58, 11952–11954. [Google Scholar] [CrossRef]

- Luo, X.; Yin, H.; Li, X.; Su, X.; Feng, Y. CO2-Triggered microreactions in liquid marbles. Chem. Commun. 2018, 54, 9119–9122. [Google Scholar] [CrossRef]

- Jin, J.; Ooi, C.H.; Dao, D.V.; Nguyen, N.T. Coalescence Processes of Droplets and Liquid Marbles. Micromachines 2017, 8, 336. [Google Scholar] [CrossRef]

- Jin, J.; Ooi, C.H.; Dao, D.V.; Nguyen, N.T. Liquid marble coalescence via vertical collision. Soft Matter 2018, 14, 4160–4168. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Fu, X.; Binks, B.; Shum, H.C. Coalescence of Electrically Charged Liquid Marbles. Soft Matter 2017, 13, 119–124. [Google Scholar] [CrossRef]

- Xue, Y.; Wang, H.; Zhao, Y.; Dai, L.; Feng, L.; Wang, X.; Lin, T. Magnetic Liquid Marbles: A “Precise” Miniature Reactor. Adv. Mater. 2010, 22, 4814–4818. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zang, D.; Zhao, L.; Qu, M.; Li, X.; Li, X.; Li, L.; Geng, X. Liquid Marble Coalescence and Triggered Microreaction Driven by Acoustic Levitation. Langmuir 2017, 33, 6232–6239. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Yang, T.; Huang, Y.; Liu, Y.; Chen, L.; Deng, L.; Shum, H.C.; Kong, T. Electrocontrolled Liquid Marbles for Rapid Miniaturized Organic Reactions. Adv. Funct. Mater. 2019, 29, 1901101. [Google Scholar] [CrossRef]

- Zhang, Y.; Fu, X.; Guo, W.; Deng, Y.; Binks, B.P.; Shum, H.C.; Binks, B. Electrocoalescence of liquid marbles driven by embedded electrodes for triggering bioreactions. Lab Chip 2019, 19, 3526–3534. [Google Scholar] [CrossRef]

- Zang, D.; Li, J.; Chen, Z.; Zhai, Z.; Geng, X.; Binks, B.P. Switchable Opening and Closing of a Liquid Marble via Ultrasonic Levitation. Langmuir 2015, 31, 11502–11507. [Google Scholar] [CrossRef] [PubMed]

- Ooi, C.H.; Jin, J.; Sreejith, K.R.; Nguyen, N.T.; Evans, G.M.; Nguyen, N.T. Manipulation of a floating liquid marble using dielectrophoresis. Lab Chip 2018, 18, 3770–3779. [Google Scholar] [CrossRef] [PubMed]

- Fujii, S.; Yusa, S.-I.; Nakamura, Y. Stimuli-Responsive Liquid Marbles: Controlling Structure, Shape, Stability, and Motion. Adv. Funct. Mater. 2016, 26, 7206–7223. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, Z.; Niu, H.; Wang, X.; Lin, T. Magnetic Liquid Marbles: Toward “Lab in a Droplet”. Adv. Funct. Mater. 2014, 25, 437–444. [Google Scholar] [CrossRef]

- Li, M.; Tian, J.; Li, L.; Liu, A.; Shen, W. Charge transport between liquid marbles. Chem. Eng. Sci. 2013, 97, 337–343. [Google Scholar] [CrossRef]

- Arbatan, T.; Al-Abboodi, A.; Sarvi, F.; Chan, P.P.Y.; Shen, W. Tumor Inside a Pearl Drop. Adv. Healthc. Mater. 2012, 1, 467–469. [Google Scholar] [CrossRef] [PubMed]

- Sarvi, F.; Jain, K.; Arbatan, T.; Verma, P.J.; Hourigan, K.; Thompson, M.C.; Shen, W.; Chan, P.P.Y. Cardiogenesis of Embryonic Stem Cells with Liquid Marble Micro-Bioreactor. Adv. Healthc. Mater. 2014, 4, 77–86. [Google Scholar] [CrossRef]

- Lin, K.; Chen, R.; Zhang, L.; Zang, D.; Geng, X.; Shen, W. Transparent Bioreactors Based on Nanoparticle-Coated Liquid Marbles for in Situ Observation of Suspending Embryonic Body Formation and Differentiation. ACS Appl. Mater. Interfaces 2018, 11, 8789–8796. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, N.; Correia, C.R.; Reis, R.L.; Mano, J.F. Liquid Marbles for High-Throughput Biological Screening of Anchorage-Dependent Cells. Adv. Healthc. Mater. 2014, 4, 264–270. [Google Scholar] [CrossRef] [PubMed]

- Tosun, A.; Erbil, H.Y. Evaporation rate of PTFE liquid marbles. Appl. Surf. Sci. 2009, 256, 1278–1283. [Google Scholar] [CrossRef]

- Dandan, M.; Erbil, H.Y. Evaporation Rate of Graphite Liquid Marbles: Comparison with Water Droplets. Langmuir 2009, 25, 8362–8367. [Google Scholar] [CrossRef]

- Aberle, C.; Lewis, M.; Yu, G.; Lei, N.; Xu, J. Liquid marbles as thermally robust droplets: Coating-assisted Leidenfrost-like effect. Soft Matter 2011, 7, 11314–11318. [Google Scholar] [CrossRef]

- Chu, Y.; Wang, Z.; Pan, Q. Constructing Robust Liquid Marbles for Miniaturized Synthesis of Graphene/Ag Nanocomposite. ACS Appl. Mater. Interfaces 2014, 6, 8378–8386. [Google Scholar] [CrossRef]

- Jeon, S.; Park, C.S.; Hackett, C.; Norbeck, J. Characteristics of steam hydrogasification of wood using a micro-batch reactor. Fuel 2007, 86, 2817–2823. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, H.; Chen, X.; Feng, X.; Yang, C. Effect of blending ratio on coke morphology and composition in co-coking of vacuum residue and bio-tar. J. Anal. Appl. Pyrolysis 2019, 141, 104629. [Google Scholar] [CrossRef]

- Ge, Z.; Jin, H.; Guo, L. Hydrogen production by catalytic gasification of coal in supercritical water with alkaline catalysts: Explore the way to complete gasification of coal. Int. J. Hygiene Energy 2014, 39, 19583–19592. [Google Scholar] [CrossRef]

- Wang, S.; Huang, X.; Yang, C. Mixing enhancement for high viscous fluids in a microfluidic chamber. Lab Chip 2011, 11, 2081. [Google Scholar] [CrossRef] [PubMed]

- Tian, J.; Arbatan, T.; Li, X.; Shen, W. Liquid marble for gas sensing. Chem. Commun. 2010, 46, 4734–4736. [Google Scholar] [CrossRef] [PubMed]

- Tian, J.; Arbatan, T.; Li, X.; Shen, W. Porous liquid marble shell offers possibilities for gas detection and gas reactions. Chem. Eng. J. 2010, 165, 347–353. [Google Scholar] [CrossRef]

- Li, X.; Shi, H.; Hu, Y. Rod-shaped liquid plasticine for gas diffusion detection. Soft Matter 2019, 15, 3085–3088. [Google Scholar] [CrossRef] [PubMed]

- Bormashenko, E.; Balter, R.; Aurbach, D. Use of liquid marbles as micro-reactors. Int. J. Chem. React. Eng. 2011, 9, S10. [Google Scholar] [CrossRef]

- Chin, J.M.; Reithofer, M.R.; Tan, T.T.Y.; Menon, A.G.; Chen, E.Y.; Chow, C.A.; Hor, A.; Xu, J. Supergluing MOF liquid marbles. Chem. Commun. 2013, 49, 493–495. [Google Scholar] [CrossRef]

- Sato, E.; Yuri, M.; Fujii, S.; Nishiyama, T.; Nakamura, Y.; Horibe, H. Liquid marbles as a micro-reactor for efficient radical alternating copolymerization of diene monomer and oxygen. Chem. Commun. 2015, 51, 17241–17244. [Google Scholar] [CrossRef]

- Sato, E.; Yuri, M.; Fujii, S.; Nishiyama, T.; Nakamura, Y.; Horibe, H. Liquid marble containing degradable polyperoxides for adhesion force-changeable pressure-sensitive adhesives. RSC Adv. 2016, 6, 56475–56481. [Google Scholar] [CrossRef]

- Gu, Z.; Ye, B.; Ding, H.; Liu, C.; Zhao, Y.; Gu, Z. Non-iridescent structural color pigments from liquid marbles. J. Mater. Chem. C 2015, 3, 6607–6612. [Google Scholar] [CrossRef]

- Sheng, Y.; Sun, G.; Ngai, T. Dopamine Polymerization in Liquid Marbles: A General Route to Janus Particle Synthesis. Langmuir 2016, 32, 3122–3129. [Google Scholar] [CrossRef] [PubMed]

- De Palma, R.; Peeters, S.; Van Bael, M.J.; Rul, H.V.D.; Bonroy, K.; Laureyn, W.; Mullens, J.; Borghs, G.; Maes, G. Silane Ligand Exchange to Make Hydrophobic Superparamagnetic Nanoparticles Water-Dispersible. Chem. Mater. 2007, 19, 1821–1831. [Google Scholar] [CrossRef]

- Jeong, Y.; Tonga, G.Y.; Duncan, B.; Yan, B.; Das, R.; Sahub, C.; Rotello, V. Solubilization of Hydrophobic Catalysts Using Nanoparticle Hosts. Small 2017, 14, 1702198. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.; Jiao, X.; Zou, H.; Yang, H.; Liu, J. Growing a hydrophilic nanoporous shell on a hydrophobic catalyst interface for aqueous reactions with high reaction efficiency and in situ catalyst recycling. J. Mater. Chem. A 2017, 5, 16162–16170. [Google Scholar] [CrossRef]

- Carter, B.O.; Adams, D.; Cooper, A.I. Pausing a stir: Heterogeneous catalysis in “dry water”. Green Chem. 2010, 12, 783–785. [Google Scholar] [CrossRef]

- Miao, Y.-E.; Lee, H.K.; Chew, W.S.; Phang, I.Y.; Liu, T.; Ling, X.Y. Catalytic liquid marbles: Ag nanowire-based miniature reactors for highly efficient degradation of methylene blue. Chem. Commun. 2014, 50, 5923–5926. [Google Scholar] [CrossRef]

- Sheng, Y.; Sun, G.; Wu, J.; Ma, G.; Ngai, T. Silica-Based Liquid Marbles as Microreactors for the Silver Mirror Reaction. Angew. Chem. 2015, 127, 7118–7123. [Google Scholar] [CrossRef]

- Pol, V.G.; Srivastava, D.N.; Palchik, O.; Palchik, V.; Slifkin, M.A.; Weiss, A.M.; Gedanken, A. Sonochemical Deposition of Silver Nanoparticles on Silica Spheres. Langmuir 2002, 18, 3352–3357. [Google Scholar] [CrossRef]

- Wei, W.; Lu, R.; Ye, W.; Sun, J.; Zhu, Y.; Luo, J.; Liu, X. Liquid Marbles Stabilized by Fluorine-Bearing Cyclomatrix Polyphosphazene Particles and Their Application as High-Efficiency Miniature Reactors. Langmuir 2016, 32, 1707–1715. [Google Scholar] [CrossRef]

- Wang, D.; Zhu, L.; Chen, J.-F.; Dai, L. Liquid Marbles Based on Magnetic Upconversion Nanoparticles as Magnetically and Optically Responsive Miniature Reactors for Photocatalysis and Photodynamic Therapy. Angew. Chem. Int. Ed. 2016, 55, 10795–10799. [Google Scholar] [CrossRef]

- Gao, W.; Lee, H.K.; Hobley, J.; Liu, T.; Phang, I.Y.; Ling, X.Y. Graphene Liquid Marbles as Photothermal Miniature Reactors for Reaction Kinetics Modulation. Angew. Chem. Int. Ed. 2015, 54, 3993–3996. [Google Scholar] [CrossRef]

- Koh, C.S.L.; Lee, H.K.; Han, X.; Lee, M.R.; Yang, Z.; Ling, X.Y.; Phan-Quang, G.C. SERS- and Electrochemically Active 3D Plasmonic Liquid Marbles for Molecular-Level Spectroelectrochemical Investigation of Microliter Reactions. Angew. Chem. Int. Ed. 2017, 56, 8813–8817. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Lee, H.K.; Lee, Y.H.; Hao, W.; Liu, Y.; Phang, I.Y.; Li, S.; Ling, X.Y. Identifying Enclosed Chemical Reaction and Dynamics at the Molecular Level Using Shell-Isolated Miniaturized Plasmonic Liquid Marble. J. Phys. Chem. Lett. 2016, 7, 1501–1506. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Koh, C.S.L.; Lee, H.K.; Chew, W.S.; Ling, X.Y. Microchemical Plant in a Liquid Droplet: Plasmonic Liquid Marble for Sequential Reactions and Attomole Detection of Toxin at Microliter Scale. ACS Appl. Mater. Interfaces 2017, 9, 39635–39640. [Google Scholar] [CrossRef]

- Tyowua, A.T.; Ahor, F.; Yiase, S.G.; Binks, B.P. Liquid marbles as microreactors for qualitative and quantitative inorganic analyses. SN Appl. Sci. 2020, 2, 345. [Google Scholar] [CrossRef]

- Fullarton, C.; Draper, T.C.; Phillips, N.; de Lacy Costello, B.P.; Adamatzky, A. Belousov–Zhabotinsky reaction in liquid marbles. J. Phys. Mater. 2019, 2, 015005. [Google Scholar] [CrossRef]

- Tsompanas, M.-A.; Fullarton, C.; Adamatzky, A. Belousov-Zhabotinsky liquid marbles in robot control. Sens. Actuators B Chem. 2019, 295, 194–203. [Google Scholar] [CrossRef]

- Adamatzky, A.; Tsomapanas, M.-A.; Draper, T.C.; Fullarton, C.; Mayne, R. Liquid Marble Photosensor. ChemPhysChem 2019, 21, 90–98. [Google Scholar] [CrossRef]

- Oliveira, N.; Reis, R.L.; Mano, J.F. The Potential of Liquid Marbles for Biomedical Applications: A Critical Review. Adv. Healthc. Mater. 2017, 6, 1700192. [Google Scholar] [CrossRef]

- Avrămescu, R.-E.; Ghica, M.-V.; Dinu-Pirvu, C.; Udeanu, D.I.; Popa, L. Liquid Marbles: From Industrial to Medical Applications. Molecules 2018, 23, 1120. [Google Scholar] [CrossRef]

- Arbatan, T.; Li, L.; Tian, J.; Shen, W. Liquid Marbles as Micro-bioreactors for Rapid Blood Typing. Adv. Healthc. Mater. 2011, 1, 80–83. [Google Scholar] [CrossRef] [PubMed]

- Kang, Z.; Yan, X.; Zhao, L.; Liao, Q.; Zhao, K.; Du, H.; Zhang, X.; Zhang, X.; Zhang, Y. Gold nanoparticle/ZnO nanorod hybrids for enhanced reactive oxygen species generation and photodynamic therapy. Nano Res. 2015, 8, 2004–2014. [Google Scholar] [CrossRef]

- Sreejith, K.R.; Gorgannezhad, L.; Jin, J.; Ooi, C.H.; Stratton, H.; Dao, D.V.; Nguyen, N.T. Liquid marbles as biochemical reactors for the polymerase chain reaction. Lab Chip 2019, 19, 3220–3227. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Liu, P.; Kaur, G.; Yao, X.; Yang, M. Transparent and Gas-Permeable Liquid Marbles for Culturing and Drug Sensitivity Test of Tumor Spheroids. Adv. Healthc. Mater. 2017, 6, 1700185. [Google Scholar] [CrossRef] [PubMed]

- Sarvi, F.; Arbatan, T.; Chan, P.P.Y.; Shen, W. A novel technique for the formation of embryoid bodies inside liquid marbles. RSC Adv. 2013, 3, 14501–14508. [Google Scholar] [CrossRef]

- Ledda, S.; Idda, A.; Kelly, J.; Ariu, F.; Bogliolo, L.; Bebbere, D. A novel technique for in vitro maturation of sheep oocytes in a liquid marble microbioreactor. J. Assist. Reprod. Genet. 2016, 33, 513–518. [Google Scholar] [CrossRef][Green Version]

- Vadivelu, R.K.; Ooi, C.H.; Yao, R.-Q.; Velasquez, J.T.; Pastrana, E.; Díaz-Nido, J.; Lim, F.; Ekberg, J.A.K.; Nguyen, N.T.; John, J.S. Generation of three-dimensional multiple spheroid model of olfactory ensheathing cells using floating liquid marbles. Sci. Rep. 2015, 5, 15083. [Google Scholar] [CrossRef]

- Vadivelu, R.K.; Kamble, H.; Munaz, A.; Nguyen, N.-T. Liquid marbles as bioreactors for the study of three-dimensional cell interactions. Biomed. Microdevices 2017, 19, 31. [Google Scholar] [CrossRef]

- Tian, J.; Fu, N.; Chen, X.D.; Shen, W. Respirable liquid marble for the cultivation of microorganisms. Colloids Surf. B Biointerfaces 2013, 106, 187–190. [Google Scholar] [CrossRef]

- Sreejith, K.R.; Ooi, C.H.; Jin, J.; Dao, D.V.; Nguyen, N.T. Digital polymerase chain reaction technology—recent advances and future perspectives. Lab Chip 2018, 18, 3717–3732. [Google Scholar] [CrossRef] [PubMed]

- Sreejith, K.R.; Gorgannezhad, L.; Jin, J.; Ooi, C.H.; Takei, T.; Hayase, G.; Stratton, H.; Lamb, K.; Shiddiky, M.J.A.; Dao, D.V.; et al. Core-Shell Beads Made by Composite Liquid Marble Technology as A Versatile Microreactor for Polymerase Chain Reaction. Micromachines 2020, 11, 242. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Fan, L.; Mu, B.; Wang, A.; Zhang, J. Palygorskite@Fe3O4 @polyperfluoroalkylsilane nanocomposites for superoleophobic coatings and magnetic liquid marbles. J. Mater. Chem. A 2016, 4, 5859–5868. [Google Scholar] [CrossRef]

- Liu, L.; Pan, Y.; Bhushan, B.; Li, F.; Zhao, X. Core-shell magnetic nanoparticles for substrate-Independent super-amphiphobic surfaces and mechanochemically robust liquid marbles. Chem. Eng. J. 2019, 391, 123523. [Google Scholar] [CrossRef]

- Gao, L.; McCarthy, T.J. Ionic Liquid Marbles. Langmuir 2007, 23, 10445–10447. [Google Scholar] [CrossRef] [PubMed]

- Marsh, K.N.; Deev, A.; Wu, A.C.-T.; Tran, E.; Klamt, A. Room temperature ionic liquids as replacements for conventional solvents—A review. Korean J. Chem. Eng. 2002, 19, 357–362. [Google Scholar] [CrossRef]

- Zhao, D.; Wu, M.; Kou, Y.; Min, E. Ionic liquids: Applications in catalysis. Catal. Today 2002, 74, 157–189. [Google Scholar] [CrossRef]

- Huddleston, J.G.; Rogers, R.D. Room temperature ionic liquids as novel media for ‘clean’ liquid–liquid extraction. Chem. Commun. 1998, 1765–1766. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Choi, Y.-K.; Park, J.; Lee, S.; Yang, Y.-H.; Kim, H.; Park, T.-J.; Kim, Y.H.; Lee, S.H. Ionic liquid-mediated extraction of lipids from algal biomass. Bioresour. Technol. 2012, 109, 312–315. [Google Scholar] [CrossRef] [PubMed]

- Achinivu, E.C.; Howard, R.M.; Li, G.; Gracz, H.; Henderson, W.A. Lignin extraction from biomass with protic ionic liquids. Green Chem. 2014, 16, 1114–1119. [Google Scholar] [CrossRef]

- Passos, H.; Freire, M.G.; Coutinho, J.A.P. Ionic liquid solutions as extractive solvents for value-added compounds from biomass. Green Chem. 2014, 16, 4786–4815. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, S.; Deng, Y. Recent advances in ionic liquid catalysis. Green Chem. 2011, 13, 2619. [Google Scholar] [CrossRef]

- Vekariya, R.L. A review of ionic liquids: Applications towards catalytic organic transformations. J. Mol. Liq. 2017, 227, 44–60. [Google Scholar] [CrossRef]

- Zhang, M.; Ettelaie, R.; Yan, T.; Zhang, S.-J.; Cheng, F.; Binks, B.P.; Yang, H. Ionic Liquid Droplet Microreactor for Catalysis Reactions Not at Equilibrium. J. Am. Chem. Soc. 2017, 139, 17387–17396. [Google Scholar] [CrossRef]

- Dickey, M.D. Stretchable and Soft Electronics using Liquid Metals. Adv. Mater. 2017, 29, 1606425. [Google Scholar] [CrossRef] [PubMed]

- Cheng, S.; Rydberg, A.; Hjort, K.; Wu, Z. Liquid metal stretchable unbalanced loop antenna. Appl. Phys. Lett. 2009, 94, 144103. [Google Scholar] [CrossRef]

- Sen, P.; Kim, C.-J. A Fast Liquid-Metal Droplet Microswitch Using EWOD-Driven Contact-Line Sliding. J. Microelectromech. Syst. 2008, 18, 174–185. [Google Scholar] [CrossRef]

- Daeneke, T.; Khoshmanesh, K.; Mahmood, N.; De Castro, I.A.; Esrafilzadeh, D.; Barrow, S.J.; Dickey, M.D.; Kalantar-Zadeh, K. Liquid metals: Fundamentals and applications in chemistry. Chem. Soc. Rev. 2018, 47, 4073–4111. [Google Scholar] [CrossRef] [PubMed]

- Bobev, S.; Merz, J.; Lima, A.; Fritsch, V.; Thompson, J.D.; Sarrao, J.L.; Gillessen, M.; Dronskowski, R. Unusual Mn—Mn spin coupling in the polar intermetallic compounds CaMn2Sb2 and SrMn2Sb2. Inorg. Chem. 2006, 45, 4047–4054. [Google Scholar]

- Benbow, E.M.; Dalal, N.S.; Latturner, S.E. Crystal growth and magnetic behavior of R6T13− xAlxMy phases (R= La, Nd; T= Mn, Fe; M= main group) grown from lanthanide-rich eutectic fluxes. J. Solid State Chem. 2009, 182, 3055–3062. [Google Scholar] [CrossRef]

- Yazdanpanah, M.M.; Harfenist, S.A.; Safir, A.; Cohn, R.W. Selective self-assembly at room temperature of individual freestanding Ag2Ga alloy nanoneedles. J. Appl. Phys. 2005, 98, 73510. [Google Scholar] [CrossRef]

- Gille, P.; Ziemer, T.; Schmidt, M.; Kovnir, K.; Burkhardt, U.; Armbrüster, M. Growth of large PdGa single crystals from the melt. Intermetallics 2010, 18, 1663–1668. [Google Scholar] [CrossRef]

- Wang, W.; Chen, W.; Zhao, X.; Chen, D.; Yang, K. Effect of composition on the reactivity of Al-rich alloys with water. Int. J. Hydrogen Energy 2012, 37, 18672–18678. [Google Scholar] [CrossRef]

- Xu, S.; Zhao, X.; Liu, J. Liquid metal activated aluminum-water reaction for direct hydrogen generation at room temperature. Renew. Sustain. Energy Rev. 2018, 92, 17–37. [Google Scholar] [CrossRef]

- Sivan, V.; Tang, S.; O’Mullane, A.P.; Petersen, P.; Eshtiaghi, N.; Kalantar-Zadeh, K.; Mitchell, A. Liquid Metal Marbles. Adv. Funct. Mater. 2012, 23, 144–152. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).