Phenomenological Analysis of Thermo-Mechanical-Chemical Properties of GFRP during Curing by Means of Sensor Supported Process Simulation

Abstract

1. Introduction

2. Materials and Methods

2.1. Objective of the Test Series

2.2. Choice of Material

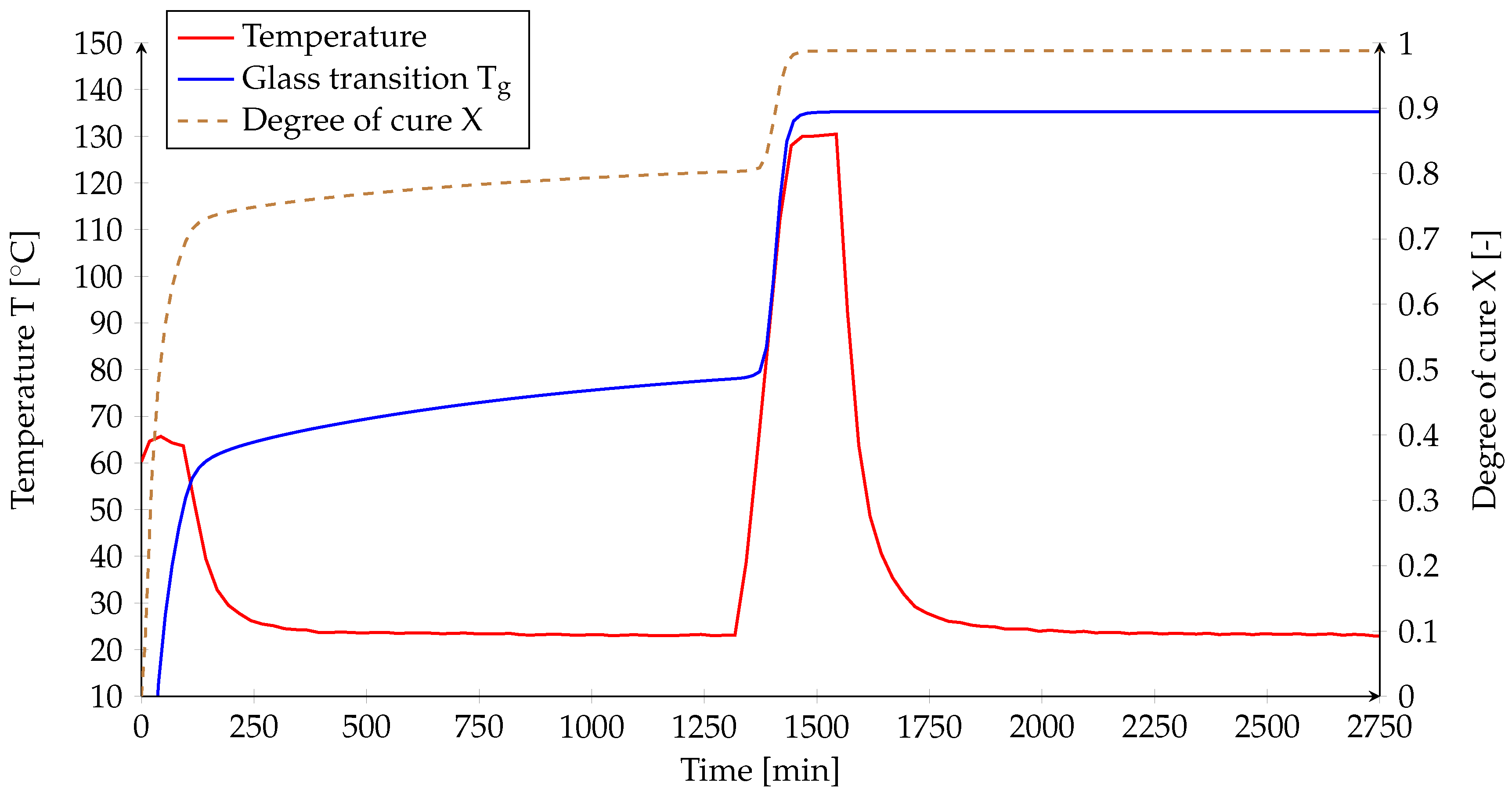

2.3. Process Simulation

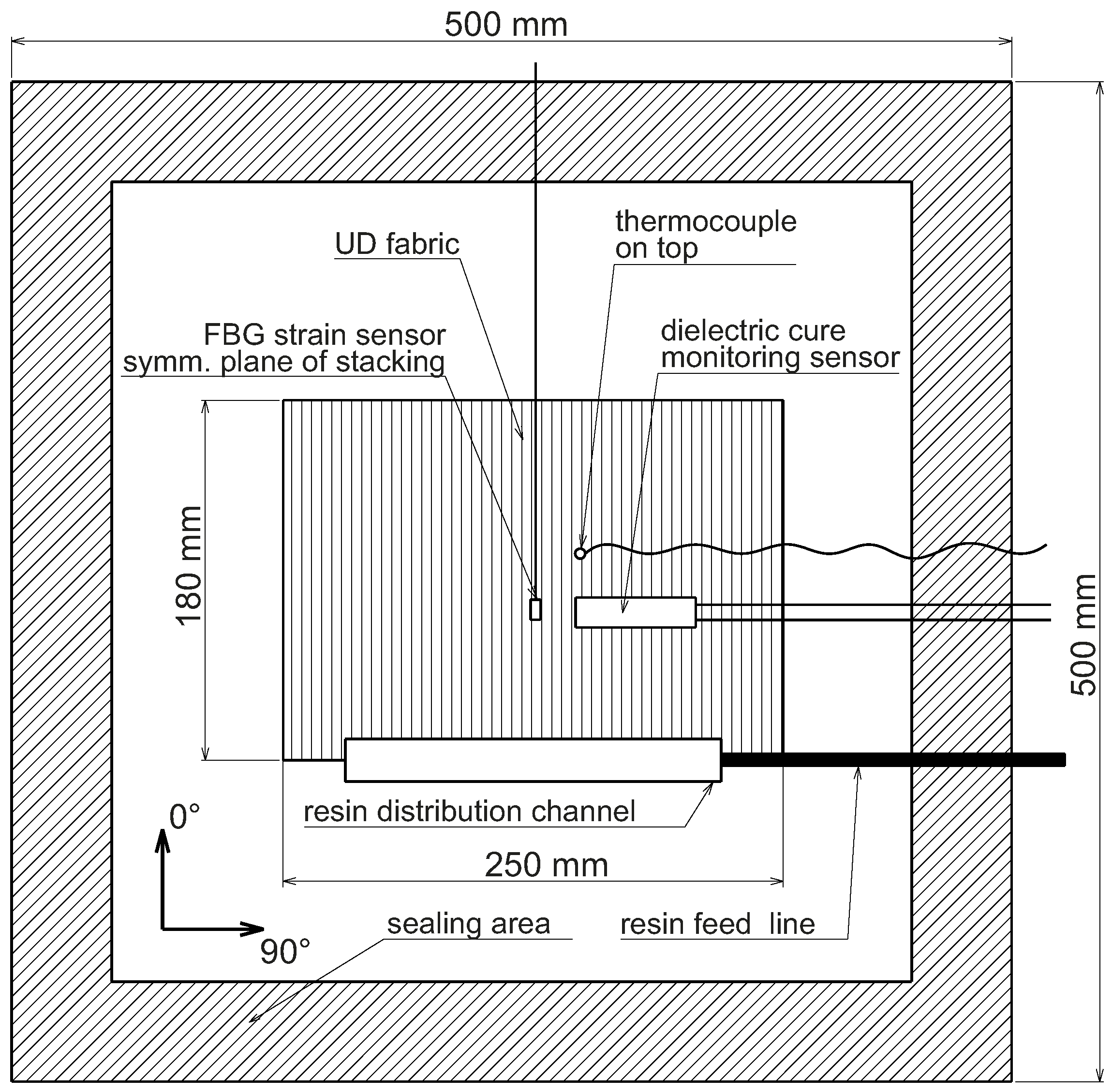

3. Experimental Set-Up

3.1. Applied Manufacturing Process

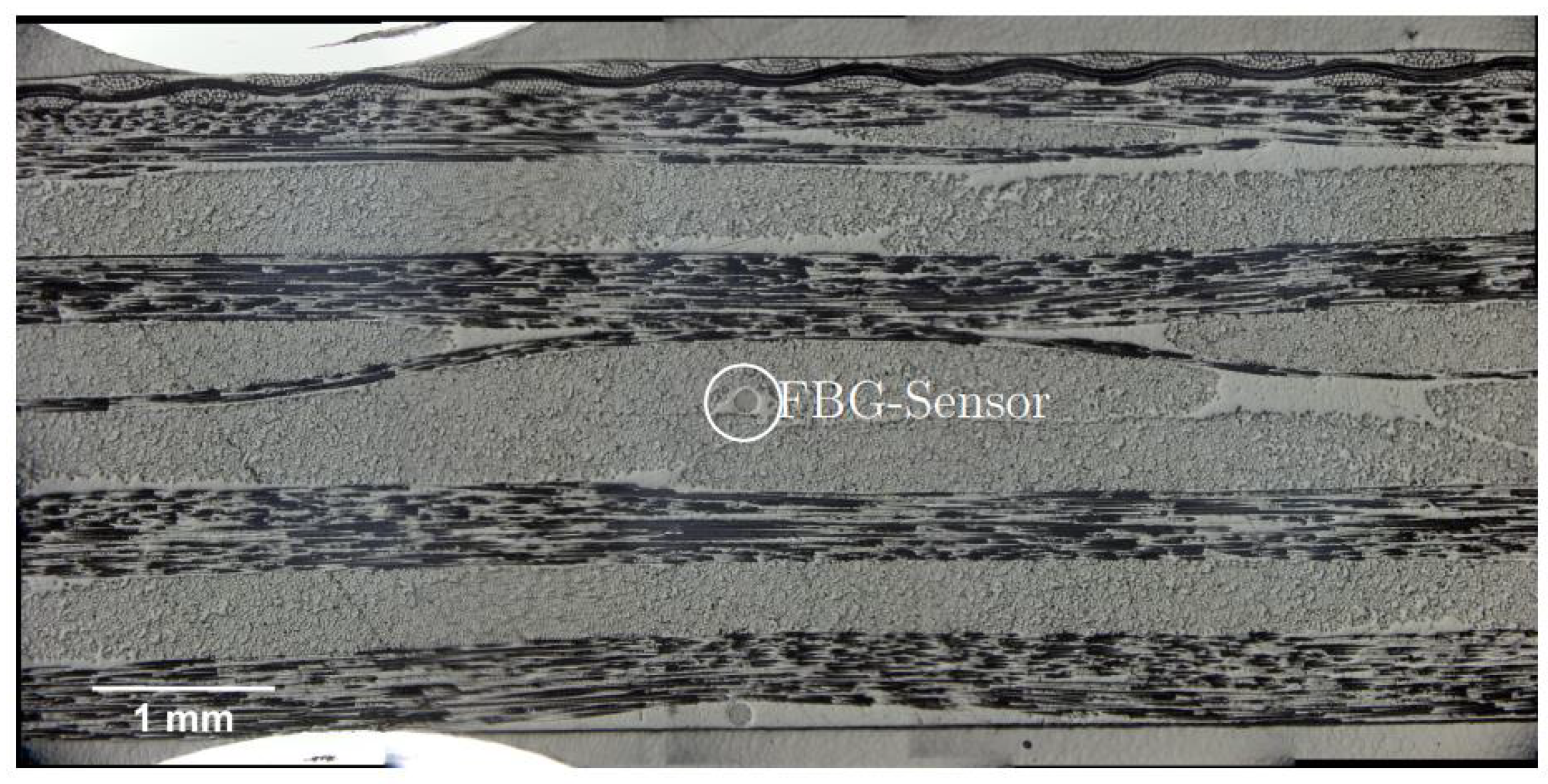

3.2. Fiber Bragg Grating Sensors

3.3. Dielectric Cure Monitoring

4. Experimental Results

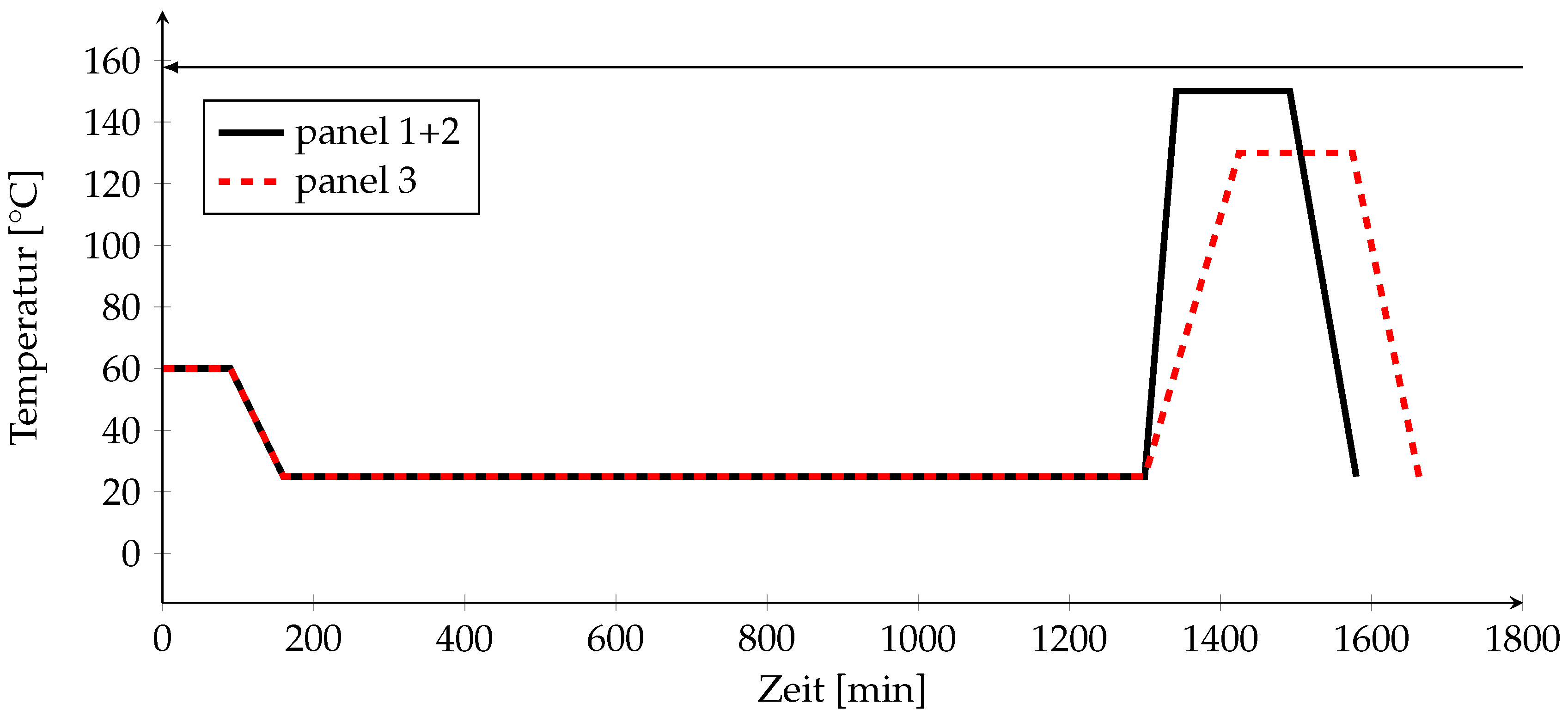

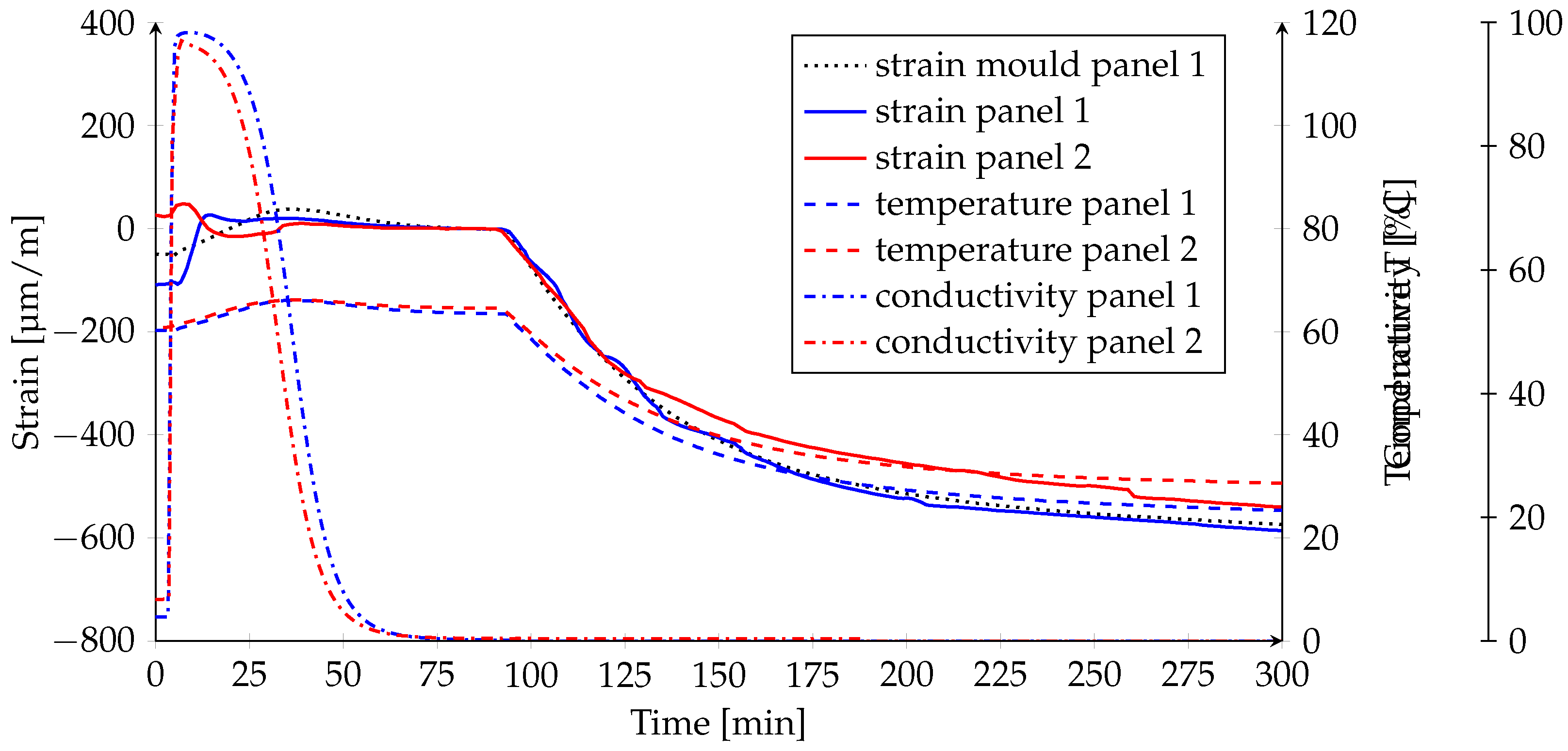

4.1. Results Panel 1 and Panel 2

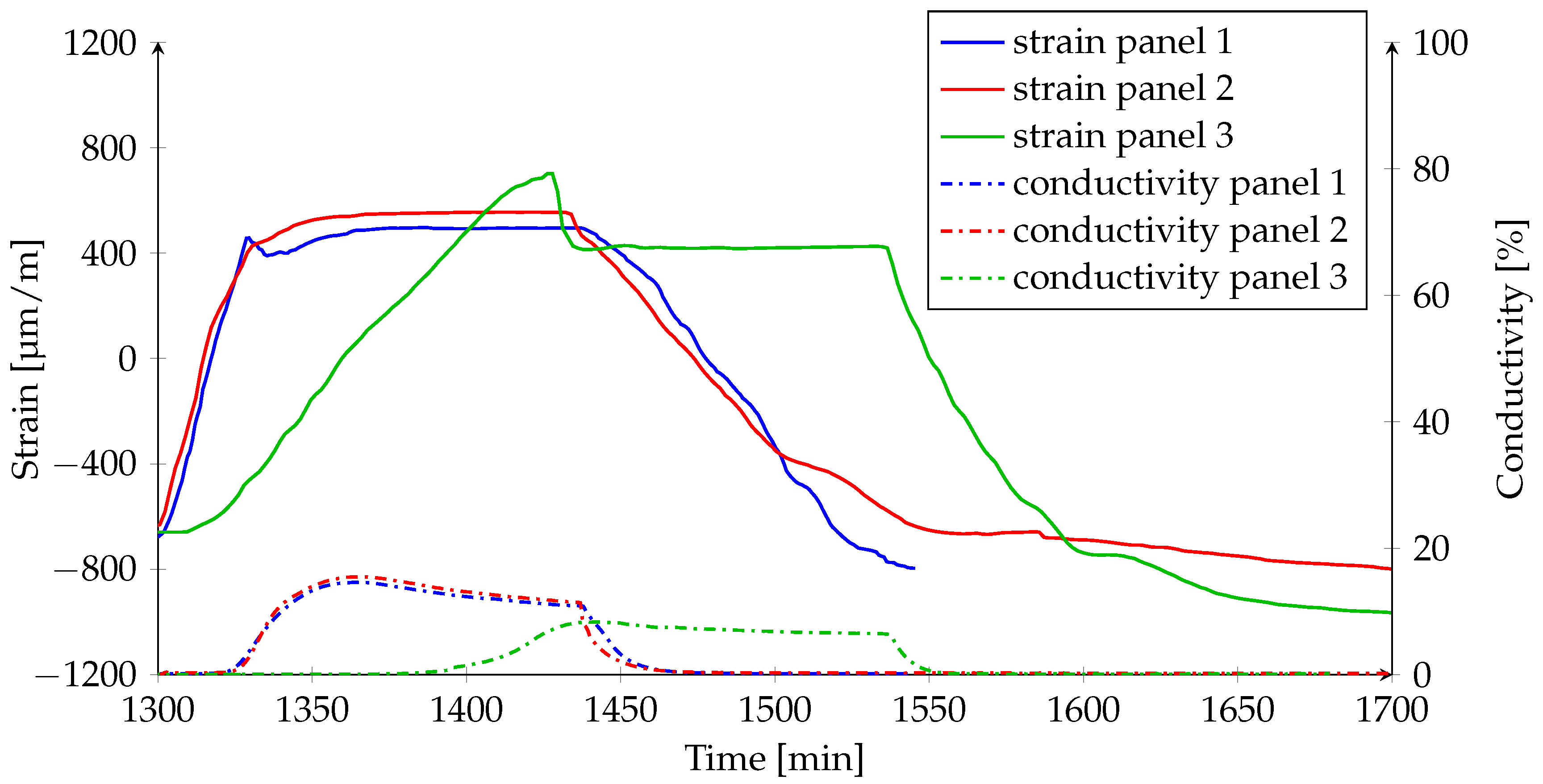

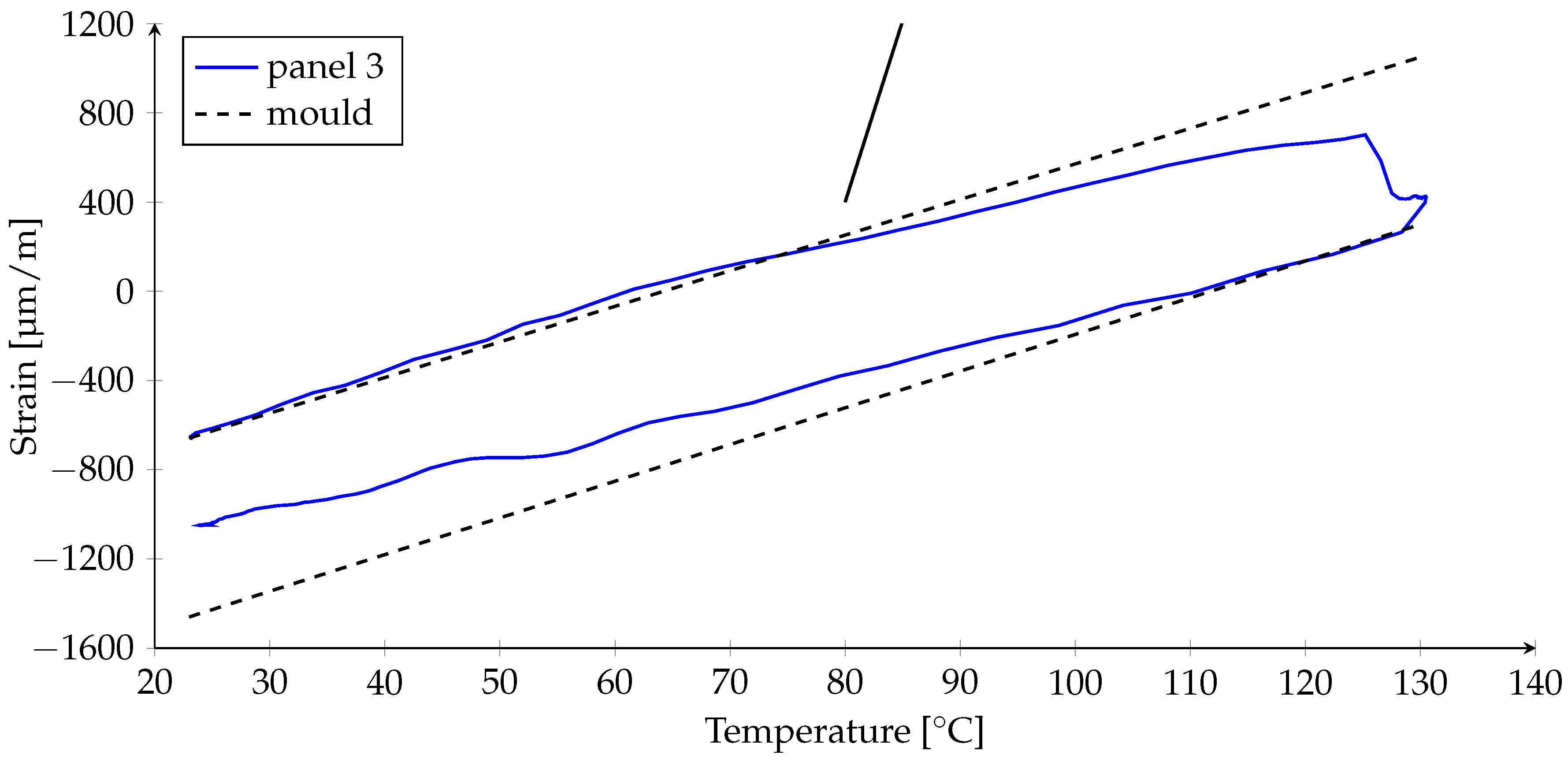

4.2. Results Panel 3

5. Process Simulation

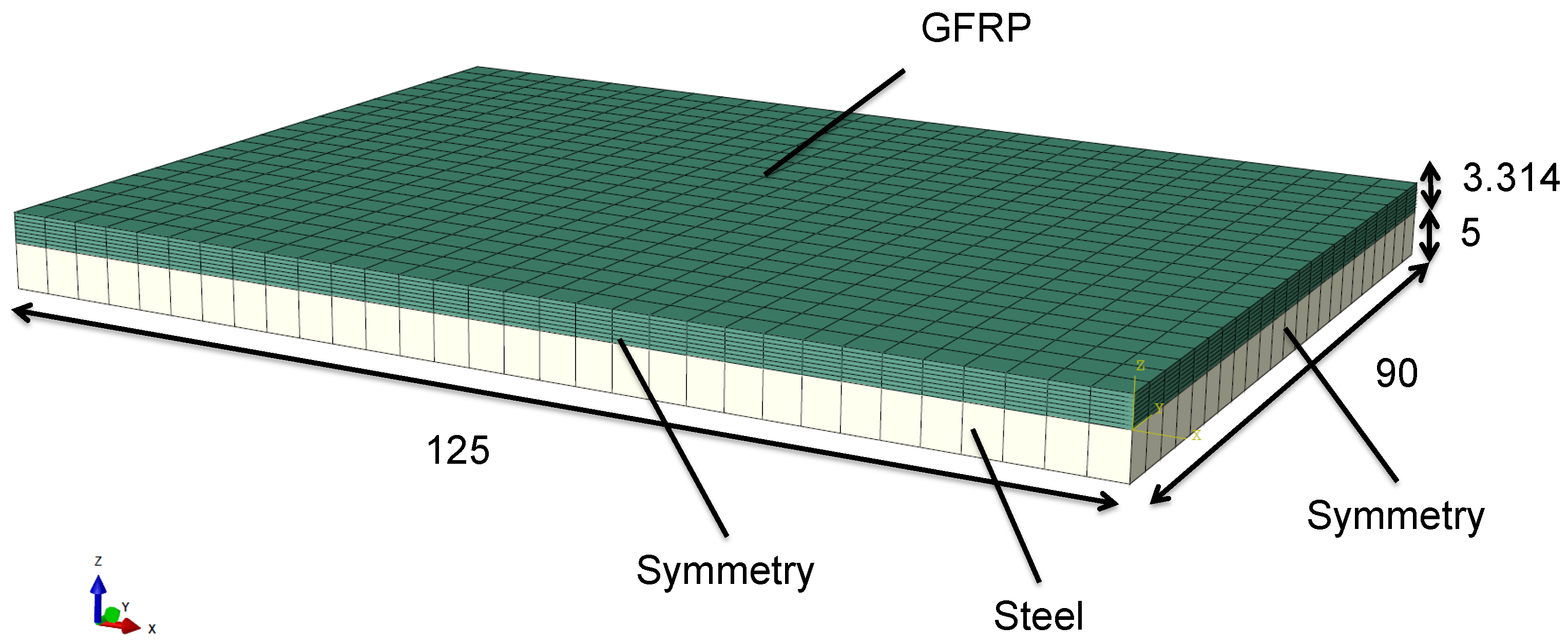

5.1. FE-Model and Boundary Conditions

5.2. Simulation Results

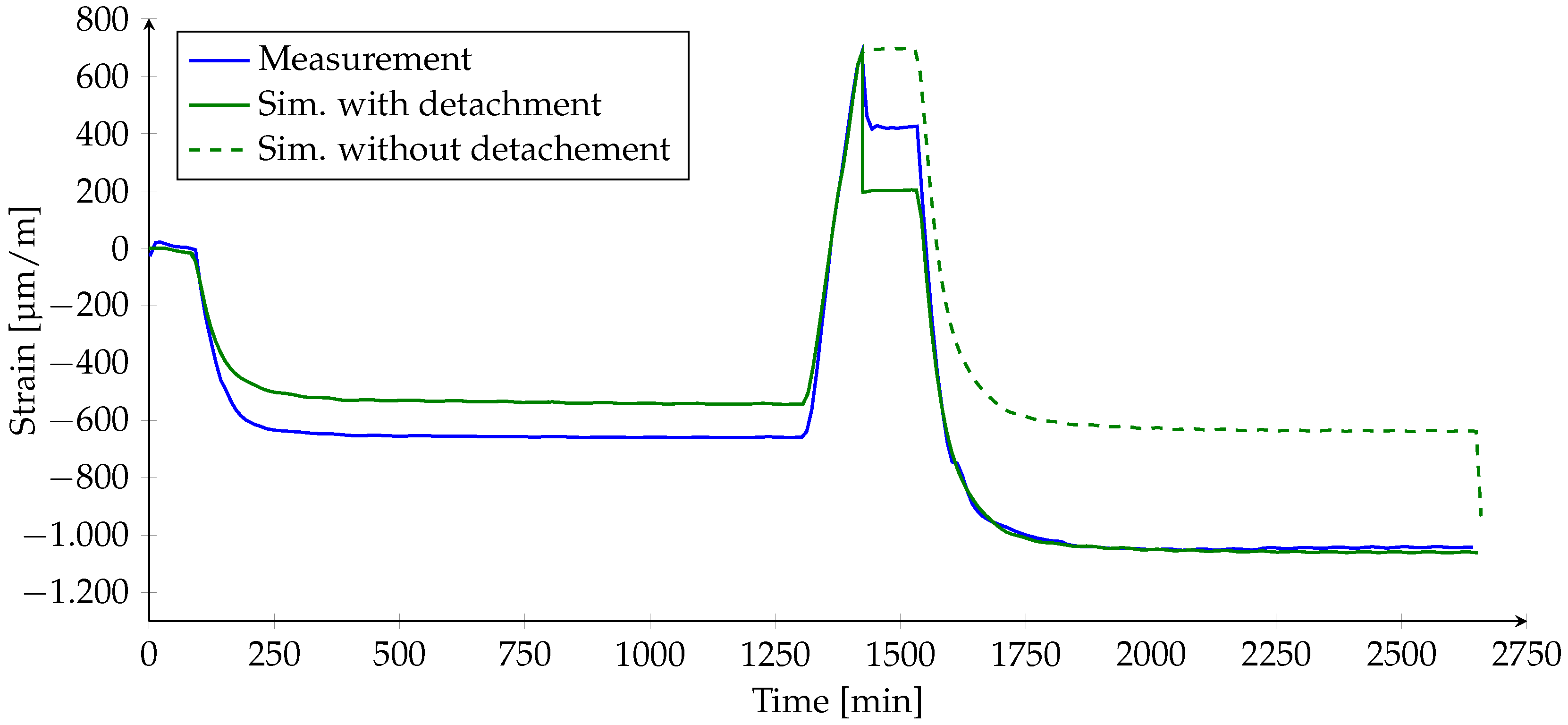

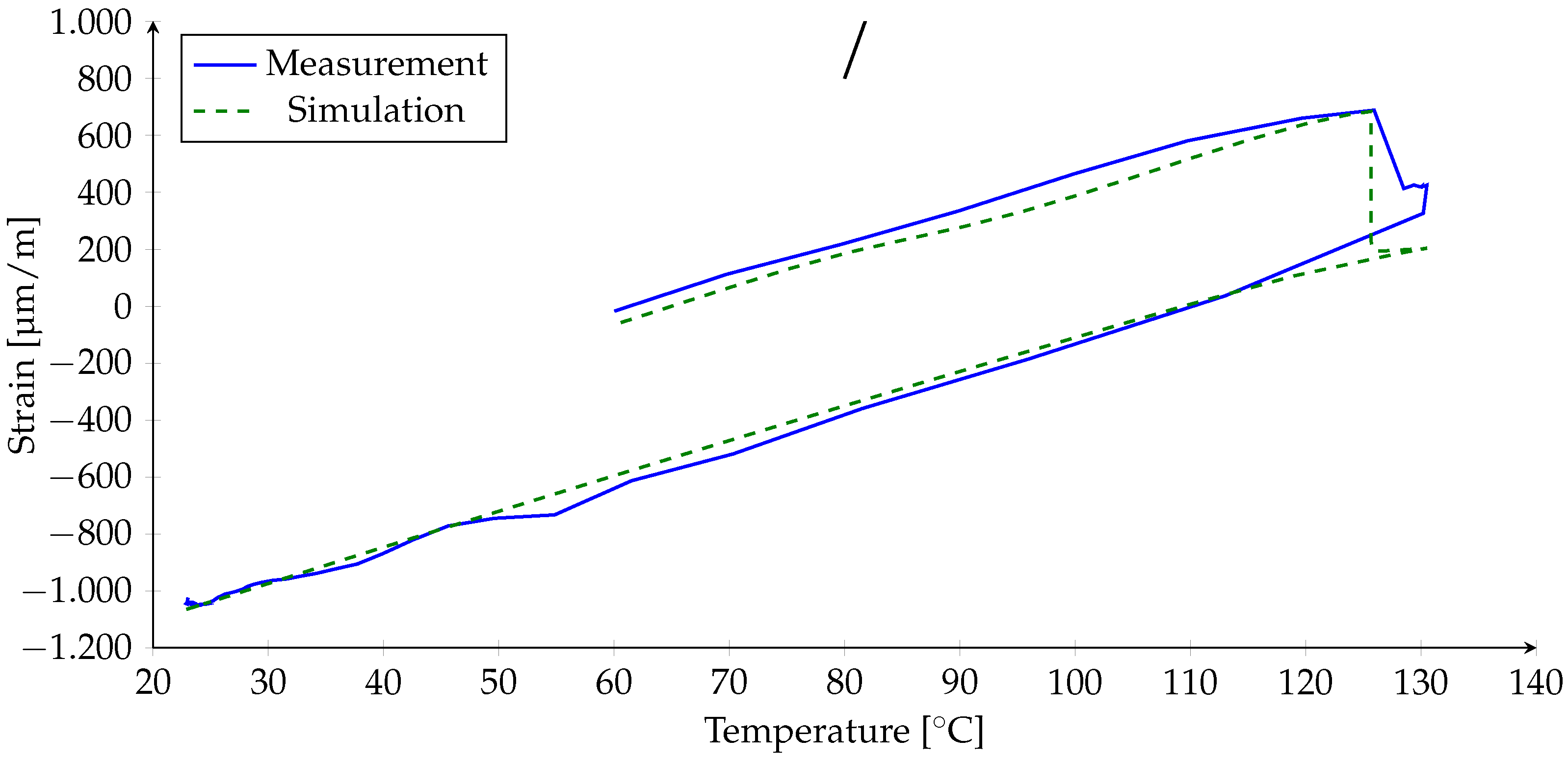

Comparison of the Strains

6. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CLT | Classical laminate theory |

| CTE | Coefficient of thermal expansion |

| DSC | Differential scanning calorimetry |

| FBG | Fibre Bragg grating |

| GFRP | Glass fiber-reinforced plastics |

| MRCC | Manufacturer recommended cure cycle |

| PID | Process-induced deformations |

| TMA | Thermomechanical analysis |

References

- Kaps, R. Kombinierte Prepreg- und Infusionstechnologie für integrale Faserverbundstrukturen. Ph.D. Thesis, Technical University of Braunschweig, Braunschweig, Germany, 2010. [Google Scholar]

- Shokrieh, M.; Ghanei Mohammadi, A. The importance of measuring residual stresses in composite materials. In Residual Stresses in Composite Materials; Woodhead Publishing: Cambridge, UK, 2014; pp. 3–14. [Google Scholar] [CrossRef]

- Puck, A. Analysis of Failure in Fiber Polymer Laminates-The Theory of Alfred Puck; Springer: Berlin/Heidelberg, Germany, 2008; p. 208. [Google Scholar]

- Brauner, C. Analysis of Process-Induced Distortions and Residual Stresses of Composite Structures. Ph.D. Thesis, Faserinstitut Bremen, Bremen, Germany, 2013. [Google Scholar]

- Harsch, M. Methoden und Ansätze zur spannungsarmen Vernetzung von Epoxidharzen. Ph.D. Thesis, TU Kaiserslautern, Kaiserslautern, Germany, 2008. [Google Scholar]

- Prussak, R.; Stefaniak, D.; Kappel, E.; Hühne, C.; Sinapius, M. Smart cure cycles for fiber metal laminates using embedded fiber Bragg grating sensors. Compos. Struct. 2019, 213, 252–260. [Google Scholar] [CrossRef]

- Svanberg, J.M. Predictions of Manufacturing Induced Shape Distortions—High Perfomance Thermoset Composites. Ph.D. Thesis, Lulea University of Technology, Lulea, Sweden, 2002. [Google Scholar]

- Oliveira, R.D.; Lavanchy, S.; Chatton, R.; Costantini, D.; Michaud, V.; Salathé, R.; Månson, J.E. Experimental investigation of the effect of the mould thermal expansion on the development of internal stresses during carbon fiber composite processing. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1083–1090. [Google Scholar] [CrossRef]

- Nielsen, M.W. Prediction of Process Induced Shape Distortions and Residual Stresses in Large Fibre Reinforced Composite Laminates—With Application to Wind Turbine Blades. Ph.D. Thesis, Technical University of Denmark, DTU, Lyngby, Denmark, 2012. [Google Scholar]

- Balvers, J.M. In Situ Strain & Cure Monitoring in Liquid Composite Moulding by Fibre Bragg Grating Sensors. Ph.D. Thesis, TU Delft, Delft, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Johnston, A.A. An Integrated Model of the Development of Process-Induced Deformation in Autoclave Processing of Composite Structures. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 1997. [Google Scholar]

- Huntsmann International LCC. Araldite ® LY 564* / Aradur ® 2954 *. Available online: https://www.mouldlife.net/ekmps/shops/mouldlife/resources/Other/araldite-ly564-aradur-2954-eur-e-1-.pdf (accessed on 23 January 2020).

- Hein, R. Vorhersage und In-Situ Bewertung fertigungsbedingter Deformationen und Eigenspannungen in Kompositen. Ph.D. Thesis, Technical University of Braunschweig, Braunschweig, Germany, 2019. [Google Scholar]

- DIN EN ISO 11357-1-2017-02—Beuth.de. Plastics—Differential scanning calorimetry (DSC)—Part 1: General principles. Available online: https://www.beuth.de/de/norm/din-en-iso-11357-1/264864949 (accessed on 8 November 2019).

- Mettler Toledo. Available online: http://www.mt.com/de/de/home.html (accessed on 23 January 2020).

- Owens Cornings. SE 1500 Roving Datasheet. Available online: http://www.ocvreinforcements.com/pdf/products/10009978_B_SingleEndRovings_SE1500_ww_11_2012_Rev3.pdf (accessed on 23 January 2020).

- Poon, H.; Ahmad, M.F. A material point time integration procedure for anisotropic, thermo rheologically simple, viscoelastic solids. Comput. Mech. 1998, 21, 236–242. [Google Scholar] [CrossRef]

- Zocher, M.A.; Groves, S.E.; Allen, D.H. A three-dimensional finite element formulation for thermoviscoelastic orthotropic media. Int. J. Numer. Methods Eng. 1997, 40, 2267–2288. [Google Scholar] [CrossRef]

- Hein, R.; Wille, T.; Gabtni, K.; Dias, J.P.P. Prediction of Process-Induce Distortions and Residual Stresses of an composite Suspension Blade. Defect Diffus. Forum 2015, 362, 224–243. [Google Scholar] [CrossRef]

- Dassault Systemes. Abaqus 6.14-1 Documentation; Technical Documentation; Dassault Systemes: Boston, MA, USA, 2014. [Google Scholar]

- Thyssenkrupp. Werkstoffdatenblatt 1.4301. Available online: https://de.materials4me.com/media/pdf/ef/e6/6c/Werkstoffdatenblatt_zum_Werkstoff_1-4301.pdf (accessed on 4 May 2015).

- ChemTrend. Zyvax Departure Release Agent. Available online: https://chemtrend.com/brand/zyvax/ (accessed on 13 November 2019).

- Hill, K.O.; Meltz, G. Fiber Bragg Grating Technology Fundamentals and Overview. J. Lightw. Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

- Prussak, R.; Stefaniak, D.; Hühne, C.; Sinapius, M. Evaluation of residual stress development in FRP-metal hybrids using fiber Bragg grating sensors. Prod. Eng. 2018, 12, 259–267. [Google Scholar] [CrossRef]

- Kappel, E.; Prussak, R.; Wiedemann, J. On a simultaneous use of fiber-Bragg-gratings and strain-gages to determine the stress-free temperature T sf during GLARE manufacturing. Compos. Struct. 2019, 227, 111279. [Google Scholar] [CrossRef]

- Gel Instrumente AG. Gelnorm PDET-1. Available online: https://www.gelinstrumente.ch/de/produkte/aushaerteverlauf-mit-leitwert/gelnorm-pdet-1 (accessed on 11 November 2019).

- Exner, W.; Kühn, A.; Szewieczek, A.; Opitz, M.; Mahrholz, T.; Sinapius, M.; Wierach, P. Determination of volumetric shrinkage of thermally cured thermosets using video-imaging. Polymer Test. 2016, 49, 100–106. [Google Scholar] [CrossRef]

- Fernlund, G.; Rahman, N.; Courdji, R.; Bresslauer, M.; Poursartip, A.; Willden, K.; Nelson, K. Experimental and numerical study of the effect of cure cycle, tool surface, geometry, and lay-up on the dimensional fidelity of autoclave-processed composite parts. Compos. Part A Appl. Sci. Manuf. 2002, 33, 341–351. [Google Scholar] [CrossRef]

- ISO 527-1:2012—Beuth.de. Plastics—Determination of tensile properties—Part 1: General principles. Available online: https://www.beuth.de/de/norm/din-en-iso-527-1/147683249 (accessed on 11 August 2019).

| Ply | Angle | Material |

|---|---|---|

| Tooling | ||

| 1 | 90° | UD fabric |

| 2 | 0° | UD fabric |

| 3 | 90° | UD fabric |

| 4 | 0° | UD fabric |

| Symmetrical Plane/FBG Sensor | ||

| 5 | 0° | UD fabric |

| 6 | 90° | UD fabric |

| 7 | 0° | UD fabric |

| 8 | 90° | UD fabric |

| 9 | - | Peel ply |

| Cure Monitoring Sensor/Peel Ply | ||

| Vacuum Bagging/Thermocouples | ||

| Property | Description | Unit | Value |

|---|---|---|---|

| Young’s modulus in fiber direction | MPa | 39206 | |

| Young’s modulus in fiber cross direction | MPa | 12389 | |

| In-plane shear modulus | MPa | 3427 | |

| In-plane poisson ratio | - | 0.26 | |

| CTE in fiber direction | 6.38 × 10−6 | ||

| CTE in cross direction | 39.13 × 10−6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hein, R.; Prussak, R.; Schmidt, J. Phenomenological Analysis of Thermo-Mechanical-Chemical Properties of GFRP during Curing by Means of Sensor Supported Process Simulation. Processes 2020, 8, 192. https://doi.org/10.3390/pr8020192

Hein R, Prussak R, Schmidt J. Phenomenological Analysis of Thermo-Mechanical-Chemical Properties of GFRP during Curing by Means of Sensor Supported Process Simulation. Processes. 2020; 8(2):192. https://doi.org/10.3390/pr8020192

Chicago/Turabian StyleHein, Robert, Robert Prussak, and Jochen Schmidt. 2020. "Phenomenological Analysis of Thermo-Mechanical-Chemical Properties of GFRP during Curing by Means of Sensor Supported Process Simulation" Processes 8, no. 2: 192. https://doi.org/10.3390/pr8020192

APA StyleHein, R., Prussak, R., & Schmidt, J. (2020). Phenomenological Analysis of Thermo-Mechanical-Chemical Properties of GFRP during Curing by Means of Sensor Supported Process Simulation. Processes, 8(2), 192. https://doi.org/10.3390/pr8020192