In many industrial heating and cooling applications, convective heat transfer is very important. By changing the boundary conditions, flow geometry or fluids’ thermophysical properties can enhance the convective heat transfer rate of a thermal system. The addition of nanoparticles to the base fluids is one of the promising ways of improving the thermophysical properties of fluids. Such kinds of suspensions are named as nanofluids. Nanofluids have attracted several researchers from all over the world because they have the ability to improve the heat transfer rate for different applications including electrical and electronics. Since nanofluids are considered to be the next generation coolants, researchers are focused on developing nanofluids with ultrahigh cooling performance, thus representing a significant cooling technology for cross-cutting applications. The main aim of nanofluid is to achieve the best thermal properties in the lowest concentrations with uniform dispersion and stable suspension of nanoparticles in base fluids. Numerous experimental [

1,

2,

3,

4,

5] and theoretical analyses [

6,

7,

8,

9,

10] of nanofluids’ thermophysical properties were conducted by many scientists. In general, the temperature and volume fraction were considered as important factors for developing the classical models of thermophysical properties especially thermal conductivity and viscosity [

11,

12,

13,

14]. Other than temperature and volume fraction, parameters such as particle shape, particle type and mixing ratio also influence the thermophysical properties of nanofluids. Accurate thermophysical properties of nanofluids under various parameters cannot be predicted easily. Furthermore, in terms of the conventional particle–liquid suspensions models, the heat transport mechanism for nanofluid is hard to understand. Currently, most of the available models are applicable for nanofluids with a lower concentration of nanoparticles (0.01 to 0.5 vol %) and uniform dispersion. Nevertheless, these models do not represent the correlation between thermophysical properties and shape; temperature and the high cost is the obstacle for practical applications. The measurement of thermophysical properties of nanofluids for a specific temperature, concentration, size and shape requires a lot of time, huge data and money. In order to overcome these issues, many scholars have suggested computational frameworks or empirical models for the prediction of nanofluid properties. The easiest way to determine the thermophysical properties of various nanofluids is by utilizing soft computational approaches such as Artificial Neural Networks (ANNs) and Genetic Algorithms (GA) which require a massive quantity of data for analysis.

Computational networks that involve the simulation of nerve cells or neurons of the network that mimic the central biological nervous system are known as Artificial Neural Networks. These are incredibly easy in computation and algorithmic types and have a self-organizing function that helps them to solve several problems. One of the important roles of ANNs is that they enable high-level programming in their gross imitation of a biological network to facilitate the solution of complex issues especially nonanalytical, nonlinear and nonstationary in a self-organizing way that can be implied to resolve a large number of problems. Ma et al. [

15] developed ANN models of viscosity and thermal conductivity based on the distribution of nanoparticles in nanofluids that can also be termed as Uniformity Coefficient of Nanoparticles Distribution (UCND). Authors found that the results projected by the ANN models are compatible with the experimental values with R

2 values of more than 0.97 for viscosity and thermal conductivity. Toghraie et al. [

16] predicted the viscosity of silver/EG nanofluids using the ANN technique that comprised data points of 42 samples at various temperatures (25–55 °C) and volume fractions (0.25–2%) and validated with the correlation method where they obtained a maximum deviation of 0.0858. A dissimilar ANN was proposed by Akhgar et al. [

17] to determine the thermal conductivity of hybrid nanofluids (MWCNT-TiO

2/Water-EG) through sensitivity analysis which proved that the empirical results obtained by the ANN technique were better than the correlation-based results. Sadeghi et al. [

18] utilized the ANN technique to verify the experimental results of thermal characteristics (energy and exergy) of Copper oxide/Water nanofluid in an evacuated tube solar collector via multilayer perceptron (MLP) and radial basis function (RBF). Authors observed that the MLP models’ maximum error rate was smaller than the RBF model. A multiobjective optimization model comprising an ANN and GA was developed by Bagherzadeh et al. [

19] to predict the thermophysical properties and heat transfer coefficient (HTC) of CuO/Paraffin nanofluid with a view on increasing the HTC and decreasing the pressure drop ratio. Finally, they concluded that the multiobjective optimization test results from the genetic algorithm revealed the optimal front of Pareto was responsible for enhancing the heat transfer coefficient. The effects of temperature and volume fraction on the thermal conductivity of MWCNT-CuO/Water nanofluid were considered for the development of an ANN and SVR (Support Vector Regression) to compare the persistence of accuracy, precision and generalization. They clearly demonstrated that the generalization of SVR is more useful than the ANN because it requires only fewer parameters with better endurance to overfitting. Naphon et al. [

20] investigated the heat transfer and flow characteristics of titanium/deionized water nanofluids numerically (Eulerian two-phase approach), experimentally and with ANN (Levenberg–Marquardt back-propagation training algorithm). In all the cases, the average variance between the calculated and forecasted data was 1.25%.

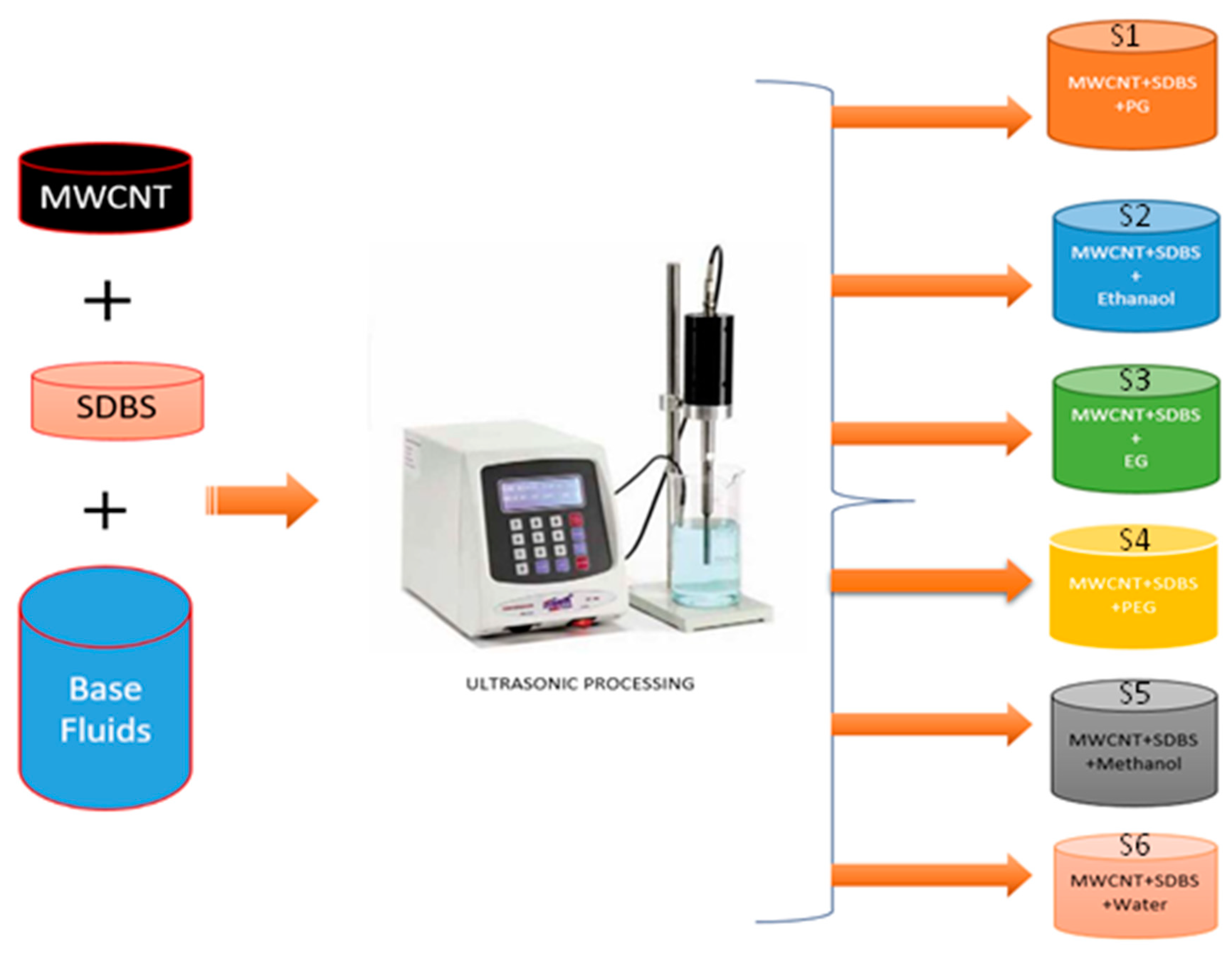

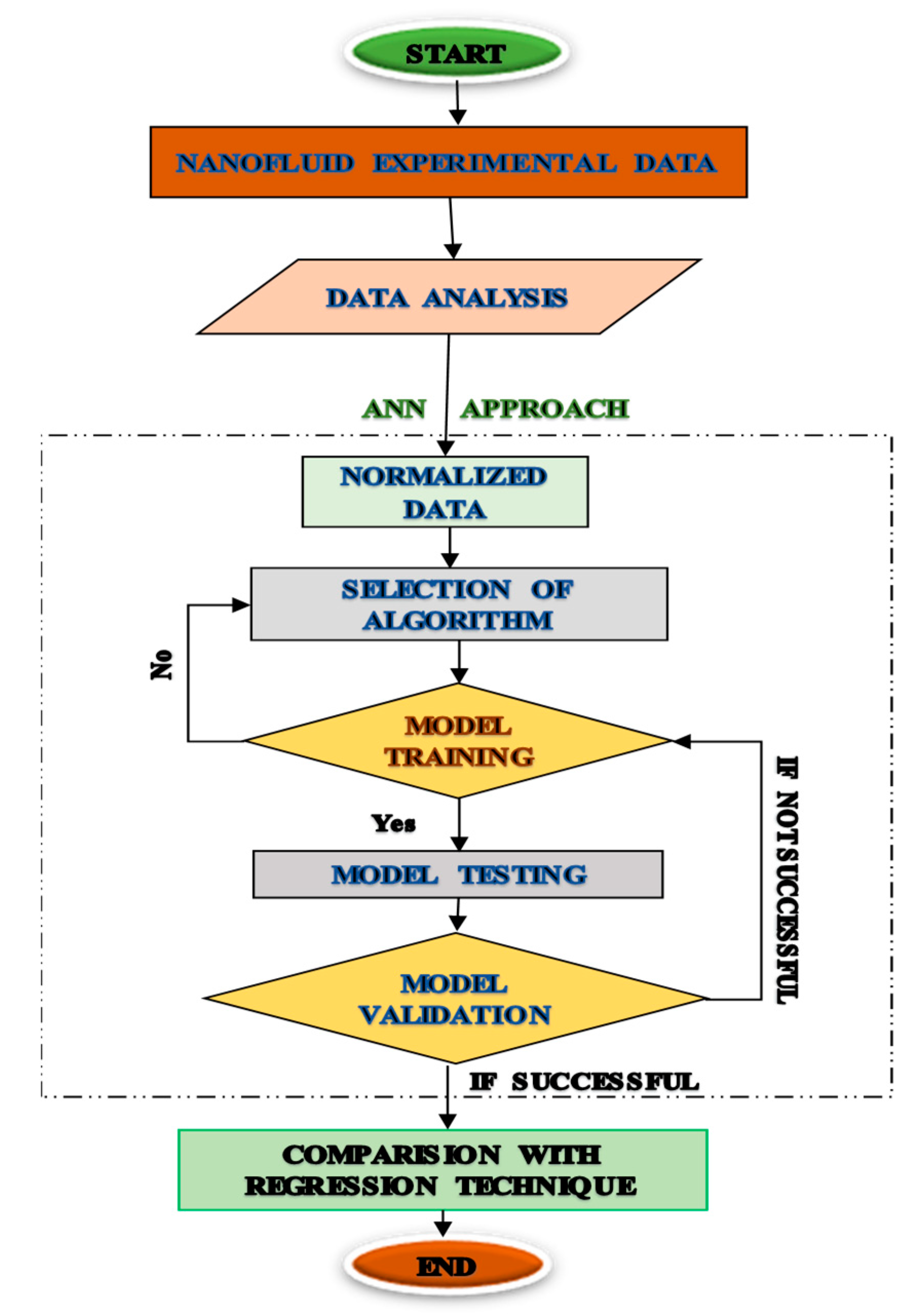

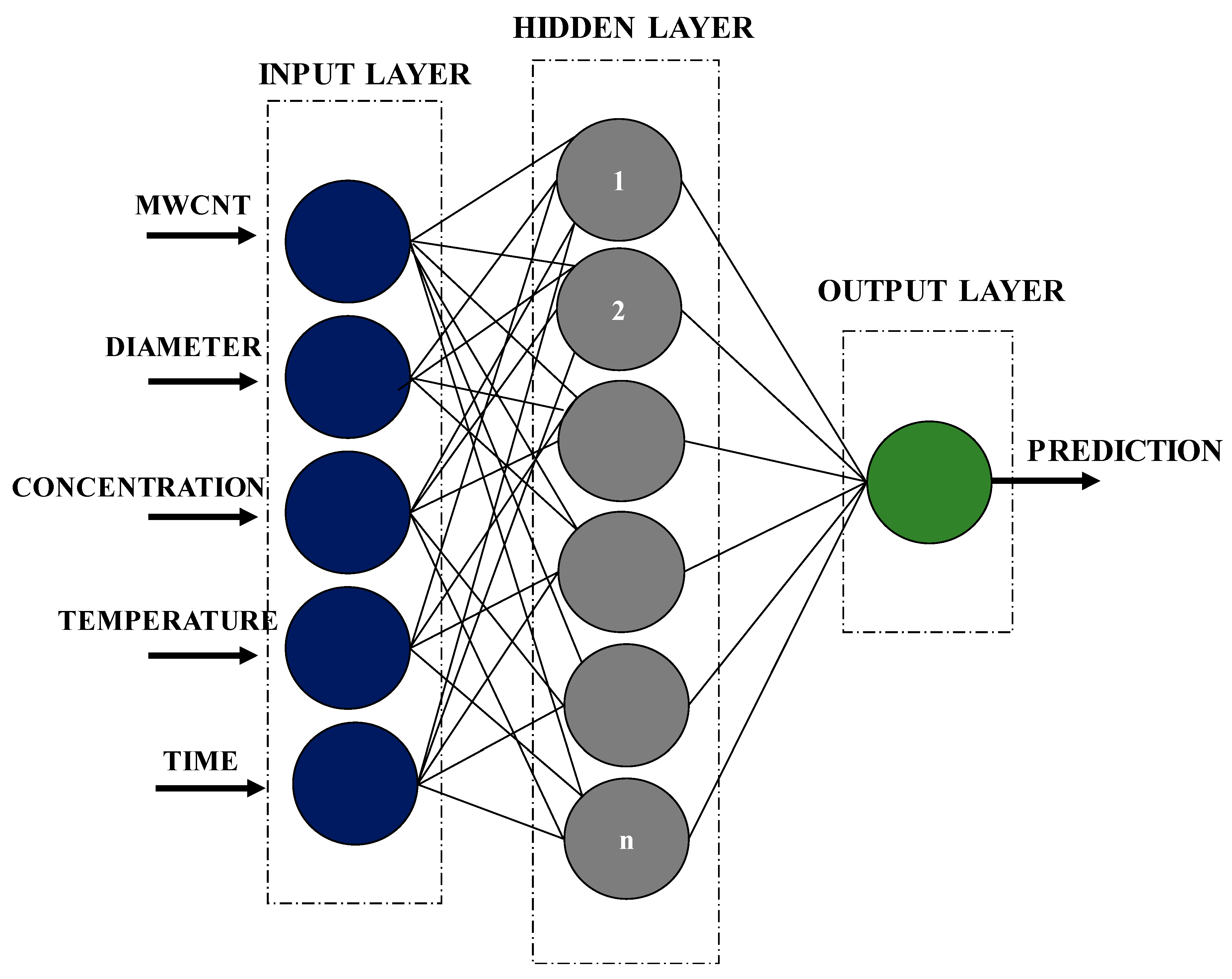

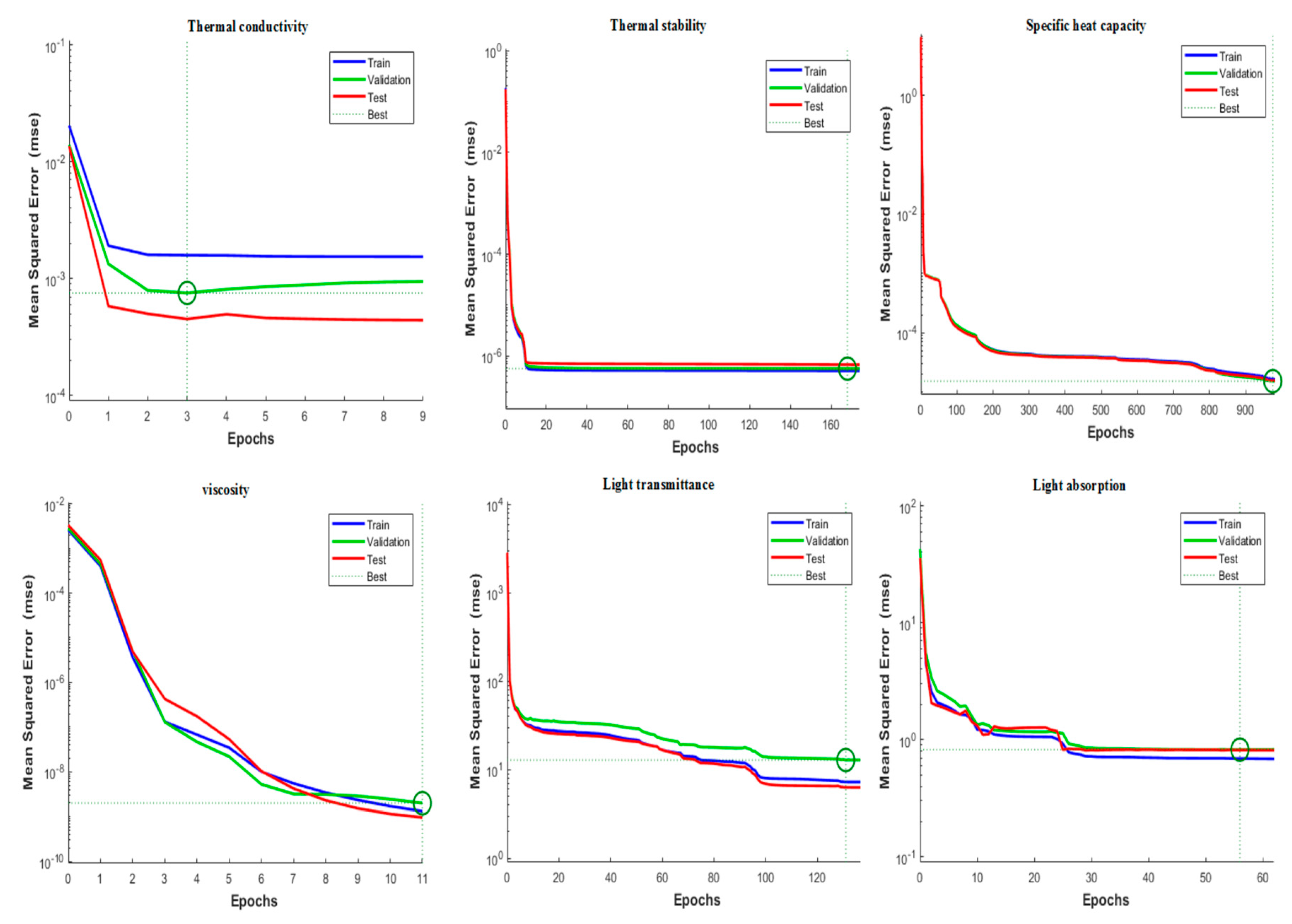

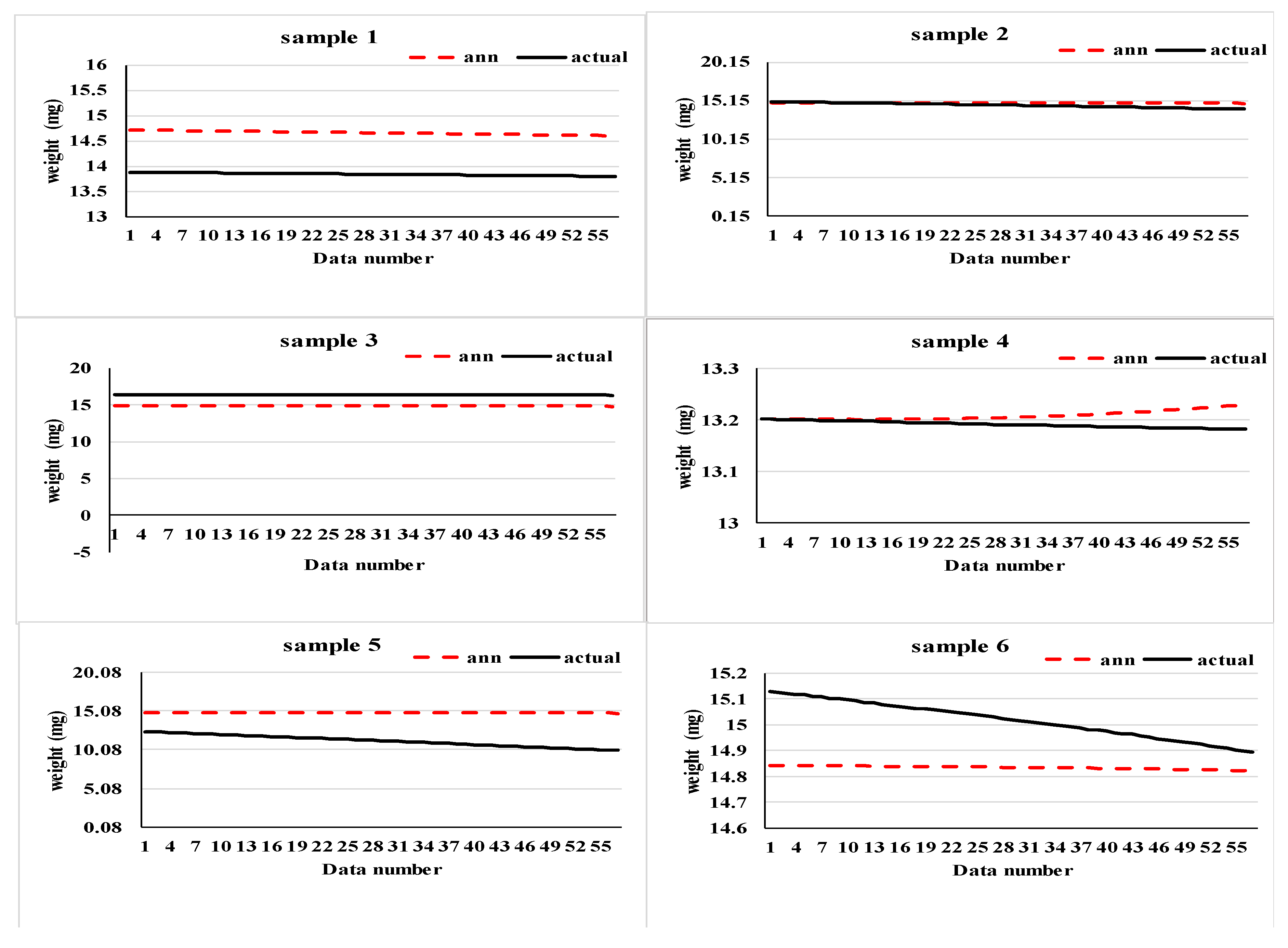

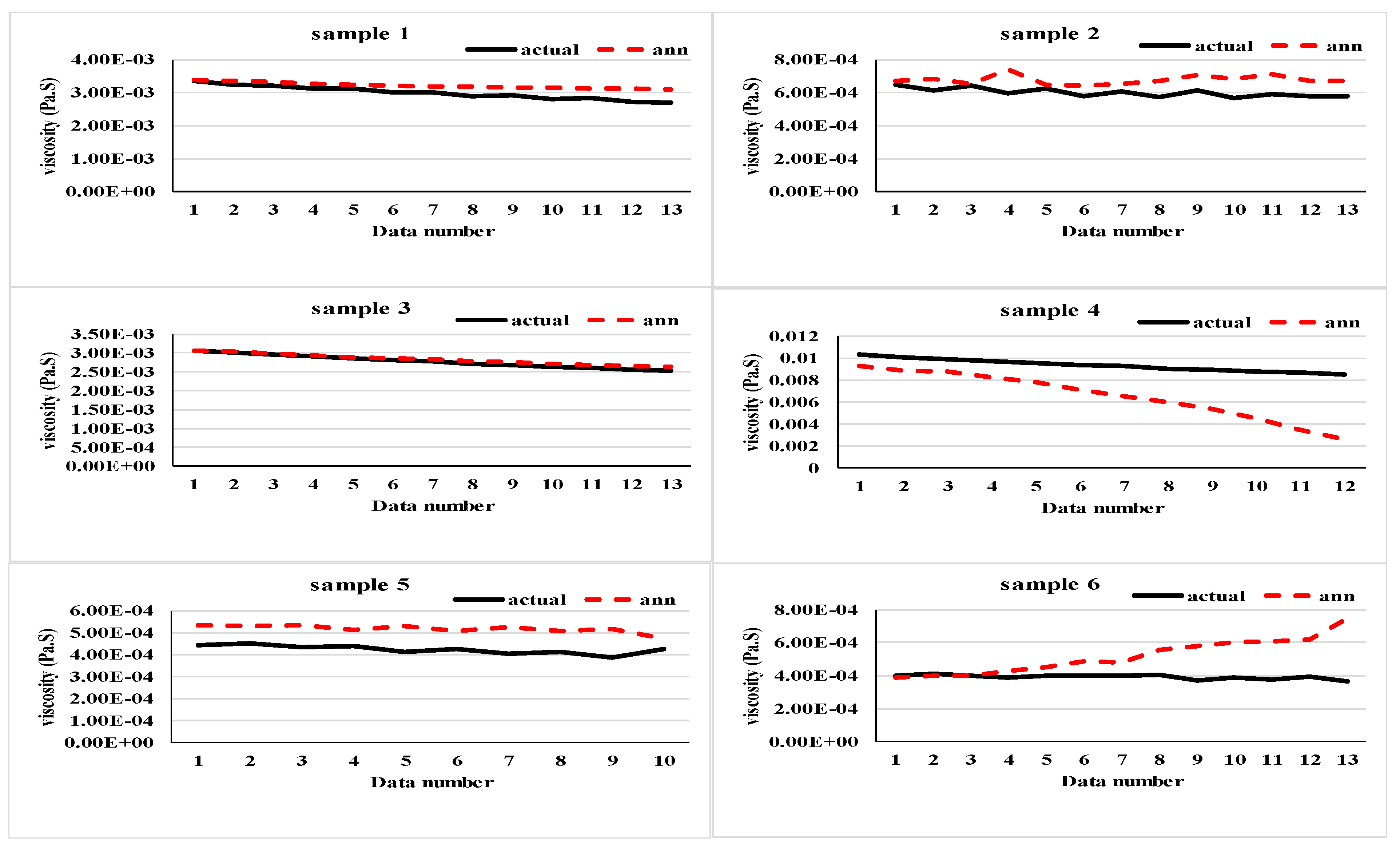

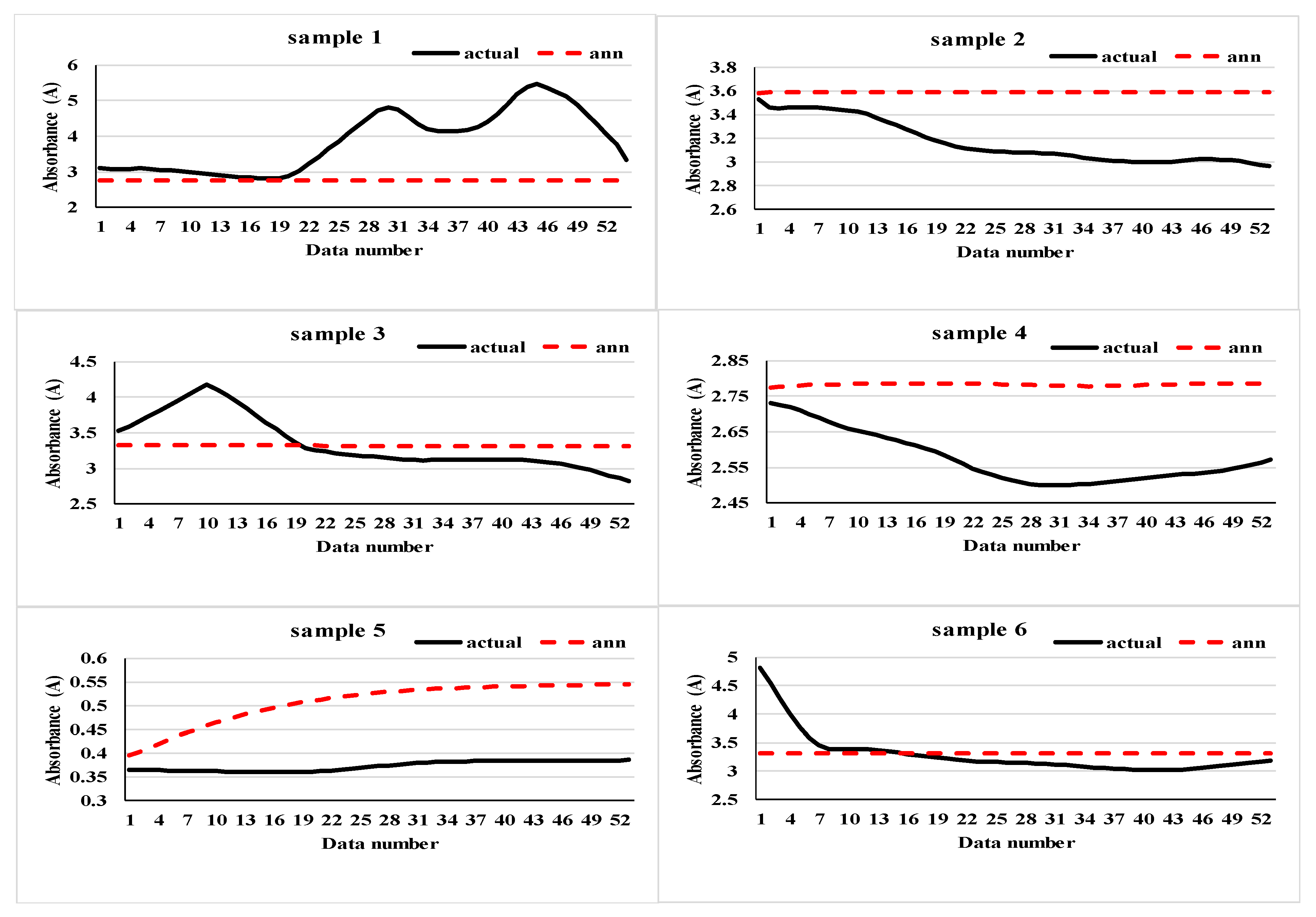

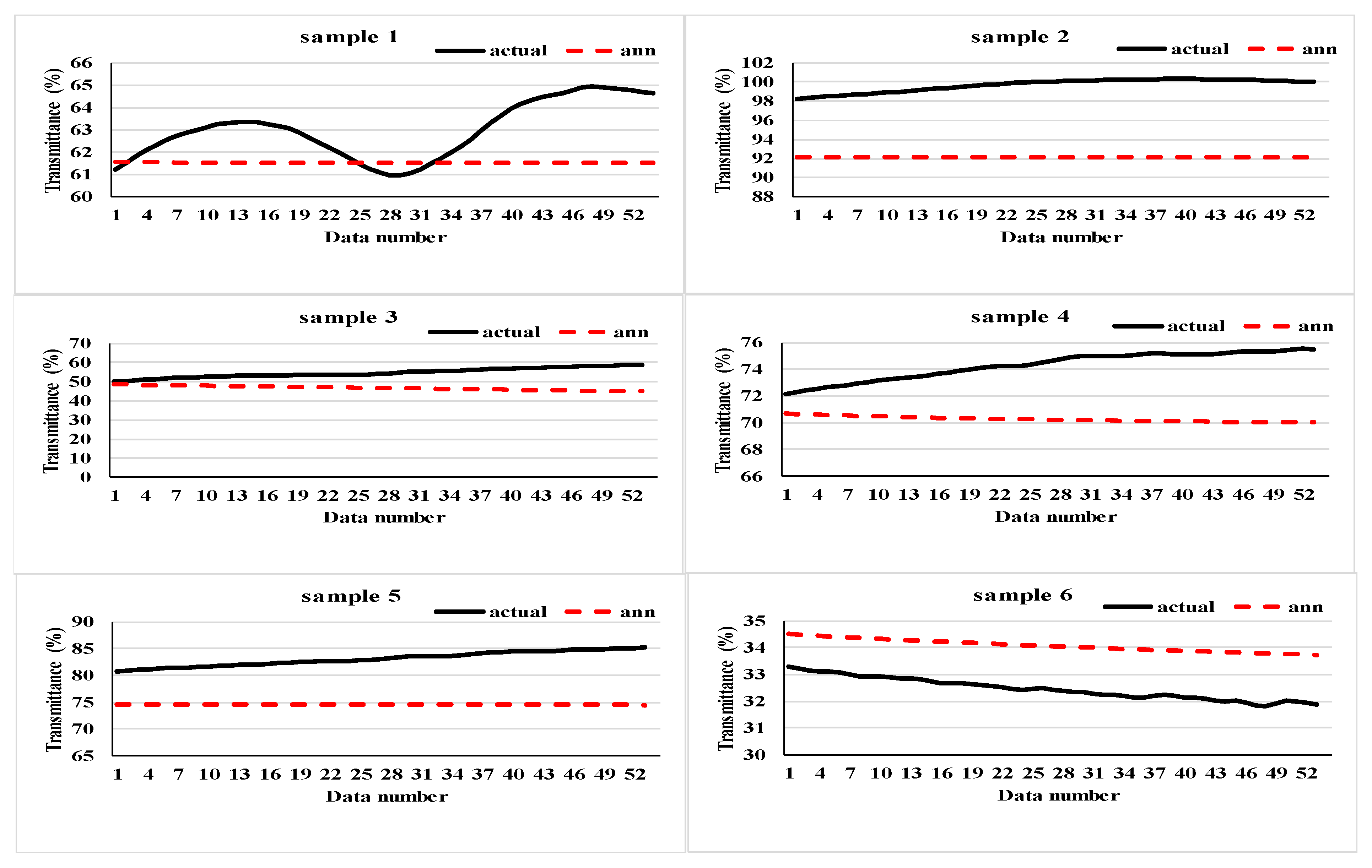

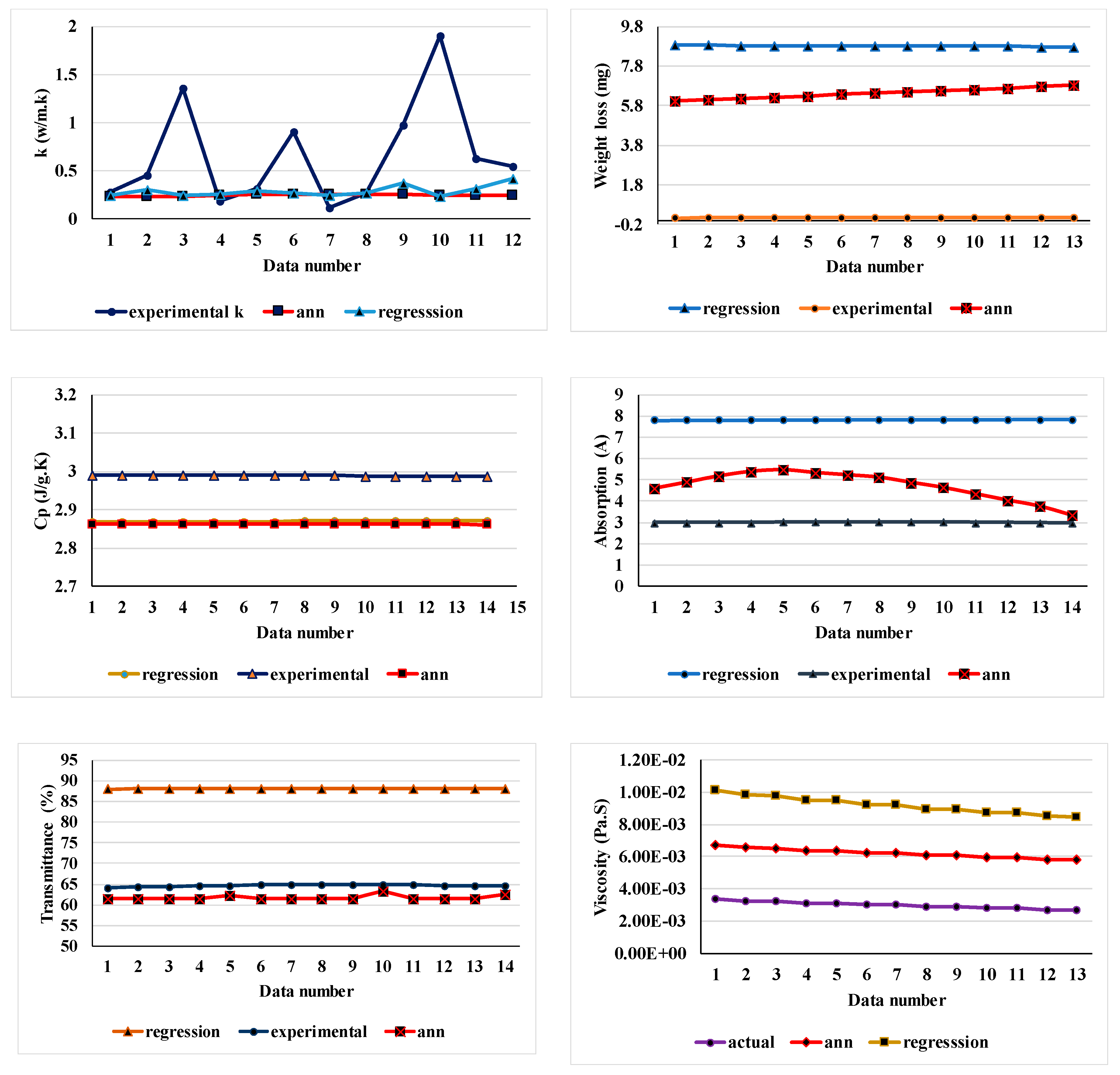

As discussed above, several researchers have investigated the thermophysical properties of nanofluids in different systems. In addition, many researchers focused on the application of ANNs to nanofluid-based thermal systems due to their complex problem-solving capacity with less cost and time. In the present work, experimental data are obtained from the available literature [

21] where the thermophysical properties of six different nanofluids containing Multiwalled Carbon Nanotubes (MWCNT) nanoparticles dispersed in propylene glycol, ethanol, ethylene, polyethylene glycol, methanol and water with SDBS surfactant at 0.5 wt % nanoparticle concentration was studied. No general model is currently available to reliably estimate a broad variety of effective parameters for MWCNT nanofluids. While various researches were performed to predict the thermophysical properties of nanofluid using ANN, those were only for thermal conductivity and viscosity. Along with thermal conductivity and stability, properties such as specific heat capacity, thermal stability, light absorption and transmission were also investigated using ANN in this research. The purpose of this study is to evaluate the thermophysical properties of MWCNT nanofluids with ANN. The results acquired from the experimental data are verified with ANN and compared with regression analysis.