Eucalyptus Kraft Lignin as an Additive Strongly Enhances the Mechanical Resistance of Tree-Leaf Pellets

Abstract

1. Introduction

2. Materials and Methods

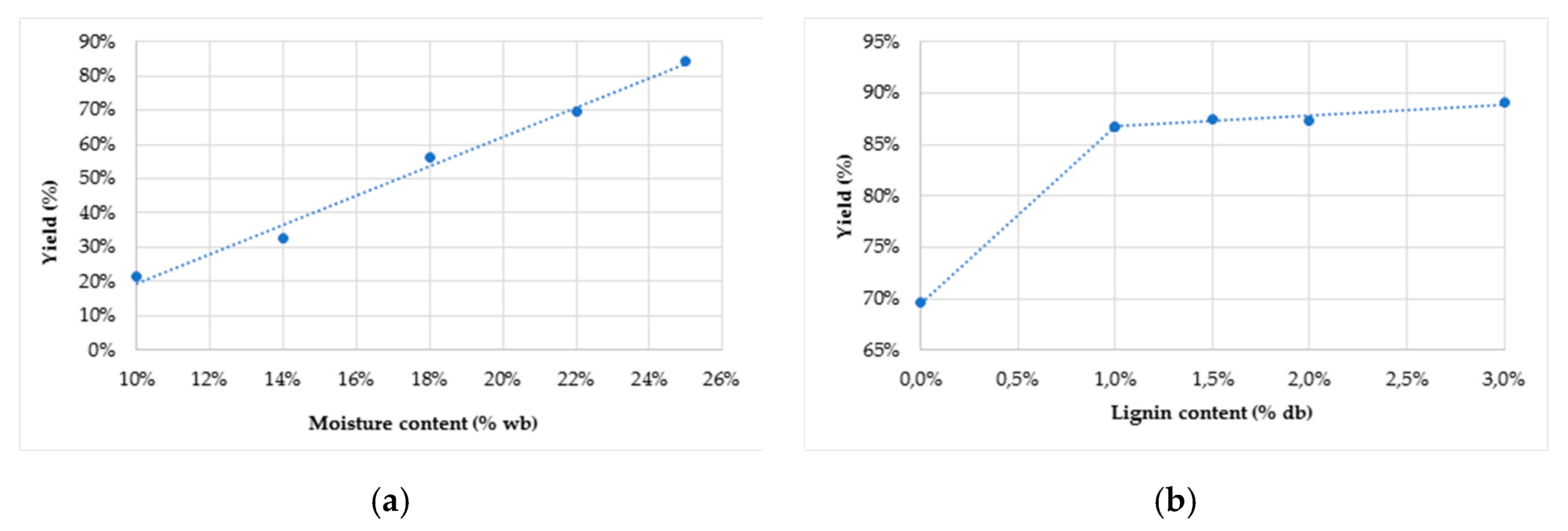

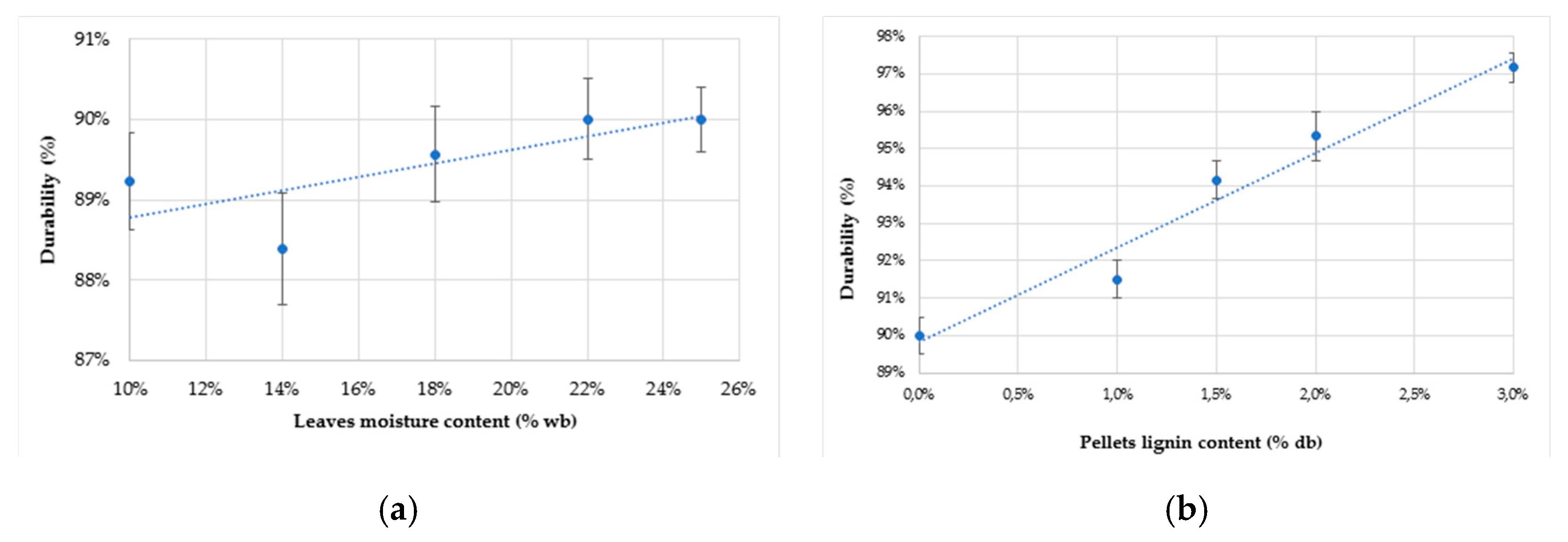

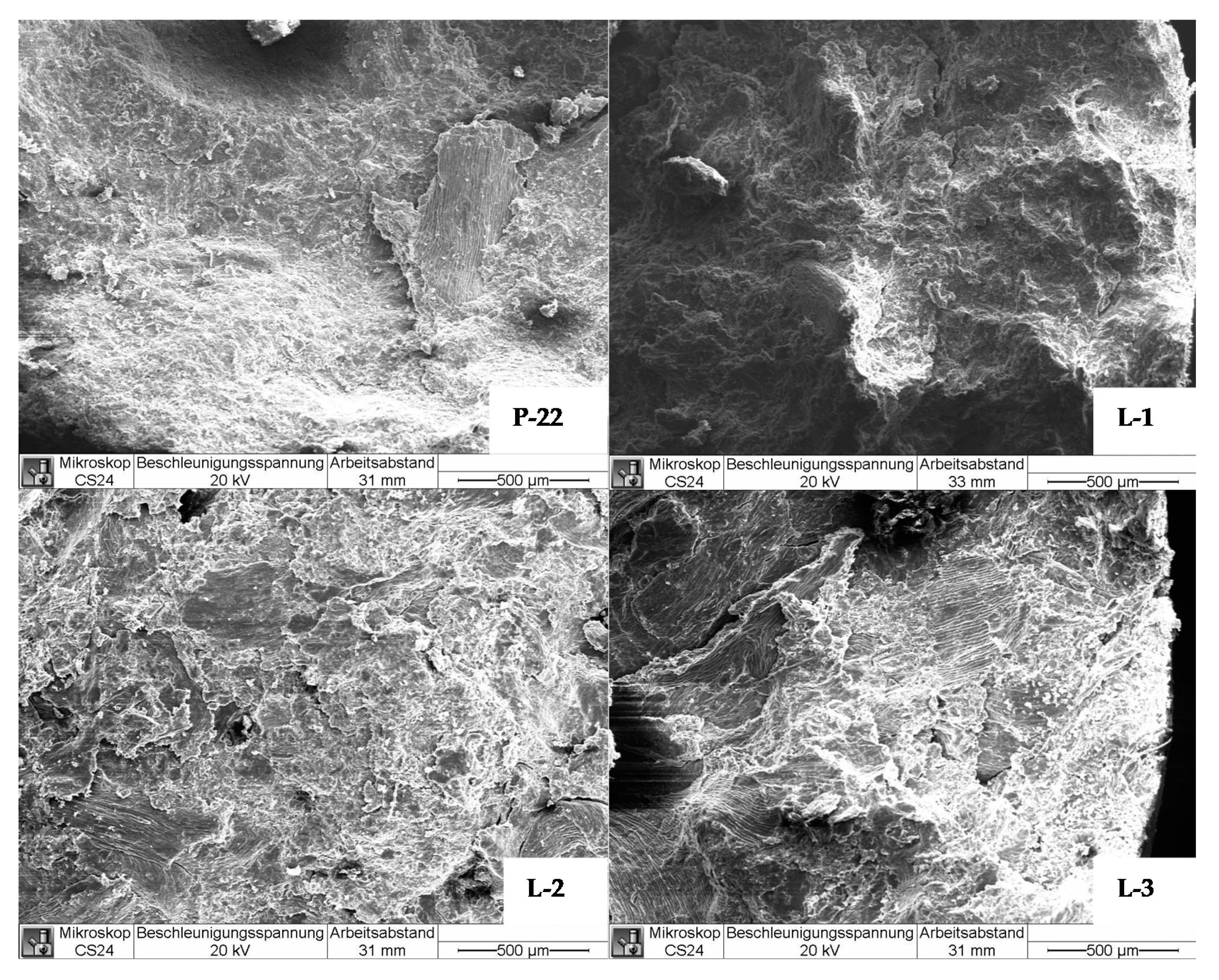

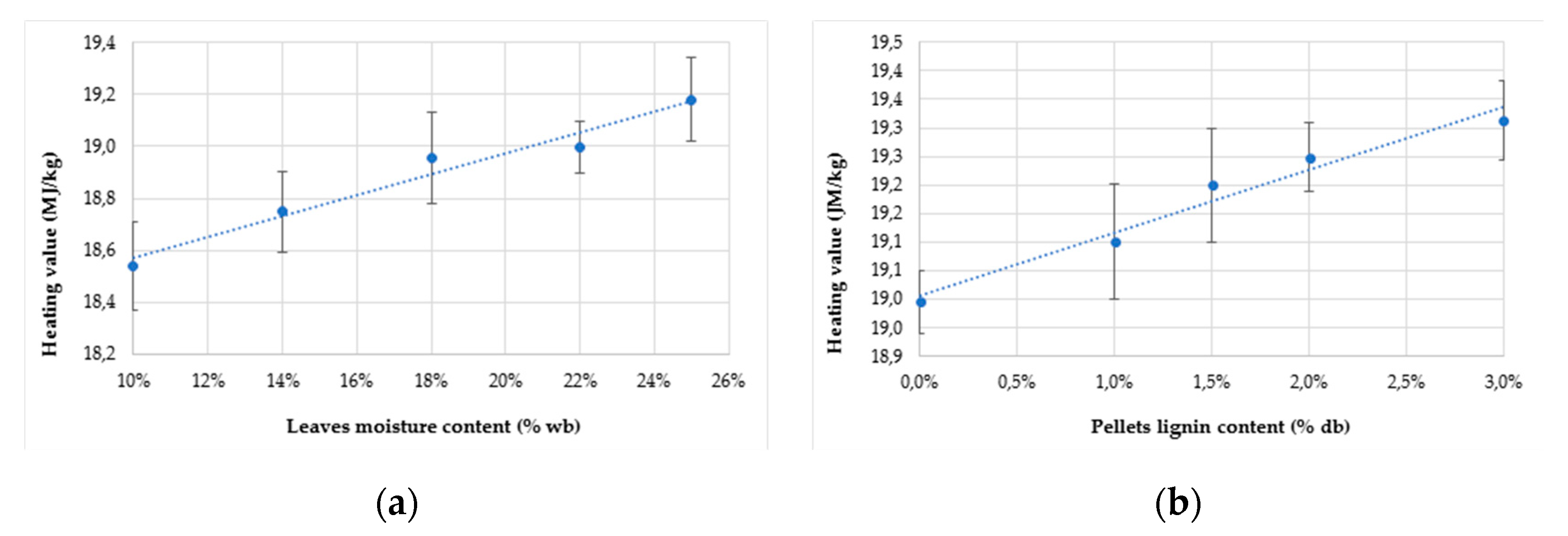

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lehtikangas, P. Quality properties of pelletised sawdust, logging residues and bark. Biomass Bioenergy 2001, 20, 351–360. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Evaluation of compaction equations applied to four biomass species. Can. Biosyst. Eng./Le Genie Des Biosystemes Au Canada 2004, 46, 55–61. [Google Scholar]

- Mitchell, P.; Kiel, J.; Livingston, B.; Dupont-Roc, G. Torrefied biomass-A foresighting study into the business case for pellets from torrefied Biomass as a new solid fuel. All Energy 2007, 24, 1–27. [Google Scholar]

- Fasina, O.O.; Sokhansanj, S. Storage and handling characteristics of alfalfa pellets. Powder Handl. Process. 1996, 8, 361–366. [Google Scholar]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefin. 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Nilsson, D.; Bernesson, S.; Hansson, P.A. Pellet production from agricultural raw materials–A systems study. Biomass Bioenergy 2011, 35, 679–689. [Google Scholar] [CrossRef]

- Mani, S.; Sokhansanj, S.; Bi, S.; Turhollow, A. Economics of producing fuel pellets from biomass. Appl. Eng. Agric. 2006, 22, 421–426. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations, FAOSTAT. Available online: http://www.fao.org/faostat/es/?#data/FO (accessed on 11 November 2019).

- Telmo, C.; Lousada, J. Heating values of wood pellets from different species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- Quirino, W.F.; Do Vale, A.T.; De Andrade, A.P.A.; Abreu, V.L.S.; Azevedo, A.C.D.S. Poder calorífico da madeira e de materiais ligno-celulósicos. Revista Da Madeira 2005, 89, 100–106. [Google Scholar]

- Tarasov, D.; Shahi, C.; Leitch, M. Effect of additives on wood pellet physical and thermal characteristics: A review. ISRN For. 2013, 2013, 876939. [Google Scholar] [CrossRef]

- García-Maraver, A.; Popov, V.; Zamorano, M. A review of European standards for pellet quality. Renew. Energy 2011, 36, 3537–3540. [Google Scholar] [CrossRef]

- International Organization for Standardization. Solid Biofuels–Fuel Specifications and Clases–Part 2: Graded Wood Pellets; ISO 17225-2:2014; International Organization for Standardization: Geneva, Switzerland, 2014; Available online: https://www.iso.org/obp/ui/#iso:std:iso:17225:-2:dis:ed-2:v1:en (accessed on 25 February 2020).

- Kaliyan, N.; Vance Morey, R. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Williams, O.; Taylor, S.; Lester, E.; Kingman, S.; Giddings, D.; Eastwick, C. Applicability of mechanical test for biomass pellet characterization for bioenergy applications. Materials 2018, 11, 1329. [Google Scholar] [CrossRef] [PubMed]

- Hedlund, F.H.; Astad, J.; Nichols, J. Inherent hazards, poor reporting and limited learning in the solid biomass energy sector: A case study of a wheel loader igniting wood dust, leading to fatal explosion at wood pellet manufacturer. Biomass Bioenergy 2014, 66, 450–459. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. The Pellet Handbook: The Production and Thermal Utilization of Pellets; Taylor & Francis: London, UK, 2010. [Google Scholar]

- International Organization for Standardization. Solid Biofuels–Determination of Mechanical Durability of Pellets and Briquettes–Part 1: Pellets; ISO 17831-1:2015; International Organization for Standardization: Geneva, Switzerland, 2015; Available online: https://www.iso.org/standard/60695.html (accessed on 25 February 2020).

- Kaliyan, N.; Vance Morey, R. Factors affecting strength and durability of densified products. In Proceedings of the American Society of Agricultural and Biological Engineers meeting, Portland, OR, USA, 9–12 July 2006. [Google Scholar] [CrossRef]

- Thomas, M.; van del Poel, A.F.B. Physical quality of pelleted animal feed. 1-Criteria for pellet quality. Anim. Feed. Sci. Technol. 1996, 61, 89–112. [Google Scholar] [CrossRef]

- Pietsch, W. Agglomeration Processes–Phenomena, Technologies, Equipment; Wiley-VCH: Weinheim, Germany, 2002. [Google Scholar]

- European Pellet Council. Handbook for the Certification of Wood Pellets for Heating Purposes, 3rd ed.; ENplus: Brussels, Belgium, 2015. [Google Scholar]

- Van Dam, J.E.G.; van den Oever, M.J.A.; Teunissen, W.; Keijsers, E.R.P.; Peralta, A.G. Process for production of high density/high performance binderless boards from whole coconut husk: Part 1: Lignin as intrinsic thermosetting binder resin. Ind. Crop. Prod. 2004, 19, 207–216. [Google Scholar] [CrossRef]

- Petisco, C.; García-Criado, B.; Mediavilla, S.; Vázquez De Aldana, B.R.; Zabalgogeazcoa, I.; García-Ciudad, A. Near-infrared reflectance spectroscopy as a fast and non-destructive tool to predict foliar organic constituents of several woody species. Anal. Bioanal. Chem. 2006, 386, 1823–1833. [Google Scholar] [CrossRef] [PubMed]

- The Official Website of Berlin, City Trees: Overview of the Stock Data. Available online: https://www.berlin.de/senuvk/umwelt/stadtgruen/stadtbaeume/en/daten_fakten/uebersichten/index.shtml (accessed on 20 December 2019).

- Tumurulu, J.S.; Wright, C.T.; Kenny, K.L.; Hess, J.R. A Review on Biomass Densification Technologies for Energy Application; Idaho National Laboratory. U.S. Department of Energy: Idaho Falls, ID, USA, 2010. [Google Scholar]

- Dieste, A.; Clavijo, L.; Torres, A.I.; Barbe, S.; Oyarbide, I.; Bruno, L.; Cassella, F. Lignin from Eucalyptus spp. kraft black liquor as biofuel. Energy Fuels 2016, 30, 10494–10498. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Fenton, J. Cost Benefit of Biomass Supply and Pre-Processing; BIOCAP Canada Foundation: Kingston, ON, Canada, 2006. [Google Scholar]

- Alakangas, E. New European Pellets Standards–EN 14961-1; Eubionet3; VTT: Jyväskyla, Finland, 2011. [Google Scholar]

| Property | Value |

|---|---|

| Ash content (%) | 12.0 ± 0.9 |

| Klason lignin (%) | 73.0 ± 0.5 |

| Soluble lignin (%) | 11.3 ± 0.8 |

| Total lignin (%) | 84 ± 1 |

| Tg (°C) | 132 ± 1 |

| Net heating value (MJ/kg) | 29.1 ± 0.1 |

| Sample | Raw Material Moisture Content (% wb) | Pellet Moisture Content (% wb) |

|---|---|---|

| P-10 | 10.0 ± 0.2 | 9.2 ± 0.1 |

| P-14 | 14.0 ± 0.3 | 8.5 ± 0.3 |

| P-18 | 18.0 ± 0.1 | 8.0 ± 0.1 |

| P-22 | 22.0 ± 0.2 | 9.1 ± 0.1 |

| P-25 | 25.0 ± 0.1 | 8.9 ± 0.1 |

| Sample | Ash Content (% db) |

|---|---|

| Leaves | 10.2 ± 0.1 |

| P-10 | 11.0 ± 0.4 |

| P-14 | 10.9 ± 0.9 |

| P-18 | 10.9 ± 0.5 |

| P-22 | 11.6 ± 0.2 |

| P-25 | 12.3 ± 0.2 |

| L-1.0 | 10.7 ± 0.4 |

| L-1.5 | 11.1 ± 0.6 |

| L-2 | 11.8 ± 0.1 |

| L-3 | 12.7 ± 0.2 |

| Sample | IT 1 (°C) | ST 2 (°C) | HT 3 (°C) | FT 4 (°C) |

|---|---|---|---|---|

| P-10 | 1232 | >1500 | >1500 | >1500 |

| P-14 | 1119 | 1310 | 1371 | 1398 |

| P-18 | 1232 | >1500 | >1500 | >1500 |

| P-22 | 1281 | >1500 | >1500 | >1500 |

| P-25 | 1227 | 1416 | 1437 | 1440 |

| L-1 | 1304 | >1500 | >1500 | >1500 |

| L-1.5 | 1336 | >1500 | >1500 | >1500 |

| L-2 | 1314 | >1500 | >1500 | >1500 |

| L-3 | 1240 | >1500 | >1500 | >1500 |

| Sample | Ca (mg/g) | Mg (mg/g) | Na (mg/g) | K (mg/g) | As (ppm) | Cd (ppm) | Cr (ppm) | Cu (ppm) | Ni (ppm) | Pb (ppm) | Zn (ppm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Content | ≤1 | ≤0.5 | ≤10 | ≤10 | ≤10 | ≤10 | ≤100 | ||||

| P-10 | 19.0 | 3.0 | 0.5 | 7.9 | <0.2 | <0.5 | <5.0 | 8.1 | 2.0 | 6.0 | 23.9 |

| P-14 | 20.3 | 3.3 | 0.1 | 8.4 | <0.2 | <0.5 | <5.0 | 3.5 | 1.8 | 5.9 | 17.2 |

| P-18 | 17.8 | 2.8 | 0.1 | 7.4 | <0.2 | <0.5 | <5.0 | 4.3 | 1.5 | 6.0 | 15.2 |

| P-22 | 15.8 | 2.6 | 0.1 | 6.5 | <0.2 | <0.5 | <5.0 | 2.9 | 1.3 | 5.5 | 11.3 |

| P-25 | 20.0 | 3.2 | 0.3 | 8.3 | <0.2 | <0.5 | <5.0 | 2.8 | 1.5 | 7.6 | 16.8 |

| L-1 | 15.2 | 2.5 | 0.2 | 6.3 | <0.2 | <0.5 | <5.0 | 1.3 | 0.8 | 4.1 | 21.3 |

| L-1.5 | 16.7 | 2.7 | 0.8 | 6.9 | <0.2 | <0.5 | <5.0 | 2.2 | 1.1 | 5.1 | 12.5 |

| L-2 | 21.8 | 3.6 | 1.5 | 9.1 | <0.2 | <0.5 | <5.0 | 4.6 | 1.4 | 5.3 | 17.2 |

| L-3 | 19.8 | 3.3 | 1.9 | 8.2 | <0.2 | <0.5 | <5.0 | 4.1 | 1.4 | 7.0 | 17.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Clavijo, L.; Zlatanovic, S.; Braun, G.; Bongards, M.; Dieste, A.; Barbe, S. Eucalyptus Kraft Lignin as an Additive Strongly Enhances the Mechanical Resistance of Tree-Leaf Pellets. Processes 2020, 8, 376. https://doi.org/10.3390/pr8030376

Clavijo L, Zlatanovic S, Braun G, Bongards M, Dieste A, Barbe S. Eucalyptus Kraft Lignin as an Additive Strongly Enhances the Mechanical Resistance of Tree-Leaf Pellets. Processes. 2020; 8(3):376. https://doi.org/10.3390/pr8030376

Chicago/Turabian StyleClavijo, Leonardo, Slobodan Zlatanovic, Gerd Braun, Michael Bongards, Andrés Dieste, and Stéphan Barbe. 2020. "Eucalyptus Kraft Lignin as an Additive Strongly Enhances the Mechanical Resistance of Tree-Leaf Pellets" Processes 8, no. 3: 376. https://doi.org/10.3390/pr8030376

APA StyleClavijo, L., Zlatanovic, S., Braun, G., Bongards, M., Dieste, A., & Barbe, S. (2020). Eucalyptus Kraft Lignin as an Additive Strongly Enhances the Mechanical Resistance of Tree-Leaf Pellets. Processes, 8(3), 376. https://doi.org/10.3390/pr8030376