Assessment and Prediction of Complex Industrial Steam Network Operation by Combined Thermo-Hydrodynamic Modeling

Abstract

1. Introduction

- Seasonal ambient air temperature variations impact on system operation is rarely considered which might prevent the performed study to reveal the season-related system bottlenecks [21].

- Though system operation change/improvement projects (re-insulation, new pipelines commissioning, impact of new production units on system operation) are commonly considered and tested, the testing procedure frequently does not consider all possible network operational states, or, at least, all those states that were recorded in the past [14,19]. This in turn limits the testing ability to identify system bottlenecks possibly resulting from improvement project implementation.

- Creation of a mathematical model that would be able to detect and to predict troublesome spots formation within the steam networks with increased possibility of cold spots or bottlenecks occurrence.

- Its testing on a real complex steam system of a refinery; its use to reveal particular operation problems and limits in the existing system.

- The use of the developed model to predict the impact of planned investments in the refinery on the operation stability of the steam system, considering seasonal system operation changes.

- Proposal and simulation of the system changes for its operation improvement.

2. Problem Description

- The “safe” layout of the refinery—all operational units in the refinery are located relatively far apart. Thus, there is a need to transport steam over long distances, leading to increased heat losses to the surroundings.

- Several steam-drives at the SLOVNAFT refinery have been switched to electro-drives, except important devices, that are still being driven by steam turbines as a safety measure. Switching between electro- and steam-drives is important not just from the economical point of view but allows the steam balance to be influenced. With too many devices switched to electro-drives (which is economically effective), steam supply from a CHP unit would drop significantly and result in steam condensation in pipelines. Therefore, the economics is not the only decision-making factor. Operational safety is important as well.

- Seasonal impact on operational state of steam networks. Summer months in particular are problematic due to excessive steam supply from secondary energy sources (SEC, all steam supplying units except CHP). The aforementioned switching between electro- and steam-drives reduces the possibilities of its utilization by production units. Steam excess is disposed of, by its condensation in air condensers, or, in worst situations, by its exhaust to the atmosphere.

- Keeping balance between steam production and its consumption.

- Maximal utilization of steam produced in CHP unit and secondary heat sources.

- Maximization of waste heat utilization in the form of low-pressure steam (LPS) produced at production units.

- Preserving steam quality parameters in desired intervals.

- Elimination of cold spots in steam networks.

- Utilization of electro-drives.

- Minimization of steam let-downs in CHP unit and other production units.

- Creation of mathematical models of steam networks and their application in the refinery on all pressure levels based on available operation data, visual controls and plant layouts.

- Mass and heat balances setup in order to determine current operational state of steam networks in the refinery.

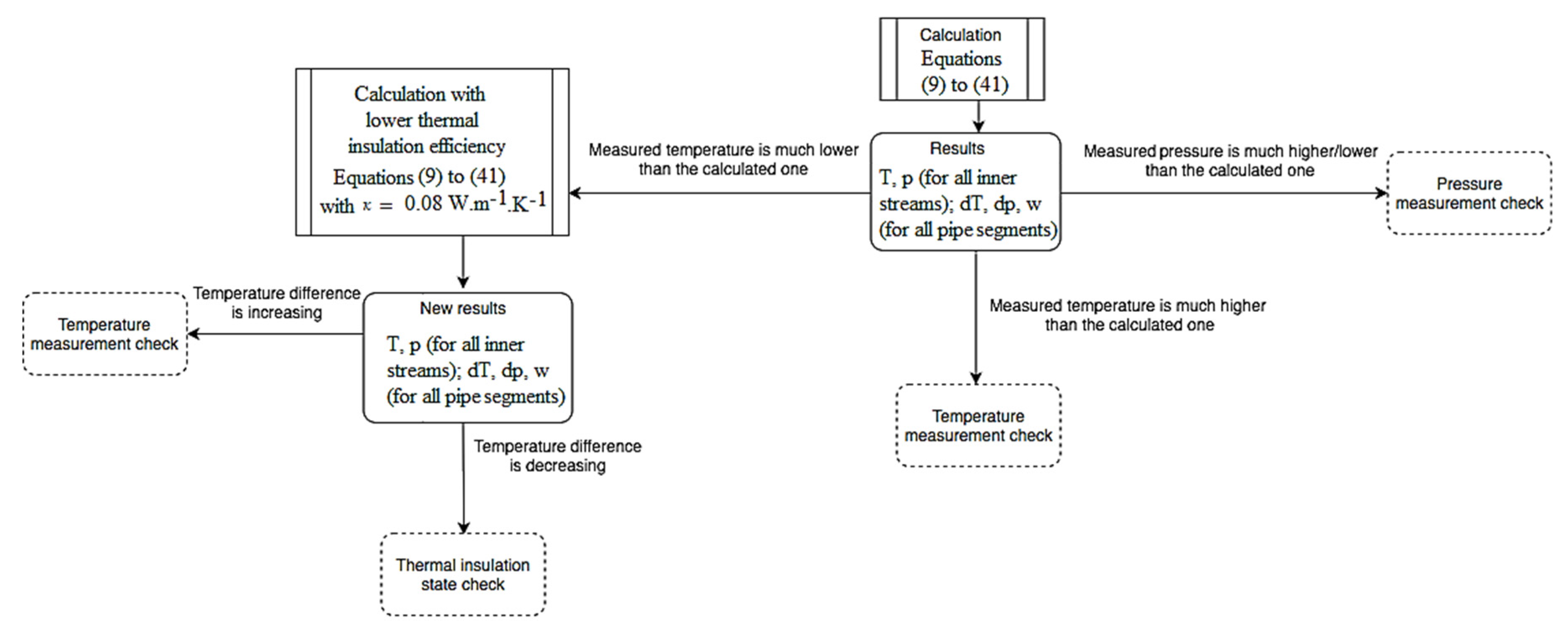

- Confronting the simulation results with measured values of operational data to identify incorrect local measurement tools (steam pressure, temperature and mass flow).

- Assessment of troublesome spots formation risk in terms of low or very high steam flow velocity within individual sections of steam networks.

- Reviewing the impact of proposed projects within steam networks on its stability by a mathematical model expressed as steam temperature differences at individual steam-delivery points.

- Suitable measures proposal aimed at an improvement in the operational state of steam networks and the associated operating costs reduction.

3. Model Formulation

3.1. Operational Data Analysis

3.2. Balance Model

- Steam flows at individual production units (import, export or both, since some production units may act like steam importer and exporter at the same steam pressure level).

- Steam temperature and pressure at individual production units.

- Steam pipeline characteristics (lengths and diameters of individual pipe sections).

- Steam mass balance difference (i.e., the difference between steam mass supplied and consumed within the steam network).

- Steam heat balance difference (i.e., the difference between the heat supplied and consumed within the steam network in the form of steam).

- Steam flow velocities in individual pipe segments calculated according to steam mass flows in these pipe segments.

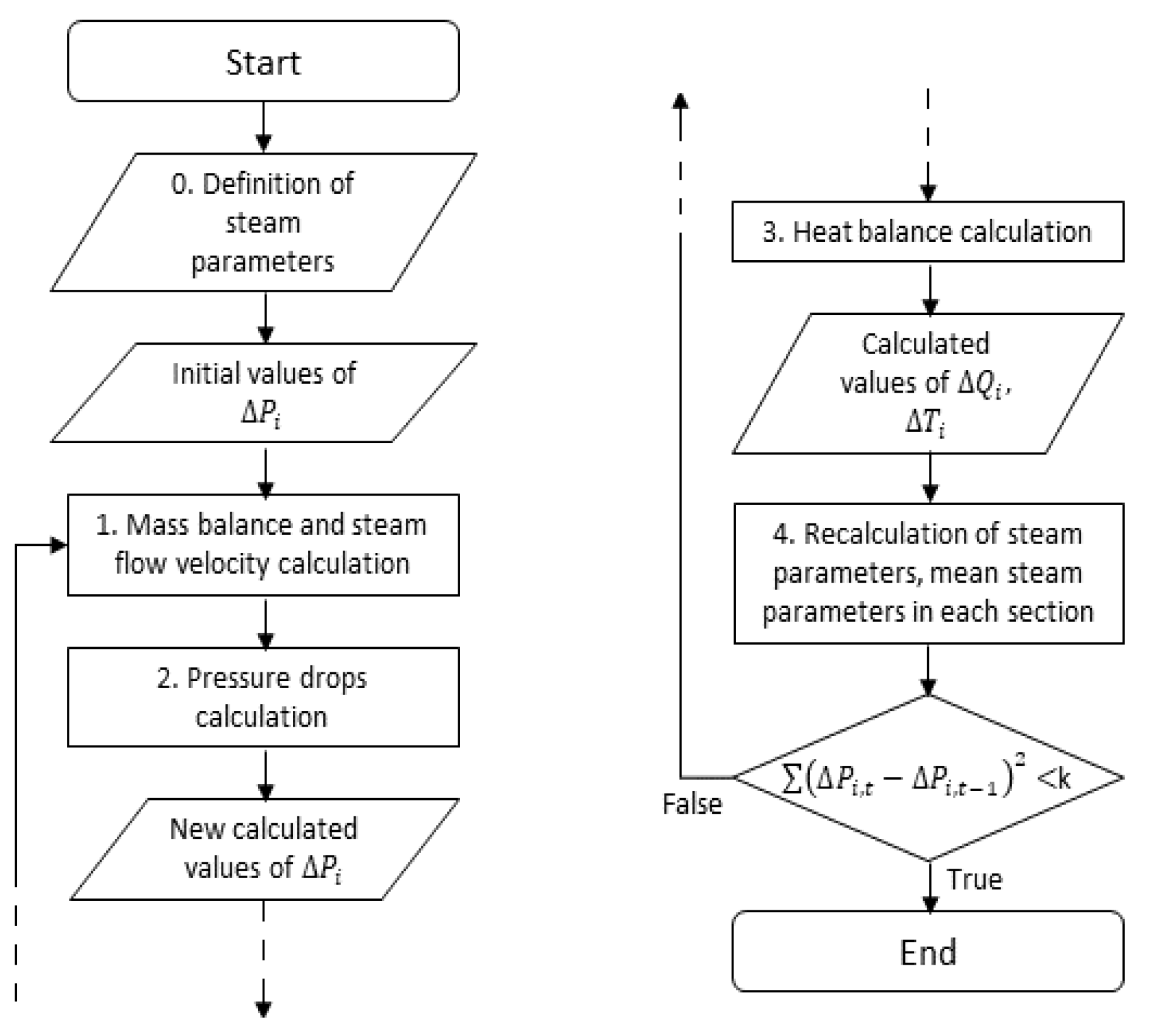

3.3. Combined Thermo-Hydrodynamic Model

- Simulation of single—or multiphase flow pressure drop with possible selection of calculation method.

- Heat-transfer calculation including outside weather conditions or physical properties of pipes.

- Calculation of profiles of different physical properties in pipe sections.

3.3.1. Pressure Drop Calculation

- Length;

- Inner diameter and outer diameter or tube wall thickness;

- Construction material (and its roughness);

- Elevation (increase or decrease of geodetic height).

3.3.2. Heat-Transfer Intensity Calculation

- Zero heat transfer;

- Simple heat transfer—this sub-model assumes, that the heat transfer is directly proportional to the temperature difference between the fluid and the environment, ΔT. The resulting heat loss, is expressed by Equation (35), with U referring to the overall heat-transfer coefficient:

- Detailed heat transfer—a complex heat-transfer sub-model that allows specifying more detailed set of heat-transfer parameters to model the heat transfer between the fluid, the vessel and the environment due to conduction and convection.

- Heat transfer through natural (or forced) convection between the vessel fluid and the pipe wall;

- Heat transfer through conduction through the wall and insulation layers;

- Heat transfer through natural or forced convection from the insulation surface to the environment.

- Pipe wall thickness;

- Specific heat capacity;

- Mass density of construction material;

- Thermal conductivity

- From the vessel outer wall to ambient air;

- From vessel contents to inner wall;

- From vapor to liquid phase inside the vessel

3.3.3. Model Validation (Analysis of Actual Operation)

- Temperatures of all inner and outlet streams;

- Pressures of all inner and outlet streams;

- Temperature drops in each pipe segment;

- Pressure drops in each pipe segment;

- Steam flow velocities in each pipe segment.

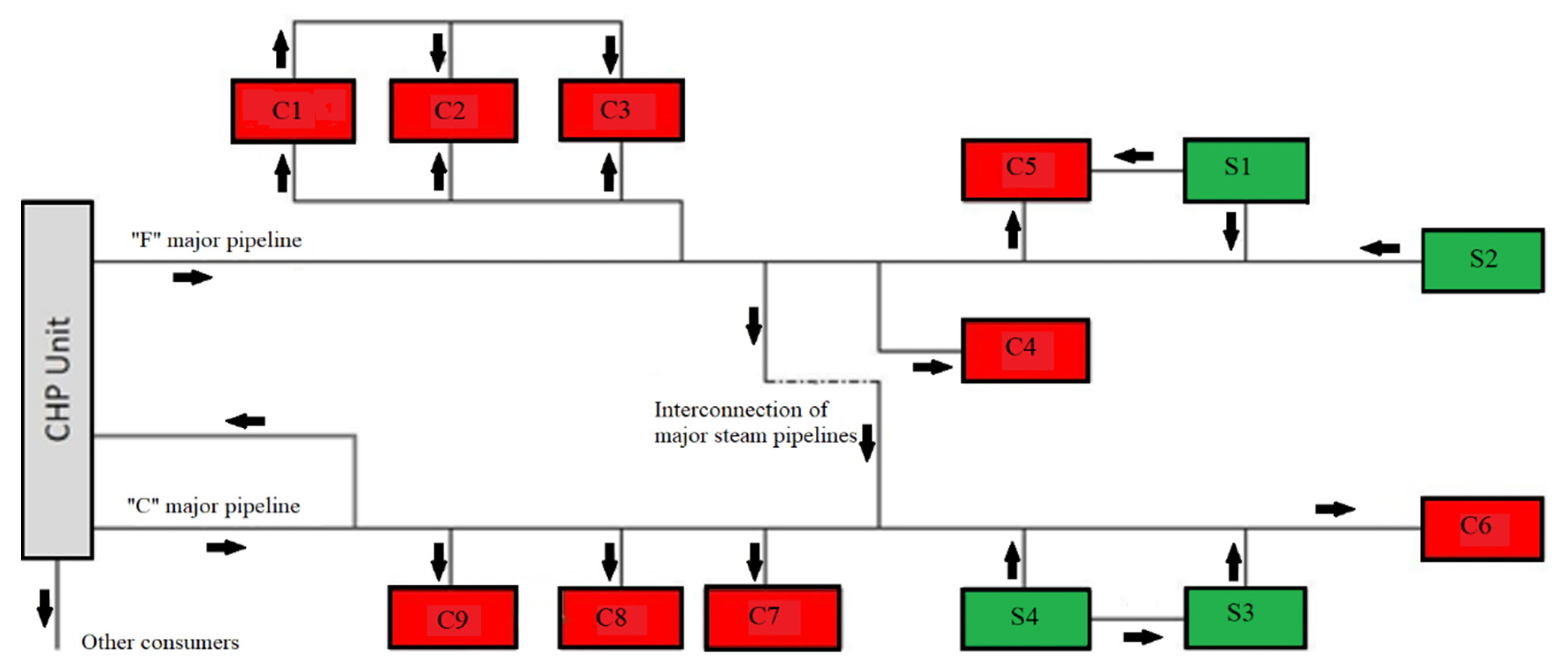

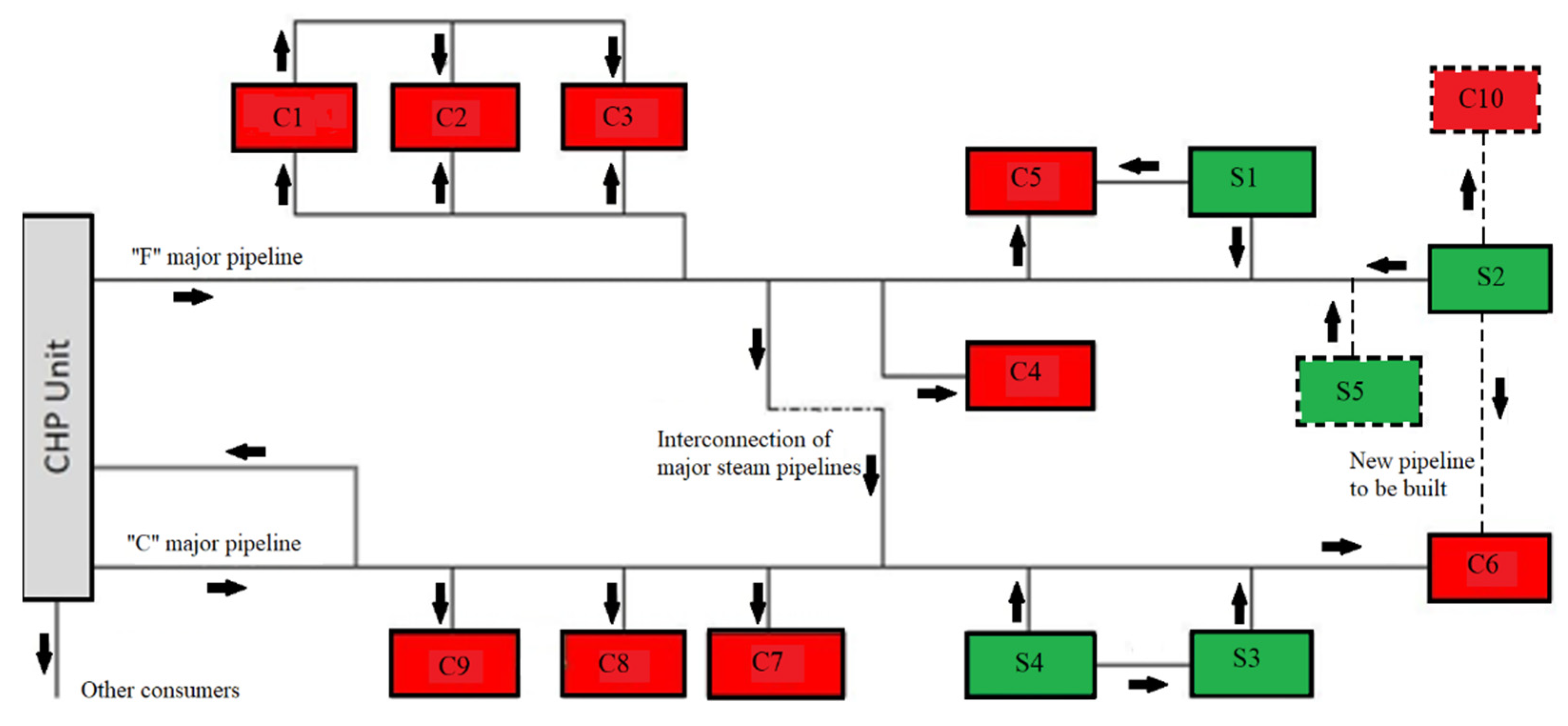

3.3.4. The Impact of Proposed Changes on Steam Network Operation

- Direct connection of units C6 and S2 by a new steam pipeline;

- Commissioning of new production unit C10;

- Commissioning new hydrogen production plant S5 thus replacing the old unit S1.

4. Results and Discussion

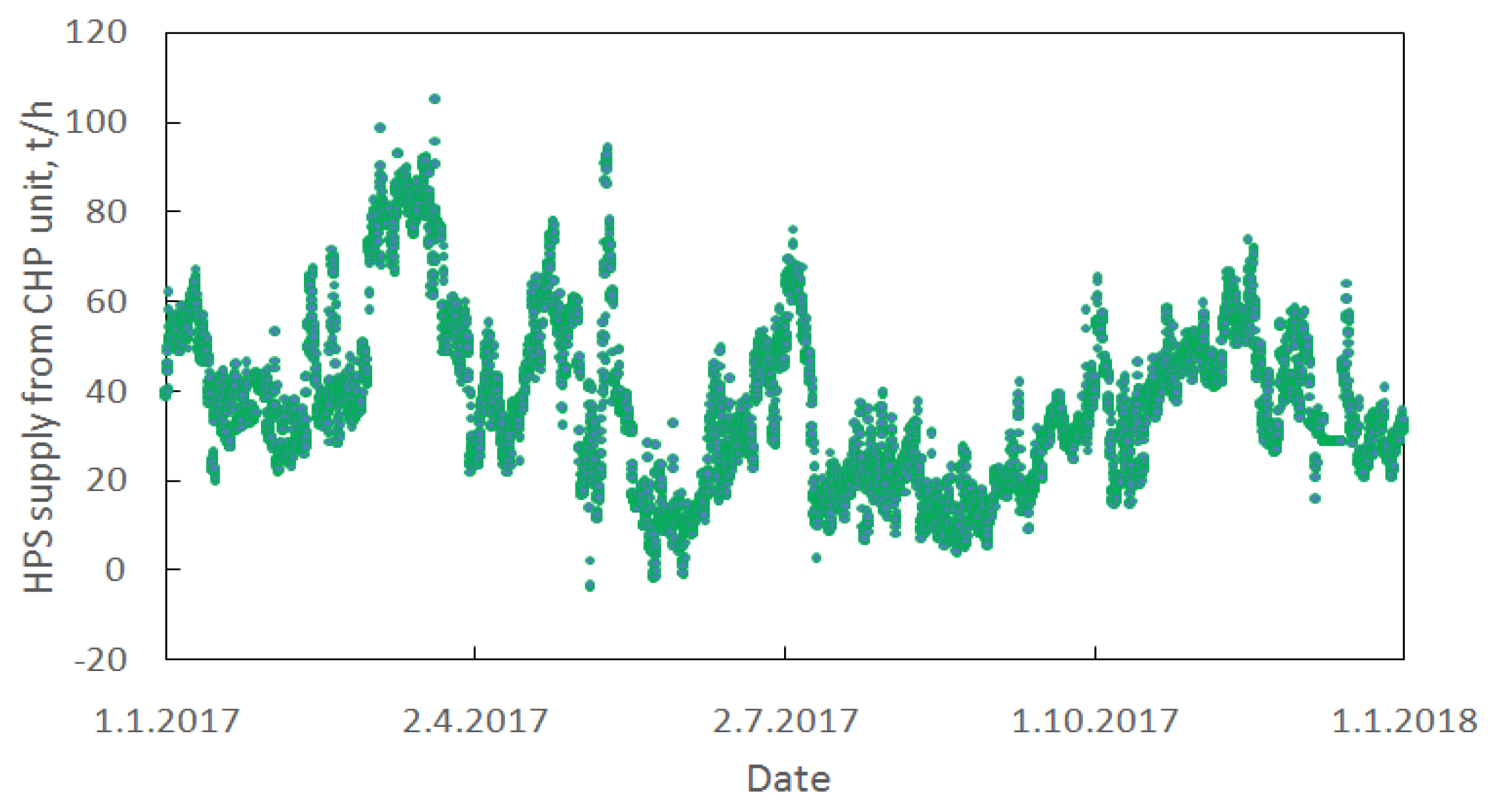

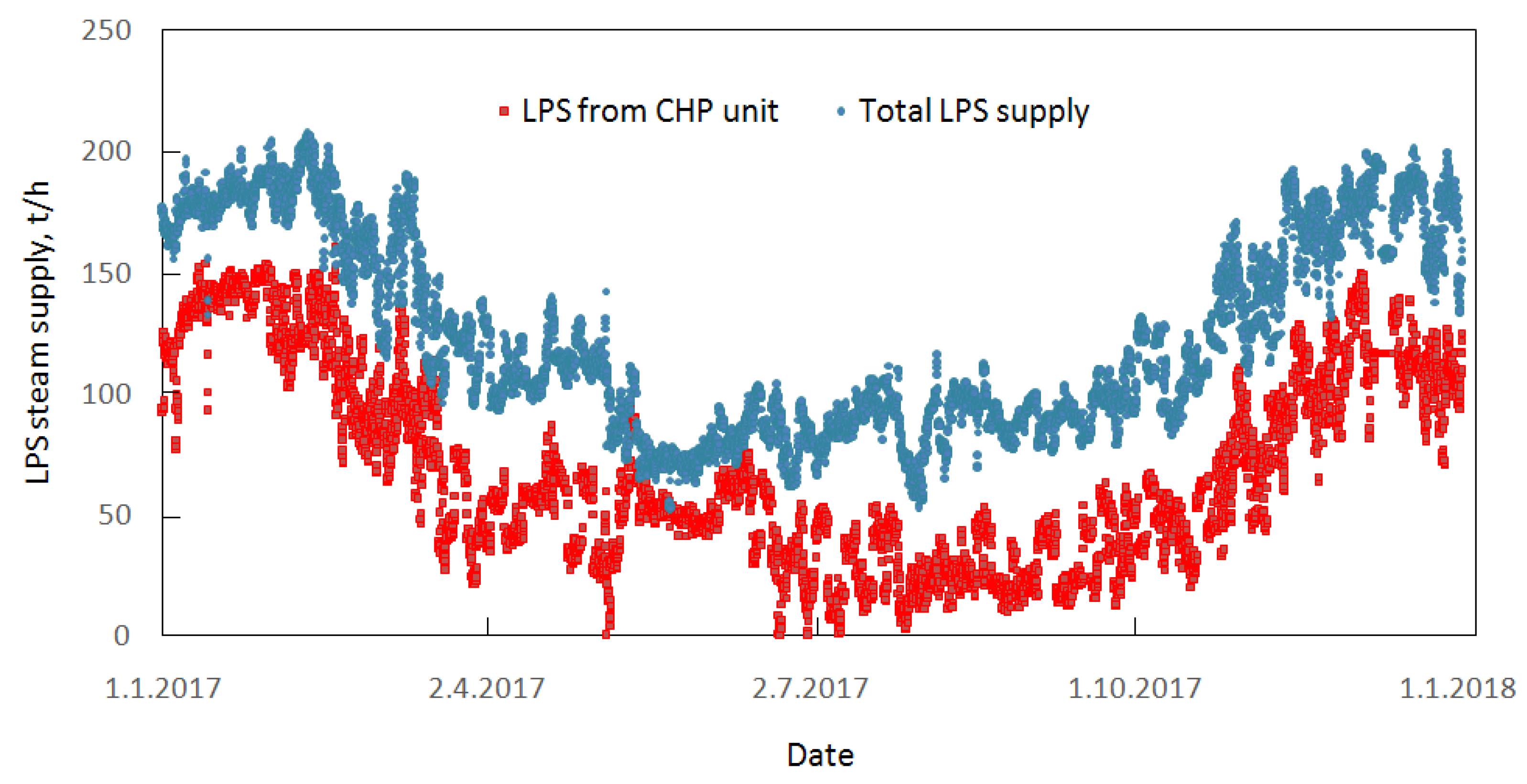

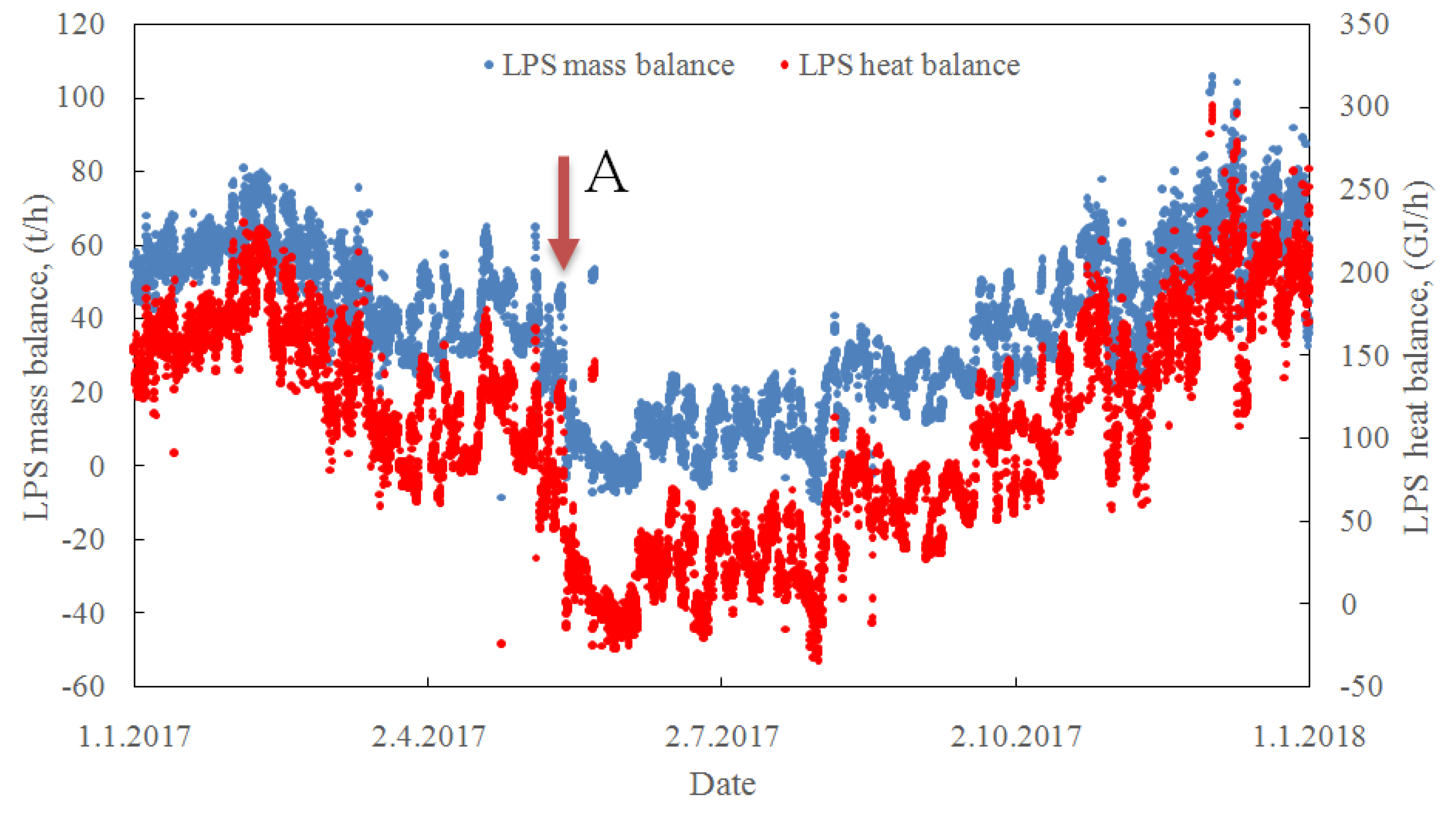

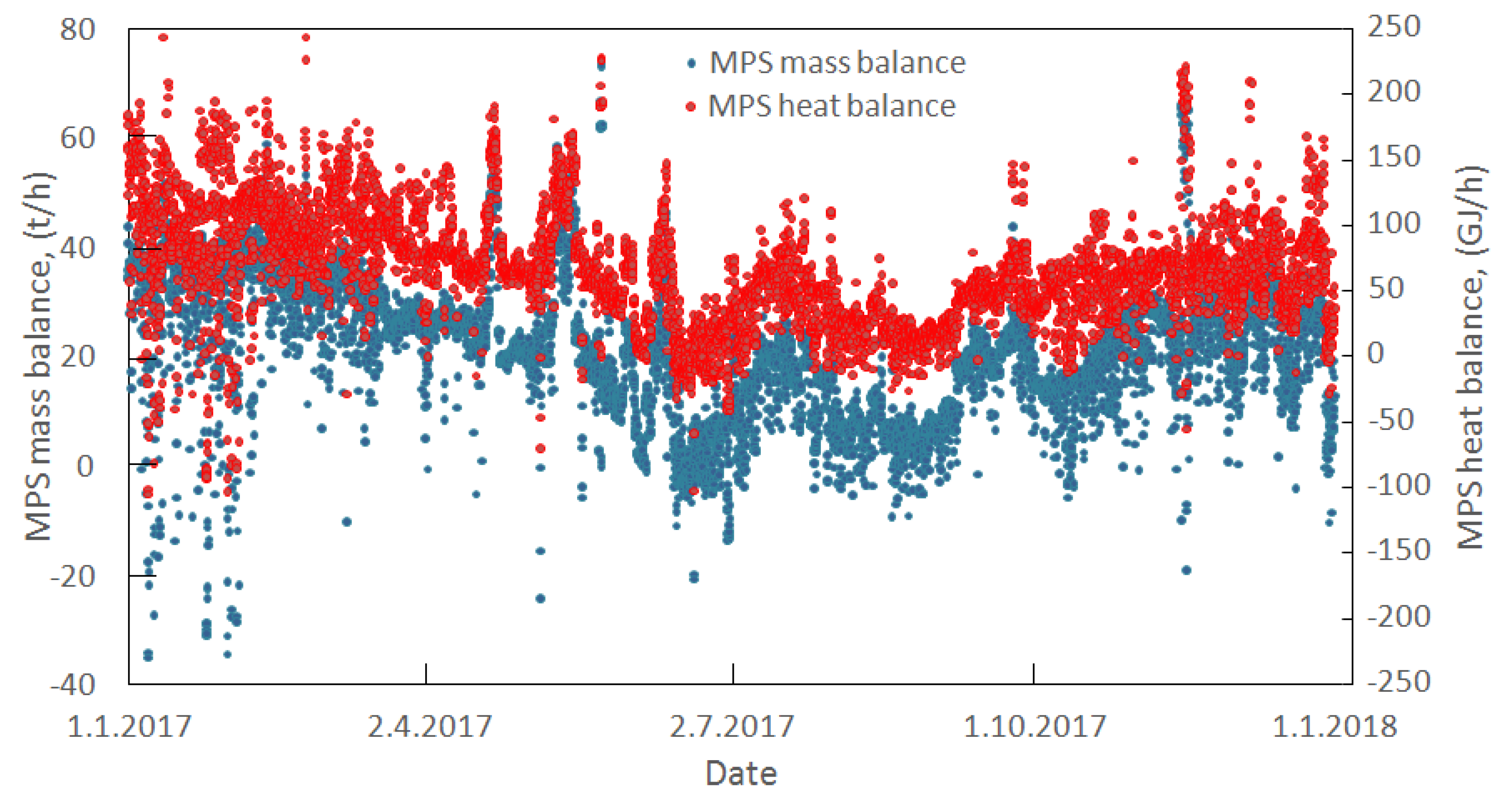

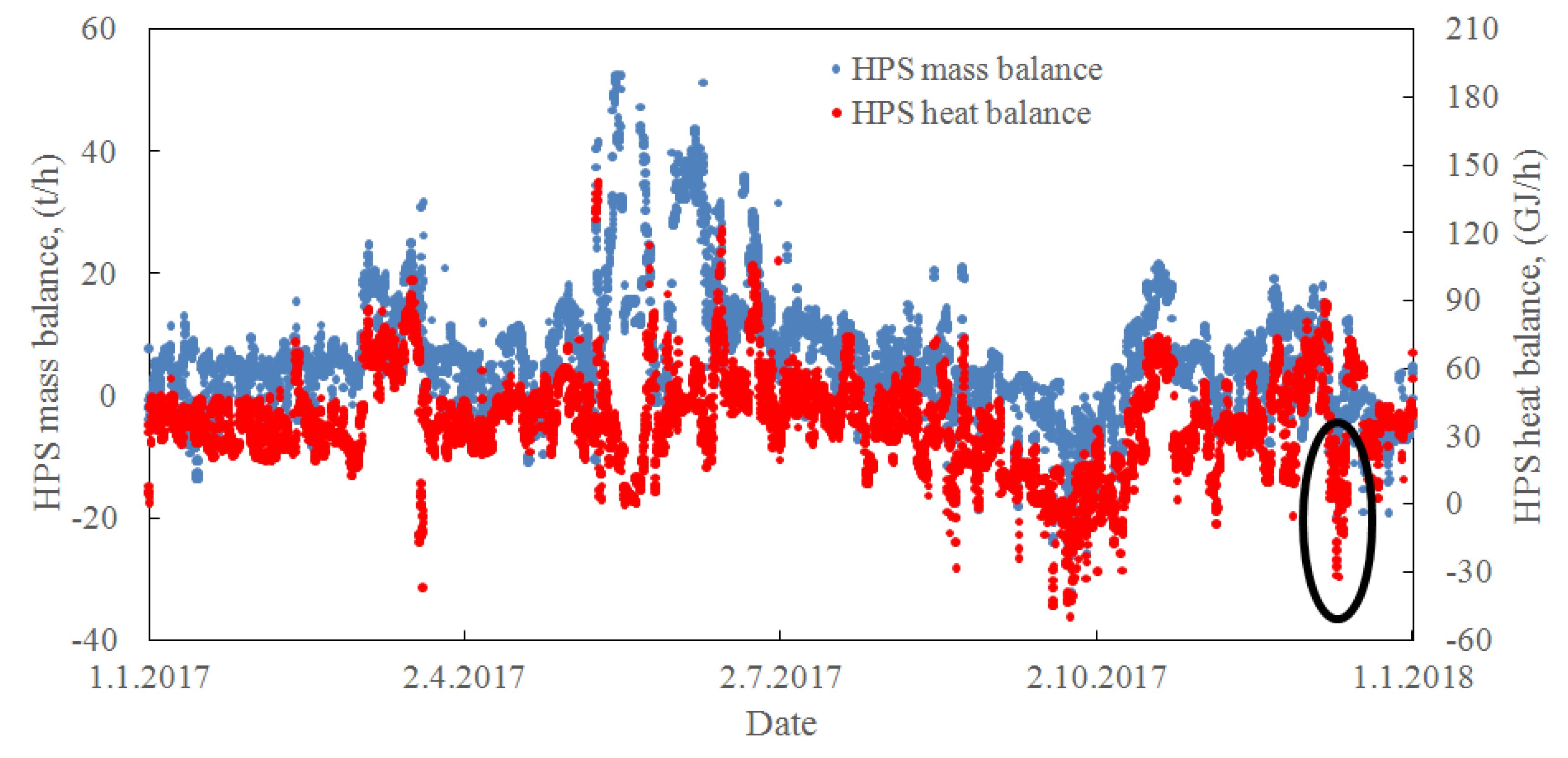

4.1. Data Analysis

4.2. Balance Model

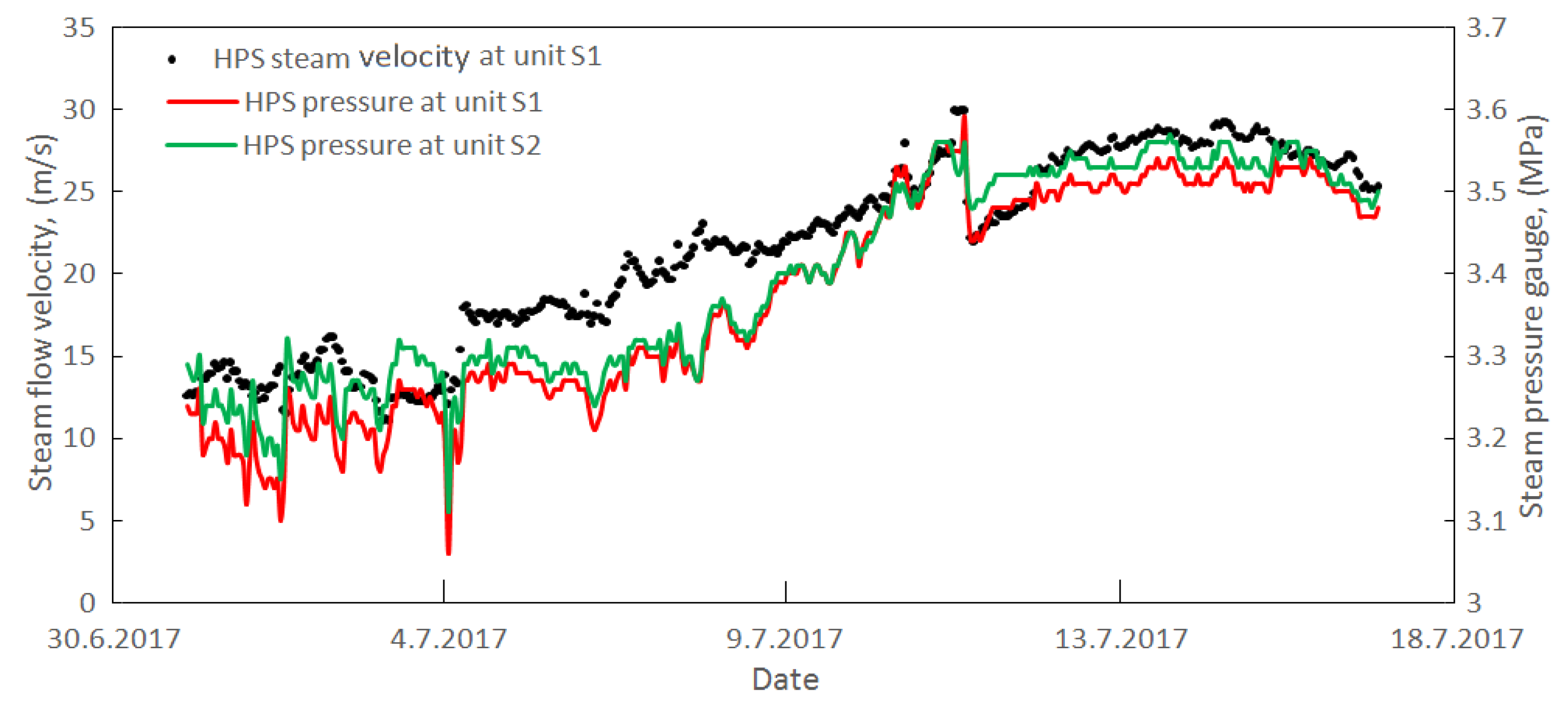

- Section from the C-F main pipeline interconnection to units C5, S1 and S2—this section is problematic due to high amounts of HPS transported as well as due to low steam temperature from S2 unit close to its dew point, which can lead to steam flow velocities over 30 m/s and its condensation.

- The CHP unit export into HPS pipelines E and F. At normal operation, their capacity is sufficient, but can become a bottleneck especially during the winter.

- The CHP unit export into MPS pipeline D—the same reason as indicated in point 2. Moreover, this pipeline supplies the MPS steam to an external consumer and must be able to transport significant amounts of steam in the heating period.

4.3. Thermo-Hydrodynamic Model

- A large balance difference distributed to all outlet streams could have caused significant relative errors of the thermo-hydrodynamic model.

- The complexity of the LPS network and many interconnections between each pipeline may also have caused large errors.

- Finally, the nominal values of temperature as well as pressure are lowest in the LPS network which means that the same absolute difference yields in higher relative error in LPS network than in the other ones.

4.4. The Impact of Proposed Changes on Steam Network Operation

- Only the connection of units C6 and S2 itself will not improve the steam temperature at C6 unit. Continuous operation of this pipeline will not be effective, otherwise a significant temperature drop will be observed leading to unacceptable operation conditions.

- Also commissioning the new unit C10 will not improve the steam quality at C6 unit (case A+B). Although it will lower the load of unit S2, the supplied steam from S2 will flow in the direction of unit C6 anyway.

- The operation of new unit S5 would improve the steam temperature at unit C6 only slightly (case A+C). The reason is the high steam pressure of steam supplied from unit S2 that will make the steam from unit S5 to flow in the opposite direction (from unit S5 to S1 and C5).

4.5. Improvement of Steam Network Operation

- Regular inspection of steam traps’ operation;

- Regular visual inspection of steam pipelines and isolation;

- Improve the steam condensate recovery system and prevent from its disposal into the ground;

- Regular inspection and calibration of measurement tools.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviations | ||

| ANN | Artificial neural networks | |

| CFD | Computational fluid dynamics | |

| DAE | Differential-algebraic equations | |

| HPS | High-pressure steam | |

| CHP | Combined heat and power unit | |

| LPS | Low-pressure steam | |

| MILP | Mixed-integer linear programming | |

| MINLP | Mixed-integer non-linear programming | |

| MPS | Middle-pressure steam | |

| NLP | Non-linear programming | |

| ODE | Ordinary differential equations | |

| PDE | Partial differential equations | |

| SES | Secondary energy sources | |

| Symbols | ||

| a, b, c | Parameters in Equation (23) | |

| A, B | Parameters in Equation (27) | |

| Atot | Total heat-transfer area | m2 |

| d/, e, f, j | Parameters in Equation (26) | |

| Cp | Specific isobaric heat capacity | J/kg/K |

| C | Parameter in Equation (25) | |

| D | Diameter | |

| ftp | Friction factor estimated by Equation (31) | |

| fn | Friction factor for smooth pipes | |

| g | Gravitational acceleration | 9.81 m/s2 |

| Grf | Grashof number | |

| h | Specific enthalpy | kJ/kg |

| HL(0) | Liquid holdup in a horizontal pipeline | |

| HL(φ) | Liquid holdup in an inclined pipeline | |

| L | Length | |

| L1 to L4 | Dimensionless parameters in Equations (10)–(13) | |

| Mass flow | kg/s | |

| Balanced mass flow of i-th stream | kg/s | |

| n | Pipe wall relative roughness | |

| N | Count of data sets | |

| NFr | Froude number | |

| P | Pressure (absolute) | Pa |

| Prf | Prandtl number | |

| Heat losses | W | |

| Re | Reynolds number | |

| S | (pipeline) cross-section | m2 |

| U | Overall heat-transfer coefficient | W/m2/K |

| v | Specific volume | m3/kg |

| V | Parameter in Equation (31) | |

| w | Flow velocity | m/s |

| X | Characteristic vessel dimension | |

| y | Parameter in Equation (32) | |

| z | Geodetic height | m |

| Greek | ||

| α | Heat-transfer coefficient | W/m2/K |

| β | Thermal expansion coefficient | K−1 |

| γ | Dimensionless parameter in Equation (2) | |

| Average relative difference | ||

| Δ | Difference | |

| ε | Specific energy | J/kg |

| φ | Pipe inclination angle | |

| ξ | Coefficient of local energy dissipation | |

| κ | Thermal conductivity | |

| λ | Fluid flow friction factor | |

| ν | Kinematic viscosity | Pa.s |

| Ψ | Liquid holdup correction factor | |

| ρ | Density | kg/m3 |

| Subscripts | ||

| a | a = T, P | |

| AVG | average | |

| c | calculated | |

| dis | dissipated | |

| f | friction | |

| intermittent | intermittent (flow regime) | |

| in | inlet (stream) | |

| inn | inner (diameter, wall) | |

| L | liquid | |

| LM | logarithmic mean | |

| loc | local (dissipation) | |

| m | mixture (two phase) | |

| max | maximal | |

| meas | measured | |

| min | minimal | |

| o | outer (diameter, wall) | |

| out | outlet (stream) | |

| pump | (related to) pump | |

| segregated | segregated (flow regime) | |

| t | theoretical (enthalpy value) | |

| T | temperature | |

| transition | transition (flow regime) | |

References

- U.S. Department of Energy (DoE), Advanced Manufacturing Office (AMO). Improving Steam System Performance: A Sourcebook for Industry, 2nd ed.; 2012; 64p. Available online: https://www.energy.gov/sites/prod/files/2014/05/f15/steamsourcebook.pdf (accessed on 14 November 2018).

- Bütün, H.; Kantor, I.; Maréchal, F. Incorporating Location Aspects in Process Integration Methodology. Energies 2019, 12, 3338. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, R.; Wang, Y.; Feng, X. An area-wide layout design method considering piecewise steam piping and energy loss. Chem. Eng. Res. Des. 2018, 138, 405–417. [Google Scholar] [CrossRef]

- Nishio, M.; Itoh, J.; Shiroko, K.; Umeda, T. A thermodynamic approach to steam-power system design. Ind. Eng. Chem. Process. Des. Dev. 1980, 19, 306–312. [Google Scholar] [CrossRef]

- Papoulias, S.A.; Grossmann, I.E. A Structural Optimization Approach in Process Synthesis. Part II: Heat Recovery Networks. Comput. Chem. Eng. 1983, 7, 707–721. [Google Scholar] [CrossRef]

- Bruno, J.C.; Fernandez, F.; Castells, F.; Grossmann, I.E. A rigorous MINLP model for the optimal synthesis and operation of utility plants. Trans. Inst. Chem. Eng. 1998, 76, 246–258. [Google Scholar] [CrossRef]

- Varbanov, P.S.; Doyle, S.; Smith, R. Modelling and optimization of utility systems. Chem. Eng. Res. Des. 2004, 82, 561–578. [Google Scholar] [CrossRef]

- Reddy, C.C.S.; Naidu, S.V.; Rangaiah, G.P. Optimization of a steam network. Chem. Eng. 2013, 52, 54–59. [Google Scholar]

- Variny, M.; Mierka, O.; Godó, Š.; Illés, P.; Margetíny, T. The Optimization of the High Pressure Steam Consumption and the Steam Pipeline Network Management in the Slovnaft Refinery. In Proceedings of the ICCT 2014, sborník Abstraktů a Plných textů, 2. Mezinárodní Chemicko-Technologická Konference, Mikulov, Czech Republic, 7–9 April 2014; ČSPCH: Praha, Czech Republic, 2014; 6p, ISBN 978-80-86238-61-6. [Google Scholar]

- Magalhaes, E.G.; Wada, K.; Secchi, A.R. Steam Production Optimization in a Petrochemical Industry. In 4th MERCOSUR Congress on Process Systems Engineering: 2nd MERCOSUR Congress on Chemical Engineering: Proceedings of Enpromer; 2005; 10p, Available online: https://www.lume.ufrgs.br/handle/10183/8315 (accessed on 6 December 2019).

- Bungener, S.L.; Van Eetvelde, G.; Maréchal, F. Optimal Operations and Resilient Investments in Steam Networks. Front. Energy Res. 2016, 4. [Google Scholar] [CrossRef][Green Version]

- Hachicha, A.A. Thermo-hydraulic modelling for direct steam generation. Energy Procedia 2017, 143, 705–712. [Google Scholar] [CrossRef]

- Price, T.; Majozi, T. Using Process Integration for Steam System Network Optimization with Sustained Boiler Efficiency. In Proceedings of the 19th European Symposium on Computer Aided Process Engineering—ESCAPE 19, Cracow, Poland, 14–17 June 2009; pp. 1281–1287. [Google Scholar]

- Magalhaes, E.G.; Fronza, T.; Wada, K.; Secchi, A.R. Steam and Power Optimization in a Petrochemical Industry. In Proceedings of the International Symposium on Advanced Control of Chemical Processes ADCHEM 2006, Shenyang, China, 25–27 July 2018; pp. 839–843. [Google Scholar]

- Bojić, M.; Stojanović, B. MILP Optimization of a CHP energy system. Energy Convers. Manag. 1998, 39, 637–642. [Google Scholar] [CrossRef]

- Zhu, Q.; Luo, X.; Zhang, B.; Chen, Y.; Mo, S. Mathematical modeling, validation, and operation optimization of an industrial complex steam turbine network-methodology and application. Energy 2016, 97, 191–213. [Google Scholar] [CrossRef]

- Chen, C.L.; Chen, H.C. A mathematical approach for retrofit and optimization of total site steam distribution networks. Process. Saf. Environ. Prot. 2014, 92, 532–544. [Google Scholar] [CrossRef]

- Luo, X.; Huang, X.; El-Halwagi, M.M.; Ponce-Ortega, J.M.; Chen, Y. Simultaneous synthesis of utility system and heat exchanger network incorporating steam condensate and boiler feedwater. Energy 2016, 113, 875–893. [Google Scholar] [CrossRef]

- Zhao, L.; Zhong, W.; Du, W. Data-Driven Robust Optimization for Steam Systems in Ethylene Plants under Uncertainty. Processes 2019, 7, 744. [Google Scholar] [CrossRef]

- Luo, X.; Yuan, M.; Wang, H.; Jia, Y.; Wu, F. On steam pipe network modeling and flow rate calculation. Procedia Eng. 2012, 29, 1897–1903. [Google Scholar] [CrossRef]

- Ziping, T.; Fumin, B. Real time simulation in computer for oversize steam networks. J. Shanghai Jiao Tong Univ. 2000, 34, 486–489. [Google Scholar]

- Chen, Z.; Wang, J. Heat, mass, and work exchange networks. Front. Chem. Sci. Eng. 2012, 6, 484–502. [Google Scholar] [CrossRef]

- Isafiade, A.J.; Short, M. Synthesis of Renewable Energy Integrated Combined Heat and Mass Exchange Networks. Process. Integr. Optim. Sustain. 2019, 3, 437–453. [Google Scholar] [CrossRef]

- Xiao, W.; Zhou, R.-J.; Dong, H.-G.; Meng, N.; Lin, C.-Y.; Adi, V.S.K. Simultaneous optimal integration of water utilization and heat exchange networks using holistic mathematical programming. Korean J. Chem. Eng. 2009, 26, 1161–1174. [Google Scholar] [CrossRef]

- Liu, Q.T.; Zhang, Z.G.; Pan, J.H.; Guo, J.Q. A coupled thermo-hydraulic model for steam flow in pipe networks. J. Hydrodyn. 2009, 21, 861–866. [Google Scholar] [CrossRef]

- Zhong, W.; Feng, H.; Wang, X.; Wu, D.; Xue, M.; Wang, J. Online hydraulic calculation and operation optimization of industrial steam heating networks considering heat dissipation in pipes. Energy 2015, 87, 566–577. [Google Scholar] [CrossRef]

- García-Gutiérrez, A.; Hernández, A.F.; Martínez, J.I.; Ceceñas, M.; Ovando, R.; Canchola, I. Hydraulic model and steam flow numerical simulation of the Cerro Prieto geothermal field, Mexico, pipeline network. Appl. Therm. Eng. 2015, 75, 1229–1243. [Google Scholar] [CrossRef]

- Teixeira, R.G.D.; Secchi, A.R.; Biscaia, E.C., Jr. Two-Phase Flow in Pipes: Numerical Improvements and Qualitative Analysis for a Refining Process. Oil Gas. Sci. Technol. 2015, 70, 497–510. [Google Scholar] [CrossRef][Green Version]

- Wang, H.; Meng, H.; Zhu, T. New model for onsite heat loss state estimation of general district heating network with hourly measurements. Energy Convers. Manag. 2018, 157, 71–85. [Google Scholar] [CrossRef]

- Wang, H.; Wang, H.; Zhu, T.; Deng, W. A novel model for steam transportation considering drainage loss in steam network. Appl. Energy 2017, 188, 178–189. [Google Scholar] [CrossRef]

- Milosevic, Z.; Ponhöfer, C. Refiner improves steam system with custom simulation/optimization package. Oil Gas. J. 1997, 95, 90–94. [Google Scholar]

- De, S.; Kaiadi, M.; Fast, M.; Assadi, M. Development of an artificial neural network model for the steam process of a coal biomass cofired combined heat and power (CHP) plant in Sweden. Energy 2007, 32, 2099–2109. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, L.; Du, W.; Qian, F. Modeling and Optimization of the Steam Turbine Network of an Ethylene Plant. Chin. J. Chem. Eng. 2013, 21, 520–528. [Google Scholar] [CrossRef]

- Manesh, M.H.K.; Abadi, S.K.; Amidpour, M.; Ghalami, H.; Hamedi, M.H. New emissions targeting strategy for site utility of process industries. Korean J. Chem. Eng. 2013, 30, 796–812. [Google Scholar] [CrossRef]

- Strušnik, D.; Avsec, J. Artificial neural networking and fuzzy logic exergy controlling model of combined heat and power system in thermal power plant. Energy 2015, 80, 318–330. [Google Scholar] [CrossRef]

- Dettori, S.; Colla, V.; Salerno, G.; Signorini, A. Steam Turbine models for monitoring purposes. Energy Procedia 2017, 105, 524–529. [Google Scholar] [CrossRef]

- Beangstrom, S.G.; Majozi, T. Steam system network synthesis with hot liquid reuse: I. The mathematical model for steam level selection. Comput. Chem. Eng. 2016, 85, 210–215. [Google Scholar] [CrossRef]

- Nemet, A.; Klemeš, J.J.; Varbanov, P.S.; Mantelli, V. Heat Integration retrofit analysis—An oil refinery case study by Retrofit Tracing Grid Diagram. Front. Chem. Sci. Eng. 2015, 9, 163–182. [Google Scholar] [CrossRef]

- Beangstrom, S.G.; Majozi, T. Steam system network synthesis with hot liquid reuse: II. Incorporating shaft work and optimum steam levels. Comput. Chem. Eng. 2016, 85, 202–209. [Google Scholar] [CrossRef]

- Majanne, Y. Model predictive pressure control of steam networks. Control. Eng. Practice 2005, 13, 1499–1505. [Google Scholar] [CrossRef]

- Dzedzemane, R.; le Roux, J.D.; Muller, C.J.; Craig, I.K. Steam Header State-Space Model Development and Validation. IFAC PapersOnLine 2018, 51, 207–212. [Google Scholar] [CrossRef]

- The International Association for the Properties of Water and Steam. The IAPWS Industrial Formulation 1997 for the Thermodynamic Properties of Water and Steam; IAPWS: Eflangen, Germany, 1997. [Google Scholar]

- Product Marketing, Aspen Technology, Inc. An. Integrated Approach to Modeling Pipeline Hydraulics in a Gathering and Production System; Aspen Technology, Inc.: Bedford, MA, USA, 2015; Available online: https://www.aspentech.com/en/-/media/aspentech/home/resources/white-papers/pdfs/11-7579-wp_pipeline_hydraulics_d.pdf (accessed on 21 October 2019).

- Brkić, D.; Praks, P. Unified Friction Formulation from Laminar to Fully Rough Turbulent Flow. Appl. Sci. 2018, 8, 2036. [Google Scholar] [CrossRef]

- Sutera, S.P.; Skalak, R. The history of Poiseuille’s law. Annu. Rev. Fluid Mech. 1993, 25, 1–20. Available online: https://www.annualreviews.org/doi/10.1146/annurev.fl.25.010193.000245 (accessed on 6 December 2019). [CrossRef]

- Blasius, H. Grenzschichten in Flüssigkeiten mit kleiner Reibung. Z. Angew. Math. Phys. 1908, 56, 1–37. [Google Scholar]

- Round, G.F. An explicit approximation for the friction factor—Reynolds number relation for rough and smooth pipes. Can. J. Chem. Eng. 1980, 58, 122–123. [Google Scholar] [CrossRef]

- Reddy, C.C.S.; Naidu, S.V.; Rangaiah, G.P. Waste heat recovery methods and technologies. Chem. Eng. 2013, 120. Available online: https://www.chemengonline.com/waste-heat-recovery-methods-and-technologies/?printmode=1 (accessed on 5 December 2019).

- Spirax-Sarco. The Steam and Condensate Loop. Effective Steam Engineering for Today; Spirax-Sarco Limited: Cheltenham, UK, 2011; ISBN 978-0-9550691-5-4. [Google Scholar]

- Praks, P.; Kopustinskas, V.; Masera, M. Probabilistic modelling of security of supply in gas networks and evaluation of new infrastructure. Reliab. Eng. Syst. Saf. 2015, 144, 254–264. [Google Scholar] [CrossRef]

| Eq. Number | Equation | Conditions of Use | Author |

|---|---|---|---|

| (6) | n = 0; Re < 2300 | Hagen-Poiseuille [45] | |

| (7) | n = 0; 2300<Re<105 | Blasius (1913) [46] | |

| (8) | Round (1980) [47] |

| Fitting Type | ξ |

|---|---|

| Manual valve—opened | 3 |

| Straight valve—opened | 0.5 to 0.8 |

| Reverse flap | 6 |

| 90° elbow | 1.26 |

| 45° elbow | 0.5 |

| Tee | 1 |

| Flow Pattern | a | b | c |

|---|---|---|---|

| Segregated | 0.9800 | 0.4846 | 0.0868 |

| Intermittent | 0.8450 | 0.5351 | 0.0173 |

| Distributed | 1.0650 | 0.5824 | 0.0609 |

| Flow Pattern | d′ | e | f | j |

|---|---|---|---|---|

| Segregated uphill | 0.0110 | −3.7680 | 3.5390 | −1.6140 |

| Intermittent uphill | 2.9600 | 0.3050 | −0.44703 | 0.0978 |

| Distributed uphill | No correction, | |||

| All patterns downhill | 4.7000 | −0.3692 | 0.1244 | −0.5056 |

| Steam Network | Steam Export Change, t/h | ||

|---|---|---|---|

| A | B | C | |

| LPS | - | - | −9.2 |

| MPS | - | +7.3 | - |

| HPS | - | −11.6 | +25.0 |

| Date, Time | Ambient Temperature, °C | Wind Speed, m/s | HPS Supply from the CHP Unit, t/h | Total HPS Supply, t/h | |

|---|---|---|---|---|---|

| Winter | 3.1.2017, 10:00 | −5 | 2 | 53.18 | 112.3 |

| Spring | 22.4.2017, 6:00 | 10 | 3 | 60.93 | 101.13 |

| Summer | 10.7.2017, 19:00 | 30 | 3 | 28.07 | 97.67 |

t/h | GJ/h | |||||

|---|---|---|---|---|---|---|

| LPS | 38.13 | 0.3054 | 0.5579 | 104.97 | 0.2943 | 0.5323 |

| MPS | 21.52 | 0.2116 | 0.2770 | 65,74 | 0.2294 | 0.2739 |

| HPS | 6.05 | 0.0646 | 0.1634 | 26.57 | 0.0922 | 0.2265 |

| Total | 44.50 | 0.1423 | 0.2401 | 136.17 | 0.1463 | 0.2456 |

| Steam Pressure Level | ht [GJ/t] | h [GJ/t] | hmin [GJ/t] | hmax [GJ/t] |

|---|---|---|---|---|

| LPS | 2.75 | 2.84 | 2.76 | 2.91 |

| MPS | 3.05 | 3.01 | 2.87 | 3.09 |

| HPS | 4.39 | 3.07 | 3.03 | 3.13 |

| LPS | MPS | HPS | |

|---|---|---|---|

| 4.98 | 2.25 | 3.21 | |

| 1.03 | 0.35 | 1.10 | |

| 9.51 | 5.01 | 9.40 | |

| 3.54 | 2.87 | 3.38 | |

| 0.06 | 0.30 | 0.20 | |

| 9.33 | 8.52 | 7.02 |

| Scenario | Steam Temperature, °C | |||||

|---|---|---|---|---|---|---|

| C6 | C5 | C4 | C7 | C8 | C9 | |

| Present | 308.8 | 300.0 | 288.6 | 316.8 | 311.4 | 313.7 |

| A | 292.9 | 302.5 | 291.1 | 331.1 | 325.8 | 328.1 |

| A+B | 292.9 | 305.2 | 337.4 | 335.3 | 329.8 | 332.2 |

| A+C | 293.7 | 330.4 | 317.2 | 315.4 | 310.4 | 312.6 |

| A+B+C | 295.8 | 330.4 | 317.2 | 315.0 | 310.1 | 312.2 |

| B+C | 308.8 | 315.3 | 303.4 | 319.9 | 314.3 | 316.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hanus, K.; Variny, M.; Illés, P. Assessment and Prediction of Complex Industrial Steam Network Operation by Combined Thermo-Hydrodynamic Modeling. Processes 2020, 8, 622. https://doi.org/10.3390/pr8050622

Hanus K, Variny M, Illés P. Assessment and Prediction of Complex Industrial Steam Network Operation by Combined Thermo-Hydrodynamic Modeling. Processes. 2020; 8(5):622. https://doi.org/10.3390/pr8050622

Chicago/Turabian StyleHanus, Kristián, Miroslav Variny, and Peter Illés. 2020. "Assessment and Prediction of Complex Industrial Steam Network Operation by Combined Thermo-Hydrodynamic Modeling" Processes 8, no. 5: 622. https://doi.org/10.3390/pr8050622

APA StyleHanus, K., Variny, M., & Illés, P. (2020). Assessment and Prediction of Complex Industrial Steam Network Operation by Combined Thermo-Hydrodynamic Modeling. Processes, 8(5), 622. https://doi.org/10.3390/pr8050622