Investigation of an Improved Polymer Flooding Scheme by Compositionally-Tuned Slugs

Abstract

1. Introduction

1.1. Background

1.2. Factors That Impact Performance in Polymer Flooding

2. Methodology

2.1. Polymer Flow in Porous Media

2.2. Polymer Flooding Using Compositionally-Tuned Slugs

2.3. Reference Polymer Flooding Using Constant Composition

2.4. Description of Variables for DoE Study

2.5. Description of Objective Functions for DoE Study

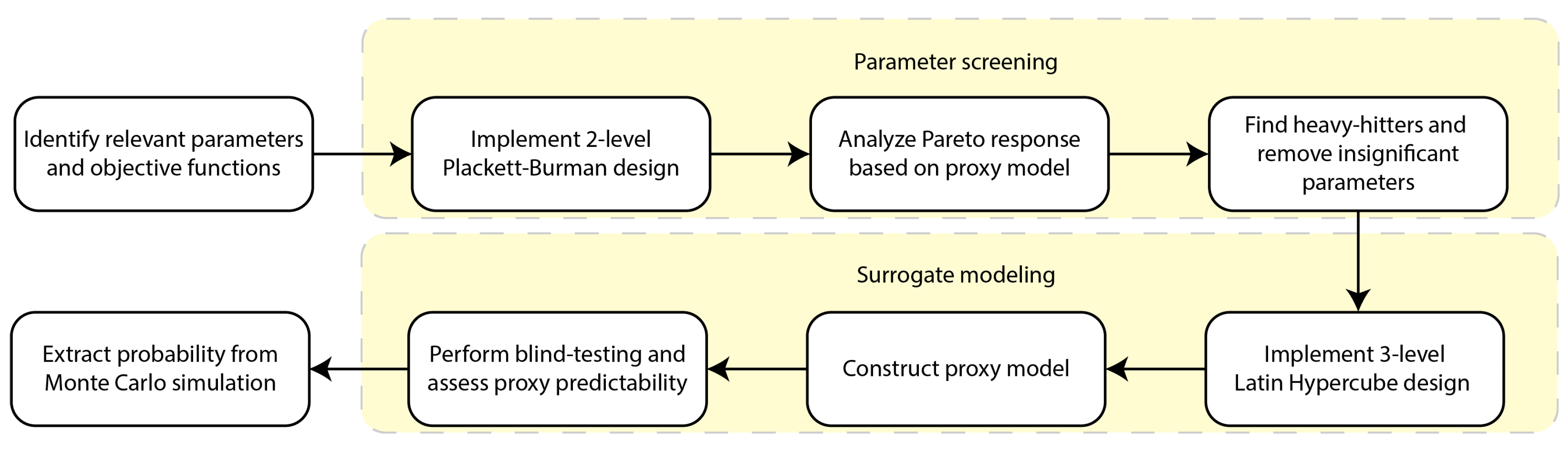

2.6. DoE Workflow

3. Results and Discussion

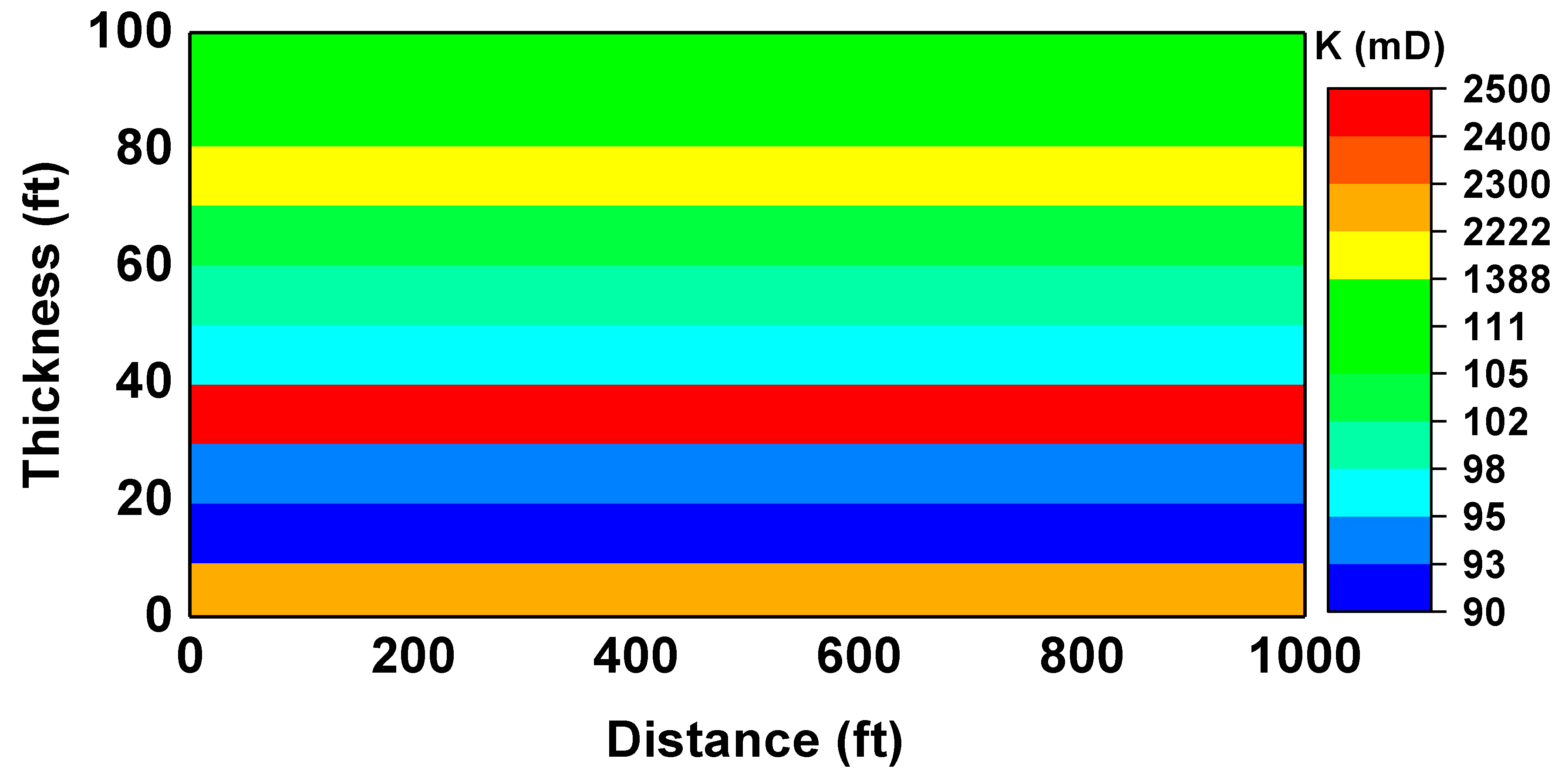

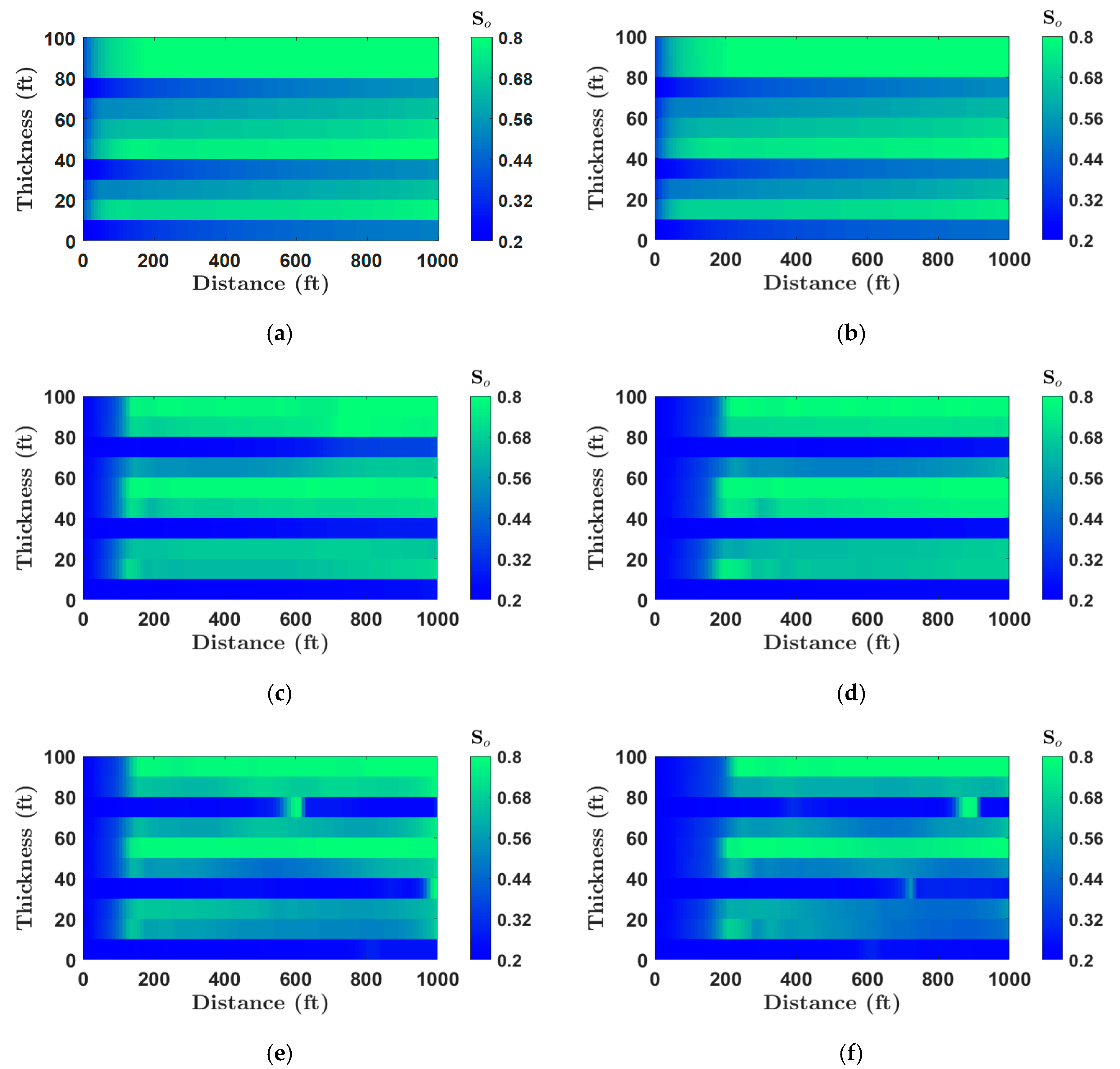

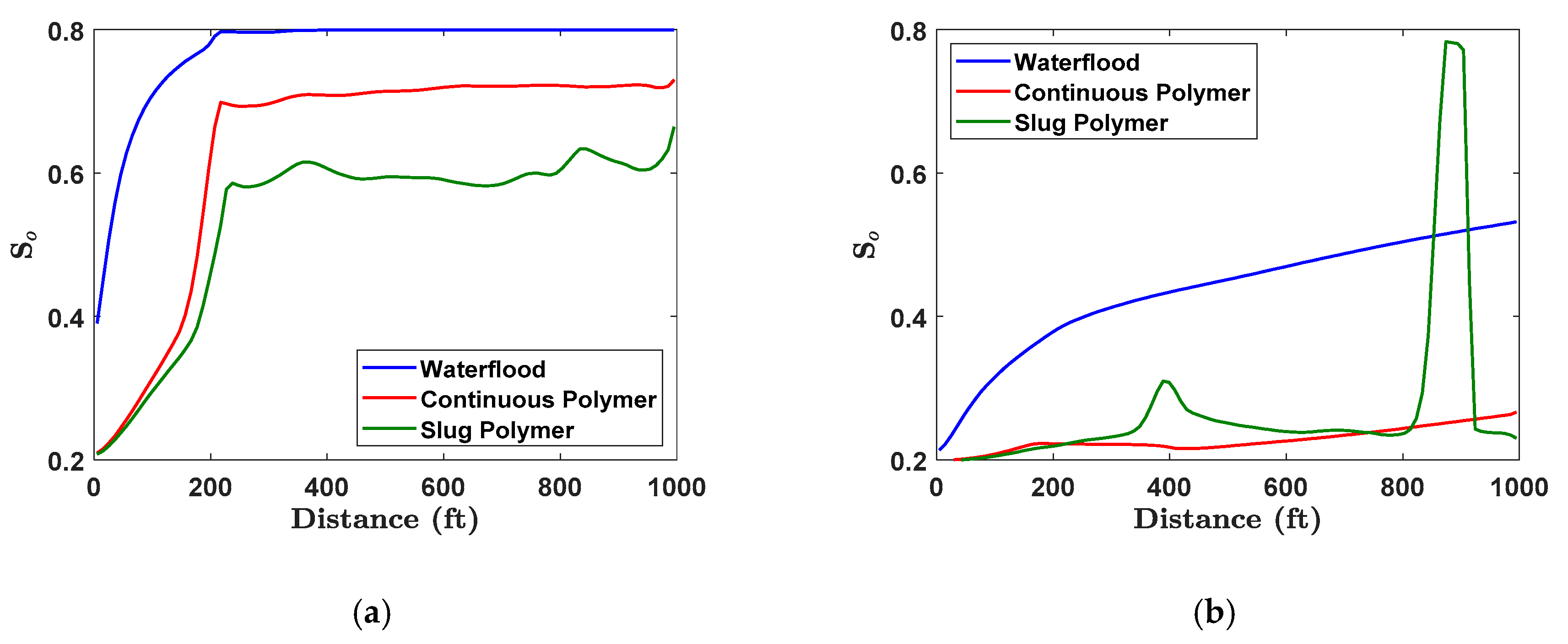

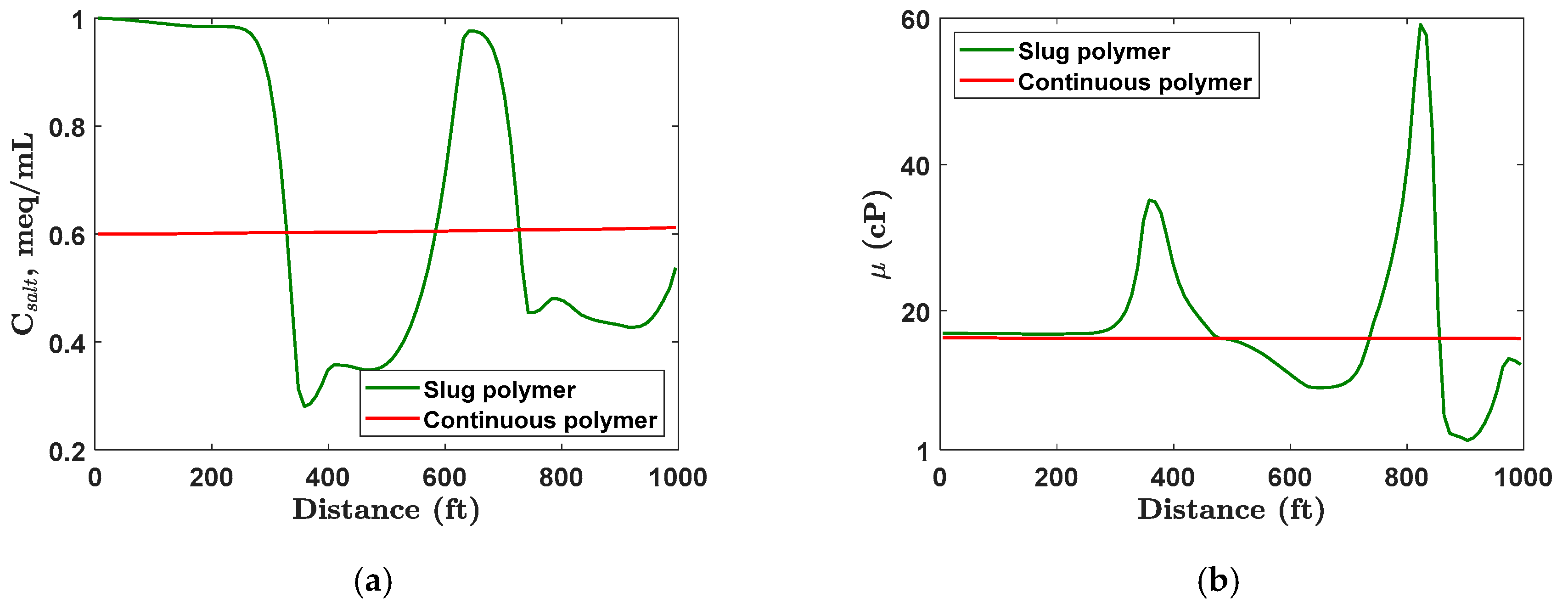

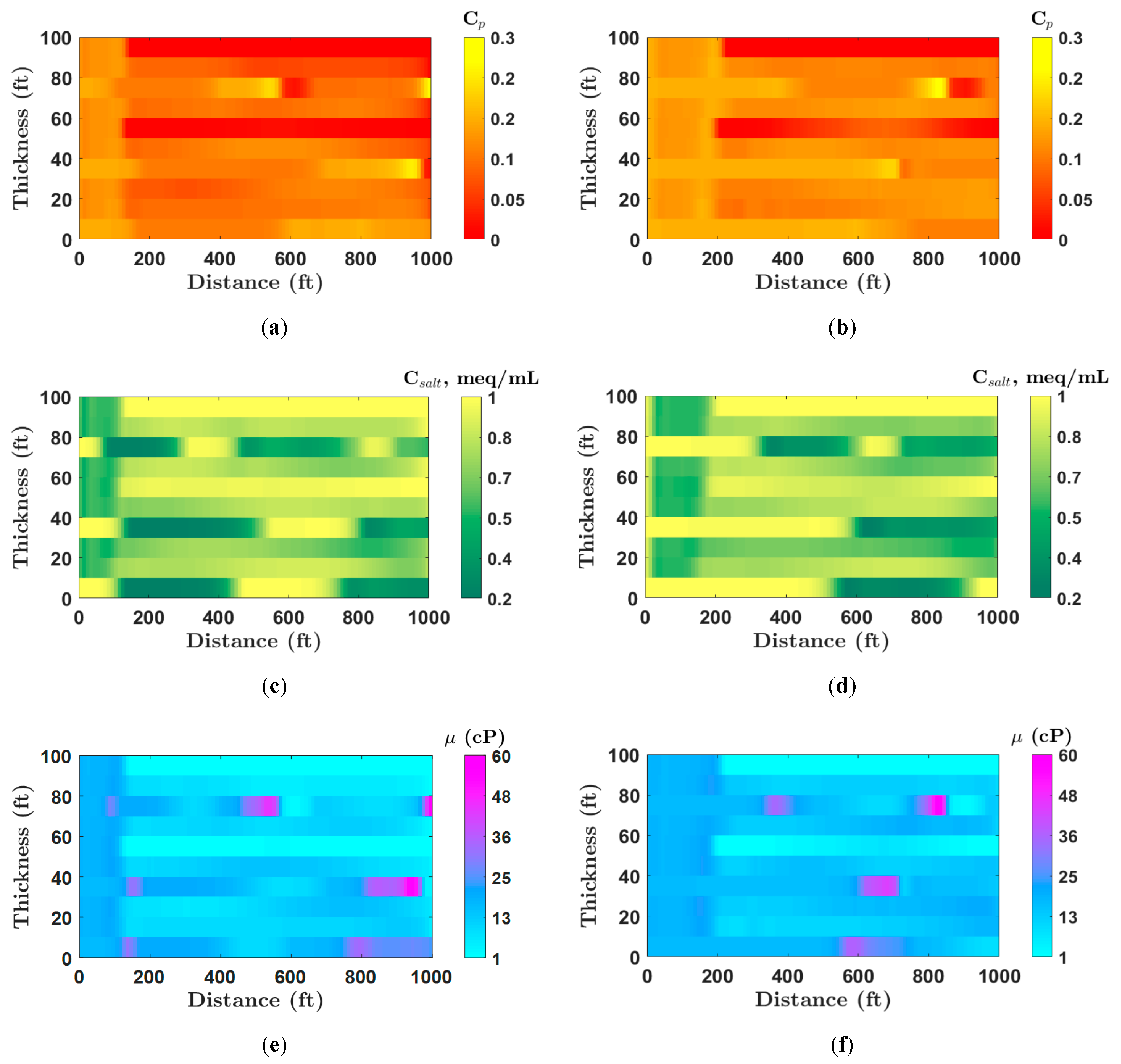

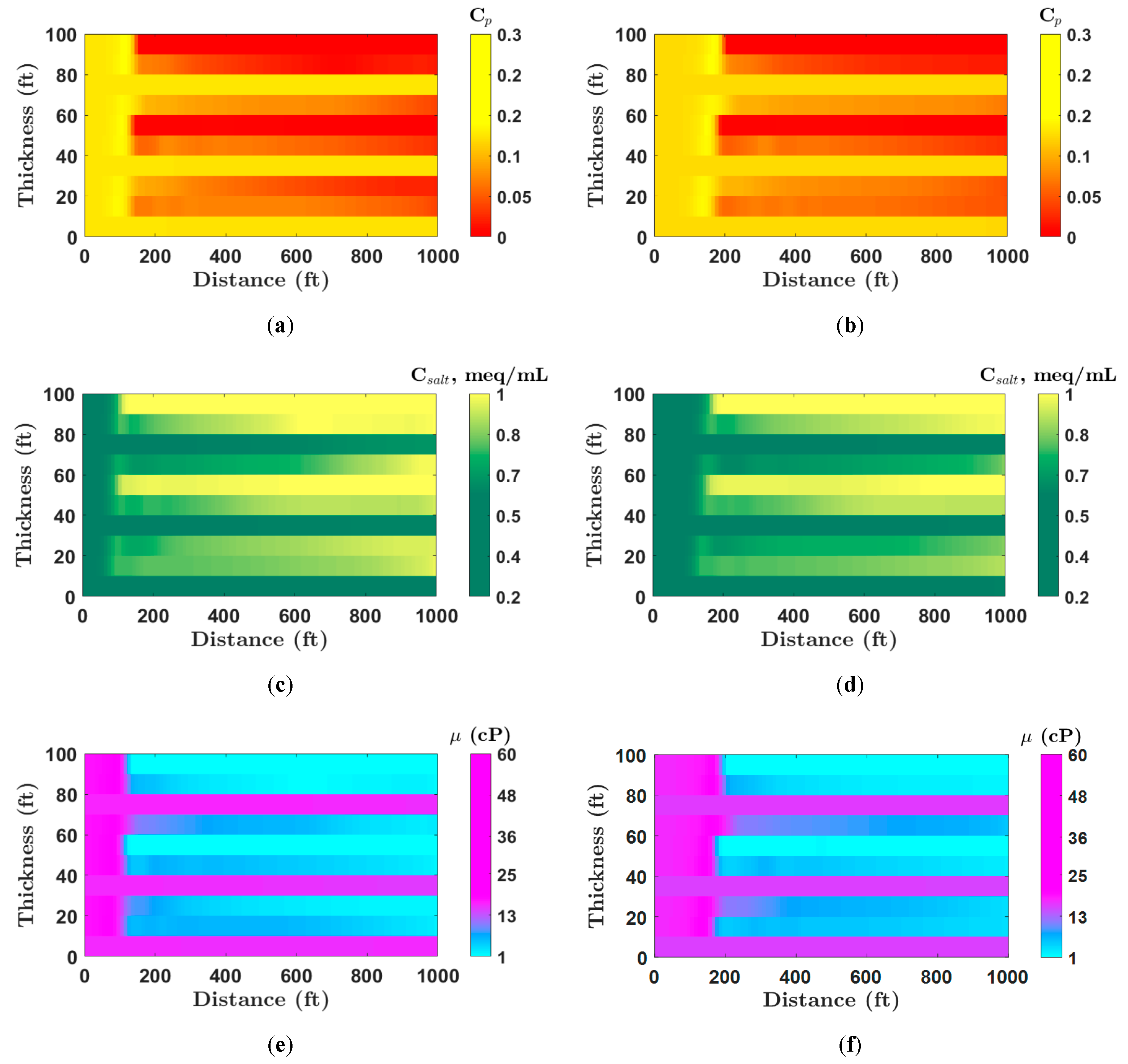

3.1. Recovery Mechanism in the Slug-Based Scheme

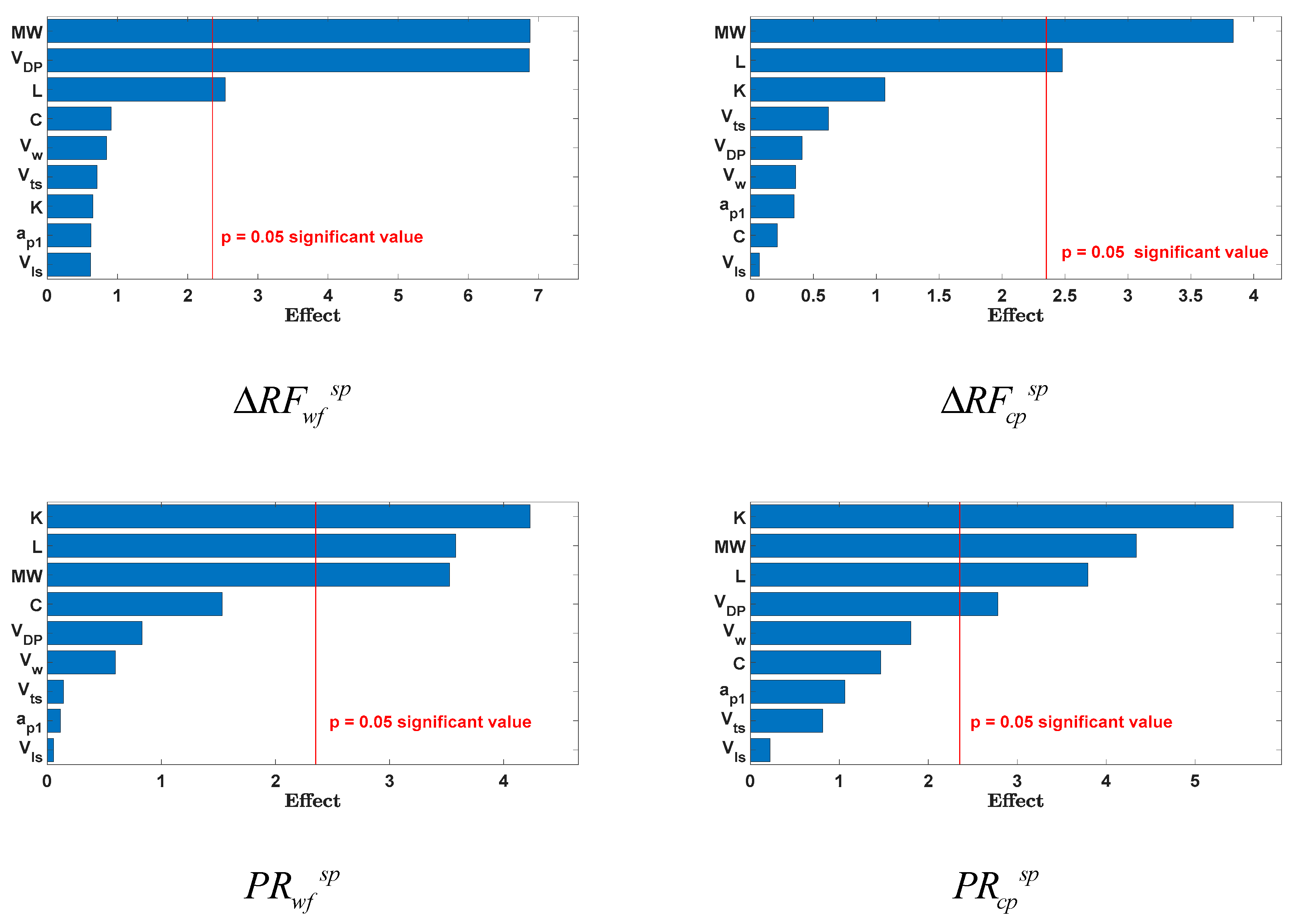

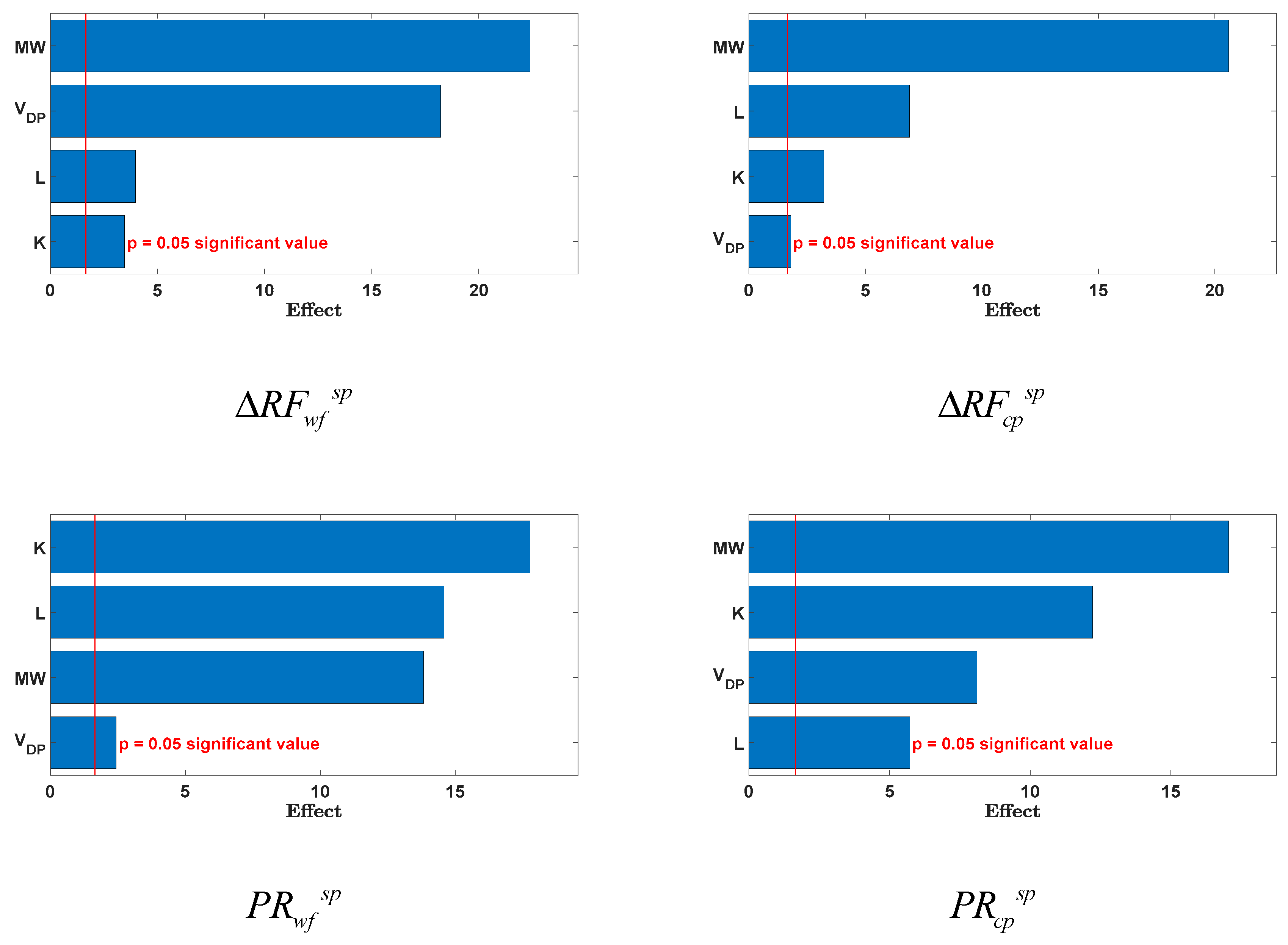

3.2. Parameter Screening

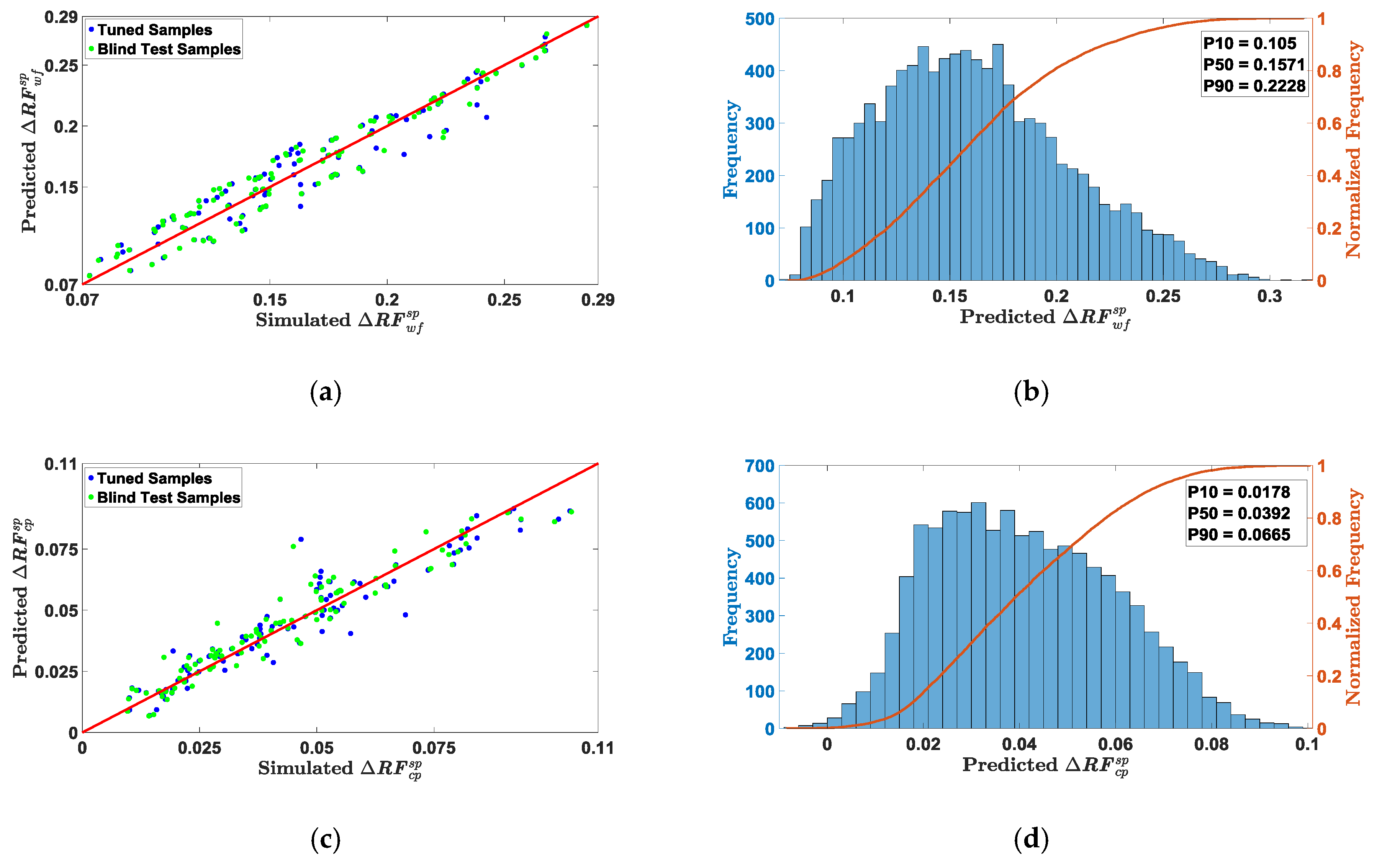

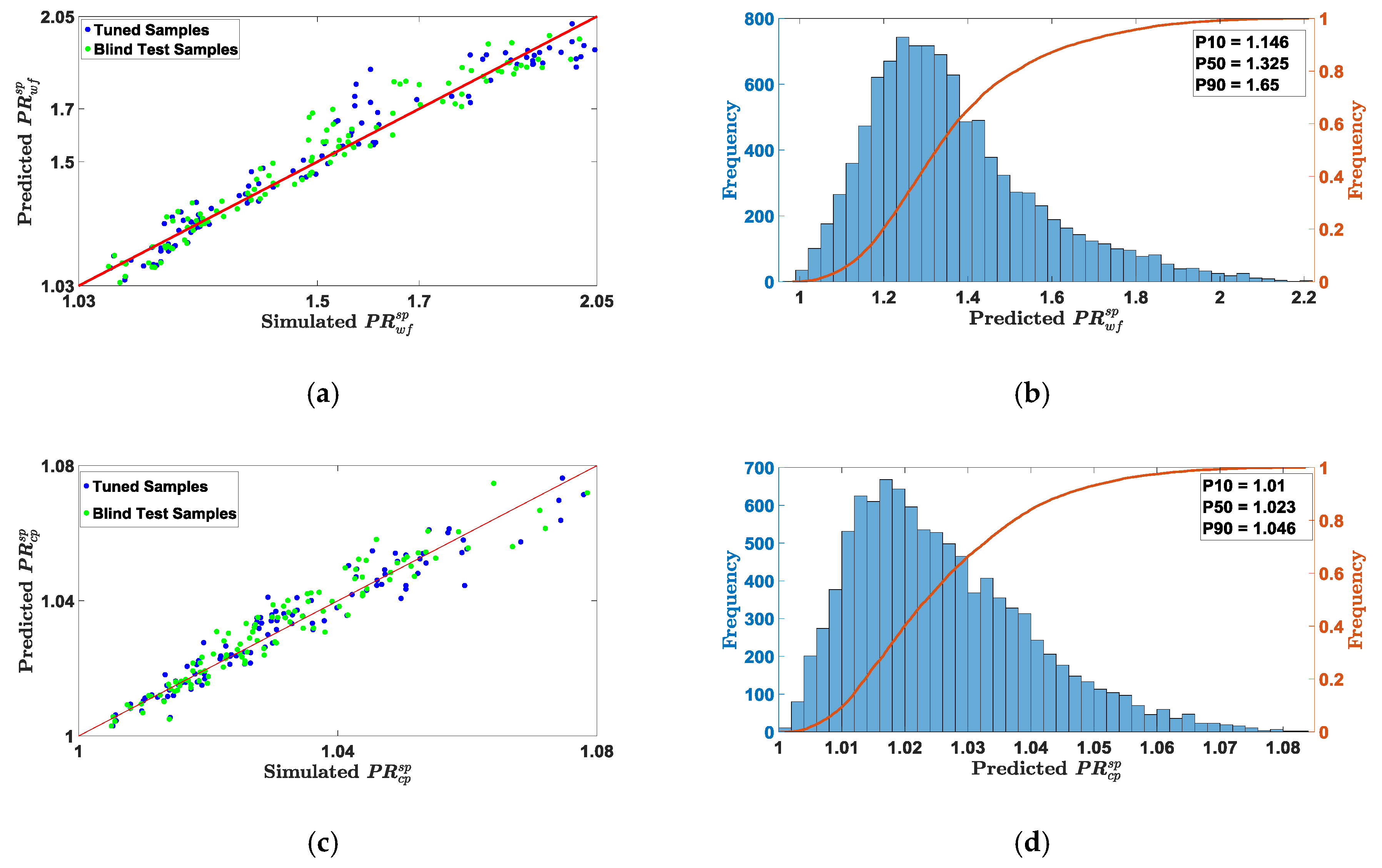

3.3. Uncertainty Quantification

4. Summary

- The new slug-based polymer injection scheme is demonstrated using simulations to increase oil recovery over traditional polymer flooding for all cases considered, without hampering polymer injectivity. This injection scheme leads to a higher recovery factor relative to traditional continuous polymer injection without a need to increase the total mass of the polymer.

- The polymer molecular weight, which controls both the inaccessible pore volume and the polymer viscosity coefficients, was found to be the most critical design parameters. High molecular weight polymer yielded the largest polymer component acceleration over the salinity component, which is responsible for the size of the transition zone.

- Vertical heterogeneity was also an important reservoir parameter that impacted the recovery performance. High reservoir heterogeneity increased mixing owing to changes in vertical velocity, which negatively impacted the performance of the recovery process.

- For the ranges considered, polymer adsorption did not play a significant role in the process performance. This behavior is expected because the cases corresponded to rocks with low to moderate adsorption, and hence polymer adsorption, which contributes to polymer component retardation, is satisfied early in the polymer injection process.

- Uncertainty quantification through surrogate modeling can be a useful, yet simple tool to estimate the process performance in the early stages of technology assessment provided that the correct parameters and objective functions are identified.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Roman | |

| Langmuir adsorption parameter | |

| Polymer viscosity parameter | |

| Langmuir adsorption parameter | |

| Permeability reduction parameter | |

| Permeability reduction parameter | |

| Volumetric composition | |

| Objective function | |

| Inaccessible pore volume | |

| Relative permeability | |

| Permeability | |

| Interwell spacing | |

| Molecular weight | |

| Number of variables | |

| Pressure | |

| Shear exponent coefficient | |

| Flow rate | |

| Phase saturation | |

| Salinity exponent | |

| Volume | |

| Variable | |

| Greek | |

| Shear rate | |

| Proxy coefficient | |

| Phase viscosity | |

| Porosity | |

| Subscripts | |

| ½ | One-half shear |

| 1 | First coefficient, variable, or objective function |

| 2 | Second coefficient, variable, or objective function |

| 3 | Third coefficient, variable, or objective function |

| 4 | Fourth variable, or objective function |

| Shear exponent | |

| Coefficient in shear rate model | |

| Displaced fluid | |

| Effective | |

| Injected fluid | |

| Injecting condition | |

| Variable | |

| Leading slug | |

| Oil phase | |

| Residual oil phase | |

| Polymer component | |

| Producing condition | |

| Reference | |

| Reservoir | |

| Permeability reduction | |

| Salt component | |

| Trailing slug | |

| Water phase | |

| Irreducible water phase | |

| z-direction | |

| Superscripts | |

| Continuous injection | |

| Objective function | |

| Leading slug | |

| Initial | |

| Trailing slug | |

References

- Lake, L.; Johns, R.; Rossen, B.; Pope, G. Fundamentals of Enhanced Oil Recovery; Society of Petroleum Engineers: Richardson, TX, USA, 2014. [Google Scholar]

- Ekkawong, P.; Han, J.; Olalotiti-Lawal, F.; Datta-Gupta, A. Multiobjective design and optimization of polymer flood performance. J. Pet. Sci. Eng. 2017, 153, 47–58. [Google Scholar] [CrossRef]

- Torrealba, V.A.; Hoteit, H. Improved polymer flooding injectivity and displacement by considering compositionally-tuned slugs. J. Pet. Sci. Eng. 2019, 178, 14–26. [Google Scholar] [CrossRef]

- Bowman, K.P.; Sacks, J.; Chang, Y.-F. Design and analysis of numerical experiments. J. Atmos. Sci. 1993, 50, 1267–1278. [Google Scholar] [CrossRef][Green Version]

- Leray, S.; Douarche, F.; Tabary, R.; Peysson, Y.; Moreau, P.; Preux, C. Multi-objective assisted inversion of chemical EOR corefloods for improving the predictive capacity of numerical models. J. Pet. Sci. Eng. 2016, 146, 1101–1115. [Google Scholar] [CrossRef]

- Antony, J. Design of Experiments for Engineers and Scientists, 2nd ed.; Elsevier Ltd.: Burlington, MA, USA, 2014; ISBN 9780080994178. [Google Scholar]

- Fisher, R.A. Studies in crop variation: I. An examination of the yield of dressed grain from broadbalk. J. Agric. Sci. 1921, 11, 107–135. [Google Scholar] [CrossRef]

- Fisher, R.A. Theory of Statistical Estimation. Math. Proc. Camb. Philos. Soc. 1925, 22, 700–725. [Google Scholar] [CrossRef]

- Sawyer, D.N.; Cobb, W.M.; Stalkup, F.I.; Braun, P.H. Factorial Design Analysis of Wet-Combustion Drive. Soc. Pet. Eng. J. 1974, 14, 25–34. [Google Scholar] [CrossRef]

- Damsleth, E.; Hage, A.; Volden, R. Maximum information at minimum cost: A north sea field development study with an experimental design. J. Pet. Technol. 1992, 44, 1350–1356. [Google Scholar]

- Friedmann, F.; Chawathe, A.; Larue, D.K. Assessing uncertainty in channelized reservoirs using Experimental Designs. SPE Reserv. Eval. Eng. 2003, 6, 264–274. [Google Scholar] [CrossRef]

- Ghaderi, S.M.; Clarkson, C.R.; Chen, S. Optimization of WAG process for coupled CO2 EOR-storage in tight oil formations: An experimental design approach. In Proceedings of the SPE Canadian Unconventional Resources Conference, Calgary, AB, Canada, 30 October–1 November 2012. [Google Scholar]

- Ogunbanwo, O.; Gerritsen, M.; Kovscek, A.R. Uncertainty analysis on in-situ combustion simulations using experimental design. In Proceedings of the Society of Petroleum Engineers Western Regional Meeting, San Jose, CA, USA, 23–26 April 2012; pp. 599–612. [Google Scholar]

- Bevillon, D.; Mohagerani, S. Miscible EOR project in a mature, offshore, carbonate middle east reservoir-Uncertainty analysis with proxy models based on experimental design of reservoir simulations. In Proceedings of the SPE Reservoir Characterisation and Simulation Conference and Exhibition, Abu Dhabi, UAE, 14–16 September 2015; Society of Petroleum Engineers: Houston, TX, USA, 2015; pp. 752–775. [Google Scholar]

- Bengar, A.; Moradi, S.; Ganjeh-Ghazvini, M.; Shokrollahi, A. Optimized polymer flooding projects via combination of experimental design and reservoir simulation. Petroleum 2017, 3, 461–469. [Google Scholar] [CrossRef]

- Adepoju, O.O.; Hoteit, H.; Chawathe, A. Assessment of chemical performance uncertainty in chemical EOR simulations. In Proceedings of the Society of Petroleum Engineers—SPE Reservoir Simulation Conference 2017, Montgomery, TX, USA, 20–22 February 2017; Society of Petroleum Engineers: Houston, TX, USA, 2017; pp. 127–140. [Google Scholar]

- Santoso, R.; Hoteit, H.; Vahrenkamp, V. Optimization of energy recovery from geothermal reservoirs undergoing re-injection: Conceptual application in Saudi Arabia. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 18–21 March 2019; Society of Petroleum Engineers (SPE): Houston, TX, USA, 2019. [Google Scholar]

- Ram, M.; Delshad, M. A Compositional Reservoir Simulator on Distributed Memory Parallel Computers. In Proceedings of the SPE Reservoir Simulation Symposium, San Antonio, TX, USA, 12–15 February 1995. [Google Scholar]

- Zhang, J.; Delshad, M.; Sepehrnoori, K.; Pope, G.A. An Efficient Reservoir-Simulation Approach To Design and Optimize Improved Oil-Recovery-Processes With Distributed Computing. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Bogotá, Colombia, 17–19 March 2005; Society of Petroleum Engineers: Houston, TX, USA, 2005. [Google Scholar]

- Zhang, J.; Delshad, M.; Sepehrnoori, K. A Framework to Design and Optimize Surfactant-Enhanced Aquifer Remediation. In Proceedings of the SPE/EPA/DOE Exploration and Production Environmental Conference, Galveston, TX, USA, 7–9 March 2005; Society of Petroleum Engineers: Houston, TX, USA, 2005. [Google Scholar]

- UTCHEM-9.0 Technical Documentation; The University of Texas at Austin: Austin, TX, USA, 2000.

- Liauh, W.C.; Duda, J.L.; Klaus, E.E. An Iinvestigation of the Inaccessible Pore Volume Phenomena. In Proceedings of the 84th National American Institute of Chemical Engineers Meeting, Atlant, GA, USA, 28 Februray–1 March 1978. [Google Scholar]

- Dawson, R.; Lantz, R.B. Inaccesible Pore Volume in Polymer Flooding. SPE J. 1972, 12, 448–452. [Google Scholar]

- Pancharoen, M. Physical Properties of Associative Polymer Solutions; Stanford University: Stanford, CA, USA, 2009. [Google Scholar]

- Pancharoen, M.; Thiele, M.R.; Kovscek, A.R. Inaccessible Pore Volume of Associative Polymer Floods. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010; Society of Petroleum Engineers: Houston, TX, USA, 2010. [Google Scholar]

- De Gennes, P.G. Dynamics of Entangled Polymer Solutions. I. The Rouse Model. Macromolecules 1976, 9, 587–593. [Google Scholar] [CrossRef]

- De Gennes, P.G. Dynamics of Entangled Polymer Solutions. II. Inclusion of Hydrodynamic Interactions. Macromolecules 1976, 9, 594–598. [Google Scholar] [CrossRef]

- Nouri, H.H.; Root, P.J. A Study of Polymer Solution Rheology, Flow Behavior, and Oil Displacement Processes. In Proceedings of the Fall Meeting of the Society of Petroleum Engineers of AIME, Cincinnati, OH, USA, 19–21 January 1971; Society of Petroleum Engineers: Houston, TX, USA, 1971. [Google Scholar]

- Szabo, M.T. Molecular and Microscopic Interpretation of the Flow of Hydrolyzed Polyacrylamide Solution Through Porous Media. In Proceedings of the Fall Meeting of the Society of Petroleum Engineers of AIME, San Antonio, TX, USA, 8–11 October 1972; Society of Petroleum Engineers: Houston, TX, USA, 1972. [Google Scholar]

- Hirasaki, G.J.; Pope, G.A. Analysis of Factors Influencing Mobility and Adsorption in the Flow of Polymer Solution Through Porous Media. Soc. Pet. Eng. J. 1974, 14, 337–346. [Google Scholar] [CrossRef]

- Maerker, J.M. Shear Degradation of Partially Hydrolyzed Polyacrylamide Solutions. Soc. Pet. Eng. J. 1975, 15, 311–322. [Google Scholar] [CrossRef]

- Szabo, M.T. Laboratory Investigations of Factors Influencing Polymer Flood Performance. Soc. Pet. Eng. J. 1975, 15, 338–346. [Google Scholar] [CrossRef]

- Forsman, W.C.; Hughes, R.E.; Forsmant, W.C. Adsorption of Polymer Molecules at Low Surface Coverage. J. Chem. Phys. 1963, 38, 2558. [Google Scholar]

- Dominguez, J.G.; Willhite, G.P. Retention and Flow Characteristics of Polymer Solutions in Porous Media. Soc. Pet. Eng. J. 1977, 17, 111–121. [Google Scholar] [CrossRef]

- Delshad, M.; Pope, G.A.; Sepehrnoori, K. A compositional simulator for modeling surfactant enhanced aquifer remediation, 1 Formulation. J. Contam. Hydrol. 1996, 23, 303–327. [Google Scholar] [CrossRef]

- Ahmed, H.; Glass, J.E.; McCarthy, G.J. Adsorption of Water-Soluble Polymers on High Surface Area Clays. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 4–7 October 1981; Society of Petroleum Engineers: Houston, TX, USA, 1981. [Google Scholar]

- Krebs, H.J. Wilmington Field, California, Polymer Flood—A Case History. J.Pet. Technol. 1976, 28, 1473–1480. [Google Scholar] [CrossRef]

- Shuler, P.J.; Kuehne, D.L.; Uhl, J.T.; Walkup, G.W. Improving Polymer Injectivity at West Coyote Field, California. SPE Reserv. Eng. 1987, 2, 271–280. [Google Scholar] [CrossRef]

- Darcy, H. Les Fontaines Publiques de la Ville de Dijon; Librairie Des Corps Impérial Des Ponts et Chaussees et Des Mines: Paris, France, 1856. [Google Scholar]

- Pope, G.A.; Hong, C.H.; Sepehrnoori, K.; Lake, L.W. Two Dimensional Simulation of Chemical Flooding. In Proceedings of the SPE California Regional Meeting, Bakersfield, CA, USA, 25–27 March 1981; Society of Petroleum Engineers: Houston, TX, USA, 1981. [Google Scholar]

- Lake, L.W.; Johnston, J.R.; Stegemeir, G.L. Simulation and Performance Prediction of A Large-Scale Surfactant/Polymer Project. Soc. Pet. Eng. J. 1981, 21, 731–739. [Google Scholar] [CrossRef]

- Jensen, J.L.; Hinkley, D.V.; Lake, L.W. Statistical Study of Reservoir Permeability: Distributions, Correlations, and Averages. SPE Form. Eval. 1987, 2, 461–468. [Google Scholar] [CrossRef]

- Wang, J.; Wang, D.; Sui, X.; Zeng, H.; Bai, W. Combining Small Well Spacing With Polymer Flooding to Improve Oil Recovery of Marginal Reservoirs. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 22–26 April 2006; Society of Petroleum Engineers: Houston, TX, USA, 2006. [Google Scholar]

- Wang, D.; Dong, H.; Lv, C.; Fu, X.; Nie, J. Review of practical experience of polymer flooding at Daqing. SPE Reserv. Eval. Eng. 2009, 12, 470–476. [Google Scholar] [CrossRef]

- Hughes, D.S.; Teeuw, D.; Cottrell, C.W.; Tollas, J.M. Appraisal of the use of polymer injection to suppress aquifer influx and to improve volumetric sweep in a viscous oil reservoir. SPE Reserv. Eng. 1990, 5, 33–40. [Google Scholar] [CrossRef]

- Wisniewska, A.; Sozanski, K.; Kalwarczyk, T.; Kedra-Krolik, K.; Holyst, R. Scaling Equation for Viscosity of Polymer Mixtures in Solutions with Application to Diffusion of Molecular Probes. Macromolecules 2017, 50, 4555–4561. [Google Scholar] [CrossRef]

- Delamaide, E.; Technologies, I.F.P.; Tabary, R.; Rousseau, D.; Energies, I.F.P. SPE-169673-MS Chemical EOR in Low Permeability Reservoirs. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 31 March–2 April 2014; Volume 1963, pp. 1–15. [Google Scholar]

- Jensen, J.L.; Lake, L.W.; Corbett, P.W.M.; Goggin, D.J. Statistics for Petroleum Engineers and Geoscientists; Elsevier: Amsterdam, The Netherlands, 1997. [Google Scholar]

- Hoteit, H.; Chawathe, A. Making field-scale chemical enhanced-oil-recovery simulations a practical reality with dynamic gridding. SPE J. 2016, 21. [Google Scholar] [CrossRef]

- Najafabadi, N.F.; Chawathe, A. Proper Simulation of Chemical EOR (CEOR) Pilots—A Real Case Study. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 9–13 April 2016; Society of Petroleum Engineers: Houston, TX, USA, 2016. [Google Scholar]

- Naik, P.; Pandita, P.; Aramideh, S.; Bilionis, I.; Ardekani, A.M. Bayesian model calibration and optimization of surfactant-polymer flooding. Comput. Geosci. 2019, 23, 981–996. [Google Scholar] [CrossRef]

- Torrealba, V.A.; Hoteit, H.; Chawathe, A. Improving Chemical-Enhanced-Oil-Recovery Simulations and Reducing Subsurface Uncertainty Using Downscaling Conditioned to Tracer Data. SPE Reserv. Eval. Eng. 2019, 22. [Google Scholar] [CrossRef]

- Li, H.; Sarma, P.; Zhang, D. A comparative study of the probabilistic-collocation and experimental-design methods for petroleum-reservoir uncertainty quantification. SPE J. 2011, 16, 429–439. [Google Scholar] [CrossRef]

| Parameter | Test Case | Low | Middle | High |

|---|---|---|---|---|

| 1000 | 500 | 1000 | 1500 | |

| 681 | 500 | 1000 | 2000 | |

| , fraction | 0.7 | 0.5 | 0.7 | 0.9 |

| , fraction | 0.25 | 0.1 | 0.2 | 0.3 |

| * | ||||

| , dimensionless | 1.0 | 0.5 | 1.0 | 1.5 |

| , wt.% | ||||

| 0.75 | 0.5 | 0.75 | 1.0 | |

| 0.075 | 0.05 | 0.075 | 0.1 | |

| 0.075 | 0.05 | 0.075 | 0.1 |

| , mD | |||||

| 0.28 | 1000 | 0.1 | 0.2 | 0.2 | |

| , cP | , cP | ||||

| 0.5 | 1.5 | 1 | 30 | -0.5 | 4 |

| , ml/meq | , wt.%−1 | ,wt.%−1 | , D1/2 | ||

| 47 | 1.7 | 0.5 | 100 | 1.0 | 0 |

| Coefficient | ||||

|---|---|---|---|---|

| 0.1573 | 0.0447 | 1.0275 | 1.3762 | |

| 0.0095 | 0.0118 | 0.0065 | 0.1828 | |

| −0.0470 | −0.0020 | 0.0079 | 0.0126 | |

| −0.0096 | −0.0063 | −0.0147 | −0.2604 | |

| 0.0577 | 0.0291 | 0.0173 | 0.1772 | |

| 0.0013 | 0.0014 | 0.0000 | 0.0029 | |

| −0.0071 | −0.0028 | −0.0035 | −0.1188 | |

| 0.0052 | 0.0043 | −0.0030 | −0.0121 | |

| 0.0053 | 0.0036 | 0.0002 | 0.0793 | |

| −0.0155 | 0.0056 | 0.0090 | 0.0179 | |

| −0.0016 | −0.0043 | −0.0078 | −0.1003 | |

| 0.0003 | −0.0002 | −0.0011 | −0.0082 | |

| 0.0150 | −0.0122 | −0.0021 | 0.0207 | |

| 0.0013 | 0.0006 | 0.0026 | 0.0953 | |

| −0.0034 | 0.0032 | 0.0034 | −0.0127 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santoso, R.; Torrealba, V.; Hoteit, H. Investigation of an Improved Polymer Flooding Scheme by Compositionally-Tuned Slugs. Processes 2020, 8, 197. https://doi.org/10.3390/pr8020197

Santoso R, Torrealba V, Hoteit H. Investigation of an Improved Polymer Flooding Scheme by Compositionally-Tuned Slugs. Processes. 2020; 8(2):197. https://doi.org/10.3390/pr8020197

Chicago/Turabian StyleSantoso, Ryan, Victor Torrealba, and Hussein Hoteit. 2020. "Investigation of an Improved Polymer Flooding Scheme by Compositionally-Tuned Slugs" Processes 8, no. 2: 197. https://doi.org/10.3390/pr8020197

APA StyleSantoso, R., Torrealba, V., & Hoteit, H. (2020). Investigation of an Improved Polymer Flooding Scheme by Compositionally-Tuned Slugs. Processes, 8(2), 197. https://doi.org/10.3390/pr8020197