Renewable Pulverized Biomass Fuel for Internal Combustion Engines

Abstract

1. Introduction

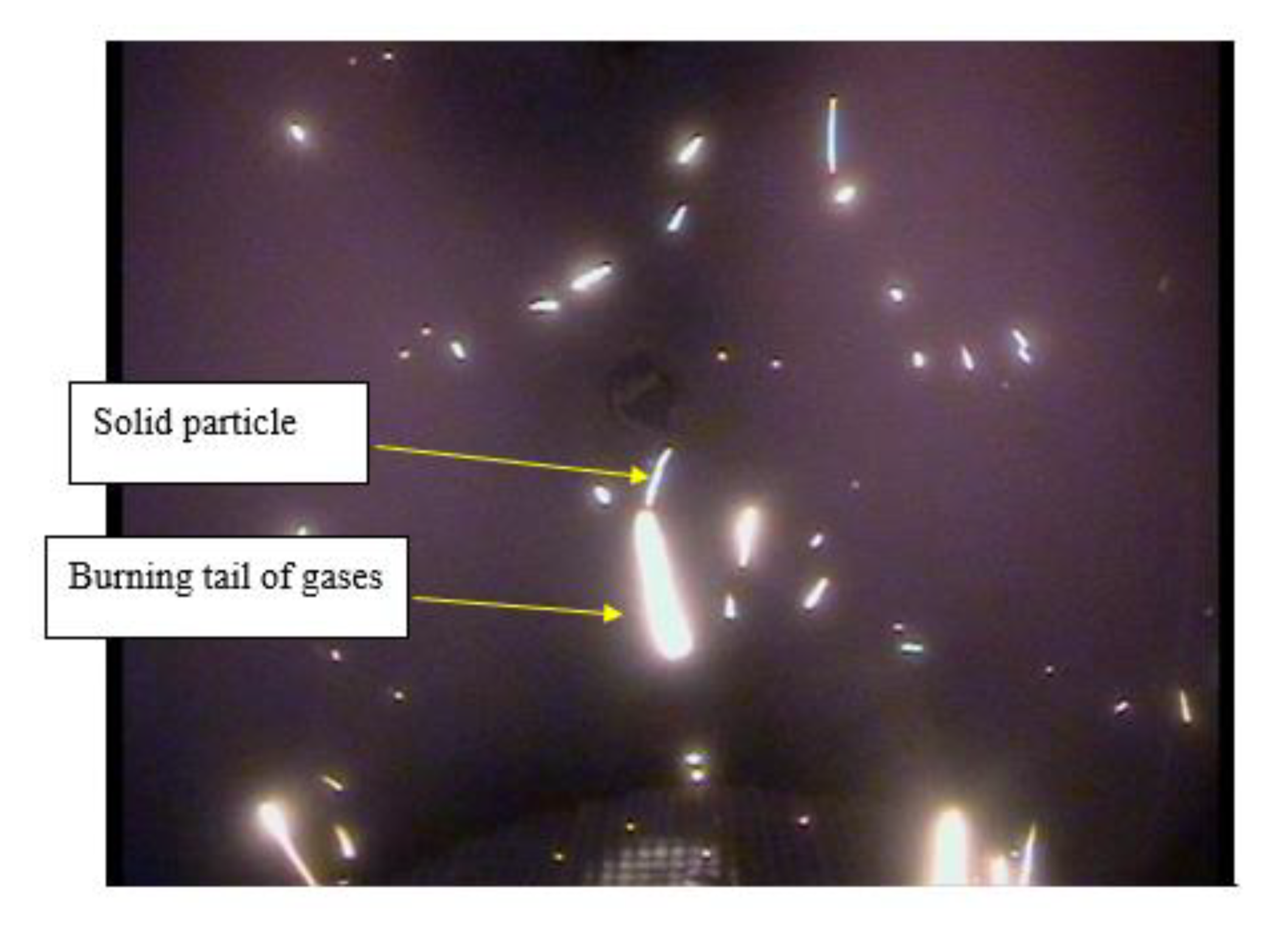

2. Experimental Data

3. Mathematical Models and Methods

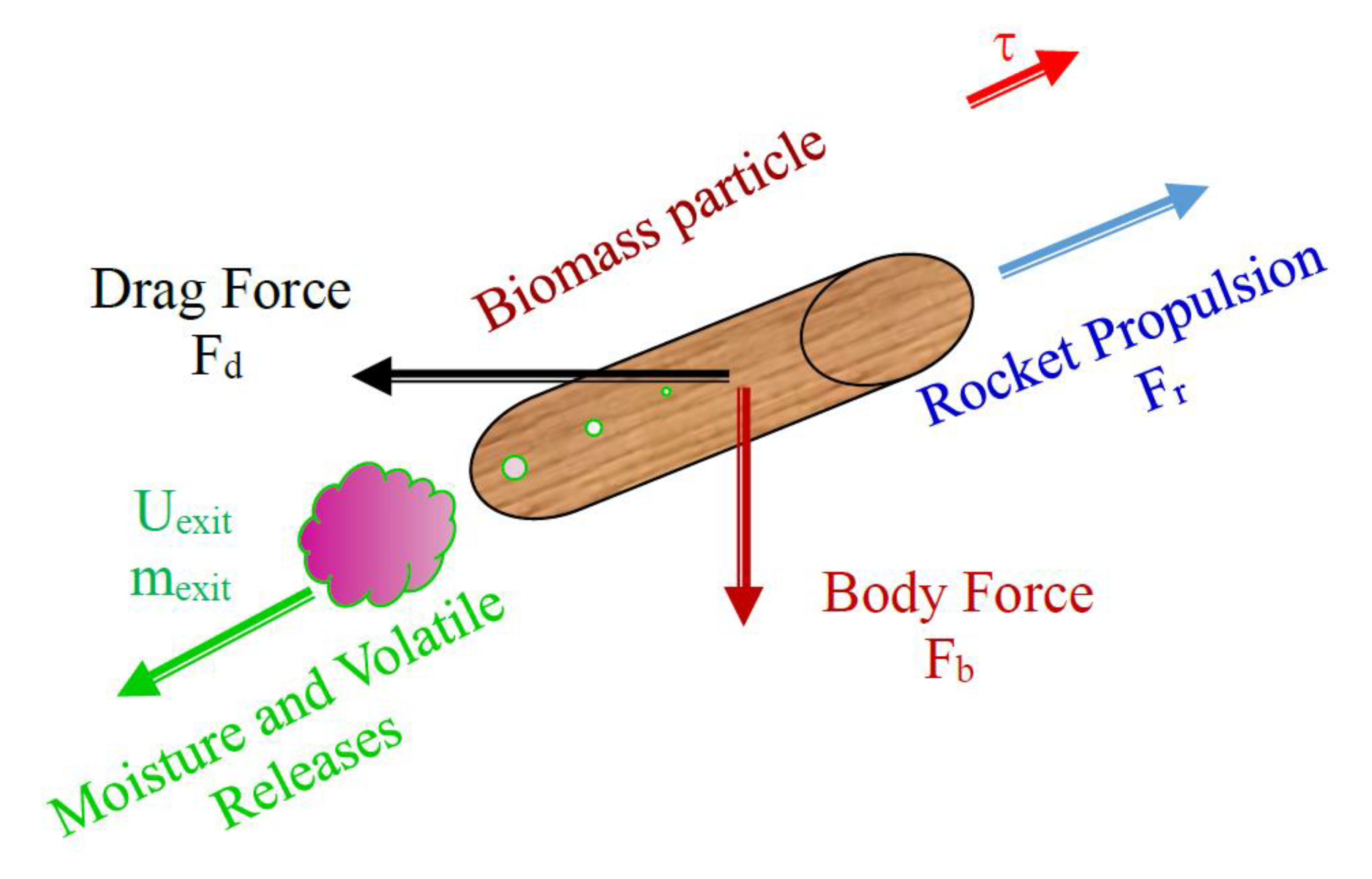

3.1. Particle Transport Model

3.2. Modeling of Rocket Propulsion

3.3. Particle Heating and Drying Model

3.4. Gasification/Devolatilization Models

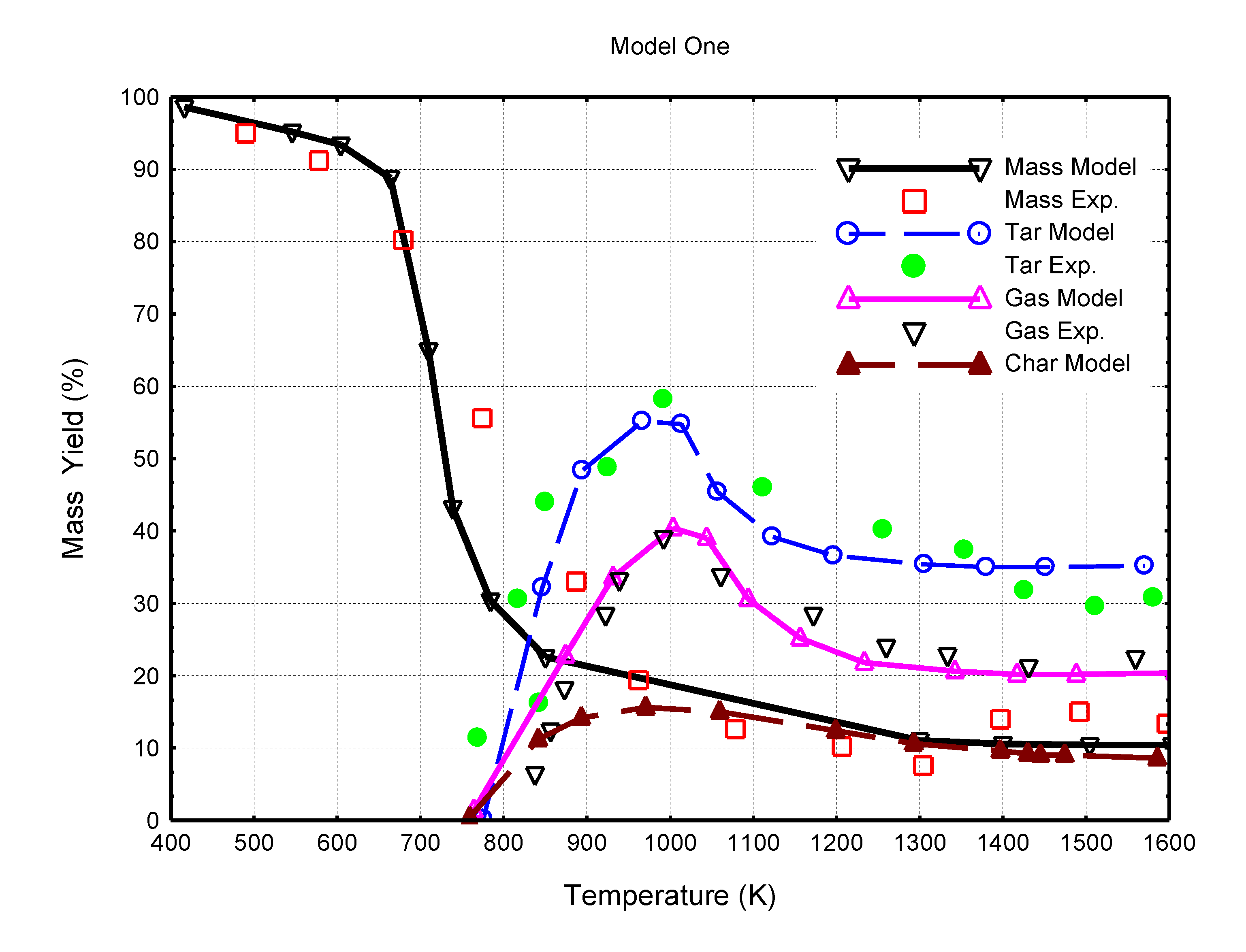

3.4.1. Gasification/Devolatilization Model 1

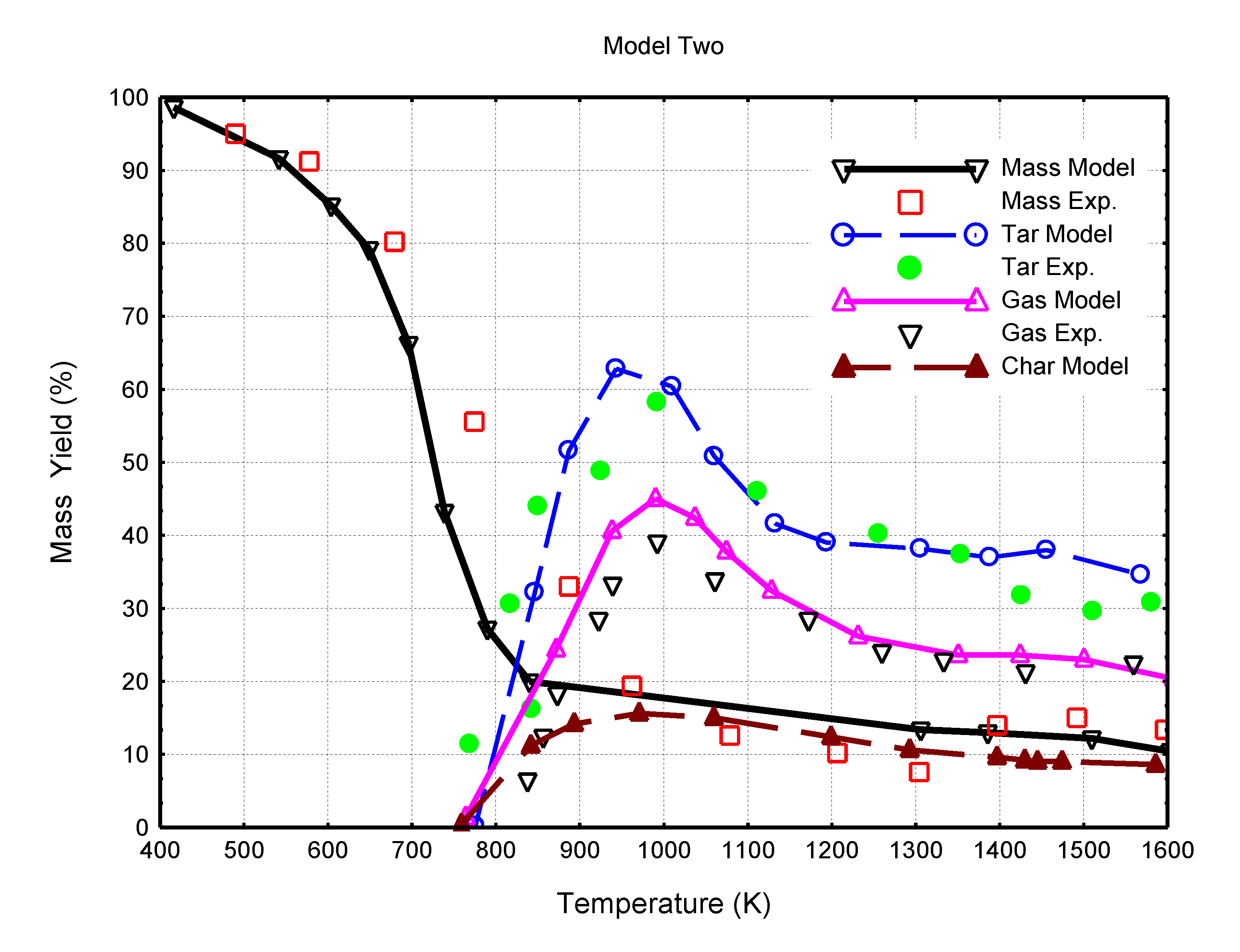

3.4.2. Gasification/Devolatilization Model 2

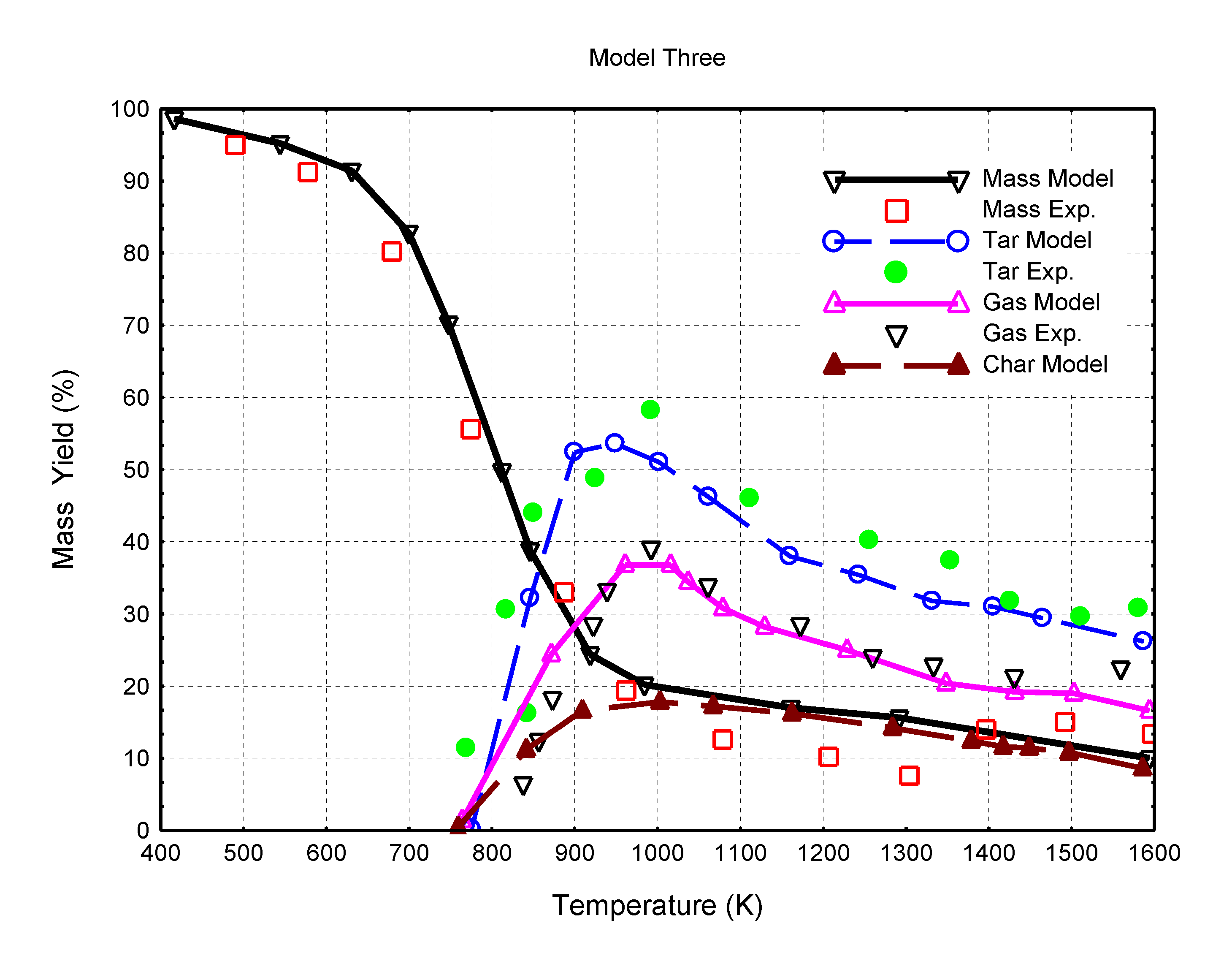

3.4.3. Gasification/Devolatilization Model 3

3.5. Tar Gasification and/or Devolatilization Model

3.6. Biomass Powder Shrinkage Model

3.7. Simulation Scheme and Methods

4. Results and Discussions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Elfasakhany, A. Investigation on performance and emissions characteristics of an internal combustion engine fuelled with petroleum gasoline and a hybrid methanol-gasoline fuel. Int. J. Eng. Technol. 2013, 13, 24–43. [Google Scholar]

- Elfasakhany, A. The Effects of Ethanol-Gasoline Blends on Performance and Exhaust Emission Characteristics of Spark Ignition Engines. Int. J. Automot. Eng. 2014, 4, 608–620. [Google Scholar]

- Elfasakhany, A. Experimental study on emissions and performance of an internal combustion engine fueled with gasoline and gasoline/n-butanol blends. Energy Convers. Manag. 2014, 88, 277–283. [Google Scholar] [CrossRef]

- Elfasakhany, A. Experimental investigation on SI engine using gasoline and a hybrid iso-butanol/gasoline fuel. Energy Convers. Manag. 2015, 95, 398–405. [Google Scholar] [CrossRef]

- Elfasakhany, A. Investigations on the effects of ethanol-methanol-gasoline blends in a spark-ignition engine: Performance and emissions analysis. Eng. Sci. Technol. 2015, 18, 713–719. [Google Scholar] [CrossRef]

- Elfasakhany, A. Experimental study of dual n-butanol and iso-butanol additives on spark-ignition engine performance and emissions. Fuel 2016, 163, 166–174. [Google Scholar] [CrossRef]

- Elfasakhany, A. Performance and emissions analysis on using acetone–gasoline fuel blends in spark ignition engine. Eng. Sci. Technol. 2016, 19, 1224–1232. [Google Scholar] [CrossRef][Green Version]

- Elfasakhany, A.; Mahrous, A.-F. Performance and emissions assessment of n-butanol–methanol–gasoline blends as a fuel in spark-ignition engines. Alex. Eng. J. 2016, 55, 3015–3024. [Google Scholar] [CrossRef]

- Elfasakhany, A. Engine performance evaluation and pollutant emissions analysis using ternary bio-ethanol–iso-butanol–gasoline blends in gasoline engines. J. Clean. Prod. 2016, 139, 1057–1067. [Google Scholar] [CrossRef]

- Elfasakhany, A. Performance and emissions of spark-ignition engine using ethanol–methanol–gasoline, n-butanol–iso-butanol–gasoline and iso-butanol–ethanol–gasoline blends: A comparative study. Eng. Sci. Technol. 2016, 19, 2053–2059. [Google Scholar] [CrossRef]

- Elfasakhany, A. Investigations on performance and pollutant emissions of spark-ignition engines fueled with n-butanol–, iso-butanol–, ethanol–, methanol–, and acetone–gasoline blends: A comparative study. Renew. Sustain. Energy Rev. 2017, 71, 404–413. [Google Scholar] [CrossRef]

- Elfasakhany, A. Exhaust emissions and performance of ternary iso-butanol–bio-methanol–gasoline and n-butanol–bio-ethanol–gasoline fuel blends in spark-ignition engines: Assessment and comparison. Energy 2018, 158, 830–840. [Google Scholar] [CrossRef]

- Elfasakhany, A. Alcohols as Fuels in Spark Ignition Engines: Second Blended Generation; Lambert Academic Publishing: Saarbrucken, Germany, 2017; ISBN 978-3-659-97691-9. [Google Scholar]

- Elfasakhany, A. Biofuels in Automobiles: Advantages and Disadvantages: A Review. Curr. Altern. Energy 2019, 3, 1–7. [Google Scholar] [CrossRef]

- Elfasakhany, A. Benefits and Drawbacks on the Use Biofuels in Spark Ignition Engines; Lambert Academic Publishing: Saarbrucken, Germany, 2017; ISBN 978-620-2-05720-2. [Google Scholar]

- Elfasakhany, A.; Bai, X.S. Simulation of Wood Powder Flames in a Vertical Furnace, 3rd ed.; Combustion Symposium: Marrakech, Morocco, 2003; p. 144. [Google Scholar]

- Elfasakhany, A.; Tao, L.X.; Bai, X.S. Transport of pulverized wood particles in turbulent flow: Numerical and experimental studies. Energy Procedia 2014, 61, 1540–1543. [Google Scholar] [CrossRef]

- Vamvuka, D.; Karakas, E.; Kastanaki, E.; Grammelis, P. Pyrolysis characteristics and kinetics of biomass residuals mixtures with lignite. Fuel 2003, 82, 1949–1960. [Google Scholar] [CrossRef]

- Elfasakhany, A. Modelling of Pulverised Wood Flames. Ph.D. Thesis, Lund Univ., Lund, Sweden, 2005. [Google Scholar]

- Elfasakhany, A.; Bai, X.S. Numerical and experimental studies of irregular-shape biomass particle motions in turbulent flows. Eng. Sci. Technol. 2019, 22, 249–265. [Google Scholar] [CrossRef]

- Elfasakhany, A.; Bai, X.S.; Espenas, B.; Tao, L.; Larfeldt, J. Effect of Moisture and Volatile Releases on Motion of Pulverised Wood Particles. In Proceedings of the 7th Int. Conf. on Energy for a Clean Environment, Lisbon, Portugal, 7–10 July 2003; p. 167. [Google Scholar]

- Tao, L.; Berge, N.; Elfasakhany, A.; Bai, X.S. Experimental and Numerical Studies of a Pulverised Wood Flame. In Proceedings of the 6th European Conf. on Industrial Furnaces and Boilers, Lisbon, Portugal, 2–5 April 2002. [Google Scholar]

- Elfasakhany, A.; Tao, L.; Espenas, B.; Larfeldt, J.; Bai, X.S. Pulverised Wood Combustion in a Vertical Furnace: Experimental and Computational Analyses. Appl. Energy 2013, 112, 454–464. [Google Scholar] [CrossRef]

- Elfasakhany, A.; Bai, X.S. Modelling of pulverised wood combustion: A comparison of different models. Prog. Comput. Fluid Dyn. 2006, 6, 188–199. [Google Scholar] [CrossRef]

- Sadhukhan, A.K.; Gupta, P.; Goyal, T.; Saha, R.K. Modelling of pyrolysis of coal–biomass blends using thermogravimetric analysis. Bioresour. Technol. 2008, 99, 8022–8026. [Google Scholar] [CrossRef] [PubMed]

- Sepman, A.V.; de Goey, L.P.H. Plate reactor as an analysis tool for rapid pyrolysis of biomass. Biomass Bioenergy 2011, 35, 2903–2909. [Google Scholar] [CrossRef]

- Kaushal, P.; Abedi, J.; Mahinpey, N. A comprehensive mathematical model for biomass gasification in a bubbling fluidized bed reactor. Fuel 2010, 89, 3650–3661. [Google Scholar] [CrossRef]

- Hatakeyama, T.; Quinn, F.X. Thermal Analysis—Fundamentals and Applications to Polymer Science; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 1999. [Google Scholar]

- Haykiri-Acma, H.; Yaman, S. Synergy in devolatilization characteristics of lignite and hazelnut shell during co-pyrolysis. Fuel 2007, 86, 273–380. [Google Scholar] [CrossRef]

- Meesri, C.; Moghtaderi, B. Lack of synergetic effects in the pyrolytic characteristics of woody biomass/coal blends under low and high heating rate regimes. Biomass Bioenergy 2002, 23, 55–66. [Google Scholar] [CrossRef]

- Nassar, M.N. Thermal analysis of kinetics of Bagasse and Rice Straw. Energy Sources 1999, 21, 131–137. [Google Scholar] [CrossRef]

- Vuthaluru, H.B. Investigation into the pyrolytic behaviour of coal/biomass blends using thermogravimetric analysis. Bioresour. Technol. 2004, 92, 187–195. [Google Scholar] [CrossRef]

- Sutcu, H. Pyrolysis by thermogravimetric analysis of blends of peat with coals of different characteristics and biomass. J. Chin. Inst. Chem. Eng. 2007, 38, 245–249. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, Y.; Huang, Q.; Cai, J. Thermogravimetric characteristics and kinetics of plastic and biomass blends co-pyrolysis. Fuel Process. Technol. 2006, 87, 963–969. [Google Scholar] [CrossRef]

- Di Blasi, C. Modelling chemical and physical processes of wood and biomass pyrolysis. Prog. Energy Combust. Sci. 2008, 34, 47–90. [Google Scholar] [CrossRef]

- Rodrigo, C.R.L.; Manoel, F.M.N.; Danielle, R.S.G. CFD modeling of a small-scale cyclonic combustor chamber using biomass powder. Energy Procedia 2017, 120, 556–563. [Google Scholar] [CrossRef]

- Fabio, C.L.; Stefano, C.; Alessandro, M.; Vincenzo, M. Vittorio Rocco. Analysis of Residual biomass Fast Pyrolysis at Laboratory Scale: Experimental and Numerical Evaluation of Spent Coffee powder Energy Content. Energy Procedia 2017, 105, 817–822. [Google Scholar]

- Saad, A.; El-Sayed, M.E.M. Pyrolysis characteristics and kinetic parameters determination of biomass fuel powder by differential thermal gravimetric analysis (TGA/DTG). Energy Convers. Manag. 2014, 85, 2014. [Google Scholar]

- Xu, G.; Li, M.; Lu, P. Experimental investigation on flow properties of different biomass and torrefied biomass powder. Biomass Bioenergy 2019, 122, 63–75. [Google Scholar] [CrossRef]

- Pachón-Morales, J.; Colin, J.; Pierre, F.; Puel, F.; Perré, P. Effect of torrefaction intensity on the flow properties of lignocellulosic biomass powder. Biomass Bioenergy 2019, 120, 301–312. [Google Scholar] [CrossRef]

- Pachón-Morales, J.; Huy, D.; Colin, J.; François, P.; Dingena, S. DEM modelling for flow of cohesive lignocellulosic biomass powders: Model calibration using bulk tests. Adv. Powder Technol. 2019, 30, 732–750. [Google Scholar] [CrossRef]

- Li, M.; Li, Y.; Cai, Q.; Zhou, S. Spraying carbon powder derived from mango wood biomass as high-performance anode in bio-electrochemical system. Bioresour. Technol. 2020, 300, 122623. [Google Scholar] [CrossRef] [PubMed]

- Medina, C.H.; Phylaktou, H.N.; Sattar, H.; Andrews, G.E.; Gibbs, B.M. The development of an experimental method for the determination of the minimum explosible concentration of biomass powder. Biomass Bioenergy 2013, 53, 95–104. [Google Scholar] [CrossRef]

- Joel, F.; Robert, J.; Markus, B.; Sylvia, H.L. Mass flow and variability in screw feeding of biomass powder—Relations to particle and bulk properties. Powder Technol. 2015, 276, 80–88. [Google Scholar]

- He, F.; Yi, W.; Li, Y.; Zha, J.; Luo, B. Effects of fuel properties on the natural downward smoldering of piled biomass powder: Experimental investigation. Biomass Bioenergy 2014, 67, 288–296. [Google Scholar] [CrossRef]

- Xie, T.; Wei, R.; Wang, Z.; Wang, J. Comparative analysis of thermal oxidative decomposition and fire characteristics for different straw powder via thermogravimetry and cone calorimetry. Process Saf. Environ. Prot. 2020, 134, 121–130. [Google Scholar] [CrossRef]

- Bridgwater, A.V.; Peacock, G.V.C. Fast pyrolysis processes for biomass. Renew. Sustain. Energy Rev. 2000, 4, 1–73. [Google Scholar] [CrossRef]

- Goyal, H.B.; Seal, D.; Saxena, R.C. Bio-fuels from thermochemical conversion of renewable resources: A review. Renew. Sustain. Energy Rev. 2008, 12, 504–517. [Google Scholar] [CrossRef]

- Elfasakhany, A. Powder biomass fast pyrolysis as in combustion conditions: Numerical prediction and validation. Renew. Energy Focus 2018, 27, 78–87. [Google Scholar] [CrossRef]

- Howard, T.R.N.J.; Longwell, J.; Peters, W. Product compositions and kinetics in the rapid pyrolysis of sweet gum hardwood. Ind. Eng. Chem. Proc. Des. Dev. 1985, 24, 836–844. [Google Scholar]

- Rusaas, J. Numerical Simulation of Gas-Particle Flow Linked to Pulverised Coal Combustion. Ph.D. Thesis, Institute of Energy Technology, Aalborg University, Aalborg, Denmark, 1998. [Google Scholar]

- Ganser, G.H. A rational approach to drag prediction of spherical and nonspherical particles. Powder Technol. 1993, 77, 143–152. [Google Scholar] [CrossRef]

- Chhabra, R.P.; Agarwal, L.; Sinha, N.K. Drag on non-spherical particles: An evaluation of available methods. Powder Technol. 1999, 101, 288–295. [Google Scholar] [CrossRef]

- Shin, D.; Choi, S. The combustion of simulated waste particle in a fixed bed. Combust. Flame 2020, 121, 167–180. [Google Scholar] [CrossRef]

- Bryden, K.M.; Ragland, K.W.; Rutland, C.J. Modeling thermally thick pyrolysis of wood. Biomass Bioenergy 2002, 22, 41–53. [Google Scholar] [CrossRef]

- Hasanah, U.; Setiaji, B.; Anwar, C. The Chemical Composition and Physical Properties of the Light and Heavy Tar Resulted from Coconut Shell Pyrolysis. J. Pure Appl. Chem. Res. 2012, 1, 26–32. [Google Scholar] [CrossRef]

- Elfasakhany, A. Modelling of Secondary Reactions of Tar (SRT) Using a Functional Group Model. Int. J. Mech. Eng. Tech. 2012, 3, 123–136. [Google Scholar]

- Magnussen, B.; Hjertager, B. On mathematical modelling of turbulent combustion with special emphasis on soot formation and combustion. Proc. Combust. Inst. 1976, 16, 719–729. [Google Scholar] [CrossRef]

- Larfeldt, J.; Leckner, B.; Melaaen, M.C. Modeling and measurements of the pyrolysis of large wood particles. Fuel 2000, 79, 1637–1643. [Google Scholar] [CrossRef]

- Di Blasi, C. Heat, momentum and mass transfer through a shrinkage biomass particle exposed to thermal radiation. Chem. Eng. Sci. 1996, 51, 1121–1132. [Google Scholar] [CrossRef]

- Kops, S.M.B.; Malte, P.C. Simulation and Modelling of Wood Dust Combustion in Cyclone Burners—Final Technical Report; U.S. Department of Energy: Washington, DC, USA, 2004. [Google Scholar]

- Felipe, R.C.; Rogério, B.; Francis, H.R.F.; Cristiano, V.S. Application of the WSGG model for the calculation of gas–soot radiation in a turbulent non-premixed methane–air flame inside a cylindrical combustion chamber. Int. J. Heat Mass Transf. 2016, 93, 742–753. [Google Scholar]

- Elfasakhany, A.; Klason, T.; Bai, X.S. Modelling of pulverised wood combustion using a functional group model. Combust. Theory Model. 2008, 12, 883–904. [Google Scholar] [CrossRef]

| Model | mi/mwood [%] | Ai (s−1) | Ei (kJ/mol) |

|---|---|---|---|

| 15.00 | ─ | ─ | |

| 45.70 | 1.646 × 106 | 82.624 | |

| 10.00 | 7.411 × 105 | 99.225 | |

| 7.460 | 2.291 × 103 | 61.126 | |

| 10.76 | 5.888 × 103 | 59.870 | |

| 2.800 | 6.166 × 103 | 69.499 | |

| 3.140 | 6.310 × 105 | 89.176 | |

| 5.140 | 2.239 × 103 | 48.147 | |

| Model | mi/mwood [%] | Ai (s−1) | Ei (kJ/mol) |

|---|---|---|---|

| 15.00 | ─ | ─ | |

| 55.70 | 1.646 × 106 | 82.624 | |

| 7.460 | 2.291 × 103 | 61.126 | |

| 10.76 | 5.888 × 103 | 59.870 | |

| 0.800 | 6.166 × 103 | 69.499 | |

| 5.140 | 2.239 × 103 | 48.147 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elfasakhany, A.; Alsehli, M.; Saleh, B.; Aly, A.A.; Bassuoni, M. Renewable Pulverized Biomass Fuel for Internal Combustion Engines. Processes 2020, 8, 465. https://doi.org/10.3390/pr8040465

Elfasakhany A, Alsehli M, Saleh B, Aly AA, Bassuoni M. Renewable Pulverized Biomass Fuel for Internal Combustion Engines. Processes. 2020; 8(4):465. https://doi.org/10.3390/pr8040465

Chicago/Turabian StyleElfasakhany, Ashraf, Mishal Alsehli, Bahaa Saleh, Ayman A. Aly, and Mohamed Bassuoni. 2020. "Renewable Pulverized Biomass Fuel for Internal Combustion Engines" Processes 8, no. 4: 465. https://doi.org/10.3390/pr8040465

APA StyleElfasakhany, A., Alsehli, M., Saleh, B., Aly, A. A., & Bassuoni, M. (2020). Renewable Pulverized Biomass Fuel for Internal Combustion Engines. Processes, 8(4), 465. https://doi.org/10.3390/pr8040465