Abstract

The extraction of glycyrrhizin from licorice root and stolon with ethanol/water solutions leaves a lignocellulosic residue, which could be potentially applied in biocomposites. This process proved difficult in principle, given the considerable hardness of this material as received, which impedes its use in polymer resins in large amounts. After ball milling, up to 10% of this fibrous residue, which shows very variable aspect ratio, was introduced into an epoxy matrix, to investigate its possible future application in sustainable polymers. Of the three composites investigated, containing 1, 5 and 10 wt% of licorice waste, respectively, by performing flexural testing, it was found that the introduction of an intermediate amount of filler proved the most suitable for possible development. Thermal characterization by thermogravimetry (TGA) did not indicate large variation of degradation properties due to the introduction of the filler. Despite the preliminary characteristics of this study, an acceptable resin-filler interface has been obtained for all filler contents. Issues to be solved in future study would be the possibility to include a larger amount of filler by better compatibilization and a more uniform distribution of the filler, considering their orientation, since most of it maintains an elongated geometry after ball milling.

1. Introduction

The generation of lignocellulosic fibrous waste is abundant in the agro-food sector, from a large variety of botanical species: from this waste, the extraction of lignin has been attempted as an option to increase its profile of use, getting away from energy recovery to the production of new materials [1]. A large number of possibilities are offered by the different methods of lignin extraction, while on the other hand, a simpler yet not always viable possibility is given by their integration into biopolymers, especially if their yield in lignin is not likely to be very high [2].

In particular, the root and the stolon from licorice (Glycyrrhiza glabra) have a very long tradition of use in different regions in the world, including China, Turkey, Israel and some parts of southern Europe, such as in southern Italy [3]. Their traditional applications were as medicinal plants, then in confectionery, but have gradually expanded, even to use in cosmetics; the value of the licorice market was evaluated at USD 42 million in 2007 [4].

The root constitutes a lignocellulosic material: analysis performed in [5] measured it as having only a 3% content of water-soluble polysaccharides, 30.7% cellulose, 27.5% lignin according to Komarov’s method [6] and 25.1% lignin determined by hydrochloric acid method, with, in any case, a large amount of hemicellulose [7]. Licorice root is mainly employed in the food industry as a sweetener and flavoring agent, and also in the tobacco industry, or as a source of saponin [8] or flavonoids, the latter known also for their anti-inflammatory action [9]. The main component of interest for the production of licorice is glycyrrhizin, which is a saponin compound formed by the conjugation of glycyrrhetic acid, a triterpenoid aglycone, with a disaccharide of glucuronic acid. The extraction of glycyrrhizin is often performed using an ethanol solution at high temperatures [10]. Uses in both traditional and herbal medicine are particularly related to the inhibitory effect to the action of Helicobacter pylori, therefore working as a liver protector, due to flavonoids found in licorice root [11]. More recently, this potential was also suggested for employing licorice extracts for the incorporation in active anti-oxidation food packaging films based on soy protein [12].

However, a large amount of biomass is still available from the residue of glycyrrhizin extraction from licorice roots. In particular, quite recent data from China suggest that about 6–7 million tons of residues of the local licorice species are produced yearly [13]. A number of applications external to the food industry have been also proposed, none of which appear to have been industrialized as particularly successful. For example, licorice root powdered biomass showed some potential when used as a co-compost with cow manures for its suppression of some types of fungi, such as Fusarium oxysporum f. sp. melonis (FOM) [14]. Another possibility that has been investigated is the production of active carbons from licorice waste, namely for the removal of methylene blue [15]. This has also been experimented in mixtures, in particular with pistachio shells, another abundant waste from high-added value productions in the food sector: the blend of the two wastes offered good properties as an active carbon precursor for the removal of mercury [16]. A further option very recently explored has been the use of licorice as a source for cellulose nanofiber (CNF) materials: this showed some potential, although it involves a considerable transformation of the residue and limited yielding, also due to the not very large cellulose content of the raw material [17].

In this situation, and especially considering that in terms of a circular economy, even a relatively small production system, such as the one based on licorice in southern Italy, mainly in the Calabria region, needs to act with a zero waste philosophy. In practice, the production of licorice from Calabria is in the order of a few hundred tons per year, but it needs to be considered that the yield offered by dried roots is only around 20% in licorice, with the rest becoming residue; therefore, thousands of tons per year of residue are available [18].

It is important, therefore, to find applications compatible with the full use of residues from production, for example as a prospective filler for polymer matrices, which is the objective of this work. The use of waste biomass resulting from agricultural, textile or food industry processes, as the filler for composites, has been often proposed recently, to subtract it, if possible and convenient, to an energy recovery function. In contrast, its recycling in new materials would be recommendable according to the waste hierarchy disposed by the European directive 98/2008. Normally, these studies have been aimed at the introduction in a biopolymer: however, initial evaluations have been carried out using a traditional oil-based polymer. This, although not biodegradable and not compatible with the biomass, offers indications for preliminary considerations on the suitability of the process. The leading idea is that reusing waste biomass is limiting its mechanical and chemical transformation, for economical and environmental reasons. Examples of this way of proceeding on waste from large productive systems were offered about oil palm fibers [19] and coconut and banana fibers [20].

In the case of licorice root residue, on which limited knowledge of its performance as a material is available, the introduction in an epoxy matrix, although preferable for an initial study for its simplicity, is likely to create some problems due to matrix–filler compatibility, which will possibly limit the amount of lignocellulosic residue used. On the other side, this can be considered an operation carried out in a particularly difficult situation, to understand the possibility for further developments using more appropriate and possibly compatible thermoplastic polymers.

2. Materials and Methods

2.1. Materials

2.1.1. Residues of Licorice Root

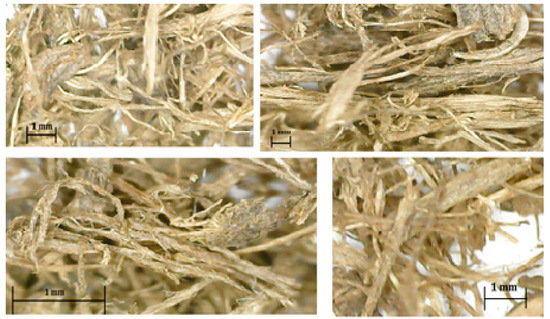

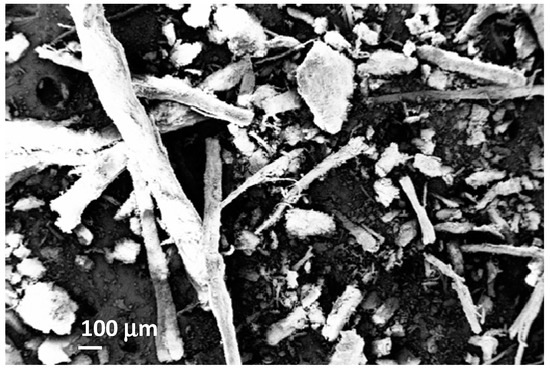

From licorice root, glycyrrhizin was extracted using an ethanol/water (1:1, v/v) solvent, with a sample to solvent ratio of 1:5 (w/v), during 1 h: residues obtained after extraction were supplied by Amarelli and Fallani, Rossano Calabro, Italy, and their use as a filler in a composite is the objective of this study. Before starting any use, the material was stored for a period of around 6 months. The aspect in which the material was before milling is reported in Figure 1; some agglomeration of fibrous structures is visible, while on the other hand, in some cases, ribbon-like thinner parts are also visible. It is also likely that the extraction of glycyrrhizin was not complete, since some blackish staining on the fibers is also noticeable. To prepare them for introduction in the resin, checking that the material did not include pieces with dimensions larger than 10 mm, they were suitable for ball milling. Therefore, the root residues were milled for 2 h using a Retsch PM 100 planetary ball mill with a 250 mL chamber in agate and equipped with 10 zirconia particles with diameter 10 mm as milling agents.

Figure 1.

Optical microscopy images of the licorice waste residue as obtained.

2.1.2. Preparation of the Composites

EPON™ Resin 828, a difunctional bisphenol A/epichlorohydrin derived liquid epoxy resin, kindly supplied by Hexion (Solbiate Olona (Varese), Italy), was employed as a matrix for the development of composites. Triethylenetetramine, supplied by Sigma-Aldrich, was selected as a curing agent (12.9 phr) for the epoxy.

For the production of the blends, three filler concentrations were considered: 1, 5 and 10 wt%. These concentrations were calculated using the total weight of the reactive system (epoxy monomer + hardener). Before introducing the filler in the resin, it was dehydrated for 16 h in an oven at 40 °C. To obtain a good dispersion of licorice waste, the epoxy monomer and the root fibers were mixed together at room temperature via high-shear mechanical mixer for about 30 minutes. Five specimens per filler concentration were produced and tested, to be compared with five pure epoxy specimens.

After this phase, the systems were sonicated in an ultrasonic bath for 30 min for degassing. In order to completely remove air bubbles, the blends were further placed in a vacuum chamber. The obtained composite blends are referred in this paper as L-1%, L-5% and L-10%. The neat epoxy was produced and used as a benchmark (Pure Epoxy). The correct amount of hardener was added and manually mixed, paying attention not to entrap air in the blend. The reactive systems were poured in a Teflon mold and left to cure. The curing cycle was 12 h at room temperature and a post-cure at 90° C for 1 further hour. In this way, samples for mechanical characterization and thermo-gravimetric analysis (TGA) were obtained.

2.2. Characterisation Methods

Before carrying out the milling operation, the licorice root waste as received was morphologically characterized using a field-emission scanning electron microscope (SEM) (FESEM Zeiss, model Supra 25, Zeiss AG, Oberkochen 73447, Germany). The microscope was also used to evaluate the dimension and shape of the milled root fibers before their addition in the epoxy matrix, so to compare the effect of ball milling. After milling, the licorice root waste was introduced into the composites. A morphological investigation was again carried out using the same SEM apparatus to evaluate the dispersion of the licorice root in the composites. For all analysis carried out, the samples were metallized with gold.

The mechanical properties of composites were evaluated with a flexural characterization using a dynamometer LLOYD Instruments model LR30K (Lloyd Instruments Ltd., Bognor Regis PO22 9ST, UK): three-point bending tests were carried following the normative ASTM D790M-93 (ASTM, West Conshohocken, Penns., United States).

The thermal stability of the milled waste material, the resin and the composites was evaluated by TGA. The tests were performed in air and nitrogen with a thermogravimetric analyzer, Seiko model Exstar 6300, and consisted of dynamic scans at the heating rate of 10 °C/min from 30 to 900 °C. Bulk samples of about 10 ± 1 mg were used. To obtain a good reproducibility, at least five samples for each material were tested.

Additionally, FTIR-ATR (attenuated total reflection) analysis was performed for a qualitative characterization of the reported licorice root residue. The IR spectrum was recorded with a Perkin Elmer (20126 Milan, Italy) FTIR spectrometer Spectrum Two UATR equipped with ZnSe crystal (range from 4000 to 450 cm−1) performing 16 scans.

3. Results and Discussions

3.1. Characterization of Licorice Root Extract

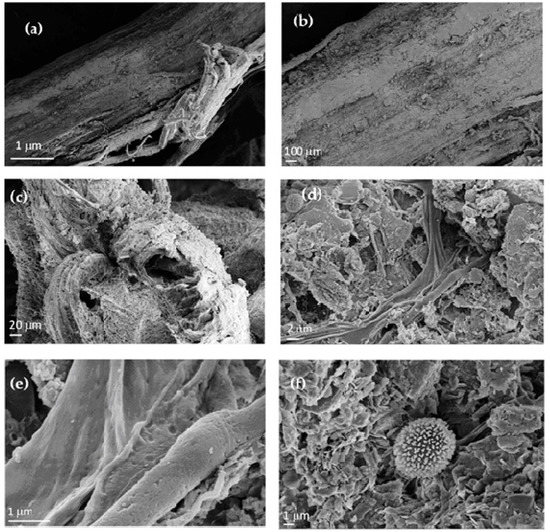

The first observations concerned the evaluation of the material as received under the scanning electron microscope. Due to the limited literature coverage on the specific roots, the explanations would rather concentrate on what can be deduced from extraction processes carried out on lignocellulosic waste materials. In particular, it is expected that the extraction would lead to preserving basically the whole of the lignin structure and a non-negligible part of cellulosic materials [21]. Specific features were observed. In particular, the material appears to be very fibrous and in fragments of maximum dimensions exceeding a few millimeters, as is apparent in Figure 2a. The fibers appear to be connected by a softer matter, in practice allowing their separation or fracture by cleavage (Figure 2b). Evidence of the hierarchical levels of the botanical structure is also offered, with the spiral winding of the fibrous material being shown in Figure 2c. Cellulose microfibrils are represented in Figure 2d,e at different magnifications: here, the typical etched striations are revealed [22]. These are embedded in a more compact and plate-like structure, most likely attributed to lignin. In the material, as received, the presence of some spores, as represented in Figure 2f, was also revealed. From the point of view of the present research, this demonstrates the persistence in the waste material, after extraction, of root exudates, such as organic acids, amino acids and phenolic compounds, which assist in the development of plant–fungal symbiosis by inducing spore germination [23]. This would need further investigation in the sense of possibly affecting the stability of biopolymer in cases when licorice waste is used as filler.

Figure 2.

SEM micrographs of the raw material as obtained: (a) view over the whole width of a particle; (b) details of cleavage structure; (c) spiraliform arrangement of the fibrous material; (d) bundle of cellulose micro-fibrils; (e) etched surface of cellulosic micro-fibrils; (f) spore germinated in as-received material.

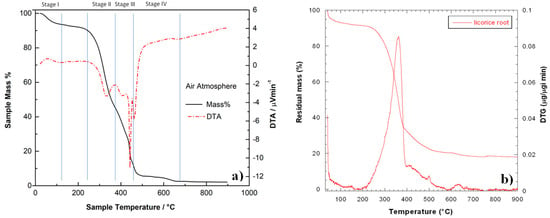

To have some more information about the content of cellulose, hemicellulose and lignin, which constitute the three principal components of biomass, thermogravimetric measurements were carried out. In particular, as reported in Figure 3, TG-DTA analysis carried out in air on the material as received led to the clear indication of four different stages, which are here reported, with their respective amounts. It is not possible in general terms to identify in this way the three separate components, namely hemicellulose, cellulose and lignin. It has, however, been suggested that the onset of degradation of the three components may start in the order in which they are mentioned above, although co-existence of the different degradation phenomena is also frequent [24].

Figure 3.

Weight loss of licorice root residue sample during heating rate at 10 °C/min under air (a) and nitrogen (b) flow.

Stage I (7%) is the dehydration process, which is due to water and ethanol content into the intrinsic mass of the residue, ending around 120 °C.

Stage II (41%), where most degradation takes place, is likely to start from hemicellulose, which is the simplest to pyrolyze among the three major fractions of a lignocellulosic biomass, due to its linear polymer structure with short side chains, hence decomposing at temperatures between 200 and 350 °C (Tonset for Stage II = 287.2 °C) [25].

Stage III (30%) is mainly correlated with cellulose, which is constructed of semicrystalline arrangements of chains associated with one another, and decomposing in a temperature range from 350 to 425 °C (Tonset for Stage III = 415.3 °C). It is suggested that the strong interaction between the different components would contribute to elevating the cellulose degradation temperature [26].

Stage IV (12%) is when it is most likely that lignin decomposition would occur. Lignin is a complex structure of phenolic polymer that enclose the polysaccharides of the cell walls which produces hard and durable composite materials [27,28], in fact, lignin steadily decompose from 450 to 550 °C and over 800 °C (Stage IV Tonset = 457.3 °C), reflecting the different structures of lignin.

The four stages are not covering the whole temperature range; therefore, around 10% of the material is not attributed to any of the degradation stages.

In the case of the thermogravimetric tests of the licorice root residues in nitrogen atmosphere, as reported in Figure 3b, we measured a loss of around 12% below 100 °C, which may indicate the not negligible presence of moisture, or possibly ethanol residues. In contrast, the onset of material degradation, as indicated by the inflection point of the differential thermogravimetric analysis (DTG) curve, appears to be at around 260 °C, reaching its maximum at 360 °C and completed around 400 °C, as is normally the case for lignocellulosic structures. Furthermore, from the amount of mineral mass remaining at 800 °C, in the region of 20%, it can be suggested that the behavior of the licorice waste was mainly closer to that of hemicellulose, which is in fact its main constituent [29].

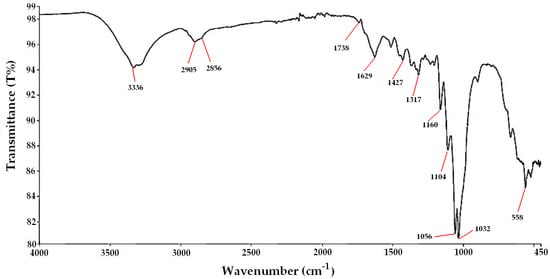

More detailed information about the nature of licorice root residue is also offered by FTIR-ATR measurements. For the qualitative determination of biomass components in the MID-IR region Fourier transform mid-infrared spectroscopic analysis is also a rapid and non-destructive technique. Lignocellulosic biomass is mostly composed of lignin, hemicellulose, and cellulose, but there are small differences between the proportion and structure of the chemical compositions in different biomass species. As mentioned above, FTIR provides information about certain components in the plant cell wall through absorbance bands (see Figure 4).

Figure 4.

FTIR-ATR spectra of licorice root residue.

The major absorption peaks for the present study are selected as follows (Figure 4): the -OH stretching is represented by very strong peaks at 3336 cm−1, as well as the established aliphatic -CH and -CH2 stretching at 2856–2904 cm−1. The non-conjugated -C=O in hemicellulose stretching vibration absorption peak is seen at around 1738 cm−1, while the absorption peak at around 1629 cm−1 is assigned to aromatic skeletal vibration allied to the out-of-plane stretching of aromatic –CH. The peak at 558 cm−1 is assigned to C–OH out-of-plane in cellulose [30], while those in the region from 1031 to 1160 cm−1 are assigned to the -C-O stretching vibration in holocellulose, and the peak at 1427 cm−1 is assigned to the -CH, -CH2 bending of aliphatic carbons. The small intensity of peaks at around 1738 cm−1 shows a very low holocellulose to lignin ratio [31]. The strong peak of licorice root at 1316 cm−1 indicates the high proportion of syringyl units in lignin, combined with the 1629 cm−1 peak. This appears different from other roots, as reported from Wang et al. [32], who reported instead on those with a high amount of guaiacyl units.

3.2. Introduction into Epoxy Matrix and Characterization of the Composites

The idea was to evaluate the possibility to introduce it in a polymer matrix, in particular a traditional thermosetting one, with the idea, in case the results were promising, to proceed, if at all possible, in further studies towards the use of biopolymers. In practical terms, the material, introduced as received, proved too hard and of scattered dimensions for the purpose, leading to clogging within the matrix, even in very small amounts. Therefore, a ball mill grinding process was applied to reduce the size of the filler.

After material grinding, the introduction of licorice waste into the epoxy matrix was revealed to be possible to an amount of up to 10% wt., after which again the problems in mixing with the resin were substantial. The variability of the geometries obtained after grinding was considerable, as reported in Figure 5, and most particles obtained had a shape far removed from the cylindrical one. An initial measurement, based on the average length and diameter of the particles as appearing from the SEM observation, suggested that in a sample of 50 particles, with lengths between 50 microns and 1.5 mm, the average aspect ratio (= length/diameter) was 5.5, and only about 20% of the particles had an aspect ratio above 10. This value of aspect ratio is indicated to offer fibers which are likely to offer some reinforcement effect, even in small amounts and in a random configuration [33]. As a consequence, the improvement in mechanical performance expected over the pure resin is likely to be limited. A previous attempt related to the introduction of as-received lignocellulosic waste biomass from Opuntia fibers into a thermoplastic starch (TPS) matrix indicated an increase only in stiffness, with considerable issues in maintaining the same stress of the pure matrix, despite its compatibility with the filler [34].

Figure 5.

The aspect of licorice waste after ball mill grinding.

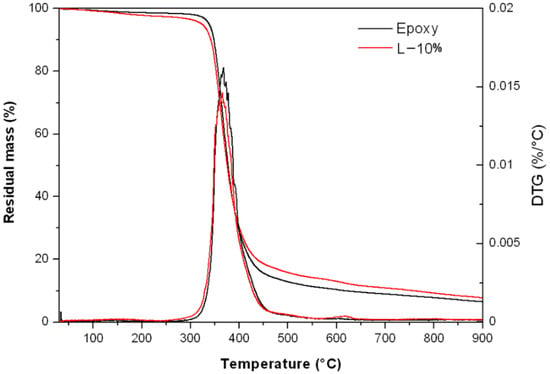

In comparison, thermogravimetric tests of the neat epoxy resin and of the composite with the highest amount of filler (L-10%) (Figure 6) indicated that the degradation temperature of epoxy and of the licorice root waste were quite close to each other, so that the effect of the introduction of filler in epoxy on the degradation temperature was really small.

Figure 6.

Thermogravimetric tests results in nitrogen atmosphere of pure epoxy and 10% licorice waste composite (L-10%).

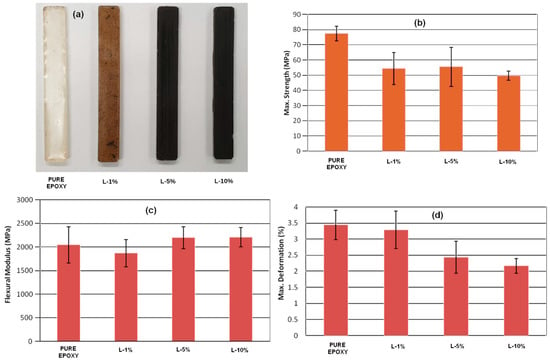

Samples for flexural characterization, which was deemed to be the most significant testing type for the initial evaluation of randomly oriented lignocellulosic filler in a resin, are shown in Figure 7a. The results obtained, which are reported in Figure 7b (strength), Figure 7c (stiffness) and Figure 7d (strain), indicate that the introduction of licorice waste, even in very small quantities, results in a significant reduction in flexural strength. This is expected when it is not very easy to control the distribution of the filler particles and therefore they act more as defects, just increasing the rigidity of the resin, despite some elongated particles also existing, which would possibly behave as reinforcement. A suggestion could be applying some separation with appropriate sieve meshes, which should not present particular problems, in view of the relative hardness of the filler material. On the other hand, there is a small effect on stiffness, yielding an increase of a few percent both with the introduction of 5 wt% and of 10 wt% of licorice root waste, which appears to have a limited significance, due to the small amount of filler introduced and to the fact that five specimens per category were tested. The best compromise, in view of the larger strain retained, can be suggested to be the one obtained by the introduction of 5 wt% filler, although, in view of the maximal re-use of waste, going up to 10 wt% could be reasonable.

Figure 7.

(a) Examples of the four series of samples tested; (b) flexural strength (average and standard deviation) results; (c) flexural modulus (average and standard deviation) results; (d) flexural maximum strain (average and standard deviation) results.

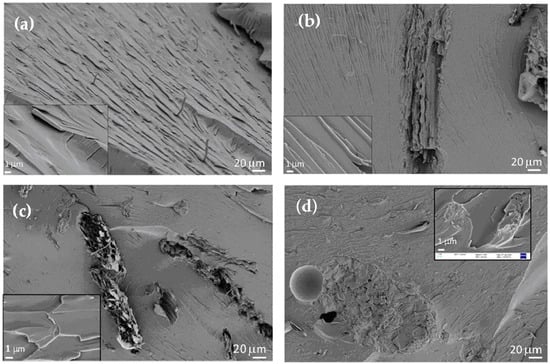

Scanning electron microscopy (SEM) images of fracture surfaces, reported in Figure 8, are especially focused on controlling the formation of an effective interface between the filler and the resin. This is particularly observed from the accommodation of the resin strain, which appears as such in Figure 8a, and by the different amounts of filler introduced, 1, 5, and 10 wt%, in Figure 8b–d, respectively. Here, again, the most promising situation appears to be shown by the intermediate amount of filler, hence 5 wt%, where the most interesting modification with respect to pure epoxy is revealed. In contrast, there is a notable effect of the filler orientation in the case of 1 wt%, and a noteworthy presence of air inclusions, which are likely to be due to the difficult introduction of a possibly excessive amount of filler, in the case of 10 wt%.

Figure 8.

SEM images of bending fracture surfaces: (a) pure epoxy; (b) L-1%; (c) L-5%; (d) L-10%.

The limited compatibility between the resin and the filler also played a role, but it was quite promising that a minimal improvement was observed over the resin properties, at least in terms of stiffness. To ensure the repeatability of the results and possibly avoid the strength loss, a number of strategies would be necessary, including the control of the aspect ratio by appropriate meshing of the particles and chemical treatment, e.g., by alkali, for the removal of loose and non-structural parts, etc.

4. Conclusions

The introduction of licorice waste in an epoxy resin proved feasible in lower amounts, not exceeding 10 wt%, and provided some improvement to the flexural stiffness of the resin, even with only 5 wt% waste, despite the random arrangement of the filler introduced with a very scattered aspect ratio. The interface obtained between the matrix and the filler was of limited strength, although no particular tendency towards pull-out was observed, due to the low amount of fibers introduced. Other critical aspects were also revealed, in particular the tendency towards spore germination on the waste, despite long storage, due to it not being dried immediately after glycyrrhizin extraction, and the difficult mixing with the polymer. While the former suggested a further difficulty in the possible future use of this waste as the filler of biopolymers, leading to early degradation, the latter would limit the amount of waste used in the prospective composite. Indications for improvement would be the treatment of the material to make it less prone to rotting, excluding fibers with too low an aspect ratio or applying alternative mixing processes, such as production using three-roll calendering. On the other hand, the attempt to use a refuse from the agro-food industry as received for introduction into a composite material retains its environmental value, at least as a reference for future developments.

Author Contributions

Conceptualization, C.S. and D.P.; Methodology, M.R., D.P. and S.G.; Investigation, M.R., D.P. and S.G.; Writing-Original Draft Preparation, C.S.; Writing-Review and Editing, M.R., D.P. and S.G.; Supervision, L.T. and E.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The residue of licorice root from glycyrrhizin extraction has been supplied by Teresa Carnevale, whose assistance is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Collins, M.N.; Nechifor, M.; Tanasă, F.; Zănoagă, M.; Mc Loughlin, A.; Stróżyk, M.A.; Culebras, M.; Teacă, C.A. Valorization of lignin in polymer and composite systems for advanced engineering applications—A review. Int. J. Biol. Macromol. 2019, 131, 828–849. [Google Scholar] [CrossRef] [PubMed]

- Motaung, T.E.; Linganiso, L.Z. Critical review on agrowaste cellulose applications for biopolymers. Int. J. Plast. Technol. 2018, 22, 185–216. [Google Scholar] [CrossRef]

- Housemn, P.A.; Lacey, H.Y. The licorice root in industry. Ind. Eng. Chem. 1929, 21, 915–917. [Google Scholar] [CrossRef]

- Hayashi, H.; Sudo, H. Economic importance of licorice. Plant Biotechnol. 2009, 26, 101–104. [Google Scholar] [CrossRef]

- Sdykov, T.; Abduazimov, K.A. Lignins of Allochruza paniculata and Glycyrrhiza glabra. Chem. Nat. Compd. 2002, 38, 288–290. [Google Scholar] [CrossRef]

- Komarov, F.P. Guide to Laboratory Work on the Chemistry of Wood and Cellulose; Gostekhlesizdat: Leningrad, Russia, 1934; p. 12. (In Russian) [Google Scholar]

- Edwards, C.S. Determination of lignin and cellulose in forages by extraction with triethylene glycol. J. Sci. Food Agric. 1973, 24, 381–388. [Google Scholar] [CrossRef]

- Schmid, C.; Dawid, C.; Peters, V.; Hofmann, T. Saponins from European licorice roots (Glycyrrhiza glabra). J. Nat. Prod. 2018, 81, 1734–1744. [Google Scholar] [CrossRef]

- Bai, M.; Yao, G.D.; Ren, Q.; Li, Q.; Liu, Q.-B.; Zhang, Y.; Wang, X.B.; Huang, X.-X.; Song, S.-J. Triterpenoid saponins and flavonoids from licorice residues with anti-inflammatory activity. Ind. Crops Prod. 2018, 125, 50–58. [Google Scholar] [CrossRef]

- Kim, H.-S.; Lee, S.-Y.; Kim, B.-Y.; Lee, E.-K.; Ryu, J.-H.; Lim, G.-B. Effects of modifiers on the supercritical CO2 extraction of glycyrrhizin from licorice and the morphology of licorice tissue after extraction. Biotechnol. Bioprocess Eng. 2004, 9, 447–453. [Google Scholar] [CrossRef]

- Fukai, T.; Marumo, A.; Kaitou, K.; Kanda, T.; Terada, S.; Nomura, T. Anti-Helicobacter pylori flavonoids from licorice extract. Life Sci. 2002, 71, 1449–1463. [Google Scholar] [CrossRef]

- Han, Y.; Yu, M.; Wang, L. Preparation and characterization of antioxidant soy protein isolate films incorporating licorice residue extract. Food Hydrocoll. 2018, 75, 13–21. [Google Scholar] [CrossRef]

- Gui, X.H.; Wang, G.L.; Hu, M.J.; Yan, Y.J. Combined fungal and mild acid pretreatment of glycyrrhiza uralensis residue for enhancing enzymatic hydrolysis and oil production. Bioresources 2013, 8, 5485–5499. [Google Scholar] [CrossRef]

- Medina, S.; Krassnovsky, A.; Yogev, A.; Raviv, M. Horticultural characteristics of licorice waste compost. Compost Sci. Util. 2011, 19, 163–169. [Google Scholar] [CrossRef]

- Ghaedi, M.; Ghazanfarkhani, M.D.; Khodadoust, D.; Sohrabib, N.; Oftade, M. Acceleration of methylene blue adsorption onto activated carbon prepared from dross licorice by ultrasonic: Equilibrium, kinetic and thermodynamic studies. J. Ind. Eng. Chem. 2014, 20, 2548–2560. [Google Scholar] [CrossRef]

- Wang, S.; Wang, X.; Liu, W.; Zhang, L.; Ouyang, H.; Hou, Q.; Fan, K.; Li, J.; Liu, P.; Liu, X. Fabricating cellulose nanofibril from licorice residues and its cellulose composite incorporated with natural nanoparticles. Carbohydr. Polym. 2020, 229, 115464. [Google Scholar] [CrossRef] [PubMed]

- Kaghazchi, T.; Asasian, N.; Soleimani, K.M. Licorice residue and Pistachio-nut shell mixture: A promising precursor for activated carbon. J. Ind. Eng. Chem. 2010, 16, 368–374. [Google Scholar] [CrossRef]

- Italian Licorice: A Fortune Grown in Calabria. Available online: https://www.bottegadicalabria.com/blog/italian-licorice-a-fortune-grown-in-calabria/ (accessed on 12 June 2020).

- Valášek, P.; Ruggiero, A.; Müller, M. Experimental description of strength and tribological characteristic of EFB oil palm fibres/epoxy composites with technologically undemanding preparation. Compos. B 2017, 122, 79–88. [Google Scholar] [CrossRef]

- Wang, J.; Hu, Y. Novel particleboard composites made from coir fiber and waste banana stem fiber. Waste Biomass Valorization 2016, 7, 1447–1458. [Google Scholar] [CrossRef]

- Angelini, S.; Cerruti, P.; Scarinzi, G.; Malinconico, M. Extraction and fractionation of a lignocellulosic biomass and its use as a bio-filler in poly(3-hydroxybutyrate). Cell. Chem. Technol. 2016, 50, 429–437. [Google Scholar]

- Maheswari, C.U.; Reddy, K.O.; Muzenda, E.; Guduric, B.R.; Rajulu, A.V. Extraction and characterization of cellulose microfibrils from agricultural residue—Cocos nucifera L. Biomass Bioenergy 2012, 46, 555–563. [Google Scholar] [CrossRef]

- Dagar, J.C.; Yadav, R.K.; Dar, S.R.; Ahamad, S. Liquorice (Glycyrrhiza glabra): A potential salt-tolerant, highly remunerative medicinal crop for remediation of alkali soils. Curr. Sci. 2015, 108, 1683–1688. [Google Scholar]

- Balla, K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Ganesh, J.; Tadimeti, D. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Zhou, X.; Li, W.; Mabon, R.; Broadbelt, L.J. A critical review on hemicellulose pyrolysis. Energy Technol. 2017, 5, 52–79. [Google Scholar] [CrossRef]

- Wang, S.; Guo, X.; Wang, K.; Luo, Z. Influence of the interaction of components on the pyrolysis behavior of biomass. J. Anal. Appl. Pyrolysis 2011, 91, 183–189. [Google Scholar] [CrossRef]

- Gaur, S.; Reed, T.B. Thermal Data for Natural and Synthetic Fuels; By Soddhartha (VSLR Sciences-Dallas, TX, USA); Marcel Dekker and Thomas Reed, Inc.: New York, NY, USA, 1998. [Google Scholar]

- Chen, W.H.; Kuo, P.C. Study on torrefaction of various biomass materials and its impact on ligninocellulosic structure simulated by thermogravimetry. Energy 2010, 45, 2580–2586. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Mohomane, S.M.; Linganiso, L.Z.; Buthelezi, T.; Motaung, T.E. Effect of extraction period on properties of sugarcane bagasse and softwood chips cellulose. Wood Res. 2017, 62, 931–938. [Google Scholar]

- Colom, X.; Carrillo, F.; Nogues, F.; Garriga, P. Structural analysis of photodegraded wood by means of FTIR spectroscopy. Polym. Degrad. Stab. 2003, 80, 544–547. [Google Scholar] [CrossRef]

- Wang, X.; Ren, H. Comparative study of the photo-discoloration of Moso bamboo (Phyllostachys pubescens Mazel) and two wood species. Appl. Surf. Sci. 2008, 254, 7029–7034. [Google Scholar] [CrossRef]

- Pickering, K.L.; Aruan Efendy, M.G.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Scognamiglio, F.; Mirabile Gattia, D.; Roselli, G.; Persia, F.; De Angelis, U.; Santulli, C. Thermoplastic starch films added with dry nopal (Opuntia Ficus Indica) fibres. Fibers 2019, 7, 99. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).