Simulation of Hydraulic Fracturing Using Different Mesh Types Based on Zero Thickness Cohesive Element

Abstract

1. Introduction

2. Methodology of Pore Pressure Cohesive Zone Model

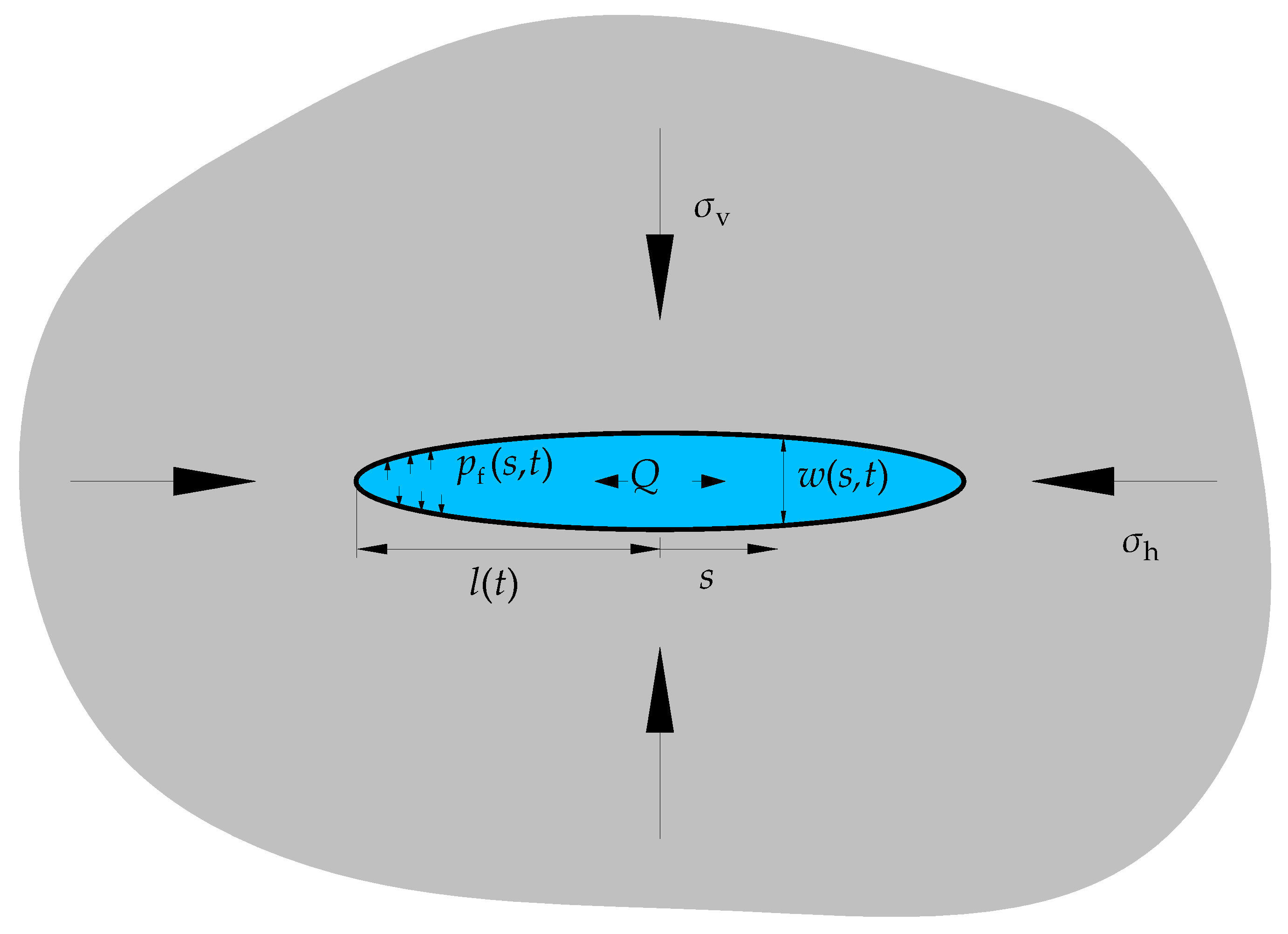

2.1. Governing Equation of Solid Medium and Fluid in the Fracture

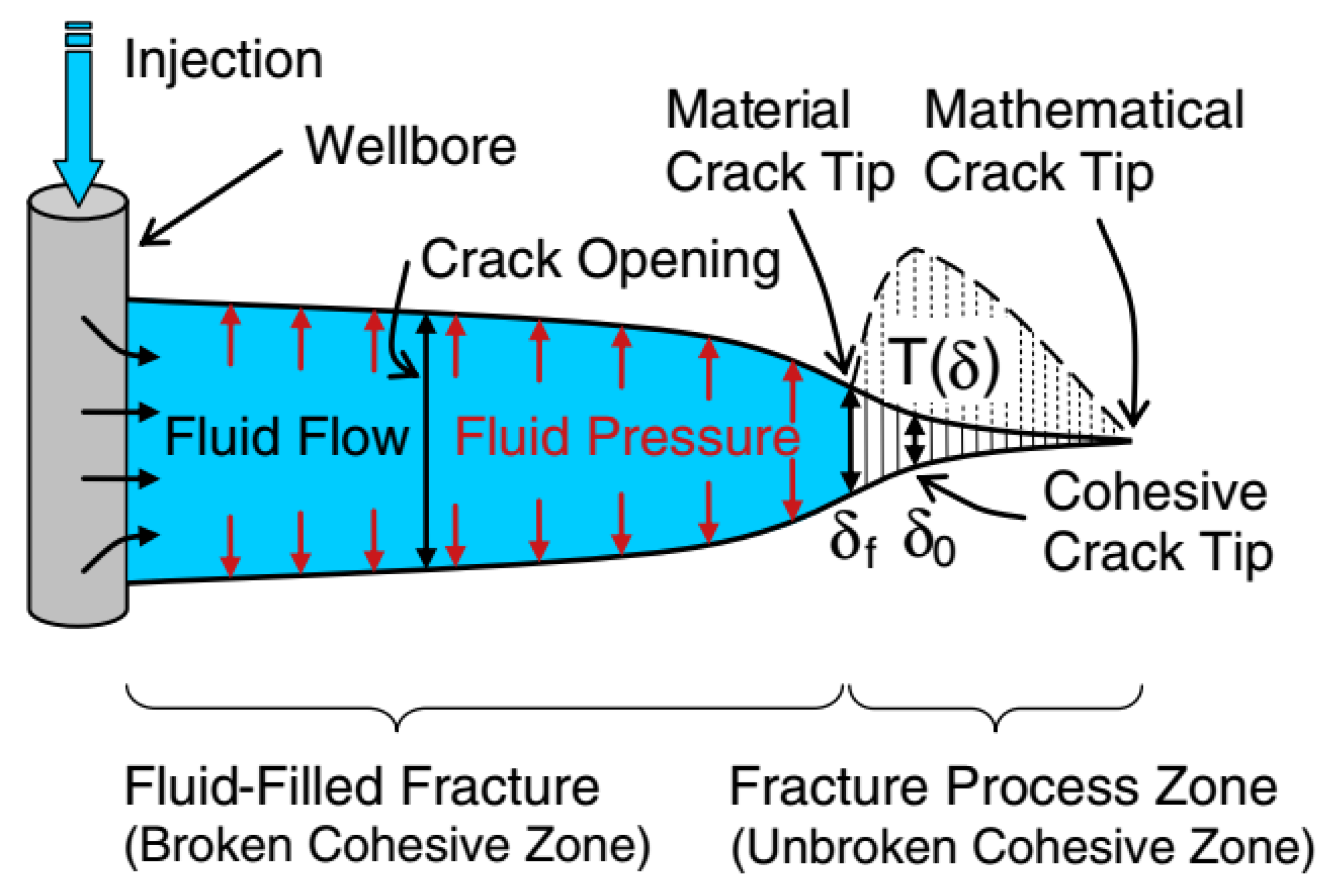

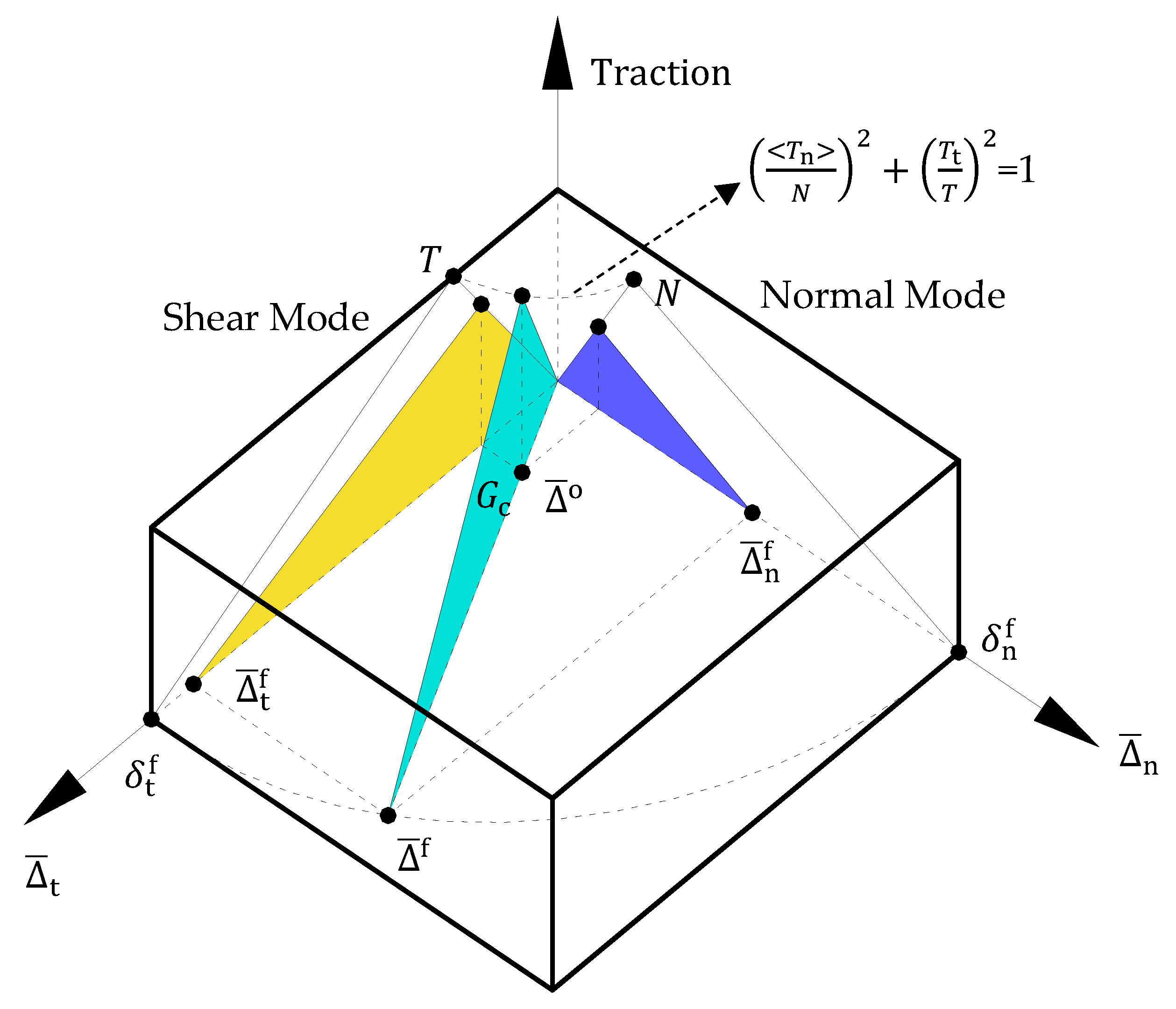

2.2. Fracture Initiation and Propagation of PPCZ Element

2.3. PPCZ Element and Numerical Implementation

2.3.1. Formulation of PPCZ Element

2.3.2. Discretization and FEM Implementation

2.3.3. Numerical Integral Scheme

3. Results and Discussion

3.1. KGD Hydraulic Fracture

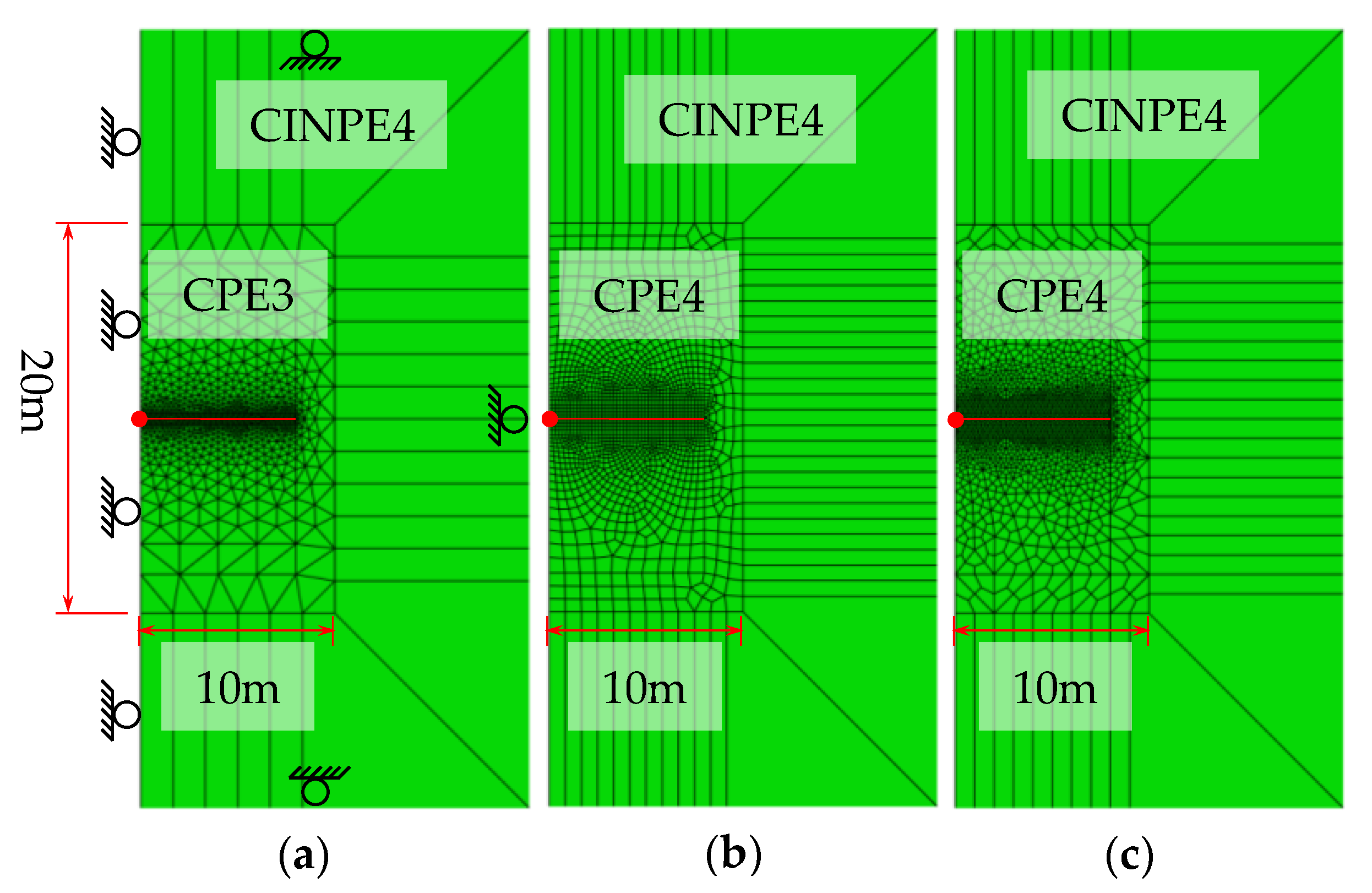

3.1.1. Simulation with Different Mesh Types

3.1.2. Simulation with Different Boundary Sizes

3.2. HF Intersection with NF

4. Conclusions

- (1)

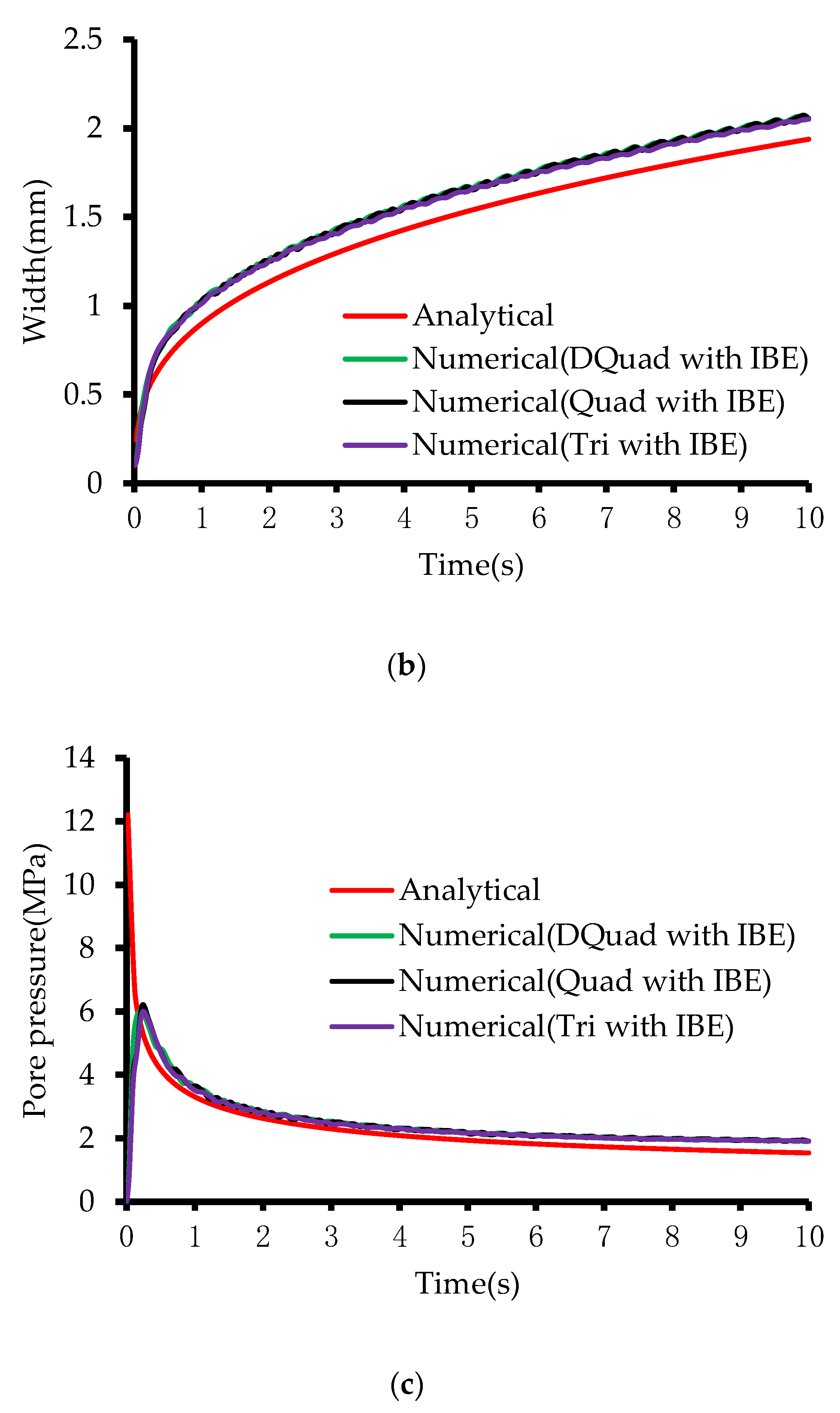

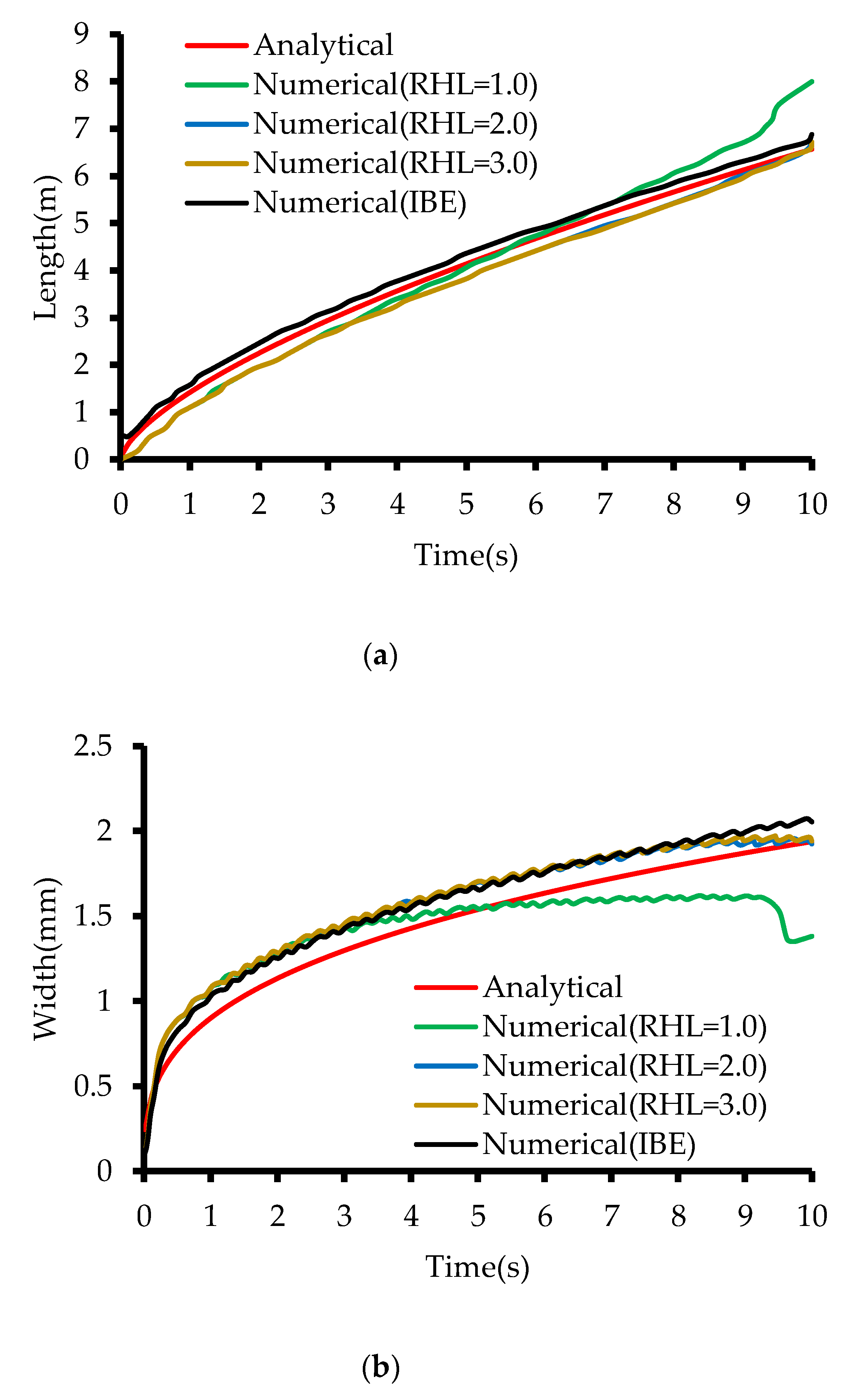

- Two types of hydraulic fracturing, large toughness and zero toughness, can be correctly captured by the PPCZ element. For the large toughness problem, numerical results solved by three types of mesh make little difference. However, with respect to the zero toughness regime, the pore pressure calculated by the triangle mesh is lower than any other mesh type at the early injection time. Therefore, the triangle mesh should be avoided treating the problem where the significance of pore pressure is terrifically striking during the early simulation period.

- (2)

- The infinite boundary element (IBE) should be utilized in solving the hydraulic fracturing problem, which cannot only enhance the computational accuracy but also alleviate the burden of the computer. In case that IBE is not available in some conditions, the ratio of model height to length (RHL) is at least equal to 3.0.

- (3)

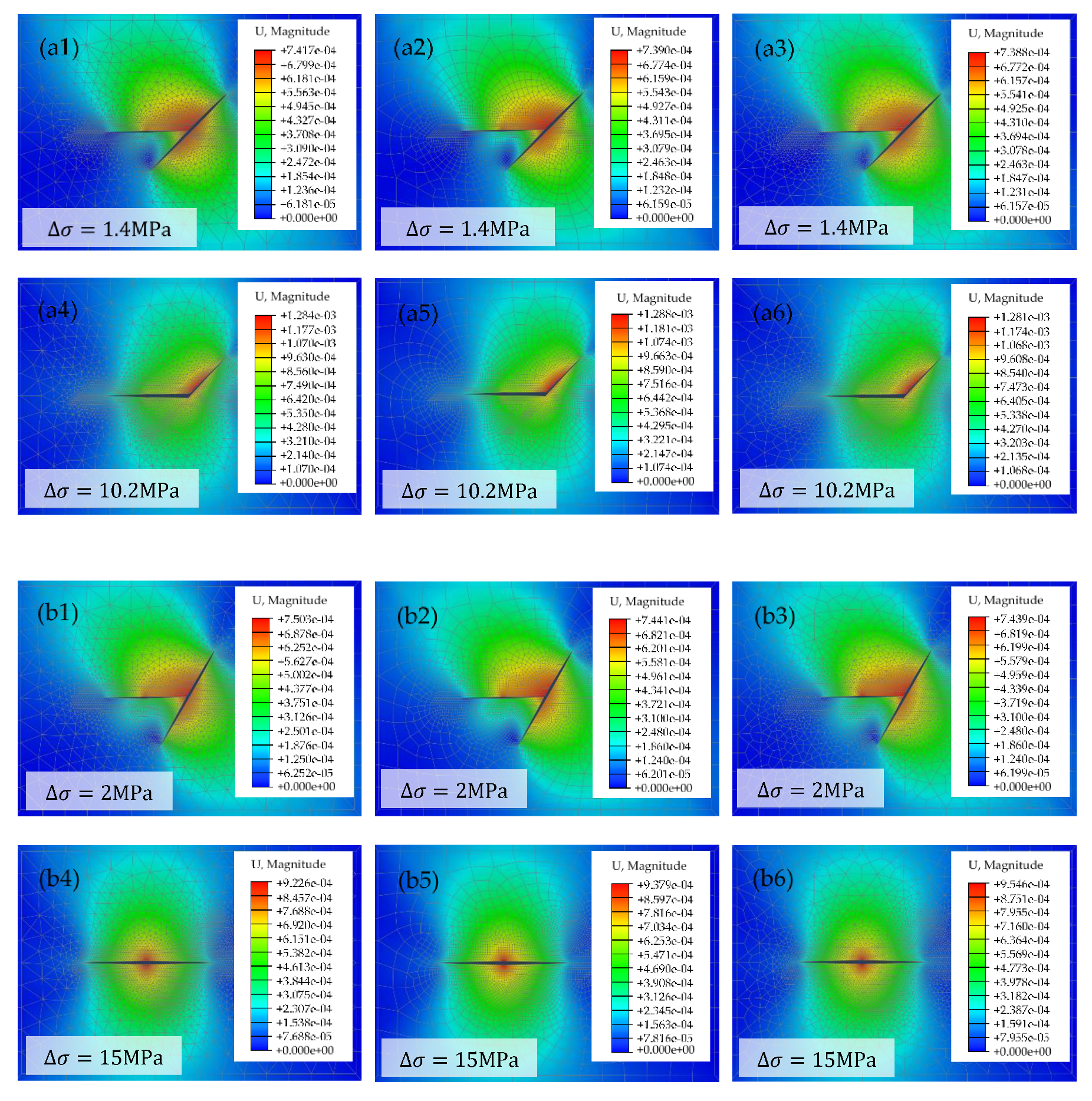

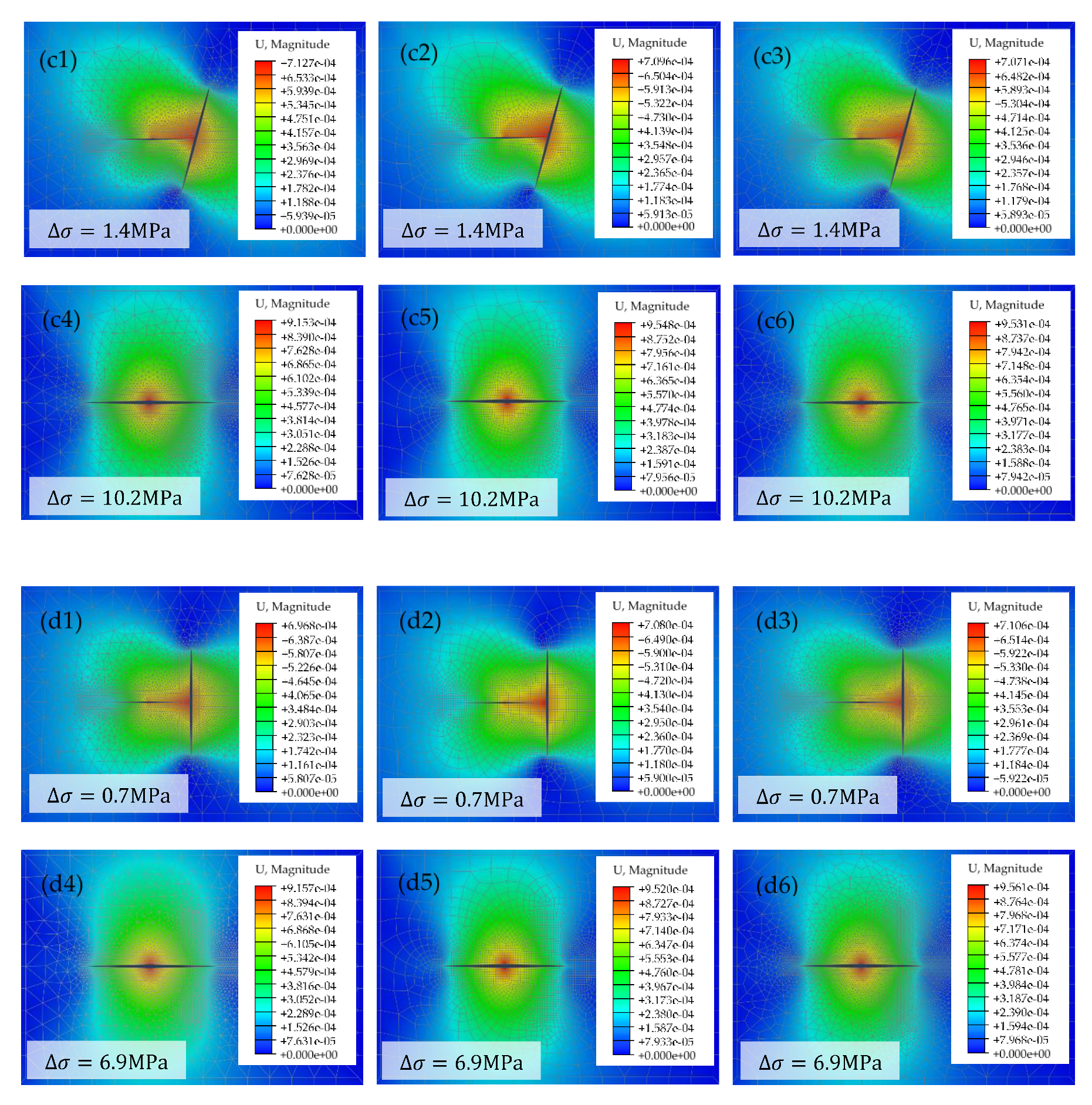

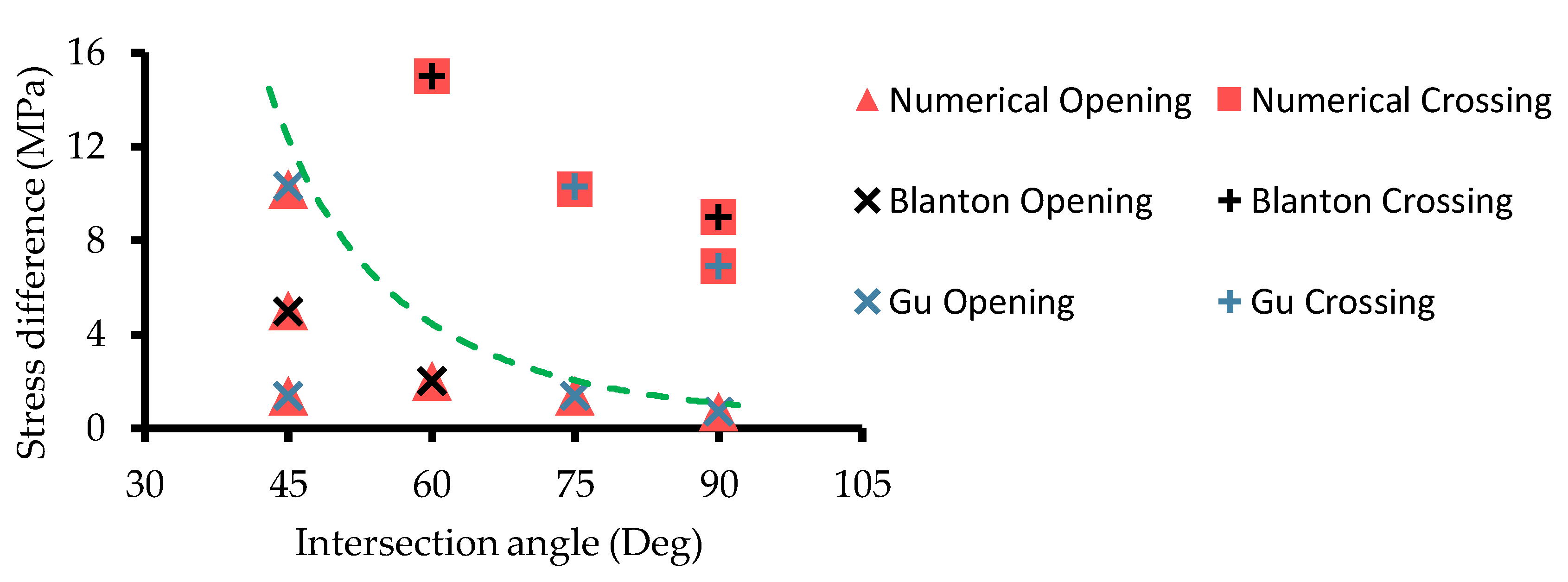

- HF will propagate along the NF when the stress contrast is small, while HF will cross the NF once becomes large. The results of HF intersection with NF simulated by three types of mesh make little difference, which all conform with the experimental results. Hence, the investigation of fracture intersection can be used by any type of mesh mentioned above. Owing to the property of the PPCZ element, only cracking along the edges of the element, triangle mesh, and deformed quadrangle mesh should be applied. In this way, there are more alternatives to cracking direction to increase the validity of the fracture pattern.

Author Contributions

Funding

Conflicts of Interest

References

- Liu, Z.; Wang, T.; Gao, Y.; Zeng, Q.; Huang, K.C. The key mechanical problems on hydraulic fracture in shale. Chin. J. Solid Mech. 2016, 37, 34–49. [Google Scholar] [CrossRef]

- Martin, S.H.; Brian, H. Shale gas in Europe—Overview, potential and research. In Proceedings of the AAPG Annual Convention and Exhibition, Colorado, CO, USA, 7–10 June 2009. [Google Scholar]

- Sharma, S.S.; Kulkarni, P. Gas strike in shale reservoir in Dholka field in Cambay basin. In Proceedings of the SPE Oil and Gas India Conference and Exhibition, Mumbai, India, 20–22 January 2010. [Google Scholar]

- Jarvie, D.; Pollastro, R.; Hill, R.; Bowker, K.; Claxton, B.; Burgess, J. Evaluation of hydrocarbon generation and storage in the Barnett shale, Ft. Worth basin, Texas. In Proceedings of the Ellison Miles Memorial Symposium, Farmers Branch, TX, USA, 22–23 June 2004; pp. 22–23. [Google Scholar]

- Weng, X.; Kresse, O.; Cohen, C.E.; Wu, R.; Gu, H. Modeling of hydraulic fracture network propagation in a naturally fractured formation. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 24–26 January 2011. [Google Scholar]

- Bunger, A.P.; Detournay, E.; Garagash, D.I. Toughness-dominated hydraulic fracture with leak-off. Int. J. Fracture 2005, 134, 175–190. [Google Scholar] [CrossRef]

- Khristianovic, S.; Zheltov, Y. Formation of vertical fractures by means of highly viscous fluids. In Proceedings of the 4th world petroleum congress, Rome, Italy, 6–15 June 1955; pp. 579–586. [Google Scholar]

- Geertsma, J.; De Klerk, F. A rapid method of predicting width and extent of hydraulically induced fractures. J. Petrol. Technol. 1969, 21, 571–581. [Google Scholar] [CrossRef]

- Perkins, T.; Kern, L. Widths of hydraulic fractures. J. Petrol. Technol. 1961, 13, 937–949. [Google Scholar] [CrossRef]

- Nordgren, R. Propagation of a vertical hydraulic fracture. Soc. Pet. Eng. J. 1972, 12, 306–314. [Google Scholar] [CrossRef]

- Detournay, E. Propagation regimes of fluid-driven fractures in impermeable rocks. Int. J. Geomech. 2004, 4, 35–45. [Google Scholar] [CrossRef]

- Xu, S.; Feng, Q.; Li, Y.; Wang, S. An integrated workflow for fracture propagation and reservoir simulation in tight oil. J. Petrol. Sci. Eng. 2019, 179, 1159–1172. [Google Scholar] [CrossRef]

- Bao, J.; Fathi, E.; Ameri, S. A coupled finite element method for the numerical simulation of hydraulic fracturing with a condensation technique. Eng. Fract. Mech. 2014, 131, 269–281. [Google Scholar] [CrossRef]

- Haddad, M.; Sepehrnoori, K. Simulation of hydraulic fracturing in quasi-brittle shale formations using characterized cohesive layer: Stimulation controlling factors. J. Unconv. Oil Gas Resour. 2015, 9, 65–83. [Google Scholar] [CrossRef]

- Chen, M.; Li, M.; Chen, W. Deflection of multi-crack synchronous propagation in horizontal well. J. Beijing Univ. Aeronaut. Astronaut. 2019, 45, 102–111. [Google Scholar]

- Belytschko, T.; Black, T. Elastic crack growth in finite elements with minimal remeshing. Int. J. Numer. Methods Eng. 1999, 45, 601–620. [Google Scholar] [CrossRef]

- Mohammadnejad, T.; Khoei, A.R. Hydro-mechanical modeling of cohesive crack propagation in multiphase porous media using the extended finite element method. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 1247–1279. [Google Scholar] [CrossRef]

- Hirmand, M.; Vahab, M.; Khoei, A.R. An augmented Lagrangian contact formulation for frictional discontinuities with the extended finite element method. Finite Elem. Anal. Des. 2015, 107, 28–43. [Google Scholar] [CrossRef]

- Khoei, A.; Vahab, M.; Hirmand, M. An enriched–FEM technique for numerical simulation of interacting discontinuities in naturally fractured porous media. Comput. Methods Appl. Mech. Eng. 2018, 331, 197–231. [Google Scholar] [CrossRef]

- Wu, K.; Olson, J.E. Investigation of the impact of fracture spacing and fluid properties for interfering simultaneously or sequentially generated hydraulic fractures. SPE Prod. Oper. 2013, 28, 427–436. [Google Scholar] [CrossRef]

- Xie, L.; Min, K.-B.; Shen, B. Simulation of hydraulic fracturing and its interactions with a pre-existing fracture using displacement discontinuity method. J. Nat. Gas Sci. Eng. 2016, 36, 1284–1294. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, L.; Pan, Z.; Han, Z. Numerical studies of interactions between hydraulic and natural fractures by smooth joint model. J. Nat. Gas Sci. Eng. 2017, 46, 592–602. [Google Scholar] [CrossRef]

- Wu, Z.; Sun, H.; Wong, L.N.Y. A cohesive element-based numerical manifold method for hydraulic fracturing modelling with voronoi grains. Rock Mech. Rock Eng. 2019, 52, 2335–2359. [Google Scholar] [CrossRef]

- Barenblatt, G.I. The formation of equilibrium cracks during brittle fracture. General ideas and hypotheses. Axially-symmetric cracks. J. Appl. Math. Mech. 1959, 23, 622–636. [Google Scholar] [CrossRef]

- Dugdale, D.S. Yielding of steel sheets containing slits. J. Mech. Phys. Solids 1960, 8, 100–104. [Google Scholar] [CrossRef]

- Chen, Z.; Bunger, A.; Zhang, X.; Jeffrey, R.G. Cohesive zone finite element-based modeling of hydraulic fractures. Acta Mech. Solida Sin. 2009, 22, 443–452. [Google Scholar] [CrossRef]

- Chen, Z. Finite element modelling of viscosity-dominated hydraulic fractures. J. Petrol. Sci. Eng. 2012, 88, 136–144. [Google Scholar] [CrossRef]

- Guo, J.; Zhao, X.; Zhu, H.; Zhang, X.; Pan, R. Numerical simulation of interaction of hydraulic fracture and natural fracture based on the cohesive zone finite element method. J. Nat. Gas Sci. Eng. 2015, 25, 180–188. [Google Scholar] [CrossRef]

- Guo, J.; Luo, B.; Lu, C.; Lai, J.; Ren, J. Numerical investigation of hydraulic fracture propagation in a layered reservoir using the cohesive zone method. Eng. Fract. Mech. 2017, 186, 195–207. [Google Scholar] [CrossRef]

- Nguyen, V.P.; Lian, H.; Rabczuk, T.; Bordas, S. Modelling hydraulic fractures in porous media using flow cohesive interface elements. Eng. Geol. 2017, 225, 68–82. [Google Scholar] [CrossRef]

- Li, J.; Dong, S.; Hua, W.; Li, X.; Pan, X. Numerical Investigation of Hydraulic Fracture Propagation Based on Cohesive Zone Model in Naturally Fractured Formations. Processes 2019, 7, 28. [Google Scholar] [CrossRef]

- Wang, H. Hydraulic Fracture Propagation in Naturally Fractured Reservoirs: Complex Fracture or Fracture Networks. J. Nat. Gas Sci. Eng. 2019, 68, 102911. [Google Scholar] [CrossRef]

- Xiang, G.; Zhou, W.; Yuan, W.; Ji, X.; Chang, X. Pore pressure cohesive zone modelling of complex hydraulic fracture propagation in a permeable medium. Eur. J. Environ. Civil Eng. 2019. [Google Scholar] [CrossRef]

- Adachi, J.I.; Detournay, E. Plane strain propagation of a hydraulic fracture in a permeable rock. Eng Fract Mech 2008, 75, 4666–4694. [Google Scholar] [CrossRef]

- Terzaghi, K.; Peck, R.B.; Mesri, G. Soil Mechanics; John Wiley & Sons: New York, NY, USA, 1996. [Google Scholar]

- Camanho, P.P.; Davila, C.G.; De Moura, M. Numerical simulation of mixed-mode progressive delamination in composite materials. J. Compos. Mater 2003, 37, 1415–1438. [Google Scholar] [CrossRef]

- Systemes, D. Abaqus User Subroutines Reference Guide; Version 6.14; Dassault Systemes Simulia Corp.: Providence, RI, USA, 2014. [Google Scholar]

- Cordero, J.A.R.; Sanchez, E.C.M.; Roehl, D. Hydromechanical modeling of unrestricted crack propagation in fractured formations using intrinsic cohesive zone model. Eng. Fract. Mech. 2019, 221, 106655. [Google Scholar] [CrossRef]

- Blanton, T.L. An experimental study of interaction between hydraulically induced and pre-existing fractures. In Proceedings of the SPE unconventional gas recovery symposium, Pittsburgh, PA, USA, 16–18 May 1982. [Google Scholar]

- Gu, H.; Weng, X.; Lund, J.B.; Mack, M.G.; Ganguly, U.; Suarez-Rivera, R. Hydraulic fracture crossing natural fracture at nonorthogonal angles: A criterion and its validation. SPE Prod. Oper. 2012, 27, 20–26. [Google Scholar] [CrossRef]

| Category | Symbol | Value |

|---|---|---|

| Rock parameters | ||

| Young’s modulus (GPa) | E | 20 |

| Poisson’s ratio | 0.2 | |

| PPCZ parameters (HF) | ||

| Stiffness (MPa/m) | K | 2.4 × 106 (LT) |

| 3.0 × 105 (ZT) | ||

| Normal fracture energy (Pa·m) | GI | 2.34 × 103 (LT) |

| 292.5 (ZT) | ||

| Shear fracture energy (Pa·m) | GII | 4.68 ×103 (LT) |

| 585 (ZT) | ||

| Normal strength (MPa) | N | 8.0 (LT) |

| 1.0 (ZT) | ||

| Shear strength (MPa) | T | 16.0 (LT) |

| 5.0 (ZT) | ||

| Friction coefficient | 0.6 | |

| Fluid parameters | ||

| Injection rate (m3/s) | Q | 0.001 |

| Viscosity (Pa·s) | 0.001 (LT) | |

| 5.0 (ZT) |

| Category | Symbol | Value |

|---|---|---|

| Rock parameters | ||

| Young’s modulus (GPa) | E | 20 |

| Poisson’s ratio | 0.2 | |

| In-situ stress (MPa) | 1–13 | |

| Intersection angle (Deg) | 45–90 | |

| PPCZ parameters (HF) | ||

| Stiffness (MPa/m) | K | 1.5 × 106 |

| Normal fracture energy (Pa·m) | GI | 20,475 |

| Shear fracture energy (Pa·m) | GII | 43,875 |

| Normal strength (MPa) | N | 7.0 |

| Shear strength (MPa) | T | 15.0 |

| Friction coefficient | μf | 0.6 |

| PPCZ parameters (NF) | ||

| Stiffness (MPa/m) | K | 1.5 × 106 |

| Normal fracture energy (Pa·m) | GI | 2925 |

| Shear fracture energy (Pa·m) | GII | 17,550 |

| Normal strength (MPa) | N | 1.0 |

| Shear strength (MPa) | T | 6.0 |

| Friction coefficient | μf | 0.6 |

| Fluid parameters | ||

| Injection rate (m3/s) | Q | 0.0001 |

| Viscosity (Pa·s) | 01 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, M.; Li, M.; Wu, Y.; Kang, B. Simulation of Hydraulic Fracturing Using Different Mesh Types Based on Zero Thickness Cohesive Element. Processes 2020, 8, 189. https://doi.org/10.3390/pr8020189

Chen M, Li M, Wu Y, Kang B. Simulation of Hydraulic Fracturing Using Different Mesh Types Based on Zero Thickness Cohesive Element. Processes. 2020; 8(2):189. https://doi.org/10.3390/pr8020189

Chicago/Turabian StyleChen, Minwei, Min Li, Yanzeng Wu, and Boqi Kang. 2020. "Simulation of Hydraulic Fracturing Using Different Mesh Types Based on Zero Thickness Cohesive Element" Processes 8, no. 2: 189. https://doi.org/10.3390/pr8020189

APA StyleChen, M., Li, M., Wu, Y., & Kang, B. (2020). Simulation of Hydraulic Fracturing Using Different Mesh Types Based on Zero Thickness Cohesive Element. Processes, 8(2), 189. https://doi.org/10.3390/pr8020189