Multi-Objective Optimal Configuration of the CCHP System

Abstract

1. Introduction

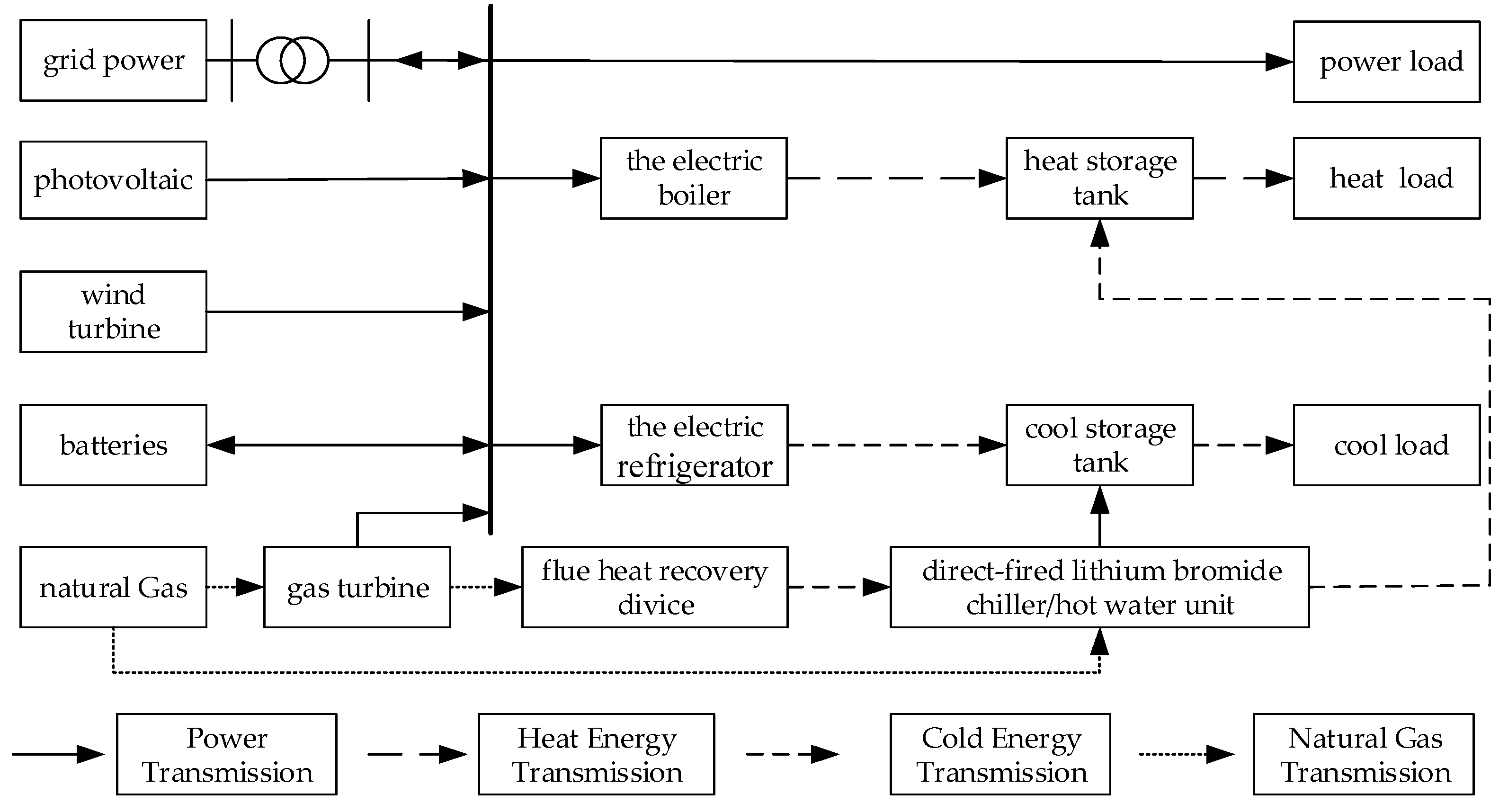

2. The Construction of CCHP System

3. The Optimal Configuration Model of the Proposed CCHP System

3.1. The Construction of the Objective Function

3.2. Constraint

3.2.1. Constraint of the Energy Storage Unit

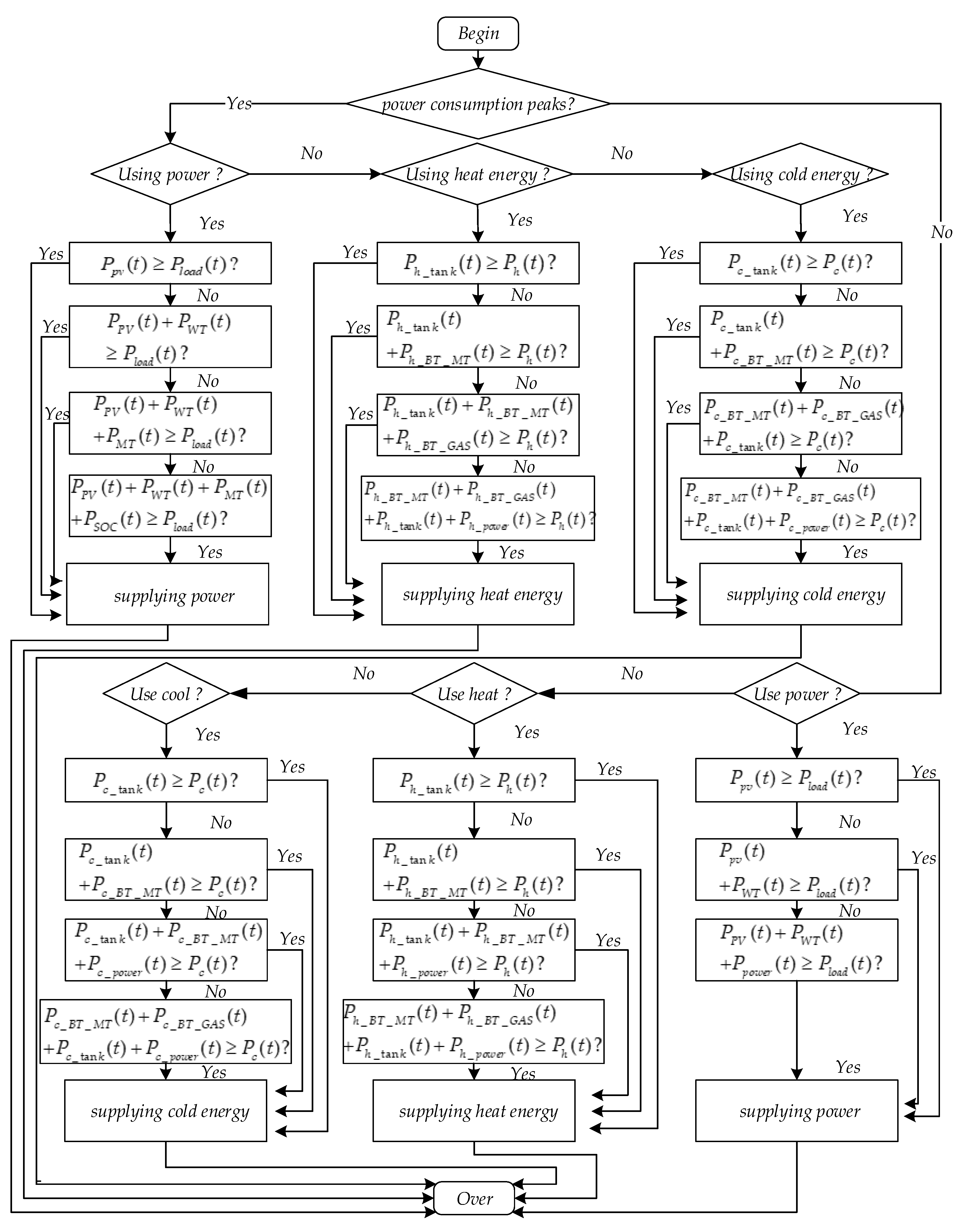

3.2.2. Energy Supply and Demand Constraint

3.2.3. Constraint of Energy Output Equipment

4. The Optimization Configuration Evaluation Metrics of CCHP System

4.1. Reliability Evaluation Metric

4.2. Economic Evaluation Metric

4.3. Environmental Protection Evaluation Metric

5. Experiment

5.1. Energy Supply and Demand Analysis of the CCHP System

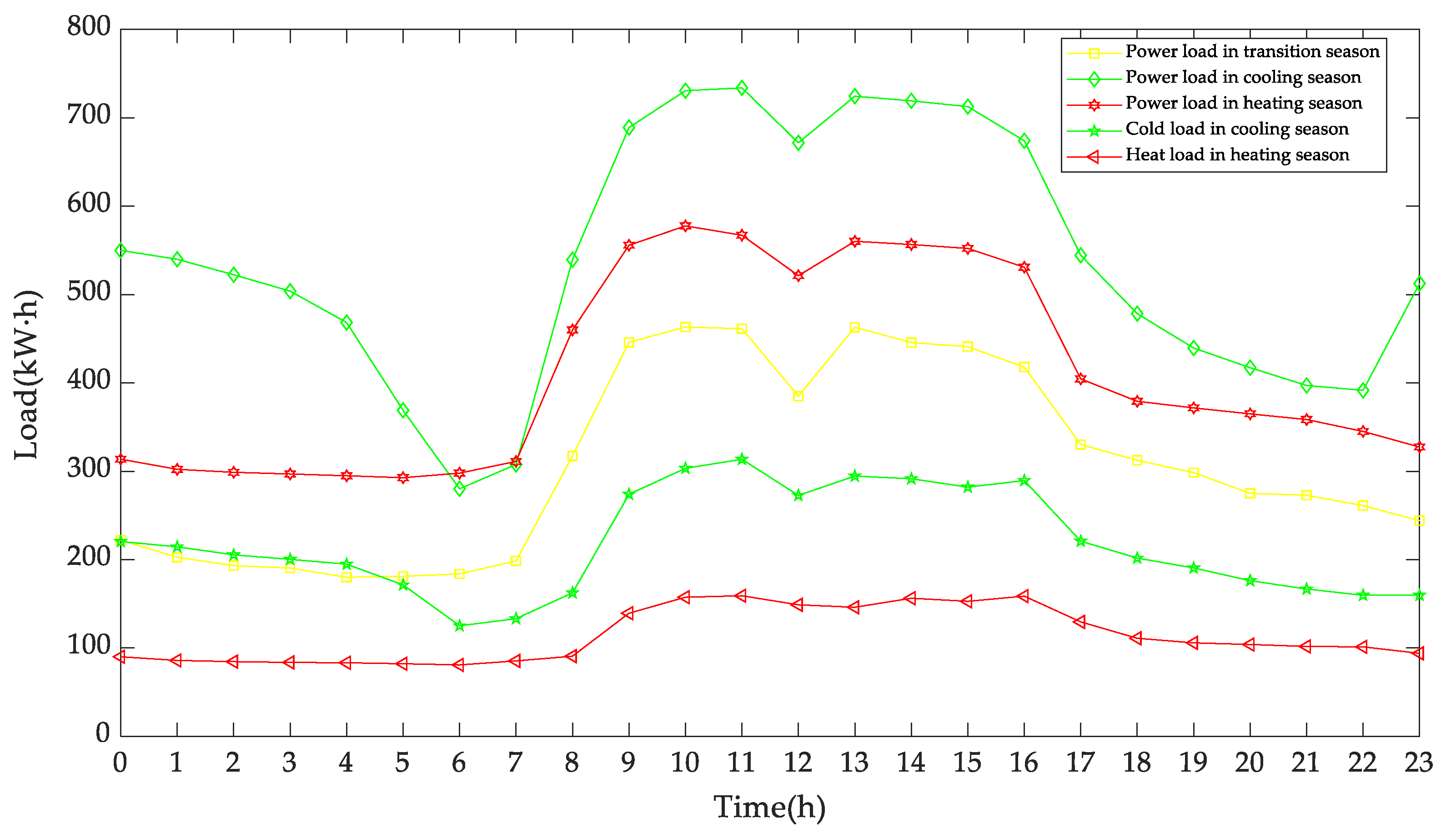

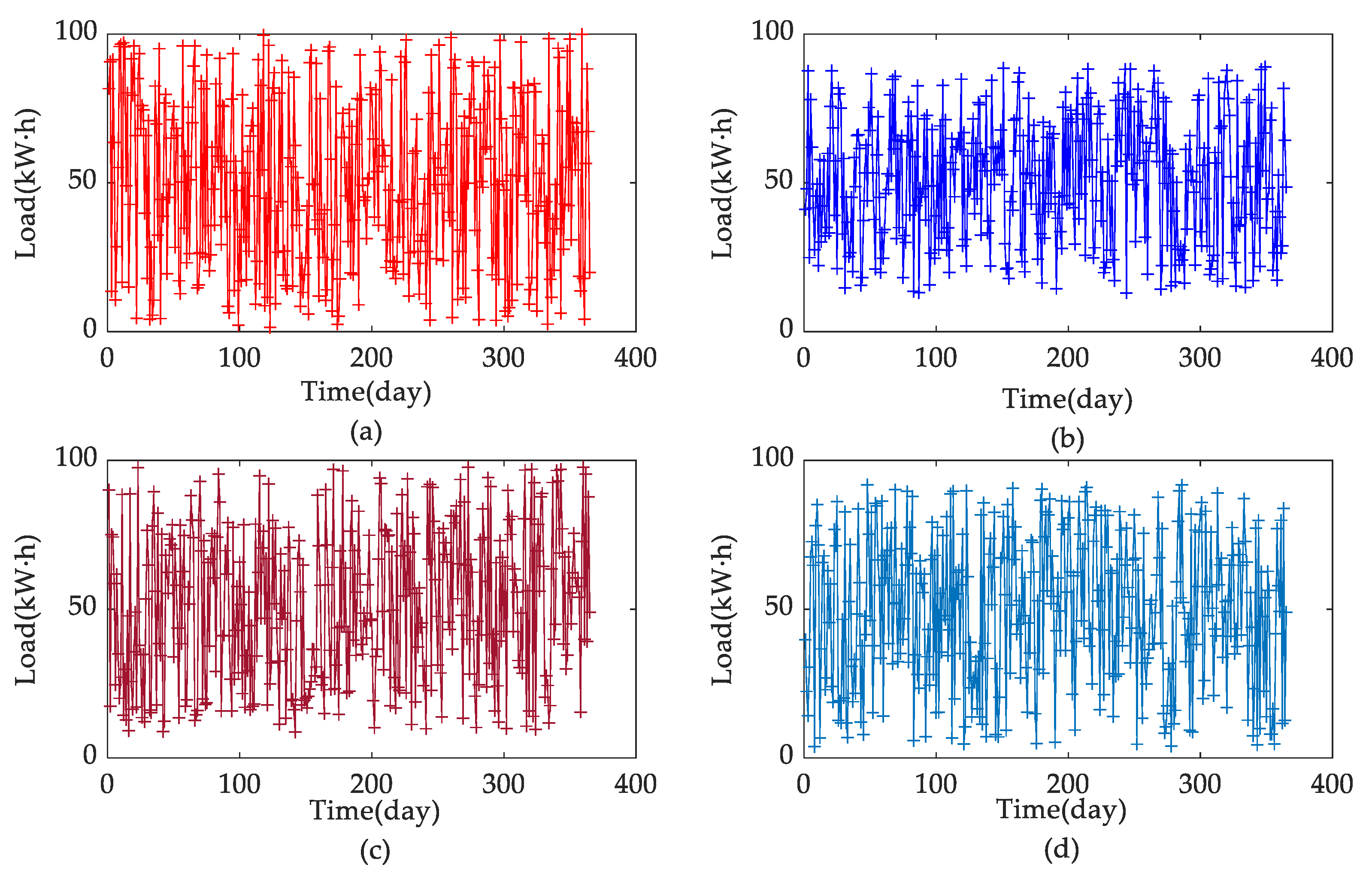

5.1.1. Load Analysis

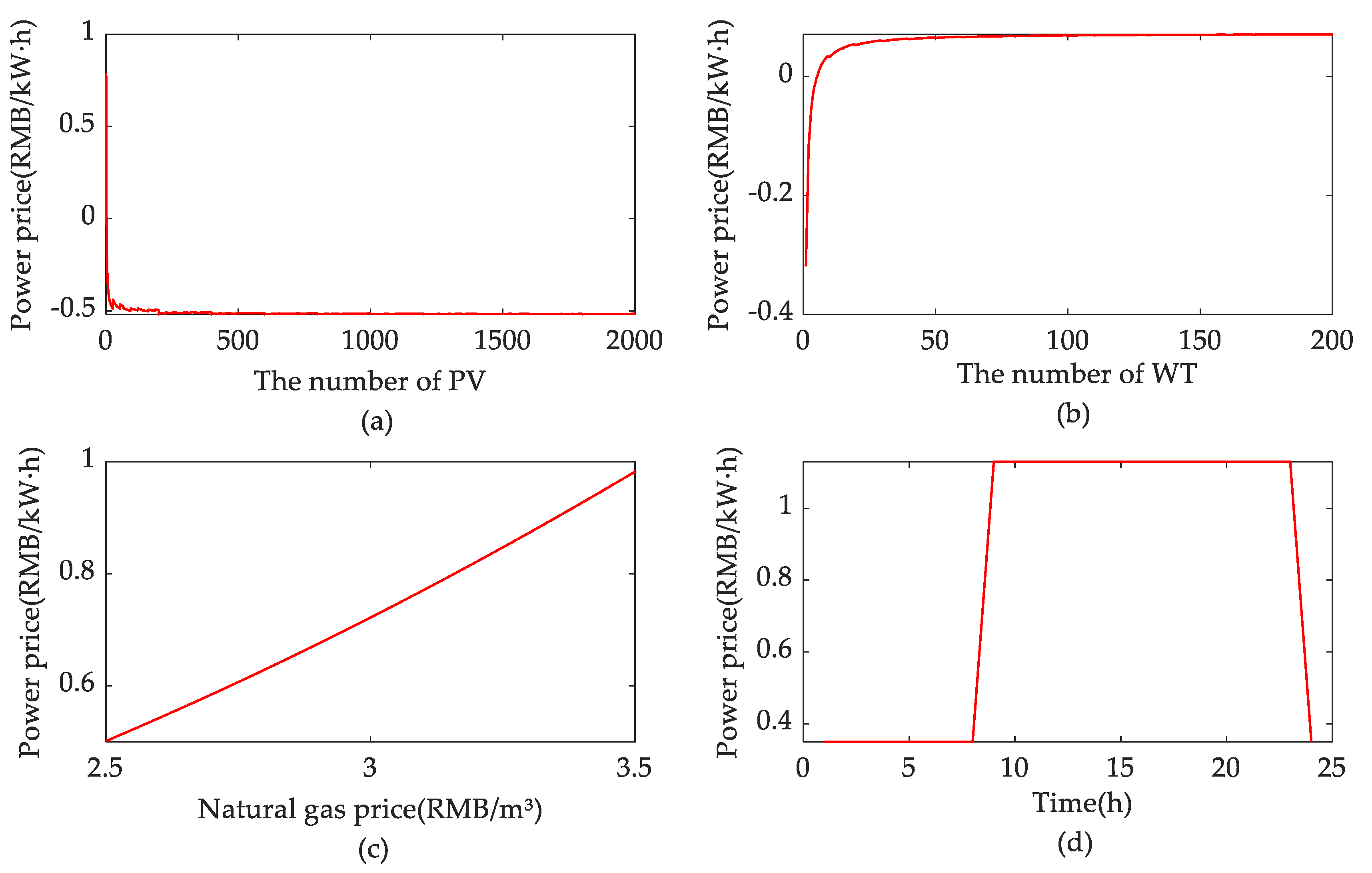

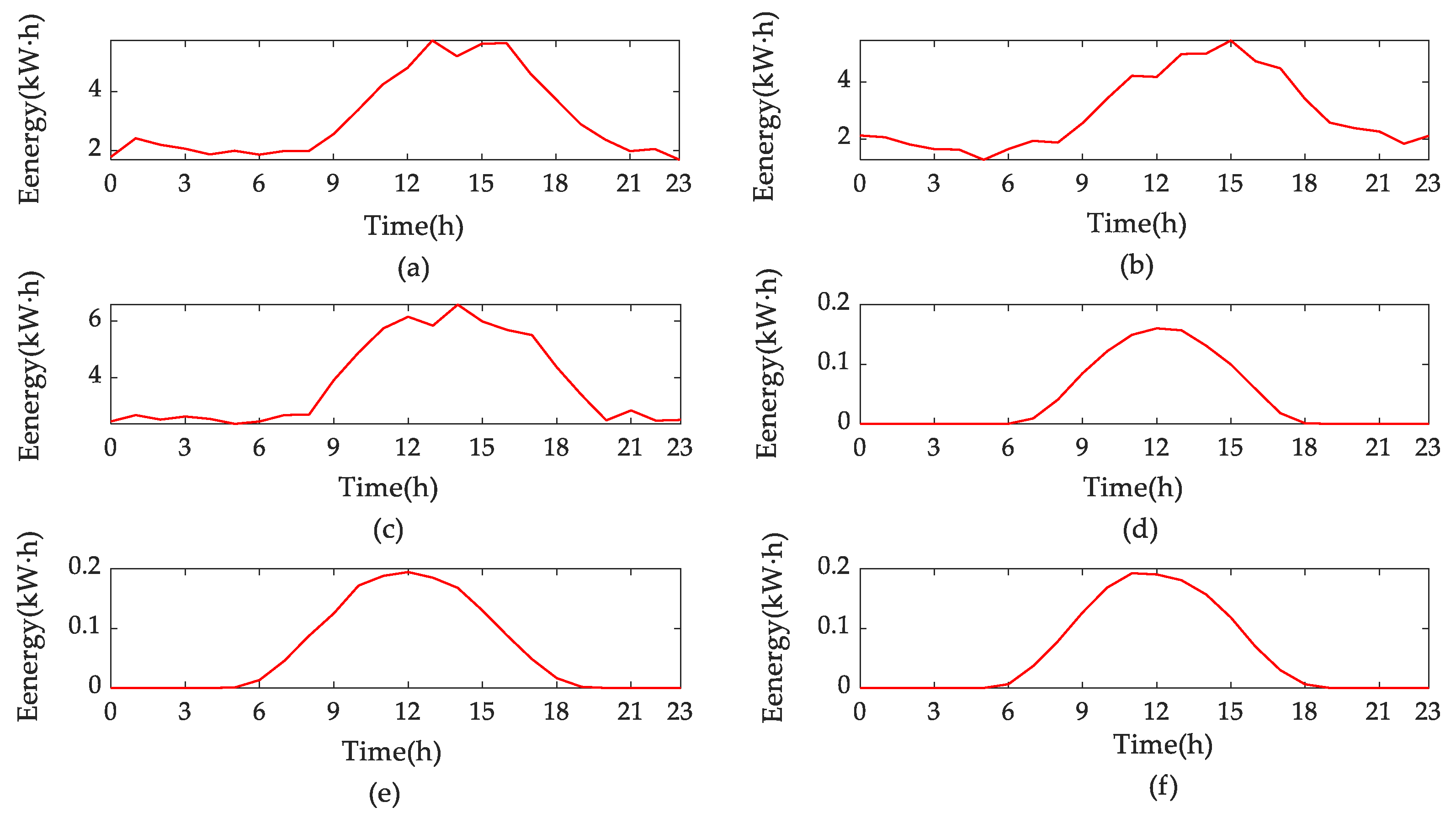

5.1.2. The Power Output Analysis of Uncontrollable Unit

5.2. Optimization Allocation of the System

5.2.1. Algorithm Analysis

5.2.2. Model Solution

5.3. Evaluation of the System

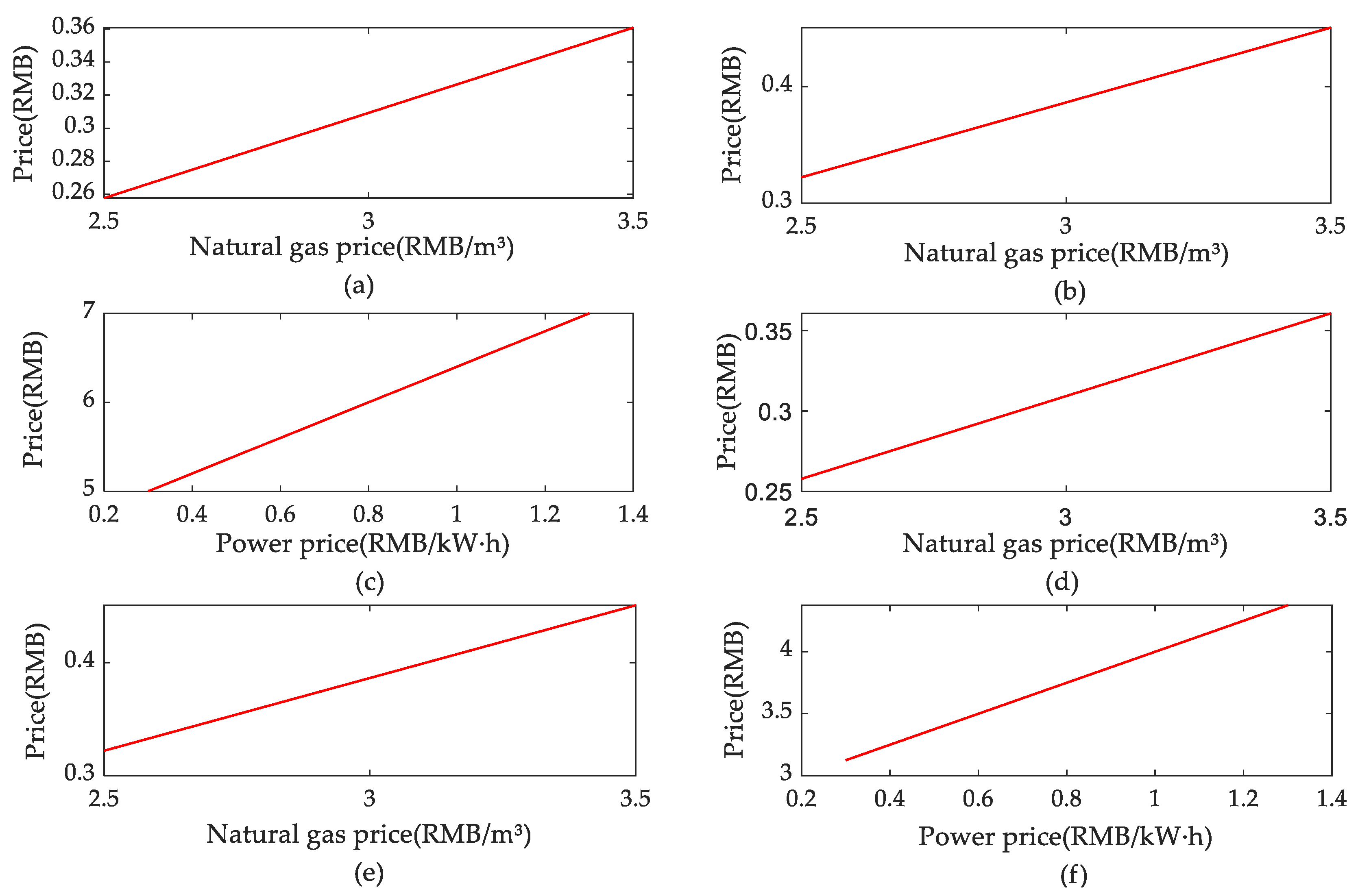

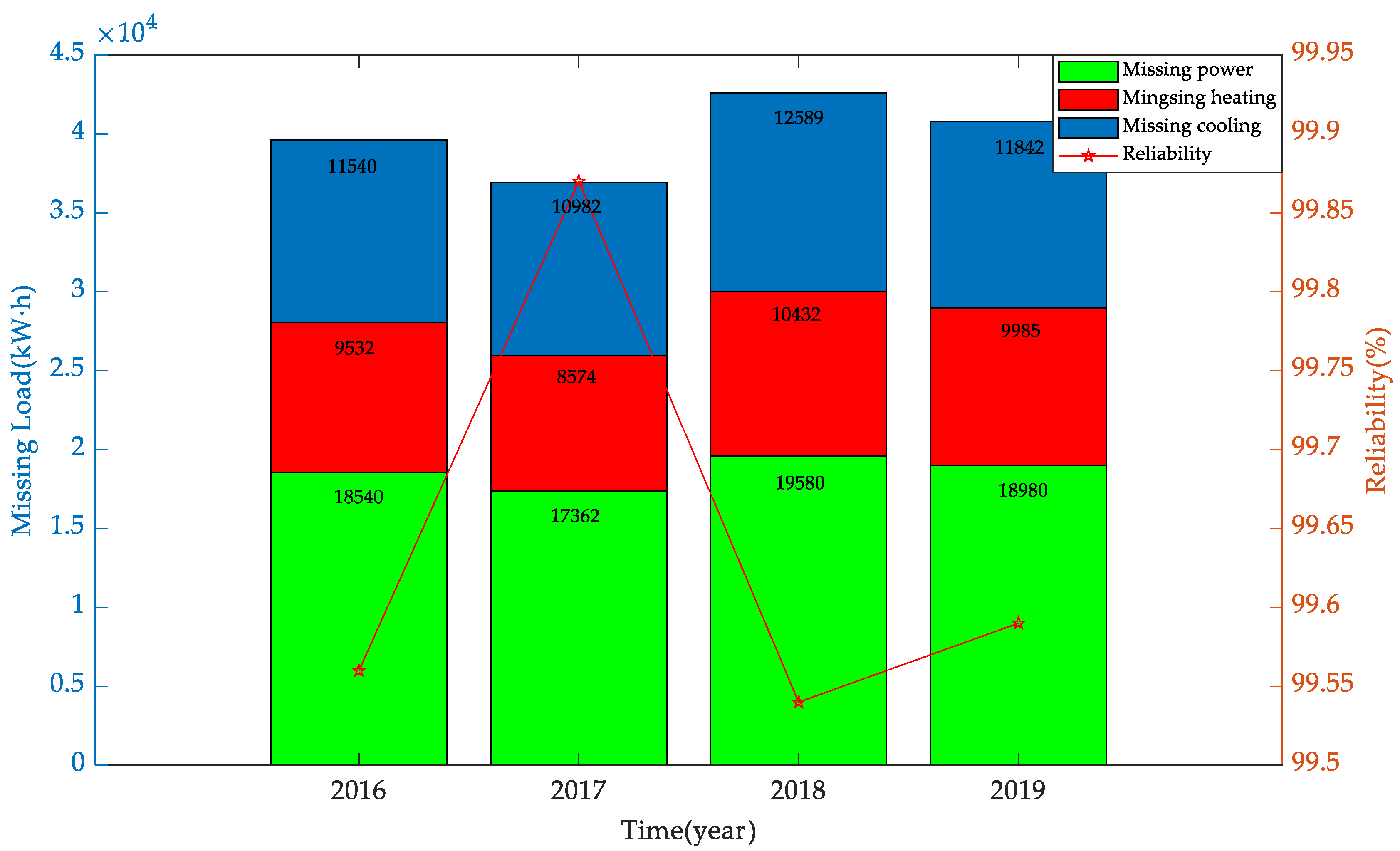

5.3.1. Evaluating Reliability of the System

5.3.2. Evaluating the Economy Benefits of the System

5.3.3. Evaluating the System in Environmental Protection

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

References

- Li, Y.J.; Xia, Y. DES/CCHP: The best utilization mode of natural gas for China’s low carbon economy. Energy Policy 2013, 53, 477–483. [Google Scholar] [CrossRef]

- Cho, H.J.; Mago, P.D.; Luck, R.; Chamra, L.M. Evaluation of CCHP systems performance based on operational cost, primary energy consumption, and carbon dioxide emission by utilizing an optimal operation scheme. Appl. Energy 2009, 86, 2540–2549. [Google Scholar] [CrossRef]

- Gu, W.; Wu, Z.; Wang, R. Multi-objective optimization of combined heat and power microgrid considering pollutant emission. Dianli Xitong Zidonghue 2012, 36, 177–185. (In Chinese) [Google Scholar]

- Kuang, J.Y.; Zhang, C.H.; Li, F.; Sun, B. Dynamic Optimization of Combined Cooling, Heating, and Power Systems with Energy Storage Units. Energies 2018, 11, 2288. [Google Scholar] [CrossRef]

- Wang, J.; Dai, W.; Zhou, Y.X. Multi-types of distributed generators planning based on free search algorithm. In Proceedings of the 5th IEEE International Conference on Electric Utility Deregulation, Restructuring and Power Technologies, DRPT 2015, Changsha, China, 26–29 November 2015. [Google Scholar]

- Wang, C.S.; Hong, B.W.; Guo, L.; Zhang, D.J.; Liu, W.J. A general modeling method for optimal dispatch of combined cooling, heating and power microgrid. Zhongguo Dianji Gongcheng Xuebao 2013, 33, 26–33. (In Chinese) [Google Scholar]

- Wang, L.; Lu, J.; Wang, W.; Ding, J. Feasibility analysis of CCHP system with thermal energy storage driven by micro turbine. Energy Procedia 2017, 105, 2396–2402. [Google Scholar] [CrossRef]

- Shao, Y.Y.; Chen, B.M.; Xiao, H.M.; Qin, F.G.F. Discussion on Performance Evaluation Method of Distributed Combined Cooling, Heating, and Power System. J. Therm. Sci. 2019, 28, 1212–1220. [Google Scholar] [CrossRef]

- Hu, R.; Ma, J.; Li, Z.K.; Lu, Q.; Zhang, D.H.; Qian, X. Optimal allocation and applicability analysis of distributed combined cooling-heating-power system. Dianwang Jishu 2017, 41, 418–425. (In Chinese) [Google Scholar]

- Ma, X.Y.; Wu, Y.W.; Fang, H.L.; Sun, Y.Z. Optimal sizing of hybrid solar-wind distributed generation in an islanded microgrid using improved bacterial foraging algorithm. Zhongguo Dianji Gongcheng Xuebao 2011, 31, 17–25. (In Chinese) [Google Scholar]

- Li, M.; Mu, H.L.; Li, N.; Ma, B.Y. Optimal design and operation strategy for integrated evaluation of CCHP (combined cooling heating and power) system. Energy 2016, 99, 202–220. [Google Scholar] [CrossRef]

- Wang, J.J.; Jing, Y.Y.; Zhang, C.F. Optimization of capacity and operation for CCHP system by genetic algorithm. Appl. Energy 2010, 87, 1325–1335. [Google Scholar] [CrossRef]

- Wang, J.J.; Zhai, Z.Q.; Jing, Y.Y.; Zhang, C.F. Particle swarm optimization for redundant building cooling heating and power system. Appl. Energy 2010, 87, 3668–3679. [Google Scholar] [CrossRef]

- Liu, Y.; Luo, Y. Optimal design of distributed CCHP system. In Proceedings of the 2011 International Conference on Transportation, Mechanical, and Electrical Engineering, TMEE 2011, Changchun, China, 16–18 December 2011. [Google Scholar]

- Huang, H.; Liang, D.P.; Tong, Z. Integrated energy micro-grid planning using electricity, heating and cooling demands. Energies 2018, 11, 2810. [Google Scholar] [CrossRef]

- Luo, X.J.; Fong, K.F. Development of multi-supply-multi-demand control strategy for combined cooling, heating and power system primed with solid oxide fuel cell-gas turbine. Energy Convers. Manag. 2017, 154, 538–561. [Google Scholar] [CrossRef]

- Wang, J.; Ye, X.; Li, Y.; Gui, X.Q.; Guo, H.L. An energy efficiency evaluation method of distributed CCHP system based on attribute theory for optimal investment strategy. Energy Procedia 2018, 152, 95–100. [Google Scholar] [CrossRef]

- Singh, S.; Singh, M.; Kaushik, S.C. Feasibility study of an islanded microgrid in rural area consisting of PV, wind, biomass and battery energy storage system. Energy Convers. Manag. 2016, 128, 178–190. [Google Scholar] [CrossRef]

- Lorestani, A.; Gharehpetian, G.B.; Nazari, M.H. Optimal sizing and techno-economic analysis of energy- and cost-efficient standalone multi-carrier microgrid. Energy 2019, 178, 751–764. [Google Scholar] [CrossRef]

- Huicochea, A.; Rivera, W.; Gutiérrez-Urueta, G.; Bruno, J.C.; Coronas, A. Thermodynamic analysis of a trigeneration system consisting of a micro gas turbine and a double effect absorption chiller. Appl. Therm. Eng. 2011, 31, 3347–3353. [Google Scholar] [CrossRef]

- Dong, X.F.; Quan, C.; Jiang, T. Optimal planning of integrated energy systems based on coupled CCHP. Energies 2018, 11, 2621. [Google Scholar] [CrossRef]

- Wang, J.J.; Fu, C.; Yang, K.; Zhang, X.T.; Shi, G.H.; Zhai, J. Reliability and availability analysis of redundant BCHP (building cooling, heating and power) system. Energy 2013, 61, 531–540. [Google Scholar] [CrossRef]

- Lai, C.S.; Jia, Y.; Xu, Z.; Lai, L.L.; Li, X.; Cao, J.; McCulloch, M.D. Levelized cost of electricity for photovoltaic/biogas power plant hybrid system with electrical energy storage degradation costs. Energy Convers. Manag. 2017, 153, 34–47. [Google Scholar] [CrossRef]

- Li, Y.; Liang, W.H.; Tan, R.S. Optimal design of installation capacity and operation strategy for distributed energy system. Appl. Therm. Eng. 2017, 125, 756–766. [Google Scholar] [CrossRef]

- Luo, Z.; Yang, S.; Xie, N.; Xie, W.W.; Liu, J.X.; Souley Agbodjan, Y.; Liu, Z.Q. Multi-objective capacity optimization of a distributed energy system considering economy, environment and energy. Energy Convers. Manag. 2019, 200, 112081. [Google Scholar] [CrossRef]

- Saman, S.; Mohamad, H.M.; Mehri, M. Modeling a novel CCHP system including solar and wind renewable energy resources and sizing by a CC-MOPSO algorithm. Appl. Energy 2016, 184, 375–395. [Google Scholar]

- Lee, K.Y.; Park, J.B. Application of particle swarm optimization to economic dispatch problem: Advantages and disadvantages. In Proceedings of the 2006 IEEE PES Power Systems Conference and Exposition, PSCE 2006, Atlanta, GA, USA, 29 October–1 November 2006. [Google Scholar]

- Zhan, Z.H.; Zhang, J.; Li, Y.; Chung, H.S.H. Adaptive Particle Swarm Optimization. IEEE Trans. Syst. Man Cybern. Part B Cybern. 2009, 39, 1362–1381. [Google Scholar] [CrossRef]

| Name of the Energy Output Device | Installed Capacity (kW·h) |

|---|---|

| SP | 1140.4 |

| WT | 980 |

| GT | 325 |

| DLB | 260 |

| ER | 283 |

| EB | 268.7 |

| Battery | 1200 |

| Heating energy storage tank | 2000 |

| Cooling storage tank | 4500 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, L.; Wang, X.; Jiang, B. Multi-Objective Optimal Configuration of the CCHP System. Processes 2020, 8, 351. https://doi.org/10.3390/pr8030351

Zheng L, Wang X, Jiang B. Multi-Objective Optimal Configuration of the CCHP System. Processes. 2020; 8(3):351. https://doi.org/10.3390/pr8030351

Chicago/Turabian StyleZheng, Liukang, Xiaoli Wang, and Baochen Jiang. 2020. "Multi-Objective Optimal Configuration of the CCHP System" Processes 8, no. 3: 351. https://doi.org/10.3390/pr8030351

APA StyleZheng, L., Wang, X., & Jiang, B. (2020). Multi-Objective Optimal Configuration of the CCHP System. Processes, 8(3), 351. https://doi.org/10.3390/pr8030351