Ultrasonic-Assisted Extraction (UAE) Process on Thymol Concentration from Plectranthus Amboinicus Leaves: Kinetic Modeling and Optimization

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample preparation

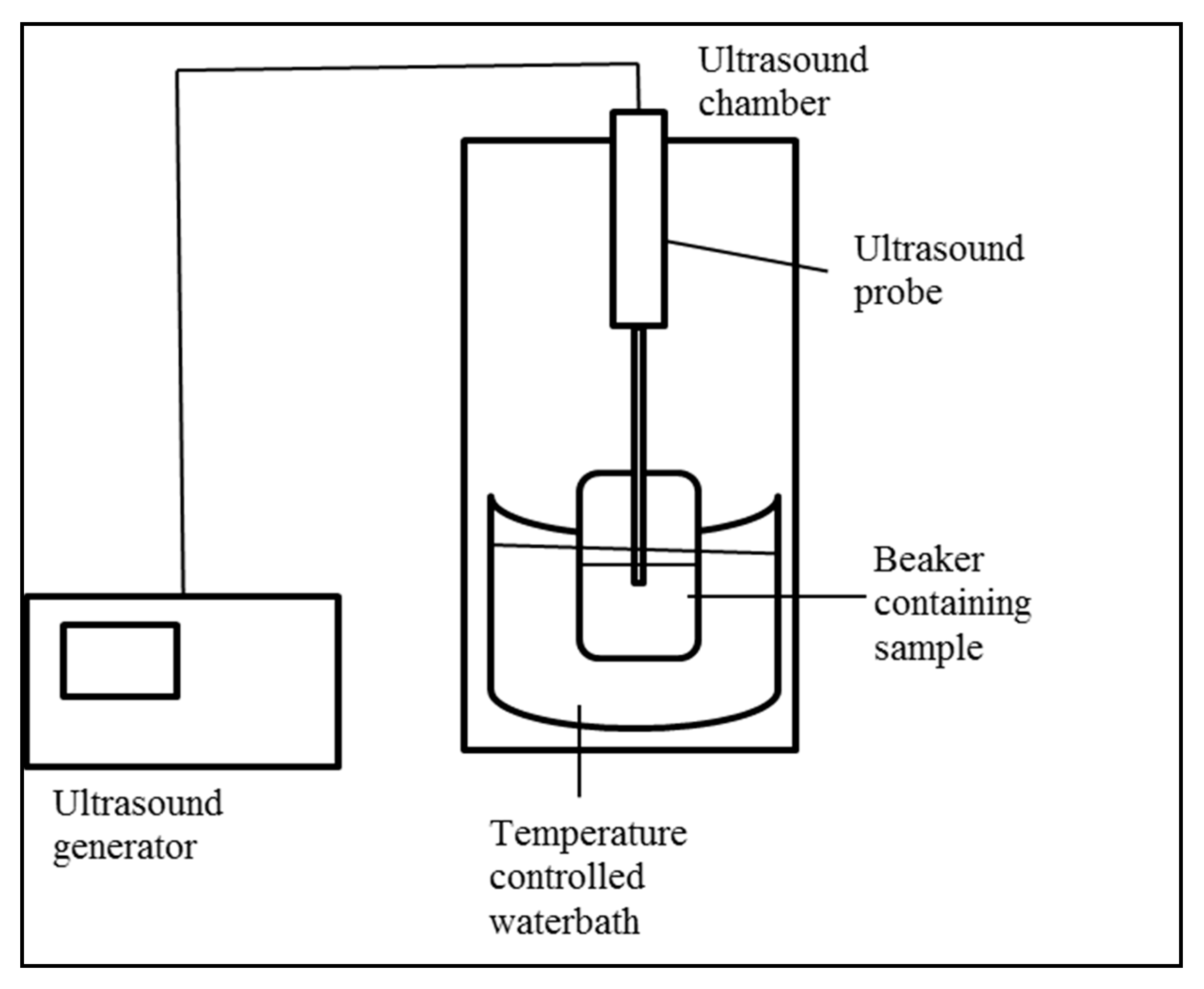

2.2. Ultrasonic-Assisted Extraction

2.3. Extraction Kinetics Studies

2.4. Extraction Kinetic Models

2.4.1. Pseudo-First-Order Model

2.4.2. Peleg Model

2.4.3. Power Model

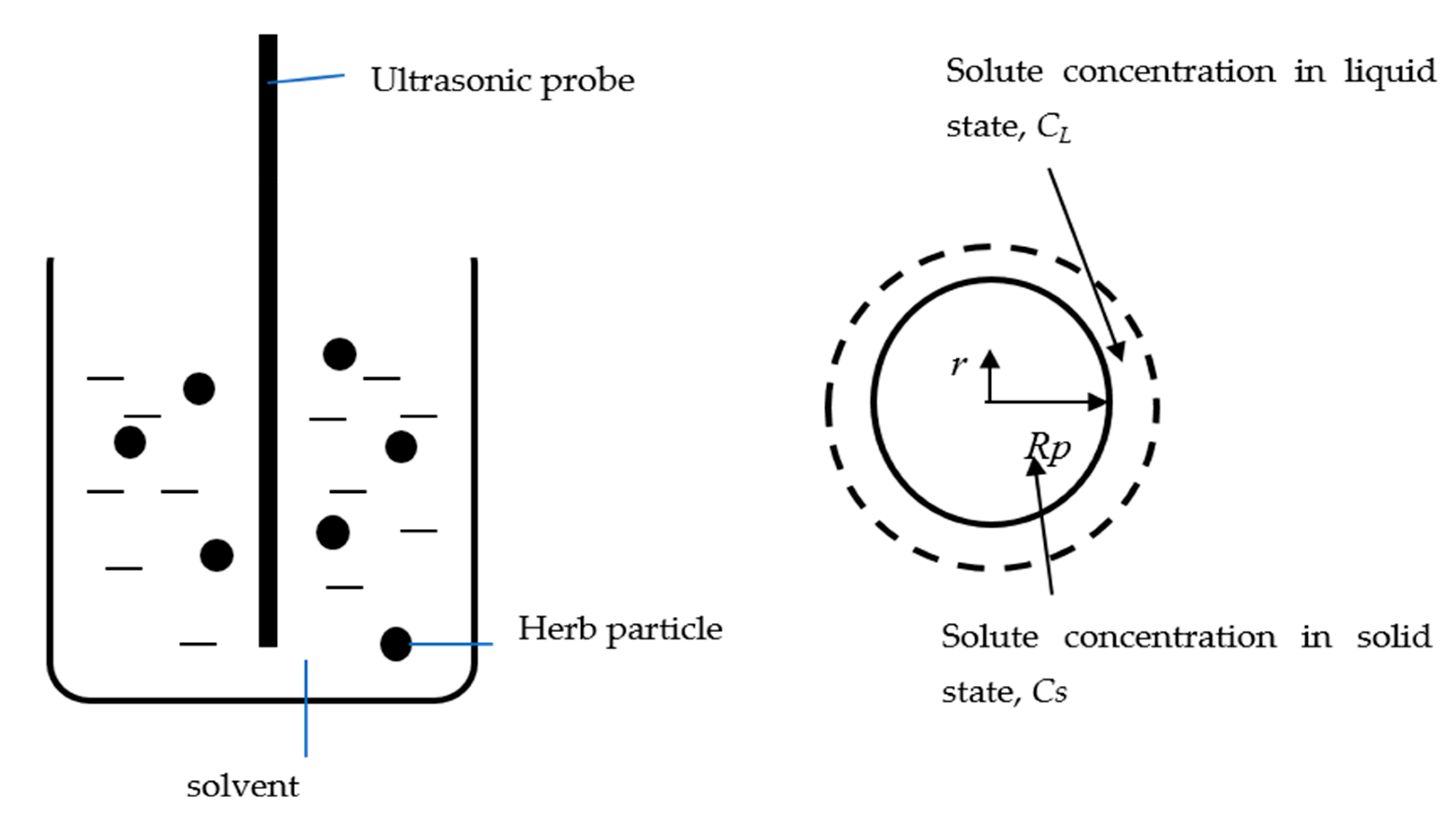

2.4.4. Equilibrium-Dependent Solid–Liquid Extraction (EDSLE) Model

- The liquid phase is initially free of solute.

- The solute concentration within the solid is uniform throughout the process.

- The liquid phase is well mixed.

- The system is at a constant temperature.

2.4.5. Solution of Mathematical Models

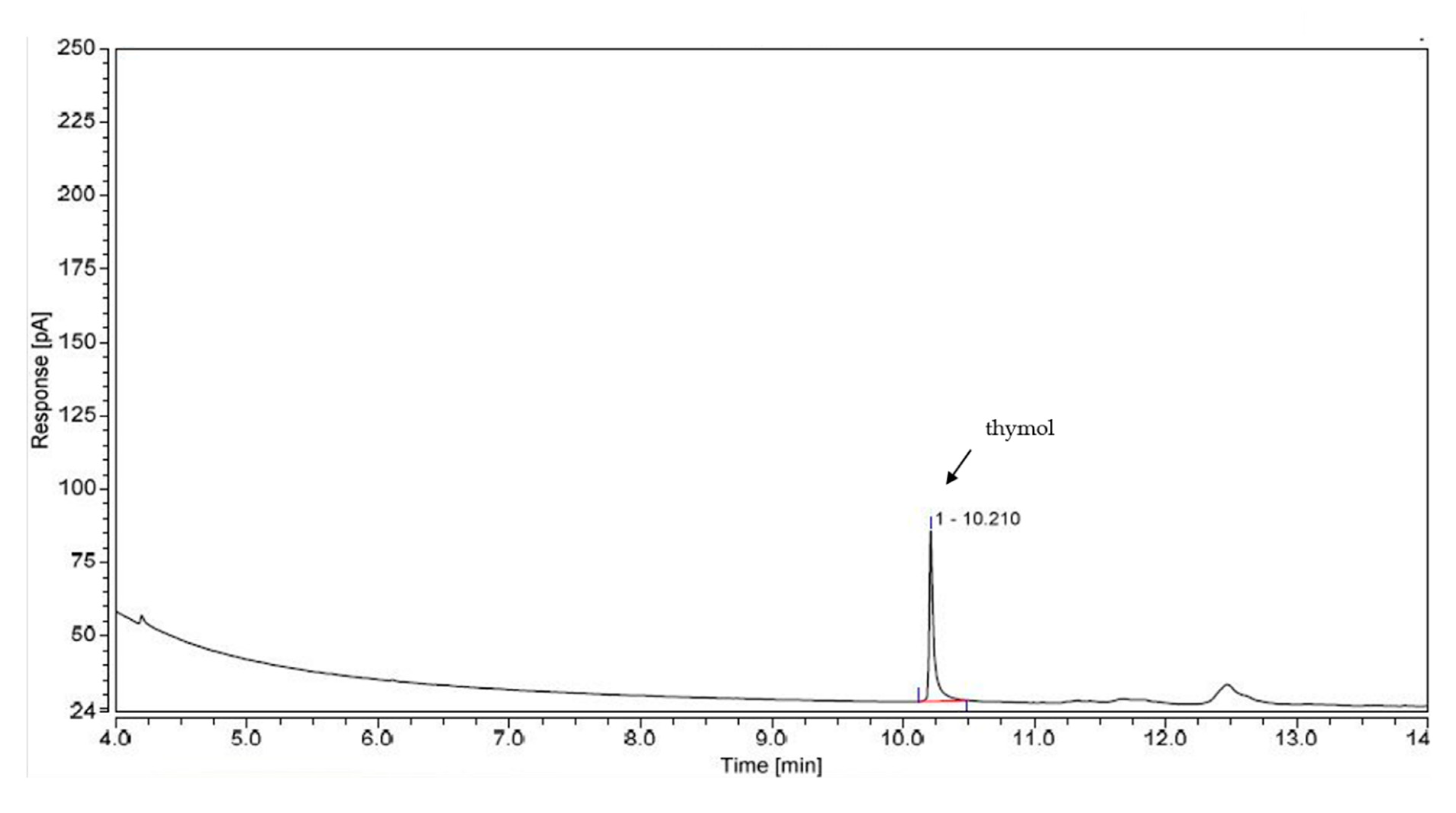

2.5. Gas Chromatography (GC)

2.6. Optimization of Concentration of Thymol from Extraction of P. amboinicus

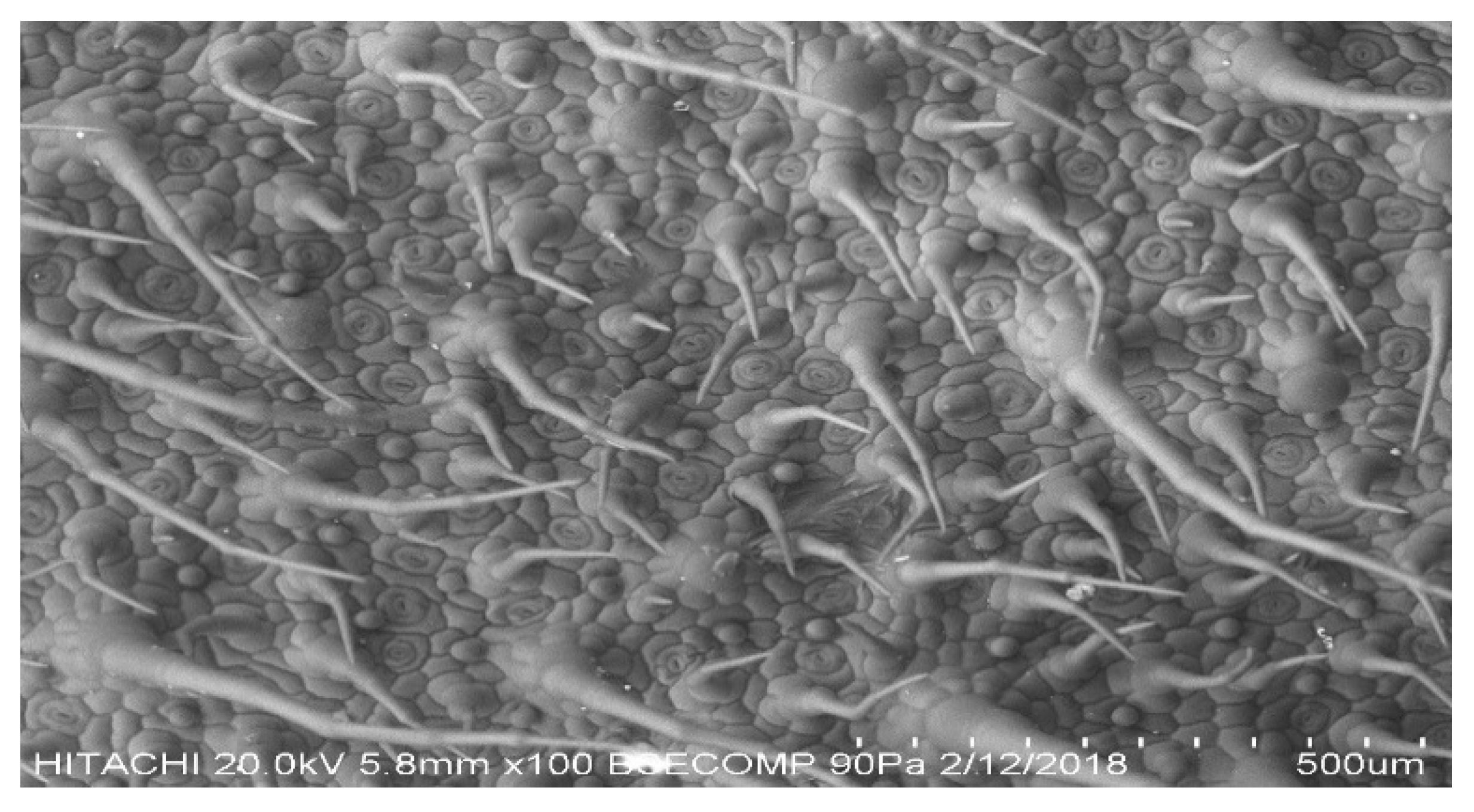

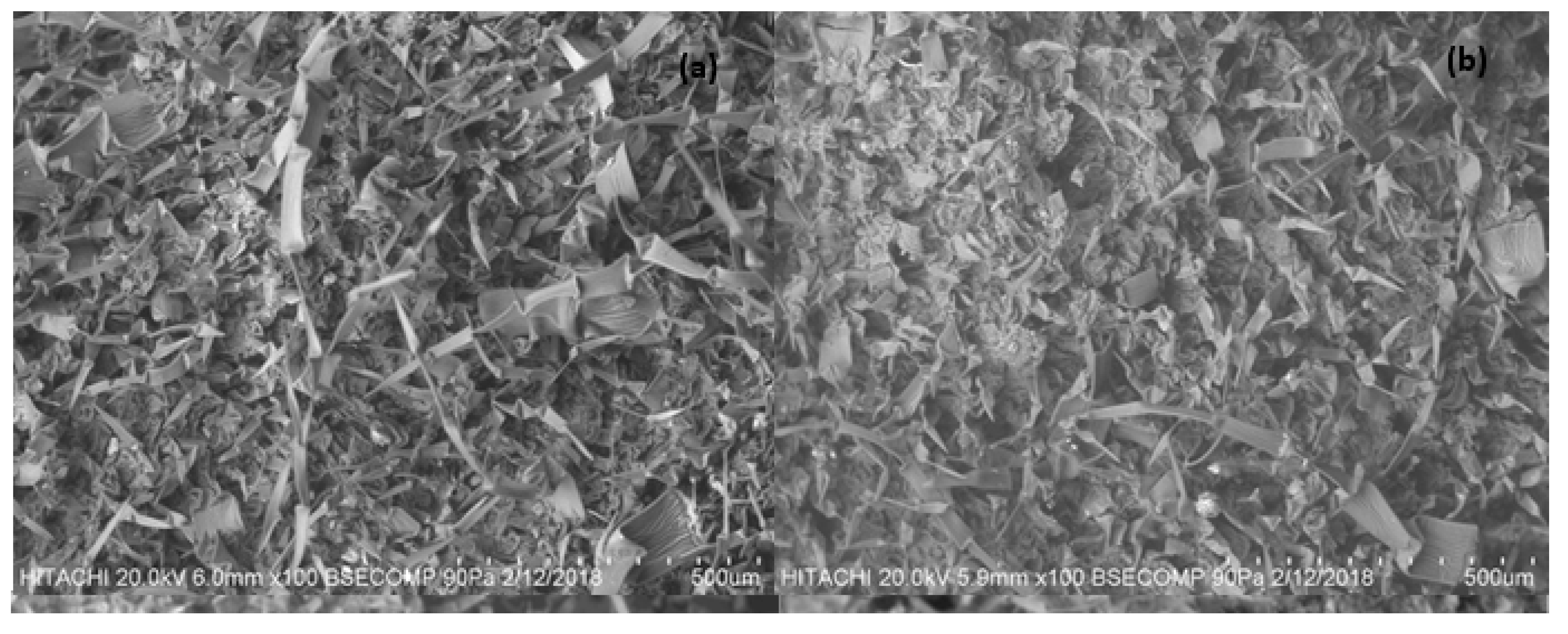

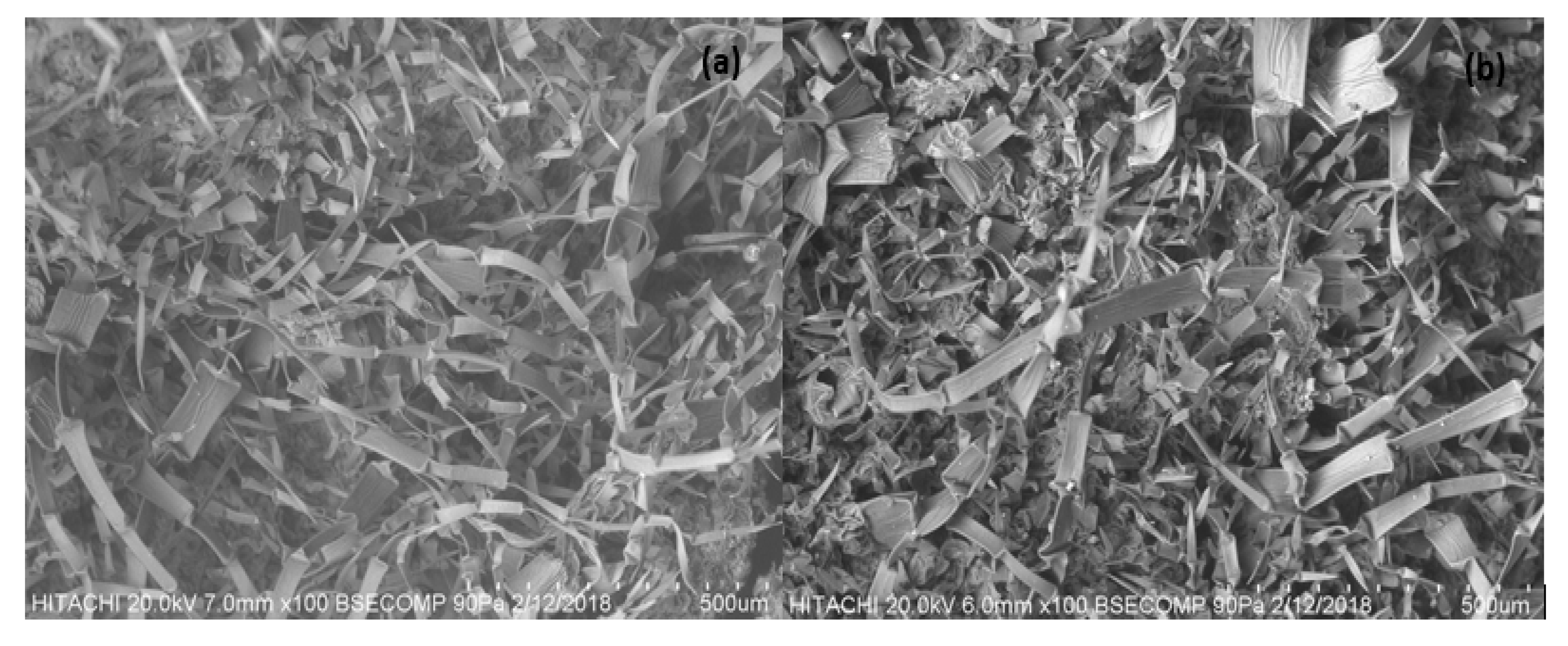

2.7. Leaf Surface Structure: Morphological and Roughness Analysis

3. Results and Discussion

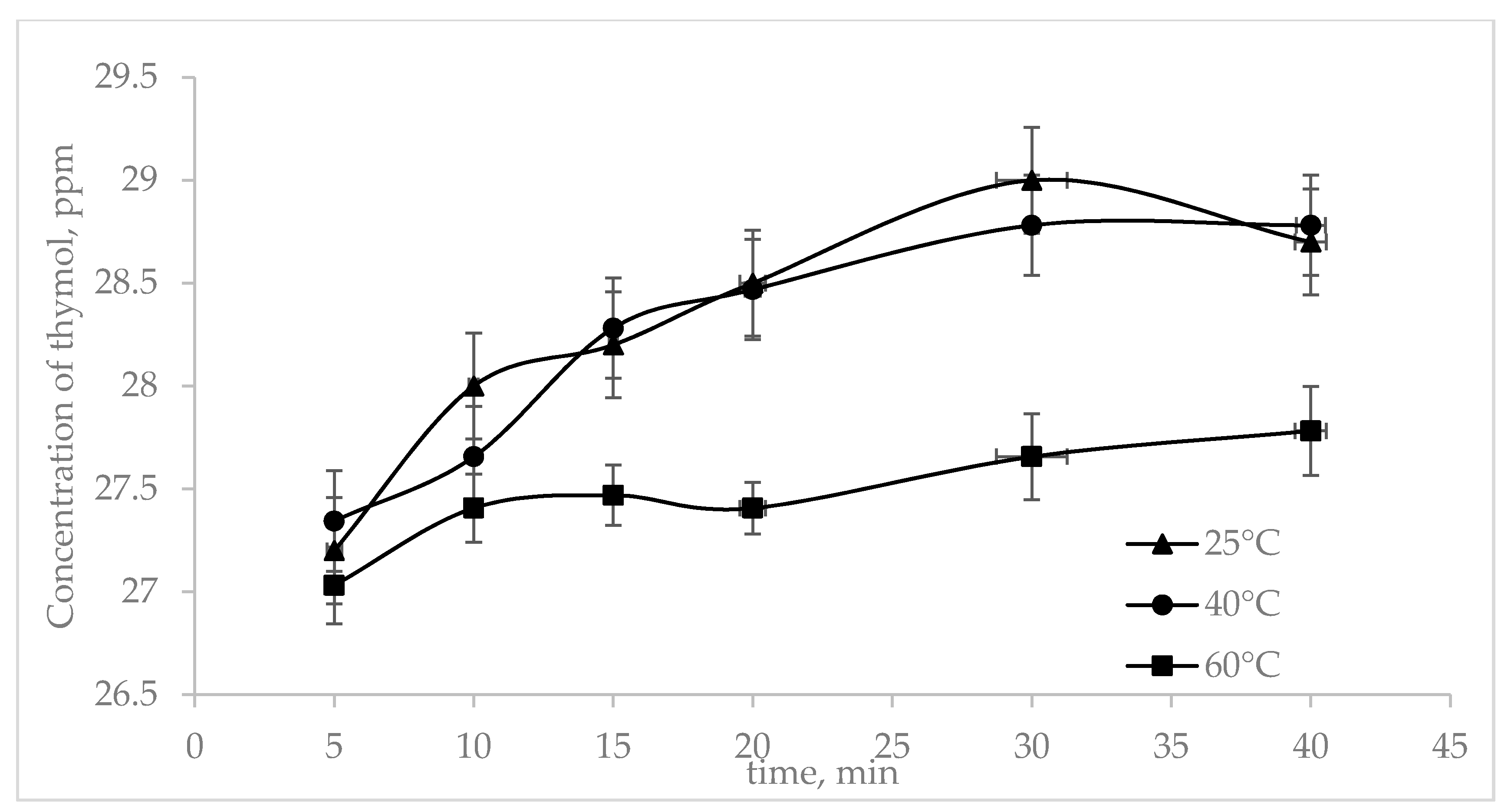

3.1. Kinetic Study of Thymol Extraction

3.2. Extraction Kinetic Models

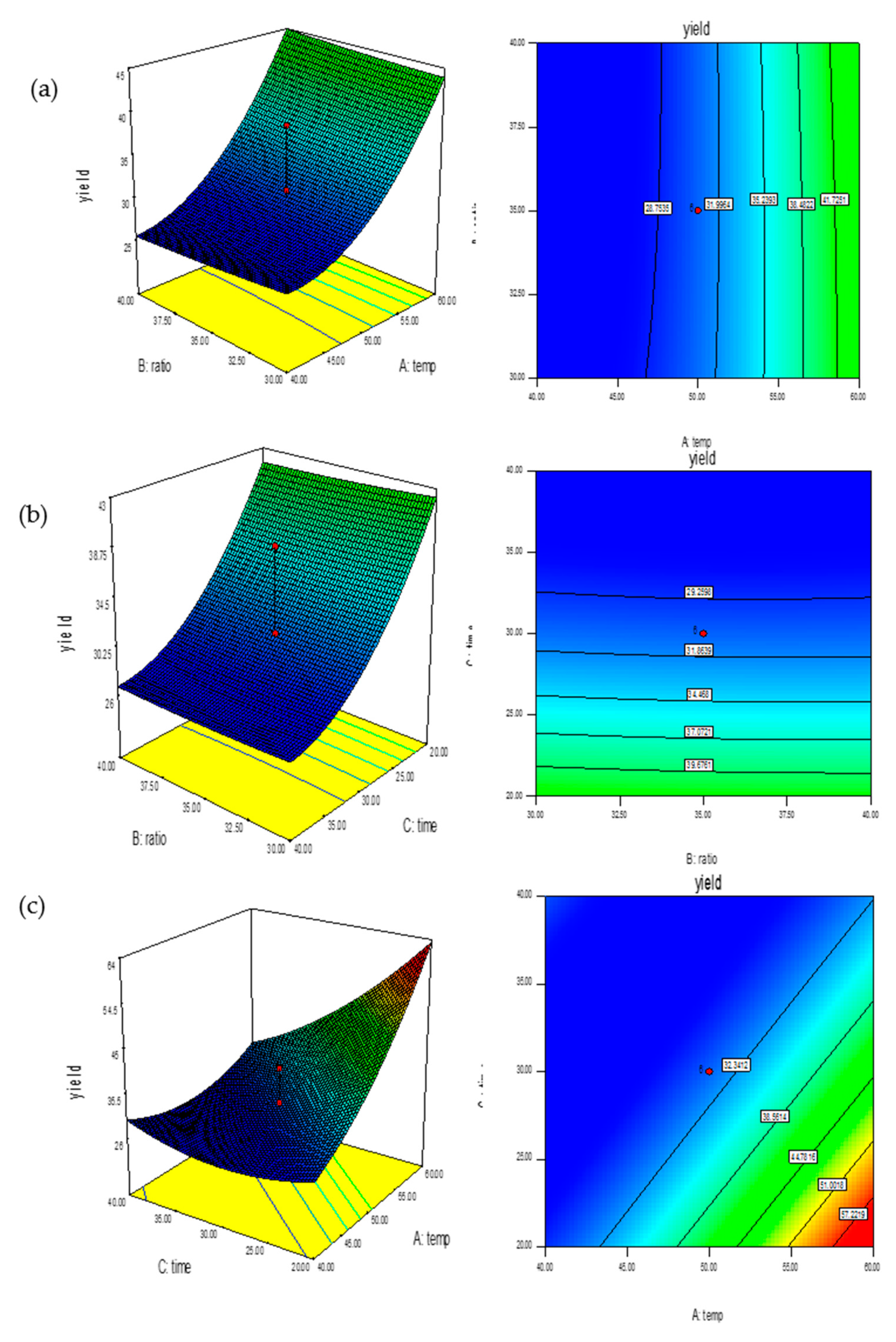

3.3. Optimization of UAE Parameter Using CCD

(B)(C) + 4.44 (A2) + 0.11 (B2) + 5.51(C2),

3.4. Validation of Optimization Parameter

3.5. Mechanism of Thymol Extraction Using UAE

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Swamy, K.M.; Pokharen, N.; Dahal, S. Phytochemical and antimicrobial studies of leaf extract of Euphorbia neriifolia. J. Med. Plants Res. 2011, 5, 5785–5788. [Google Scholar]

- De Lira Mota, K.S.; De Oliveira Pereira, F.; De Oliveira, W.A.; Lima, I.O.; De Oliveira Lima, E. Antifungal activity of Thymus vulgaris L. essential oil and its constituent phytochemicals against rhizopus oryzae: Interaction with ergosterol. Molecules 2012, 17, 14418–14433. [Google Scholar] [CrossRef] [PubMed]

- Asiimwe, S.; Karlsson, A.B.; Azeem, M.; Mugisha, K.M.; Namutebi, A.; Gakunga, N.J. Chemical composition and toxicological evaluation of the aqueous leaf extracts of Plectranthus amboinicus Lour. Spreng. Int. J. Pharm. Sci. Invent. 2014, 3, 19–27. [Google Scholar]

- Sathasivam, A.; Elangovan, K. Evaluation of phytochemical and antibacterial activity of Plectranthus Amboinicus. Int. J. Res. Ayurveda Pharm. 2011, 2, 292–294. [Google Scholar]

- Azwanida, N. A Review on the extraction methods use in medicinal plants, principle, strength and limitation. Med. Aromat. Plants 2015, 4, 3–8. [Google Scholar]

- Mnayer, D.; Fabiano-Tixier, A.S.; Petitcolas, E.; Ruiz, K.; Hamieh, T.; Chemat, F. Extraction of green absolute from thyme using ultrasound and sunflower oil. Resour. -Effic. Technol. 2017, 3, 12–21. [Google Scholar] [CrossRef]

- Roldán-Gutiérrez, J.M.; Ruiz-Jiménez, J.; De Castro, M.L. Ultrasound-assisted dynamic extraction of valuable compounds from aromatic plants and flowers as compared with steam distillation and superheated liquid extraction. Talanta 2008, 75, 1369–1375. [Google Scholar] [CrossRef]

- Aghamohammadi, A.; Azadbakht, M.; Hosseinimehr, S.J. Quantification of thymol content in different extracts of Zataria multiflora by HPLC method. Pharm. Biomed. Res. 2016, 2, 8–13. [Google Scholar] [CrossRef][Green Version]

- Gujar, J.G.; Wagh, S.J.; Gaikar, V.G. Experimental and modeling studies on microwave-assisted extraction of thymol from seeds of Trachyspermum ammi (TA). Sep. Purif. Technol. 2010, 70, 257–264. [Google Scholar] [CrossRef]

- Malik, N.R. Optimization of process parameters in extraction of Thyme oil using response surface methodology (RSM). Sci. Eng. Technol. 2016, 16, 248–258. [Google Scholar]

- Villanueva Bermejo, D.; Angelov, I.; Vicente, G.; Stateva, R.P.; Rodriguez García-Risco, M.; Reglero, G.; Fornari, T. Extraction of thymol from different varieties of thyme plants using green solvents. J. Sci. Food Agric. 2015, 95, 2901–2907. [Google Scholar] [CrossRef] [PubMed]

- Basch, E.; Ulbricht, C. Thyme (Thymus vulgaris L.), Thymol thyme (Thymus vulgaris L.). Thymol. J. Herb. Pharm. 2014, 4, 49–67. [Google Scholar] [CrossRef]

- Senthilkumar, A.; Venkatesalu, V. Chemical composition and larvicidal activity of the essential oil of Plectranthus amboinicus (Lour.) Spreng against Anopheles stephensi: A malarial vector mosquito. Parasitol. Res. 2010, 107, 1275–1278. [Google Scholar] [CrossRef] [PubMed]

- Chuyen, H.V.; Roach, P.D.; Golding, J.B.; Parks, S.E.; Nguyen, M.H. Ultrasound-Assisted Extraction of GAC Peel: An Optimization of Extraction Conditions for Recovering Carotenoids and Antioxidant Capacity. Processes 2020, 8, 8. [Google Scholar] [CrossRef]

- Kuok Loong, N.G.; Wahida, P.F.; Chong, C.H. Optimisation of extraction of thymol from Plectranthus amboinicus leaves using response surface methodology. J. Eng. Sci. Technol. 2014, 2013, 79–88. [Google Scholar]

- Veljkovi, V.B.; Milenovi, D.M. Extraction of resinoids from St. John’s wort (Hypericum perforatum L). II. Modeling of extraction kinetics. Hem. Ind 2002, 56, 60–67. [Google Scholar] [CrossRef]

- Sovova, H. Rate of the vegetable oil extraction with supercritical CO2 -I. Modeling of extraction curves. Chem. Eng. Sci. 1994, 49, 409–414. [Google Scholar] [CrossRef]

- Dias, A.L.B.; Sergio, C.S.S.; Santos, P.; Barbero, G.F.; Rezende, C.A.; Martinez, J. Ultrasound-assisted extraction of bioactive compounds from dedo de moça pepper (Capsicum baccatum L.): Effects on the vegetable matrix and mathematical modeling. J. Food Eng. 2017, 198, 36–44. [Google Scholar] [CrossRef]

- Peleg, M. An empirical model for the description of moisture sorption curves. J. Food Sci. 1988, 53, 1212–1217. [Google Scholar] [CrossRef]

- Tuˇsek, A.J.; Benkovi´c, M.; Cvitanovi´c, A.B.; Valinger, D.; Jurina, T.; Kljusuri´c, J.G. Kinetics and thermodynamics of the solid-liquid extraction process of total polyphenols, antioxidants and extraction yield from Asteraceae plants. Ind. Crop. Prod. 2016, 91, 205–214. [Google Scholar]

- Dong, Z.; Gu, F.J.; Xu, F.; Wang, Q. Comparison of four kinds of extraction techniques and kinetics of microwave-assisted extraction of vanillin from Vanilla planifolia Andrews. Food Chem. 2014, 149, 54–61. [Google Scholar] [CrossRef] [PubMed]

- Pin, K.Y.; Chuah, A.L.; Rashih, A.A.; Rasadah, M.A.; Law, C.L.; Choong, T.S.Y. Solid-liquid extraction of betel leaves (Piper betle L.). J. Food Process Eng. 2009, 34, 549–565. [Google Scholar] [CrossRef]

- Kuo, C.H.; Chen, B.Y.; Liu, Y.C.; Chang, C.M.J.; Deng, T.S.; Chen, J.H.; Shieh, C.J. Optimized ultrasound-assisted extraction of phenolic compounds from Polygonum cuspidatum. Molecules 2014, 19, 67–77. [Google Scholar] [CrossRef] [PubMed]

- Tekin, K.; Akalın, M.K.; Şeker, M.G. Ultrasound bath-assisted extraction of essential oils from clove using central composite design. Ind. Crop. Prod. 2015, 77, 954–960. [Google Scholar] [CrossRef]

- Medina-Torres, N.; Ayora-Talavera, T.; Espinosa-Andrews, H.; Sánchez-Contreras, A.; Pacheco, N. Ultrasound assisted extraction for the recovery of phenolic compounds from vegetable sources. Agronomy 2017, 7, 47. [Google Scholar] [CrossRef]

- Esclapez, M.D.; García-Pérez, J.V.; Mulet, A.; Cárcel, J.A. Ultrasound-assisted extraction of natural products. Food Eng. Rev. 2011, 3, 108. [Google Scholar] [CrossRef]

- Kowalski, R.; Wawrzykowski, J. Effect of ultrasound-assisted maceration on the quality of oil from the leaves of thyme Thymus vulgaris L. Flavour Fragr. J. 2009, 24, 69–74. [Google Scholar] [CrossRef]

- Tabaraki, R.; Nateghi, A. Optimization of ultrasonic-assisted extraction of natural antioxidants from rice bran using response surface methodology. Ultrason. Sonochem. 2011, 18, 1279–1286. [Google Scholar] [CrossRef]

- Novak, J.; Lukas, B.; Franz, C. Temperature influences thymol and carvacrol differentially in Origanum spp. (Lamiaceae). J. Essent. Oil Res. 2010, 22, 412–415. [Google Scholar] [CrossRef]

- Garcia-Vaquero, M.; Rajauria, G.; Tiwari, B.; Sweeney, T.; O’Doherty, J. Extraction and yield optimisation of fucose, glucans and associated antioxidant activities from Laminaria digitata by applying response surface methodology to high intensity ultrasound-assisted extraction. Mar. Drugs 2018, 16, 257. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Sicaire, A.G.; Meullemiestre, A.; Fabiano-Tixier, A.S.; Abert-Vian, M. Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef] [PubMed]

- Panda, D.; Manickam, S. Cavitation technology—The future of greener extraction method: A review on the extraction of natural products and process intensification mechanism and perspectives. Appl. Sci. 2019, 9, 766. [Google Scholar] [CrossRef]

- Azmin, S.N.H.M.; Manan, Z.A.; Alwi, S.R.W.; Chua, L.S.; Mustaffa, A.A.; Yunus, N.A. Herbal processing and extraction technologies. Sep. Puification Rev. 2016, 45, 305–320. [Google Scholar] [CrossRef]

| Factor | Name | Low Actual | High Actual | Low Coded | High Coded | Mean | References |

|---|---|---|---|---|---|---|---|

| A | Temperature, °C | 40.00 | 60.00 | −1.00 | 1.00 | 50.00 | [23,24] |

| B | Solid to solvent ratio, g/mL | 1:30.00 | 1:40.00 | −1.00 | 1.00 | 35.00 | [9,15,25] |

| C | Time, min | 20.00 | 40.00 | −1.00 | 1.00 | 30.00 | [24,25,26,27] |

| Standard | Run | Temperature ( °C) | Solid to Solvent Ratio (g:mL) | Extraction Time (min) |

|---|---|---|---|---|

| 1 | 10 | 40 | 1:30 | 20 |

| 2 | 4 | 60 | 1:30 | 20 |

| 3 | 3 | 40 | 1:40 | 20 |

| 4 | 16 | 60 | 1:40 | 20 |

| 5 | 12 | 40 | 1:30 | 40 |

| 6 | 18 | 60 | 1:30 | 40 |

| 7 | 8 | 40 | 1:40 | 40 |

| 8 | 2 | 60 | 1:40 | 40 |

| 9 | 15 | 33.18 | 1:35 | 30 |

| 10 | 6 | 66.82 | 1:35 | 30 |

| 11 | 17 | 50 | 1:26.59 | 30 |

| 12 | 9 | 50 | 1:43.41 | 30 |

| 13 | 1 | 50 | 1:35 | 13.18 |

| 14 | 11 | 50 | 1:35 | 46.82 |

| 15 | 13 | 50 | 1:35 | 30 |

| 16 | 7 | 50 | 1:35 | 30 |

| 17 | 20 | 50 | 1:35 | 30 |

| 18 | 5 | 50 | 1:35 | 30 |

| 19 | 14 | 50 | 1:35 | 30 |

| 20 | 10 | 50 | 1:35 | 30 |

| Model | Temperature ( °C) | Constants | R2 |

|---|---|---|---|

| Pseudo-first-order | 25 | A1 = 28.383 A2 = 0.627 | 0.577 |

| 40 | A1 = 28.417 A2 = 0.644 | 0.551 | |

| 60 | A1 = 27.547 A2 = 0.793 | 0.669 | |

| Peleg’s | 25 | B1 = 0.012 B2 = 0.035 | 0.898 |

| 40 | B1 = 0.11 B2 = 0.035 | 0.885 | |

| 60 | B1 = 0.002 B2 = 0.0036 | 0.577 | |

| Power | 25 | C1 = 4.593 x 1044 C2 = 0.032 | 0.894 |

| 40 | C1 = 9.059 × 1043 C2 = 0.032 | 0.871 | |

| 60 | C1 = 5.398 × 1078 C2 = 0.018 | 0.601 | |

| EDSLE | 25 | K = 4.091 Ce = 28.501 | 0.999 |

| 40 | K = 2.669 Ce = 28.443 | 0.987 | |

| 60 | K = 2.541 Ce = 27.681 | 0.981 |

| Factor | Regression Coefficient | F-Value | p-Value | Remarks |

|---|---|---|---|---|

| Intercept | 30.74 | 12.31 | 0.0009 | Significant |

| A (temperature) | 9.09 | 59.24 | <0.0001 | Significant |

| B (ratio) | −0.14 | 0.012 | 0.9159 | Not significant |

| C (time) | −7.59 | 58.41 | <0.0001 | Significant |

| AB | 0.64 | 0.12 | 0.7386 | Not significant |

| AC | −8.04 | 26.68 | 0.0009 | Significant |

| BC | 0.16 | 7.13 × 10−3 | 0.9348 | Not significant |

| A2 | 4.49 | 16.54 | 0.0036 | Significant |

| B2 | 0.16 | 0.01 | 0.9222 | Not significant |

| C2 | 3.5 | 25.5 | 0.001 | Significant |

| Lack of fit | 1.06 | 0.4434 | Not significant | |

| R2 | 0.9326 | Adjusted R2 | 0.8568 |

| Temperature (°C) | Solid-to-Solvent Ratio (g:mL) | Extraction Time (min) | Yield (ppm) | Residual (%) | |

|---|---|---|---|---|---|

| Predicted | 55 | 1:35 | 23 | 50.00 | 6.8 ± 5.8 |

| Obtained | 55 | 1:35 | 23 | 46.60 |

| Parameter | Ra (µm) |

|---|---|

| 20 min | 110.654 |

| 40 min | 122.999 |

| 40 °C | 121.545 |

| 60 °C | 111.528 |

| Raw P. amboinicus leaves | 109.259 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zahari, N.A.A.R.; Chong, G.H.; Abdullah, L.C.; Chua, B.L. Ultrasonic-Assisted Extraction (UAE) Process on Thymol Concentration from Plectranthus Amboinicus Leaves: Kinetic Modeling and Optimization. Processes 2020, 8, 322. https://doi.org/10.3390/pr8030322

Zahari NAAR, Chong GH, Abdullah LC, Chua BL. Ultrasonic-Assisted Extraction (UAE) Process on Thymol Concentration from Plectranthus Amboinicus Leaves: Kinetic Modeling and Optimization. Processes. 2020; 8(3):322. https://doi.org/10.3390/pr8030322

Chicago/Turabian StyleZahari, Nur Amirah Asifa Raisha, Gun Hean Chong, Luqman Chuah Abdullah, and Bee Lin Chua. 2020. "Ultrasonic-Assisted Extraction (UAE) Process on Thymol Concentration from Plectranthus Amboinicus Leaves: Kinetic Modeling and Optimization" Processes 8, no. 3: 322. https://doi.org/10.3390/pr8030322

APA StyleZahari, N. A. A. R., Chong, G. H., Abdullah, L. C., & Chua, B. L. (2020). Ultrasonic-Assisted Extraction (UAE) Process on Thymol Concentration from Plectranthus Amboinicus Leaves: Kinetic Modeling and Optimization. Processes, 8(3), 322. https://doi.org/10.3390/pr8030322