Potential of Jatropha curcas L. as Biodiesel Feedstock in Malaysia: A Concise Review

Abstract

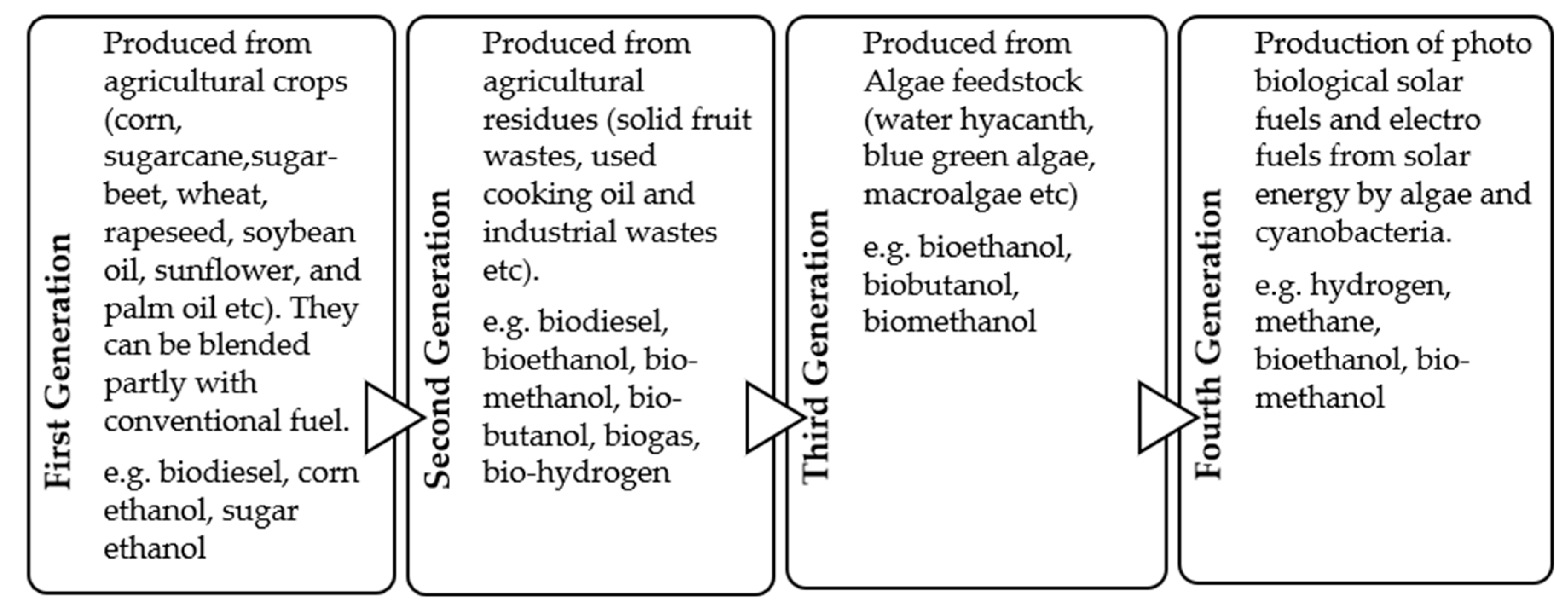

:1. Introduction

2. Distribution and Physicochemical Properties of Biodiesel Feedstock

3. Potential of Jatropha curcas as Biodiesel Feedstock

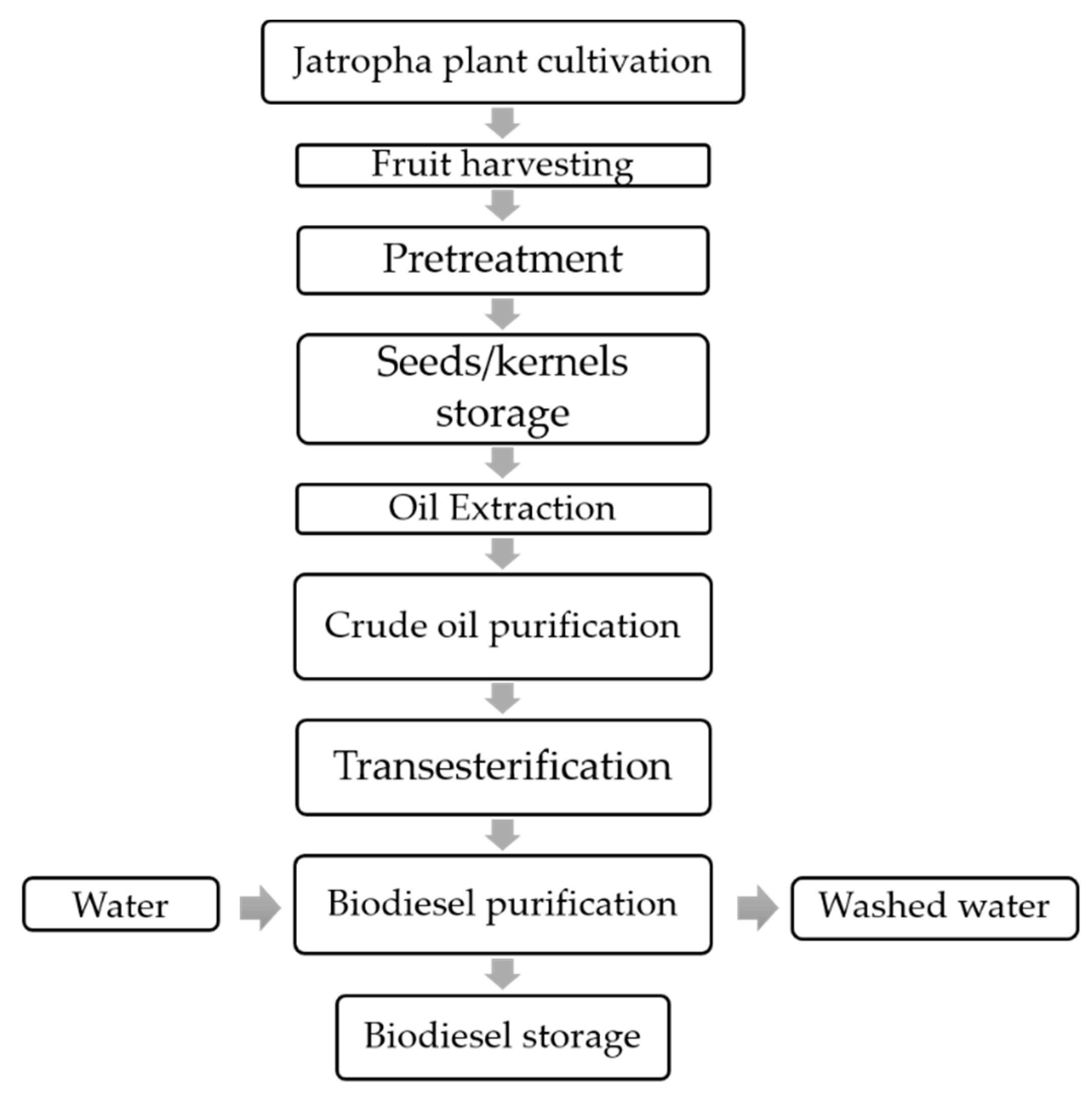

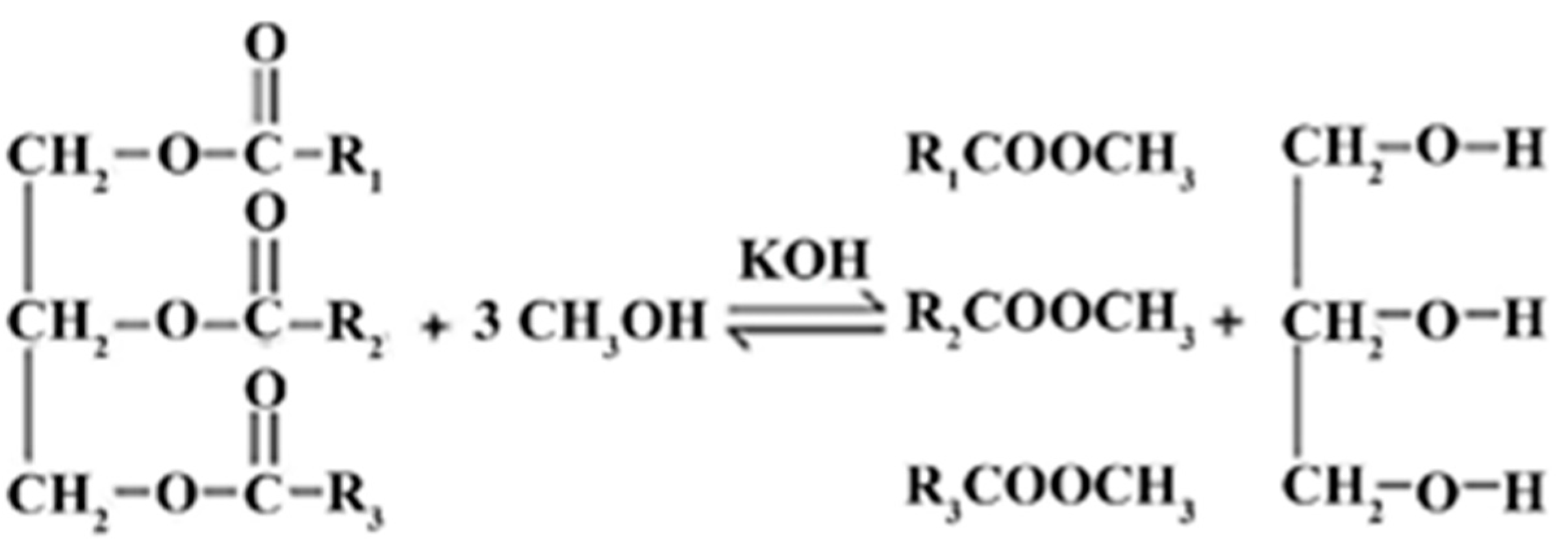

4. Biodiesel Processing from Jatropha curcas

5. Jatropha curcas Planting Challenges in Malaysia

6. Approaches to Enhance the Jatropha Seed Oil

7. Economic and Business Perspectives of Biodiesel from Jatropha Oil

- a)

- The employment of environmentally friendly, sustainable, and viable sources of energy to reduce the dependency on depleting fossil fuels;

- b)

- The enhanced prosperity and well being of all the stakeholders in the agriculture and commodity-based industries through stable and remunerative prices;

- c)

- Reducing the country’s dependence on depleting reserves of fossil fuels, promoting the demand for palm oil, and stabilizing its prices.

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sharma, B.; Ingalls, R.G.; Jones, C.L.; Khanchi, A. Biomass supply chain design and analysis: Basis, overview, modelling, challenges, and future. Renew. Sustain. Energy Rev. 2013, 24, 608–627. [Google Scholar] [CrossRef]

- Tobib, H.M.; Rostam, H.; Mossa, M.A.; Aziz Hairuddin, A.; Noor, M.M. The performance of an HCCI-DI engine fuelled with palm oil-based biodiesel. IOP Conf. Ser. Mater. Sci. Eng. 2019, 469, 012079. [Google Scholar] [CrossRef] [Green Version]

- Demirbas, A. Biodiesel fuels from vegetable oils via catalytic and non-catalytic supercritical alcohol transesterifications and other methods: A survey. Energy Convers. Manag. 2003, 44, 093–109. [Google Scholar] [CrossRef]

- Sulaiman, Z.; Ramlan, M.F. Research and development on Jatropha (Jatropha curcas) by Malaysian Rubber Board. Presented at the Malaysia-Indonesia Scientific Meeting on Jatropha Royal Chulan, Kuala Lumpur, Malaysia, 6 February 2013. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Martinez-Hernandez, E.; Murphy, R.J.; Ng, D.K.S.; Hassim, H.; Siew, K.; Kin, W.Y.; Jaye, M.F.I.; Hang, P.L.; Andiappan, V. Role of bioenergy, biorefinery and bioeconomy in sustainable development: Strategic pathways for Malaysia. Renew. Sustain. Energy Rev. 2018, 81, 1966–1987. [Google Scholar] [CrossRef]

- Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H. A review of energy scenario and sustainable energy in Malaysia. Renew. Sustain. Energy Rev. 2011, 15, 639–647. [Google Scholar] [CrossRef]

- Peng, D. The effect on diesel injector wear, and exhaust emissions by using ultralow sulphur diesel blending with biofuels. Mater. Trans. 2015, 56, 642–647. [Google Scholar] [CrossRef] [Green Version]

- Paudel, S.R.; Banjara, S.P.; Choi, O.K.; Park, K.Y.; Kim, Y.M.; Lee, J.W. Pretreatment of agricultural biomass for anaerobic digestion: Current state and challenges. Bioresour. Technol. 2017. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). Tackling Climate Change through Livestock; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013; Available online: http://www.fao.org/3/i3437e.pdf (accessed on 27 April 2020).

- Ayetor, G.K.; Sunnu, A.; Parbey, J. Effect of biodiesel production parameters on viscosity and yield of methyl esters: Jatropha curcas, Elaeis guineensis and Cocos nucifera. Alex. Eng. J. 2015, 54, 1285–1290. [Google Scholar] [CrossRef] [Green Version]

- Singh, V.; Zhao, M.; Fennell, P.S.; Shah, N.; Anthony, E.J. Progress in biofuel production from gasification. Prog. Energy Combust. Sci. 2017, 61, 189–248. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Masjuki, H.H.; Mahlia, T.M.I.; Ong, H.C.; Atabani, A.E.; Chong, W.T. A global comparative review of biodiesel production from jatropha curcas using different homogeneous acid and alkaline catalysts: Study of physical and chemical properties. Renew. Sustain. Energy Rev. 2013, 24, 514–533. [Google Scholar] [CrossRef]

- Kabir, I.; Yacob, M.; Radam, A. Households’ awareness, attitudes and practices regarding waste cooking oil recycling in Petaling, Malaysia. IOSR-JESTFT 2014, 8, 45–51. [Google Scholar] [CrossRef]

- Muanruksa, P.; Kaewkannetra, P. Combination of fatty acids extraction and enzymatic esterification for biodiesel production using sludge palm oil as a low-cost substrate. Renew. Energy 2020, 146, 901–906. [Google Scholar] [CrossRef]

- Babajide, O.; Petrik, L.; Amigun, B.; Ameer, F. Low-cost feedstock conversion to biodiesel via ultrasound technology. Energies 2010, 3, 1691–1703. [Google Scholar] [CrossRef] [Green Version]

- Akbar, E.; Yaakob, Z.; Kamarudin, S.K.; Ismail, M.; Salimon, J. Characteristic and composition of Jatropha Curcas oil seed from Malaysia and its potential as biodiesel feedstock feedstock. Eur. J. Sci. Res. 2009, 29, 396–403. [Google Scholar]

- Ismail, S.A.A.; Ali, R.F.M. Physico-chemical properties of biodiesel manufactured from waste frying oil using domestic adsorbents. Sci. Technol. Adv. Mater. 2015. [Google Scholar] [CrossRef] [Green Version]

- Saraf, S.; Thomas, B. Influence of feedstock and process chemistry on biodiesel quality. Process. Saf. Environ. Prot. 2007, 85, 360–364. [Google Scholar] [CrossRef]

- Reddy, A.N.R.; Saleh, A.A.; Islam, M.S.; Hamdan, S.; Rahman, M.R.; Masjuki, H.H. Experimental evaluation of fatty acid composition influence on Jatropha biodiesel physicochemical properties. J. Renew. Sustain. Energy 2018, 10, 013103. [Google Scholar] [CrossRef]

- Knothe, G.; Steidley, K.S. Kinematic viscosity of biodiesel fuel component and related compounds: Influence of compound structure and comparison to petrodiesel fuel components. Fuel 2005, 1059–1065. [Google Scholar] [CrossRef]

- Knothe, G.; Matheaus, A.C.; Ryan, T.W., III. Cetane numbers of branched and straight-chain fatty esters determined in an ignition quality tester. Fuel 2003, 82, 971–975. [Google Scholar] [CrossRef]

- Sims, R.E.H.; Hastings, A.; Schlamadinger, B.; Taylor, G.; Smith, P. Energy crops: Current status and future prospects. Glob. Chang. Biol. 2006, 12, 2054–2076. [Google Scholar] [CrossRef]

- Malaysian Palm Oil Board Homepage. Available online: http://bepi.mpob.gov.my (accessed on 15 April 2020).

- The Malaymail. B20 Biodiesel Programme to Be Expanded Nationwide in June 2021, Says Teresa Kok. Available online: https://www.malaymail.com (accessed on 27 March 2020).

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Hazrat, M.A.; Liaquat, A.M.; Shahabuddin, M.; Varman, M. Prospects of biodiesel from Jatropha in Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 5007–5020. [Google Scholar] [CrossRef]

- The Star. FRIM Ready to Produce Biodiesel. Available online: https://www.thestar.com.my (accessed on 27 March 2020).

- Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H.; Norhasyima, R.S. Comparison of palm oil, Jatropha curcas and Calophyllum inophyllum for biodiesel: A review. Renew. Sustain. Energy Rev. 2011, 15, 3501–3515. [Google Scholar] [CrossRef]

- Patel, C.; Chandra, K.; Hwang, J.; Agarwal, R.A.; Gupta, N. Comparative compression ignition engine performance, combustion, and emission characteristics, and trace metals in particulates from Waste cooking oil, Jatropha and Karanja oil derived biodiesels. Fuel 2019, 1366–1376. [Google Scholar] [CrossRef]

- Ramos, M.J.; Fernández, C.M.; Casas, A.; Rodríguez, L.; Pérez, Á. Influence of fatty acid composition of raw materials on biodiesel properties. Bioresour. Technol. 2009, 100, 261–268. [Google Scholar] [CrossRef] [PubMed]

- Atadashi, I.M.; Aroua, M.K.; Aziz, A.A. High-quality biodiesel and its diesel engine application: A review. Renew. Sustain. Energy Rev. 2010, 14, 1999–2008. [Google Scholar] [CrossRef]

- Chongkhong, S.; Tongurai, C.; Chetpattananondh, P.; Bunyakan, C. Biodiesel production by esterification of palm fatty acid distillate. Biomass Bioenergy 2007, 31, 563–568. [Google Scholar] [CrossRef]

- Sahoo, P.K.; Das, L.M. Process optimization for biodiesel production from Jatropha Karanja and Polanga oils. Fuel 2009, 88, 1588–1594. [Google Scholar] [CrossRef]

- Tiwari, A.K.; Kumar, A.; Raheman, H. Biodiesel production from Jatropha (Jatropha curcas) with high free fatty acids: An optimized process. Biomass Bioenergy 2007, 31, 569–575. [Google Scholar] [CrossRef]

- Ejim, C.E.; Fleck, B.A.; Amirfazli, A. Analytical study for atomization of biodiesels and their blends in a typical injector: Surface tension and viscosity effects. Fuel 2007, 86, 1534–1544. [Google Scholar] [CrossRef]

- Abedin, M.J.; Masjuki, H.H.; Kalam, M.A.; Sanjid, A.; Rahman, S.M.A.; Fattah, I.M.R. Performance, emissions, and heat losses of palm and jatropha biodiesel blends in a diesel engine. Ind. Crops Prod. 2014, 59, 96–104. [Google Scholar] [CrossRef]

- Lim, S.; Teong, L.K. Recent trends, opportunities and challenges of biodiesel in Malaysia: An overview. Renew. Sustain. Energy Rev. 2010, 14, 938–954. [Google Scholar] [CrossRef]

- Koh, M.Y.; Idaty, T.; Ghazi, M. A review of biodiesel production from Jatropha curcas L. oil. Renew. Sustain. Energy Rev. 2011, 15, 2240–2251. [Google Scholar] [CrossRef]

- Jongh, J.A.; van der Putten, E. Contributors. In The Jatropha Handbook. From Cultivation to Application; FACT Foundation: Omaha, NE, USA, 2010; ISBN1 9081521918. ISBN2 9789081521918. [Google Scholar]

- Kalam, M.A.; Ahamed, J.U.; Masjuki, H.H. Land availability of Jatropha production in Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 3999–4007. [Google Scholar] [CrossRef]

- Mehla, S.K. Biodiesel Production Technologies; Joshi, D.C., Sutar, R.F., Parmar, M.R., Singh, S.N., Eds.; Pointer Publishers: Jaipur, India, 2007; Chapter 11; ISBN1 10: 8171325173. ISBN2 13: 9788171325177. [Google Scholar]

- Vairavan, K.; Thukkaiyannan, P.; Paramathma, M.; Venkatachalam, P.; Sampathrajan, A. Biofuel Crops Cultivation and Management: Jatropha, Sweet Sorghum and Sugarbeet; Agrobios: Jodhpur, India, 2007; ISBN1 8177543164. ISBN2 9788177543162. [Google Scholar]

- Ali, R.M.; Farag, H.A.; Amin, N.A.; Farag, I.H. Abu-Tartour phosphate rock catalyst for biodiesel production from waste frying oil. JOKULL 2015, 65, 233–244. [Google Scholar]

- Berchmans, H.J.; Hirata, S. Biodiesel production from crude Jatropha curcas L. seed oil with a high content of free fatty acids. Bioresour. Technol. 2008, 99, 1716–1721. [Google Scholar] [CrossRef]

- Augustus, G.D.P.S.; Jayabalan, M.; Seiler, G.J. Evaluation and bioinduction of energy components of Jatropha curcas. Biomass Bioenergy 2002, 23, 161–164. [Google Scholar] [CrossRef]

- Emil, A.; Yaakob, Z.; Kumar, M.N.S.; Jahim, J.M.; Salimon, J. Comparative evaluation of physicochemical properties of jatropha seed oil from Malaysia, Indonesia and Thailand. JAOCS J. Am. Oil Chem. Soc. 2010, 87, 689–695. [Google Scholar] [CrossRef]

- Moniruzzaman, M.; Yaakob, Z.; Shanizuzzaman, M.; Khatun, R.; Islam, A.K.M.A. Jatropha Biofuel Industry: The Challenges; INTECH OPEN: London, UK, 2017. [Google Scholar] [CrossRef] [Green Version]

- Singh, B.; Singh, K.; Rao, G.R.; Chikara, J.; Kumar, D.; Mishra, D.K.; Saikia, S.P.; Pathre, U.V.; Raghuvanshi, N.; Rahi, T.S.; et al. Agrotechnology of Jatropha curcas for diverse environmental conditions in India. Biomass Bioenergy 2013, 48, 191–202. [Google Scholar] [CrossRef]

- Everson, C.S.; Mengistu, M.G.; Gush, M.B. A field assessment of the agronomic performance and water use of Jatropha curcas in South Africa. Biomass Bioenergy 2013, 59, 59–69. [Google Scholar] [CrossRef]

- Goswami, K.; Choudhury, H.K. Economic benefits and costs of Jatropha plantation in North-East India. Agric. Econ. Res. Rev. 2011, 24, 99–108. [Google Scholar]

- Haseeb, A.S.M.A.; Fazal, M.A.; Jahirul, M.I.; Masjuki, H.H. Compatibility of automotive materials in biodiesel: A review. Fuel 2011, 90, 922–931. [Google Scholar] [CrossRef]

- Thomas, E.W.; Fuller, R.E.; Terauchi, K. Fluoroelastomer compatibility with biodiesel. Fuels 2007. [Google Scholar] [CrossRef]

- Zhang, G.W. Existing problems and countermeasures for Jatropha curcas industrialization in China. J. Anhui Agric. Sci. 2009, 8, 182. [Google Scholar]

- Moniruzzaman, M.; Yaakob, Z.; Khatun, R. Biotechnology for Jatropha improvement: A worthy exploration. Renew. Sustain. Energy Rev. 2016, 54, 1262–1277. [Google Scholar] [CrossRef]

- Yu, B.; Tang, X.Z.; Zhu, Z.Z.; Yang, J.Y.; Zou, X.; Pang, D.B. The current situation and countermeasures of Jatropha curcas L. in Sichuan Province. Sichuan For. Explor. Des. 2007, 3, 16–18. [Google Scholar]

- Singh, R.; Singh, R.N.; Vyas, D.K.; Srivastava, N.S.L.; Narra, M. SPRERI experience on holistic approach to utilize all parts ofJatropha curcasfruit for energy. Renew. Energy 2008, 33, 1868–1873. [Google Scholar] [CrossRef]

- Then, K. The Potential of Jatropha Carcus planting as renewable energy crop under Malaysia weather condition. In Proceedings of the 16th TSAE National Conference & the 8th TSAE International Conference, Bangkok, Thailand, 17–19 March 2015. [Google Scholar]

- Ministry of Plantation Industries & Commodities (MPIC) Homepage. Available online: https://www.mpic.gov.my/mpi (accessed on 24 April 2020).

| Properties | Diesel | Palm Biodiesel | Jatropha Biodiesel | ASTM D6751 | EN 14214 |

|---|---|---|---|---|---|

| Cetane number | 45–55 | 52 | 57 | Min. 47 | Min. 51 |

| Flash point, °C | 50–98 | 181 | 135 | Min. 130 | Min. 120 |

| Viscosity, mm2/s | 2.5–5.7 | 4.9 | 4.8 | 1.9–6.0 | 3.5–5.0 |

| Density, kg/m3 | 816–840 | 879.3 | 862 | 860–900 | 860–900 |

| Feedstock | Price of B100 Biodiesel (USD/Tonne) |

|---|---|

| Jatropha | 400–500 |

| Palm oil | 720–750 |

| Soybean | 800–805 |

| Rapeseed | 940–965 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Che Hamzah, N.H.; Khairuddin, N.; Siddique, B.M.; Hassan, M.A. Potential of Jatropha curcas L. as Biodiesel Feedstock in Malaysia: A Concise Review. Processes 2020, 8, 786. https://doi.org/10.3390/pr8070786

Che Hamzah NH, Khairuddin N, Siddique BM, Hassan MA. Potential of Jatropha curcas L. as Biodiesel Feedstock in Malaysia: A Concise Review. Processes. 2020; 8(7):786. https://doi.org/10.3390/pr8070786

Chicago/Turabian StyleChe Hamzah, Nurul Husna, Nozieana Khairuddin, Bazlul Mobin Siddique, and Mohd Ali Hassan. 2020. "Potential of Jatropha curcas L. as Biodiesel Feedstock in Malaysia: A Concise Review" Processes 8, no. 7: 786. https://doi.org/10.3390/pr8070786

APA StyleChe Hamzah, N. H., Khairuddin, N., Siddique, B. M., & Hassan, M. A. (2020). Potential of Jatropha curcas L. as Biodiesel Feedstock in Malaysia: A Concise Review. Processes, 8(7), 786. https://doi.org/10.3390/pr8070786