A Novel Bearing Fault Diagnosis Method Based on GL-mRMR-SVM

Abstract

1. Introduction

- (1)

- This paper proposes a new diagnostic model in which feature fusion and feature selection are applied. The model is relatively easy to implement, and the information of the raw signal can be fully utilized by the model.

- (2)

- This model performs well in noisy environment and can process the raw data directly without any pre-denoising method.

- (3)

- The model has good generalization ability, thus it can achieve high accuracy in the face of compound faults diagnosis.

2. Fundamental Theories

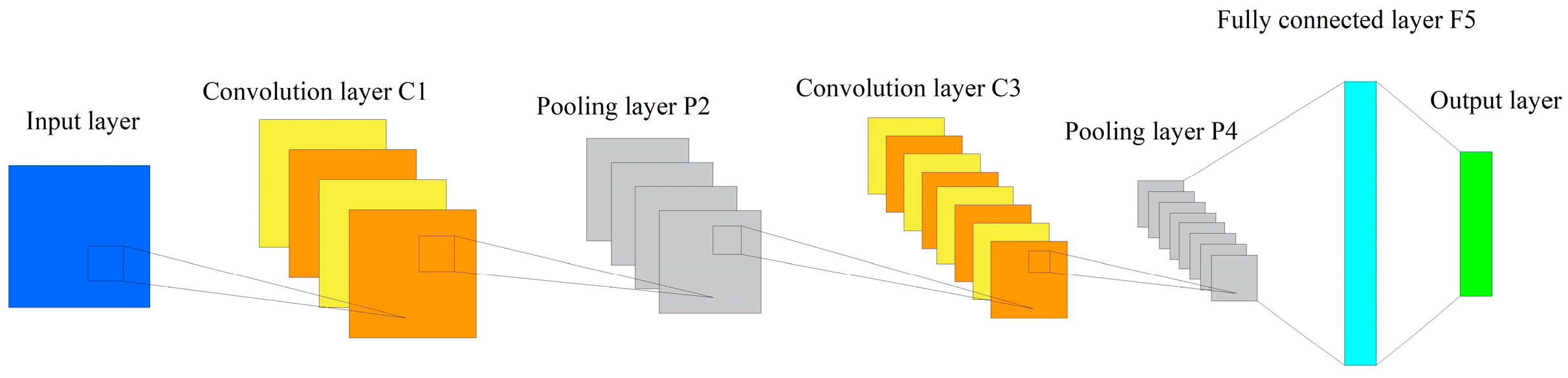

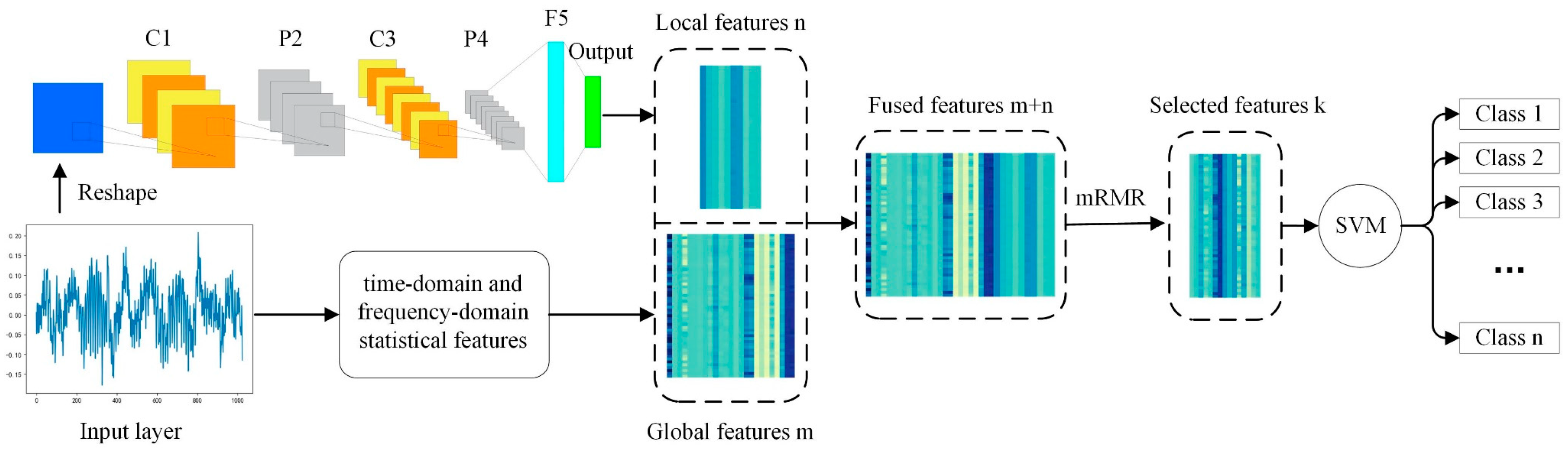

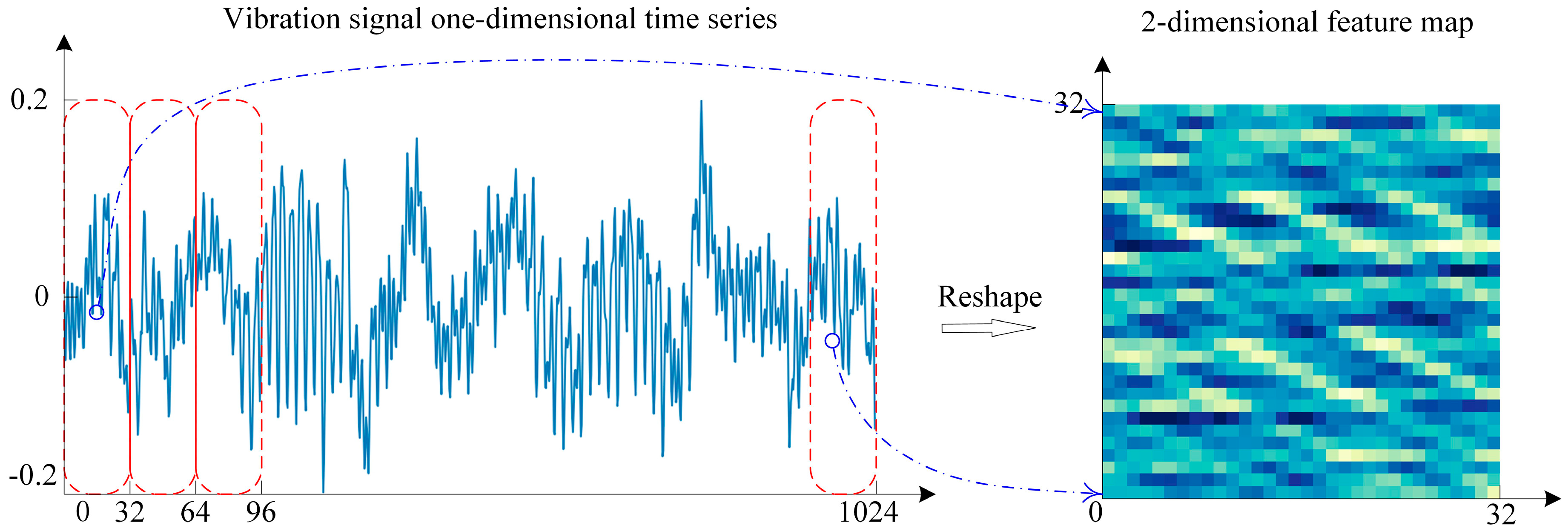

2.1. CNN Model

2.2. Feature Selection Algorithm mRMR

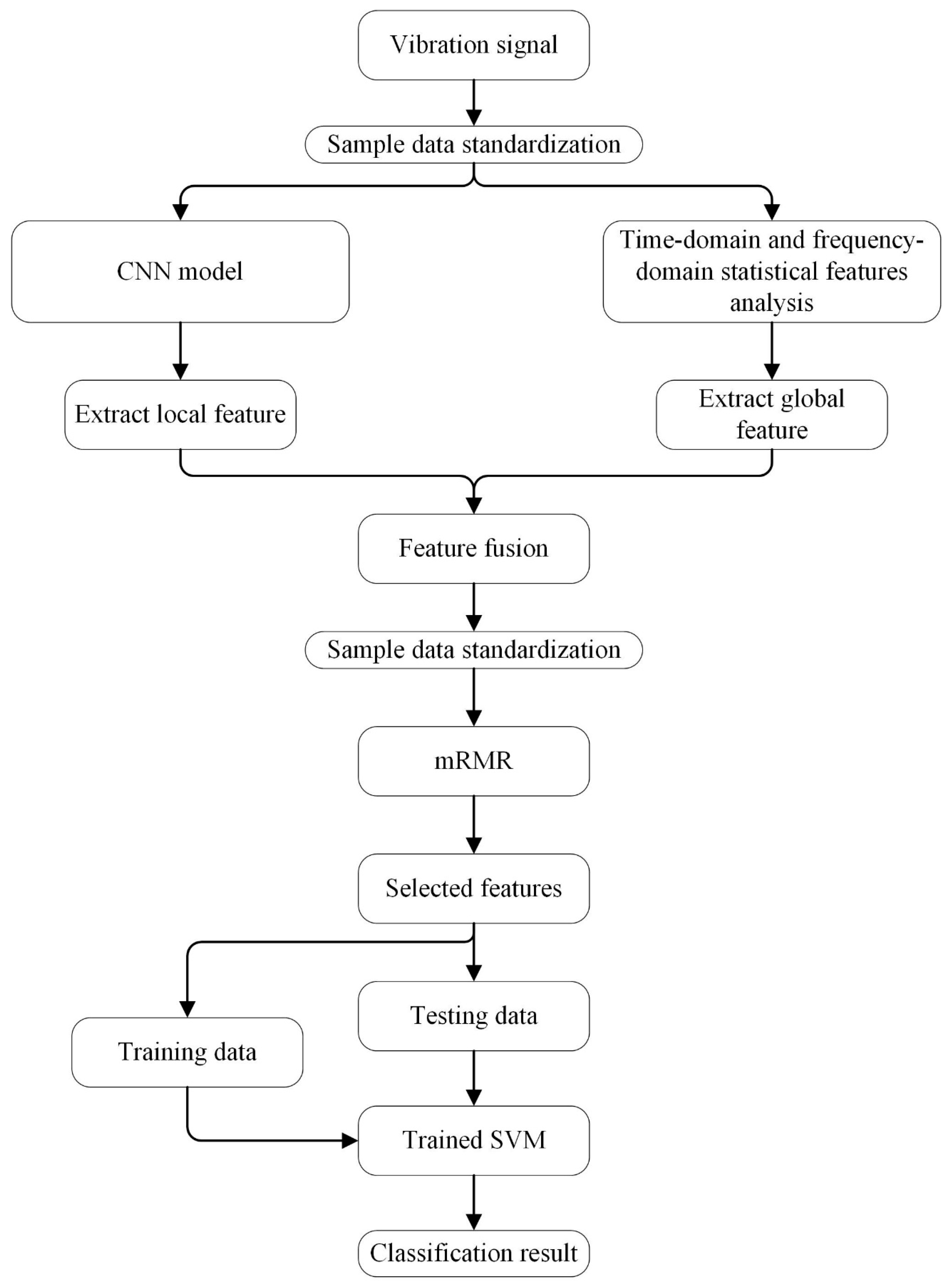

3. GL-mRMR-SVM Model

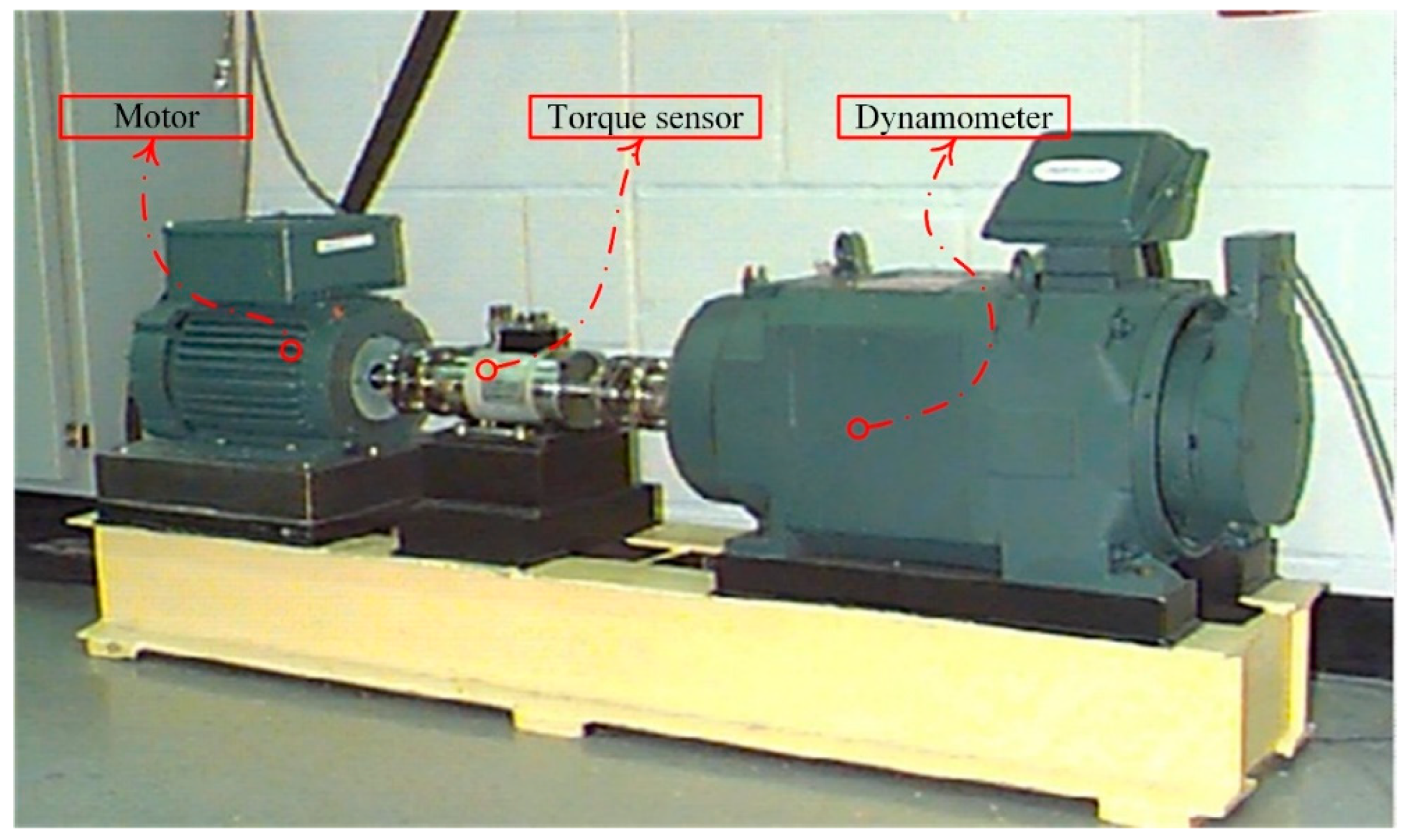

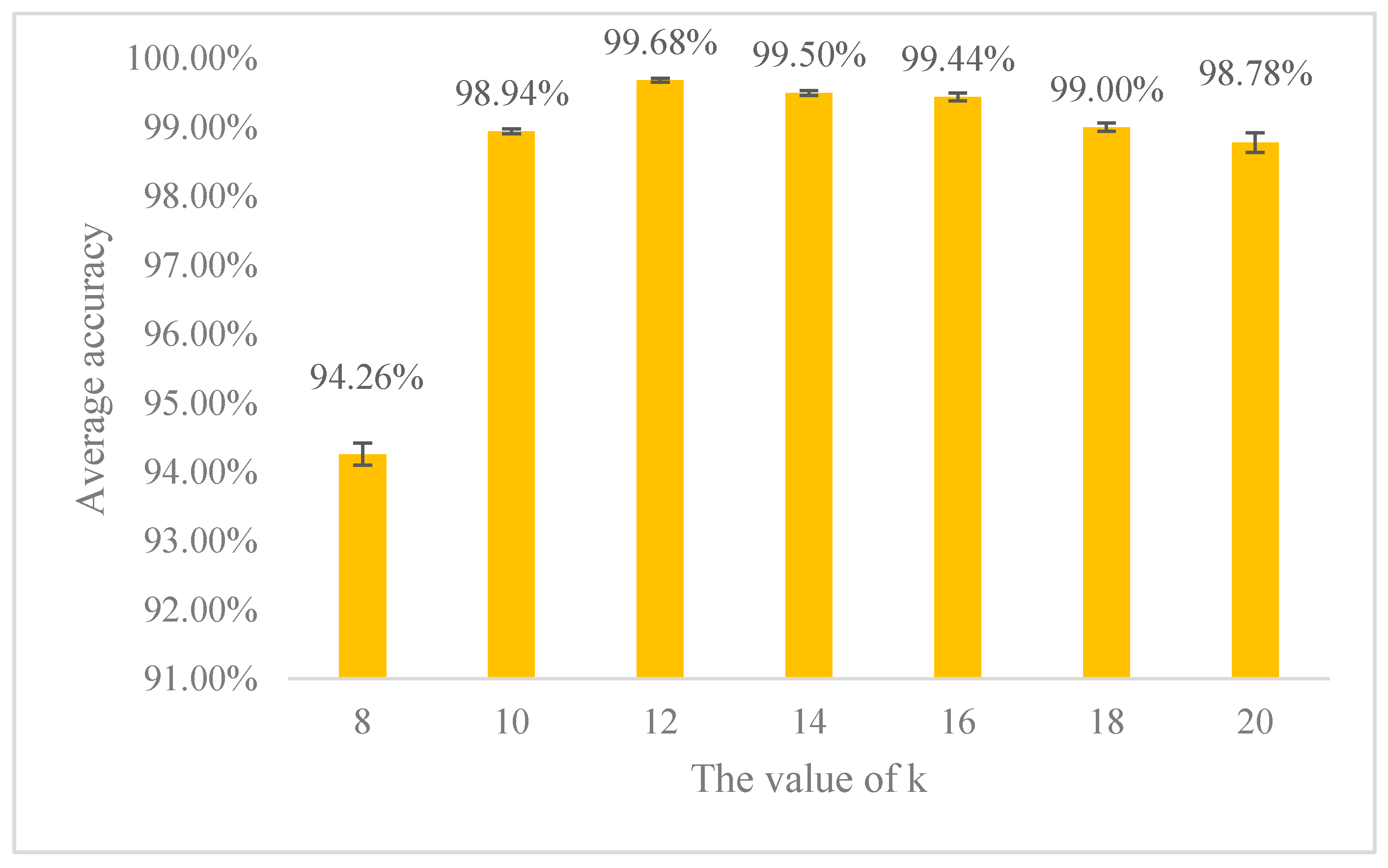

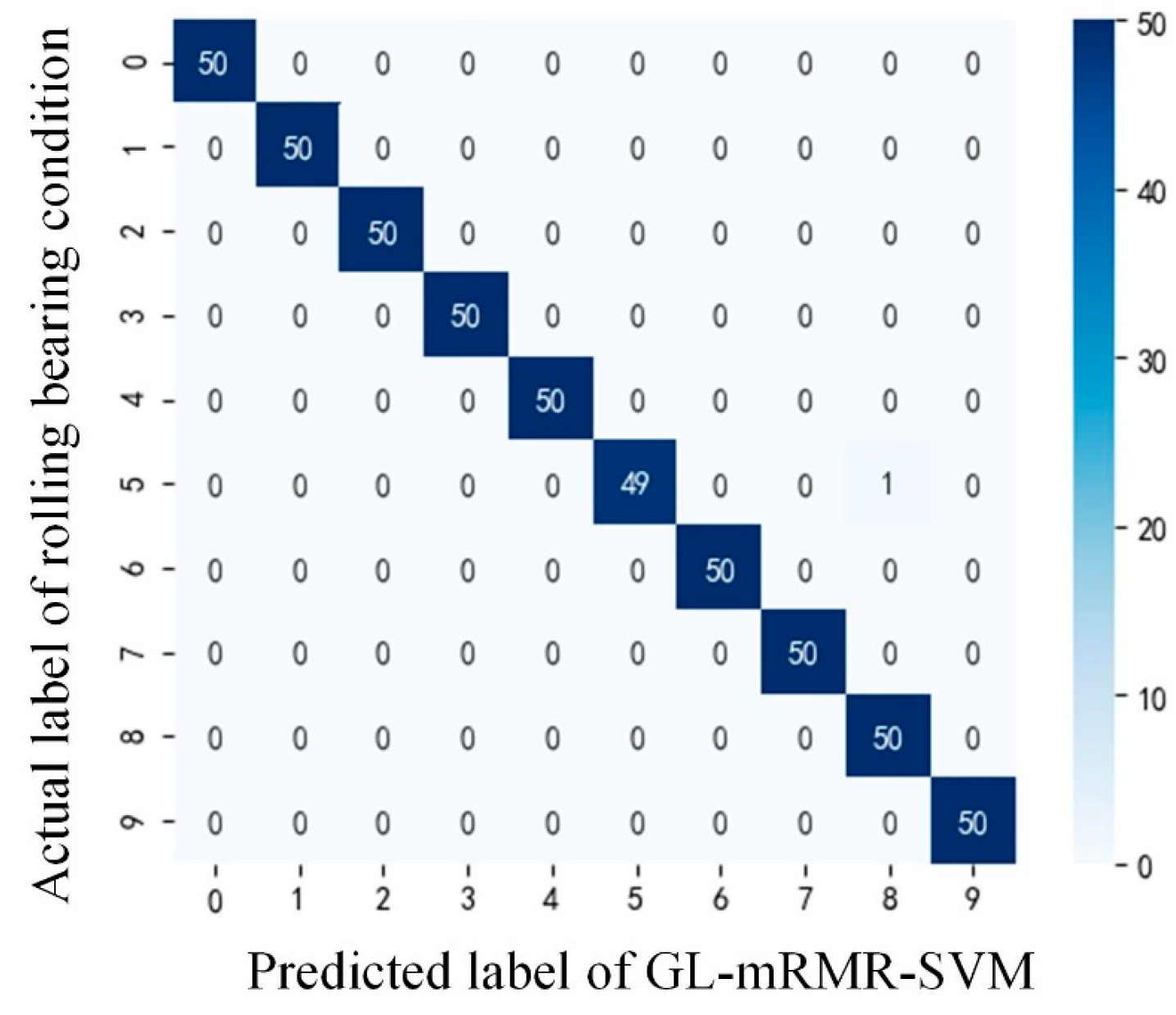

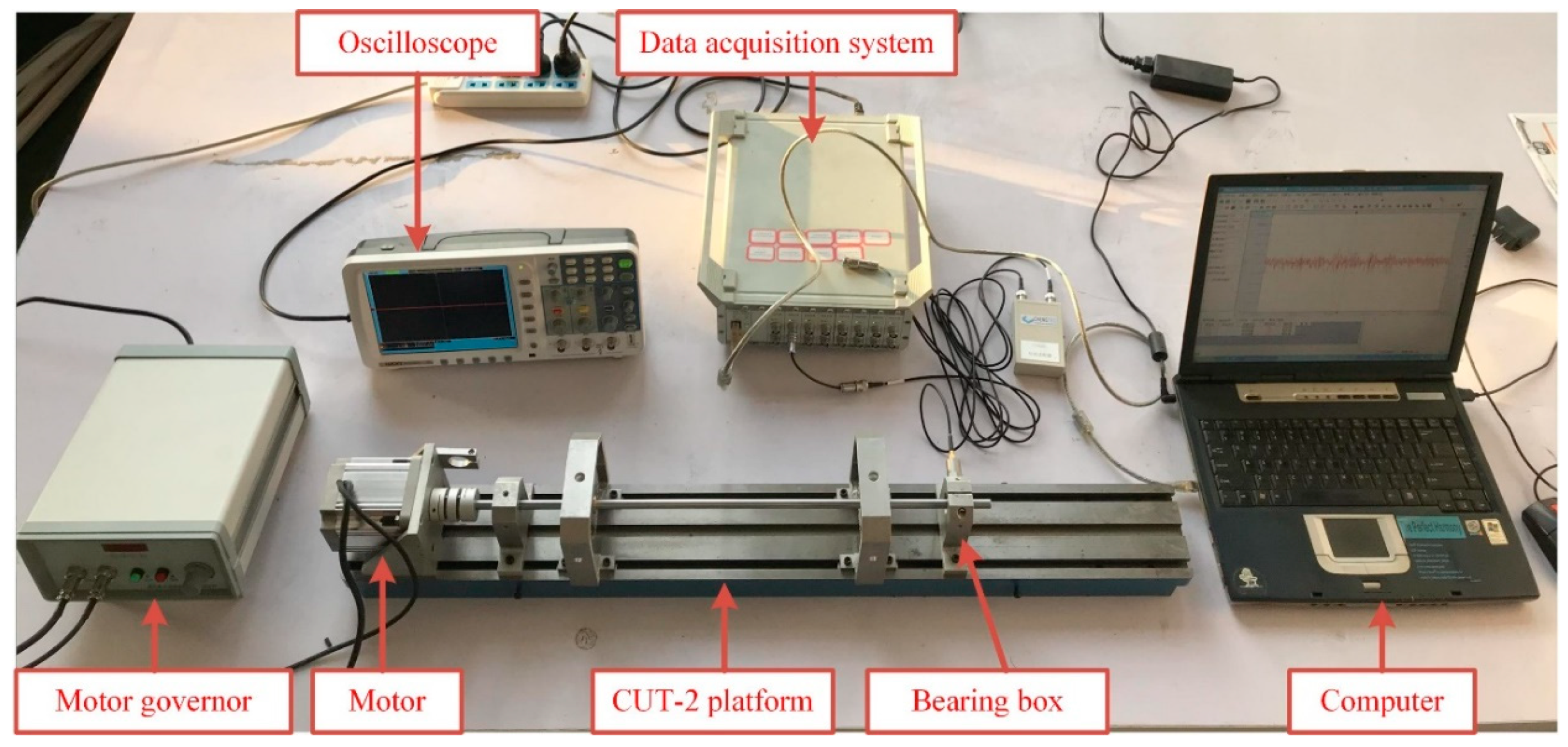

4. Experimental Evaluation

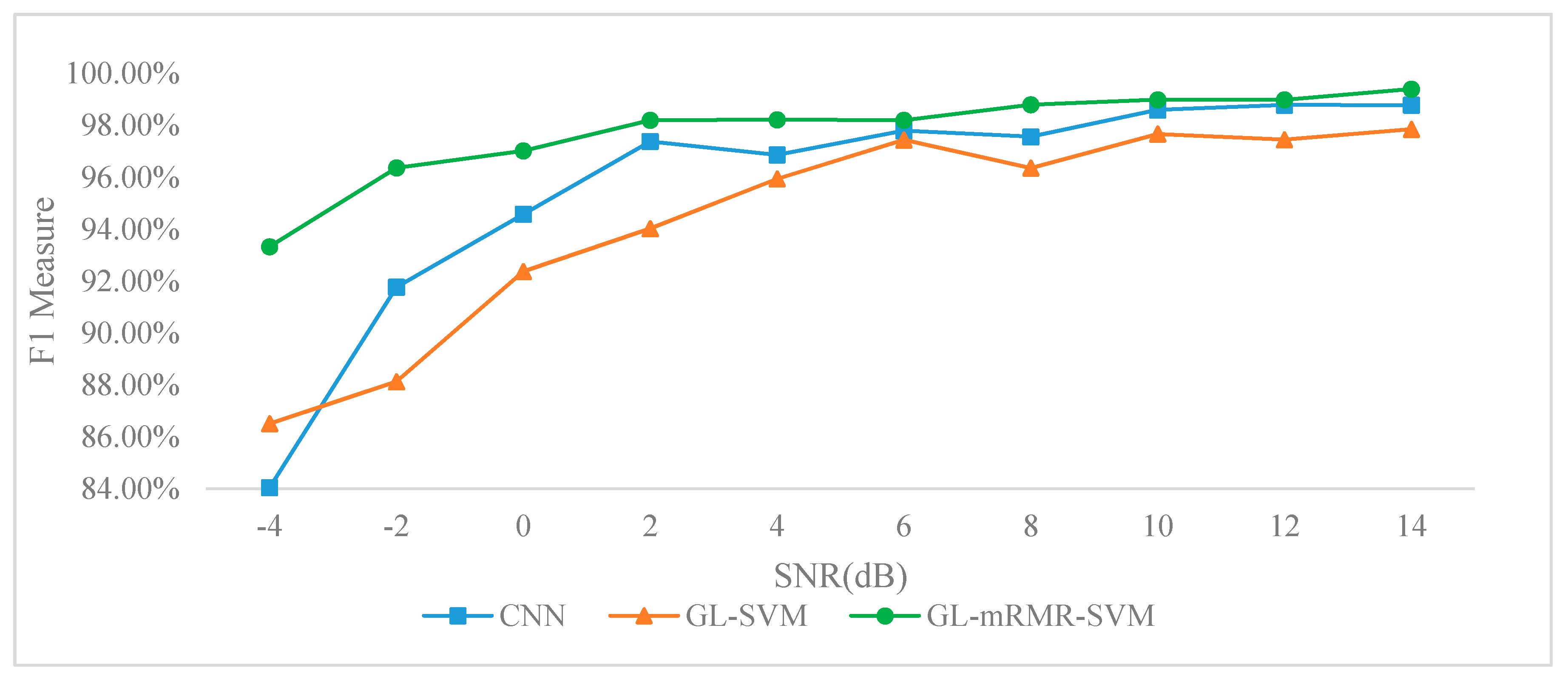

4.1. Robustness Experiment

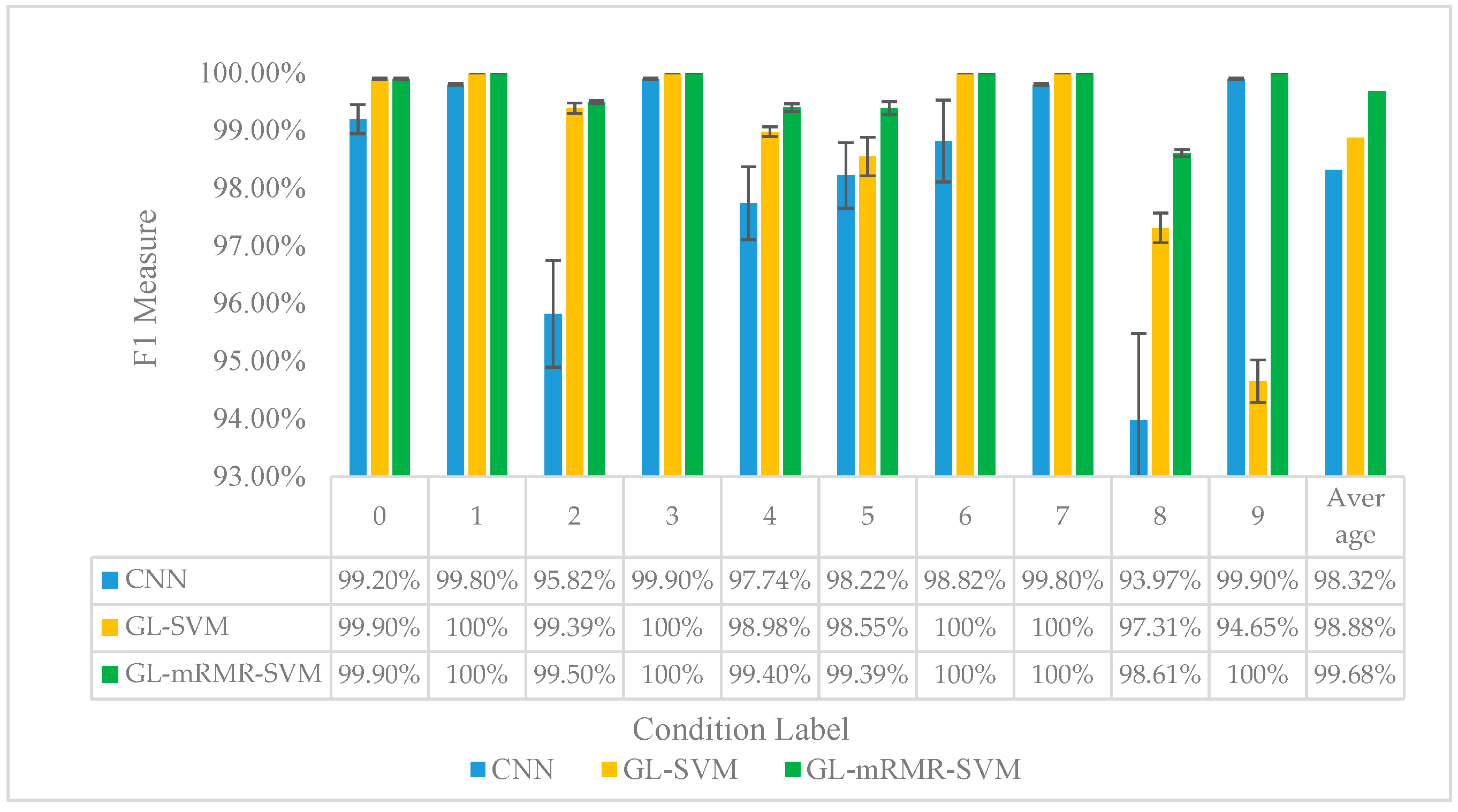

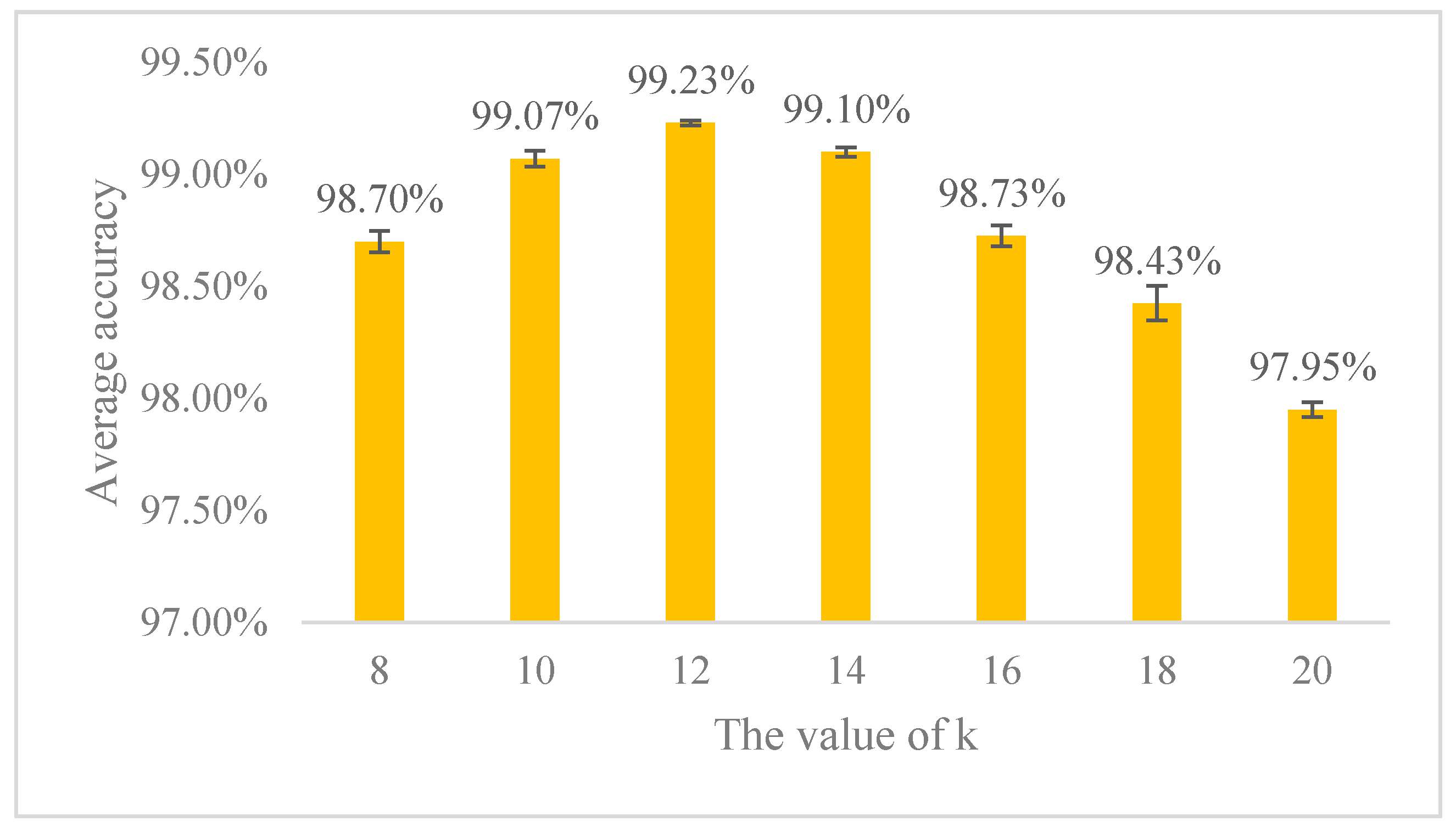

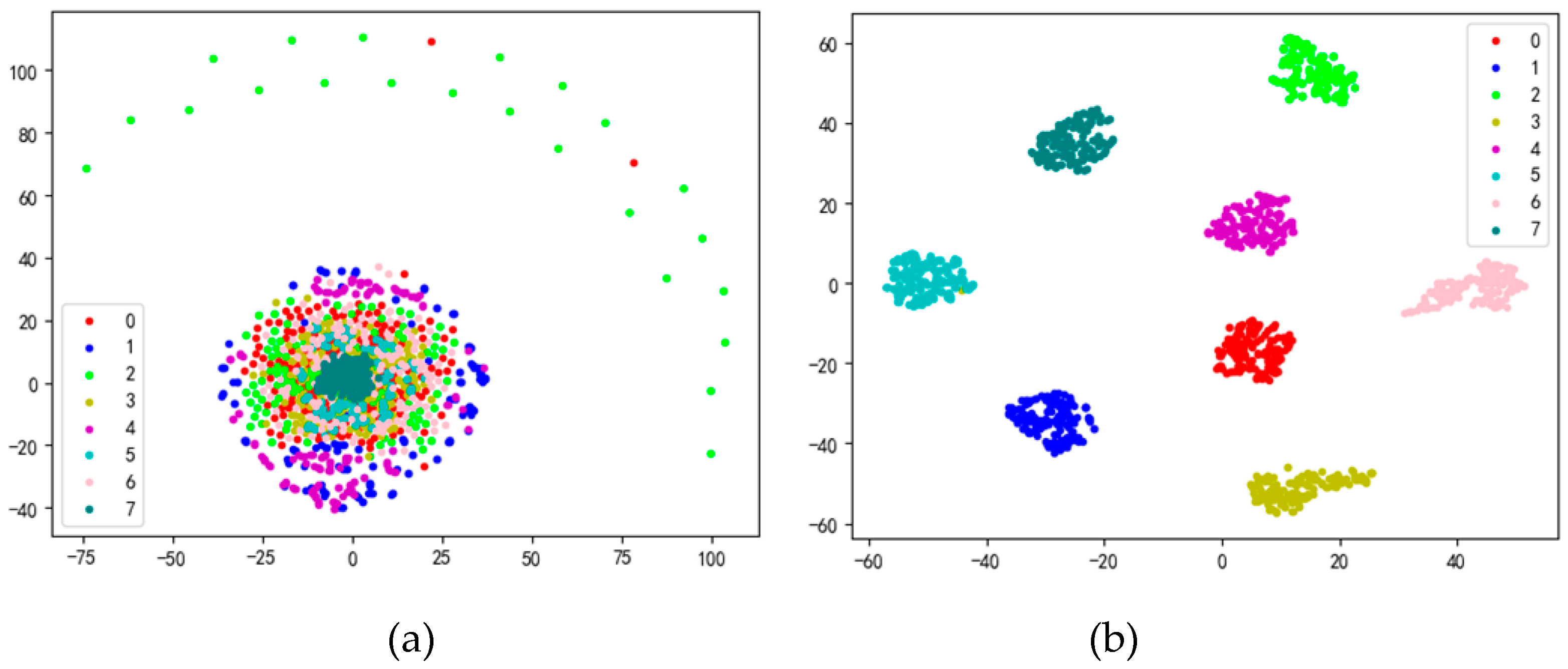

4.2. Generalization Experiment

5. Conclusions and Future Work

Data Availability

Author Contributions

Funding

Conflicts of Interest

References

- Ciabattoni, L.; Ferracuti, F.; Freddi, A.; Monteriù, A. Statistical spectral analysis for fault diagnosis of rotating machines. IEEE Trans. Ind. Electron. 2018, 65, 4301–4310. [Google Scholar] [CrossRef]

- Tra, V.; Kim, J.; Khan, S.A.; Kim, J.M. Bearing fault diagnosis under variable speed using convolutional neural networks and the stochastic diagonal Levenberg-Marquardt algorithm. Sensors 2017, 17, 2834. [Google Scholar] [CrossRef] [PubMed]

- Lei, Y.; He, Z.; Zi, Y. Application of the EEMD method to rotor fault diagnosis of rotating machinery. Mech. Syst. Signal Process. 2009, 23, 1327–1338. [Google Scholar] [CrossRef]

- Yan, R.; Gao, R.X.; Chen, X. Wavelets for fault diagnosis of rotary machines: A review with applications. Signal Process. 2014, 96, 1–15. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shin, H.H.; Zheng, Q.; Yen, N.-C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the hilbert spectrum for nonlinear and nonstationary time series analysis. Proc. R. Soc. Lond. A Math. Phys. Eng. Sci. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Lei, Y.; Zuo, M.J. Fault diagnosis of rotating machinery using an improved HHT based on EEMD andsensitive IMFs. Meas. Sci. Technol. 2009, 20, 125701. [Google Scholar] [CrossRef]

- Yu, J. Local and nonlocal preserving projection for bearing defect classification and performance assessment. IEEE Trans. Ind. Electron. 2012, 59, 2363–2376. [Google Scholar] [CrossRef]

- Liu, R.; Yang, B.; Zhang, X.; Wang, S.; Chen, X. Time–frequency atoms-driven support vector machine method for bearings incipient fault diagnosis. Mech. Syst. Signal Process. 2016, 75, 345–370. [Google Scholar] [CrossRef]

- Chikalov, I.; Hussain, S.; Moshkov, M. Totally optimal decision trees for Boolean functions with at most five variables. In Procedia Computer Science; Elsevier Science Publishers: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Lecun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef]

- Liu, R.; Meng, G.; Yang, B.; Sun, C.; Chen, X. Dislocated time series convolutional neural architecture: An intelligent fault diagnosis approach for electric machine. IEEE Trans. Ind. Inform. 2017, 13, 1310–1320. [Google Scholar] [CrossRef]

- Guoqian, J.; Haibo, H.; Jun, Y.; Xie, P. Multiscale convolutional neural networks for fault diagnosis of wind turbine gearbox. IEEE Trans. Ind. Electron. 2018, 66, 99. [Google Scholar]

- Gong, W.; Chen, H.; Zhang, Z.; Zhang, M.; Wang, R.; Guan, C.; Wang, Q. A novel deep learning method for intelligent fault diagnosis of rotating machinery based on improved CNN-SVM and multichannel data fusion. Sensors 2019, 19, 1963. [Google Scholar] [CrossRef] [PubMed]

- Huaqing, W.; Shi, L.; Liuyang, S.; Lingli, C. A novel convolutional neural network based fault recognition method via image fusion of multi-vibration-signals. Comput. Ind. 2019, 105, 182–190. [Google Scholar]

- Liu, X.; Zhou, Q.; Zhao, J.; Shen, H.; Xiong, X. Fault diagnosis of rotating machinery under noisy environment conditions based on a 1-D convolutional autoencoder and 1-D convolutional neural network. Sensors 2019, 19, 972. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Huang, J.; Ji, S. Bearing fault diagnosis with a feature fusion method based on an ensemble convolutional neural network and deep neural network. Sensors 2019, 19, 2034. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.; Liang, B.; Cheng, Y.; Meng, D.; Yang, J.; Zhang, T. Deep model based domain adaptation for fault diagnosis. IEEE Trans. Ind. Electron. 2016, 64, 99. [Google Scholar] [CrossRef]

- Li, X.; Zhang, W.; Ding, Q. Understanding and improving deep learning-based rolling bearing fault diagnosis with attention mechanism. Signal Process. 2019, 161, 136–154. [Google Scholar] [CrossRef]

- Abdeljaber, O.; Sassi, S.; Avci, O.; Kiranyaz, S.; Ibrahim, A.A.; Gabbouj, M. Fault detection and severity Identification of ball bearings by online condition monitoring. IEEE Trans. Ind. Electron. 2018, 66, 8136–8147. [Google Scholar] [CrossRef]

- Xiaoan, Y.; Minping, J. Intelligent fault diagnosis of rotating machinery using improved multiscale dispersion entropy and mRMR feature selection. Knowl. Based Syst. 2018, 163, 450–471. [Google Scholar]

- Hubel, D.H.; Wiesel, T.N. Receptive fields of single neurones in the cat’s striate cortex. J. Physiol. 1959, 148, 574–591. [Google Scholar] [CrossRef]

- Hubel, D.H.; Wiesel, T.N. Receptive fields and functional architecture of monkey striate cortex. J. Physiol. 1968, 195, 215–243. [Google Scholar] [CrossRef] [PubMed]

- Peng, H.; Long, F.; Ding, C. Feature selection based on mutual information: Criteria of max-dependency, max-relevance and min-redundancy. IEEE Trans. Pattern Anal. Mach. Intell. 2005, 27, 1226–1238. [Google Scholar] [CrossRef]

- Li, B.; Zhang, P.-L.; Tian, H.; Mi, S.-S.; Liu, D.-S.; Ren, G.-Q. A new feature extraction and selection scheme for hybrid fault diagnosis of gearbox. Expert Syst. Appl. 2011, 38, 10000–10009. [Google Scholar] [CrossRef]

- Jin, X.; Ma, E.W.M.; Cheng, L.L.; Pecht, M. Health monitoring of cooling fans based on mahalanobis distance with mRMR feature selection. IEEE Trans. Instrum. Meas. 2012, 61, 2222–2229. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Li, G.; Xu, M.; Huang, W. A fault diagnosis scheme for planetary gearboxes using modified multi-scale symbolic dynamic entropy and mRMR feature selection. Mech. Syst. Signal Process. 2017, 91, 295–312. [Google Scholar] [CrossRef]

- Srivastava, N.; Hinton, G.; Krizhevsky, A.; Sutskever, I.; Salakhutdinov, R. Dropout: A simple way to prevent neural networks from overfitting. J. Mach. Learn. Res. 2014, 15, 1929–1958. [Google Scholar]

- Noda, K.; Yamaguchi, Y.; Nakadai, K.; Okuno, H.G.; Ogata, T. Audio-visual speech recognition using deep learning. Appl. Intell. 2015, 42, 722–737. [Google Scholar] [CrossRef]

- Lou, X.; Loparo, K.A. Bearing fault diagnosis based on wavelet transform and fuzzy inference. Mech. Syst. Signal Process. 2004, 18, 1077–1095. [Google Scholar] [CrossRef]

- Tang, X.; Wang, J.; Lu, J.; Liu, G. Improving bearing fault diagnosis using maximum information coefficient based feature selection. Appl. Sci. 2018, 8, 2143. [Google Scholar] [CrossRef]

- Lei, Y.; He, Z.; Zi, Y. Fault diagnosis based on novel hybrid intelligent model. Chin. J. Mech. Eng. 2008, 44, 112–117. [Google Scholar] [CrossRef]

| CNN | SVM | ||

|---|---|---|---|

| Layers | Hyper-Parameter Settings | Training Parameters | The penalty factor C = 128; Kernel function is Gaussian Radial basis function (RBF); Kernel function parameters = 0.5 |

| Input layer | 32 × 32 inputs | Adam Batch size = 64 Learning rate = 0.003 Epoch = 20 Dropout = 0.3 (Ks is kernel size, Kn is kernel number, S is sub-sampling rate, N is number of hidden layer neuron nodes) | |

| C1 | Ks = 5 × 5, Kn = 32, Stride = 2, activation = ReLU | ||

| P2 | S = 2 | ||

| C3 | Ks = 3 × 3, Kn = 64, Stride = 1, activation = ReLU | ||

| P4 | S = 2 | ||

| F5 | N = 128, activation = ReLU | ||

| Output layer | The output is the number of classes, activation = Softmax | ||

| Fault Location | Fault Diameter (Inches) | Training | Testing | Condition Label |

|---|---|---|---|---|

| Normal | None | 150 | 50 | 0 |

| Inner Race | 0.007 | 150 | 50 | 1 |

| Ball | 0.007 | 150 | 50 | 2 |

| Outer Race | 0.007 | 150 | 50 | 3 |

| Inner Race | 0.014 | 150 | 50 | 4 |

| Ball | 0.014 | 150 | 50 | 5 |

| Outer Race | 0.014 | 150 | 50 | 6 |

| Inner Race | 0.021 | 150 | 50 | 7 |

| Ball | 0.021 | 150 | 50 | 8 |

| Outer Race | 0.021 | 150 | 50 | 9 |

| Features in Time-Domain | Features in Frequency-Domain | ||

|---|---|---|---|

| . | |||

| . | |||

| is the time-domain signal sequence, , is the number of each sample points. | is the frequency-domain signal sequence, , is the number of spectral lines. | ||

| Condition Label | Precision Rate | Recall Rate | F1 Measure | Sample Amount |

|---|---|---|---|---|

| 0 | 100% | 100% | 100% | 50 |

| 1 | 100% | 100% | 100% | 50 |

| 2 | 100% | 100% | 100% | 50 |

| 3 | 100% | 100% | 100% | 50 |

| 4 | 100% | 100% | 100% | 50 |

| 5 | 100% | 98.00% | 98.99% | 50 |

| 6 | 100% | 100% | 100% | 50 |

| 7 | 100% | 100% | 100% | 50 |

| 8 | 98.04% | 100% | 99.01% | 50 |

| 9 | 100% | 100% | 100% | 50 |

| Average/Total | 99.80% | 99.80% | 99.80% | 500 |

| Compound Fault Location and Diameter | Training | Testing | Condition Label | ||

|---|---|---|---|---|---|

| Outer Race Fault Diameter (inches) | Inner Race Fault Diameter (inches) | Ball Fault Diameter (inches) | |||

| 0.0787 | 0.0787 | Null | 150 | 50 | 0 |

| 0.1181 | 0.0787 | Null | 150 | 50 | 1 |

| Null | 0.0787 | 0.0787 | 150 | 50 | 2 |

| Null | 0.1181 | 0.0787 | 150 | 50 | 3 |

| 0.0787 | Null | 0.0787 | 150 | 50 | 4 |

| 0.0787 | Null | 0.1181 | 150 | 50 | 5 |

| 0.0787 | 0.0787 | 0.0787 | 150 | 50 | 6 |

| 0.0787 | 0.0787 | 0.1181 | 150 | 50 | 7 |

| Condition Label | Models | ||

|---|---|---|---|

| CNN | GL-SVM | GL-mRMR-SVM | |

| 0 | 97.88 ± 0.0243 | 97.53 ± 0.0266 | 98.40 ± 0.0085 |

| 1 | 97.89 ± 0.0556 | 99.59 ± 0.0046 | 99.60 ± 0.0024 |

| 2 | 99.03 ± 0.0201 | 90.97 ± 0.1292 | 99.41 ± 0.0024 |

| 3 | 96.15 ± 0.0388 | 95.49 ± 0.0347 | 98.70 ± 0.0141 |

| 4 | 98.66 ± 0.0308 | 98.77 ± 0.0189 | 99.80 ± 0.0016 |

| 5 | 99.12 ± 0.0104 | 99.60 ± 0.0045 | 99.70 ± 0.0021 |

| 6 | 96.43 ± 0.0538 | 97.83 ± 0.0277 | 98.48 ± 0.0174 |

| 7 | 99.40 ± 0.0064 | 99.49 ± 0.0047 | 99.70 ± 0.0041 |

| Average | 98.07 | 97.41 | 99.22 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, X.; He, Q.; Gu, X.; Li, C.; Zhang, H.; Lu, J. A Novel Bearing Fault Diagnosis Method Based on GL-mRMR-SVM. Processes 2020, 8, 784. https://doi.org/10.3390/pr8070784

Tang X, He Q, Gu X, Li C, Zhang H, Lu J. A Novel Bearing Fault Diagnosis Method Based on GL-mRMR-SVM. Processes. 2020; 8(7):784. https://doi.org/10.3390/pr8070784

Chicago/Turabian StyleTang, Xianghong, Qiang He, Xin Gu, Chuanjiang Li, Huan Zhang, and Jianguang Lu. 2020. "A Novel Bearing Fault Diagnosis Method Based on GL-mRMR-SVM" Processes 8, no. 7: 784. https://doi.org/10.3390/pr8070784

APA StyleTang, X., He, Q., Gu, X., Li, C., Zhang, H., & Lu, J. (2020). A Novel Bearing Fault Diagnosis Method Based on GL-mRMR-SVM. Processes, 8(7), 784. https://doi.org/10.3390/pr8070784