Thermal–Hydraulic Performance in a Microchannel Heat Sink Equipped with Longitudinal Vortex Generators (LVGs) and Nanofluid

Abstract

1. Introduction

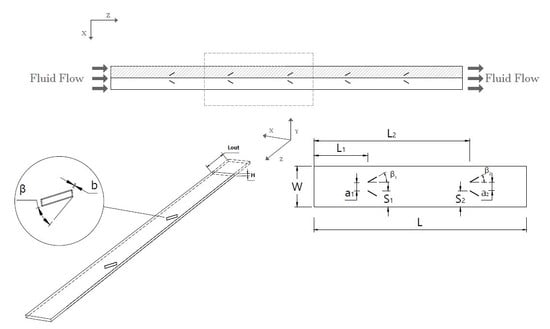

2. Model Description

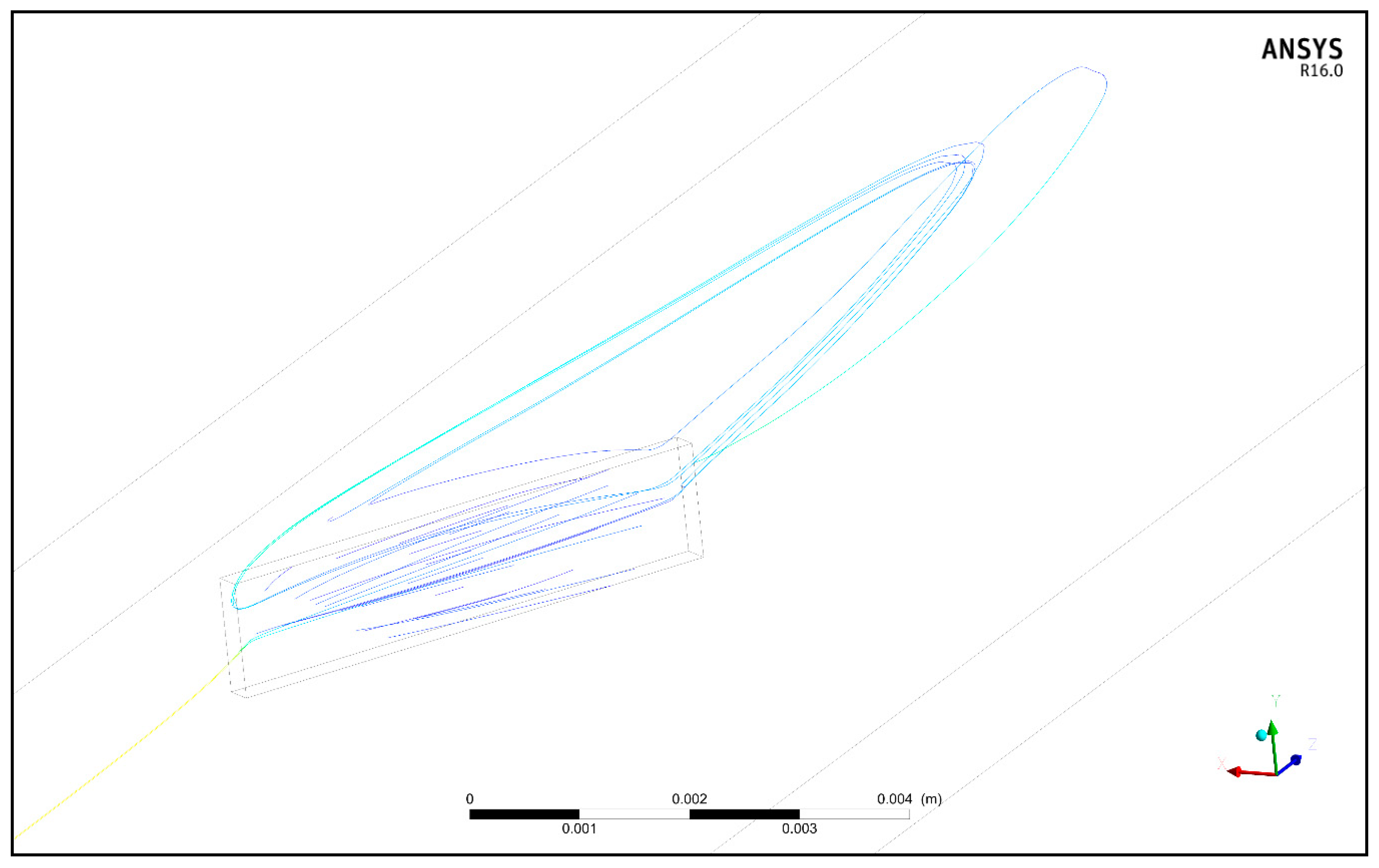

2.1. Physical and Computational Model

2.2. Mathematical Models, Boundary Conditions and Governing Equations

- The flow is considered as three dimensional, incompressible, hydraulically fully developed, steady and laminar due to the low velocity of the fluid and small pitch of the winglet.

- Working fluids were selected from different nanofluids with low volume-fraction and different sizes of Al2O3 or CuO nanoparticles dispersed in pure water, POA and ethylene glycol as base fluids.

- A single-phase model was used to effectively describe the heat transfer behavior of nanofluids and validated based on low concentration of nanoparticles with diameters smaller than 100 nm [47].

- LVG was generated based on the quasi-steady phenomenon as reported by Ferrouillat et al. [48].

- The coolant considered to be Newtonian and the thermophysical properties are dependent on the temperature, volume fraction and size of nanoparticles.

- At the inlet: the velocity is fully developed.

- At the outlet:

- No-slip boundary condition is applied at the top, bottom and side walls as

- Bottom and side walls are considered as adiabatic walls:

- At the top surface, a uniform temperature is applied as

- The conjugate heat transfer between LVG surfaces (solid) and nanofluid is applied aswhere n is a normal vector on the LVGs surface pointed out of the boundary.

- Symmetry plane

2.3. Numerical Procedures and Parameter Definitions

- Reynolds number:where

- j-Colburn factor:where Prandtl number

- Convective heat transfer coefficient:

- Total heat rate:

- Nusselt number:

- Heat transfer performance factor:

- Fanning friction factor:where

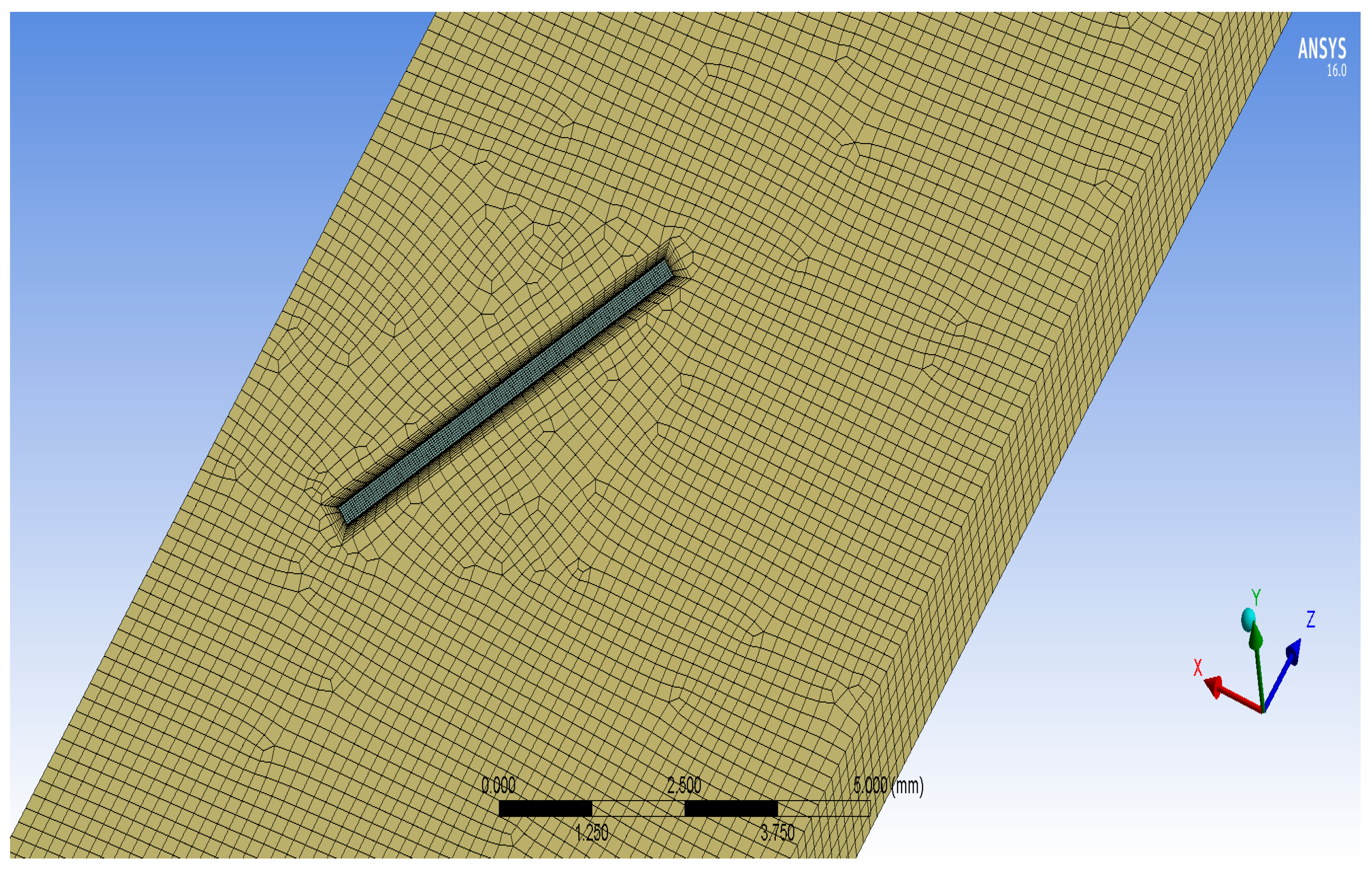

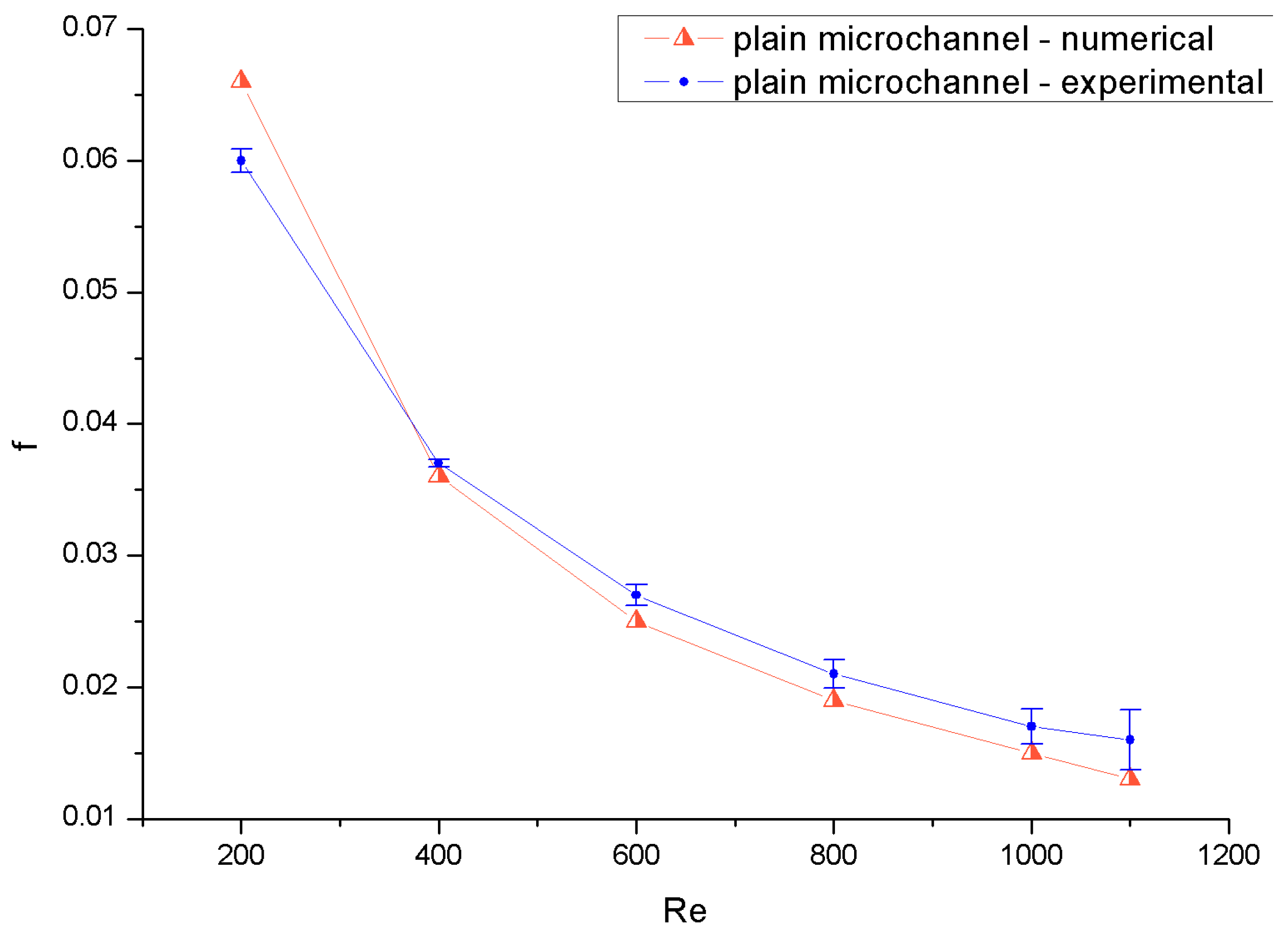

3. Grid Independency and Model Validation

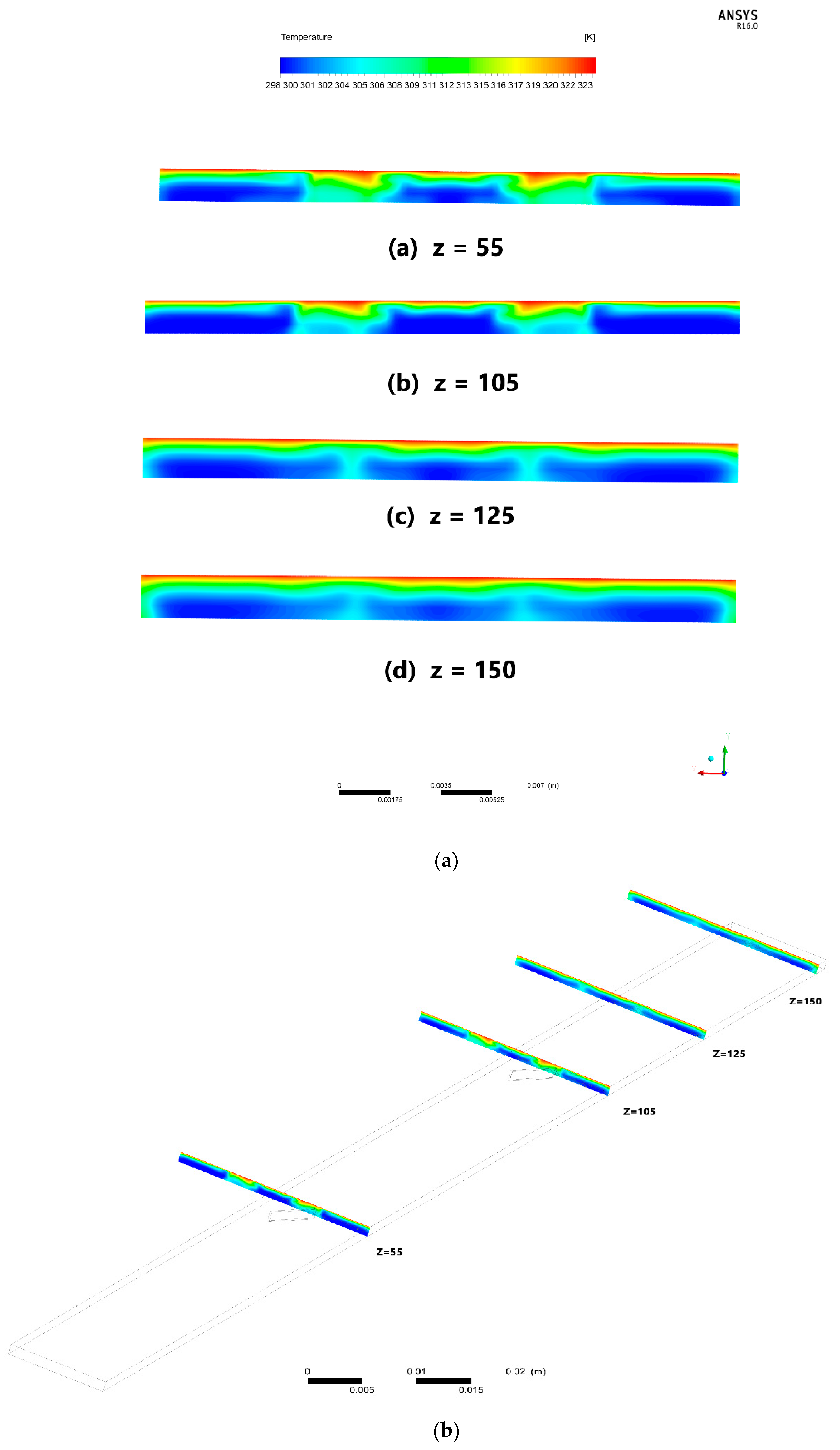

4. Results and Discussions

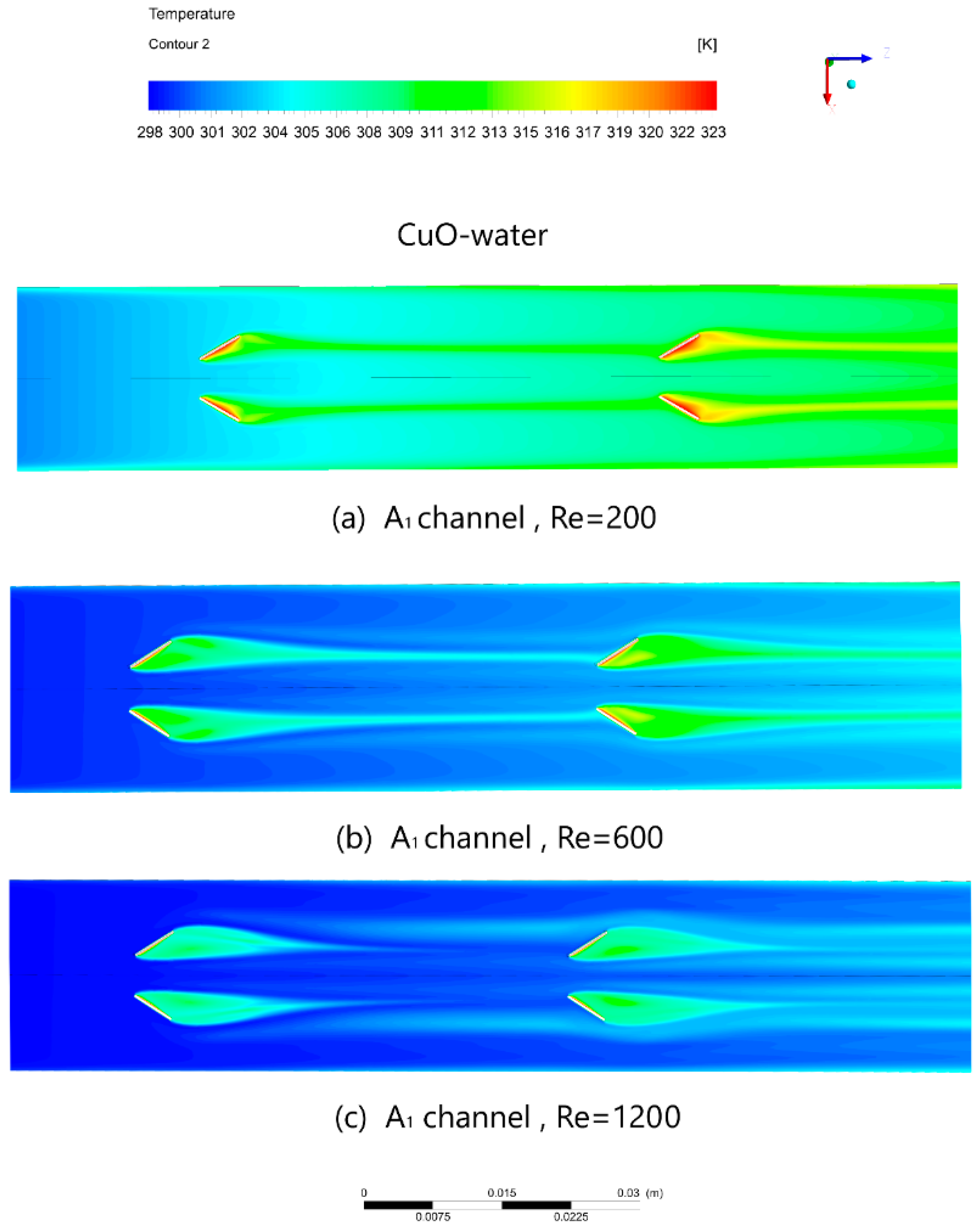

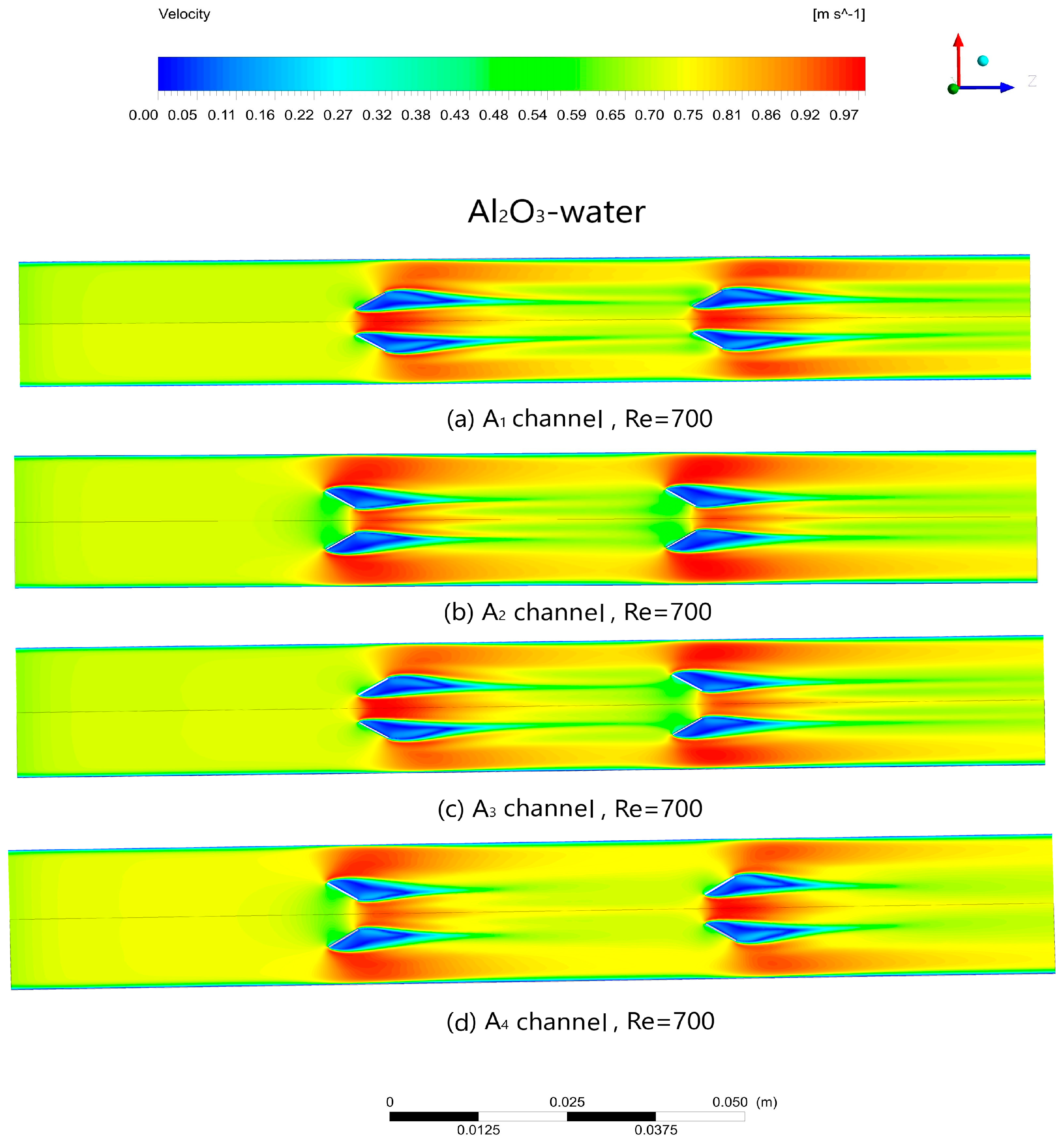

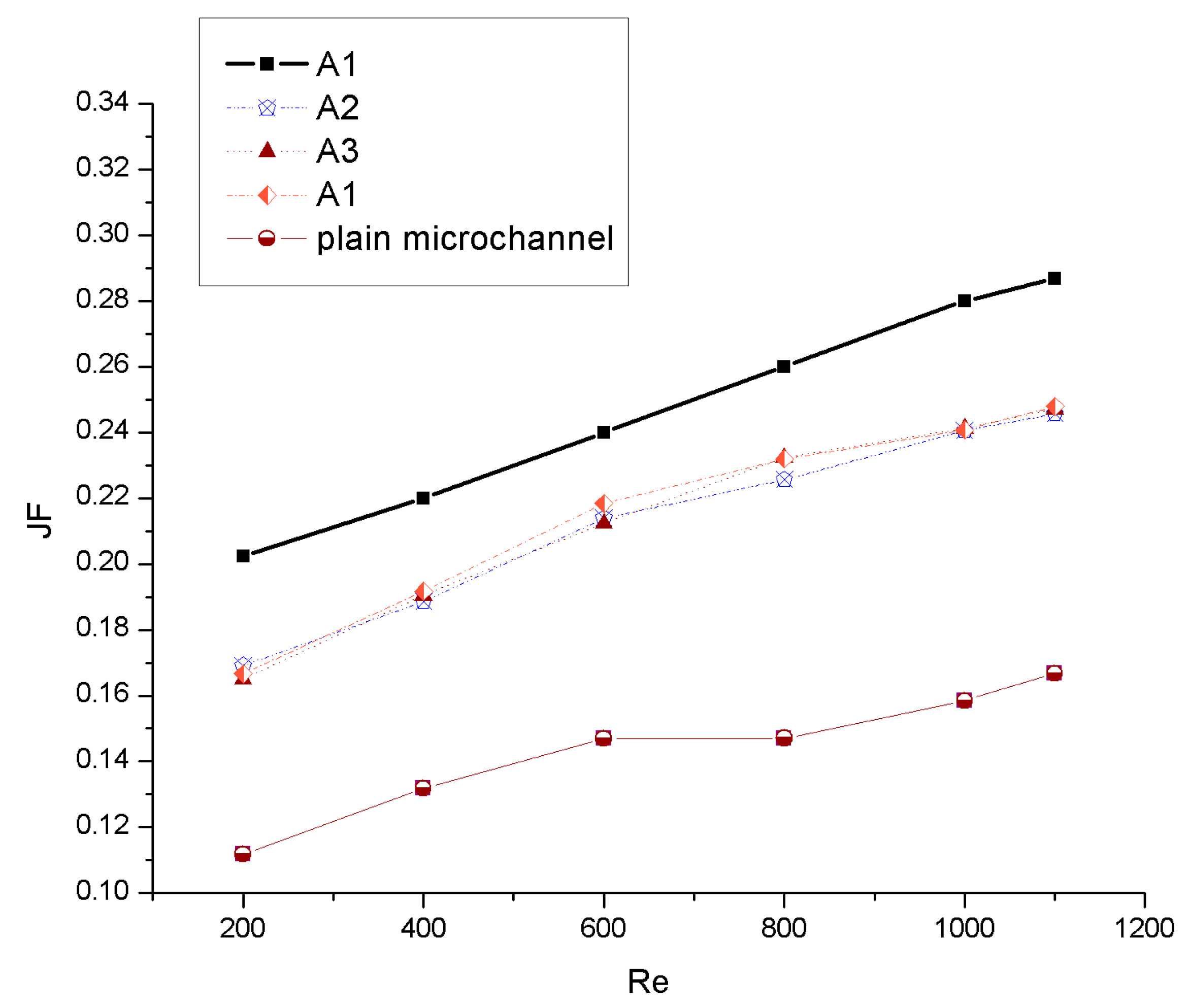

4.1. The Effect of Different Geometry Configurations

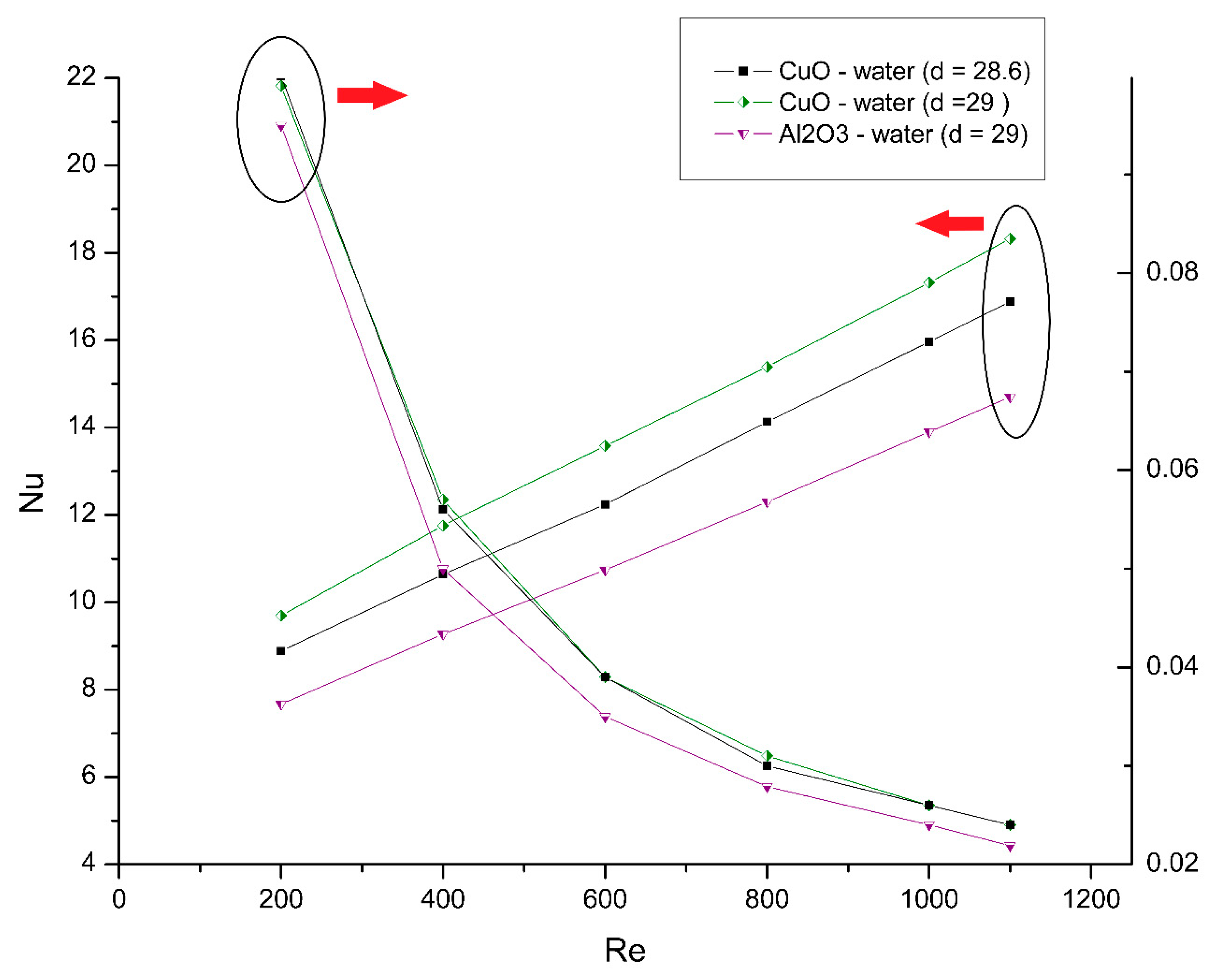

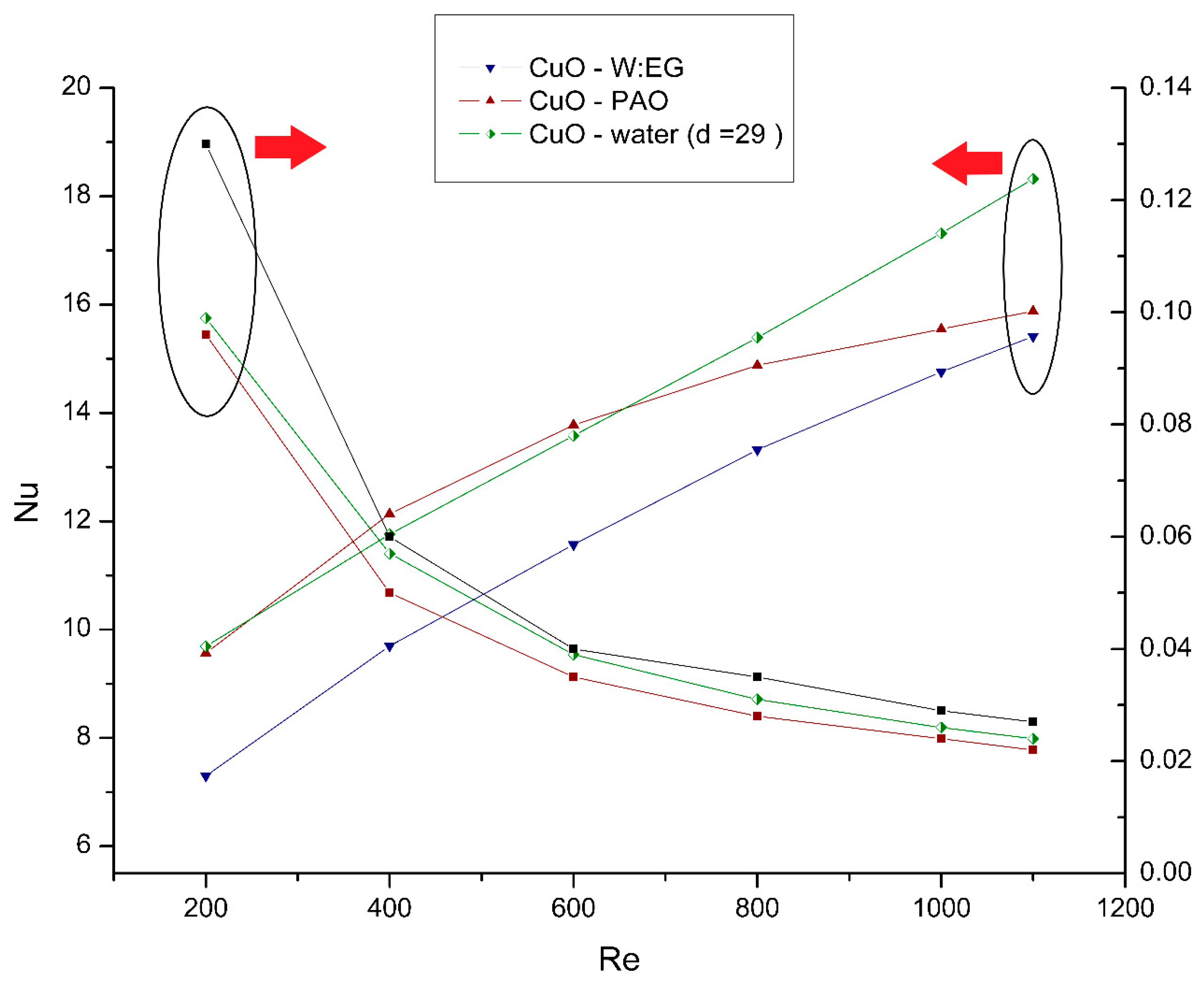

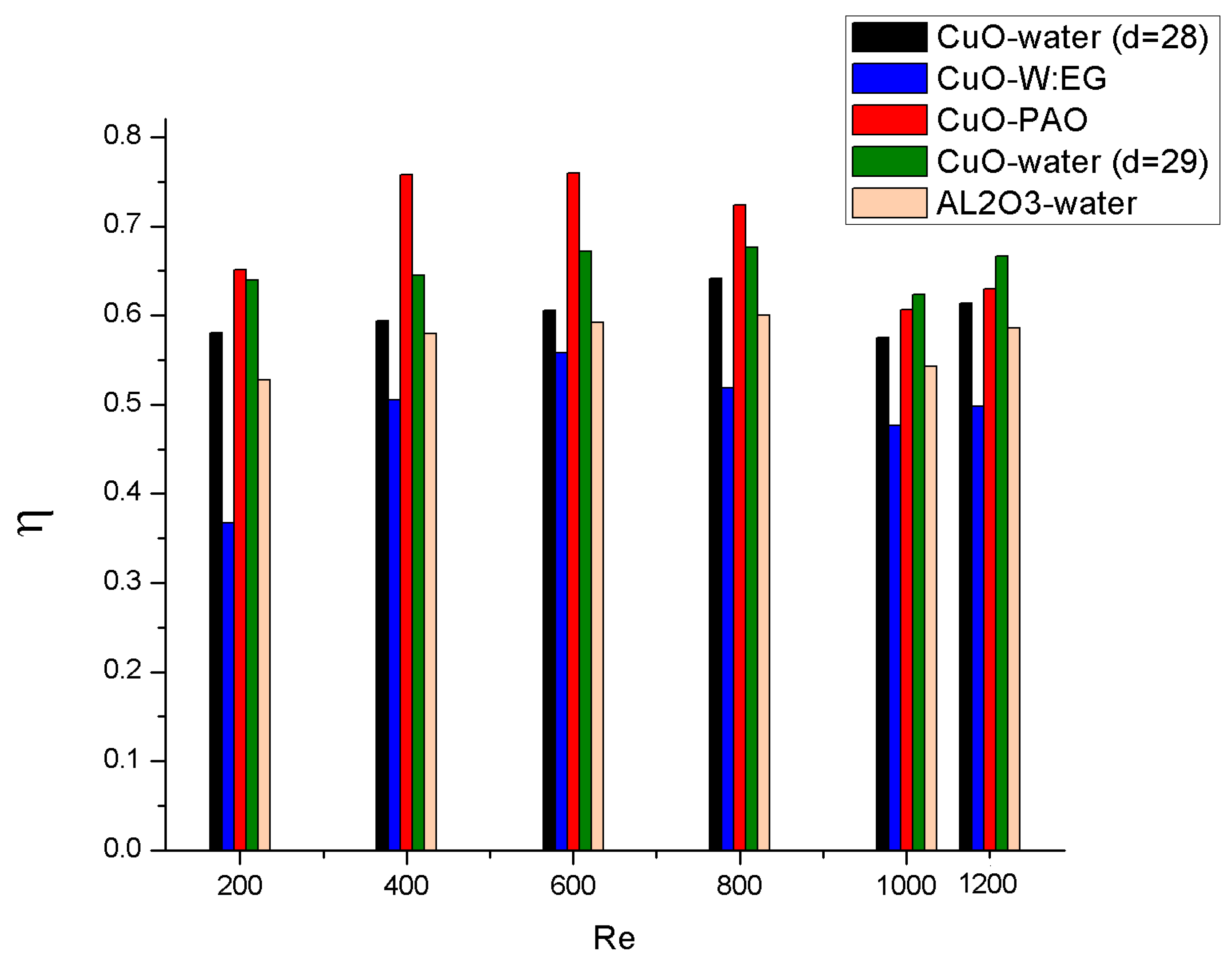

4.2. The Effect of the Different Working Fluids

5. Conclusions

- The assessment of thermal and hydraulic performance on various LVG configurations shows A1 to be the best configuration for LVG arrangement, and after that A2, A4 and A3 are in the list, respectively. The augmentation in Nusselt number was 0.9%–28.1% using the Al2O3–water nanofluid. However, it comes with the penalty of increasing the Fanning friction factor by 5.2%–28% for the Al2O3–water nanofluid with respect to the smooth microchannel.

- In case of different base fluids, CuO–PAO has the best performance. The Nusselt number values were 7.67–14.7 and 9.57–15.88, respectively, for Al2O3–water and CuO–PAO, with the penalty of increasing the Fanning friction factor by 5%–33.6% and 4.2%–26%, respectively, for Al2O3–water and CuO–PAO.

Author Contributions

Funding

Conflicts of Interest

References

- Tuckerman, D.; Pease, R. IIIB-8 implications of high-performance heat sinking for electron devices. IEEE Trans. Electron Devices 1981, 28, 1230–1231. [Google Scholar] [CrossRef]

- Adham, A.M.; Mohd-Ghazali, N.; Ahmad, R. Thermal and hydrodynamic analysis of microchannel heat sinks: A review. Renew. Sustain. Energy Rev. 2013, 21, 614–622. [Google Scholar] [CrossRef]

- Agostini, B.; Fabbri, M.; Park, J.E.; Wojtan, L.; Thome, J.R.; Michel, B. State of the art of high heat flux cooling technologies. Heat Transf. Eng. 2007, 28, 258–281. [Google Scholar] [CrossRef]

- Morini, G.L. Single-phase convective heat transfer in microchannels: A review of experimental results. Int. J. Therm. Sci. 2004, 43, 631–651. [Google Scholar] [CrossRef]

- Koyuncuoğlu, A.; Jafari, R.; Okutucu-Özyurt, T.; Külah, H. Heat transfer and pressure drop experiments on CMOS compatible microchannel heat sinks for monolithic chip cooling applications. Int. J. Therm. Sci. 2012, 56, 77–85. [Google Scholar] [CrossRef]

- Xu, B.; Ooti, K.; Wong, N.; Choi, W. Experimental investigation of flow friction for liquid flow in microchannels. Int. Commun. Heat Mass Transf. 2000, 27, 1165–1176. [Google Scholar] [CrossRef]

- Qu, W.; Mudawar, I. Experimental and numerical study of pressure drop and heat transfer in a single-phase micro-channel heat sink. Int. J. Heat Mass Transf. 2002, 45, 2549–2565. [Google Scholar] [CrossRef]

- Harms, T.M.; Kazmierczak, M.J.; Gerner, F.M. Developing convective heat transfer in deep rectangular microchannels. Int. J. Heat Fluid Flow 1999, 20, 149–157. [Google Scholar] [CrossRef]

- Tuckerman, D.B.; Pease, R.F.W. High-performance heat sinking for VLSI. IEEE Electron Device Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Xia, G.; Zhai, Y.; Cui, Z. Numerical investigation of thermal enhancement in a micro heat sink with fan-shaped reentrant cavities and internal ribs. Appl. Therm. Eng. 2013, 58, 52–60. [Google Scholar] [CrossRef]

- Xia, G.; Jiang, J.; Wang, J.; Zhai, Y.; Ma, D. Effects of different geometric structures on fluid flow and heat transfer performance in microchannel heat sinks. Int. J. Heat Mass Transf. 2015, 80, 439–447. [Google Scholar] [CrossRef]

- Fiebig, M. Vortices and heat transfer. Zamm J. Appl. Math. Mech. 1997, 77, 3–18. [Google Scholar] [CrossRef]

- Ahmed, H.; Mohammed, H.; Yusoff, M. An overview on heat transfer augmentation using vortex generators and nanofluids: Approaches and applications. Renew. Sustain. Energy Rev. 2012, 16, 5951–5993. [Google Scholar] [CrossRef]

- Sohankar, A. Heat transfer augmentation in a rectangular channel with a vee-shaped vortex generator. Int. J. Heat Fluid Flow 2007, 28, 306–317. [Google Scholar] [CrossRef]

- Tian, L.-T.; He, Y.-L.; Lei, Y.-G.; Tao, W.-Q. Numerical study of fluid flow and heat transfer in a flat-plate channel with longitudinal vortex generators by applying field synergy principle analysis. Int. Commun. Heat Mass Transf. 2009, 36, 111–120. [Google Scholar] [CrossRef]

- Fiebig, M. Embedded vortices in internal flow: Heat transfer and pressure loss enhancement. Int. J. Heat Fluid Flow 1995, 16, 376–388. [Google Scholar] [CrossRef]

- Biswas, G.; Chattopadhyay, H.; Sinha, A. Augmentation of heat transfer by creation of streamwise longitudinal vortices using vortex generators. Heat Transf. Eng. 2012, 33, 406–424. [Google Scholar] [CrossRef]

- Yadav, V.; Baghel, K.; Kumar, R.; Kadam, S. Numerical investigation of heat transfer in extended surface microchannels. Int. J. Heat Mass Transf. 2016, 93, 612–622. [Google Scholar] [CrossRef]

- Fiebig, M.; Kallweit, P.; Mitra, N.; Tiggelbeck, S. Heat transfer enhancement and drag by longitudinal vortex generators in channel flow. Exp. Therm. Fluid Sci. 1991, 4, 103–114. [Google Scholar] [CrossRef]

- Davidson, A.S.L. Effect of inclined vortex generators on heat transfer enhancement in a three-dimensional channel. Numer. Heat Transf. Part A Appl. 2001, 39, 433–448. [Google Scholar] [CrossRef]

- Mohammed, H.; Al-Shamani, A.; Sheriff, J. Thermal and hydraulic characteristics of turbulent nanofluids flow in a rib–groove channel. Int. Commun. Heat Mass Transf. 2012, 39, 1584–1594. [Google Scholar] [CrossRef]

- Islam, M.S.; Hino, R.; Haga, K.; Monde, M.; Sudo, Y. Experimental study on heat transfer augmentation for high heat flux removal in rib-roughened narrow channels. J. Nucl. Sci. Technol. 1998, 35, 671–678. [Google Scholar] [CrossRef][Green Version]

- Leu, J.-S.; Wu, Y.-H.; Jang, J.-Y. Heat transfer and fluid flow analysis in plate-fin and tube heat exchangers with a pair of block shape vortex generators. Int. J. Heat Mass Transf. 2004, 47, 4327–4338. [Google Scholar] [CrossRef]

- Wu, J.; Tao, W. Numerical study on laminar convection heat transfer in a rectangular channel with longitudinal vortex generator. Part A: Verification of field synergy principle. Int. J. Heat Mass Transf. 2008, 51, 1179–1191. [Google Scholar] [CrossRef]

- Liu, C.; Teng, J.-t.; Chu, J.-C.; Chiu, Y.-l.; Huang, S.; Jin, S.; Dang, T.; Greif, R.; Pan, H.-H. Experimental investigations on liquid flow and heat transfer in rectangular microchannel with longitudinal vortex generators. Int. J. Heat Mass Transf. 2011, 54, 3069–3080. [Google Scholar] [CrossRef]

- Chen, C.; Teng, J.-T.; Cheng, C.-H.; Jin, S.; Huang, S.; Liu, C.; Lee, M.-T.; Pan, H.-H.; Greif, R. A study on fluid flow and heat transfer in rectangular microchannels with various longitudinal vortex generators. Int. J. Heat Mass Transf. 2014, 69, 203–214. [Google Scholar] [CrossRef]

- Salleh, M.F.M.; Mohammed, H.A.; Wahid, M.A. Thermal and hydraulic characteristics of trapezoidal winglet across fin-and-tube heat exchanger (FTHE). Appl. Therm. Eng. 2019, 149, 1379–1393. [Google Scholar] [CrossRef]

- Li, Z.; Xu, X.; Li, K.; Chen, Y.; Huang, G.; Chen, C.-l.; Chen, C.-H. A flapping vortex generator for heat transfer enhancement in a rectangular airside fin. Int. J. Heat Mass Transf. 2018, 118, 1340–1356. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Roohi, E.; Kheradmand, S. Numerical study of liquid flow and heat transfer in rectangular microchannel with longitudinal vortex generators. Appl. Therm. Eng. 2015, 78, 576–583. [Google Scholar] [CrossRef]

- Xie, Y.; Zheng, L.; Zhang, D.; Xie, G. Entropy generation and heat transfer performances of Al2O3-water nanofluid transitional flow in rectangular channels with dimples and protrusions. Entropy 2016, 18, 148. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Rikhtegar, F.; Sabaghan, A.; Roohi, E. Heat transfer and entropy generation in a microchannel with longitudinal vortex generators using nanofluids. Energy 2016, 101, 190–201. [Google Scholar] [CrossRef]

- Choi, S.; Singer, D.; Wang, H. Developments and applications of non-Newtonian flows. Asme Fed 1995, 66, 99–105. [Google Scholar]

- Hamilton, R.L.; Crosser, O. Thermal conductivity of heterogeneous two-component systems. Ind. Eng. Chem. Fundam. 1962, 1, 187–191. [Google Scholar] [CrossRef]

- Brinkman, H. The viscosity of concentrated suspensions and solutions. J. Chem. Phys. 1952, 20, 571. [Google Scholar] [CrossRef]

- Corcione, M. Heat transfer features of buoyancy-driven nanofluids inside rectangular enclosures differentially heated at the sidewalls. Int. J. Therm. Sci. 2010, 49, 1536–1546. [Google Scholar] [CrossRef]

- Maxwell, J.C. 4 Treatise on Electricity and Magnetism, 2nd ed.; Clarendon Press: Oxford, UK, 1881; Volume 1, p. 435ff. [Google Scholar]

- Bruggeman, V.D. Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen. I. Dielektrizitätskonstanten und Leitfähigkeiten der Mischkörper aus isotropen Substanzen. Ann. Der Phys. 1935, 416, 636–664. [Google Scholar] [CrossRef]

- Yu, W.; Choi, S. The role of interfacial layers in the enhanced thermal conductivity of nanofluids: A renovated Maxwell model. J. Nanopart. Res. 2003, 5, 167–171. [Google Scholar] [CrossRef]

- Machrafi, H.; Lebon, G. The role of several heat transfer mechanisms on the enhancement of thermal conductivity in nanofluids. Contin. Mech. Thermodyn. 2016, 28, 1461–1475. [Google Scholar] [CrossRef]

- Shaikh, S.; Lafdi, K.; Ponnappan, R. Thermal conductivity improvement in carbon nanoparticle doped PAO oil: An experimental study. J. Appl. Phys. 2007, 101, 064302. [Google Scholar] [CrossRef]

- Lee, S.; Choi, S.-S.; Li, S.; Eastman, J. Measuring thermal conductivity of fluids containing oxide nanoparticles. J. Heat Transf. 1999, 121, 280–289. [Google Scholar] [CrossRef]

- Suresh, S.; Chandrasekar, M.; Sekhar, S.C. Experimental studies on heat transfer and friction factor characteristics of CuO/water nanofluid under turbulent flow in a helically dimpled tube. Exp. Therm. Fluid Sci. 2011, 35, 542–549. [Google Scholar] [CrossRef]

- Kalteh, M.; Abbassi, A.; Saffar-Avval, M.; Harting, J. Eulerian–Eulerian two-phase numerical simulation of nanofluid laminar forced convection in a microchannel. Int. J. Heat Fluid Flow 2011, 32, 107–116. [Google Scholar] [CrossRef]

- Gavili, A.; Isfahani, T.D.; Zabihi, F.; Hadi, I. The effect of real viscosity on the heat transfer of water based Al2O3 nanofluids in a two-sided lid-driven differentially heated rectangular cavity. Heat Mass Transf. 2013, 49, 1433–1445. [Google Scholar] [CrossRef]

- Kalteh, M.; Abbassi, A.; Saffar-Avval, M.; Frijns, A.; Darhuber, A.; Harting, J. Experimental and numerical investigation of nanofluid forced convection inside a wide microchannel heat sink. Appl. Therm. Eng. 2012, 36, 260–268. [Google Scholar] [CrossRef]

- Li, P.; Zhang, D.; Xie, Y. Heat transfer and flow analysis of Al2O3–water nanofluids in microchannel with dimple and protrusion. Int. J. Heat Mass Transf. 2014, 73, 456–467. [Google Scholar] [CrossRef]

- Seyf, H.R.; Feizbakhshi, M. Computational analysis of nanofluid effects on convective heat transfer enhancement of micro-pin-fin heat sinks. Int. J. Therm. Sci. 2012, 58, 168–179. [Google Scholar] [CrossRef]

- Ferrouillat, S.; Tochon, P.; Garnier, C.; Peerhossaini, H. Intensification of heat-transfer and mixing in multifunctional heat exchangers by artificially generated streamwise vorticity. Appl. Therm. Eng. 2006, 26, 1820–1829. [Google Scholar] [CrossRef]

- Ghale, Z.Y.; Haghshenasfard, M.; Esfahany, M.N. Investigation of nanofluids heat transfer in a ribbed microchannel heat sink using single-phase and multiphase CFD models. Int. Commun. Heat Mass Transf. 2015, 68, 122–129. [Google Scholar] [CrossRef]

- Pak, B.C.; Cho, Y.I. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp. Heat Transf. Int. J. 1998, 11, 151–170. [Google Scholar] [CrossRef]

- Glassbrenner, C.; Slack, G.A. Thermal conductivity of silicon and germanium from 3 K to the melting point. Phys. Rev. 1964, 134, A1058. [Google Scholar] [CrossRef]

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; Dewitt, D.P. Fundamentals of Heat and Mass Transfer; John Wiley Sons Inc.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Etminan-Farooji, V.; Ebrahimnia-Bajestan, E.; Niazmand, H.; Wongwises, S. Unconfined laminar nanofluid flow and heat transfer around a square cylinder. Int. J. Heat Mass Transf. 2012, 55, 1475–1485. [Google Scholar] [CrossRef]

- Yue, Y.; Mohammadian, S.K.; Zhang, Y. Analysis of performances of a manifold microchannel heat sink with nanofluids. Int. J. Therm. Sci. 2015, 89, 305–313. [Google Scholar] [CrossRef]

- Liu, K. Heat Transfer Measurement in Oil-Based Nanofluids. Ph.D. Thesis, University of Louisville, Louisville, KY, USA, 2011; p. 841. [Google Scholar]

- E.G.P. MEGlobal Guide. 2008. Available online: https://www.meglobal.biz/wp-content/uploads/2019/01/Monoethylene-Glycol-MEG-Technical-Product-Brochure-PDF.pdf (accessed on 10 February 2020).

- Koo, J.; Kleinstreuer, C. A new thermal conductivity model for nanofluids. J. Nanopart. Res. 2004, 6, 577–588. [Google Scholar] [CrossRef]

- Li, J.; Kleinstreuer, C. Thermal performance of nanofluid flow in microchannels. Int. J. Heat Fluid Flow 2008, 29, 1221–1232. [Google Scholar] [CrossRef]

- Li, J. Computational Analysis of Nanofluid Flow in Microchannels with Applications to Micro-Heat Sinks and Bio-MEMS. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2008. [Google Scholar]

- ANSYS Inc. ANSYS Fluent Theory Guide. 2013. Available online: https://www.academia.edu/38091499/ANSYS_Fluent_Theory_Guide (accessed on 10 February 2020).

- Wu, X.; Zhang, W.; Gou, Q.; Luo, Z.; Lu, Y. Numerical simulation of heat transfer and fluid flow characteristics of composite fin. Int. J. Heat Mass Transf. 2014, 75, 414–424. [Google Scholar] [CrossRef]

- Li, J.; Wang, S.; Chen, J.; Lei, Y.-G. Numerical study on a slit fin-and-tube heat exchanger with longitudinal vortex generators. Int. J. Heat Mass Transf. 2011, 54, 1743–1751. [Google Scholar] [CrossRef]

- Wu, X.; Liu, D.; Zhao, M.; Lu, Y.; Song, X. The optimization of fin-tube heat exchanger with longitudinal vortex generators using response surface approximation and genetic algorithm. Heat Mass Transf. 2016, 52, 1871–1879. [Google Scholar] [CrossRef]

- Gholami, A.A.; Wahid, M.A.; Mohammed, H.A. Heat transfer enhancement and pressure drop for fin-and-tube compact heat exchangers with wavy rectangular winglet-type vortex generators. Int. Commun. Heat Mass Transf. 2014, 54, 132–140. [Google Scholar] [CrossRef]

- Ahmed, H.E.; Mohammed, H.A.; Yusoff, M.Z. Heat transfer enhancement of laminar nanofluids flow in a triangular duct using vortex generators. Superlattices Microstruct. 2012, 52, 398–415. [Google Scholar] [CrossRef]

- Gholami, A.A.; Mohammed, H.A.; Wahid, M.A.; Khiadani, M. Parametric design exploration of fin-and-oval tube compact heat exchangers performance with a new type of corrugated fin patterns. Int. J. Therm. Sci. 2019, 144, 173–190. [Google Scholar] [CrossRef]

- Gholami, A.A.; Wahid, M.A.; Mohammed, H.A. Thermal-hydraulic performance of fin-and-oval tube compact heat exchangers with innovative design of corrugated fin patterns. Int. J. Heat Mass Transf. 2017, 106, 573–592. [Google Scholar] [CrossRef]

| Microchannel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| plain | - | - | - | - | - | - | - | 5H | |

| 50H | 100H | 4H | 4H | 8H | 8H | 30, 30 | 5H | ||

| 50H | 100H | 4H | 4H | 8H | 8H | 150,150 | 5H | ||

| 50H | 100H | 4H | 4H | 8H | 8H | 30, 150 | 5H | ||

| 50H | 100H | 4H | 4H | 8H | 8H | 150, 30 | 5H |

| Silicon [51] | Al2O3 [52] | CuO [53] | Pure-Water [54] | POA [55] | Ethylene Glycol [56] | |

|---|---|---|---|---|---|---|

| µ (Pa.s) | 873.6 | 1113 | ||||

| k (W/m.K) | 290 − 0.4 T | 36 | 76.5 | 0. 0305 | 0.00485 | |

| (J/kg.K) | 390 + 0.9 T | 765 | 535.6 | 4180 | 1396 | |

| ρ (kg/m3) | 2330 | 3970 | 6350 | 1000 | 2040 |

| Number of Cells | Predicted Nu | % Diff % | ||

|---|---|---|---|---|

| I | 201,006 (coarse) | 8.3 | I vs. II | 2.47 |

| II | 385,619 (intermediate) | 8.1 | II vs. III | 1.85 |

| III | 490,198 (fine) | 7.9 | III vs. IV | 0.38 |

| IV | 931,236 (very fine) | 7.87 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

AL Muallim, B.; Wahid, M.A.; Mohammed, H.A.; Kamil, M.; Habibi, D. Thermal–Hydraulic Performance in a Microchannel Heat Sink Equipped with Longitudinal Vortex Generators (LVGs) and Nanofluid. Processes 2020, 8, 231. https://doi.org/10.3390/pr8020231

AL Muallim B, Wahid MA, Mohammed HA, Kamil M, Habibi D. Thermal–Hydraulic Performance in a Microchannel Heat Sink Equipped with Longitudinal Vortex Generators (LVGs) and Nanofluid. Processes. 2020; 8(2):231. https://doi.org/10.3390/pr8020231

Chicago/Turabian StyleAL Muallim, Basel, Mazlan A. Wahid, Hussein A. Mohammed, Mohammed Kamil, and Daryoush Habibi. 2020. "Thermal–Hydraulic Performance in a Microchannel Heat Sink Equipped with Longitudinal Vortex Generators (LVGs) and Nanofluid" Processes 8, no. 2: 231. https://doi.org/10.3390/pr8020231

APA StyleAL Muallim, B., Wahid, M. A., Mohammed, H. A., Kamil, M., & Habibi, D. (2020). Thermal–Hydraulic Performance in a Microchannel Heat Sink Equipped with Longitudinal Vortex Generators (LVGs) and Nanofluid. Processes, 8(2), 231. https://doi.org/10.3390/pr8020231