1. Introduction

Intelligent systems are commonly employed in the manufacturing industry and allow production machines to be more easily settled and operated. As a result, mass production can be quickly achieved. In addition, during the process of mass production, the quality and quantity dimensions are of equal importance for the planning of products’ supply and demand [

1]. Furthermore, during the era of Industry 4.0, there are more opportunities for managers to perform efficient quality management [

2]. The quality of products is thus regarded as an essential matter and is related to the efficiency of the production system. In the literature, a measurement data management approach was proposed to integrate the information of quality assurance into the design of system components with an aim to maintain an adequate product quality level [

3]. Therefore, managers need to constantly monitor all factors affecting the status of products in the manufacturing process and conduct an inspection plan to guarantee adequate product quality.

Product inspections are generally distinguished into two main categories: (a) sampling inspection, and (b) total inspection. In general, under the constraints of production and delivery schedules, manufacturers often choose to conduct a sampling inspection, which is economical, time-saving, and effort-saving. However, such inspection exposes managers to the risk of rejecting conforming inspection lots or accepting nonconforming inspection lots. Therefore, additional expenses, such as costs for correction and compensation, may be faced in the follow-up processes. On the contrary, a total inspection is time-consuming and laborious but can more accurately determine whether to accept an inspection lot. To monitor the condition of product quality, several studies have addressed sampling inspections. For instance, a sampling method with a multi-stage structure was proposed to determine the acceptance or rejection of a production lot, where the lot inspection would take place at specified timings to check its applicable state [

4]. A sampling-based approach was introduced to streamline the manufacturing system in a semiconductor industry with consideration of the time limit before the release of products [

5]. A profit model was proposed to determine the optimal mean of the process in a two-stage production system, and the sampling inspection plan of this system specified the conforming items’ number range for which the production lot could be accepted [

6]. Moreover, to achieve cost savings during the production cycle, Bouslah et al. [

7] investigated the influence of a continuous sampling plan on the performance of a manufacturing system characterized by imperfect production and inspected the quality of the finished products by observing the degree of conformance with the condition-based maintenance. Note that the imperfect production system may produce both conforming and defective items. In this regard, managers are supposed to select an appropriate inspection plan, suitable for the manufacturing process, for detecting product quality with reasonable costs.

From the manufacturer’s perspective, a production process based on the assemble-to-order (ATO) configuration can be adapted to complete the finished products customized for consumers, where the assemblies and parts would be the requisite components available on demand. Moreover, the main characteristic of ATO manufacturing is the mass customization with low costs. In the literature, there are several studies focusing on the application of ATO. For instance, Sylla et al. [

8] argued that the seller should use high-quality components in ATO manufacturing for fulfilling customers’ requirements. In addition, an assembly line model was used to probe the mechatronics of automated systems at the workstations activated by mobile robots and to analyze the technique of recovering the assemblies that fail in the quality inspection for the following processes [

9]. A genetic algorithm of the process capability index was applied to propose a new allocation method, and the statistical tolerance index was used to evaluate the quality of products assembled by parts to meet customer expectation and achieve cost minimization [

10]. In the context of an ATO system, Karaarslan et al. [

11] analyzed a finished product assembled by two components and determined its optimal ordering policy through careful investigation of inventory levels with the aim to minimize the average cost. It can be thus found that the product performance with ATO configuration is closely related to the characteristics of the production system and the quality of assemblies and parts. Therefore, a sound plan of quality inspection is essential to achieve satisfactory products at a suitable cost. In general, the inspection tools include statistical process control charts, process capability analysis, histograms, and cause and effect diagrams. These tools can be used to inspect the common defects such as the abnormal product appearance, inadequate machine operation, or unexpected function failure.

In the manufacturing process, the production system often faces an imperfect situation, namely, a system with an out-of-control state, as discussed by various studies. For instance, given an imperfect production system with the defective items which can be reworked, Parveen and Rao [

12] estimated the optimal product inspection number and the ordering quantity from a cost perspective. In addition, an optimization model for the production system was developed with the aim to maximize expected profits [

13]. Such a system would allow the out-of-control state to be converted into an in-control state when encountering Type I failure and carry out minimal repair when encountering Type II failure. It also explained that a high-intensity warranty may decrease unfavorable outcomes caused by poor product quality. Additionally, a quality inspection plan for an imperfect production system was designed for minimizing the total cost, in which preventive maintenance is directly implemented at the end of the production cycle, and appropriate measures are taken to address defective items under different inspection results [

14]. In addition, given the practice of minimal repair, the optimal inspection strategies of specific types of failures are proposed, and these strategies have to carefully consider the limited inventories and the available degraded components [

15]. The optimization problem of inspection was investigated for a degradable standby system modelled by the Markov process, and then the optimal inspection schedule was planned to minimize the expected total cost [

16]. On the other hand, to monitor the performance for a deteriorating system, Ali and Shah [

17] proposed a quality inspection approach with an assumption that system renewal’s interarrival times were exponentially distributed. In addition, Shih and Wang [

18] proposed a quality inspection strategy for a production system that addressed both the in-control and out-of-control states. The adoption of such a strategy led to different types of costs with respect to both states, which contributed to the minimization of the total cost at the optimal production run length.

The results of these studies suggest that while a quality inspection plan is generally applied to an imperfect production system, managers need to find ways to provide it with the necessary support and take notice of the changes in the relevant costs corresponding to a specific plan. Accordingly, an adequate design of the inspection plan is essential to obtain a satisfactory product quality. However, most studies so far have addressed the performance of quality inspection without jointly considering the fundamental elements, such as the status of the production system, the defective rate, the working efficiency of employees, and the market demands of customers. Thus, this study adopts the manufacturer’s perspective and takes relevant factors in the decision-making process into account to determine the optimal number of conforming items for inspection to minimize the total cost.

The remainder of this study is organized as follows.

Section 2 describes the strategies of production, inspection, and warranty for an imperfect production system with ATO configuration.

Section 3 calculates the costs incurred under such a system.

Section 4 demonstrates the effectiveness of the proposed model through a numerical case, and sensitivity analyses are performed to investigate the influence of relevant factors on the optimal number of conforming items for inspection.

Section 5 provides concluding remarks.

2. Production, Inspection, and Warranty of the Product

For a manufacturer, an ATO strategy is commonly adopted to generate products customized for the consumers. Since such a strategy is concerned with mass customization, the efficiency of the assemblers and the production system is essential for the manufacturing process. In view of this, the managers are supposed to evaluate the learning effect in the assembly task and the implementation performance of the production system. In addition, due to certain factors, e.g., measurement error of mechanical properties, faulty identification of failures, and the use of wrong instruments, the production system may sometimes be out of control. Therefore, the production system may be under either an in-control or an out-of-control state, which may produce both conforming and defective items such as items with cracks in surface, abnormal joints, and malfunction of components. Such an imperfect production system is assumed to be subject to a Weibull deteriorating process [

19] with scale and shape parameters respectively denoted by

α and

β. In addition, the defective items generated by the system under the out-of-control state are supposed to be more numerous than those produced under the in-control state, and the items generated under both states can be reworked.

In this study, an inspection plan that uses negative binomial sampling is proposed, which is performed after the completion of each production run. In particular, a production lot is only accepted if the production system is in the in-control state. However, given that the production system is found to be in the out-of-control state with a defective rate denoted as φ, it would be corrected to the in-control state with correction cost cμ. In the meantime, a negative binomial sampling inspection (NBSI) is performed, which sequentially examines the products from the last product of the active production lot with inspection cost ck and terminates as soon as the optimal number of conforming items ρ is detected.

The Weibull deterioration is used to express the degenerating mode of the products after sale, in which products’ hazard functions under the in-control and out-of-control states are h1(t) and h2(t), respectively, and h2(t) > h1(t). Thus, hi(t) = (1/αi)βiβitβi−1, i = 1, 2, where α1 and α2 respectively denote the scale parameters of the failure intensities for products generated under the in-control and out-of-control states, and β1 and β2 denote the shape parameters. Furthermore, the policy of free replacement warranty is provided during the warranty period w.

4. Numerical Application

This section illustrates the proposed NBSI plan for a manufacturer, which develops the assemblies of a mechanical customized product under ATO strategy. To achieve an efficient production system and a smooth assemblers’ operation, the managers consult the experts and rely on previous manufacturing experience to reach a consensus on the parameters

T = 2 days and

w = 365 days. The other parameter values are reported in

Table 1.

The value of ρ is 21.55 and is obtained through the substitution of the estimated parameter values in Equation (19). In addition, a Bayesian approach is used to measure the quantity demanded D within the production run length. Based on the market demands for similar products developed in the past, the quantity of assemblies demanded is assumed to be normally distributed with mean Dpr = 4850 and standard deviation νpr = 26.7. In addition, the sample standard deviation of the likelihood function is estimated as σl = 23.9, and the sample size is nl = 8 with an average xb = 5002.5. Substituting these values into Equation (7), the posterior demand within T can be obtained as Dpo = 4988.62.

Equation (17) estimates the expected total cost for the manufacturer at $2,197,688. In other words, the inspection and manufacturing processes are appropriately put into practice through the NBSI plan, which sequentially examines the products from the last product of the active production lot and terminates when the 22nd conforming item is found, and which leads to the above-mentioned minimum total cost of $2,197,688 for the manufacturer. In addition, the expected number of inspection items is calculated as ns = 21.55/(1 − 0.4) = 35.92, which implies that the inspection procedure may on average stop when all 35.92 items are examined because the specified optimal number of conforming items for the inspection, ρ, is achieved.

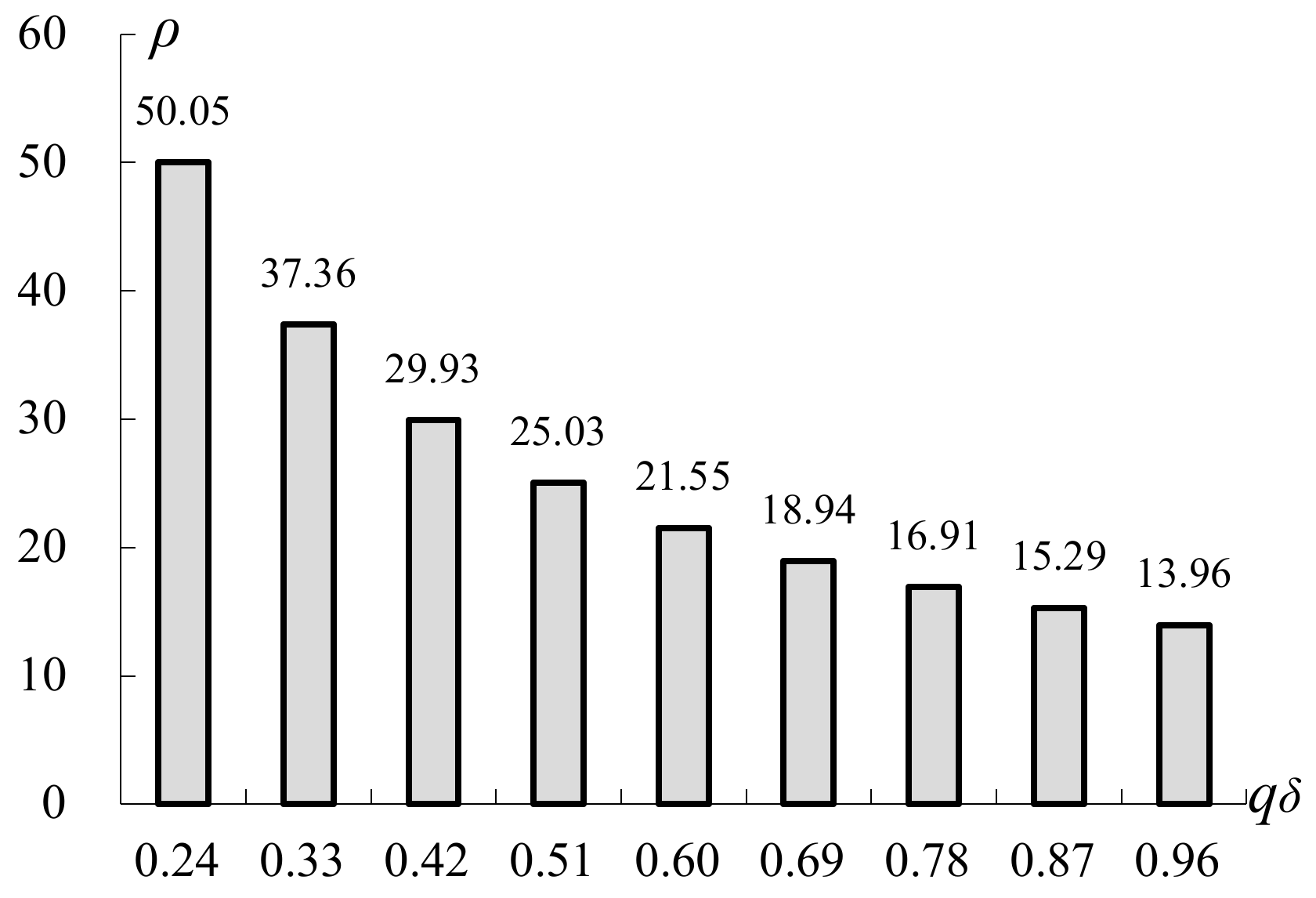

Sensitivity analyses are then performed to investigate the effects of the relevant parameters on the optimal number of conforming items for inspection. With respect to the contraction constant, the variations in

ρ within a range of 60% of the original estimate of

qδ are observed in

Figure 1, which indicates that

ρ is negatively correlated with

qδ.

The managers of the production department may set up a larger

qδ provided that they consider the decrease in the manufacturing cost owing to the learning effect is more significant. In such a case, the products of premium quality are produced by the assemblers with high working efficiency. The required number of conforming items for inspection can therefore decrease in the presence of a large contraction constant with the aim of minimizing the total cost for the manufacturer. Likewise,

Figure 2 shows that changes in the learning rate, which ranges between −60% and 60%, indicate

ρ is positively correlated with

θδ. It is due to the fact that a higher learning rate induces a lower learning effect. This may lead to a low working efficiency, which entails a higher number of conforming items for inspection to achieve cost minimization. Accordingly, it is suggested that managers should carefully observe the variations in the assemblers’ working efficiency in the manufacturing process to assign adequate values to the contraction constant and learning rate.

Figure 3 addresses the variations in

ρ with respect to the defective rate, which ranges between −60% and 60%, and shows that

ρ is negatively correlated with

φ. A higher defective rate indicates an unsteady manufacturing process with a low working efficiency. Therefore, a higher number of conforming items for inspection is necessary to achieve the minimum total cost.

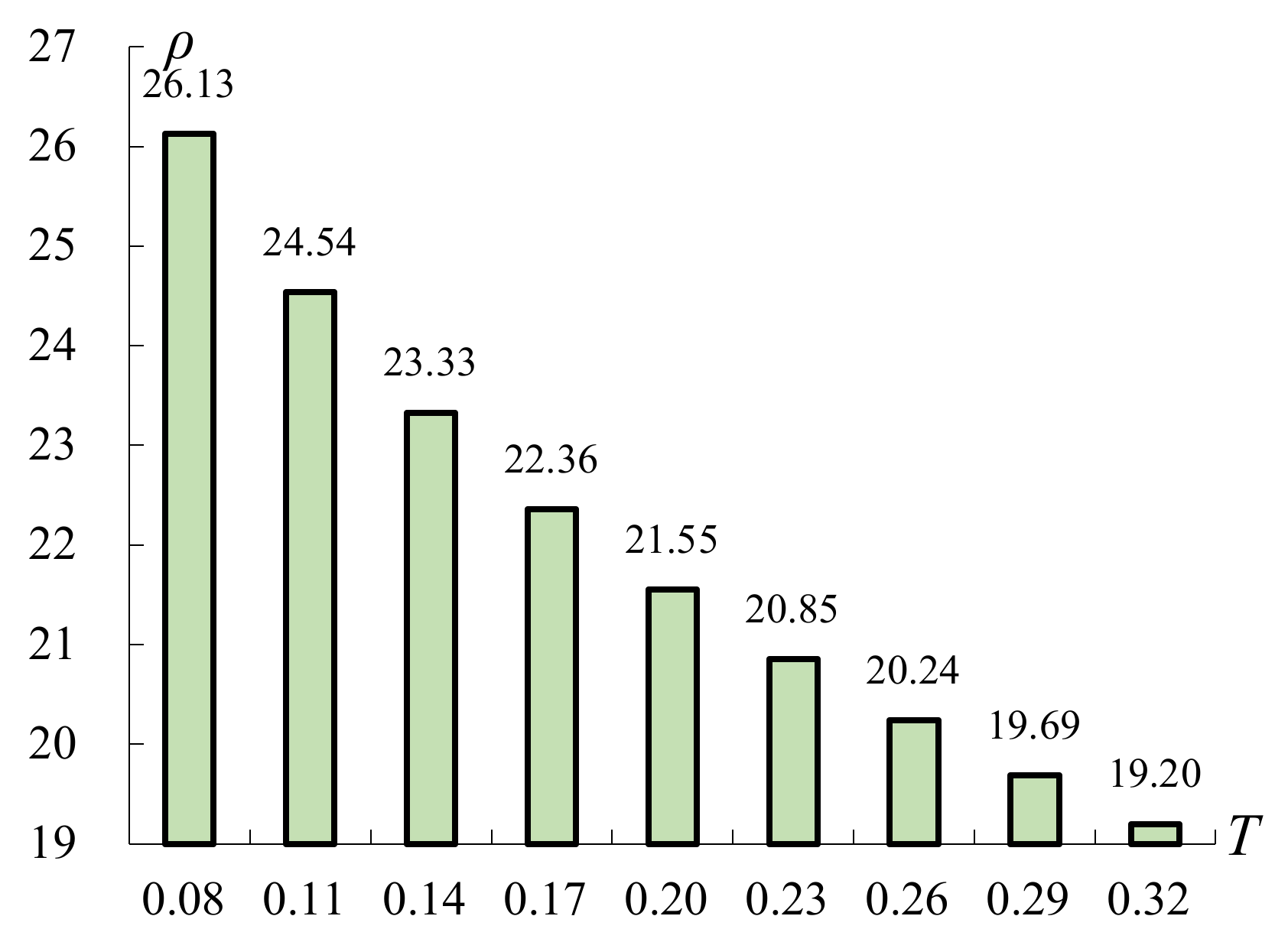

The production run length, which ranges between −60% and 60%, is analyzed to observe the corresponding variations in

ρ. It can be seen in

Figure 4 that

ρ is negatively correlated with

T. It is due to the fact that a longer production run generates a lower learning rate, which results in a higher learning effect. This may help assemblers produce high-quality products. Thus, for a long production run length, the required number of conforming items for inspection to minimize the total cost is smaller.

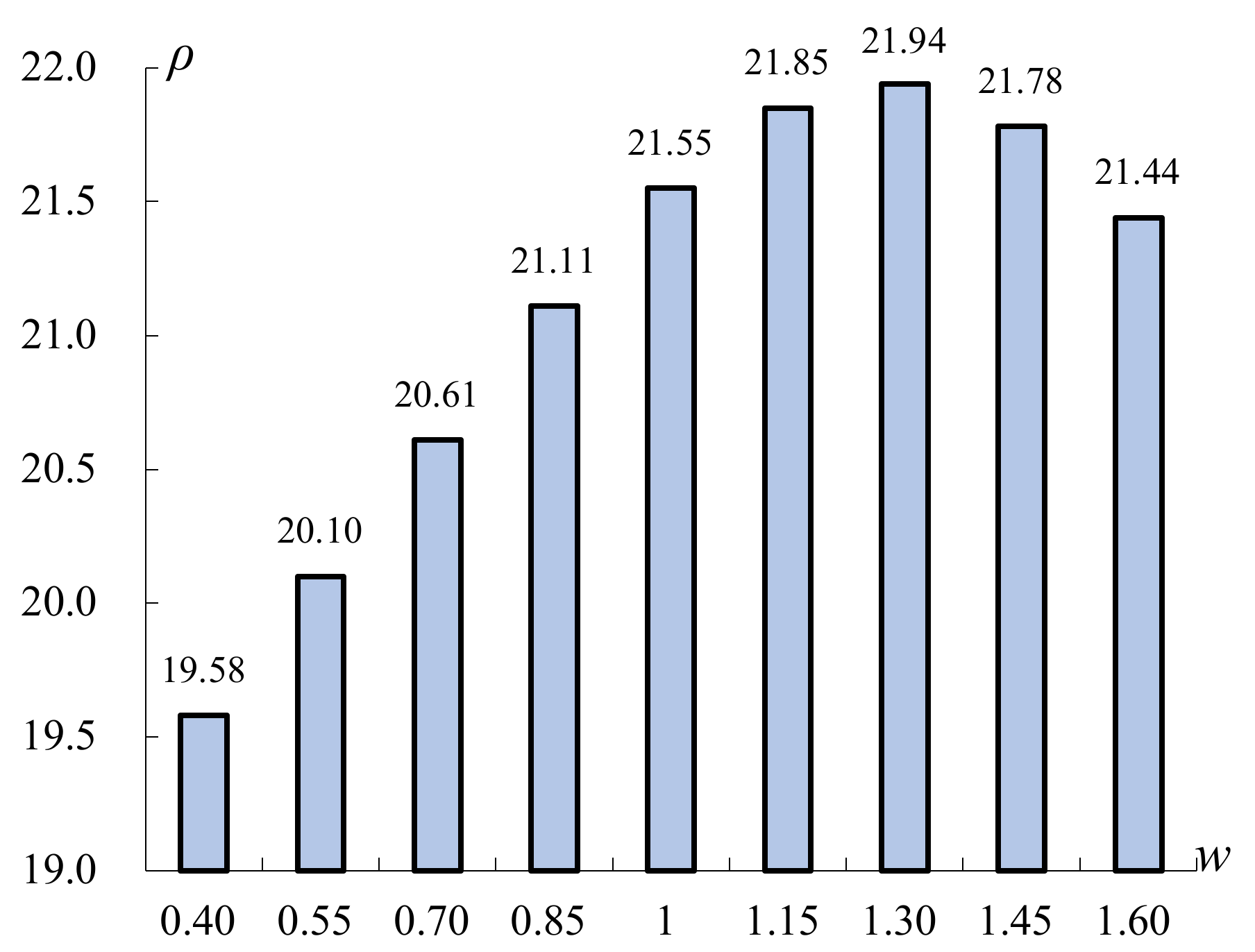

Furthermore, the warranty period, which ranges between −60% and 60%, is analyzed to observe the corresponding variations in

ρ.

Figure 5 shows that

ρ is positively correlated with

w at first; however, there is a decline in

ρ that is associated with a larger

w. It is due to the fact that a longer warranty period for products is usually accompanied by better quality assurance. The products are therefore required to undergo a stricter quality inspection. Thus, the longer the warranty period, the larger the number of conforming items for inspection. However, there is a threshold warranty period above which the maintenance effort becomes cumbersome and complicated. An excessive quality inspection for a long

w is generally avoided, thus leading to a smaller number of conforming items for inspection. Accordingly, the managers should be cautious about not only evaluating the quality characteristics of products, such as reliability, availability, and maintainability, but also the effect of consumers’ market responses on product demand for reasonably arranging an adequate production run length and warranty period.

With respect to the effect of the scale parameters of the Weibull product deterioration on

ρ,

Figure 6 addresses changes between −20% and 20% in the parameters and shows that

ρ is negatively correlated with

α1.

When the deterioration scale of the product under the in-control state grows, a correction is timely and appropriately applied to the production system. The necessity of performing quality inspection decreases, which results in a smaller number of conforming items for inspection. However, ρ is positively correlated with α2. The probability of applying a correction decreases when the product deterioration scale under the out-of-control state increases. A stricter quality inspection is thus applied to the products, and the corresponding number of conforming items for inspection increases.

As can be seen in

Figure 7, given the changes in the shape parameters of the Weibull product deterioration, which ranges between −20% and 20%,

ρ is negatively correlated with

β1, whereas

ρ is positively correlated with

β2.

The managers estimate that β1 is less than 1 under the in-control state, namely, the defective rate decreases with time at this stage, which implies that the quality of the products improves as β1 increases. The required number of conforming items for inspection can thus decrease in the presence of a large shape parameter. However, β2 is estimated to be larger than 1 under the out-of-control state, which implies that the defective rate increases with time, and the resulting product quality is more unreliable as β2 increases. Therefore, a larger number of conforming items is required for inspection to achieve cost minimization. In addition, all factors that can influence product quality attributes, such as the defective rates under different operation conditions, should be carefully monitored for adequately fitting the values of the scale and shape parameters of the Weibull product deterioration process. Additionally, the determination of ρ is more objective because it is derived by considering multiple factors with the market demand measured through Bayesian analysis.

5. Conclusions

Producing premium quality items is a common goal among manufacturers. The production lots are thus required to undergo reliable quality control, which can be achieved by a well-designed quality inspection plan. However, the managers are supposed to overall contemplate the implementation of the inspection plan and the relevant costs from an economic perspective. In this study, the model concerning an NBSI plan is proposed and applied to an imperfect production system that underwent a process of Weibull deterioration. The system with ATO configuration is operated under a status of an in-control or an out-of-control state, where ATO is characterized by high-volume customized products with low costs. Furthermore, from the manufacturer’s perspective, the endogenous and exogenous factors are both taken into account in the assessment of different types of costs incurred in an imperfect production system with ATO configuration, i.e., the status of the production system, the defective rate, the working efficiency of employees, and the market demands of customers. Through an investigation of such a system inspected by the NBSI plan, the objective of this study, i.e., the determination of the optimal number of conforming items for inspection, is accordingly accomplished with an aim to minimize the expected total cost. In addition, the findings from the sensitivity analyses suggest that managers should carefully consider variations in assemblers’ working efficiency in the manufacturing process to evaluate the learning effect of the assembly task. The effect of consumers’ market responses on product demand should also be examined to formulate a suitable production run length and warranty period. Moreover, the defective rates under different operation conditions should be carefully monitored for adequately evaluating the Weibull product deterioration.

The contribution of this study is to provide insights into developing an effective approach for the assembly of products in the manufacturing industry through the NBSI plan. The difference between the proposed model and the existing ones is that the NBSI plan is performed from a perspective of multiple factors with the market demand measured through Bayesian analysis, and therefore the determination of the optimal number of conforming items for inspection would be more objective. The proposed model can assist managers in performing the inspection and manufacturing processes and evaluating the performance of an imperfect production system with ATO configuration, because it can be easily implemented via an NBSI plan and adequately takes account of major factors affecting the costs in the implementation of the assembly task. Additionally, it is of interest to further consider the application of other sampling inspection plans to this type of imperfect production system to achieve cost minimization for the manufacturer.