1. Introduction

The steel industry is one of the most important raw material industries. The iron-making process in the early steel process is mainly done through a blast furnace [

1]. With changes in the times, a series of drawbacks of the blast furnace have gradually emerged. One is the heavy dependence on coke resources [

2], and the second is the increasing pressure on environmental protection. With the rapid depletion of natural resources and awareness regarding environmental protection, the smelting reduction process came into being. This significantly reduces energy consumption and investment by recycling the waste heat and eliminating sintering and coking plants [

3]. Among the variants of this process, representative ones are COREX [

4], jointly developed by VAI and Korf, FINEX [

5], jointly developed by POSCO Steel and VAI Engineering, HISMELT [

6], jointly developed by CRA Australia and Kloekner, and DIOS [

7], jointly developed by the Japan Iron and Steel Federation to organize eight domestic steel companies.

In the field of smelting reduction, many researchers have done considerable research on physical simulation and mathematical simulation. Zou et al. [

8,

9] proposed a two-step three segment iron bath smelting reduction process with a thick slag layer, which was developed for the gradient separation of the oxidation zone and the reduction zone by a thick slag layer with physical simulation. Srishilan et al. [

10] proposed a predictive thermochemical model of the COREX process which enables the rapid computation of process parameters. The model helps in predicting the variations in process parameters with respect to the degree of metallization and post-combustion ratio for the given raw material conditions. A series of recent representative research results have also been obtained in smelting reduction and hydrocarbon reduction. In the field of plasma reduction, for example, Behera et al. [

11] succeeded in the smelting reduction of iron ore (hematite) in thermal hydrogen plasma. Mandal et al. [

12] described a new concept for maintaining an inert atmosphere with a high temperature of about 1973 K (1700 °C) inside the furnace during smelting reduction. In terms of direct reduction, Shim et al. [

13] reported that the direct reduction rate in a melter–gasifier was roughly drawn as the product of the CO

2 content in the ascending gas and the reaction rate constant of coal with CO

2, and the way to minimize the direct reduction ratio was discussed with that diagram. You et al. [

14] used Sn-bearing complex iron ore via reduction with mixed H

2/CO gas to prepare Sn-enriched direct reduced iron (DRI). In the behavior of reduction, Park et al. [

15,

16] investigated the high-temperature behavior of a magnetite–coke composite pellet fluxed with dolomite by a customized thermogravimetric analyzer (TGA) at 1573 K (1300 °C) and the influence of different coal types on the reduction of the composite pellet. At the same time, previous research has proposed a new generation of C-H

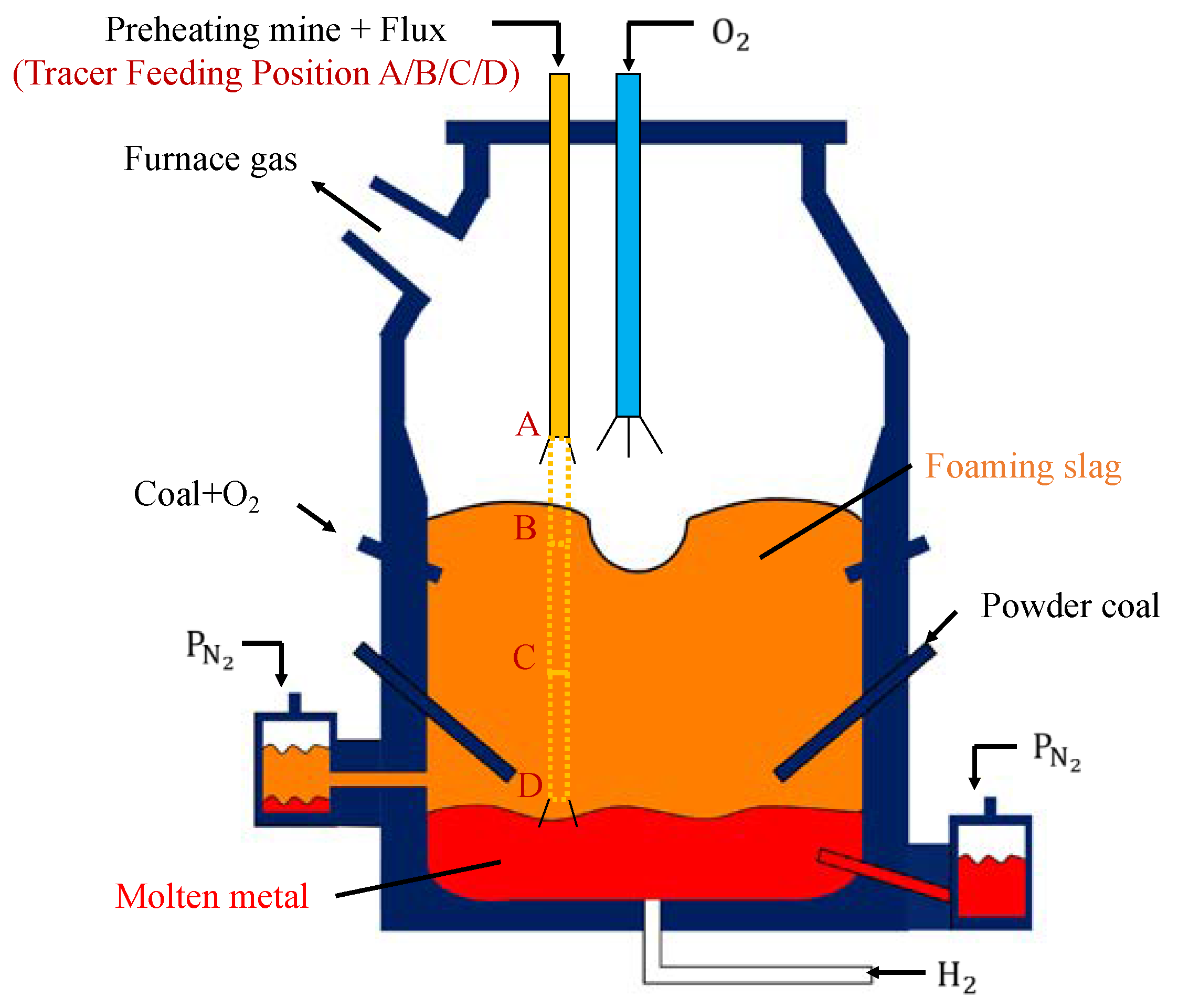

2 smelting reduction furnace (cf.

Figure 1).

The theory of similarity is the theory of experimentation. For the formulas of complex phenomena that cannot be solved by mathematical analysis, the similarity theory provides an experimental solution. The similar first theorem specifies the physical quantities that need to be measured during the experiment, as well as the conditions that the model experiment should follow. The π theorem is a universal dimensional analysis method which was proposed by E. Buckinghan in 1915, so it is also known as the Buckingham Theorem. The Buckingham Theorem is described as F(x1, x2, …, xn) = 0, if there are n variables that are mutual functions for a physical phenomenon. If these variables contain m basic quantities, they can be arranged into the functional relation φ(π 1, π 2, …, π n ≤ m) of (n ≤ m) dimensionless numbers, and then n physical quantities can be combined into (n ≤ m) dimensionless π numbers. In this paper, the dimensional analysis is based on the Buckingham theorem, which specifies how to organize the experimental results. The experimental results need to be organized into a functional relationship between dimensionless groups. Finally, the dimensionless groups and the coefficients of similarity are determined according to the experimental results. The similarity theory is used to solve the problem in various fields. Zhen et al. [

17] focuses on providing a quantitative methodology on how each parameter affects the structural response of the subsurface tension leg platform (STLP), which will facilitate establishing the unique design dimensionless groups as regards to STLP. Vatankhah et al. [

18] predicted the rate of discharge through different side holes in irrigation and hydraulic engineering. Sharp-crested side triangular orifices were studied experimentally and analytically, and several models were derived for the discharge coefficient based on Buckingham’s theorem of dimensional analysis. Meng et al. [

19] used the π theorem, an improved dimensional analysis method, and the dimensionless quantity, which can effectively reflect the relationship between the non-sinusoidal vibration parameters of a continuous casting mold, was given. The dimensionless function correlation formula, which can objectively describe the actual phenomenon, was obtained.

Side blowing is one of the key processes of smelting reduction. Fuel and enriched oxygen are injected into the furnace by a side nozzle to provide the heat required for the reduction reaction and the melt is stirred at the same time. By designing and optimizing the parameters such as the arrangement, the angle, and the flow rate of the side nozzle, this provides better reaction conditions for melting in the furnace and prolongs the service life of the side nozzle, and finally achieves the combination with the top and bottom blowing. For side blowing, many scholars had conducted relevant research in this field. For example, Feng [

20] outlined the production overview of the side-blown melting reduction furnace, introduced the construct design of main components, and listed the practice and summarized the characteristics of the side-blown reduction furnace. Due to a large number of side nozzle parameters and furnace parameters, the experimental results were not regular on the surface, so it was necessary to sort out the data through dimensional analysis and provide an analytical formula, so as to obtain the quantitative law. Wang et al. [

21] investigated the penetration behavior of immersion side-blowing gas flow in a slag lade water model by photography and the dimensional analysis method, in order to provide a theoretical base for improving the reaction speed between the gas–liquid interface and the oxygen gun jet distribution. The maximum penetration depth calculated by the empirical formula is in agreement with the measured data from the experiments.

Although many studies [

22,

23,

24] have been carried out on the C-H

2 smelting reduction furnace through physical simulation and mathematical simulation, the experimental data and results have not been quantitatively analyzed. This paper is aimed at providing a quantitative method for examining how each parameter affects the mixing time in the C-H

2 smelting reduction furnace, and proposes a dimensionless input and output parameter based on the Buckingham theory, a complete list of derived dimensionless groups. This is helpful for establishing a single design standard for C-H

2 smelting reduction furnaces. This study provides a means to understand critical parameters better and lays the foundation for the optimal design of the side blowing parameters of the C-H

2 smelting reduction furnace. The conclusions obtained are also widely applicable to the engineering design and design analysis of the smelting reduction furnace.

2. Experimental Setup and Methods

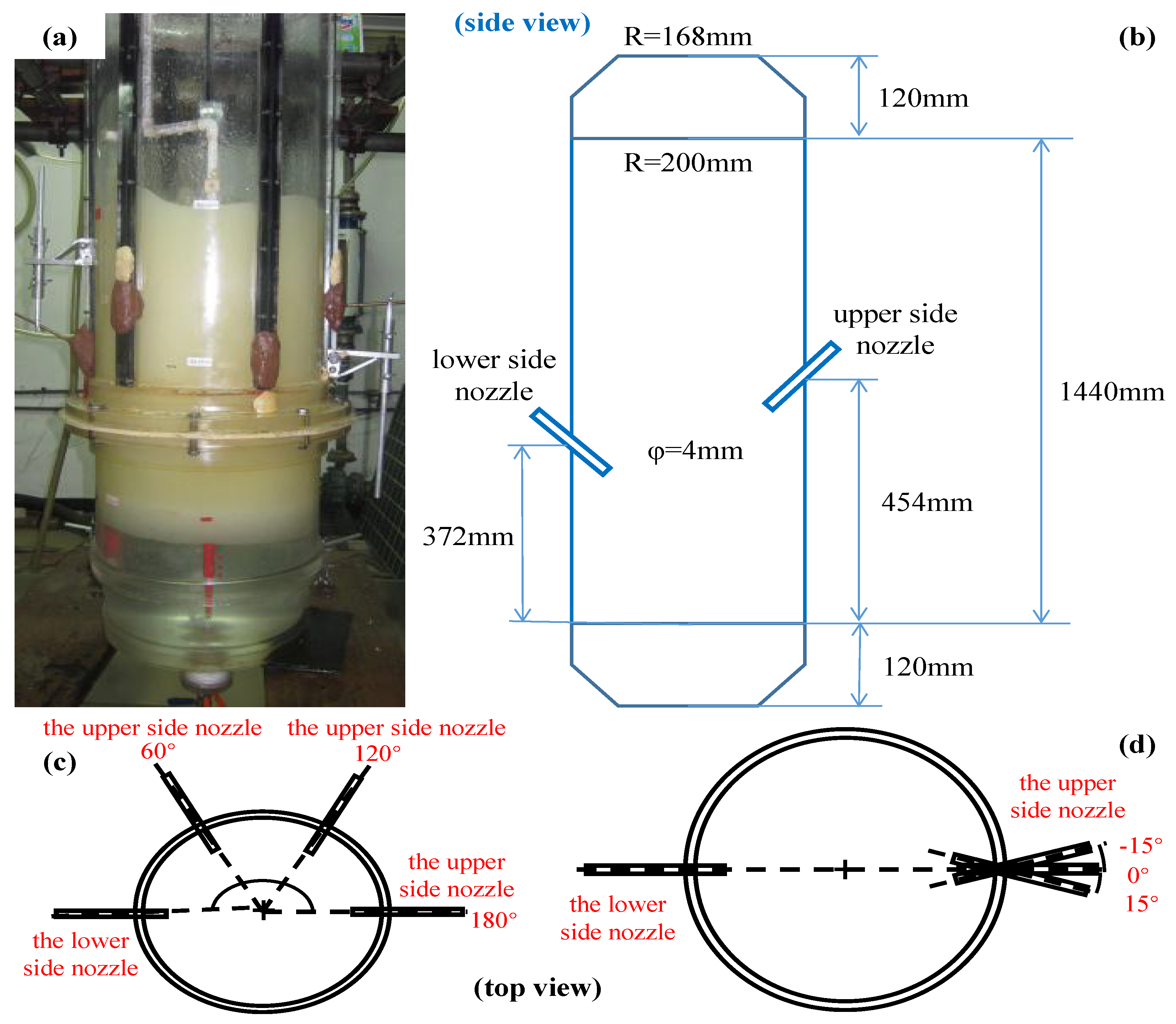

In this paper, a comprehensive experimental study on the flow characteristics of a C-H

2 smelting reduction furnace was carried out. Based on the similarity principle, the smelting reduction iron-making process under the high temperature conditions in the prototype was studied by hydraulic simulation at room temperature in this experiment. The schematic diagram of the C-H

2 smelting reduction model apparatus is shown in

Figure 2. The model was simulated by the scale ratio of 1:1 to the prototype, in which the molten iron of the prototype was 200 kg. The experiment was carried out in a cylindrical transparent plexiglass furnace with a diameter of about 0.4 m and a height of 1.68 m. In the experiment, the molten iron was simulated by water, high vacuum oil was used to simulate the slag, and oxygen-enriched air was blown on the top and bottom and side nozzle to simulate the flux injection and the bottom blowing hydrogen. The volume ratio of water to high vacuum oil in the model was 1:2 [

25,

26], in which the water phase was 0.246 m and the height of the oil phase was 0.492 m. The physical parameters of the experiment are shown in

Table 1. In the prototype, the combined top, bottom, and side blowing of the C-H

2 smelting reduction process occurs. This paper is the first phase of the project, aiming to carry out the physical simulation and dimensional analysis of the single-side blowing of double-row side nozzles. The side blowing nozzle was divided into the upper side nozzle and the lower side nozzle, and the diameter of the side nozzle was 0.004 m. The upper side nozzle was 0.574 m from the bottom and was located at 1/3 above the slag phase. The lower side nozzle was 0.492 m from the bottom and was located in the middle of the slag layer. The prototype and dimensions of the water model are shown in

Figure 3a,b, respectively.

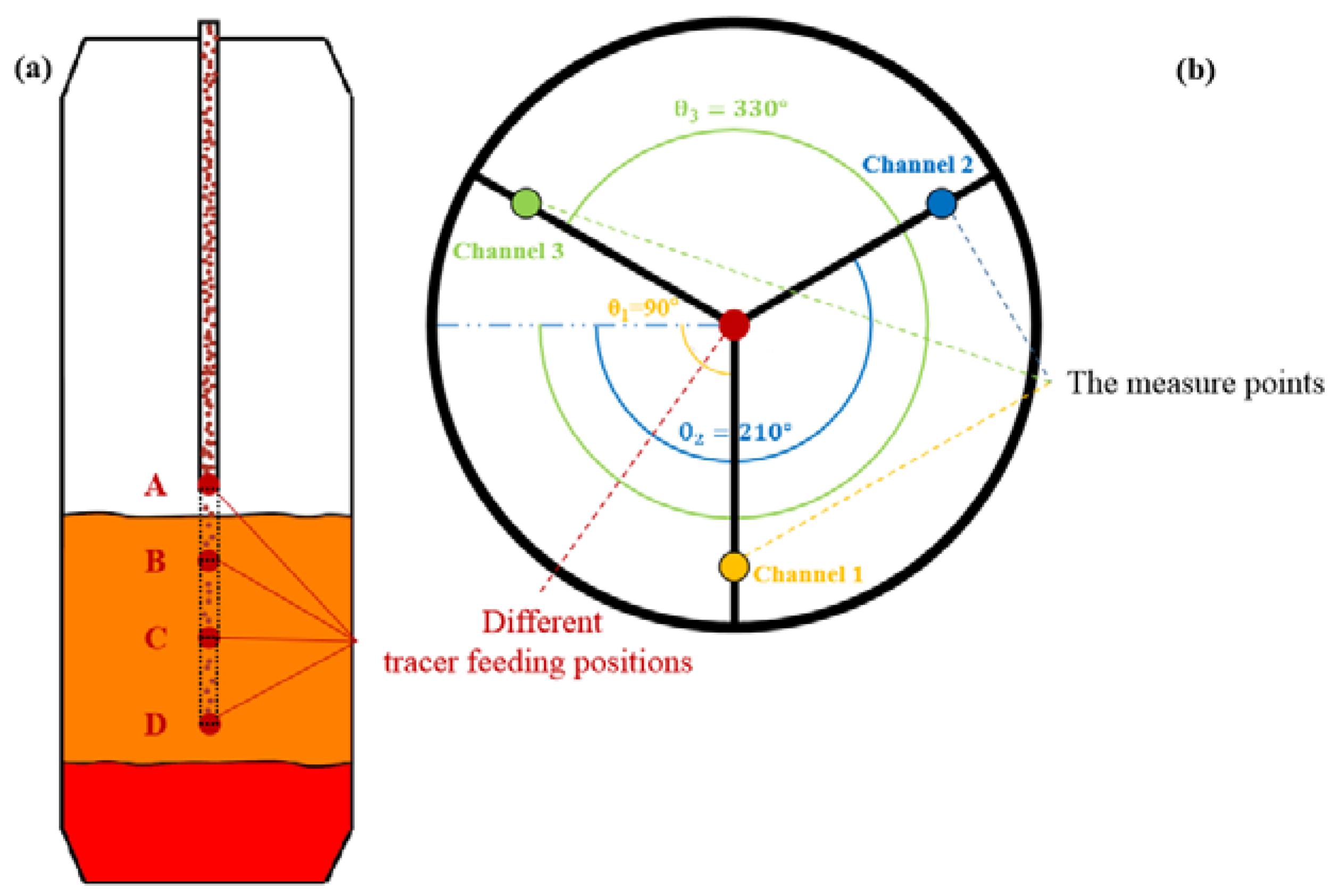

In this study, several different influencing factors were set. The effects of various factors and mixing time were obtained by orthogonal tests. By sorting out the experimental data, it was organized to be a functional relationship between the dimensionless groups. The first factor was the tracer feeding position. In the prototype, the tracer feeding port was added to the preheating mine and flux. It is of considerable significance to investigate the feeding position of raw materials for the mixing effect in the molten pool. Position A was at 2 cm above the slag interface (0.758 m from the bottom). Position B was located at 2 cm below the slag interface (0.718 m from the bottom). Position C was at the center of the slag (0.492 m from the bottom). Position D was located at 2 cm above the slag and the molten interface (0.266 m from the bottom), as shown in

Figure 4a.

Similarly, several other factors were considered separately. These included the relative angle between the upper side nozzle and the lower side nozzle (60°, asymmetrical side blowing; 120°, asymmetrical side blowing; 180°, symmetric side blowing) (cf.

Figure 3c), the horizontal angle of the upper side nozzle and the lower side nozzle (−15°, 0°, 15°) (cf.

Figure 3d), the insertion depth of the side nozzle, and the flow rate of the side nozzle.

The inside of the molten pool was strongly agitated and disturbed in the combined upper side nozzle and lower side nozzle. Therefore, the efficiency of mass transfer and heat transfer was increased, and the rate of chemical reaction was also increased. In order to study the mixing phenomenon in the C-H

2 smelting reduction bath, the mixing time was regarded as an important index. The mixing time [

27] was defined as the period required for an instantaneous tracer concentration to settle within ±5% deviation around the final tracer concentration in the C-H

2 smelting reduction reactor bath. This definition is referred to as the 95% mixing time. In the C-H

2 smelting reduction bath, the mixing time was measured by the conductivity of three electrodes, which was 0.05 m away from the bottom of the bath.

Figure 4b is the position and angle of the sensor and tracer. In the prototype, the feed port was used for feed preheating ore and flux. In this experiment, in order to simulate the effect of different raw material positions on the mixing time of the molten pool, a saturated Sodium chloride (NaCl) aqueous solution (75 mL) was fed from the intermediate to the C-H

2 smelting reduction furnace. The conductivity of water was measured by three DSS-IIA conductivity meters and recorded automatically by a computer software recorder. For each physical simulation test site in each mode of operation, the measurements were taken at least three times and the arithmetic mean of the average residence time was obtained. Through the orthogonal test and analysis, the relationship between the average residence time and various experimental parameters can be obtained. These results would eventually be organized into a functional relationship between the dimensionless groups.

3. Dimensional Analysis

The purpose of this study was to establish a relationship between the mixing time and other valid variables. Their dimensions were considered through dimensional analysis. In this method, the first step is to select the appropriate initial parameters, including the input parameters and output parameters of the mixing time. The second step is to group these initial parameters into a dimensionless group and organize the new relationships between the various parameters. In particular, it is important to select the initial parameters precisely, since there is a need for a unique relationship between the chosen parameters [

28,

29].

Several factors may affect the value of mixing time. The variables that may affect the mixing time are density

ρ, kinematic viscosity

υ, surface tension

σ, stirring energy

ε [

30], etc. In this study, 20 initial parameters were selected to identify the dimensionless groups of the parameters which can quantify the mixing time, as shown in

Table 2. Based on this, 17 corresponding dimensionless groups were obtained from the selected initial parameters, according to the Vaschy–Buckingham theorem.

The mixing time can be represented by the following functional relationships:

Meanwhile, since many factors are constant in this study, such as the height of the furnace, the height of the high vacuum oil, the height of the side nozzle, the diameter of the side nozzle and so on, the functional relationships can be further simplified to

The equation can be expressed in the following dimensionless equation:

where

π1~

π8 is a dimensionless group, and

is a functional symbol. After substituting in each variable, it gives

By replacing the other variables with

ρ,

Ds and

Vs, we get

Since the side-blown nozzle is located in the high vacuum oil, the kinematic viscosity here is selected as the high vacuum oil kinematic viscosity,

voil, m

2·s

−1. The tracer feeding position and the insertion position of the side nozzle are closely related to the total height of the water phase and oil phase, the

DS in the tracer feeding position number and the insertion depth number of side nozzle are replaced by the total height of the water phase and oil phase

Hoil+w, which can be converted into the following equation:

In this work, the angle between the upper side nozzle and the lower side nozzle is also a relatively important factor, including the relative angle and horizontal angle, so the angle factor should be taken into account when studying the dimensionless groups. The momentum dimensionless group is studied based on different angles.

δ is introduced here, that is,

where

is combined the the relative angle between the upper side nozzle and the lower side nozzle and the horizontal angle of the upper side nozzle and the lower side nozzle. This parameter synthetically considers the influence of flow velocity with various angles,

Vs is flow velocity of the side nozzle, m·s

−1.

Df is the diameter of the furnace, m, and

Qs is the volumetric flow rate, m

3·s

−1.

Through the above dimensionless group derivation, a series of dimensionless groups can be obtained as follows in

Table 3.

The original dimensionless groups mentioned above can be substituted into Equation (10) to obtain

Extracting the

τ from Equation (10) and rearranging, we get

where

υoil is the kinematic viscosity of the high vacuum oil, m

2·s

−1,

σ is the surface tension of the high vacuum oil, kg·s

−2,

g is the acceleration of gravity, m·s

−2,

ε is the stirring energy of the side nozzle, kg·m

2·s

−3,

δ is the dimensionless groups of momentum,

qs is the flow rate of the single side nozzle, m

3·s

−1,

hs is the insertion depth of the side nozzle, m,

Hoil+w is the total height of the high vacuum oil and water, m,

Ds is the diameter of the single side nozzle, m, and

Vs is the flow velocity of the side nozzle, m·s

−1.

The dimensionless groups related to Equation (11) based on a physical chemistry handbook are shown in

Table 4:

Based on the fact that

is constant in this condition, it will be removed here. At the same time,

Njm is named in order to simplify the expression of

, that is

. According to

Table 3,

Table 4 and

Table 5 and the actual working conditions of this study, the equation of dimensionless groups can be expressed as follows:

As can be seen from

Table 4,

is a constant. Since Ca is the dimensionless group representing the relative effect of viscous drag forces versus surface tension forces acting across an interface between a liquid and a gas, or between two immiscible liquids, so the Capillary number (Ca) is retained here, thus the following dimensionless groups equation can be further obtained:

where

a,

b,

c,

d,

e, and

f are the empirical coefficient, to be derived from the experimental data.

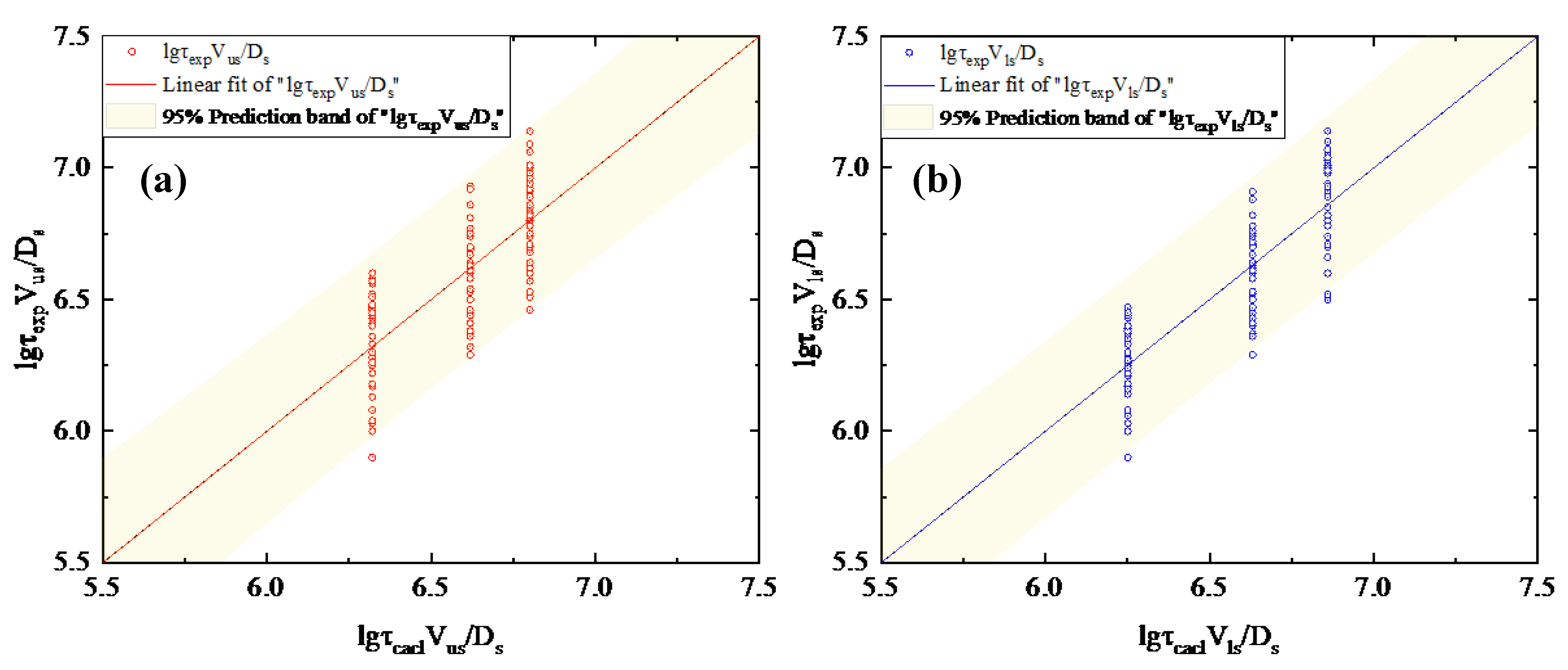

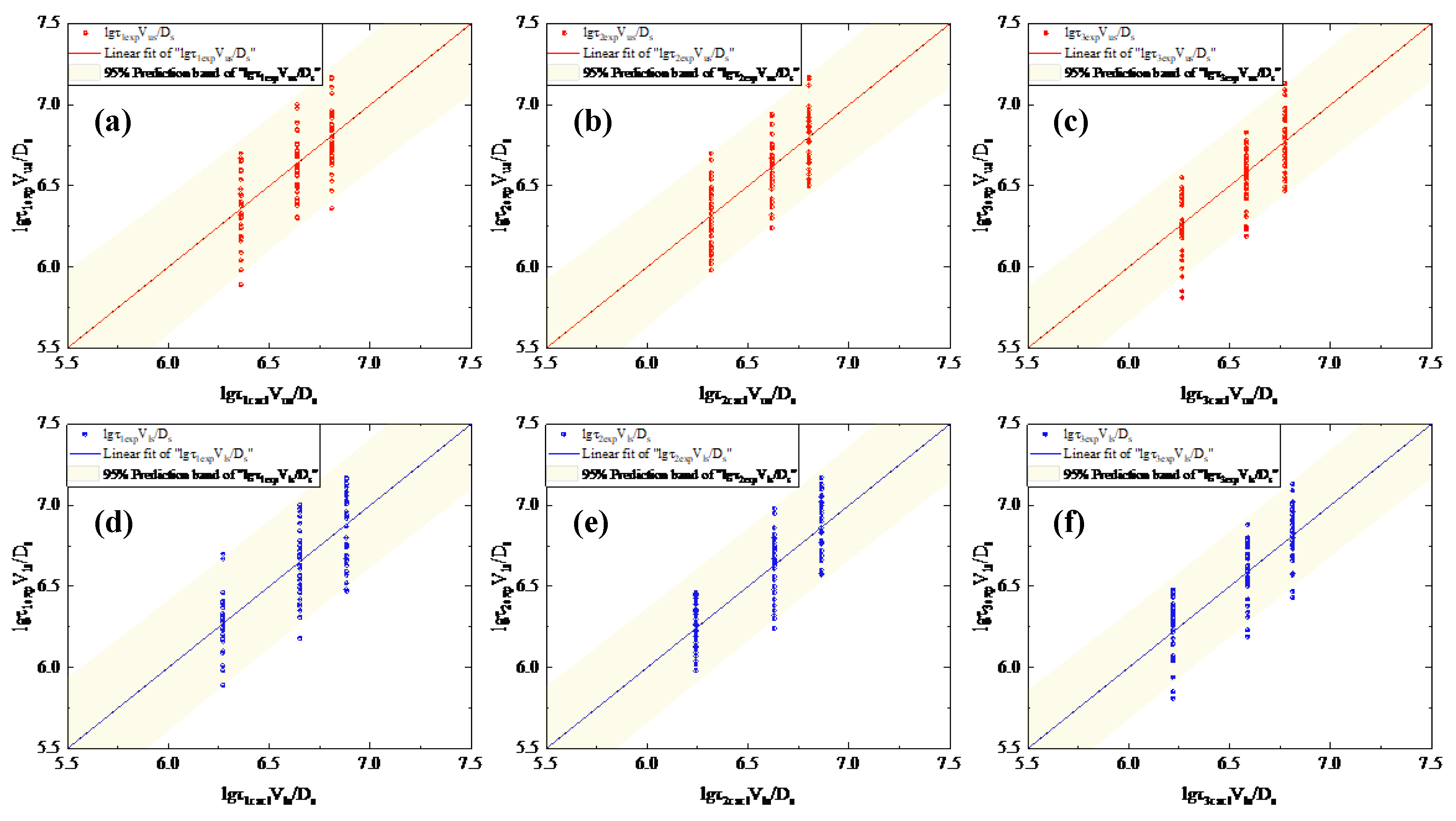

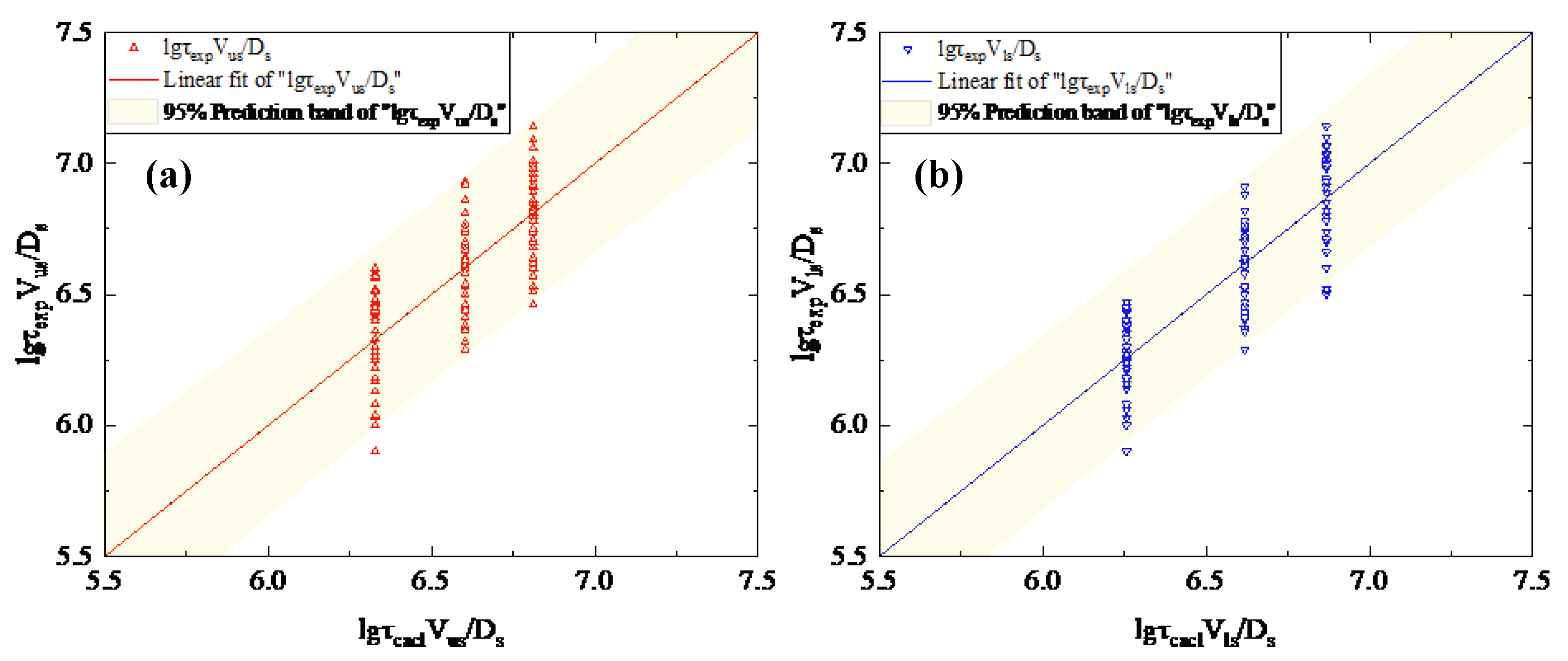

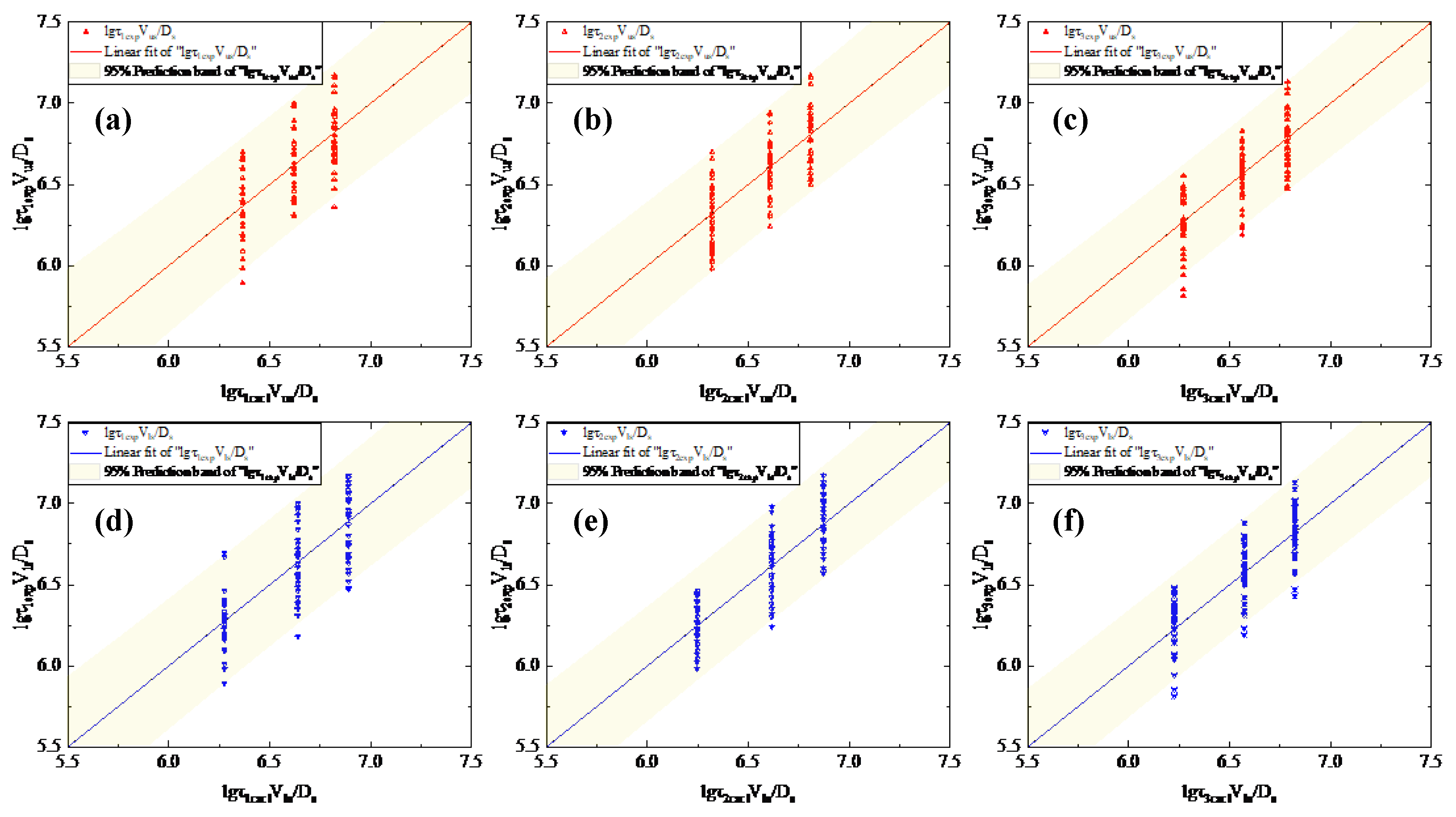

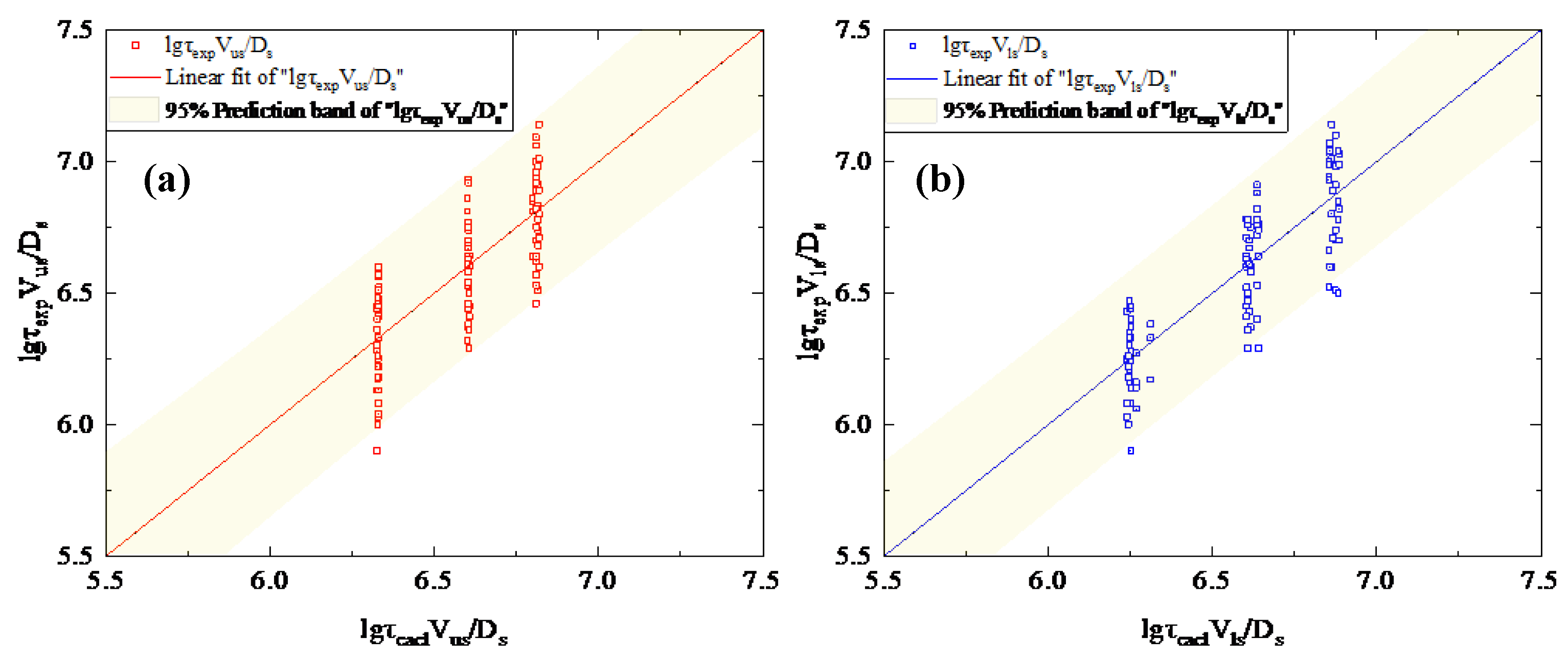

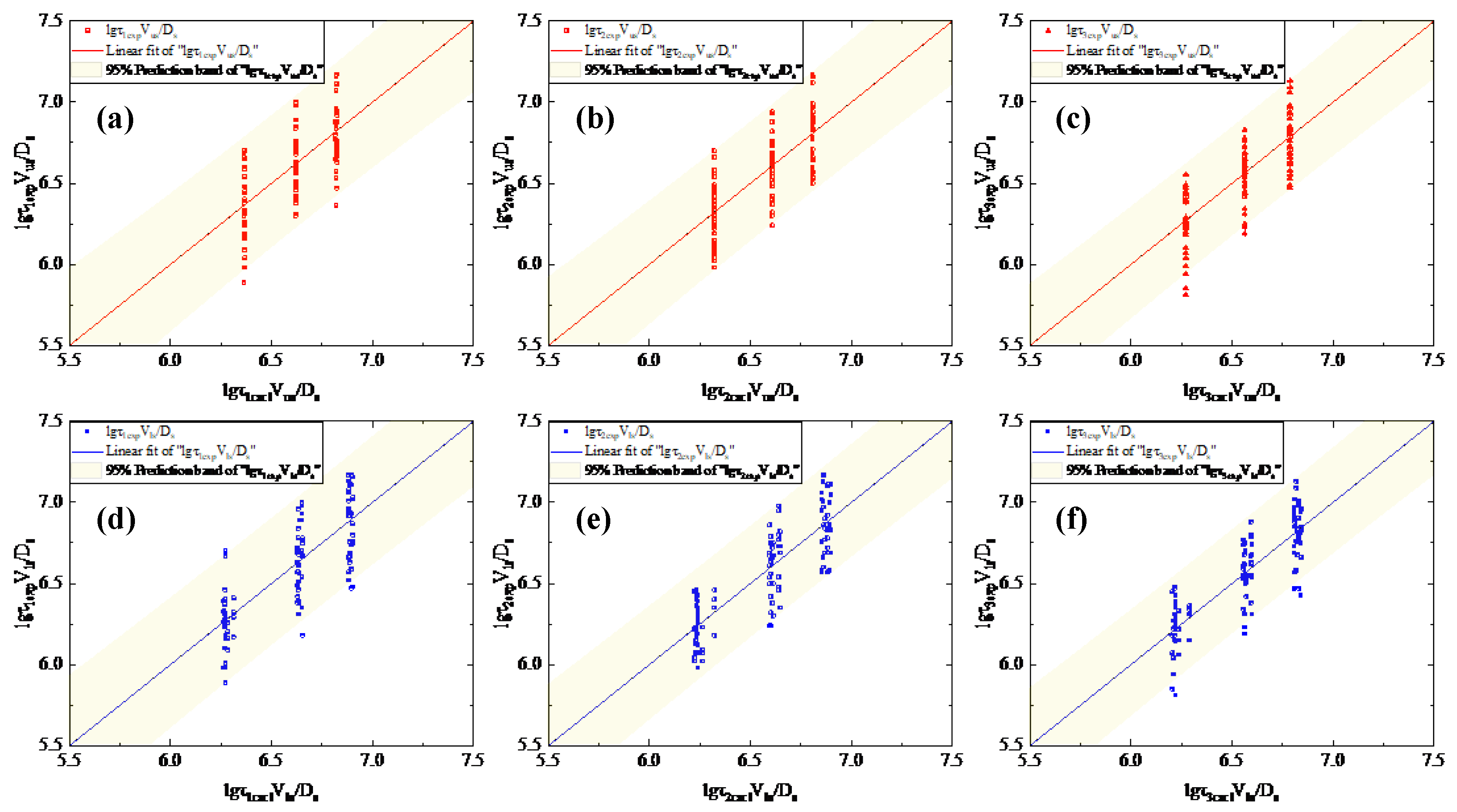

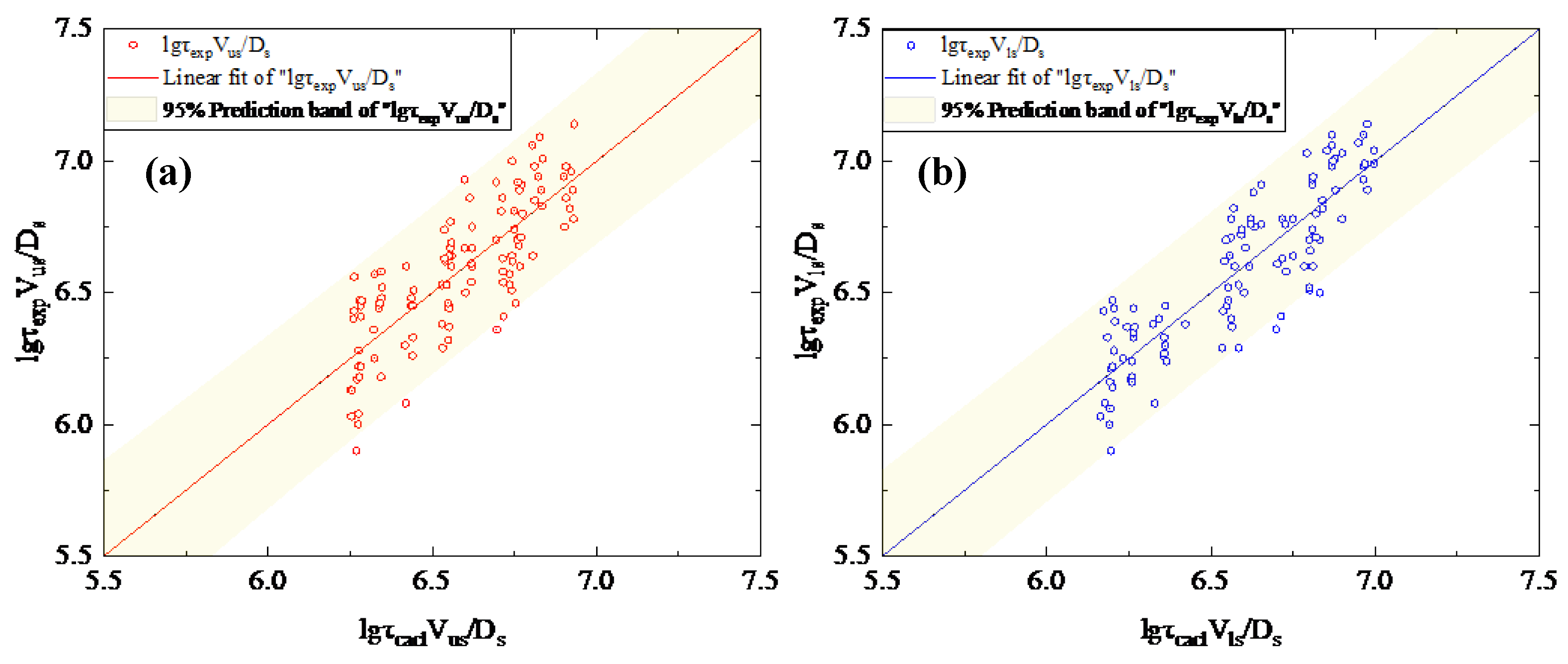

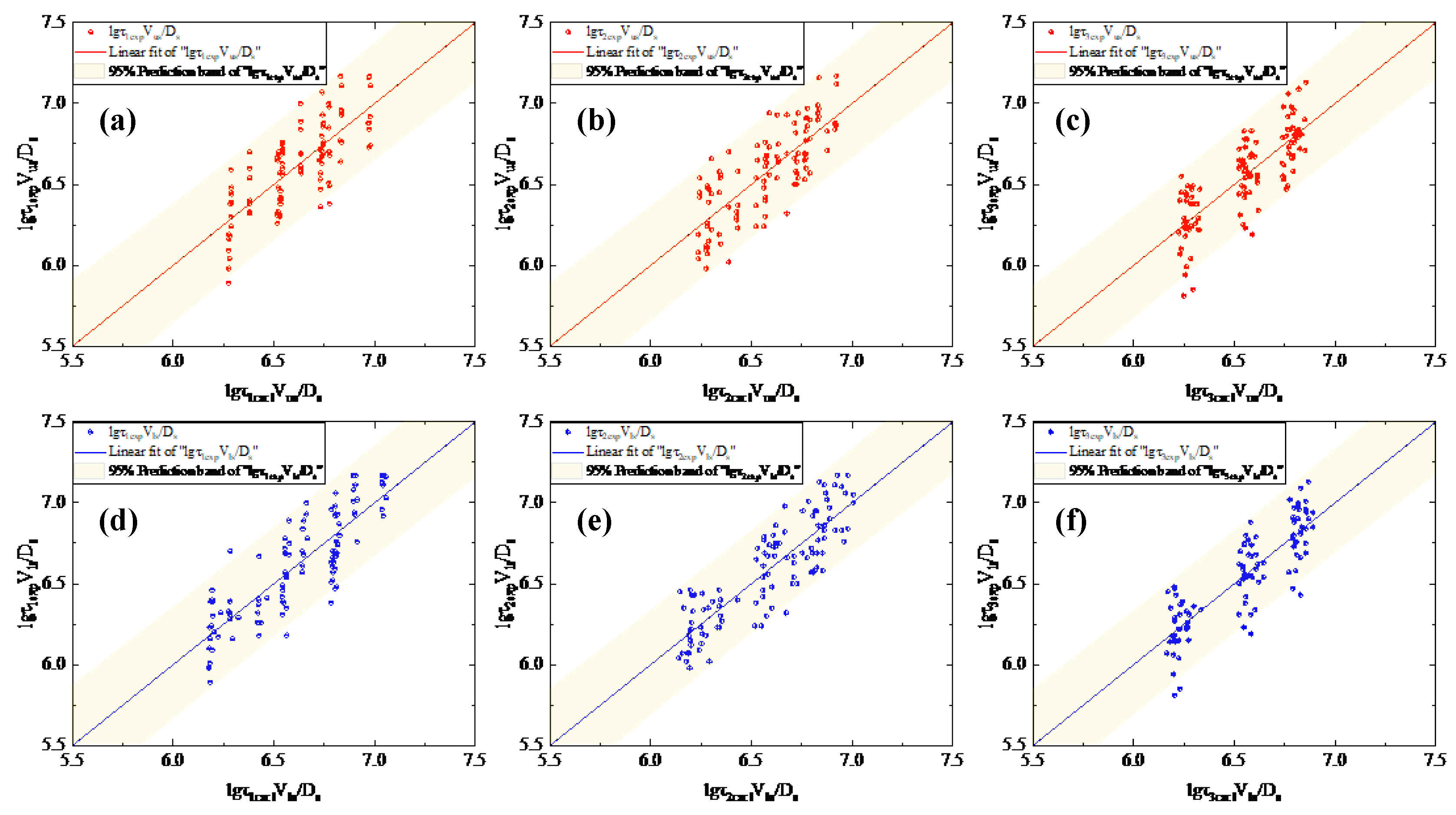

Through the analysis of the data obtained in the hydraulic simulation experiment, the influence of the dimensionless quantities and the mixing time was obtained.

5. Conclusions

Based on the experimental research and data analysis, the dimensionless groups of mixing time and kinetic viscosity, the surface tension, the tracer feeding position, the insertion depth of the side nozzle, etc., were obtained. In this paper, the expressions between the dimensionless group of mixing time and dimensionless groups such as Ca and La1 were obtained by multiple linear regression. It can be seen from the expressions that the indexes of the dimensionless groups have a higher identity when they have more than three dimensionless groups. By verifying the calculated and experimental values of the dimensionless group of mixing time, it can be seen that both have a good positive correlation. At the same time, it can also be seen from the comparison between the calculated values of τ1, τ2, τ3 and the experimental values that they are in good agreement with the corresponding τ, which indicates that the fitting expressions have higher reliability. Because density, surface tension, and other parameters of the medium have not been changed in this study, Equations (15) and (16) are more suitable for the study of the side nozzle velocity and related angle. Equations (21) and (22) will be of great significance when the density, viscosity, surface tension, and furnace diameter of the medium are changed in further work. This conclusion will better provide help for the control of key parameters, help to establish the design standard of C-H2 smelting reduction furnaces, and lay a foundation for the optimization of side nozzle parameters of C-H2 smelting reduction furnaces.