Synthesis of European Union Biorefinery Supply Networks Considering Sustainability Objectives

Abstract

:1. Introduction

- An increase in cultivated fields may lead to biodiversity loss, due to the conversion of land not currently under crop production, such as forest and grassland [15];

- Competitiveness of the use of biomass and waste heavily relies on the evaluation of the supply chain due to the seasonality and regional availability of the biomass, as well as the transportation cost [16];

- Biomass has low energy density and high moisture content. It degrades during storage and requires extensive infrastructure for harvesting, transportation, storage, and processing [17];

- Biofuels have significant land [10] and water footprints [18], and they may also have negative impact on nitrogen [19], phosphorus [20], biodiversity [21], and even carbon [14] footprints. It could jeopardize the availability of arable lands, water, soil nutrients, and increase dependence on agrochemicals [22];

- Biofuel supply chains could generate significant amounts of waste and emissions to air, water, and soil [23];

- Second and third generations of biofuels are still at an early stage of development, and there are few commercial-scale productions and none for the third-generation biofuels in the world yet, although pilot and demonstration facilities are being developed [24];

- Advantages in biotechnology could increase biofuel production; however, its potential risks and benefits, and economic and environmental impacts, are still debated [25].

2. Problem Description

2.1. Supply Network Synthesis

- Capability of accounting for different biomass types;

- Capability of optimizing the locations, types, and capacities of the processing plants and the connecting logistics of network;

- A multi-period formulation that accounts for seasonality (12 time periods, each time period represents a specific month) and the availability of resources;

- It enables determining the optimal time periods and capacities when the facilities are operating;

- Accounts for harvesting loss, biomass, and bioproducts’ degradation, and loss with time related to storage, distribution, and usage;

- Optimal selection of areas during the year for each year-round biomass resource and optimal harvesting period(s) for seasonal biomass resources;

- It includes the possibility of purchasing additionally required resources that are not produced within the region at L2 and L3;

- The products produced can be recycled and used as raw materials at L2 and L3 within other technologies;

- Energy can be reused within the network at L2 and L3 through internal and total site heat integration;

- The model is in this way formulated as a MILP problem, and therefore, the solutions obtained are globally optimal. Nonlinear non-convex terms are represented by piecewise linear approximations.

- The dry-grind process converting corn and wheat grain to bioethanol [45];

- Gasification and further catalytic synthesis converting corn stover, wheat straw, miscanthus, and forest thinning to bioethanol and hydrogen [46];

- Gasification and further syngas fermentation converting corn stover, wheat straw, miscanthus, and forest thinning to bioethanol and hydrogen [46];

- FT diesel and green gasoline production converting corn stover, wheat straw, miscanthus, and forest thinning to FT diesel and green gasoline, both from Fischer Tropsch (FT)-based technology [47];

- Hydrogen production applying gasification, water gas shift reaction, and membrane separation, converting corn stover, wheat straw, miscanthus, and forest thinning to hydrogen [48];

- Biochemical process for lignocellulosic biomass via the hydrolysis of miscanthus through dilute acid pretreatment to bioethanol [49];

- Biodiesel production from algae and waste cooking oil [50]. For algal oil, the homogeneous alkali-catalyzed transesterification process is considered, whilst for waste cooking oil, the process selected is based on the heterogeneous catalyzed transesterification. The transesterification of oil could be performed either with methanol or with recycled bioethanol [51].

2.2. Methodology Overview and Dynamic Synthesis

2.3. Objectives of the Study

2.3.1. Economic Profit

2.3.2. Eco Profit

2.3.3. Social Profit

2.3.4. Sustainability Profit

3. Biofuel and Food Supply Networks Applied to European Union (EU-27)

3.1. Regional Plan

3.2. Availability of Raw Materials

3.3. Demands for Products

3.4. Sustainability Objectives

3.5. Analyzed Scenarios

- Scenario 1: The target for biofuels (14% share of renewable energy sources (RES) within the transportation sector by 2030 [8]) and the demand for food (100%) should be satisfied in each EU Member State. It is considered that 14% of both petroleum-based fuels, gasoline and diesel, should be substituted with biofuels. For countries where the share of renewable energy exceeds 14% (Finland and Sweden, see Table 1), it is assumed that no additional biofuels are required, while also no export of the “excess” of renewable energy is considered.

- Scenario 2: Same as Scenario 1, while an eco cost of 0.5 €/m2 [68] for additional land area use beyond the land used for food production is assumed. In the case of afforestation, an eco benefit of 0.5 €/m2 is considered.

- Scenario 3: The demand for food should be satisfied, while for biofuels, no restrictions regarding demand are assumed. Corn grain and wheat are considered to be used only for satisfying the demand for food (while they cannot be used for production of biofuels), while wheat straw and corn stover could be utilized for the production of biofuels.

- Scenario 4: Same as Scenario 3, while an eco cost or eco benefit of 0.5 €/m2 is assumed for the area beyond the area required for growing food crops.

4. Results and Discussion

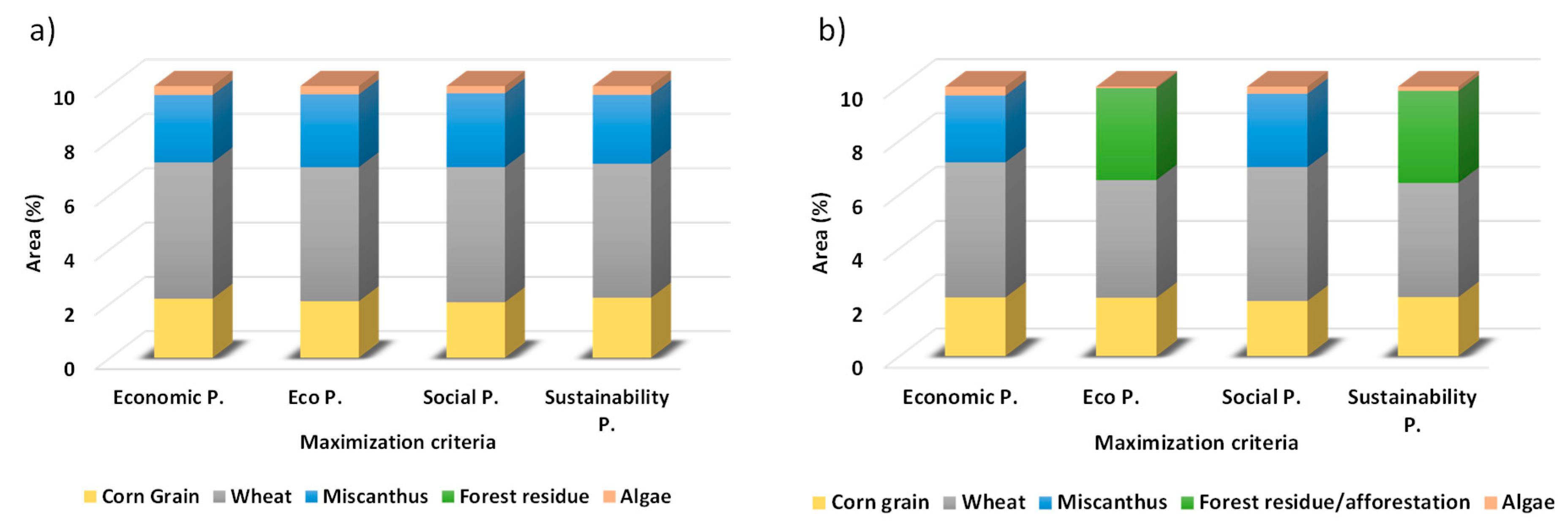

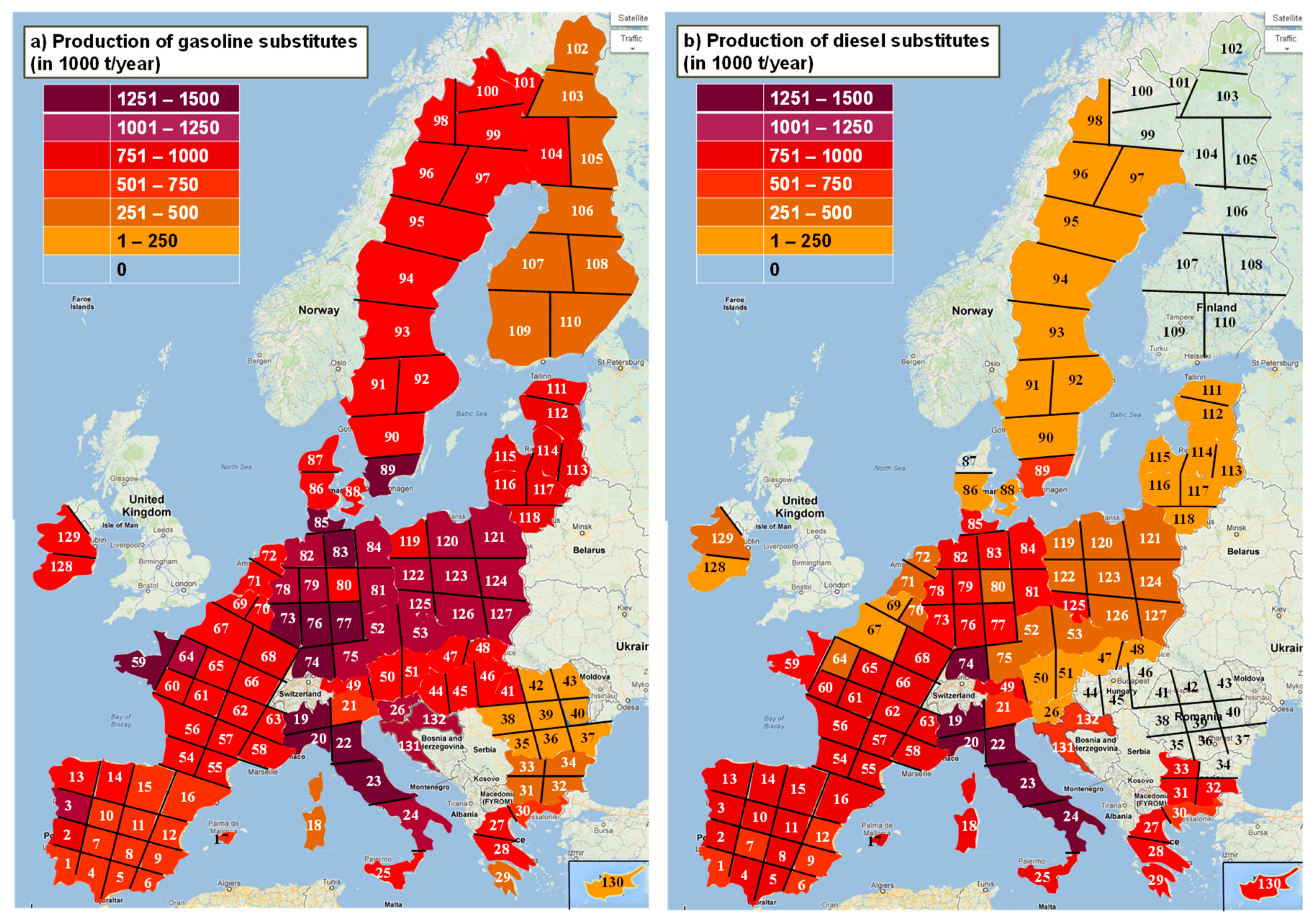

4.1. Demand Meeting Policy—Scenarios 1 and 2

4.1.1. First Scenario

4.1.2. Second Scenario

4.2. No Restrictions Regarding Biofuel Production—Scenarios 3 and 4

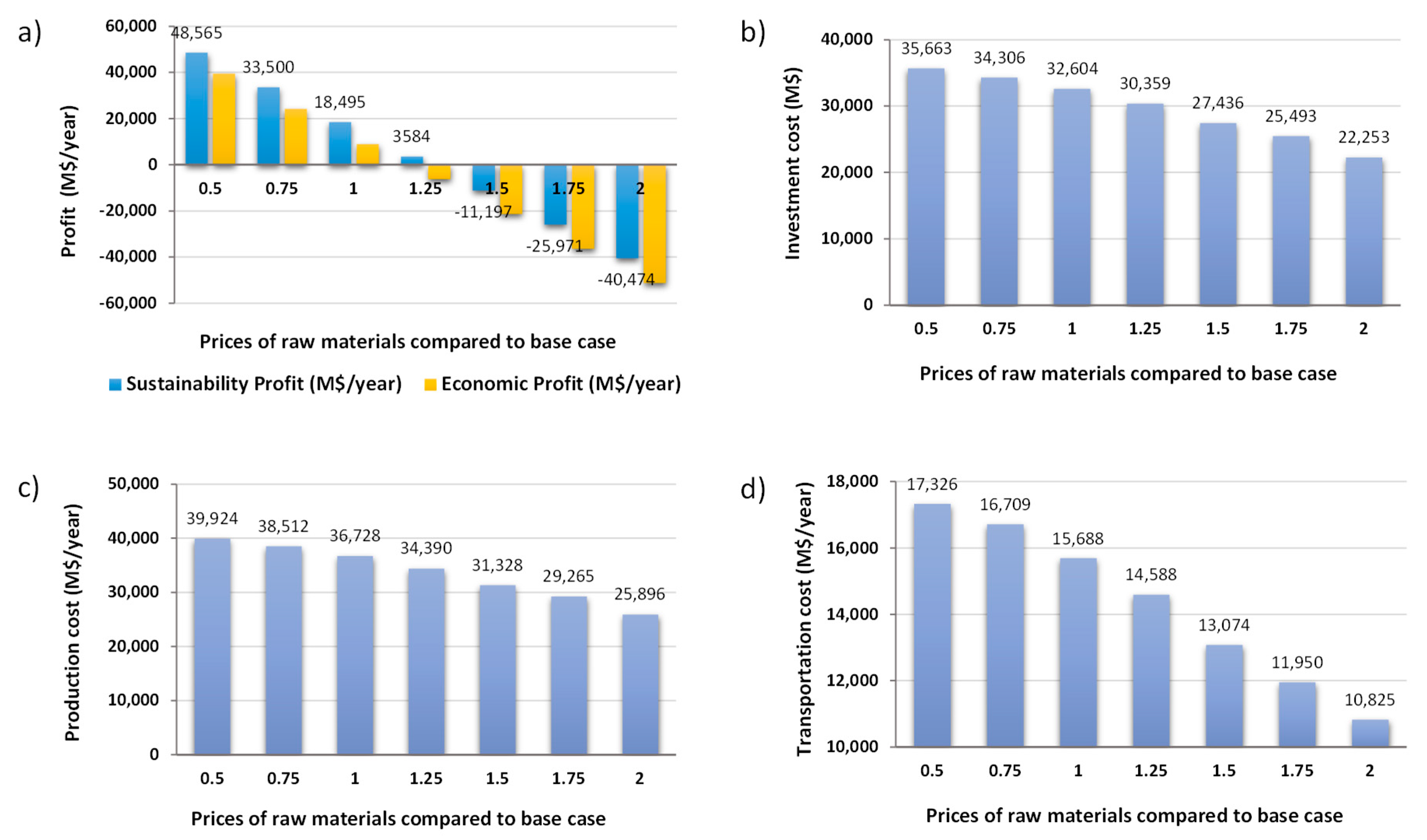

4.3. Sensitivity Analysis

4.3.1. Influence of Raw Materials Costs

4.3.2. Influence of Product Prices

4.3.3. Variation of Eco Cost/Benefit Coefficient for Additional Land Use

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| EU | European Union |

| EU-27 | EU with 27 countries as of May 2020 |

| FT | Fischer Tropsch |

| MILP | Mixed-integer linear programming |

| RED | Renewable Energy Directive |

| RES | Renewable energy sources |

| WCO | Waste cooking oil |

References

- Næss, P.; Saglie, I.-L.; Richardson, T. Urban sustainability: Is densification sufficient? Eur. Plan. Stud. 2020, 28, 146–165. [Google Scholar] [CrossRef]

- Baleta, J.; Mikulčić, H.; Klemeš, J.J.; Urbaniec, K.; Duić, N. Integration of energy, water and environmental systems for a sustainable development. J. Clean. Prod. 2019, 215, 1424–1436. [Google Scholar] [CrossRef]

- Zore, Ž.; Čuček, L.; Širovnik, D.; Novak Pintarič, Z.; Kravanja, Z. Maximizing the sustainability net present value of renewable energy supply networks. Chem. Eng. Res. Des. 2018, 131, 245–265. [Google Scholar] [CrossRef] [Green Version]

- Taliento, M.; Favino, C.; Netti, A. Impact of environmental, social, and governance information on economic performance: Evidence of a corporate ‘sustainability advantage’ from Europe. Sustainability 2019, 11, 1738. [Google Scholar] [CrossRef] [Green Version]

- Eurostat. Energy, Transport and Environment Statistics. Available online: https://ec.europa.eu/eurostat/documents/3217494/10165279/KS-DK-19-001-EN-N.pdf/76651a29-b817-eed4-f9f2-92bf692e1ed9 (accessed on 10 September 2020).

- Jungbluth, N.; Chudacoff, M.; Dauriat, A.; Dinkel, F.; Doka, G.; Faist Emmenegger, M.; Gnansounou, E.; Kljun, N.; Schleiss, K.; Spielmann, M.; et al. Life Cycle Inventories of Bioenergy, Ecoinvent Report No. 17; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Čuček, L.; Martín, M.; Grossmann, I.E.; Kravanja, Z. Multi-period synthesis of a biorefinery’s supply networks. In Computer Aided Chemical Engineering; Andrzej, K., Ilkka, T., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; Volume 32, pp. 73–78. [Google Scholar]

- The European Parliament; The Council of the European Union. Directive (EU) 2018/2001 of The European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources; European Union: Brussels, Belgium, 2018. [Google Scholar]

- Martín, M.; Grossmann, I.E. Optimal use of hybrid feedstock, switchgrass and shale gas for the simultaneous production of hydrogen and liquid fuels. Energy 2013, 55, 378–391. [Google Scholar] [CrossRef]

- De Schutter, L.; Giljum, S. A Calculation of the EU Bioenergy Land Footprint, Discussion Paper on Land Use Related to EU Bioenergy Targets for 2020 and an Outlook for 2030. Available online: foeeurope.org/sites/default/files/agrofuels/2015/foee_bioenergy_land_footprint_may2014.pdf (accessed on 30 September 2020).

- Banja, M.; Sikkema, R.; Jégard, M.; Motola, V.; Dallemand, J.-F. Biomass for energy in the EU—The support framework. Energy Policy 2019, 131, 215–228. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). Biomass Could Provide 60% of Global Renewable Energy by 2030. Available online: circularonline.co.uk/news/biomass-could-provide-60-of-global-renewable-energy-by-2030/ (accessed on 14 September 2020).

- Ajanovic, A. Biofuels versus food production: Does biofuels production increase food prices? Energy 2011, 36, 2070–2076. [Google Scholar] [CrossRef]

- Azapagic, A. Sustainability considerations for integrated biorefineries. Trends Biotechnol. 2014, 32, 1–4. [Google Scholar] [CrossRef]

- Mata, T.; Martins, A.; Sikdar, S.; Costa, C.V. Sustainability considerations of biodiesel based on supply chain analysis. Clean Technol. Environ. Policy 2011, 13, 655–671. [Google Scholar] [CrossRef]

- Yu, Y.; Bartle, J.; Li, C.-Z.; Wu, H. Mallee biomass as a key bioenergy source in western australia: Importance of biomass supply chain. Energy Fuels 2009, 23, 3290–3299. [Google Scholar] [CrossRef]

- Lam, H.L.; Varbanov, P.S.; Klemeš, J.J. Optimisation of regional energy supply chains utilising renewables: P-graph approach. Comput. Chem. Eng. 2010, 34, 782–792. [Google Scholar] [CrossRef]

- Gerbens-Leenes, P.W.; Hoekstra, A.Y.; van der Meer, T. The water footprint of energy from biomass: A quantitative assessment and consequences of an increasing share of bio-energy in energy supply. Ecol. Econ. 2009, 68, 1052–1060. [Google Scholar] [CrossRef]

- Čuček, L.; Klemeš, J.J.; Kravanja, Z. Carbon and nitrogen trade-offs in biomass energy production. Clean Technol. Environ. Policy 2012, 14, 389–397. [Google Scholar] [CrossRef]

- Elshout, P.M.F.; van der Velde, M.; van Zelm, R.; Steinmann, Z.J.N.; Huijbregts, M.A.J. Comparing greenhouse gas footprints and payback times of crop-based biofuel production worldwide. Biofuels 2019, 1–7. [Google Scholar] [CrossRef]

- Groom, M.J.; Gray, E.M.; Townsend, P.A. Biofuels and biodiversity: Principles for creating better policies for biofuel production. Conserv. Biol. 2008, 22, 602–609. [Google Scholar] [CrossRef] [PubMed]

- Benites-Lazaro, L.L.; Giatti, L.L.; Sousa, W.C., Jr.; Giarolla, A. Land-water-food nexus of biofuels: Discourse and policy debates in Brazil. Environ. Dev. 2020, 33, 100491. [Google Scholar] [CrossRef]

- Zaimes, G.G.; Vora, N.; Chopra, S.S.; Landis, A.E.; Khanna, V. Design of sustainable biofuel processes and supply chains: Challenges and opportunities. Processes 2015, 3, 634–663. [Google Scholar] [CrossRef] [Green Version]

- Čuček, L.; Martín, M.; Grossmann, I.E.; Kravanja, Z. Multi-period synthesis of optimally integrated biomass and bioenergy supply network. Comput. Chem. Eng. 2014, 66, 57–70. [Google Scholar] [CrossRef]

- Barragán-Ocaña, A.; Silva-Borjas, P.; Olmos-Peña, S.; Polanco-Olguín, M. Biotechnology and bioprocesses: Their contribution to sustainability. Processes 2020, 8, 436. [Google Scholar] [CrossRef] [Green Version]

- Nguyen Duc, D.; Nananukul, N. Advanced methodologies for biomass supply chain planning. Processes 2019, 7, 659. [Google Scholar]

- Yue, D.; You, F. 7-Biomass and biofuel supply chain modeling and optimization. In Biomass Supply Chains for Bioenergy and Biorefining; Holm-Nielsen, J.B., Ehimen, E.A., Eds.; Woodhead Publishing: Cambridge, UK, 2016; pp. 149–166. [Google Scholar]

- Lan, K.; Park, S.; Yao, Y. Chapter 10—Key issue, challenges, and status quo of models for biofuel supply chain design. In Biofuels for a More Sustainable Future; Ren, J., Scipioni, A., Manzardo, A., Liang, H., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 273–315. [Google Scholar]

- Elia, J.A.; Baliban, R.C.; Floudas, C.A. Nationwide energy supply chain analysis for hybrid feedstock processes with significant CO2 emissions reduction. AIChE J. 2012, 58, 2142–2154. [Google Scholar] [CrossRef]

- Elia, J.A.; Baliban, R.C.; Floudas, C.A.; Gurau, B.; Weingarten, M.B.; Klotz, S.D. Hardwood biomass to gasoline, diesel, and jet fuel: 2. Supply chain optimization framework for a network of thermochemical refineries. Energy Fuels 2013, 27, 4325–4352. [Google Scholar] [CrossRef]

- Marvin, A.W.; Schmidt, L.D.; Benjaafar, S.; Tiffany, D.G.; Daoutidis, P. Economic optimization of a lignocellulosic biomass-to-ethanol supply chain. Chem. Eng. Sci. 2012, 67, 68–79. [Google Scholar] [CrossRef]

- Marvin, W.A.; Schmidt, L.D.; Daoutidis, P. Biorefinery location and technology selection through supply chain optimization. Ind. Eng. Chem. Res. 2012, 52, 3192–3208. [Google Scholar] [CrossRef]

- You, F.; Wang, B. Life cycle optimization of biomass-to-liquid supply chains with distributed-centralized processing networks. Ind. Eng. Chem. Res. 2011, 50, 10102–10127. [Google Scholar] [CrossRef]

- You, F.; Tao, L.; Graziano, D.J.; Snyder, S.W. Optimal design of sustainable cellulosic biofuel supply chains: Multiobjective optimization coupled with life cycle assessment and input-output analysis. AIChE J. 2012, 58, 1157–1180. [Google Scholar] [CrossRef] [Green Version]

- Giarola, S.; Bezzo, F.; Shah, N. A risk management approach to the economic and environmental strategic design of ethanol supply chains. Biomass Bioenergy 2013, 58, 31–51. [Google Scholar] [CrossRef]

- Liu, Z.; Qiu, T.; Chen, B.A. Study of the LCA based biofuel supply chain multi-objective optimization model with multi-conversion paths in China. Appl. Energy 2014, 126, 221–234. [Google Scholar] [CrossRef]

- Egieya, J.M.; Čuček, L.; Zirngast, K.; Isafiade, A.J.; Kravanja, Z. Optimization of biogas supply networks considering multiple objectives and auction trading prices of electricity. BMC Chem. Eng. 2020, 2, 1–23. [Google Scholar] [CrossRef] [Green Version]

- Huang, E.; Zhang, X.; Rodriguez, L.; Khanna, M.; de Jong, S.; Ting, K.C.; Ying, Y.; Lin, T. Multi-objective optimization for sustainable renewable jet fuel production: A case study of corn stover based supply chain system in Midwestern U.S. Renew. Sustain. Energy Rev. 2019, 115, 109403. [Google Scholar] [CrossRef]

- Hombach, L.E.; Büsing, C.; Walther, G. Robust and sustainable supply chains under market uncertainties and different risk attitudes—A case study of the German biodiesel market. Eur. J. Oper. Res. 2018, 269, 302–312. [Google Scholar] [CrossRef]

- Zore, Ž.; Čuček, L.; Kravanja, Z. Syntheses of sustainable supply networks with a new composite criterion—Sustainability profit. Comput. Chem. Eng. 2017, 102, 139–155. [Google Scholar] [CrossRef]

- Ziolkowska, J.R. Chapter 1—Biofuels technologies: An overview of feedstocks, processes, and technologies. In Biofuels for a More Sustainable Future; Ren, J., Scipioni, A., Manzardo, A., Liang, H., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–19. [Google Scholar]

- Lam, H.L.; Klemeš, J.J.; Kravanja, Z. Model-size reduction techniques for large-scale biomass production and supply networks. Energy 2011, 36, 4599–4608. [Google Scholar] [CrossRef]

- Čuček, L.; Lam, H.L.; Klemeš, J.J.; Varbanov, P.S.; Kravanja, Z. Synthesis of regional networks for the supply of energy and bioproducts. Clean Technol. Environ. Policy 2010, 12, 635–645. [Google Scholar] [CrossRef]

- Martín, M.; Grossmann, I.E. On the systematic synthesis of sustainable biorefineries. Ind. Eng. Chem. Res. 2013, 52, 3044–3064. [Google Scholar] [CrossRef] [Green Version]

- Karuppiah, R.; Peschel, A.; Grossmann, I.E.; Martín, M.; Martinson, W.; Zullo, L. Energy optimization for the design of corn-based ethanol plants. AIChE J. 2008, 54, 1499–1525. [Google Scholar] [CrossRef]

- Martín, M.; Grossmann, I.E. Energy optimization of bioethanol production via gasification of switchgrass. AIChE J. 2011, 57, 3408–3428. [Google Scholar] [CrossRef]

- Martín, M.; Grossmann, I.E. Process optimization of FT-Diesel production from lignocellulosic switchgrass. Ind. Eng. Chem. Res. 2011, 50, 13485–13499. [Google Scholar] [CrossRef]

- Martín, M.; Grossmann, I.E. Energy optimization of hydrogen production from lignocellulosic biomass. Comput. Chem. Eng. 2011, 35, 1798–1806. [Google Scholar] [CrossRef]

- Martín, M.; Grossmann, I.E. Energy optimization of bioethanol production via hydrolysis of switchgrass. AIChE J. 2012, 58, 1538–1549. [Google Scholar] [CrossRef]

- Martín, M.; Grossmann, I.E. Simultaneous optimization and heat integration for biodiesel production from cooking oil and algae. Ind. Eng. Chem. Res. 2012, 51, 7998–8014. [Google Scholar] [CrossRef]

- Severson, K.; Martín, M.; Grossmann, I.E. Optimal integration for biodiesel production using bioethanol. AIChE J. 2013, 59, 834–844. [Google Scholar] [CrossRef]

- Google Maps. Available online: maps.google.com (accessed on 16 October 2014).

- BlueMM. Excel Formula to Calculate Distance between 2 Latitude, Longitude (lat/lon) Points (GPS Positions). Available online: bluemm.blogspot.com/2007/01/excel-formula-to-calculate-distance.html (accessed on 6 September 2020).

- Egieya, J.M.; Čuček, L.; Zirngast, K.; Isafiade, A.J.; Pahor, B.; Kravanja, Z. Synthesis of biogas supply networks using various biomass and manure types. Comput. Chem. Eng. 2019, 122, 129–151. [Google Scholar] [CrossRef]

- Bentsen, N.; Felby, C. Biomass for energy in the European Union—A review of bioenergy resource assessments. Biotechnol. Biofuels 2012, 5, 25. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- FAOSTAT. Crops. Available online: Fao.org/faostat/en/#data/QC/ (accessed on 10 August 2020).

- Ovando, P.; Caparrós, A. Land use and carbon mitigation in Europe: A survey of the potentials of different alternatives. Energy Policy 2009, 37, 992–1003. [Google Scholar] [CrossRef]

- Statista. Forecast Volume of Maize Consumed in the European Union (EU 28) from 2015 to 2028. Available online: https://www.statista.com/statistics/614398/maize-consumption-volume-european-union-28/ (accessed on 17 August 2020).

- Statista. Forecast Volume of Wheat Consumed in the European Union (EU 28) from 2015 to 2028. Available online: https://www.statista.com/statistics/545781/wheat-consumption-volume-european-union-28/ (accessed on 18 August 2020).

- Eurostat. SHARES 2018 Summary Results (Short Assessment of Renewable Energy Sources). Available online: Ec.europa.eu/eurostat/web/energy/data/shares (accessed on 12 September 2020).

- European Union. Living in the EU. Available online: europa.eu/european-union/about-eu/figures/living_en (accessed on 2 October 2020).

- Ministry of Economic Development and Technology of the Republic of Slovenia. Prices of Petroleum Products. (In Slovenian). Available online: gov.si/teme/cene-naftnih-derivatov/ (accessed on 18 September 2020).

- Zore, Ž.; Čuček, L.; Kravanja, Z. Synthesis of sustainable production systems using an upgraded concept of sustainability profit and circularity. J. Clean. Prod. 2018, 201, 1138–1154. [Google Scholar] [CrossRef]

- Delft University of Technology. The Model of the Eco-Costs/Value Ratio (EVR). Available online: ecocostsvalue.com/ (accessed on 30 September 2020).

- NREL. JEDI—Jobs and Economic Development Impact Models. Available online: nrel.gov/analysis/jedi/ (accessed on 7 September 2020).

- EUROSTAT. Unemployed Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Unemployment_statistics (accessed on 17 September 2020).

- Fischer, R. Average Monthly Salary in European Union 2020. Available online: https://www.reinisfischer.com/average-monthly-salary-european-union-2020 (accessed on 17 October 2020).

- Hendriks, C.; Vogtländer, J. The Eco Costs/Value Ratio, Materials and Ecological Engineering; AEneas, Technical Publishers: Boxtel, The Netherlands, 2004. [Google Scholar]

- Waibel, M.W.; Steenkamp, L.P.; Moloko, N.; Oosthuizen, G.A. Investigating the effects of smart production systems on sustainability elements. Procedia Manuf. 2017, 8, 731–737. [Google Scholar] [CrossRef]

| Country/Product | Corn Grain | Wheat | Gasoline | Diesel | Share of Renewable Energy |

|---|---|---|---|---|---|

| Austria | 1396 | 2189 | 1628 | 6661 | 9.8 |

| Belgium | 1806 | 2831 | 1670 | 6982 | 6.6 |

| Bulgaria | 1103 | 1730 | 490 | 2183 | 8.1 |

| Croatia | 643 | 1007 | 478 | 1502 | 3.9 |

| Cyprus | 138 | 216 | 334 | 314 | 2.7 |

| Czechia | 1679 | 2632 | 1575 | 4644 | 6.5 |

| Denmark | 915 | 1435 | 1365 | 2926 | 6.6 |

| Estonia | 209 | 327 | 261 | 539 | 3.3 |

| Finland | 870 | 1364 | 1344 | 2731 | 14.9 |

| France | 10,563 | 16,560 | 8069 | 34,362 | 9.0 |

| Germany | 13,086 | 20,516 | 17,197 | 35,541 | 7.9 |

| Greece | 1690 | 2650 | 2239 | 2687 | 3.8 |

| Hungary | 1540 | 2415 | 1398 | 3138 | 7.7 |

| Ireland | 773 | 1212 | 797 | 3190 | 7.2 |

| Italy | 9514 | 14,916 | 7167 | 23,010 | 7.7 |

| Latvia | 303 | 474 | 185 | 858 | 4.7 |

| Lithuania | 440 | 691 | 229 | 1698 | 4.3 |

| Netherlands | 2724 | 4271 | 4150 | 6231 | 9.6 |

| Poland | 5986 | 9384 | 4451 | 14,975 | 5.6 |

| Portugal | 1620 | 2540 | 1004 | 4435 | 9.0 |

| Romania | 3060 | 4798 | 1385 | 4701 | 6.3 |

| Slovakia | 859 | 1347 | 560 | 1978 | 7.0 |

| Slovenia | 328 | 514 | 408 | 1504 | 5.5 |

| Spain | 7399 | 11,599 | 4936 | 23,966 | 6.9 |

| Sweden | 1613 | 2528 | 2093 | 4576 | 29.7 |

| EU | 70,257 | 110,146 | 65,816 | 197,254 |

| Raw Material | Cost | Product | Selling Price |

|---|---|---|---|

| Corn grain | 210 | Corn grain | 260 |

| Wheat | 260 | Wheat | 290 |

| Corn stover | 60 | Ethanol | 667 |

| Wheat straw | 60 | Green gasoline | 1063 |

| Miscanthus | 56 | Biodiesel/FT diesel | 841/956 |

| Forest residue | 47 | Hydrogen | 1580 |

| Algal oil | 131 | DDGS | 170 |

| Waste cooking oil | 200 | Glycerol | 600 |

| Maximization Criteria | ||||

|---|---|---|---|---|

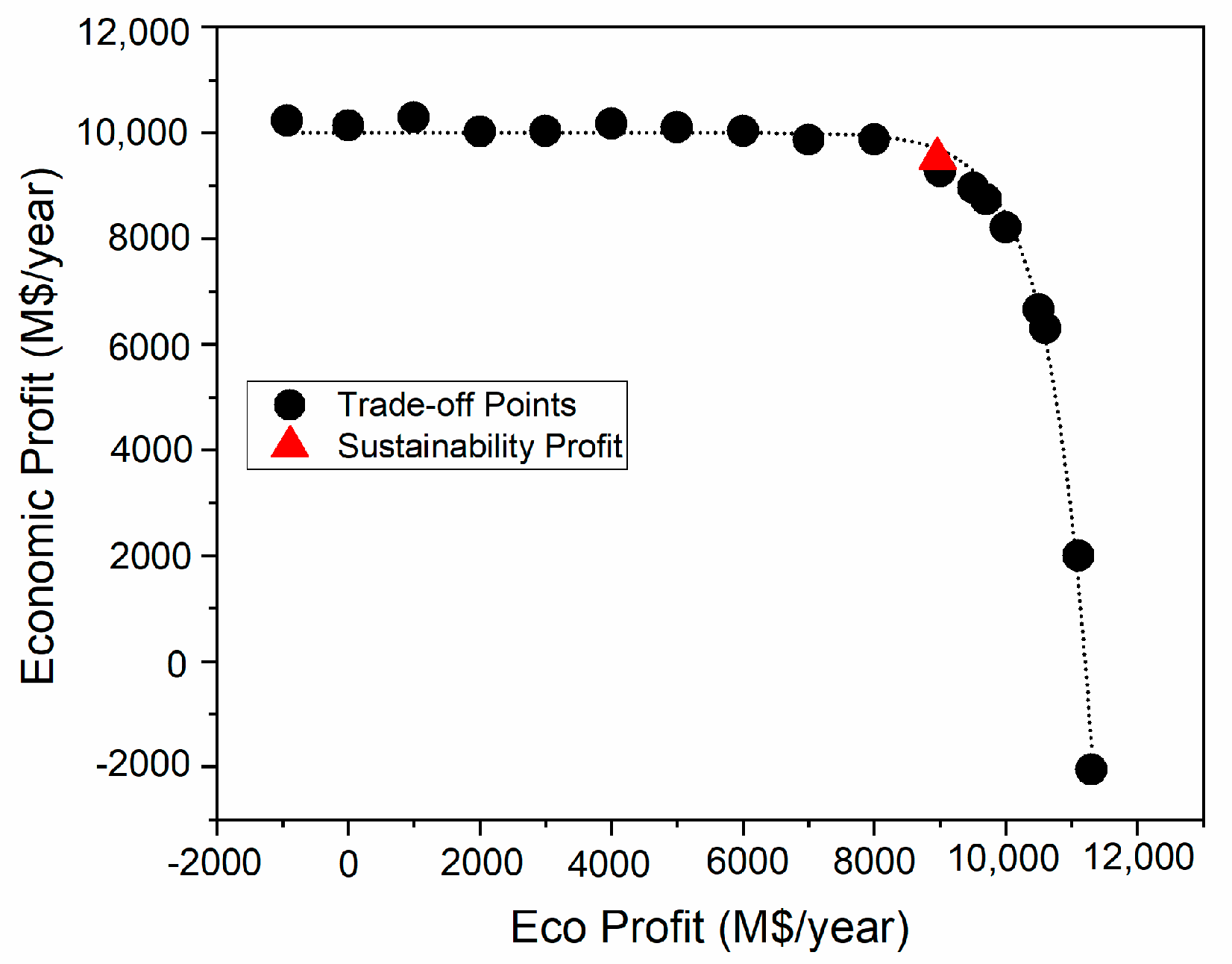

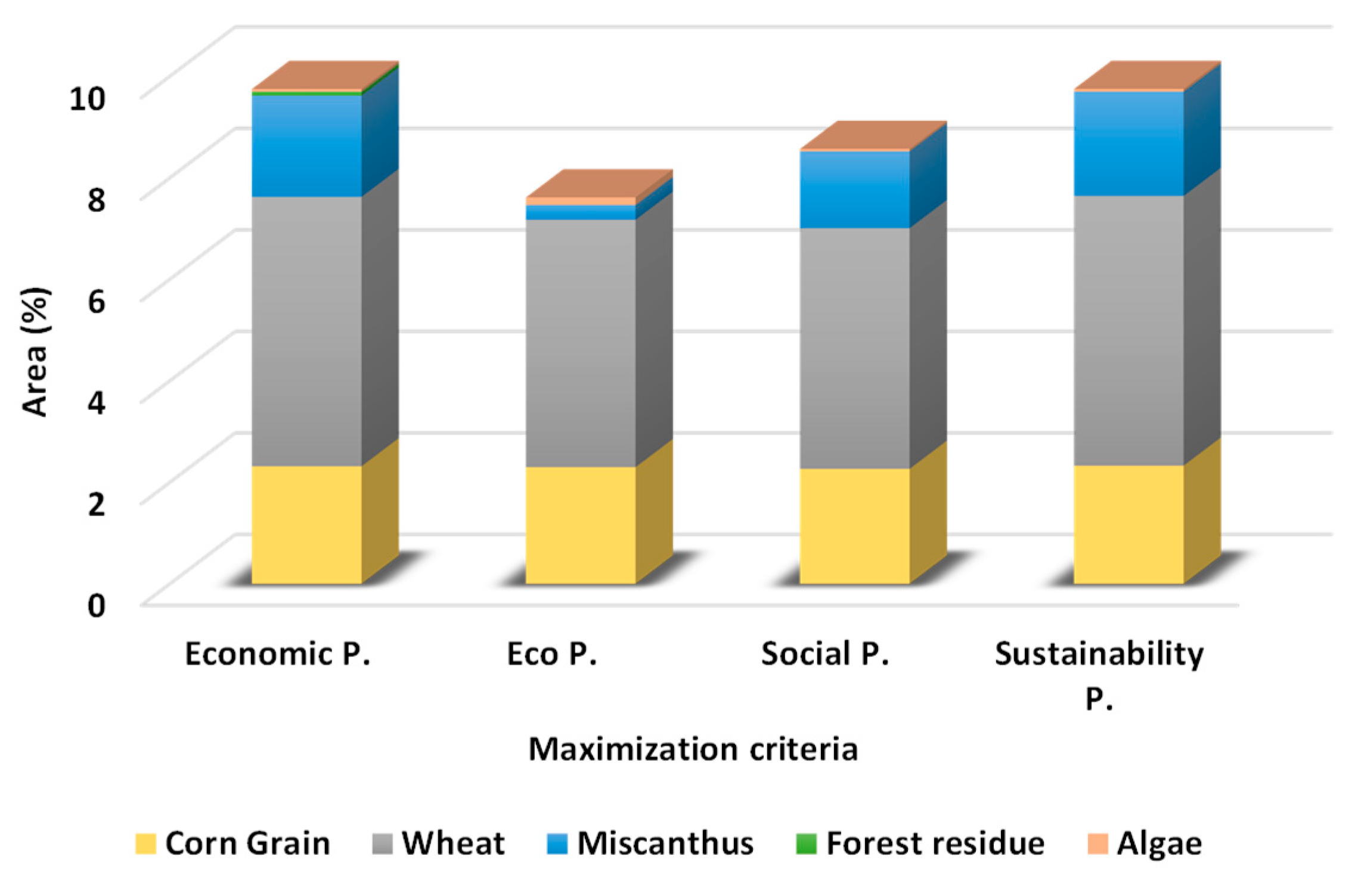

| Profit (M$/Year) | Economic Profit | Eco Profit | Social Profit | Sustainability Profit |

| Economic profit | 11,274.11 | −21,696.92 | −77,225.17 | 8955.34 |

| Eco profit | −927.31 | 12,134.86 | −18,036.33 | 9514.71 |

| Social profit | 30.56 | 15.71 | 48.87 | 25.28 |

| Sustainability profit | 10,376.99 | −9546.35 | −95,212.63 | 18,495.34 |

| Technologies | ||||

| Gasification and syngas fermentation | ● | ● | ● | |

| Gasification and catalytic synthesis | ● | |||

| Gasification and lignocellulosic hydrogen production | ● | ● | ● | |

| Biodiesel production from algae | ● | ● | ● | ● |

| Biodiesel production from waste cooking oil | ● | |||

| New jobs | 48,588 | 23,845 | 51,727 | 39,315 |

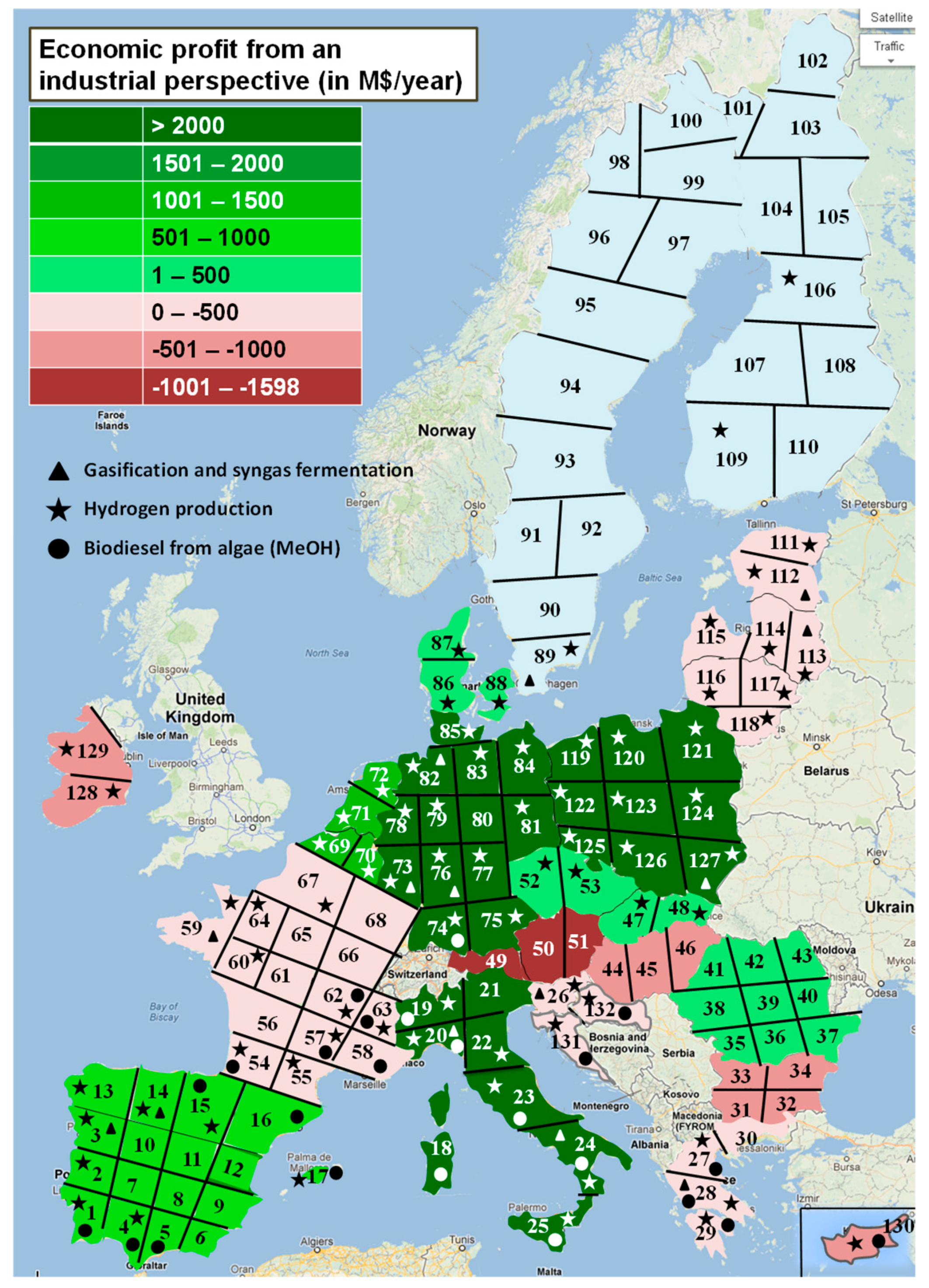

| Country | Economic Profit (M$/Year) | Normalized Profit M$/(Year·Mpeople) | Country | Economic Profit (M$/Year) | Normalized Profit M$/(Year·Mpeople) |

|---|---|---|---|---|---|

| Austria | −1597.81 | −182.13 | Ireland | −760.59 | −155.09 |

| Belgium | 987.40 | 86.98 | Italy | 5067.70 | 83.64 |

| Bulgaria | −967.49 | −136.23 | Latvia | −48.52 | −24.88 |

| Croatia | −178.73 | −43.02 | Lithuania | −31.39 | −11.02 |

| Cyprus | −588.65 | −688.64 | Netherlands | 1299.11 | 76.05 |

| Czechia | 353.59 | 33.42 | Poland | 4288.89 | 112.95 |

| Denmark | 403.86 | 70.25 | Portugal | 801.18 | 77.71 |

| Estonia | −290.49 | −220.80 | Romania | 7.75 | 0.39 |

| Finland * | - | - | Slovakia | 169.68 | 31.22 |

| France | −283.11 | −4.23 | Slovenia | −289.32 | −140.05 |

| Germany | 8781.65 | 106.42 | Spain | 718.20 | 15.44 |

| Greece | −296.26 | −27.51 | Sweden * | - | - |

| Hungary | −547.51 | −55.88 |

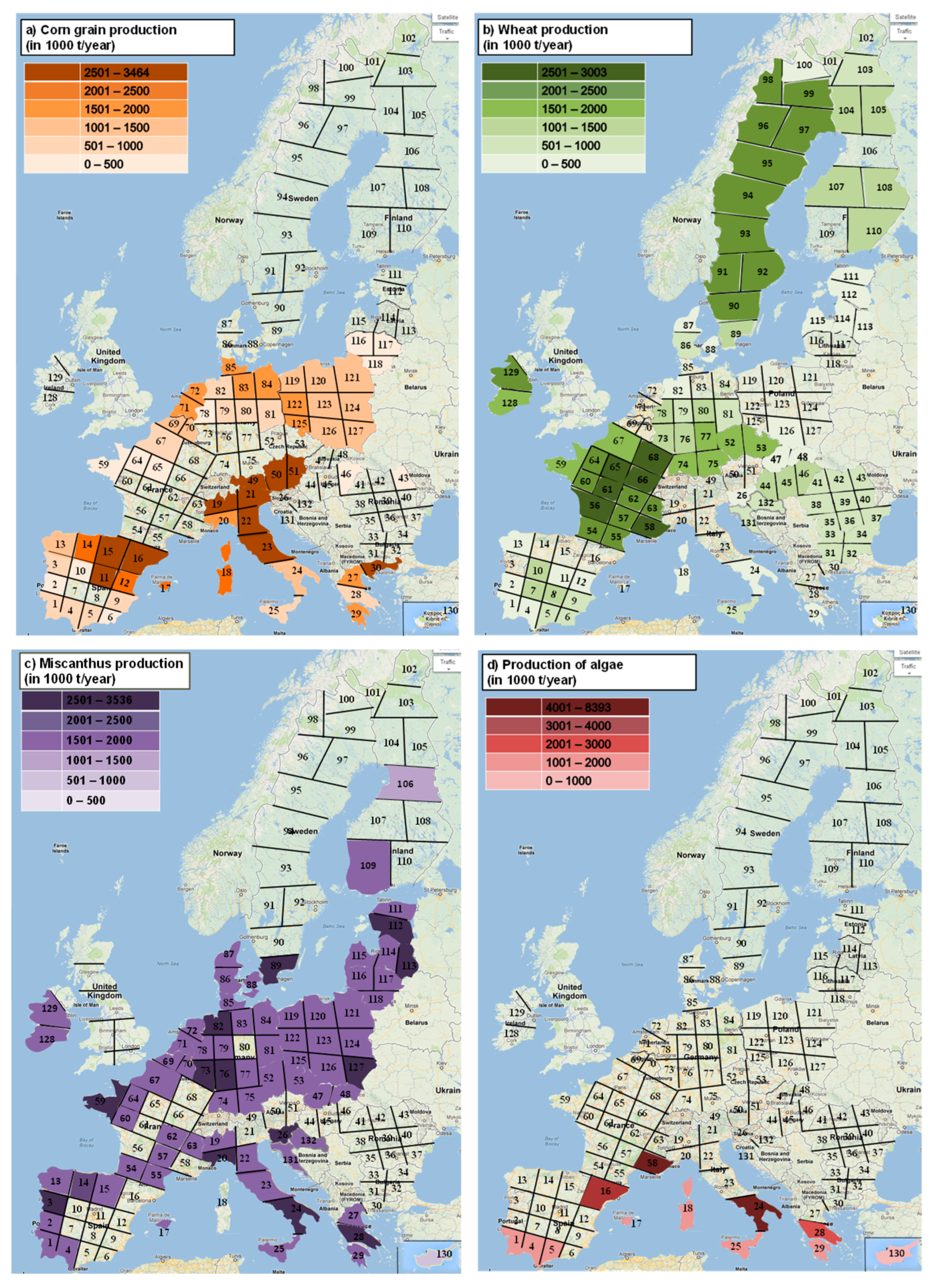

| Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | |

|---|---|---|---|---|

| Sustainability profit (M$/year) | 18,495 | 84,927 | 86,456 | 113,439 |

| Raw materials for food (kt/year) | ||||

| corn grain | 70,257 | 70,257 | 70,257 | 70,257 |

| Wheat | 110,146 | 110,146 | 110,146 | 110,146 |

| Raw materials for fuel(kt/year) | ||||

| corn stover | 13,054 | 19,786 | ||

| wheat straw | 22,088 | 107,689 | 107,890 | |

| Miscanthus | 140,495 | 206,778 | ||

| forest residue | 86 | 830 | ||

| cooking oil | 4218 | 4399 | ||

| algae (algal oil) | 14,067 | 14,067 | 35,104 | 30,959 |

| Technologies | ||||

| gasification and syngas fermentation | ● | ● | ● | ● |

| gasification and FT synthesis | ● | ● | ||

| gasification and lignocellulosic hydrogen production | ● | ● | ● | |

| biodiesel production from algae * | ● | ● | ● | ● |

| biodiesel production from WCO ** | ● | ● | ||

| Biofuels (kt/year) | ||||

| Bioethanol | 6367.15 | 6367.15 | 43,395.64 | 17,313.00 |

| green gasoline | 9879.41 | 3818.89 | ||

| Biodiesel | 13,504.86 | 13,504.86 | 37,748.44 | 33,943.78 |

| FT-diesel | 37,165.41 | 14,366.31 | ||

| Hydrogen | 14,007.46 | 992 | 4252.89 | 1815.37 |

| Afforestation (% of used area) | 0 | 3.57 | 0 | 3.40 |

| Number of new employees | 39,315 | 24,214 | 153,698 | 82,693 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Potrč, S.; Čuček, L.; Martin, M.; Kravanja, Z. Synthesis of European Union Biorefinery Supply Networks Considering Sustainability Objectives. Processes 2020, 8, 1588. https://doi.org/10.3390/pr8121588

Potrč S, Čuček L, Martin M, Kravanja Z. Synthesis of European Union Biorefinery Supply Networks Considering Sustainability Objectives. Processes. 2020; 8(12):1588. https://doi.org/10.3390/pr8121588

Chicago/Turabian StylePotrč, Sanja, Lidija Čuček, Mariano Martin, and Zdravko Kravanja. 2020. "Synthesis of European Union Biorefinery Supply Networks Considering Sustainability Objectives" Processes 8, no. 12: 1588. https://doi.org/10.3390/pr8121588

APA StylePotrč, S., Čuček, L., Martin, M., & Kravanja, Z. (2020). Synthesis of European Union Biorefinery Supply Networks Considering Sustainability Objectives. Processes, 8(12), 1588. https://doi.org/10.3390/pr8121588