On Fluid Flow Field Visualization in a Staggered Cavity: A Numerical Result

Abstract

1. Introduction

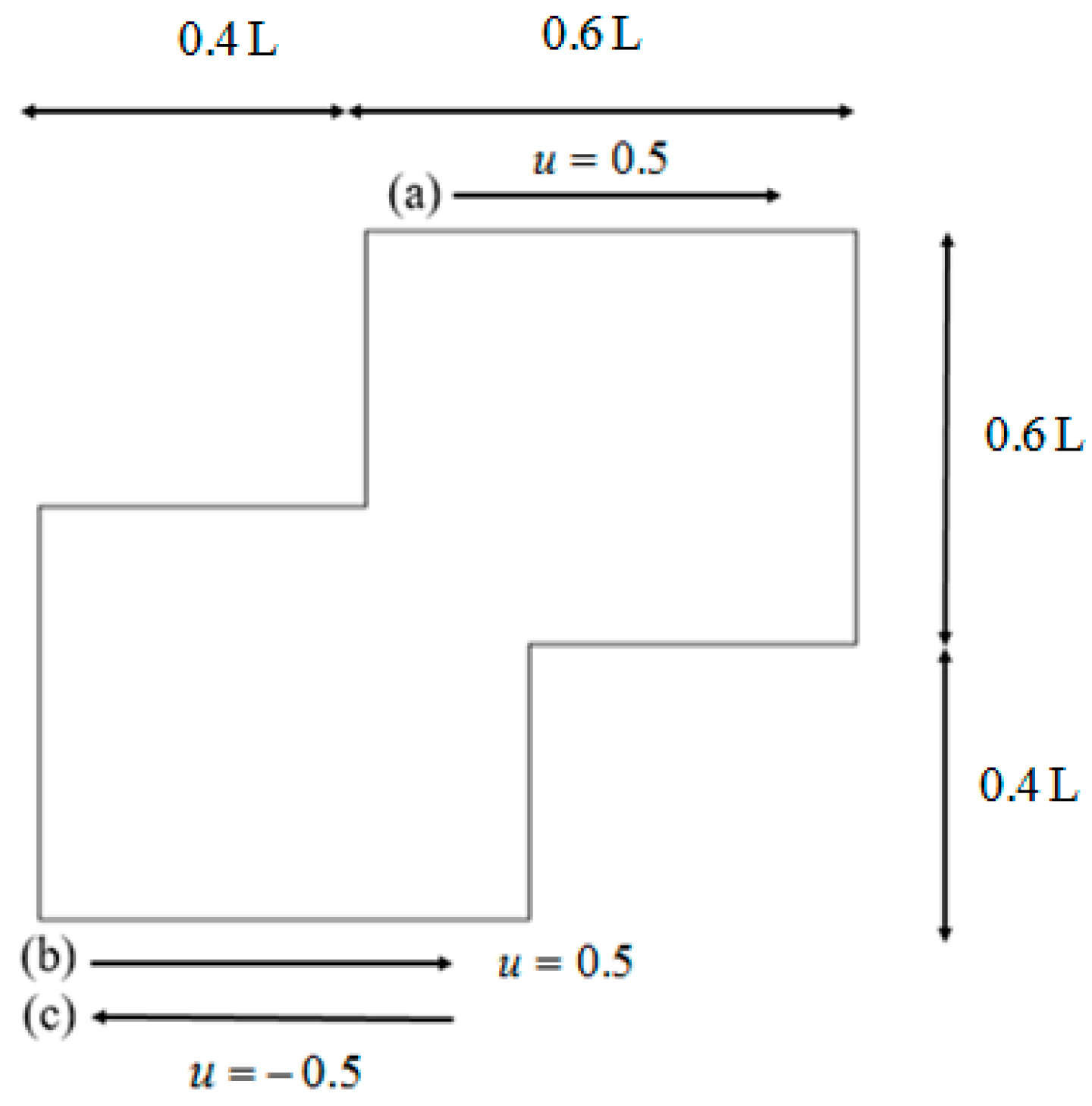

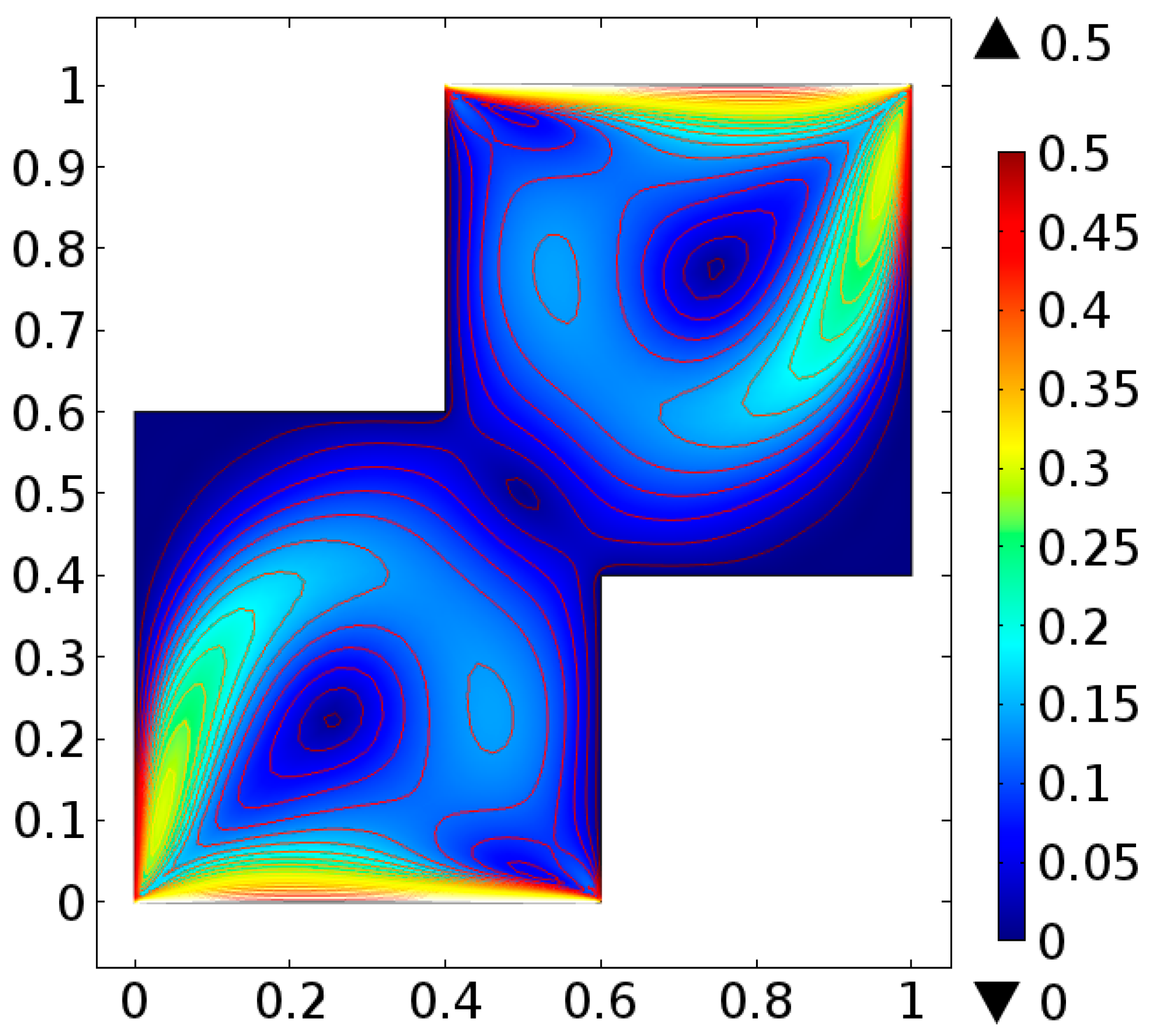

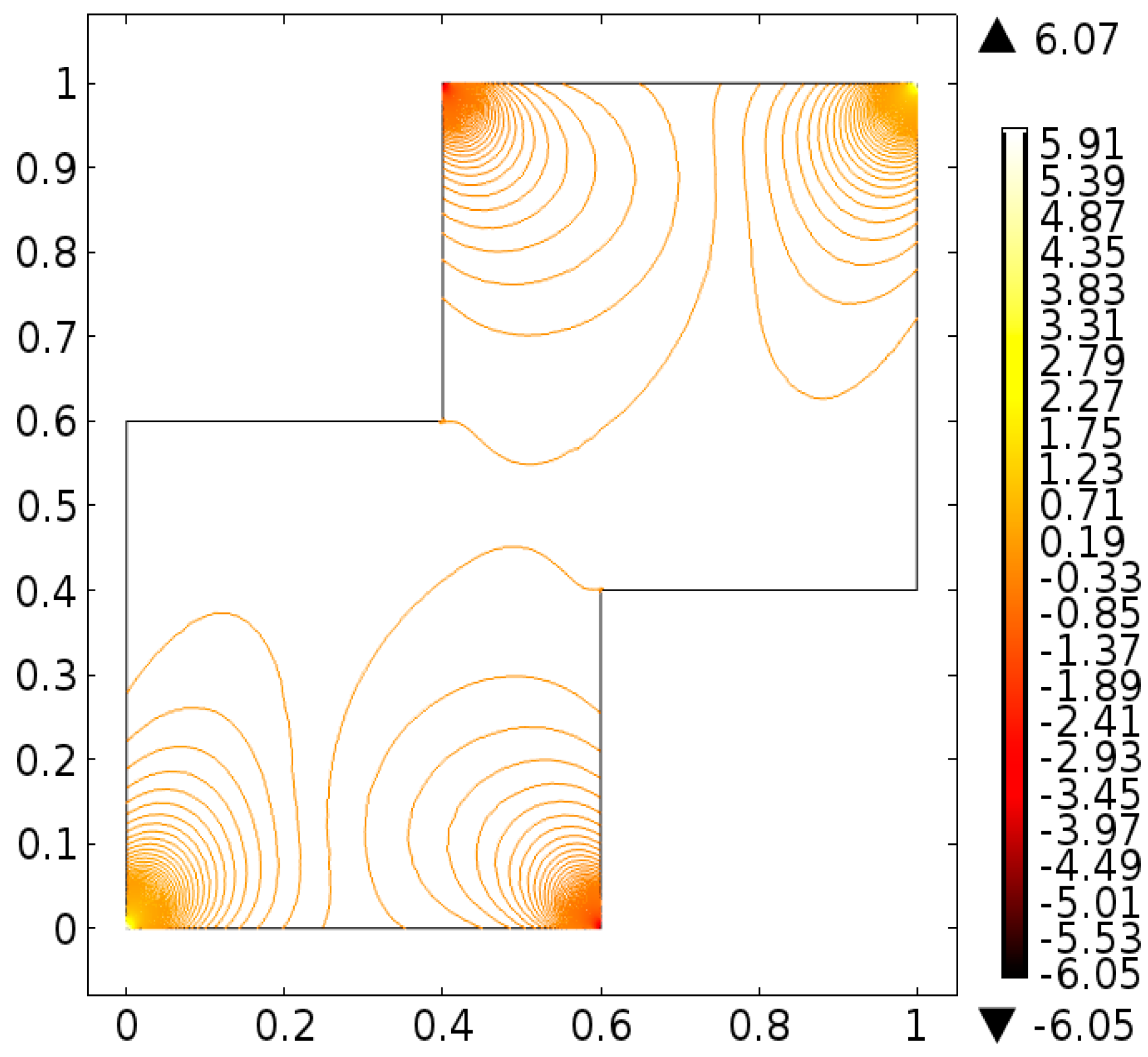

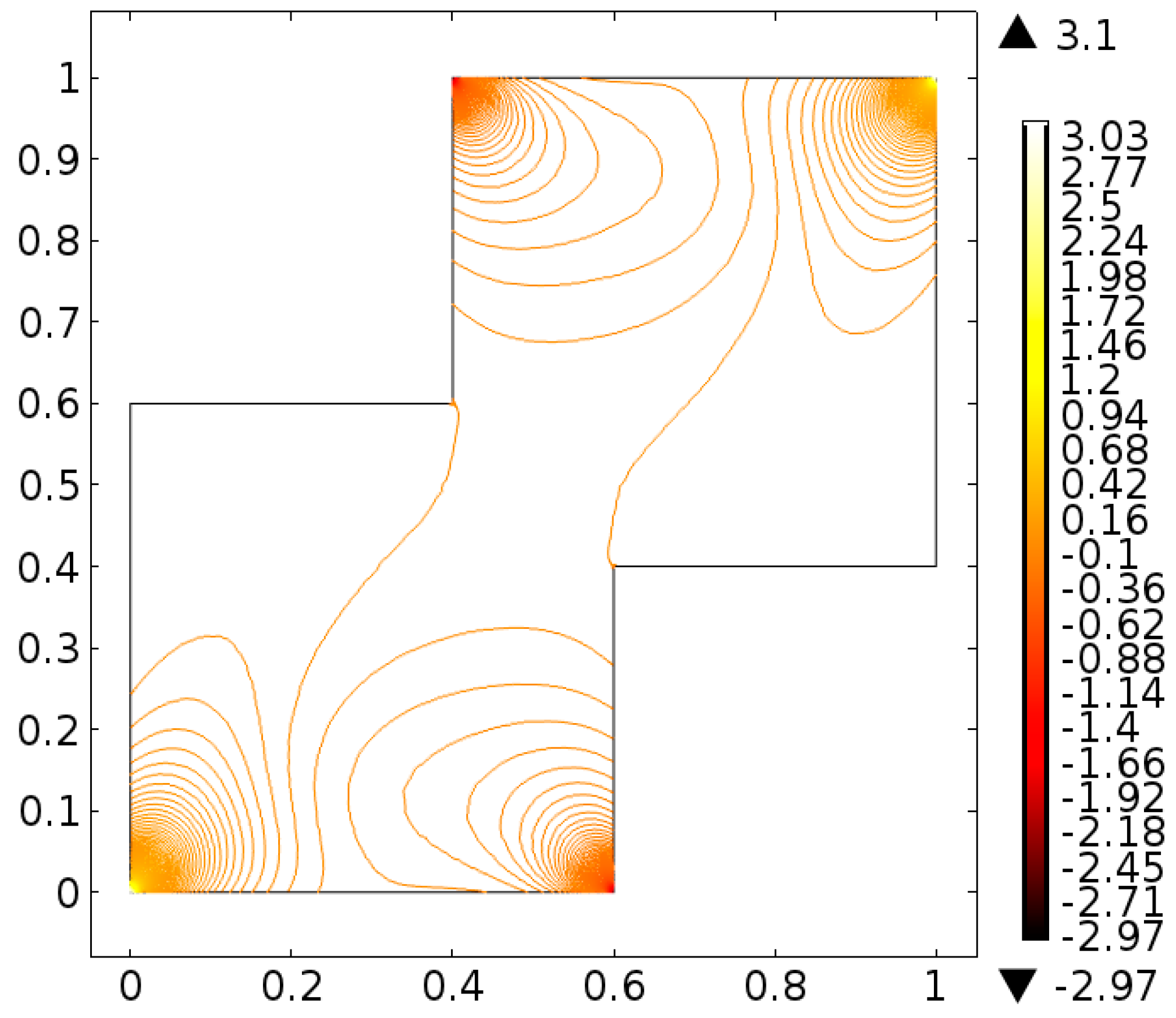

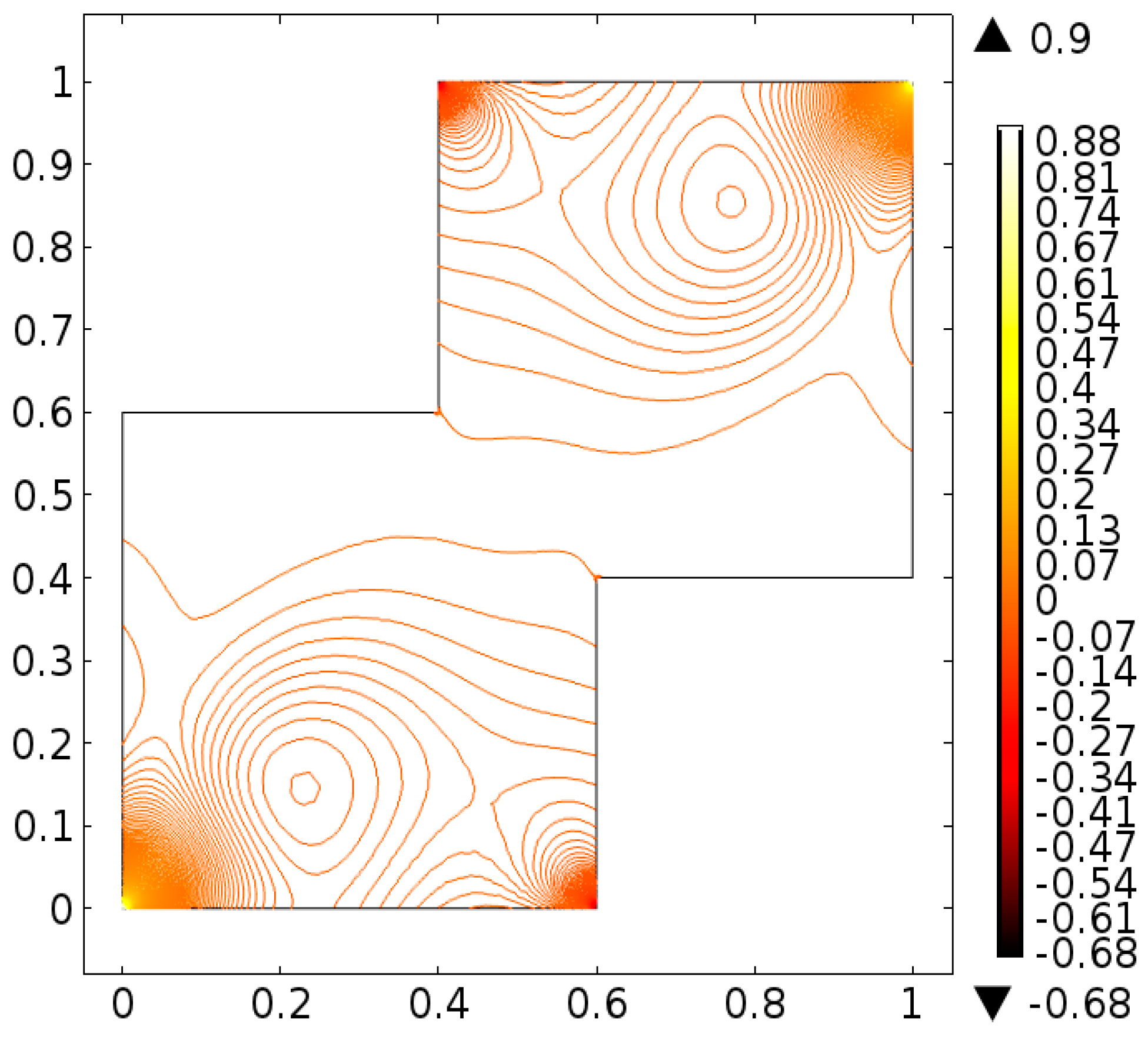

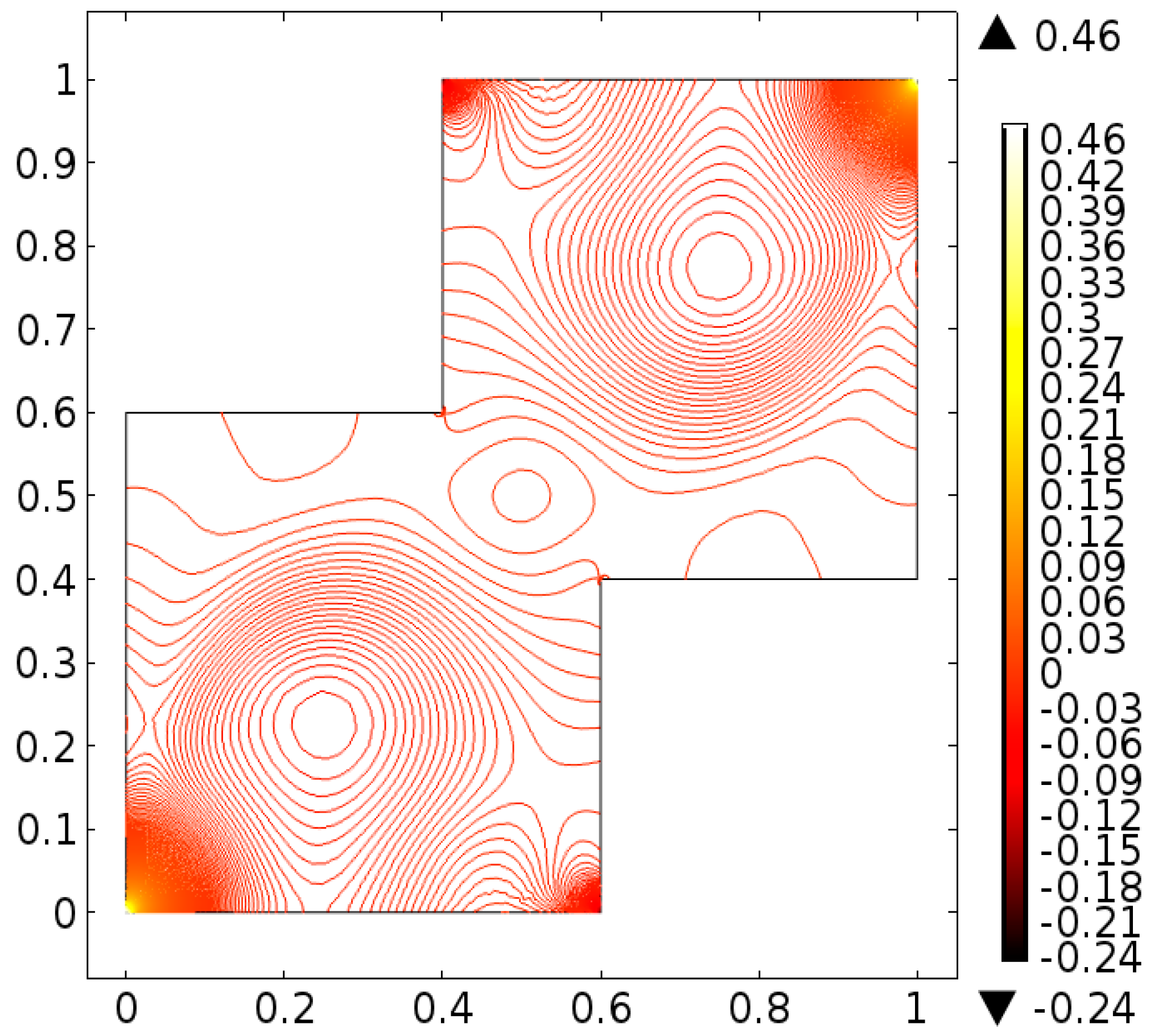

- Staggered cavity

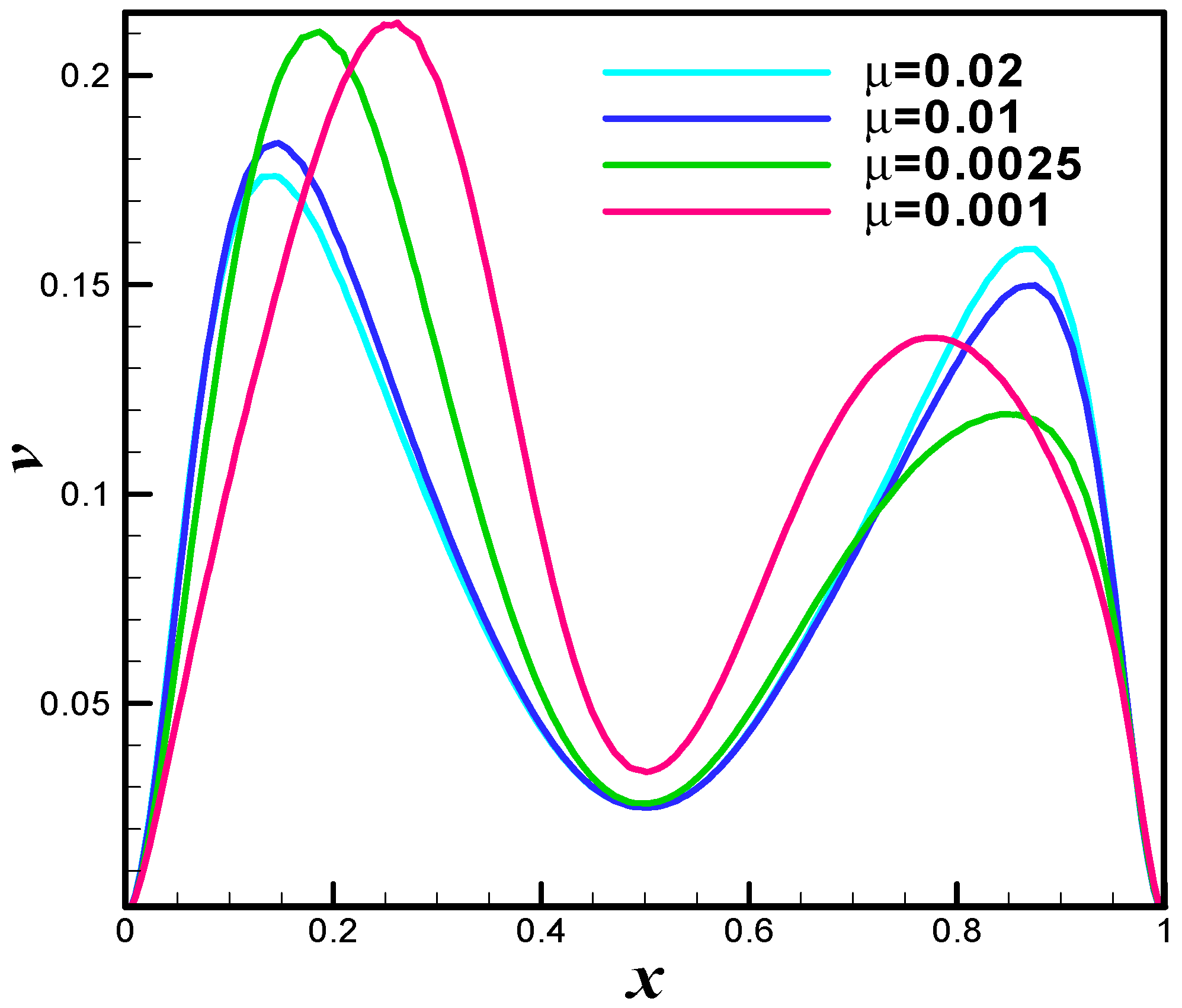

- Newtonian fluid model

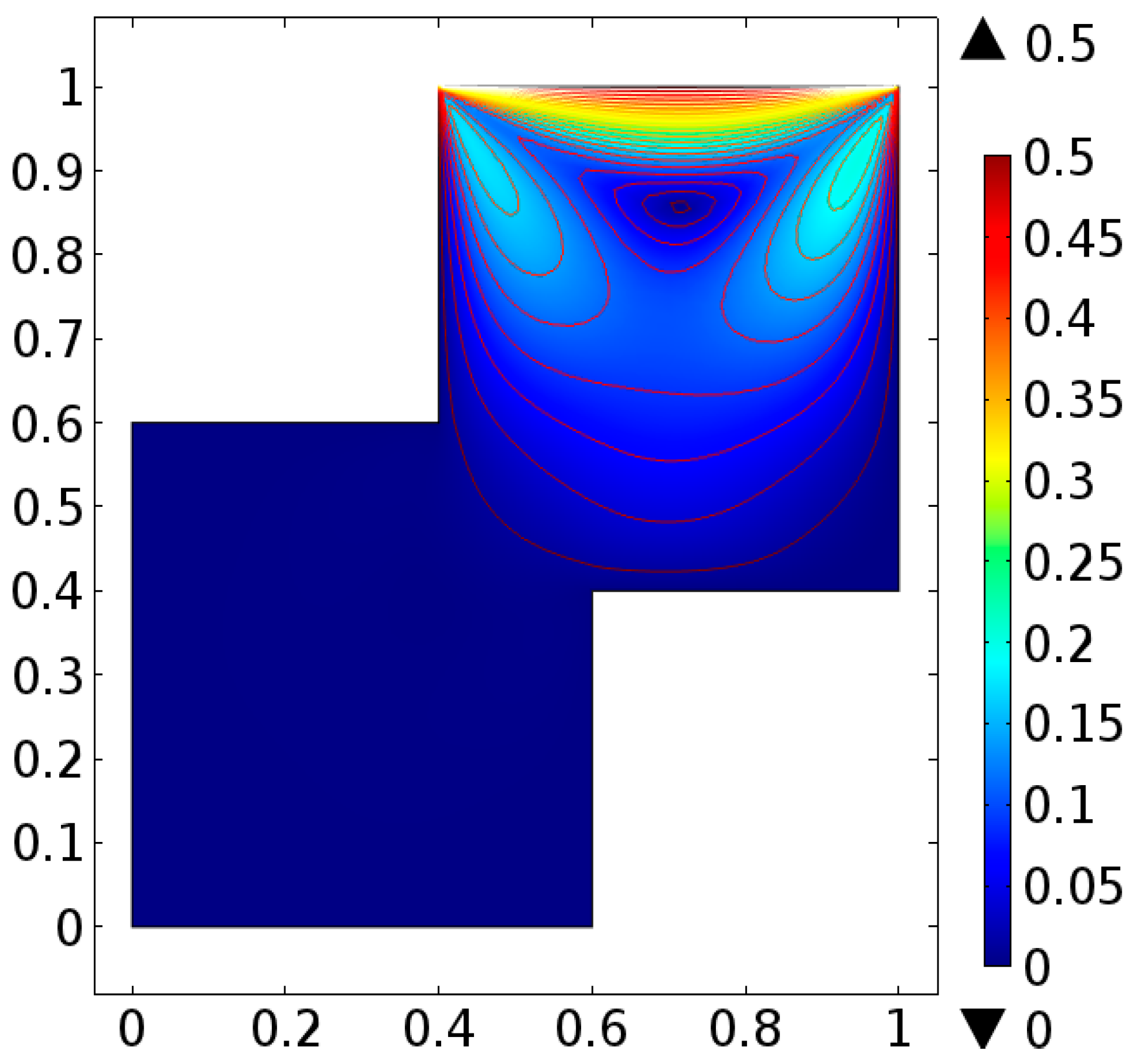

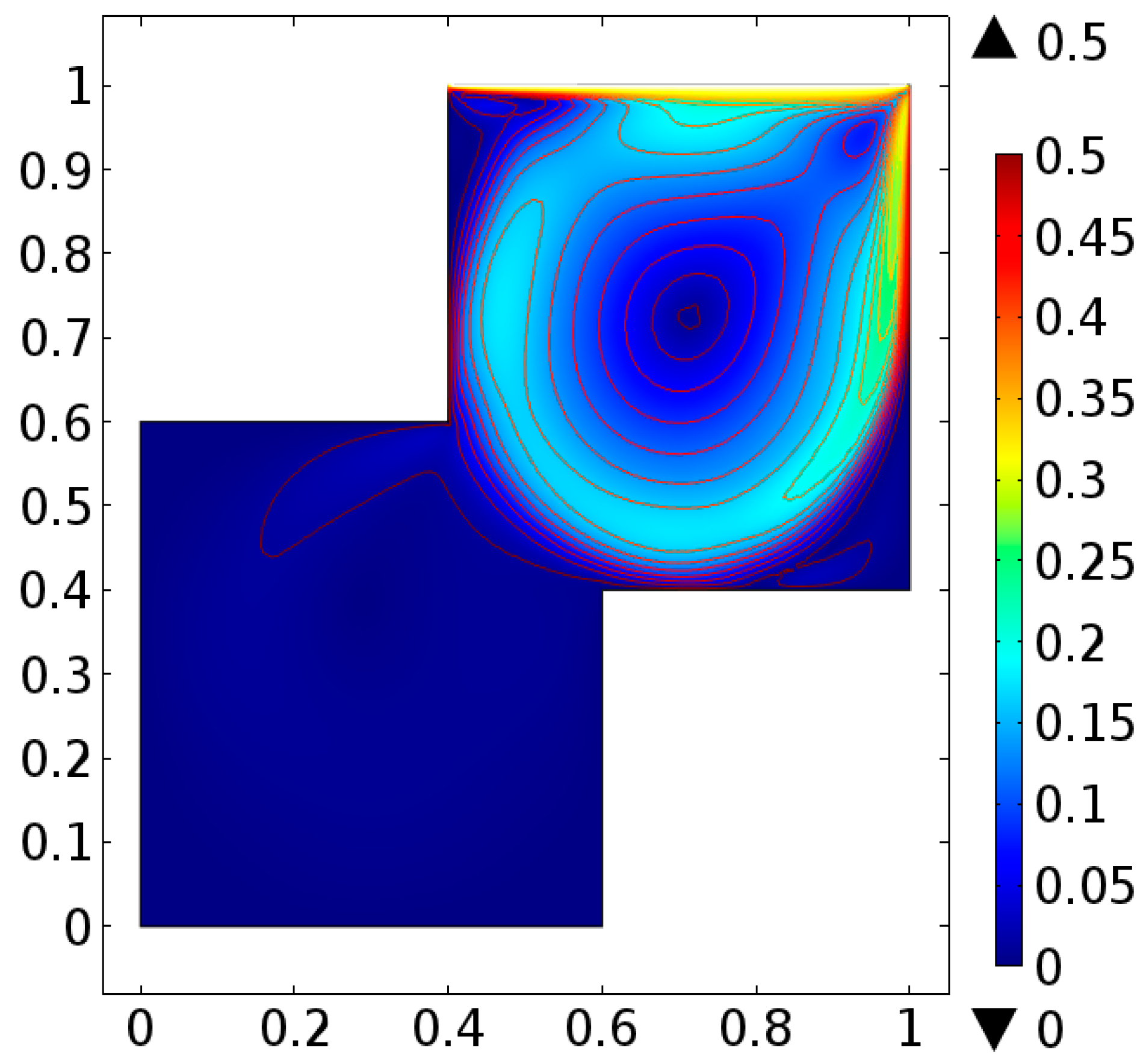

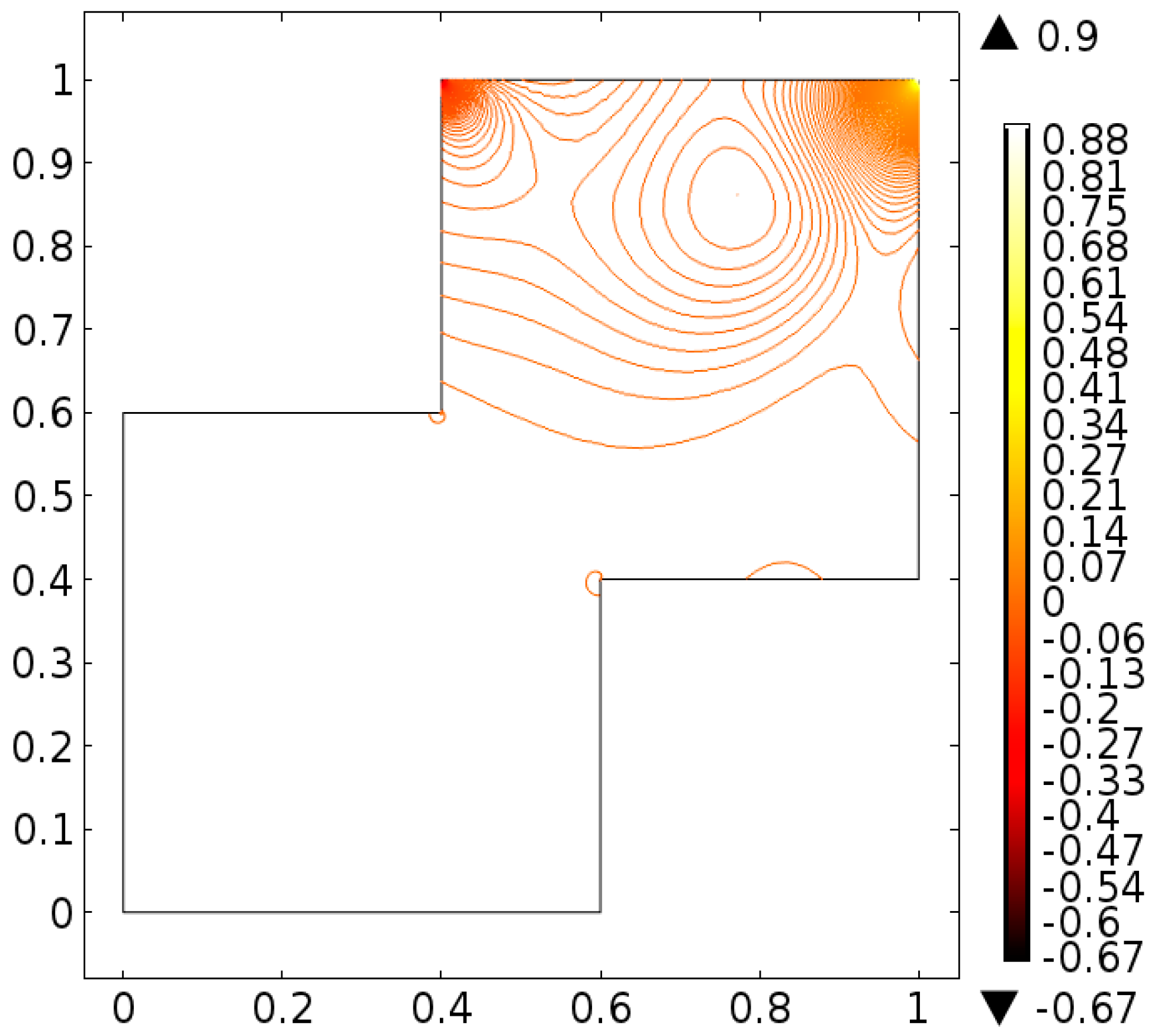

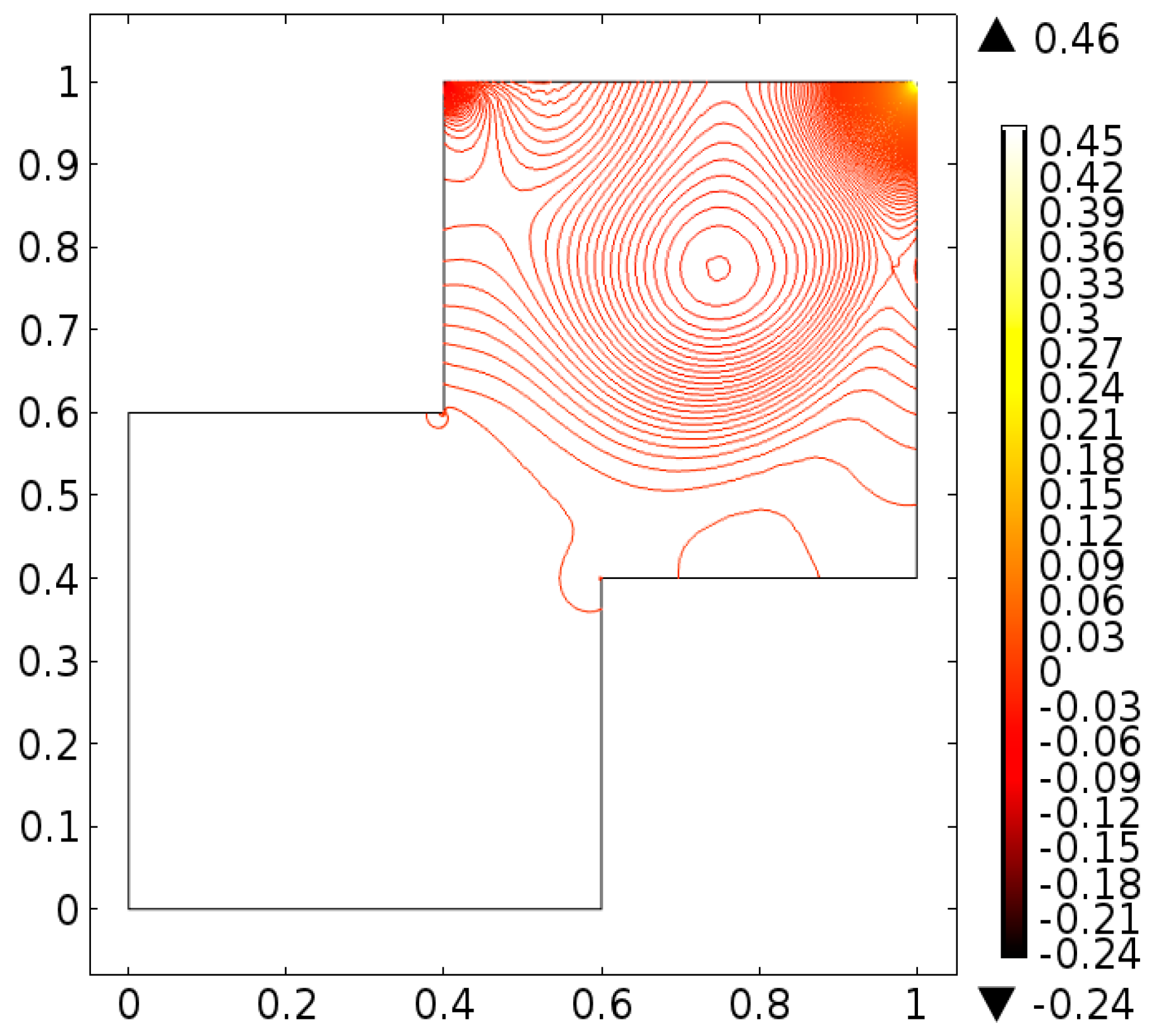

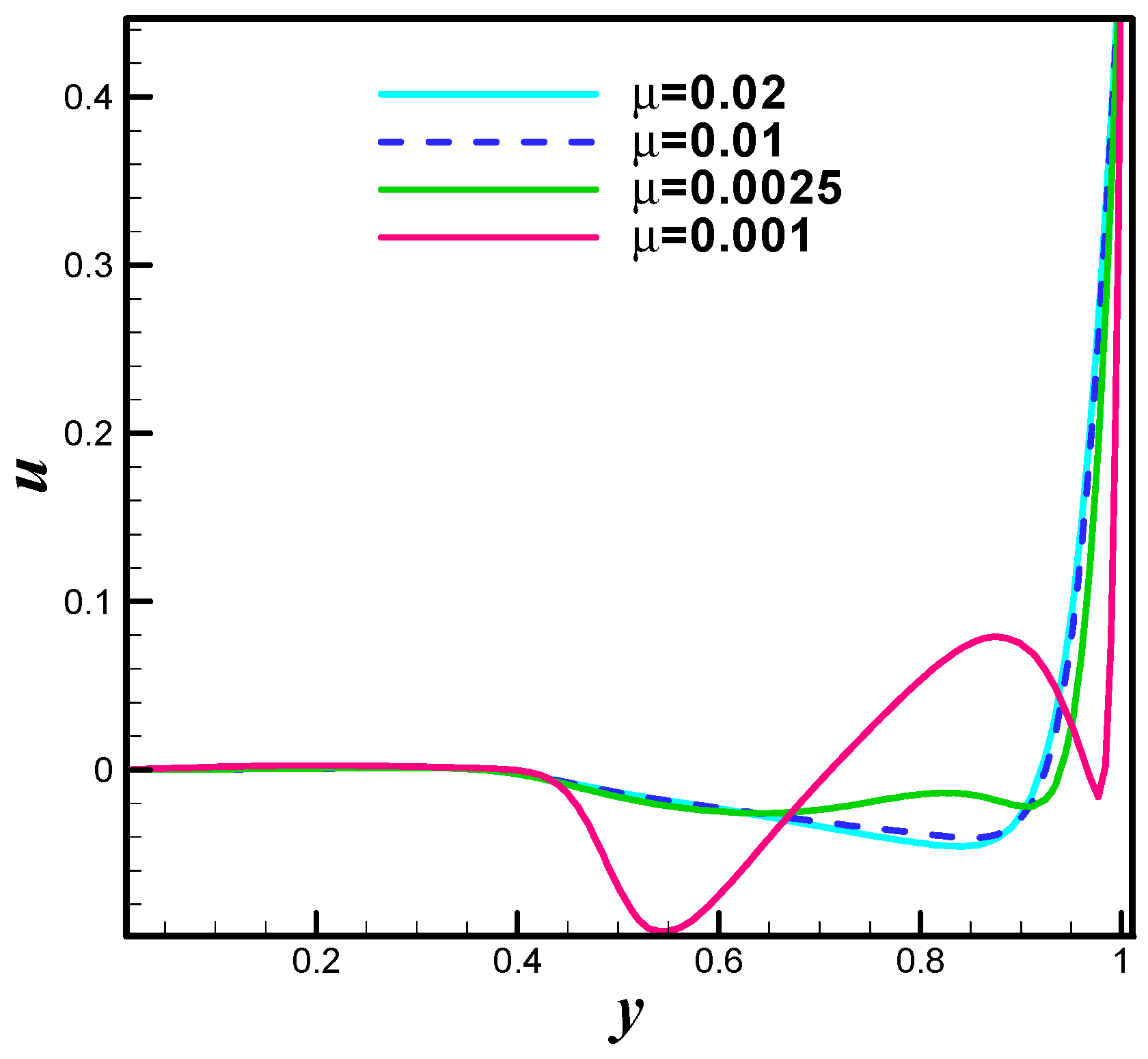

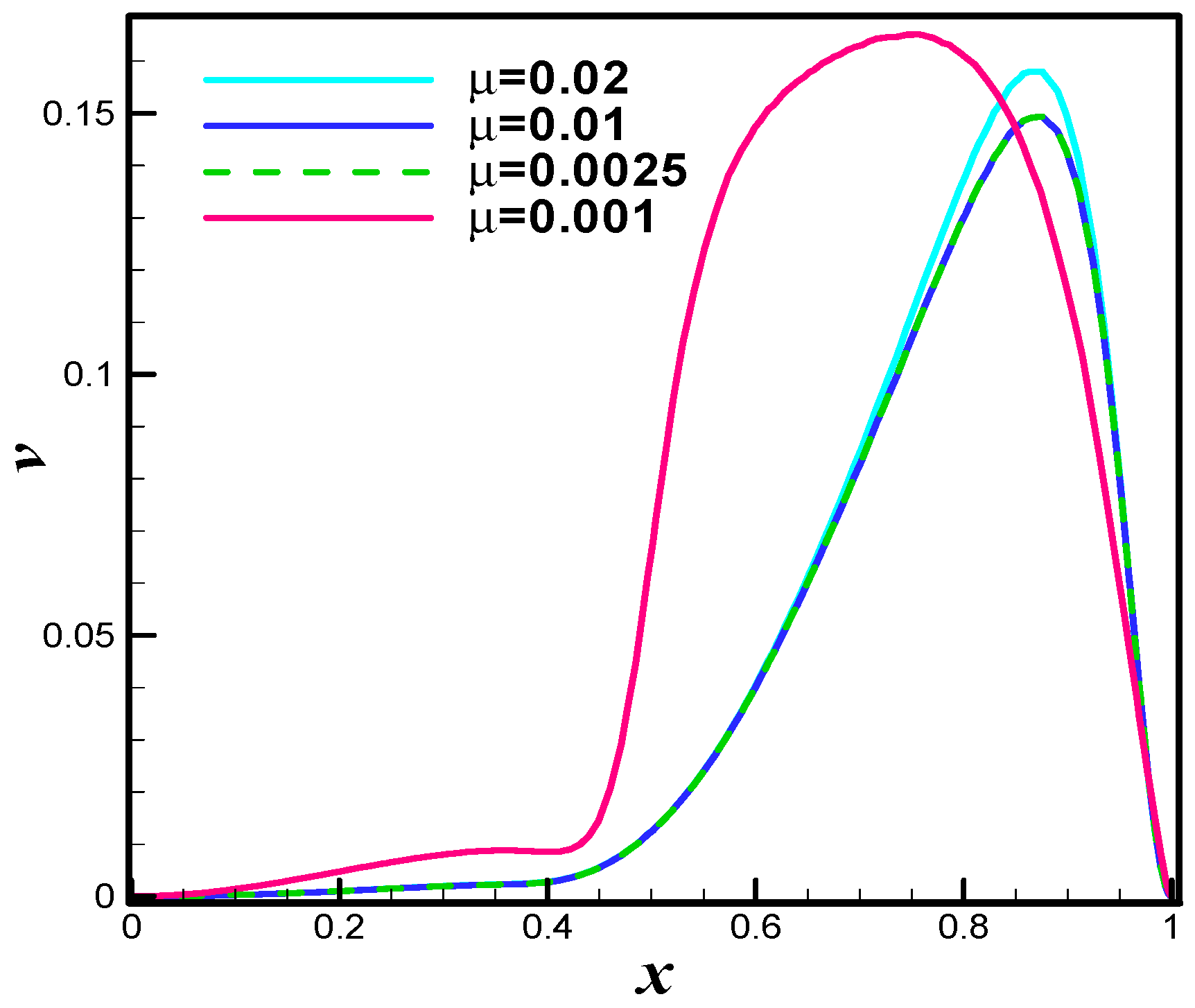

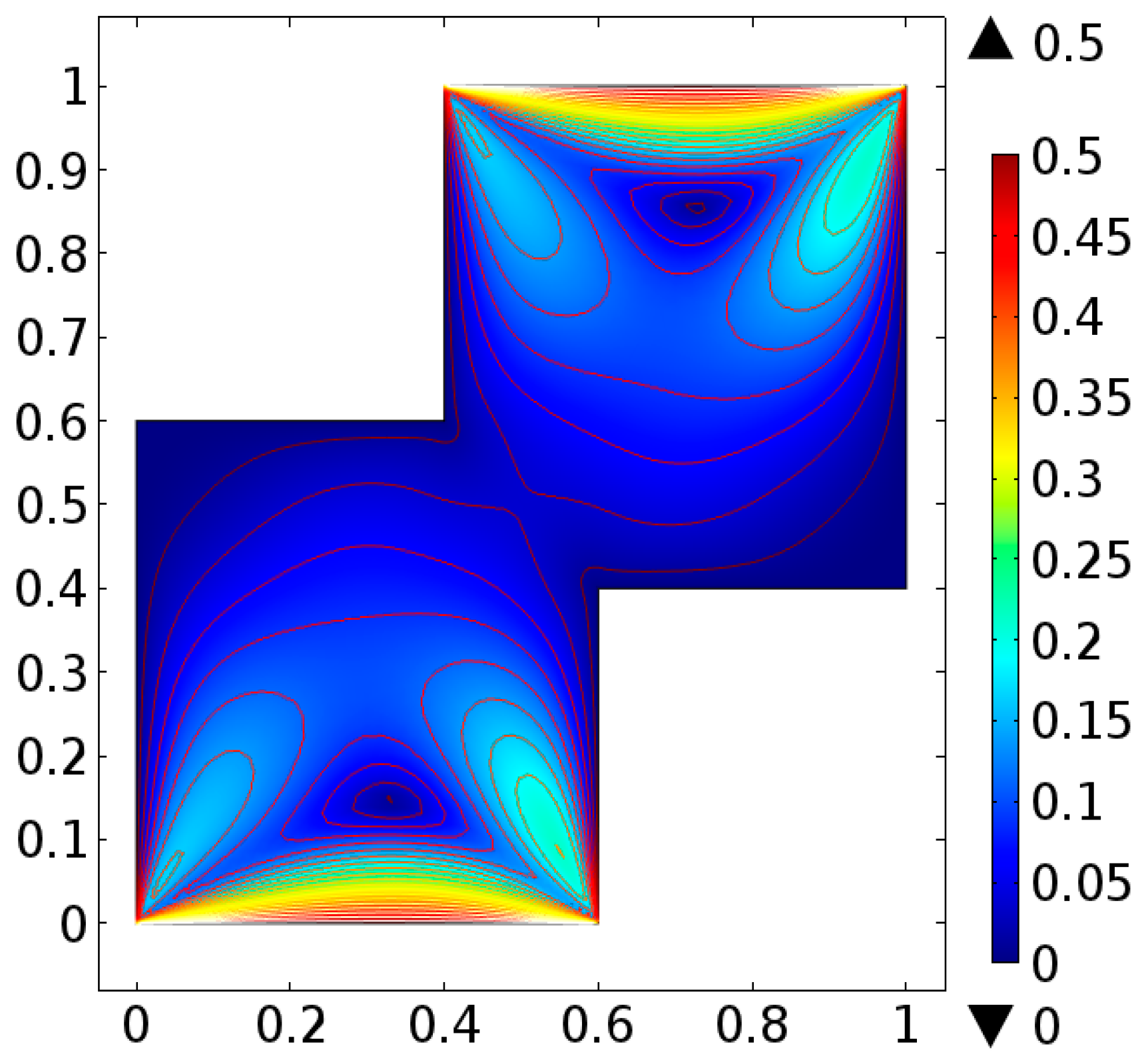

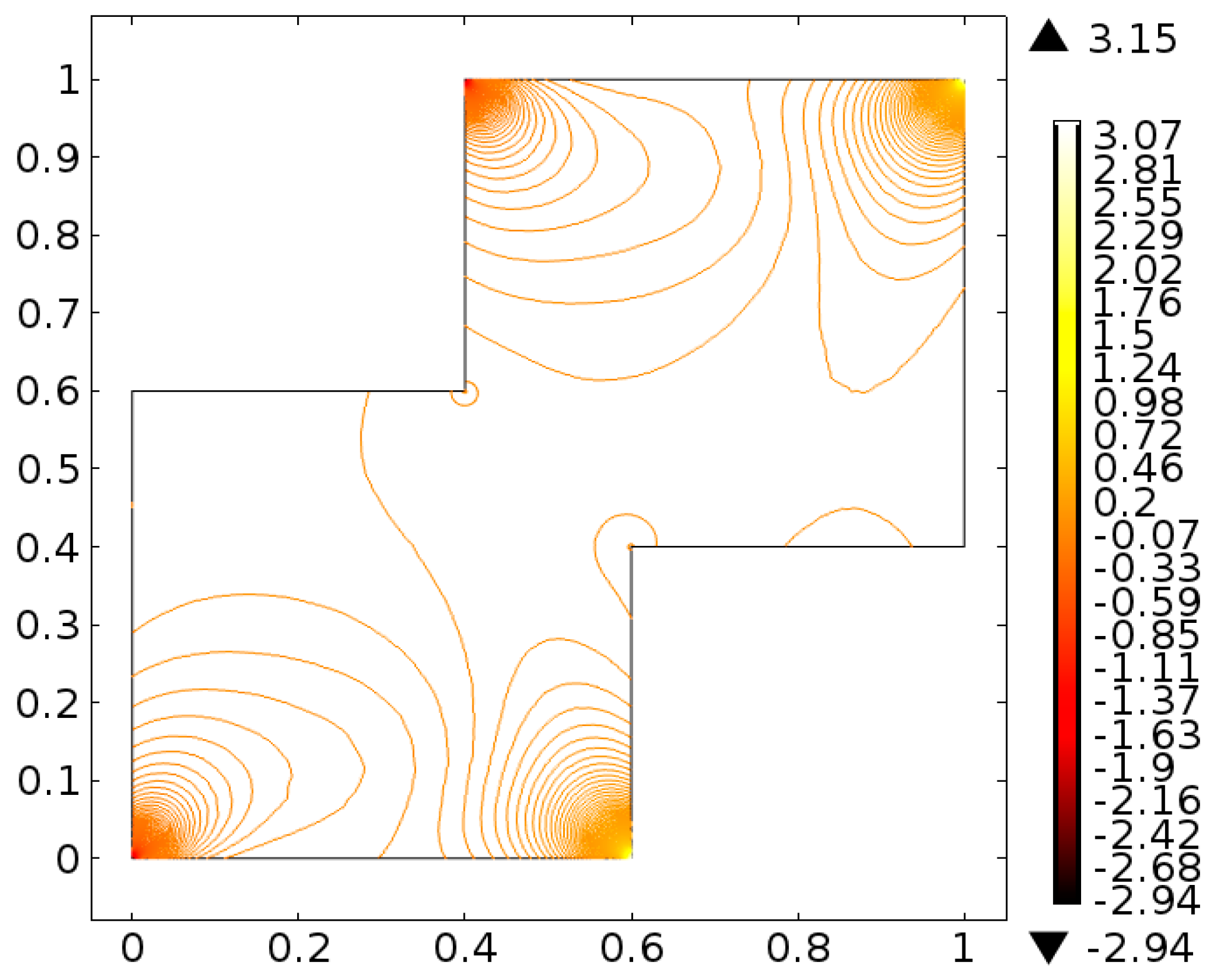

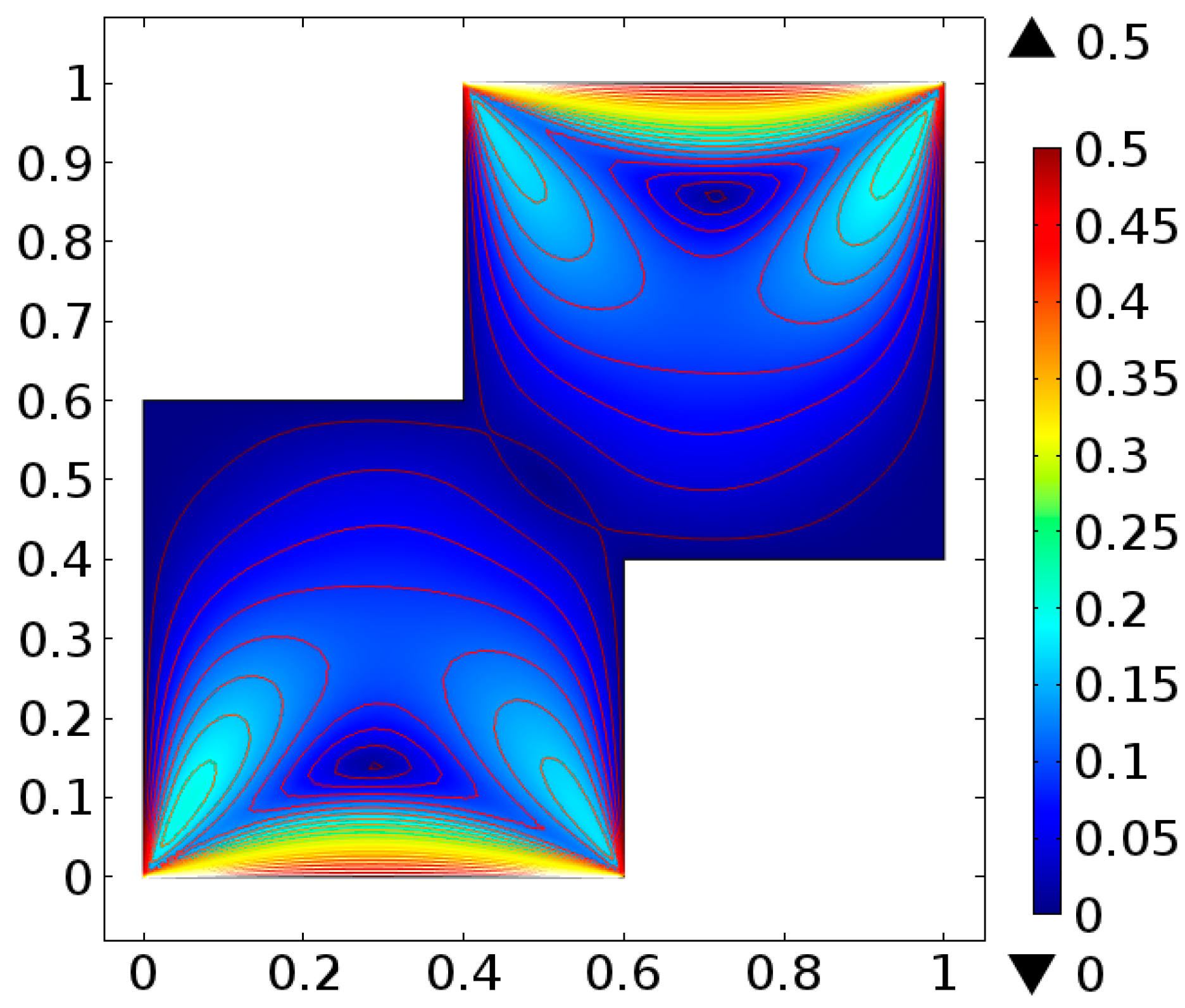

- Upper wall is moving (Case-I)

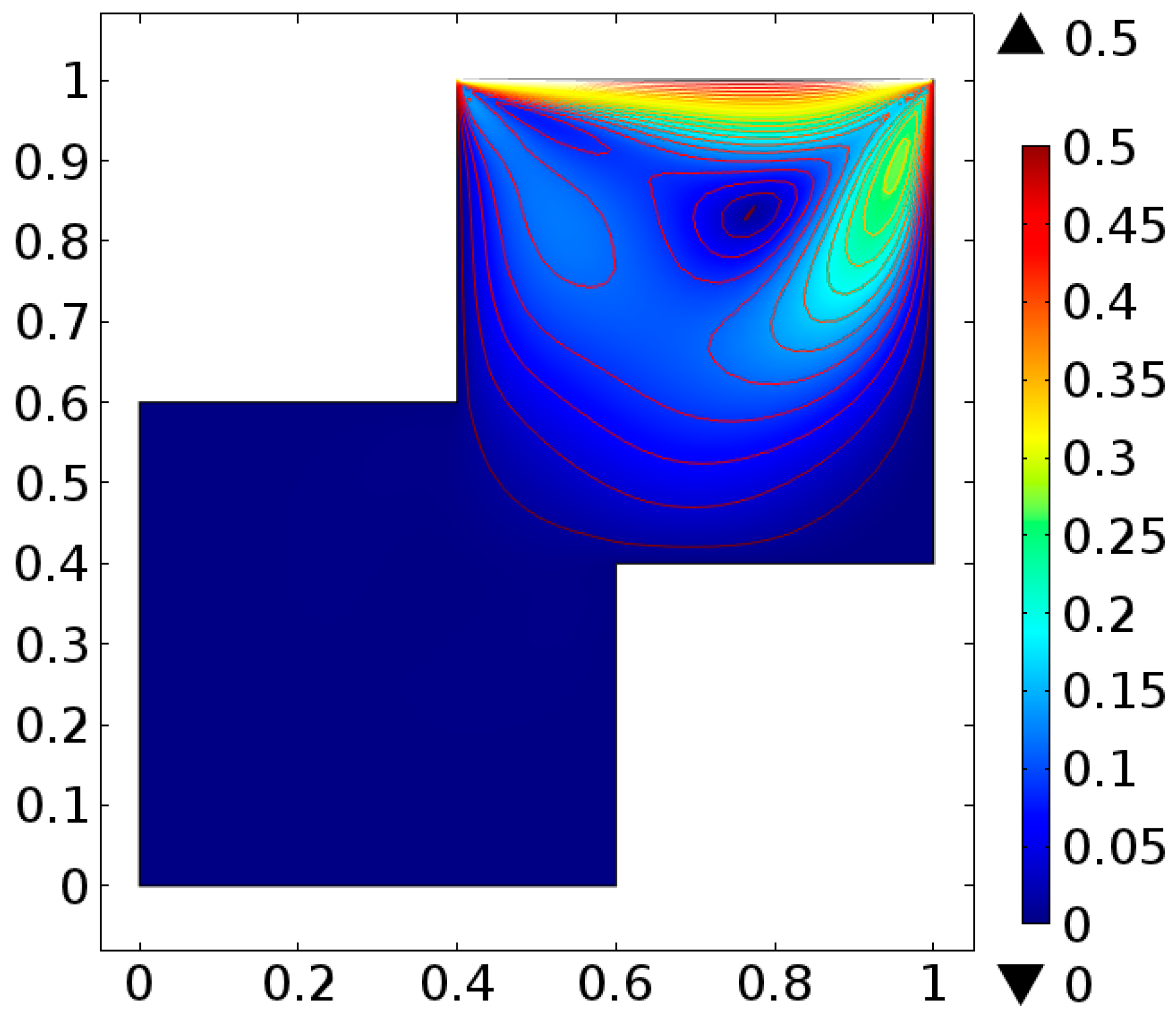

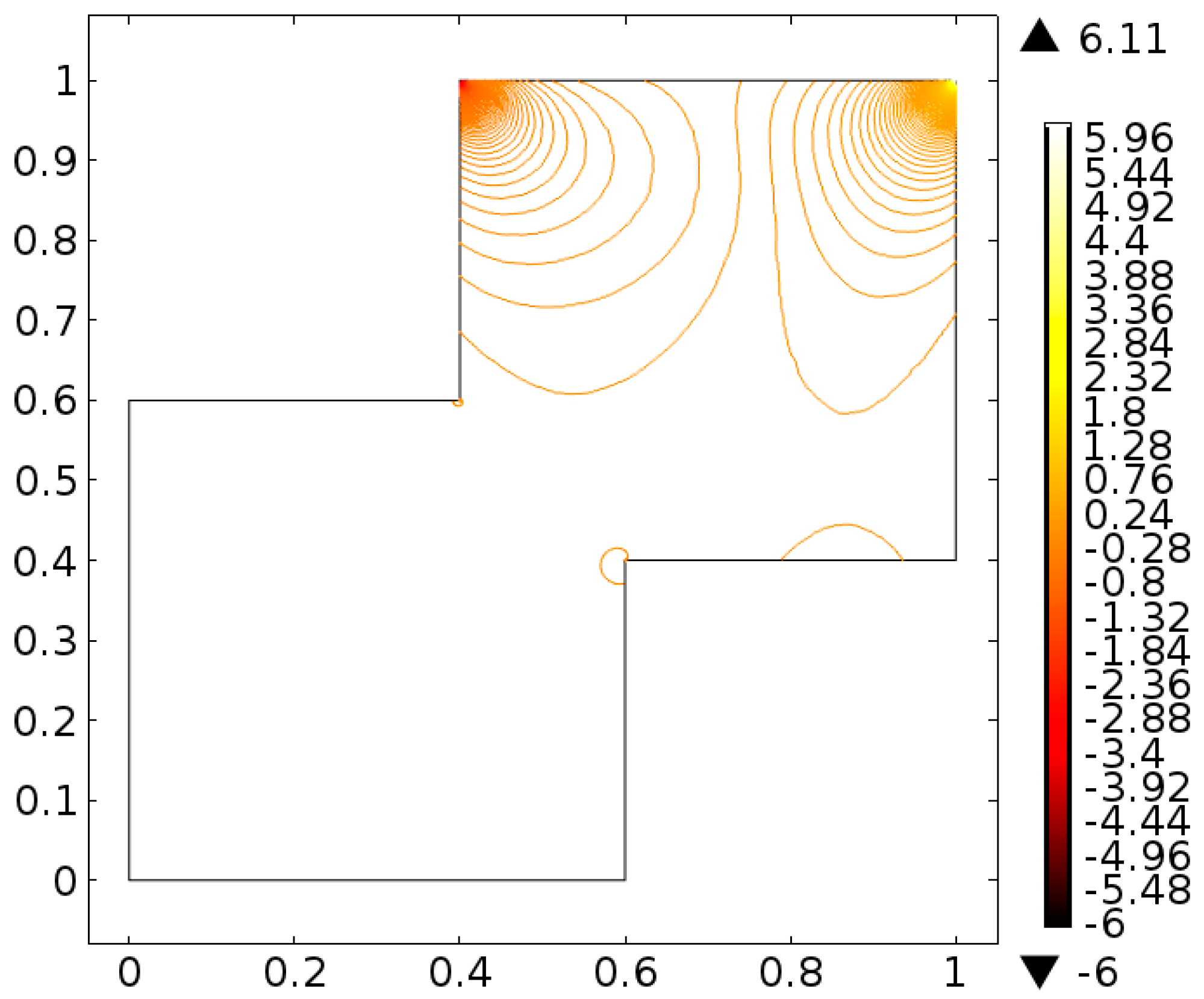

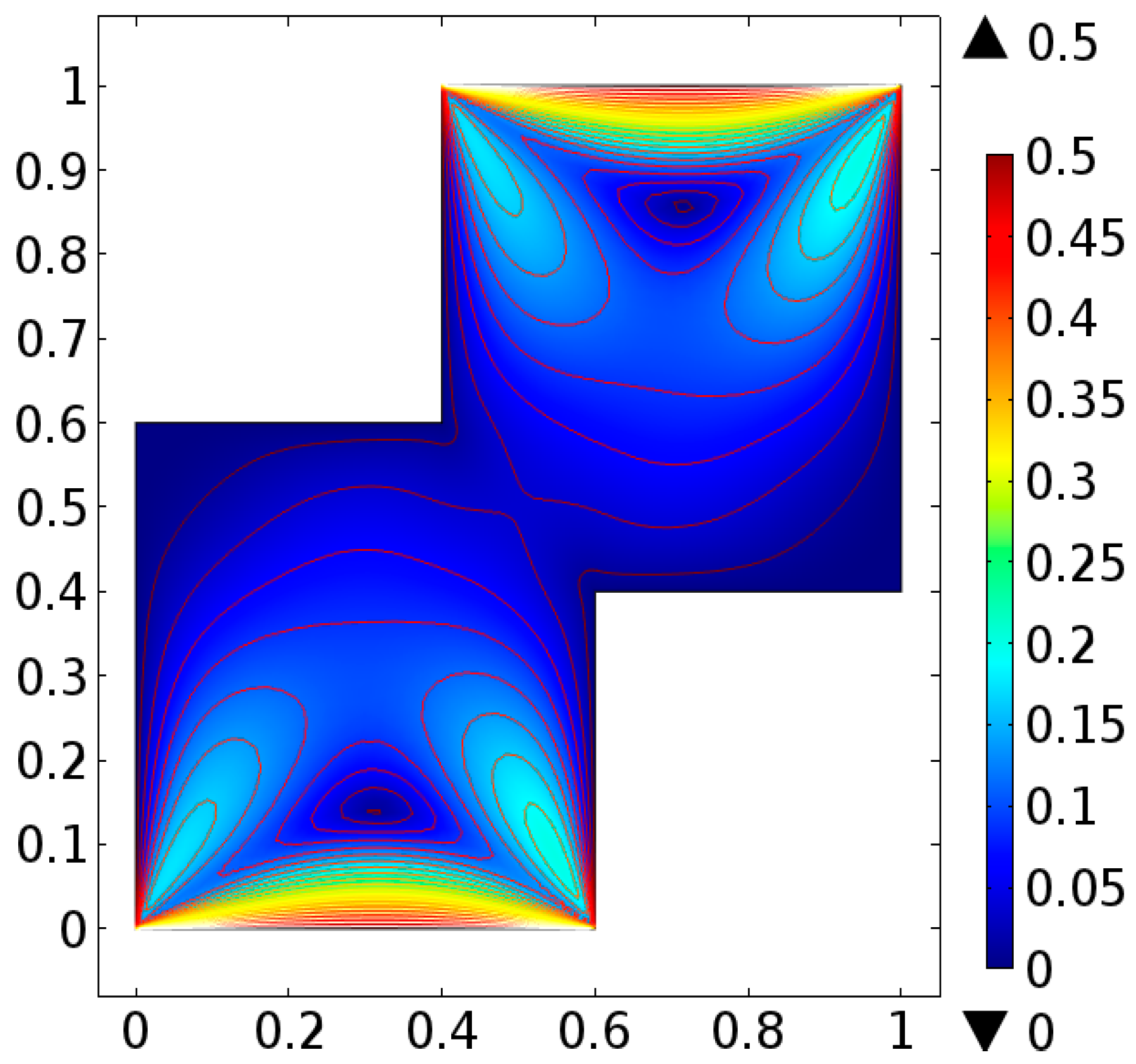

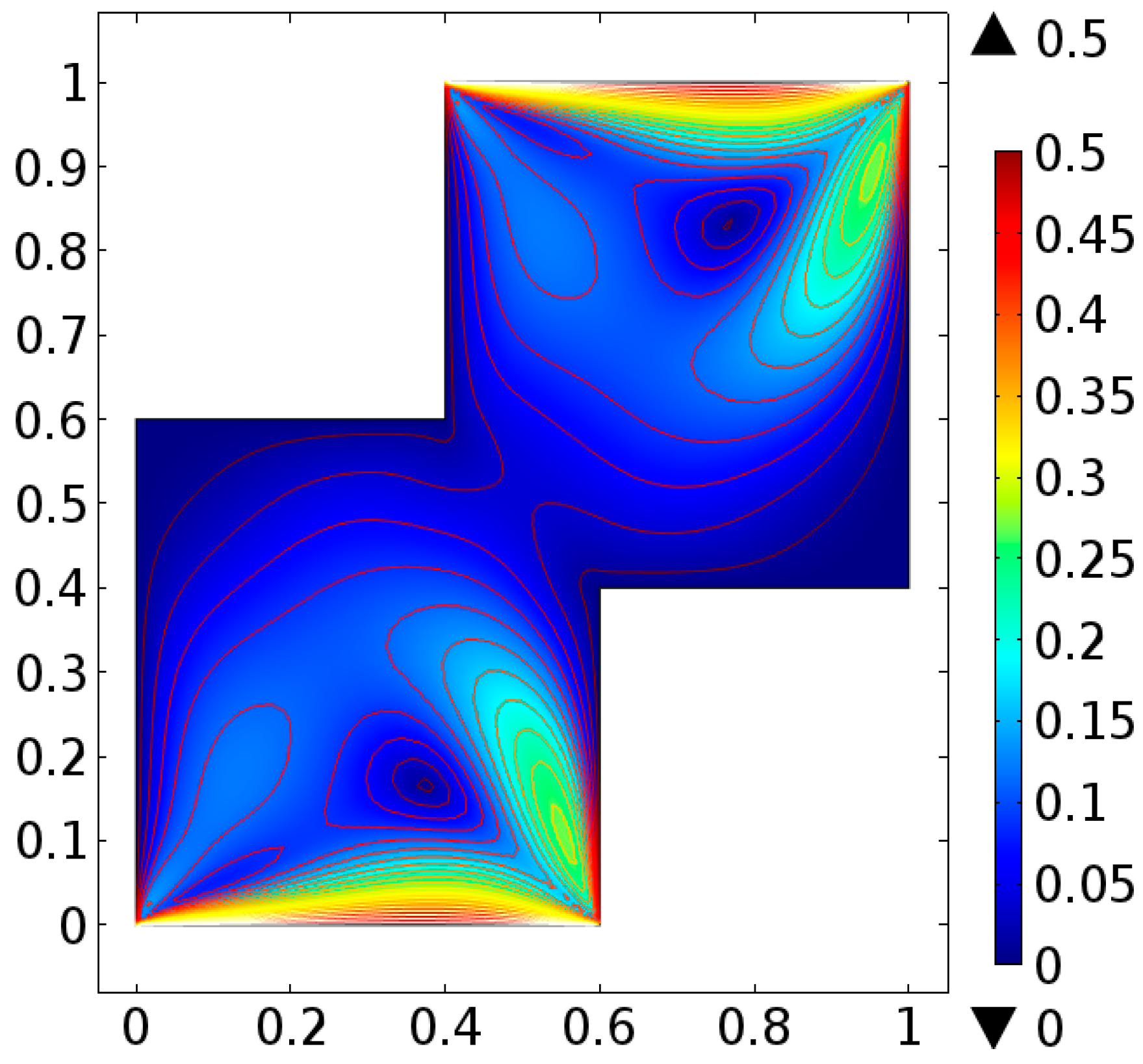

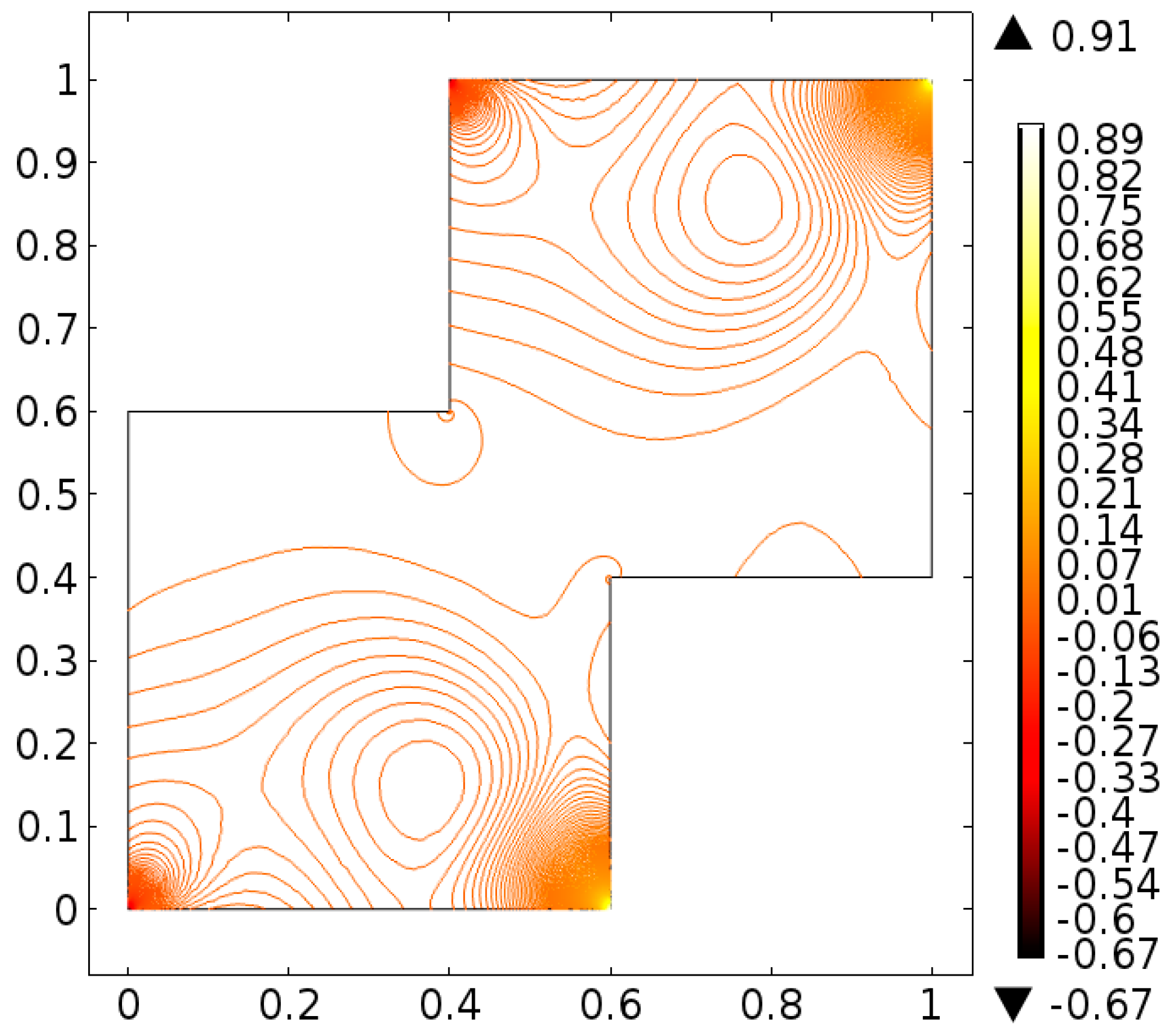

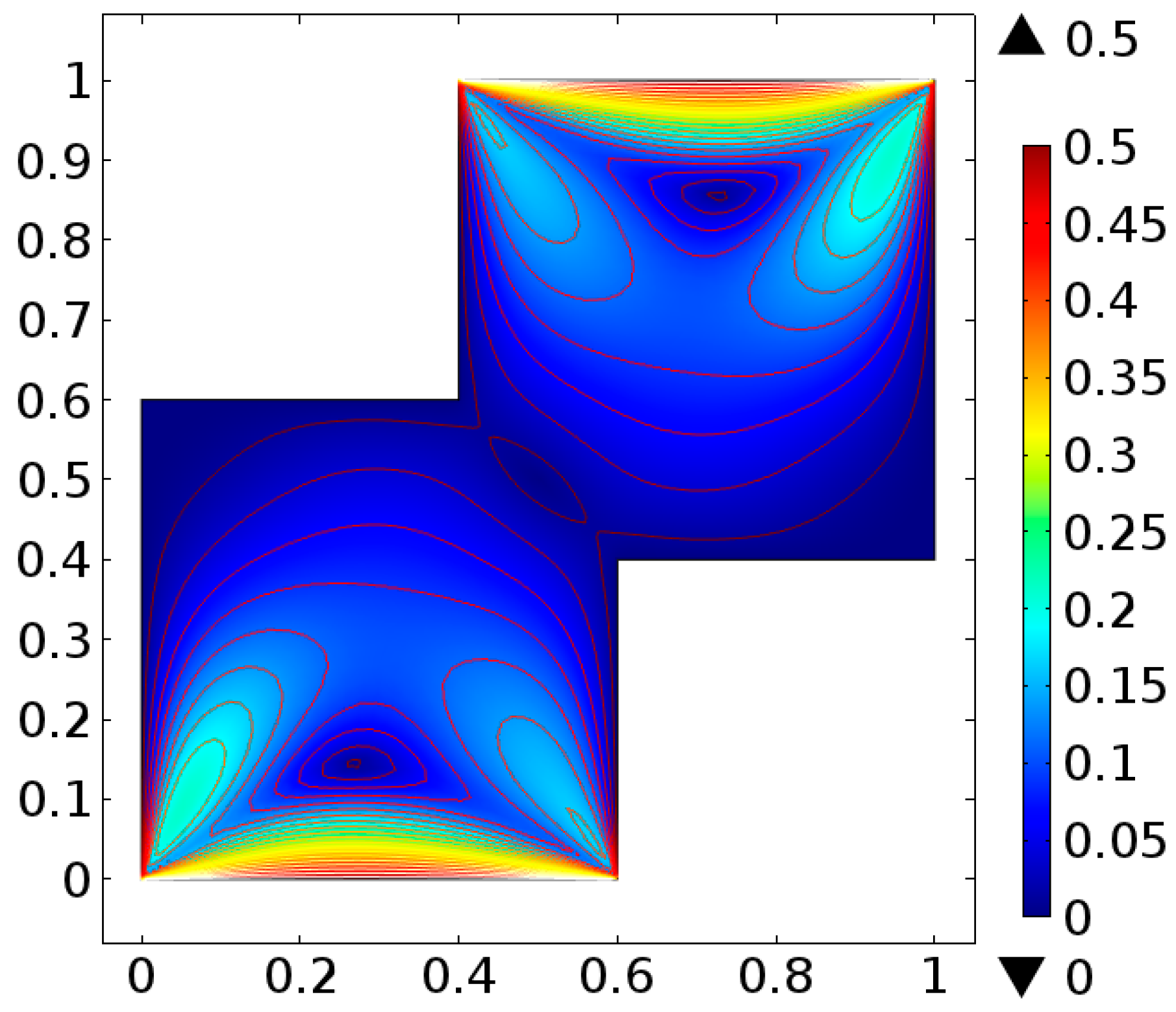

- Both upper and lower walls are moving parallel (Case-II)

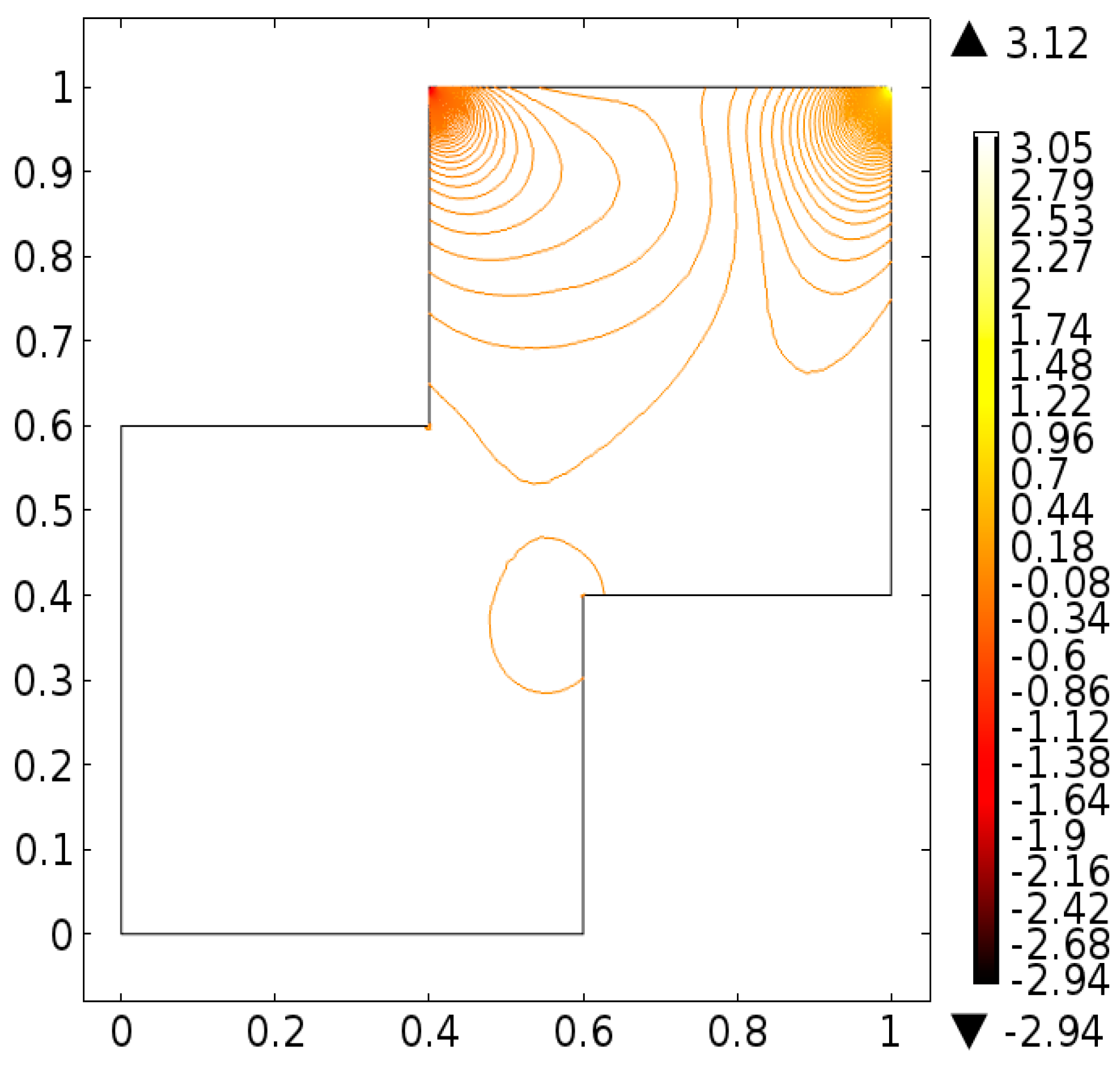

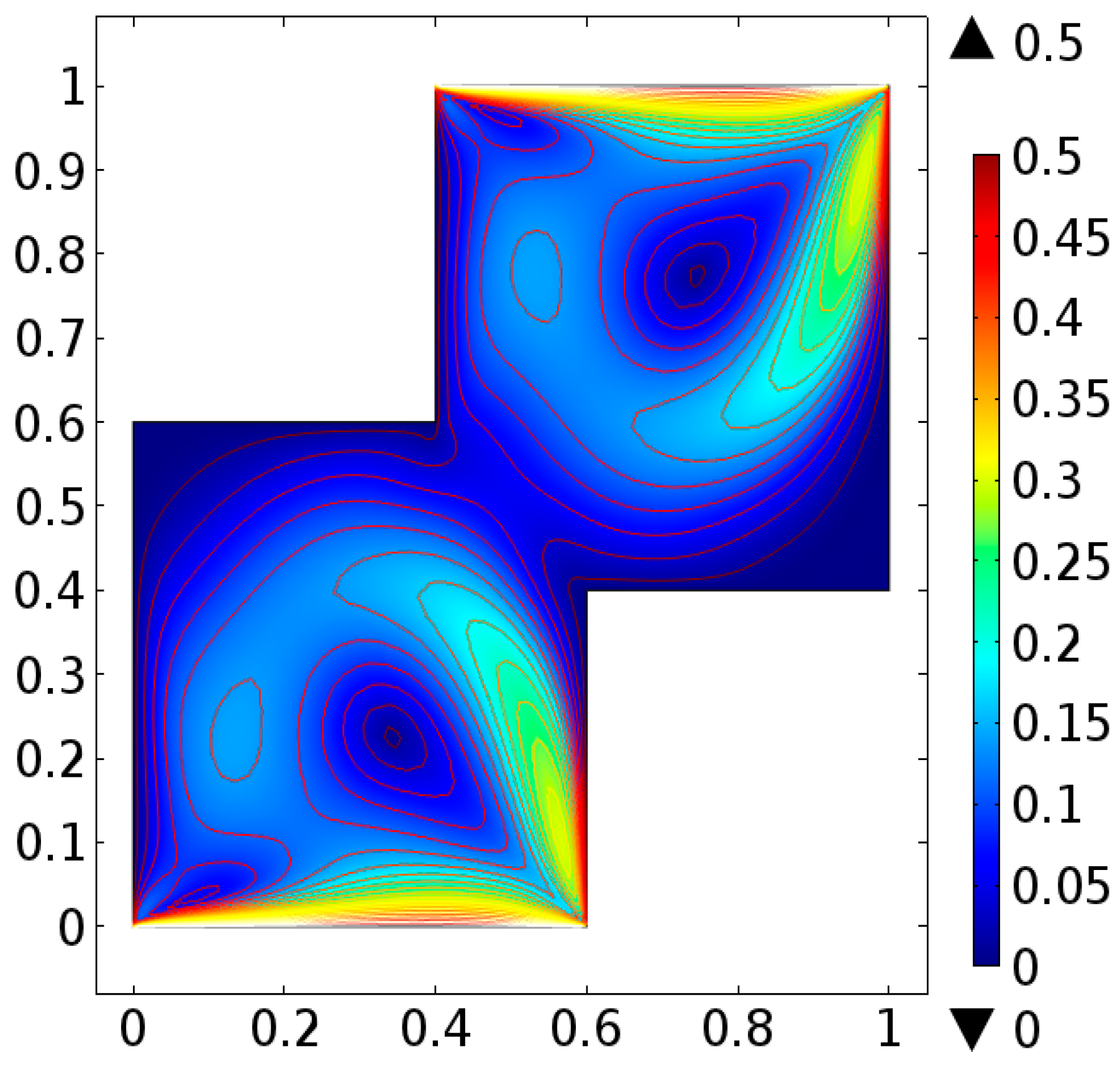

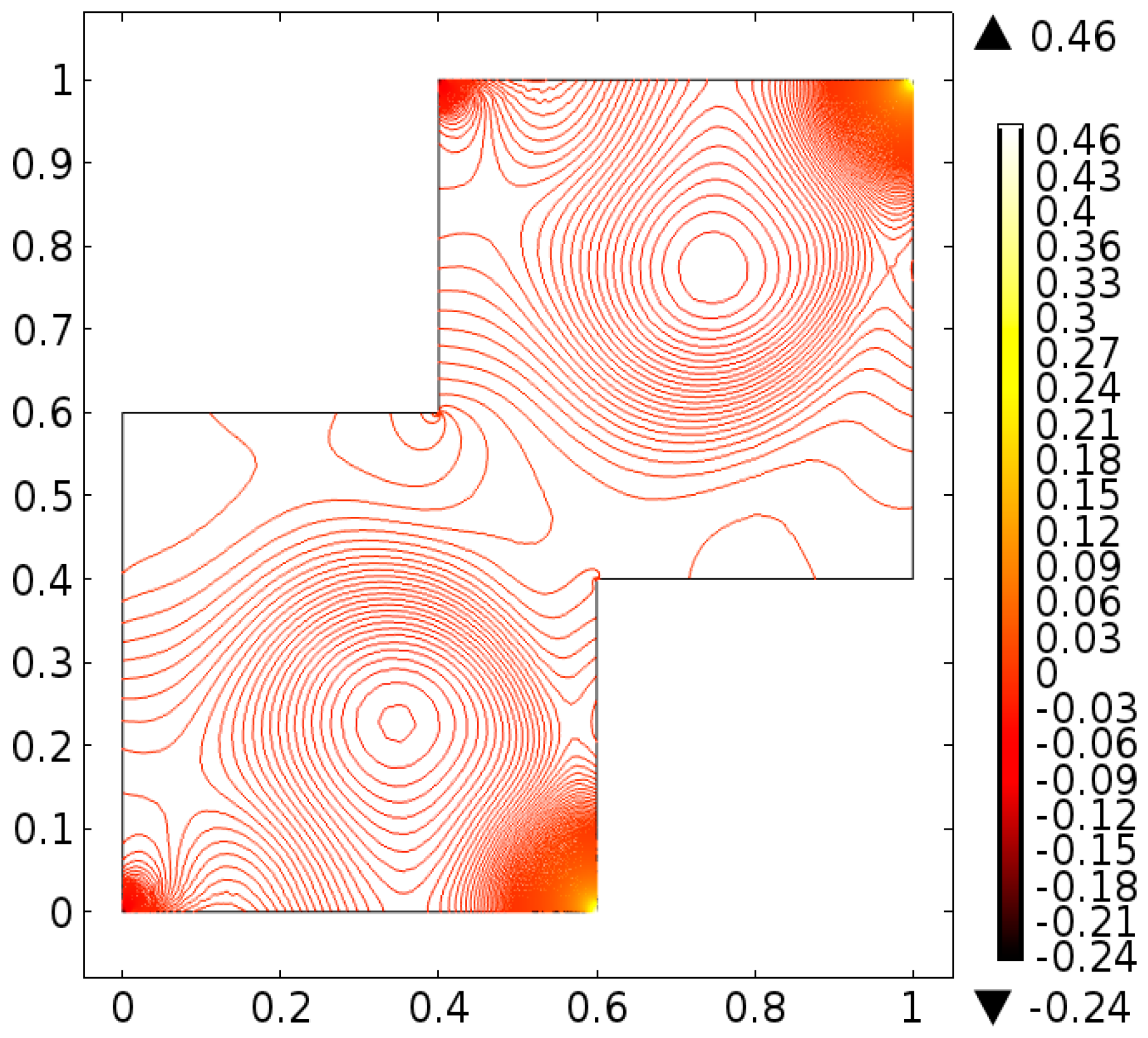

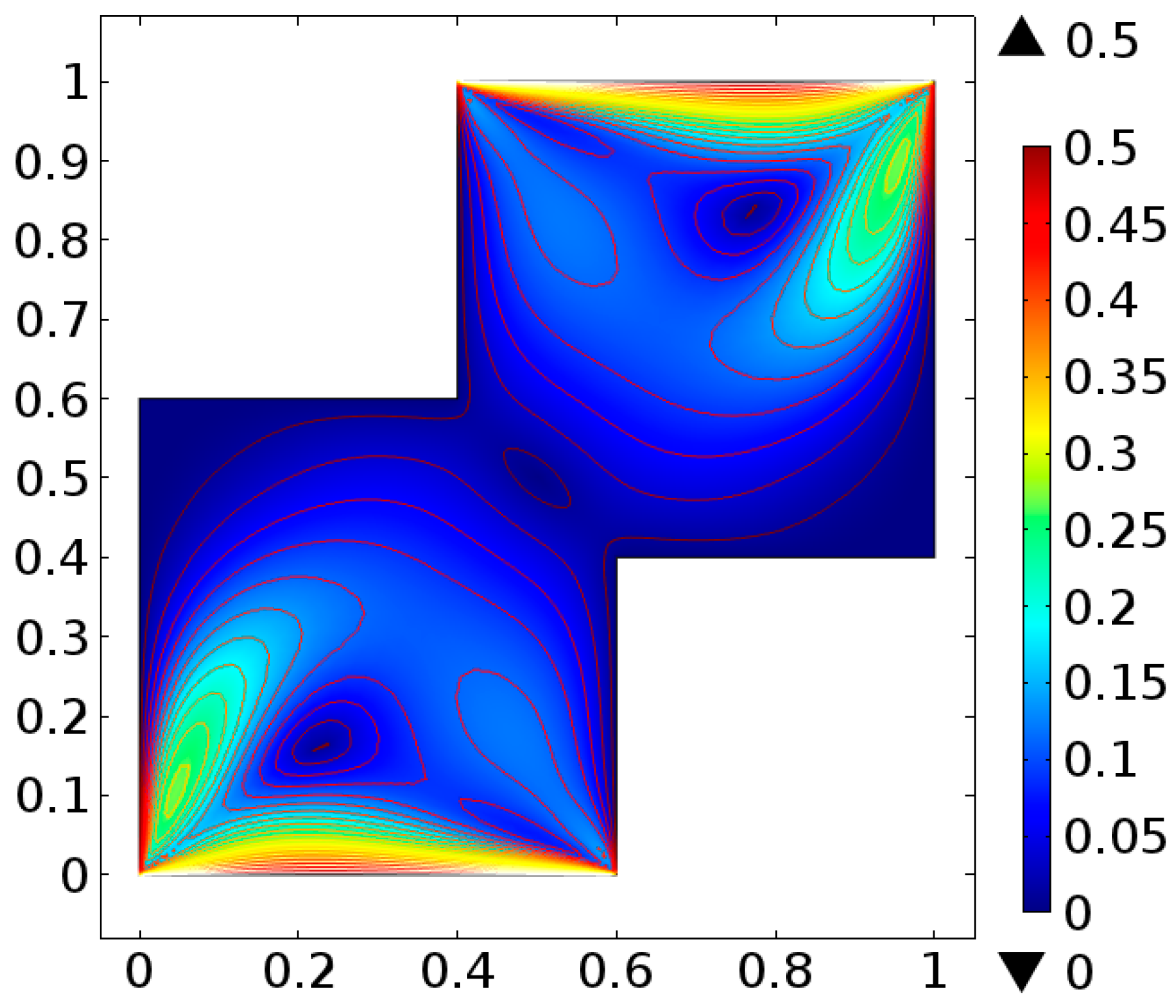

- Both upper and lower walls are moving antiparallel (Case-III)

- Kinetic energy evaluation

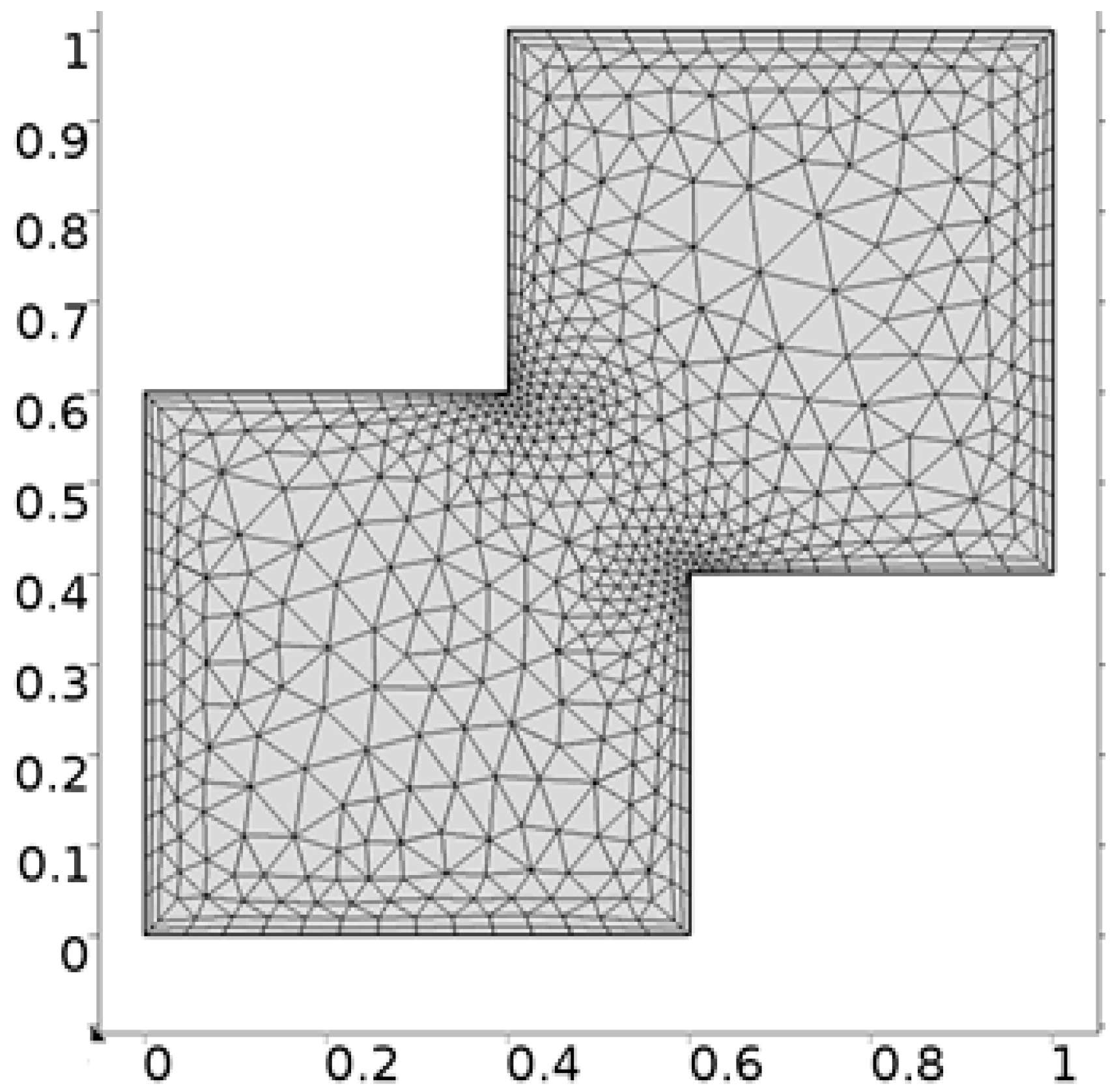

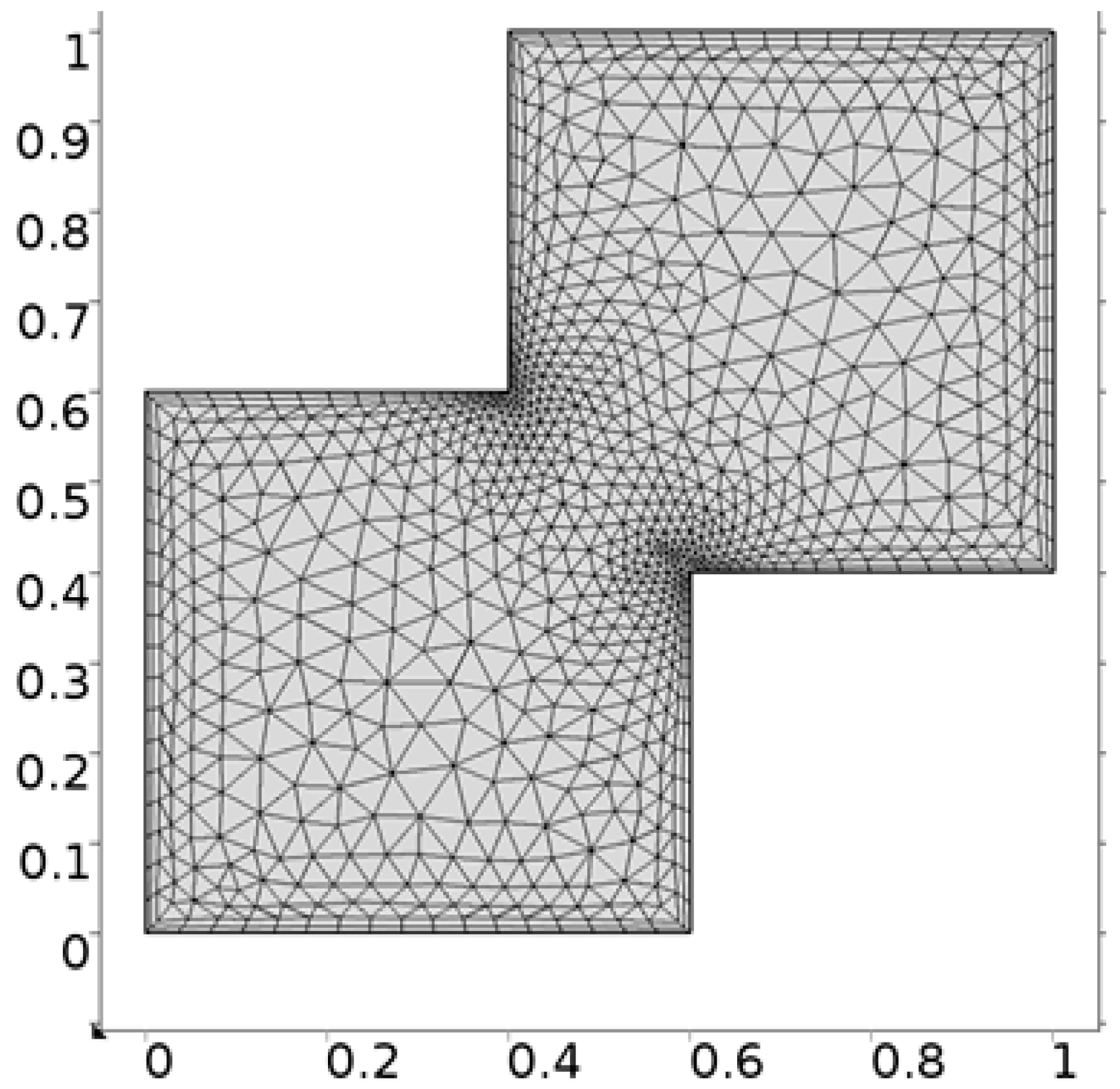

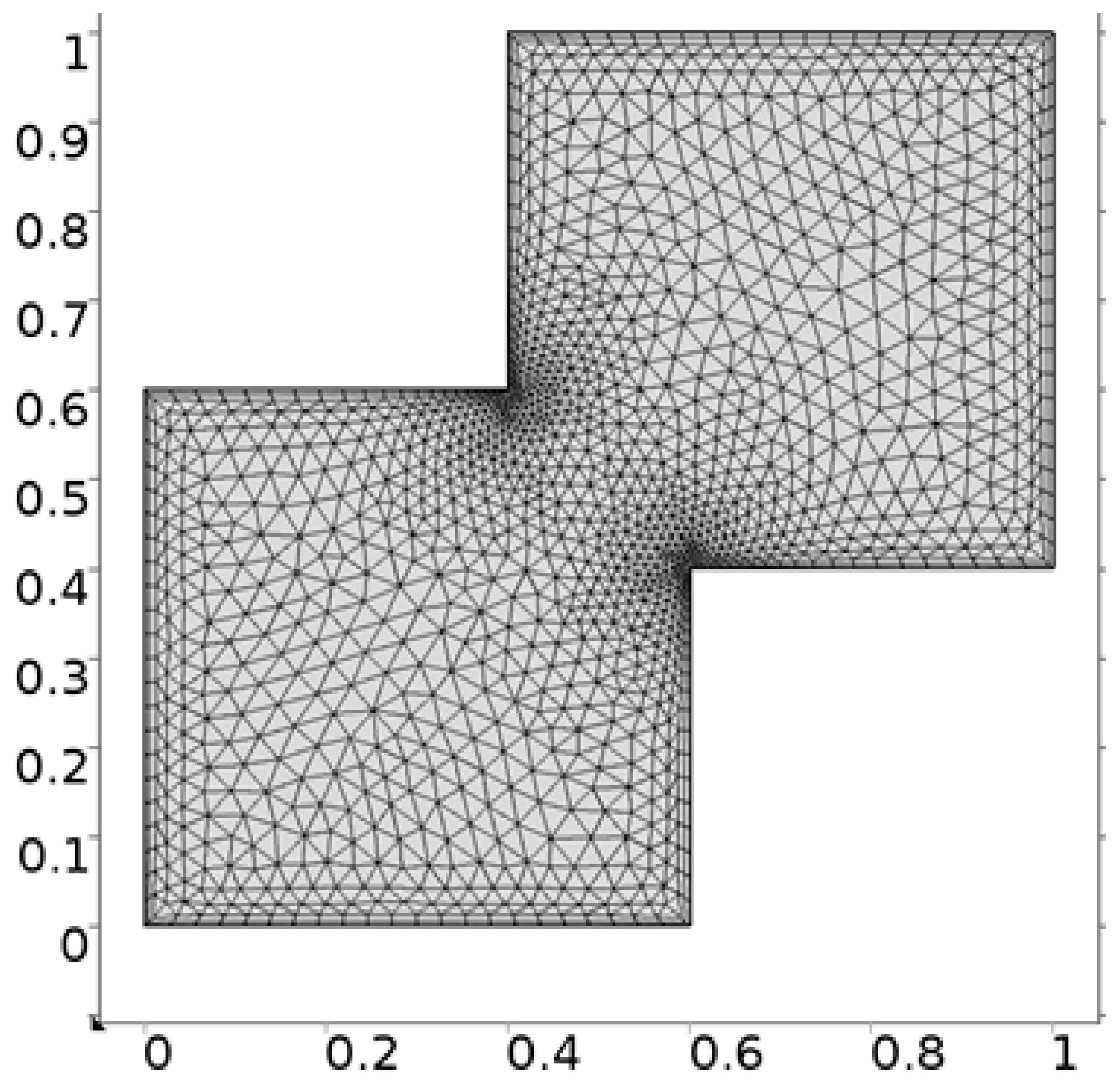

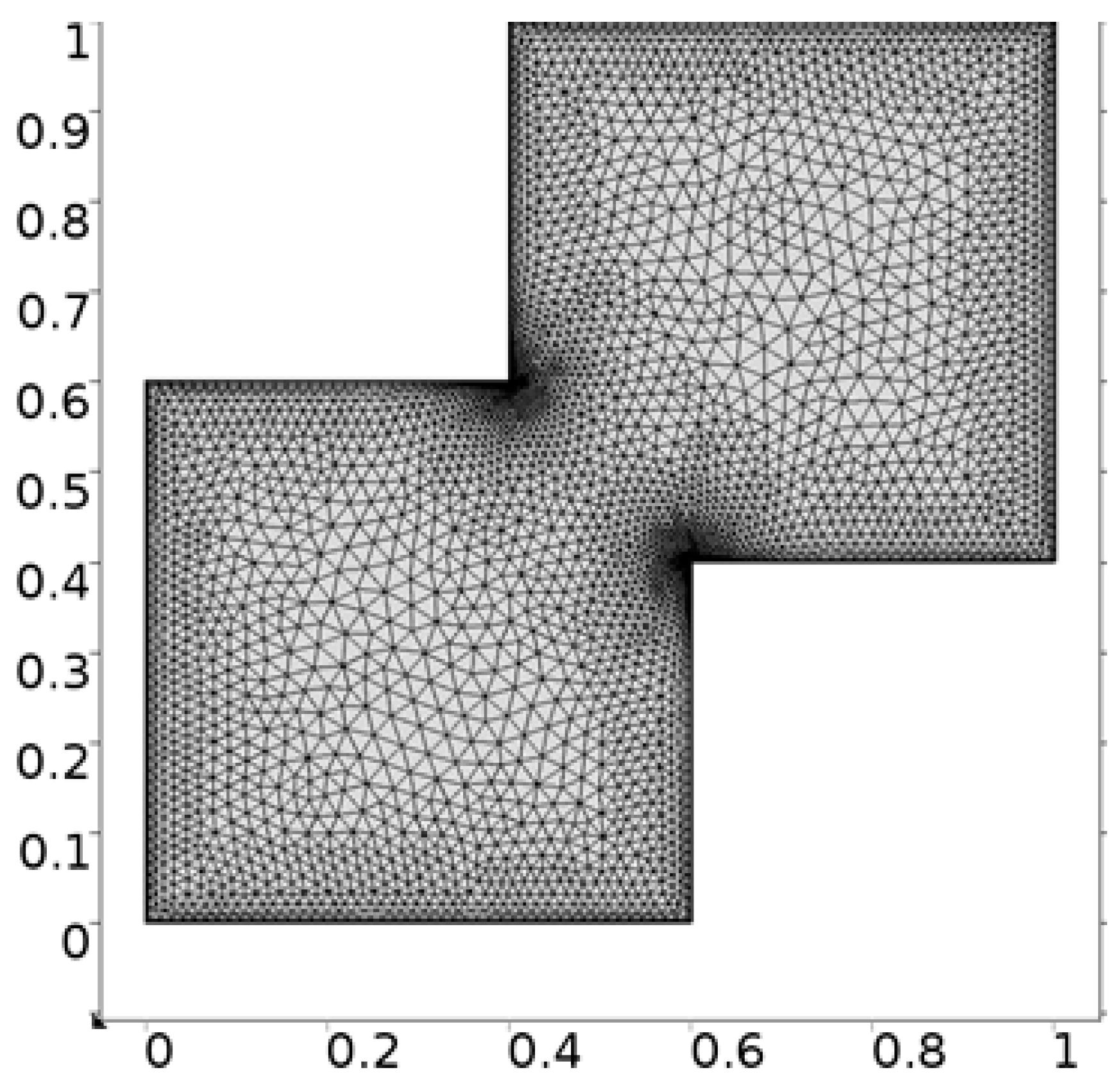

- Hybrid meshing

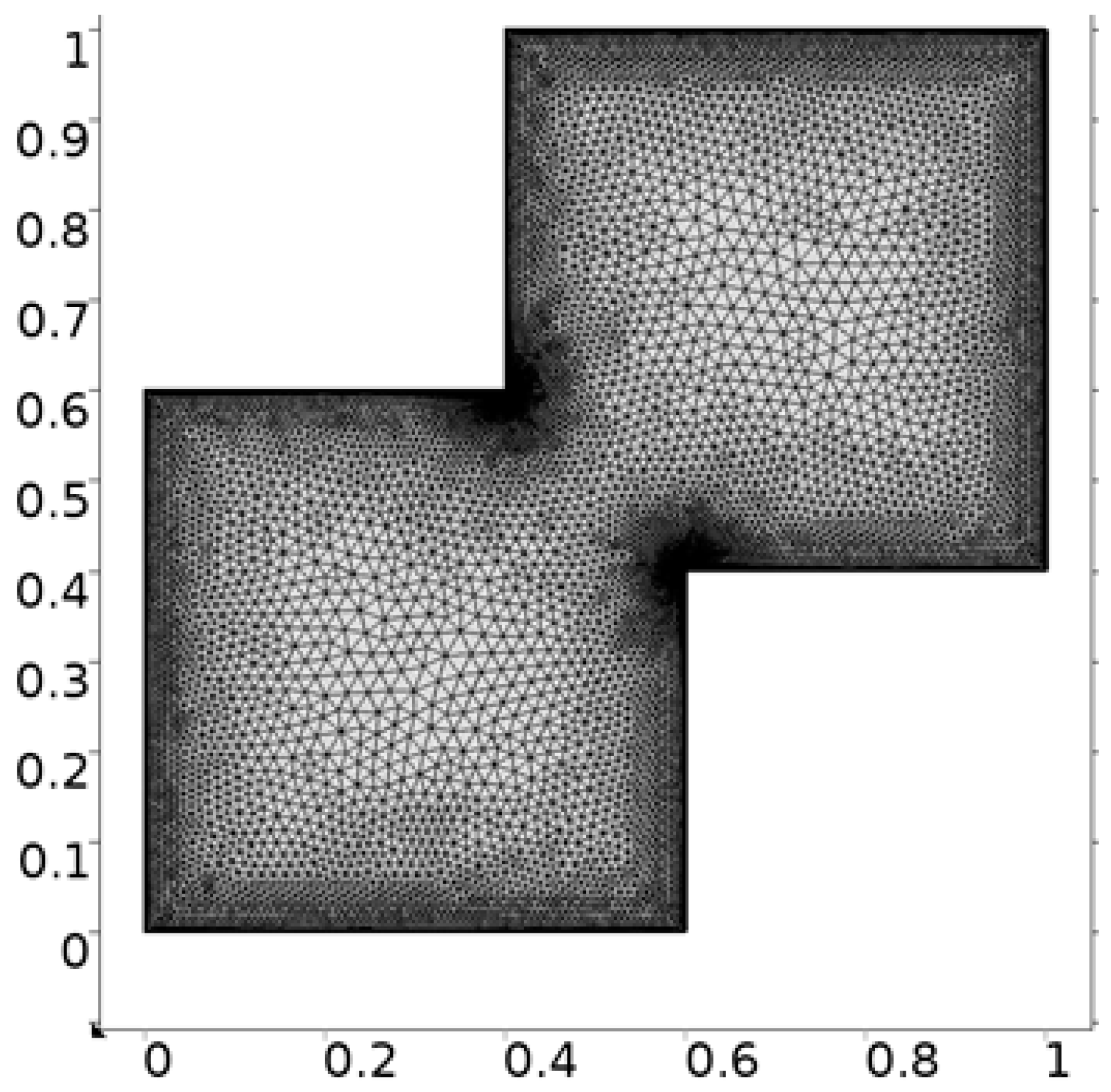

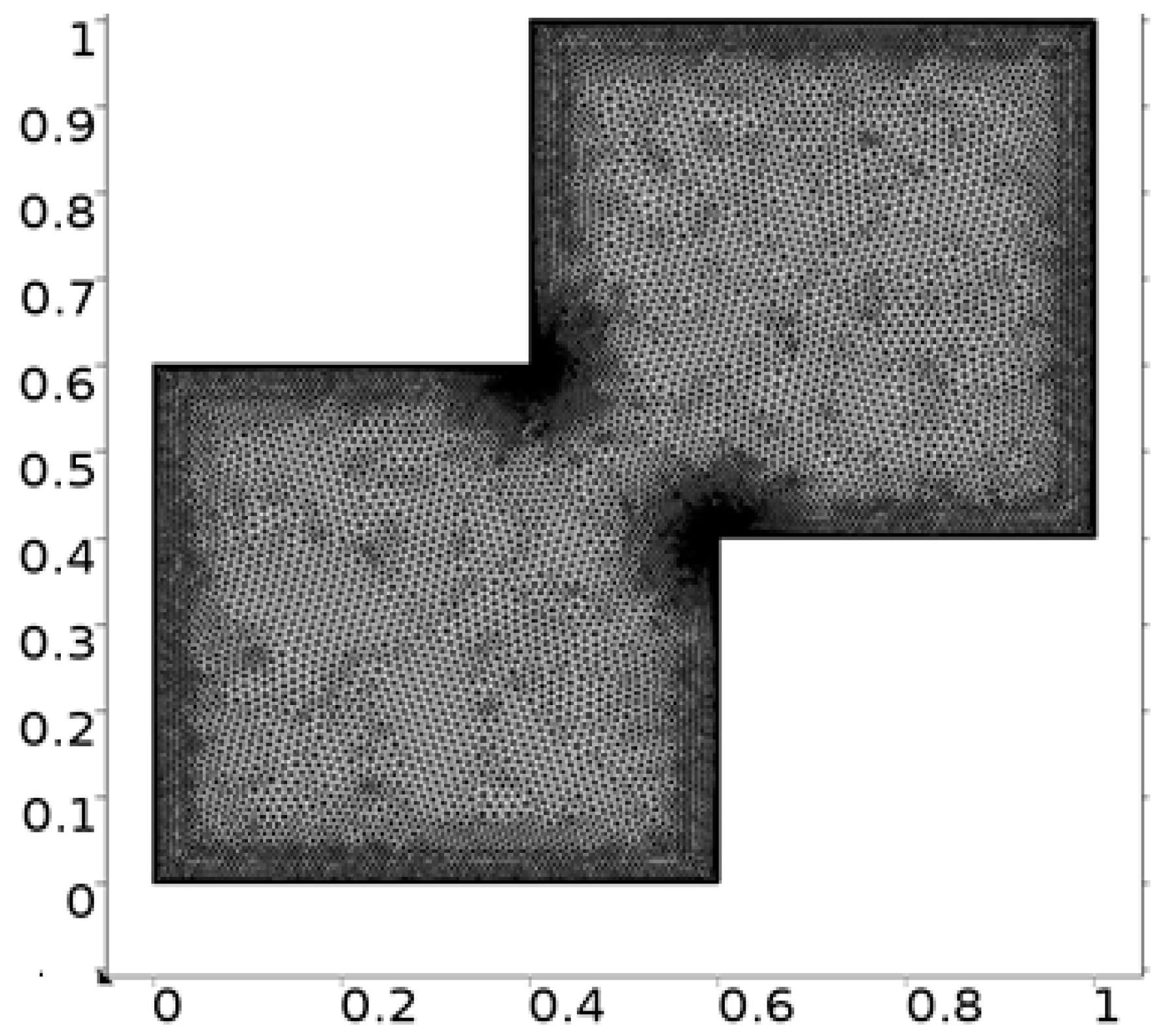

2. Mathematical Modeling

2.1. Continuity Equation

2.2. Momentum Equation

2.3. Boundary Conditions

| Case-I | (12) | |

| Upper wall velocity | ||

| Velocity of rest of walls | ||

| Case-II | (13) | |

| Upper wall velocity | ||

| Lower wall velocity | ||

| Velocity of rest of walls | ||

| Case-III | (14) | |

| Upper wall velocity | ||

| Lower wall velocity | ||

| Velocity of rest of walls | ||

3. Solution Procedure

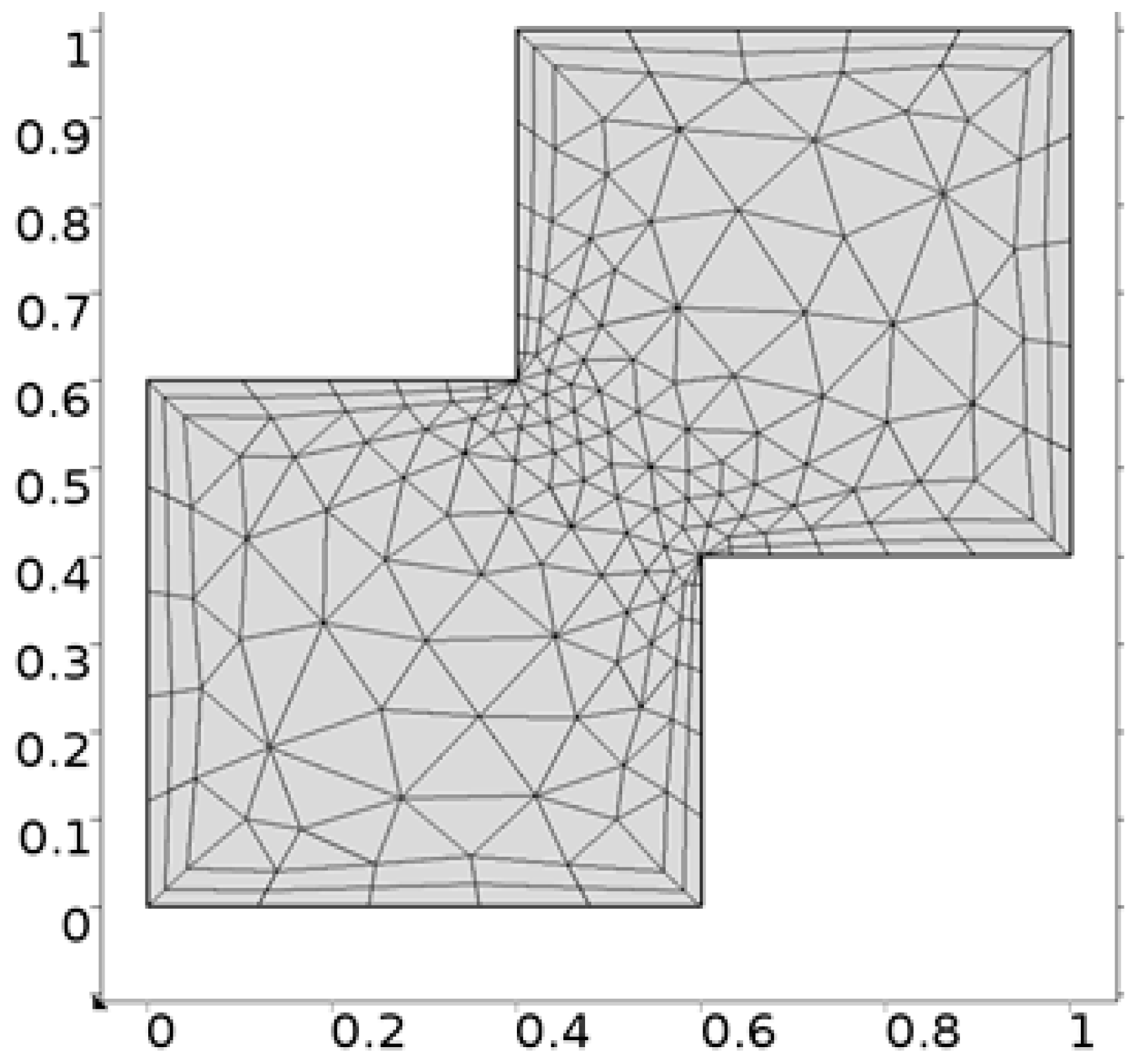

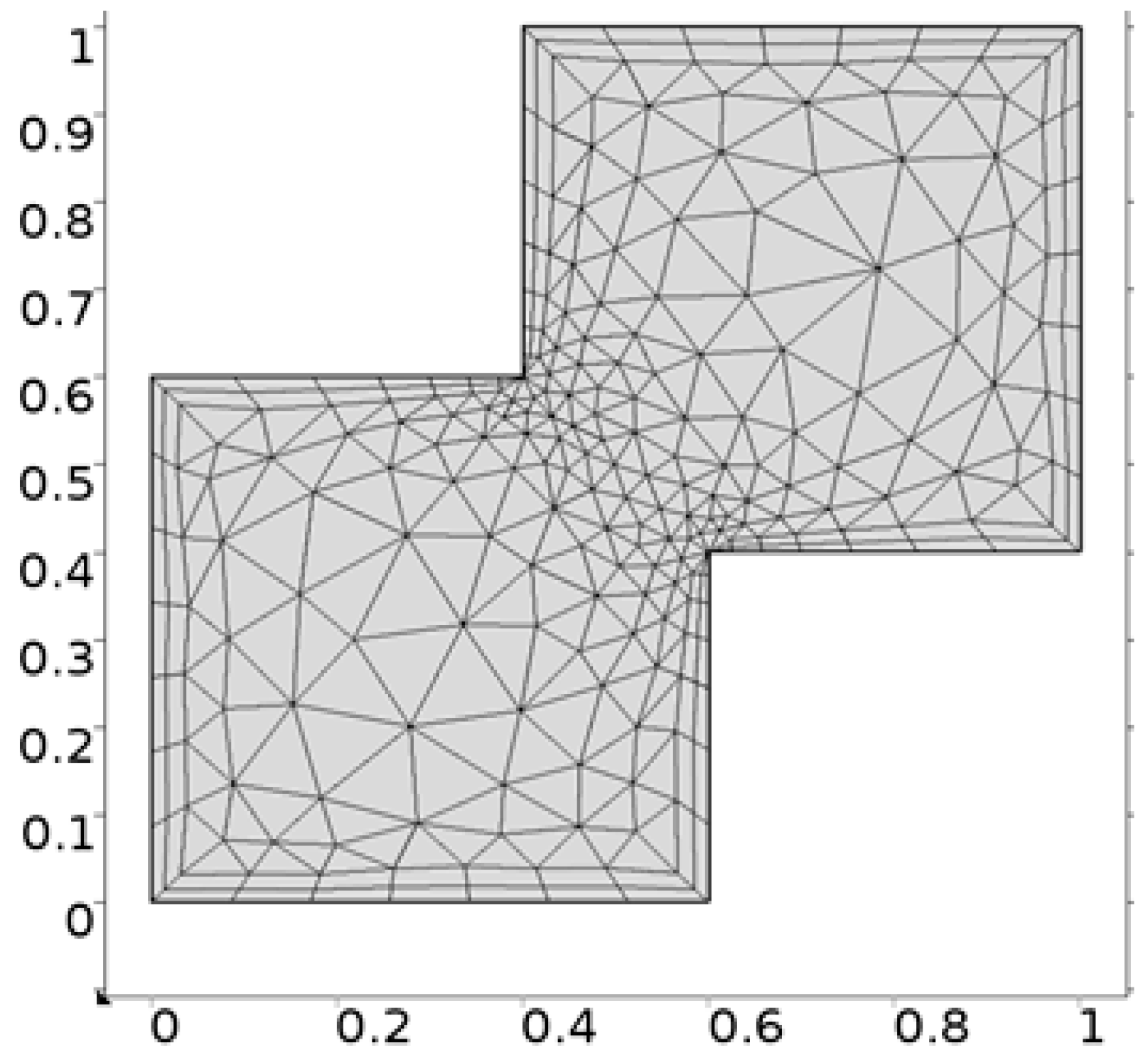

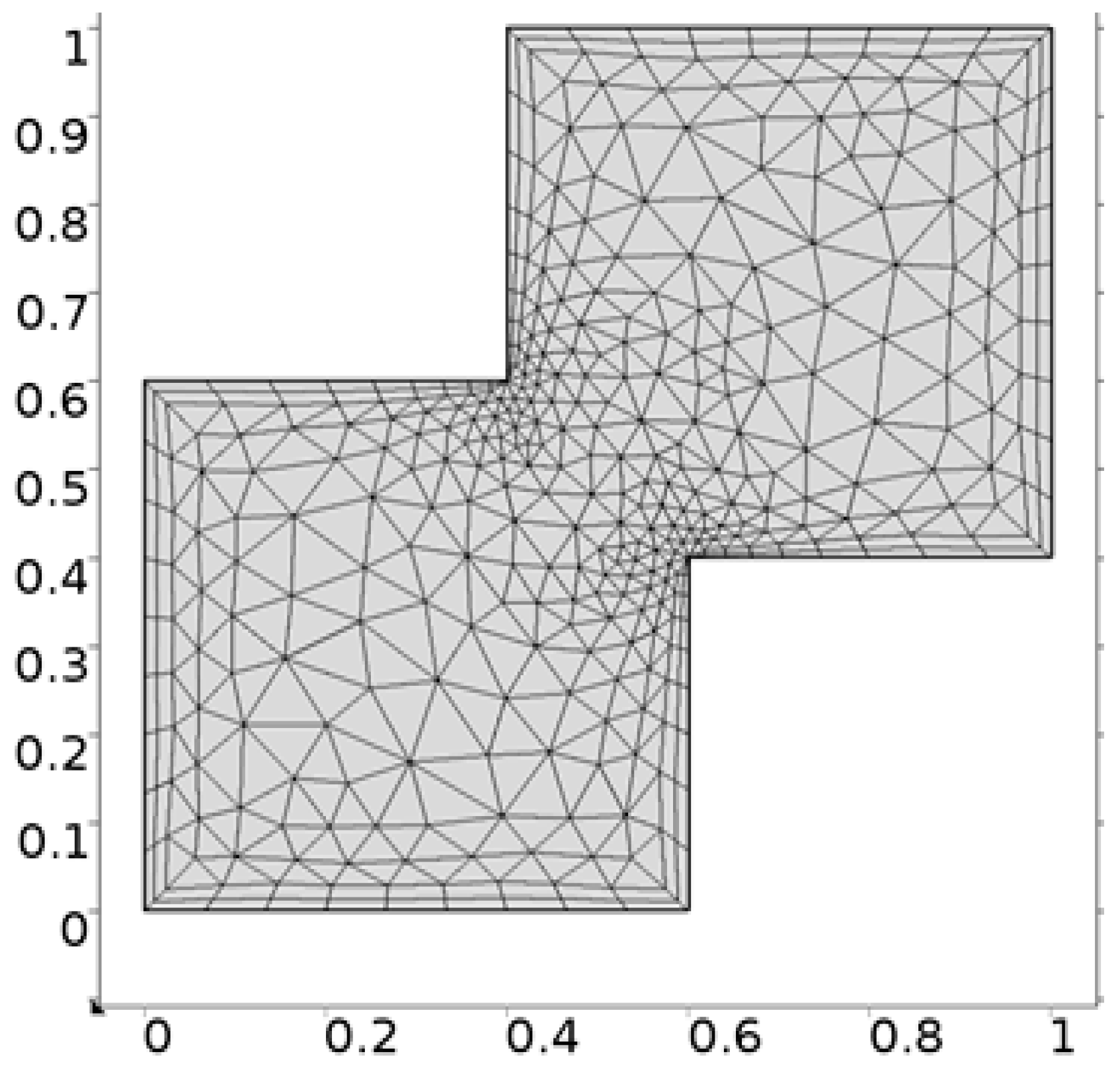

- Discretization of the domain.

- Establish simpler finite element equations.

- Assemble/Combine element equations.

- Incorporate the initial conditions or boundary constraints.

- Solve the developed equations.

- Post processing (Visualization).

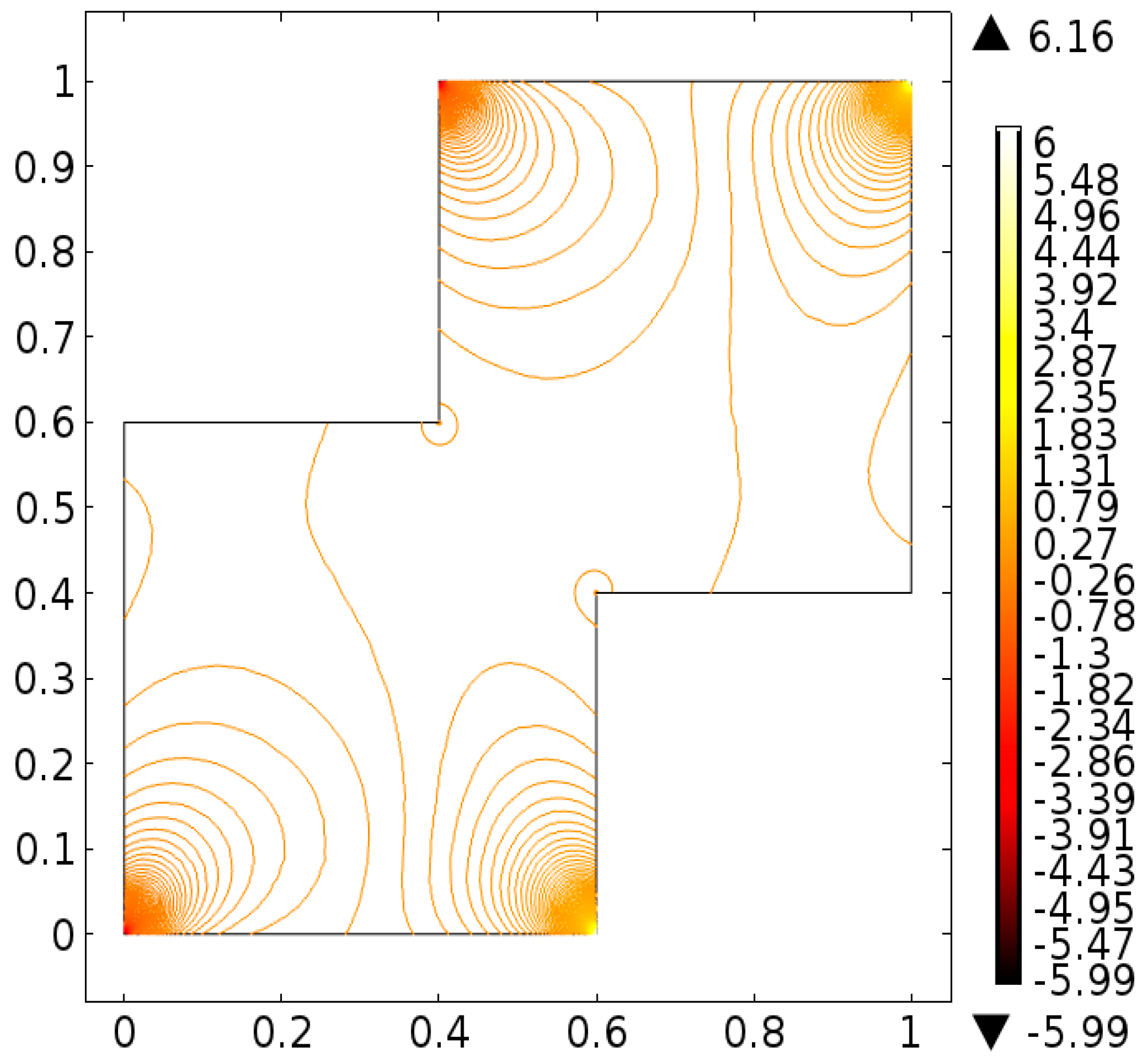

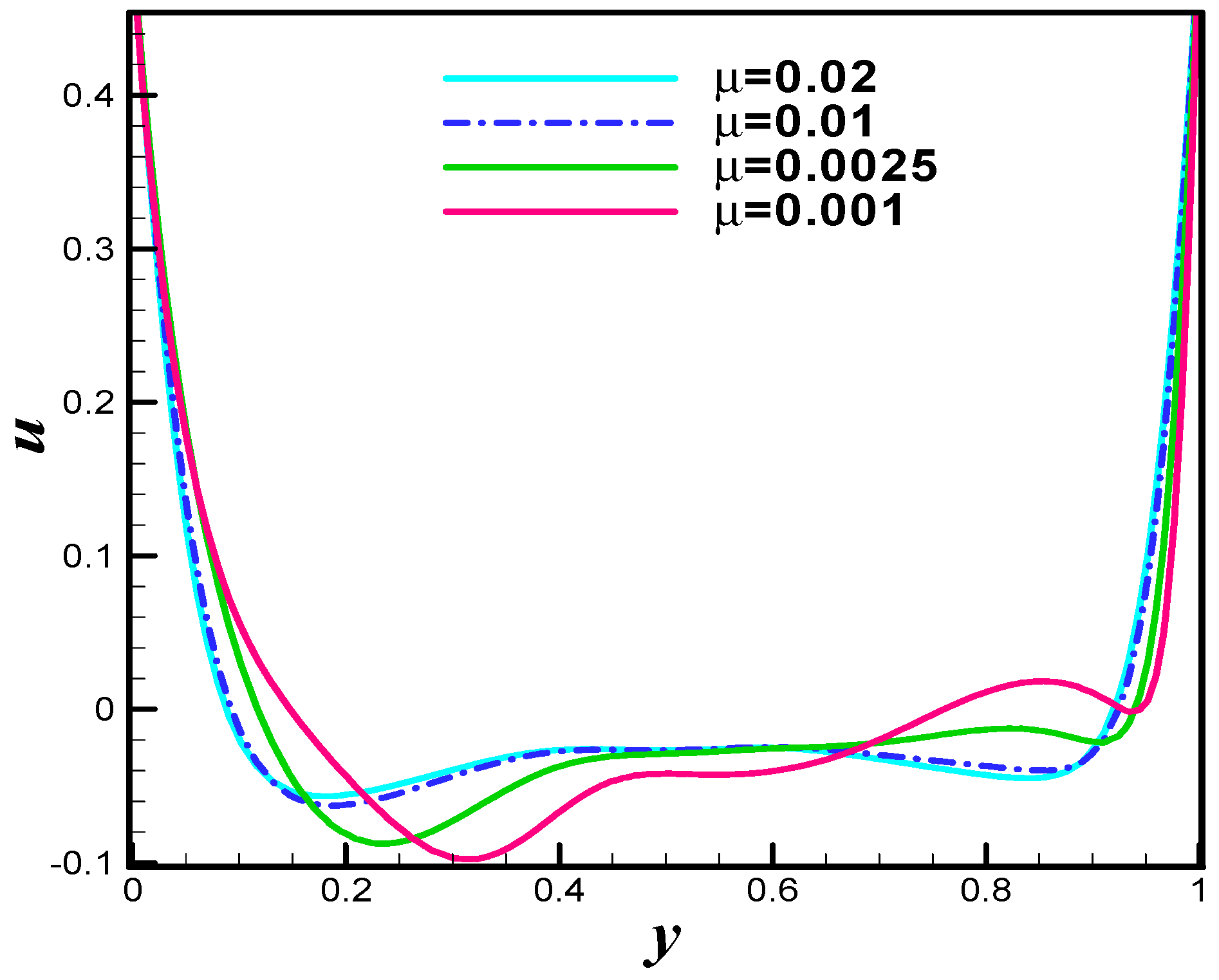

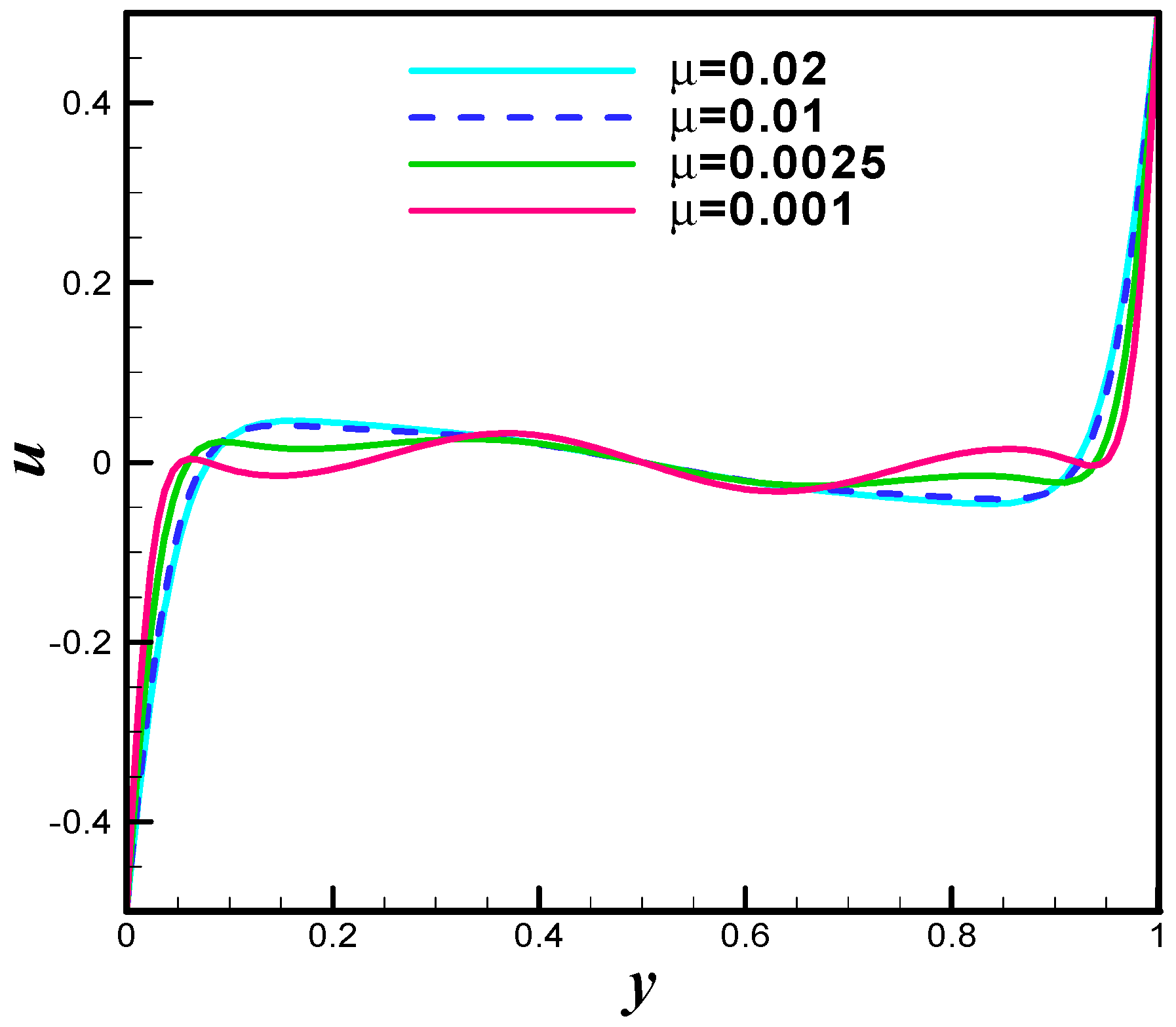

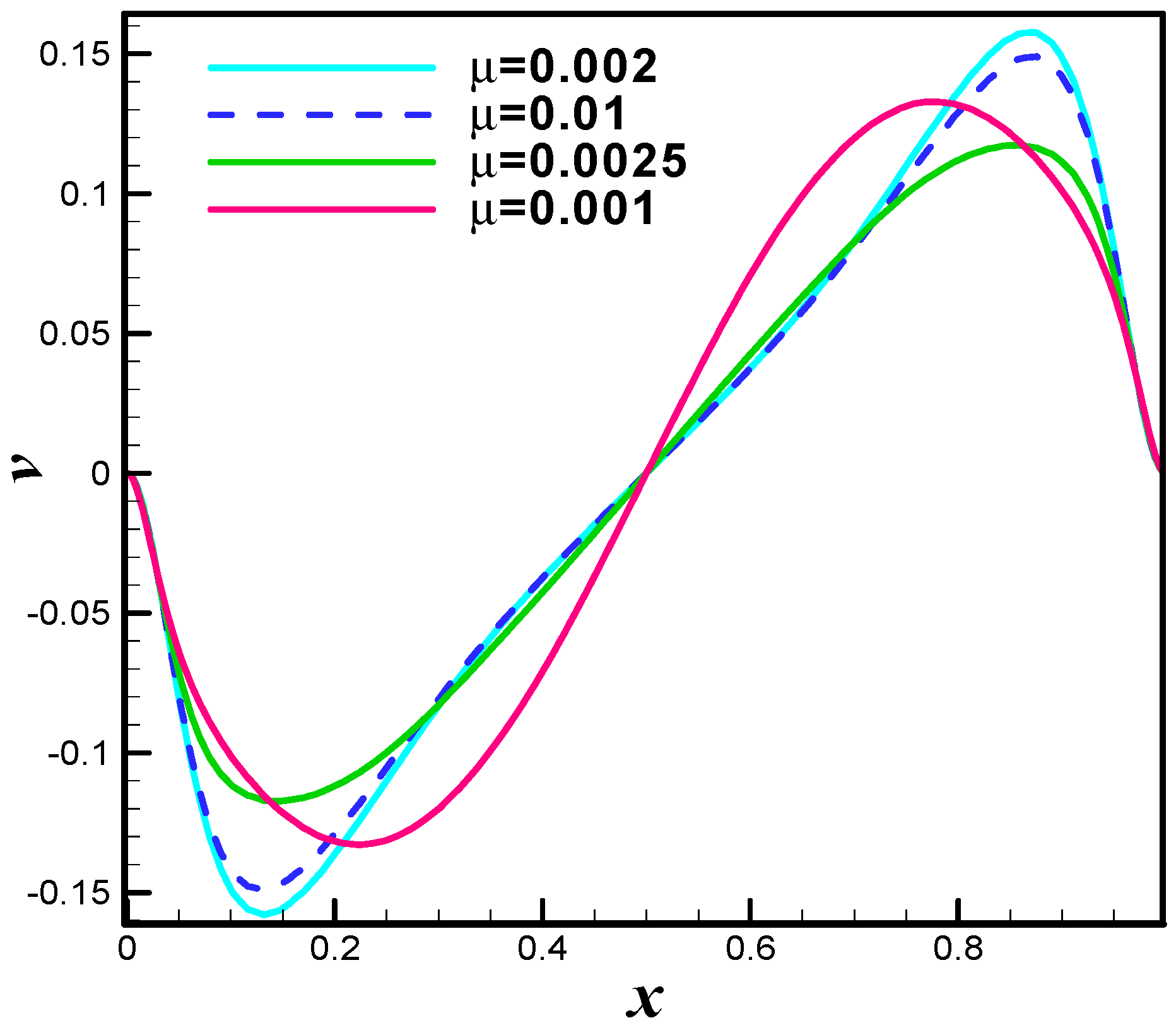

4. Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Dimensional space variables | |

| Dimensionless space variables | |

| Dimensional velocity field | |

| Dimensionless velocity field | |

| Fluid density | |

| Characteristic length | |

| Reference velocity | |

| Dimensional pressure | |

| Dimensionless pressure | |

| Reynolds number | |

| Dynamic viscosity | |

| Body force | |

| Del operator |

References

- Crane, L.J. Flow past a stretching plate. Z. Angew. Math. Phys. ZAMP 1970, 21, 645–647. [Google Scholar] [CrossRef]

- Devi, C.; Takhar, H.; Nath, G. Unsteady, three-dimensional, boundary-layer flow due to a stretching surface. Int. J. Heat Mass Transf. 1986, 29, 1996–1999. [Google Scholar] [CrossRef]

- Smith, S.H. An Exact Solution of the Unsteady Navier-Stokes Equations Resulting from a Stretching Surface. J. Appl. Mech. 1994, 61, 629–633. [Google Scholar] [CrossRef]

- Pop, I.; Na, T.-Y. Unsteady flow past a stretching sheet. Mech. Res. Commun. 1996, 23, 413–422. [Google Scholar] [CrossRef]

- Chiam, T. Heat transfer with variable conductivity in a stagnation-point flow towards a stretching sheet. Int. Commun. Heat Mass Transf. 1996, 23, 239–248. [Google Scholar] [CrossRef]

- Vajravelu, K.; Hadjinicolaou, A. Convective heat transfer in an electrically conducting fluid at a stretching surface with uniform free stream. Int. J. Eng. Sci. 1997, 35, 1237–1244. [Google Scholar] [CrossRef]

- Chamkha, A.J. Unsteady hydromagnetic flow and heat transfer from a non-isothermal stretching sheet immersed in a porous medium. Int. Commun. Heat Mass Transf. 1998, 25, 899–906. [Google Scholar] [CrossRef]

- Sarma, M.; Rao, B. Heat Transfer in a Viscoelastic Fluid over a Stretching Sheet. J. Math. Anal. Appl. 1998, 222, 268–275. [Google Scholar] [CrossRef]

- Subhas, A.; Veena, P. Visco-elastic fluid flow and heat transfer in a porous medium over a stretching sheet. Int. J. Non-linear Mech. 1998, 33, 531–540. [Google Scholar] [CrossRef]

- Vajravelu, K.; Roper, T. Flow and heat transfer in a second grade fluid over a stretching sheet. Int. J. Non-Linear Mech. 1999, 34, 1031–1036. [Google Scholar] [CrossRef]

- Yürüsoy, M.; Pakdemirli, M. Exact solutions of boundary layer equations of a special non-Newtonian fluid over a stretching sheet. Mech. Res. Commun. 1999, 26, 171–175. [Google Scholar] [CrossRef]

- Takhar, H.; Chamkha, A.; Nath, G. Flow and mass transfer on a stretching sheet with a magnetic field and chemically reactive species. Int. J. Eng. Sci. 2000, 38, 1303–1314. [Google Scholar] [CrossRef]

- Andersson, H.I.; Aarseth, J.B.; Dandapat, B.S. Heat transfer in a liquid film on an unsteady stretching surface. Int. J. Heat Mass Transf. 2000, 43, 69–74. [Google Scholar] [CrossRef]

- Vajravelu, K. Viscous flow over a nonlinearly stretching sheet. Appl. Math. Comput. 2001, 124, 281–288. [Google Scholar] [CrossRef]

- Abel, M.; Khan, S.K.; Prasad, K. Study of visco-elastic fluid flow and heat transfer over a stretching sheet with variable viscosity. Int. J. Non-Linear Mech. 2002, 37, 81–88. [Google Scholar] [CrossRef]

- Prasad, K.; Abel, S.; Datti, P. Diffusion of chemically reactive species of a non-Newtonian fluid immersed in a porous medium over a stretching sheet. Int. J. Non-Linear Mech. 2003, 38, 651–657. [Google Scholar] [CrossRef]

- Nazar, R.; Amin, N.; Filip, D.; Pop, I. Stagnation point flow of a micropolar fluid towards a stretching sheet. Int. J. Non-Linear Mech. 2004, 39, 1227–1235. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Layek, G.; Samad, S. Study of MHD boundary layer flow over a heated stretching sheet with variable viscosity. Int. J. Heat Mass Transf. 2005, 48, 4460–4466. [Google Scholar] [CrossRef]

- Hsiao, K.-L. Conjugate heat transfer of magnetic mixed convection with radiative and viscous dissipation effects for second-grade viscoelastic fluid past a stretching sheet. Appl. Therm. Eng. 2007, 27, 1895–1903. [Google Scholar] [CrossRef]

- Abel, M.S.; Nandeppanavar, M.M. Heat transfer in MHD viscoelastic boundary layer flow over a stretching sheet with non-uniform heat source/sink. Commun. Nonlinear Sci. Numer. Simul. 2009, 14, 2120–2131. [Google Scholar] [CrossRef]

- Kelson, N.A. Note on similarity solutions for viscous flow over an impermeable and non-linearly (quadratic) stretching sheet. Int. J. Non-Linear Mech. 2011, 46, 1090–1091. [Google Scholar] [CrossRef]

- Ganga, B.; Saranya, S.; Ganesh, N.V.; Hakeem, A.K.A.; Vishnu, G.N.; Abdul, H.A. Effects of space and temperature dependent internal heat generation/absorption on MHD flow of a nanofluid over a stretching sheet. J. Hydrodyn. 2015, 27, 945–954. [Google Scholar] [CrossRef]

- Bilal, S.; Rehman, K.U.; Jamil, H.; Malik, M.Y.; Salahuddin, T. Dissipative slip flow along heat and mass transfer over a vertically rotating cone by way of chemical reaction with Dufour and Soret effects. AIP Adv. 2016, 6, 125125. [Google Scholar] [CrossRef]

- Seth, G.S.; Mishra, M. Analysis of transient flow of MHD nanofluid past a non-linear stretching sheet considering Navier’s slip boundary condition. Adv. Powder Technol. 2017, 28, 375–384. [Google Scholar] [CrossRef]

- Rehman, K.U.; Khan, A.A.; Malik, M.; Ali, U. Mutual effects of stratification and mixed convection on Williamson fluid flow under stagnation region towards an inclined cylindrical surface. MethodsX 2017, 4, 429–444. [Google Scholar] [CrossRef]

- Awais, M.; Rehman, K.-U.; Malik, M.Y.; Hussain, A.; Salahuddin, T. A computational analysis subject to thermophysical aspects of Sisko fluid flow over a cylindrical surface. Eur. Phys. J. Plus 2017, 132, 392. [Google Scholar] [CrossRef]

- Rehman, K.U.; Malik, A.A.; Malik, M.; Hayat, T. Generalized Lie symmetry analysis for non-linear differential equations: A purely viscous fluid model. Results Phys. 2017, 7, 3537–3542. [Google Scholar] [CrossRef]

- Bibi, M.; Rehman, K.-U.; Malik, M.Y.; Tahir, M. Numerical study of unsteady Williamson fluid flow and heat transfer in the presence of MHD through a permeable stretching surface. Eur. Phys. J. Plus. 2018, 133, 154. [Google Scholar] [CrossRef]

- Rehman, K.U.; Alshomrani, A.S.; Malik, M.; Zehra, I.; Naseer, M. Thermo-physical aspects in tangent hyperbolic fluid flow regime: A short communication. Case Stud. Therm. Eng. 2018, 12, 203–212. [Google Scholar] [CrossRef]

- Rehman, K.U.; Shahzadi, I.; Malik, M.; Al-Mdallal, Q.M.; Zahri, M. On heat transfer in the presence of nano-sized particles suspended in a magnetized rotatory flow field. Case Stud. Therm. Eng. 2019, 14, 100457. [Google Scholar] [CrossRef]

- Jalili, B.; Sadighi, S.; Jalili, P.; Ganji, D.D. Characteristics of ferrofluid flow over a stretching sheet with suction and injection. Case Stud. Therm. Eng. 2019, 14, 100470. [Google Scholar] [CrossRef]

- Ali, U.; Rehman, K.U.; Malik, M.Y. The influence of MHD and heat generation/absorption in a Newtonian flow field manifested with a Cattaneo-Christov heat flux model. Phys. Scr. 2019, 94, 085217. [Google Scholar] [CrossRef]

- Patil, D.; Lakshmisha, K.; Rogg, B.; Patil, D. Lattice Boltzmann simulation of lid-driven flow in deep cavities. Comput. Fluids 2006, 35, 1116–1125. [Google Scholar] [CrossRef]

- Dos Santos, D.D.; Frey, S.; Naccache, M.F.; Mendes, P.D.S.; Mendes, P.D.S. Numerical approximations for flow of viscoplastic fluids in a lid-driven cavity. J. Non-Newton. Fluid Mech. 2011, 166, 667–679. [Google Scholar] [CrossRef]

- ElShehabey, H.M.; Ahmed, S.E. MHD mixed convection in a lid-driven cavity filled by a nanofluid with sinusoidal temperature distribution on the both vertical walls using Buongiorno’s nanofluid model. Int. J. Heat Mass Transf. 2015, 88, 181–202. [Google Scholar] [CrossRef]

- Gutt, R.; Grosan, T. On the lid-driven problem in a porous cavity. A theoretical and numerical approach. Appl. Math. Comput. 2015, 266, 1070–1082. [Google Scholar] [CrossRef]

- Ding, P. Solution of lid-driven cavity problems with an improved SIMPLE algorithm at high Reynolds numbers. Int. J. Heat Mass Transf. 2017, 115, 942–954. [Google Scholar] [CrossRef]

- Indukuri, J.V.; Maniyeri, R. Numerical simulation of oscillating lid driven square cavity. Alex. Eng. J. 2018, 57, 2609–2625. [Google Scholar] [CrossRef]

- Templeton, J.A.; Jones, R.E.; Lee, J.W.; Zimmerman, J.A.; Wong, B.M. A Long-Range Electric Field Solver for Molecular Dynamics Based on Atomistic-to-Continuum Modeling. J. Chem. Theory Comput. 2011, 7, 1736–1749. [Google Scholar] [CrossRef]

- Mahmood, R.; Kousar, N.; Rehman, K.U.; Mohasan, M. Lid driven flow field statistics: A non-conforming finite element Simulation. Phys. A Stat. Mech. Appl. 2019, 528, 121198. [Google Scholar] [CrossRef]

- Liu, X.; Liu, L. An immersed transitional interface finite element method for fluid interacting with rigid/deformable solid. Eng. Appl. Comput. Fluid Mech. 2019, 13, 337–358. [Google Scholar] [CrossRef]

| Levels | Kinetic Energy | Degrees of Freedom | Elements |

|---|---|---|---|

| 1 | 0.002863911552553985 | 687 | 244 |

| 2 | 0.0030835306134654886 | 918 | 338 |

| 3 | 0.0033370689891919383 | 1401 | 580 |

| 4 | 0.004028228946886208 | 2385 | 1056 |

| 5 | 0.004383161489717805 | 3429 | 1612 |

| 6 | 0.005003038830862626 | 5190 | 2606 |

| 7 | 0.005995053179359121 | 12,393 | 6568 |

| 8 | 0.006462725137468749 | 30,921 | 17,360 |

| 9 | 0.006480098617604942 | 39,024 | 22,762 |

| µ | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | Level 6 | Level 7 | Level 8 | Level 9 |

|---|---|---|---|---|---|---|---|---|---|

| 0.0050 | 0.00252 | 0.00264 | 0.00269 | 0.00277 | 0.0028 | 0.00285 | 0.00294 | 0.00299 | 0.00299 |

| 0.0025 | 0.00222 | 0.00239 | 0.00248 | 0.00265 | 0.00271 | 0.0028 | 0.00297 | 0.00306 | 0.00306 |

| 0.0016 | 0.00198 | 0.00217 | 0.00229 | 0.00254 | 0.00264 | 0.00279 | 0.00306 | 0.00319 | 0.00319 |

| 0.0012 | 0.00182 | 0.00202 | 0.00216 | 0.00246 | 0.00258 | 0.00277 | 0.00311 | 0.00328 | 0.00329 |

| 0.0010 | 0.00172 | 0.00192 | 0.00207 | 0.00239 | 0.00254 | 0.00275 | 0.00314 | 0.00334 | 0.00335 |

| 0.0008 | 0.00161 | 0.0018 | 0.00195 | 0.0023 | 0.00246 | 0.00271 | 0.00316 | 0.0034 | 0.00341 |

| 0.0007 | 0.00155 | 0.00173 | 0.00188 | 0.00223 | 0.0024 | 0.00268 | 0.00317 | 0.00343 | 0.00344 |

| 0.0006 | 0.00149 | 0.00166 | 0.00179 | 0.00215 | 0.00233 | 0.00263 | 0.00317 | 0.00346 | 0.00347 |

| 0.00055 | 0.00146 | 0.00162 | 0.00174 | 0.00209 | 0.00229 | 0.0026 | 0.00317 | 0.00347 | 0.00349 |

| 0.0005 | 0.00143 | 0.00158 | 0.00169 | 0.00204 | 0.00223 | 0.00256 | 0.00317 | 0.00349 | 0.00351 |

| 0.00041 | 0.00137 | 0.00149 | 0.00158 | 0.00191 | 0.00212 | 0.00247 | 0.00315 | 0.00351 | 0.00353 |

| 0.00033 | 0.00131 | 0.00142 | 0.00148 | 0.00177 | 0.00198 | 0.00235 | 0.0031 | 0.00352 | 0.00355 |

| 0.00025 | 0.00125 | 0.00133 | 0.00136 | 0.0016 | 0.00179 | 0.00217 | 0.00302 | 0.00351 | 0.00355 |

| 0.0002 | 0.00121 | 0.00126 | 0.00127 | 0.00147 | 0.00163 | 0.00202 | 0.00292 | 0.00348 | 0.00353 |

| 0.00016 | 0.00117 | 0.00119 | 0.00119 | 0.00136 | 0.00149 | 0.00187 | 0.0028 | 0.00342 | 0.00349 |

| 0.00014 | 0.00114 | 0.00113 | 0.00114 | 0.00129 | 0.00141 | 0.00178 | 0.00271 | 0.00338 | 0.00346 |

| 0.000125 | 0.00113 | 0.0011 | 0.0011 | 0.00124 | 0.00135 | 0.00171 | 0.00263 | 0.00334 | 0.00342 |

| 0.000111 | 0.00111 | 0.00108 | 0.00106 | 0.00118 | 0.00129 | 0.00163 | 0.00254 | 0.00329 | 0.00339 |

| 0.0001 | 0.0011 | 0.00108 | 0.00103 | 0.00113 | 0.00123 | 0.00156 | 0.00247 | 0.00324 | 0.00335 |

| µ | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | Level 6 | Level 7 | Level 8 | Level 9 |

|---|---|---|---|---|---|---|---|---|---|

| 0.0050 | 0.00518 | 0.00526 | 0.00539 | 0.00556 | 0.00565 | 0.00574 | 0.00591 | 0.006 | 0.00601 |

| 0.0025 | 0.00464 | 0.00476 | 0.00498 | 0.00531 | 0.00547 | 0.00565 | 0.00598 | 0.00615 | 0.00616 |

| 0.0016 | 0.00418 | 0.00432 | 0.00461 | 0.0051 | 0.00536 | 0.00563 | 0.00616 | 0.00642 | 0.00643 |

| 0.0012 | 0.00387 | 0.004 | 0.00434 | 0.00494 | 0.00525 | 0.00561 | 0.00628 | 0.00661 | 0.00663 |

| 0.0010 | 0.00368 | 0.0038 | 0.00315 | 0.00481 | 0.00516 | 0.00557 | 0.00634 | 0.00673 | 0.00675 |

| 0.0008 | 0.00347 | 0.00356 | 0.00391 | 0.00462 | 0.00502 | 0.00549 | 0.00639 | 0.00685 | 0.00688 |

| 0.0007 | 0.00335 | 0.00342 | 0.00377 | 0.00449 | 0.00491 | 0.00543 | 0.00641 | 0.00692 | 0.00695 |

| 0.0006 | 0.00323 | 0.00326 | 0.00359 | 0.00432 | 0.00477 | 0.00534 | 0.00642 | 0.00699 | 0.00702 |

| 0.00055 | 0.00317 | 0.00318 | 0.0035 | 0.00422 | 0.00468 | 0.00528 | 0.00641 | 0.00702 | 0.00705 |

| 0.0005 | 0.00311 | 0.00309 | 0.00339 | 0.00411 | 0.00458 | 0.0052 | 0.00641 | 0.00705 | 0.00709 |

| 0.00041 | 0.00299 | 0.00292 | 0.00317 | 0.00386 | 0.00435 | 0.00503 | 0.00637 | 0.00710 | 0.00714 |

| 0.00033 | 0.00288 | 0.00276 | 0.00296 | 0.00358 | 0.00407 | 0.0048 | 0.00629 | 0.00712 | 0.00718 |

| 0.00025 | 0.00276 | 0.00257 | 0.00271 | 0.00323 | 0.0037 | 0.00447 | 0.00613 | 0.00710 | 0.00719 |

| 0.0002 | 0.00267 | 0.00244 | 0.00253 | 0.00297 | 0.0034 | 0.00416 | 0.00595 | 0.00704 | 0.00716 |

| 0.00016 | 0.00257 | 0.00232 | 0.00236 | 0.00273 | 0.00312 | 0.00385 | 0.00571 | 0.00694 | 0.00709 |

| 0.00014 | 0.00253 | 0.00224 | 0.00227 | 0.00259 | 0.00296 | 0.00367 | 0.00554 | 0.00686 | 0.00703 |

| 0.000125 | 0.00249 | 0.00219 | 0.00219 | 0.00248 | 0.00283 | 0.00352 | 0.00539 | 0.00678 | 0.00698 |

| 0.000111 | 0.00245 | 0.00213 | 0.00211 | 0.00236 | 0.0027 | 0.00336 | 0.00522 | 0.00668 | 0.00690 |

| 0.0001 | 0.00243 | 0.00209 | 0.00204 | 0.00226 | 0.00257 | 0.00322 | 0.00506 | 0.00657 | 0.00683 |

| µ | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | Level 6 | Level 7 | Level 8 | Level 9 |

|---|---|---|---|---|---|---|---|---|---|

| 0.0050 | 0.00504 | 0.00524 | 0.00534 | 0.00552 | 0.00558 | 0.00569 | 0.00586 | 0.00595 | 0.00595 |

| 0.0025 | 0.00445 | 0.00475 | 0.00494 | 0.00527 | 0.00539 | 0.00559 | 0.00591 | 0.00608 | 0.00609 |

| 0.0016 | 0.00397 | 0.00431 | 0.00456 | 0.00506 | 0.00524 | 0.00555 | 0.00607 | 0.00633 | 0.00634 |

| 0.0012 | 0.00365 | 0.004 | 0.00428 | 0.00489 | 0.00513 | 0.00552 | 0.00617 | 0.00651 | 0.00653 |

| 0.0010 | 0.00345 | 0.0038 | 0.00409 | 0.00476 | 0.00503 | 0.00547 | 0.00622 | 0.0066 | 0.00663 |

| 0.0008 | 0.00323 | 0.00356 | 0.00386 | 0.00457 | 0.00486 | 0.00538 | 0.00624 | 0.0067 | 0.00672 |

| 0.0007 | 0.00311 | 0.00343 | 0.00371 | 0.00443 | 0.00475 | 0.00530 | 0.00623 | 0.00672 | 0.00675 |

| 0.0006 | 0.00299 | 0.00328 | 0.00354 | 0.00426 | 0.00459 | 0.00519 | 0.00618 | 0.00669 | 0.00672 |

| 0.00055 | 0.00293 | 0.00319 | 0.00344 | 0.00415 | 0.0045 | 0.00511 | 0.00611 | 0.00661 | 0.00664 |

| 0.0005 | 0.00286 | 0.00311 | 0.00334 | 0.00403 | 0.00438 | 0.00500 | 0.006 | 0.00646 | 0.00648 |

| 0.00041 | 0.00275 | 0.00294 | 0.00312 | 0.00376 | 0.00412 | 0.00473 | 0.00561 | 0.00603 | 0.00604 |

| 0.00033 | 0.00264 | 0.00279 | 0.00291 | 0.00344 | 0.0038 | 0.00432 | 0.00513 | 0.00555 | 0.00555 |

| 0.00025 | 0.00252 | 0.00261 | 0.00266 | 0.00302 | 0.00333 | 0.00377 | 0.00455 | 0.00504 | 0.00498 |

| 0.0002 | 0.00243 | 0.00247 | 0.00248 | 0.00272 | 0.00297 | 0.00336 | 0.00411 | 0.00496 | 0.00456 |

| 0.00016 | 0.00234 | 0.00234 | 0.0023 | 0.00246 | 0.00265 | 0.00299 | 0.0037 | 0.00487 | 0.00416 |

| 0.00014 | 0.0023 | 0.00227 | 0.0022 | 0.00233 | 0.00248 | 0.00282 | 0.00347 | 0.0048 | 0.00394 |

| 0.000125 | 0.00226 | 0.00221 | 0.00212 | 0.00222 | 0.00235 | 0.00268 | 0.00328 | 0.00474 | 0.00375 |

| 0.000111 | 0.00223 | 0.00216 | 0.00204 | 0.00210 | 0.00222 | 0.00255 | 0.00308 | 0.00467 | 0.00356 |

| 0.0001 | 0.00221 | 0.00221 | 0.00198 | 0.00202 | 0.00212 | 0.00221 | 0.00292 | 0.00459 | 0.0034 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rehman, K.U.; Kousar, N.; Khan, W.A.; Fatima, N. On Fluid Flow Field Visualization in a Staggered Cavity: A Numerical Result. Processes 2020, 8, 226. https://doi.org/10.3390/pr8020226

Rehman KU, Kousar N, Khan WA, Fatima N. On Fluid Flow Field Visualization in a Staggered Cavity: A Numerical Result. Processes. 2020; 8(2):226. https://doi.org/10.3390/pr8020226

Chicago/Turabian StyleRehman, Khalil Ur, Nabeela Kousar, Waqar A. Khan, and Nosheen Fatima. 2020. "On Fluid Flow Field Visualization in a Staggered Cavity: A Numerical Result" Processes 8, no. 2: 226. https://doi.org/10.3390/pr8020226

APA StyleRehman, K. U., Kousar, N., Khan, W. A., & Fatima, N. (2020). On Fluid Flow Field Visualization in a Staggered Cavity: A Numerical Result. Processes, 8(2), 226. https://doi.org/10.3390/pr8020226