Neural Modelling of APS Thermal Spray Process Parameters for Optimizing the Hardness, Porosity and Cavitation Erosion Resistance of Al2O3-13 wt% TiO2 Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Atmospheric Plasma Spray Process Parameters

2.2. Investigation into the Functional Properties of Al2O3-13 wt% TiO2 Coatings

2.3. Modeling and Optimization Procedures—Artificial Neural Network (ANN) and Multi-Objective Genetic Algorithm (MOGA)

3. Results and Discussion

3.1. Properties and Cavitation Erosion Damage of the Coatings

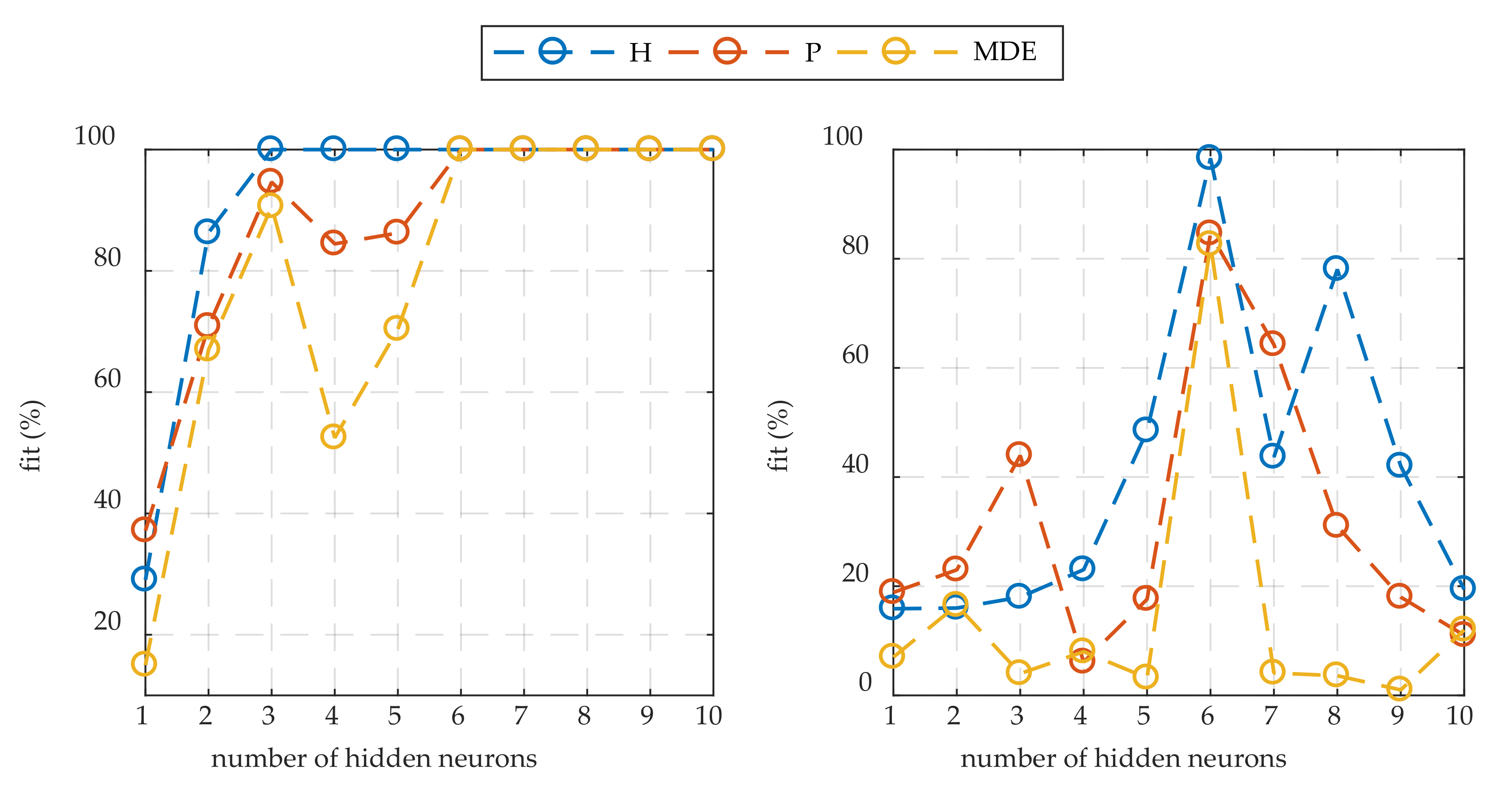

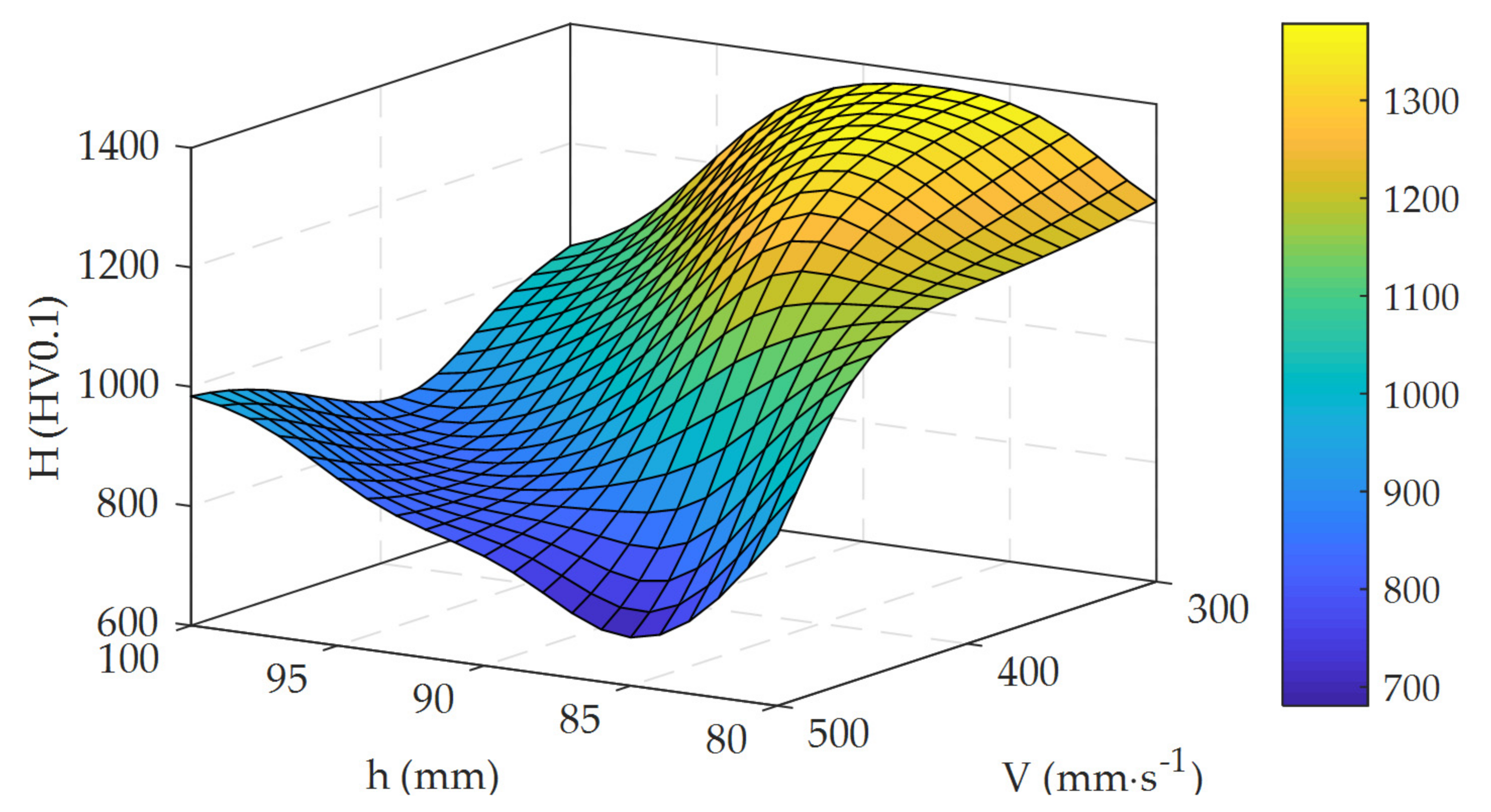

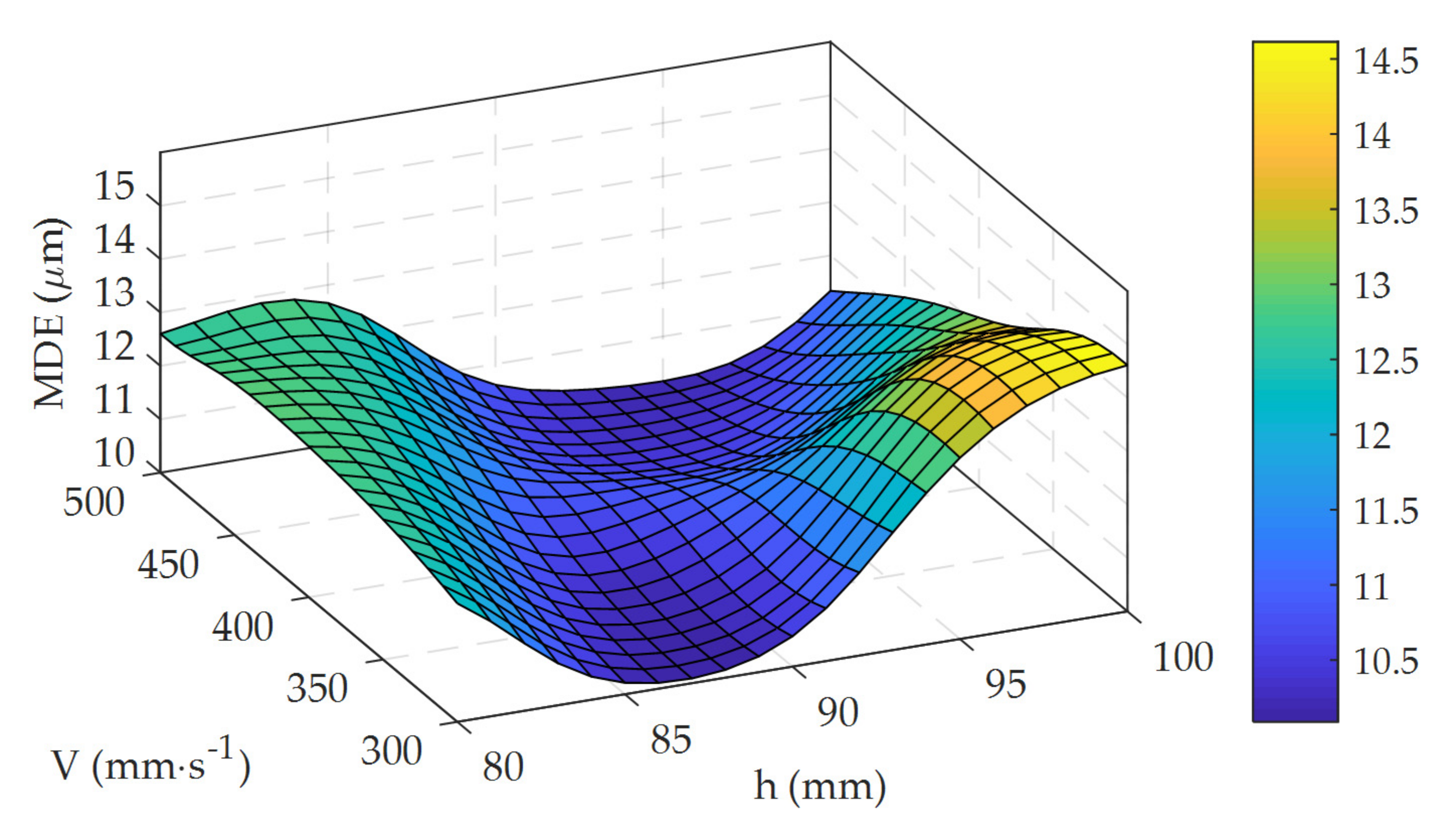

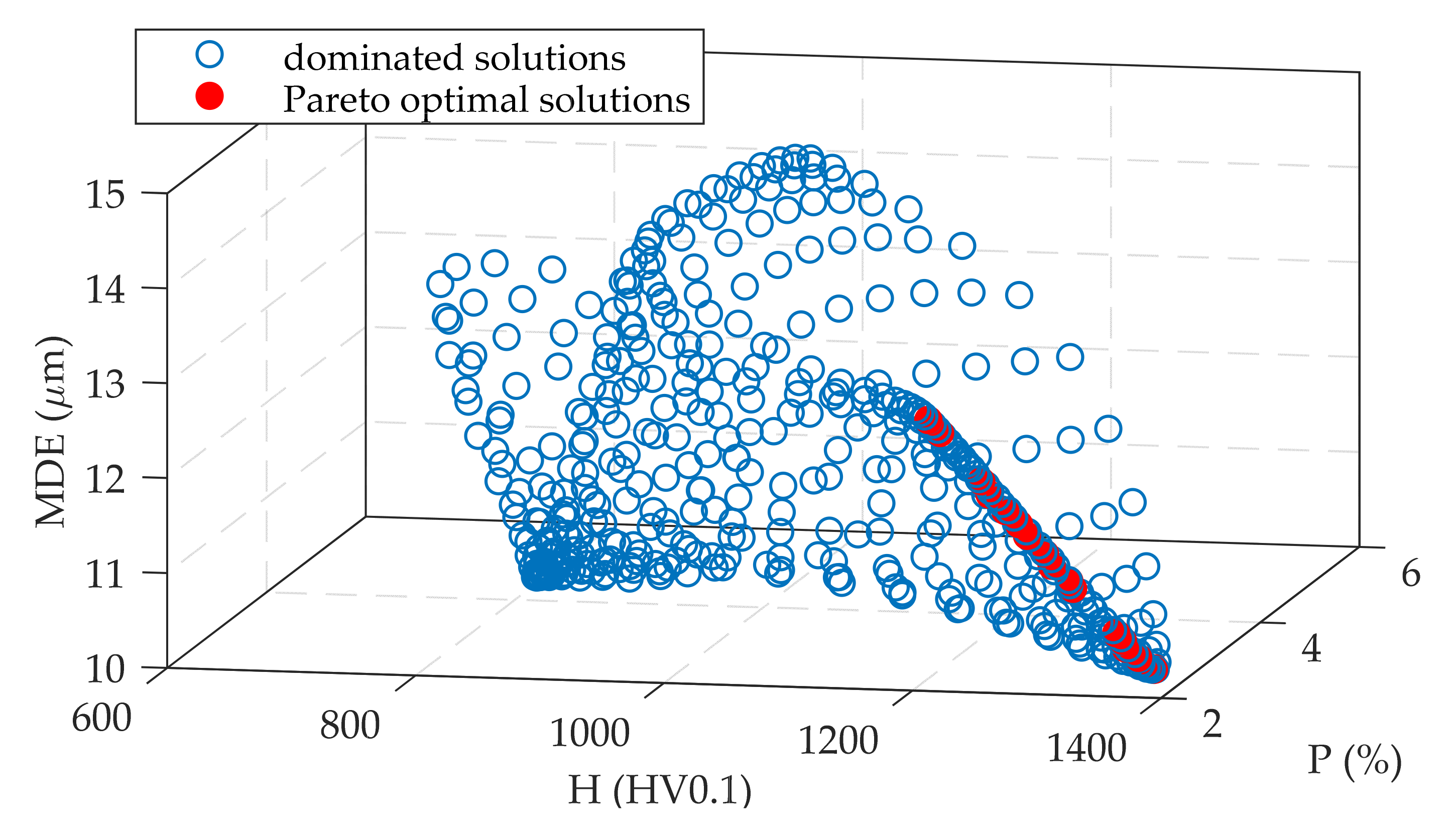

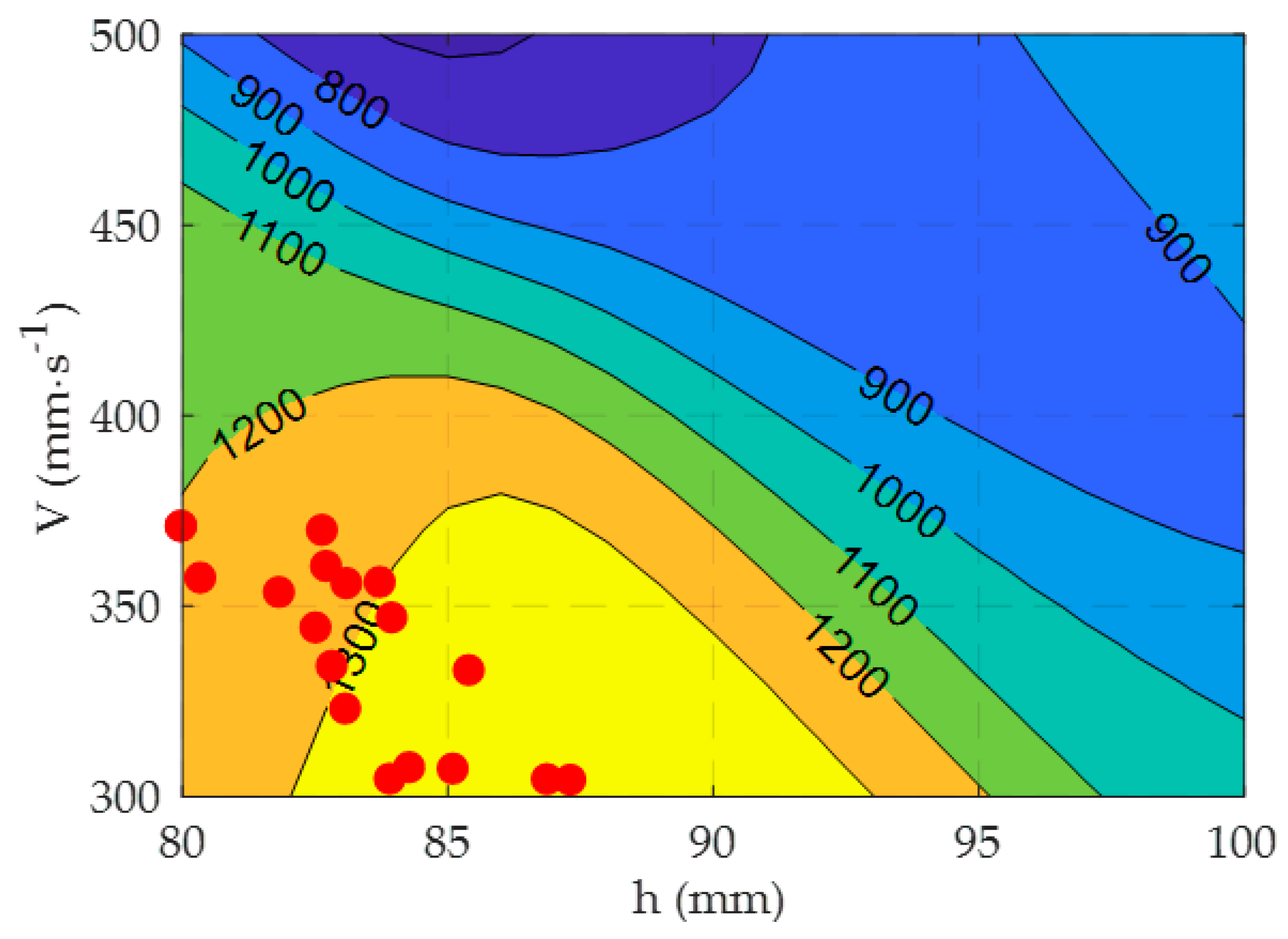

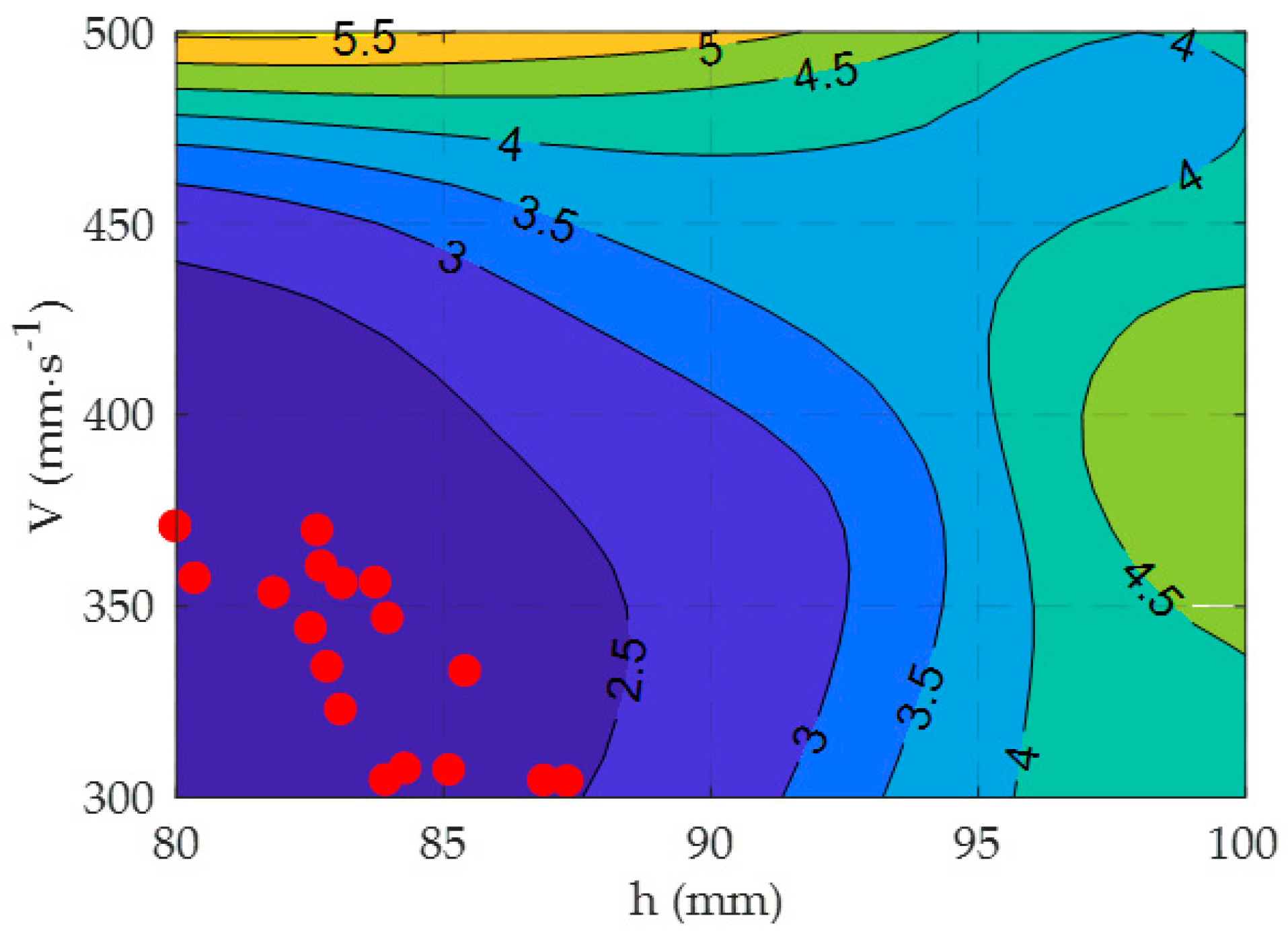

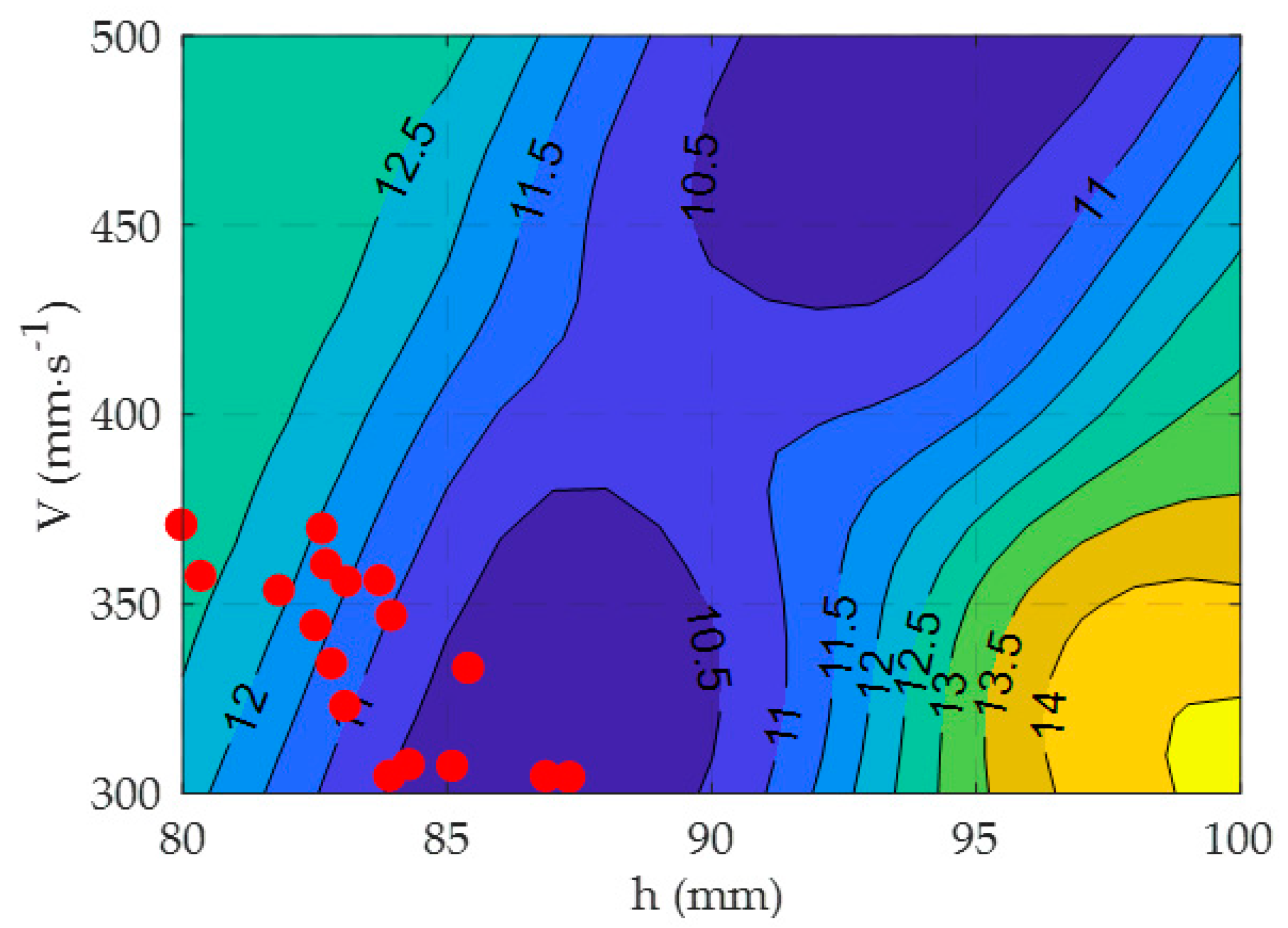

3.2. Model Development and Process Optimization

4. Conclusions

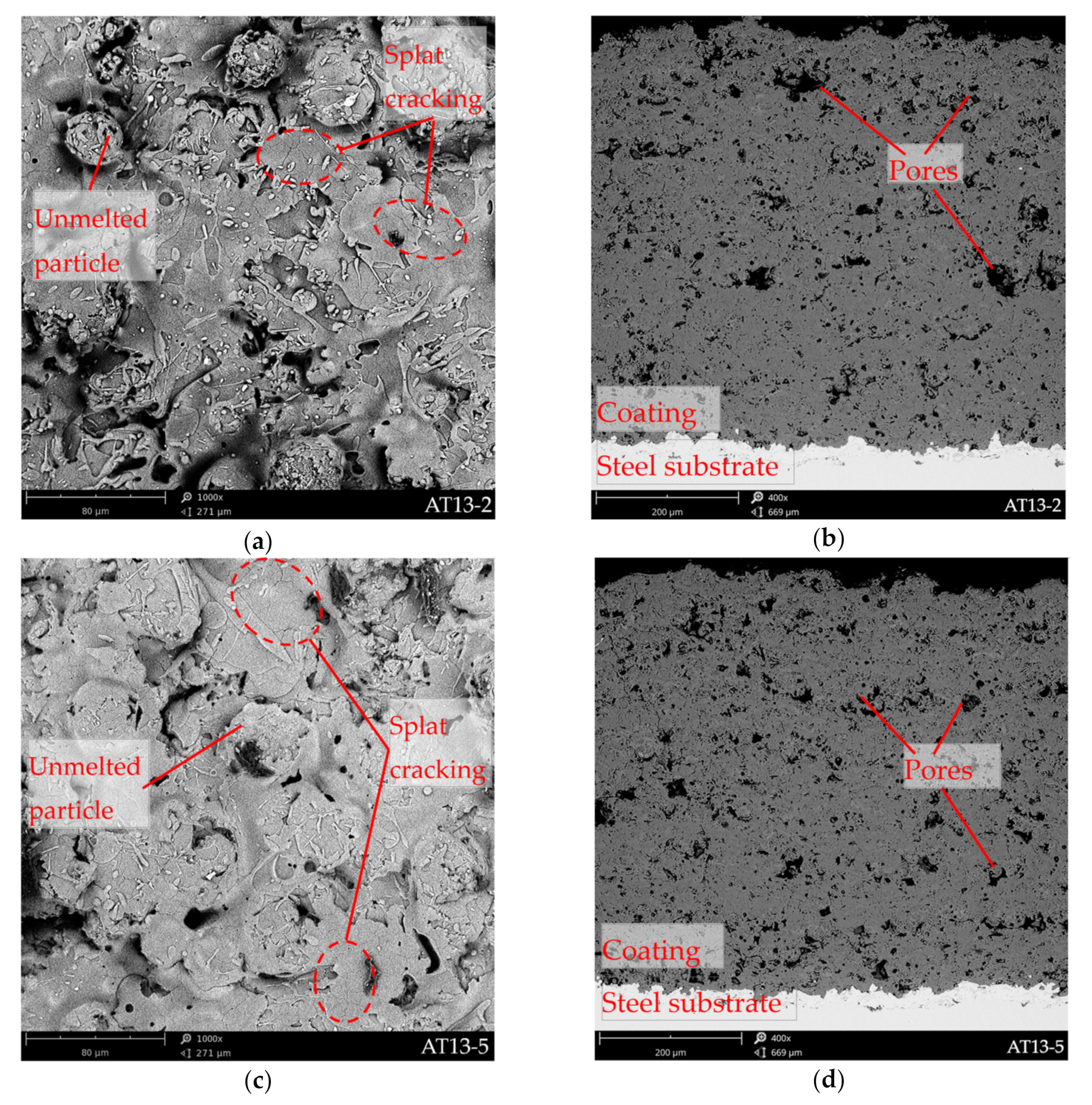

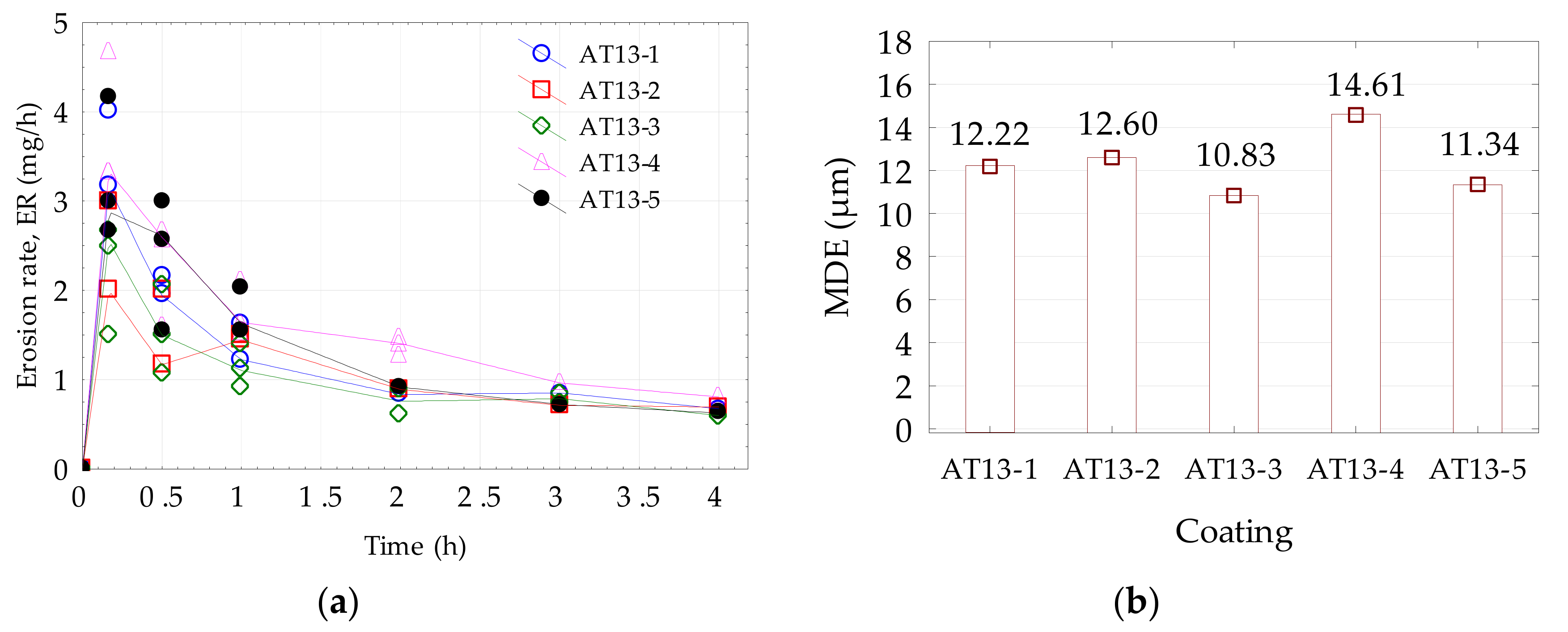

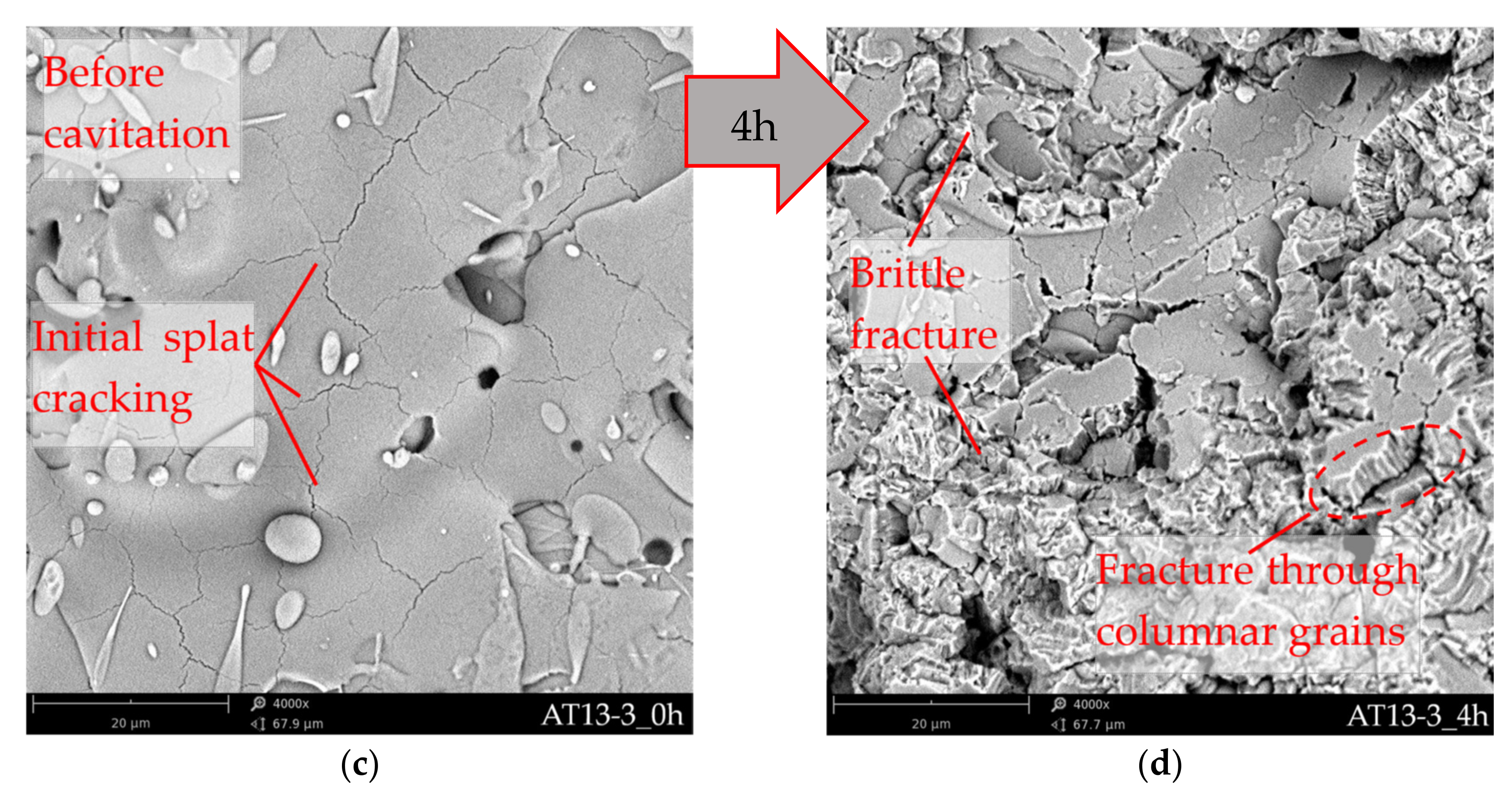

- The APS ceramic coatings exhibit a relatively dense lamellar microstructure with initial cracking of the lamellas, and they also contain unmelted feedstock powder and splats built up from columnar grains. The hardness of the coatings ranges from 885 HV0.1 to 1235 HV0.1 and their porosity ranges from 5.59% to 2.30%. The hardness and porosity of the coatings depend on the ASP process parameters.

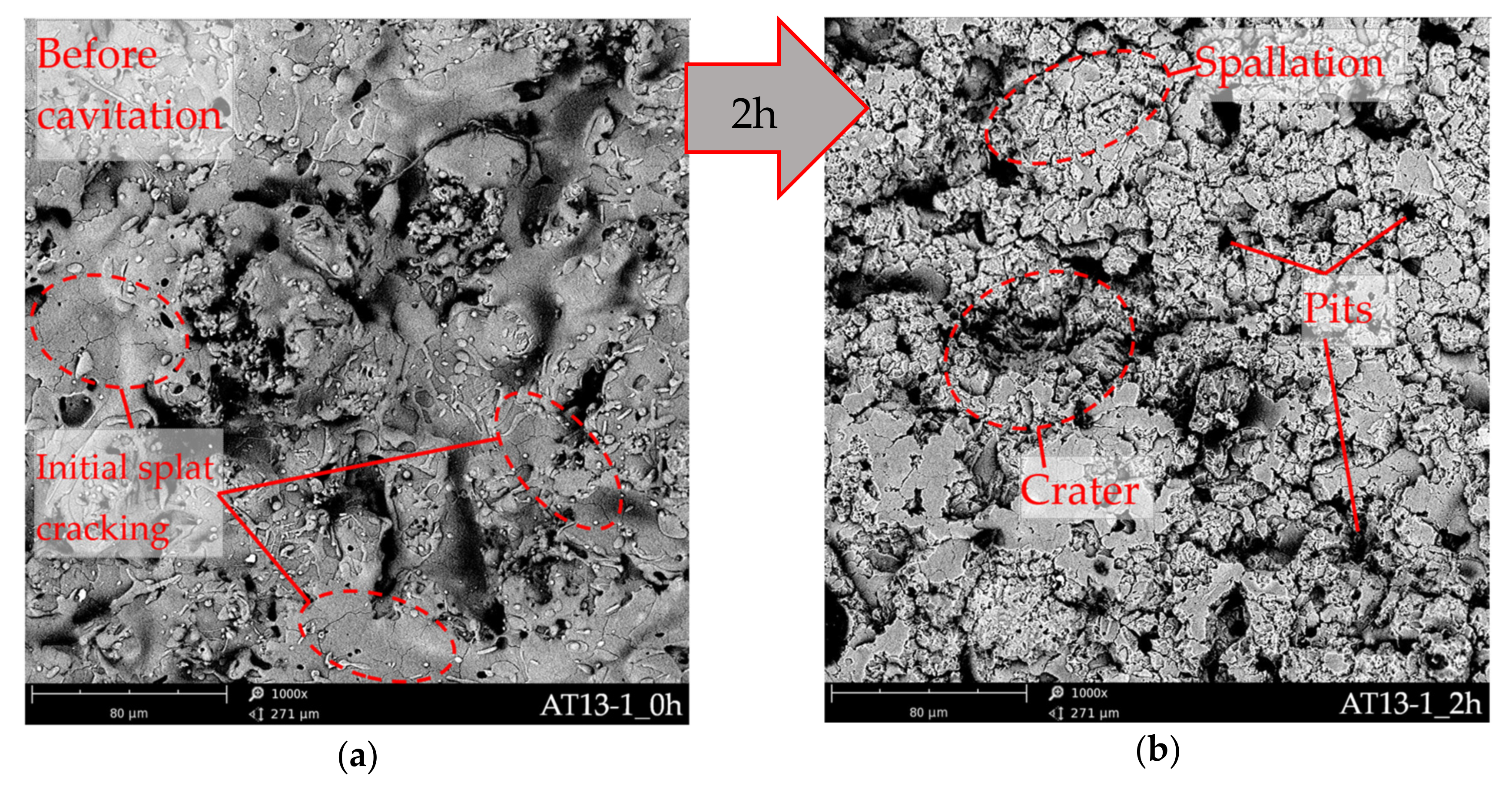

- The AT13-3 specimen deposited with h = 90 mm and V = 400 m/s exhibits the highest CER resistance. The cavitation erosion mechanism identified for the coatings relies on brittle fracture propagating through the columnar grains; furthermore, it is accelerated by the presence of coating non-uniformities such as pores, cracks and particles of unmelted material.

- The selection of APS process parameters to obtain coatings with the required properties is a multicriteria decision problem. The fusion of artificial neural network and genetic algorithm is a novel approach. This promising method can be employed for solving complex problem such as the selection of spray parameters in the design of ceramic coatings with specified hardness, porosity and superior cavitation erosion resistance.

- By applying multi-objective optimization, we found a set of Pareto-optimal solutions. Summing up the optimization results, the highest hardness and, at the same time, the lowest mean depth of erosion, i.e., 1377 HV0.1 and 10.1 µm, respectively, were obtained with h = 86.9 mm, V = 304 mm∙s−1 and h = 87.3 mm, V = 304 mm∙s−1, while the lowest porosity of 2.28% was obtained with h = 80 mm, V = 371 mm∙s−1 and h = 80.4 mm, V = 357 mm∙s−1. These parameters are optimal for APS Al2O3-13 wt% TiO2 ceramic coatings.

Author Contributions

Funding

Conflicts of Interest

References

- Pawlowski, L. The Science and Engineering of Thermal Spray Coatings, 2nd ed.; Wiley: Chichester, UK; Hoboken, NJ, USA, 2008; ISBN 978-0-471-49049-4. [Google Scholar]

- Principles of Thermal Spraying—Plasma-Spray Coating—Wiley Online Library. Available online: https://onlinelibrary.wiley.com/doi/10.1002/9783527614851.ch02 (accessed on 17 September 2020).

- Boulos, M.I.; Fauchais, P.L.; Pfender, E. Handbook of Thermal Plasmas; Springer International Publishing: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Lugscheider, E.; Barimani, C.; Eckert, P.; Eritt, U. Modeling of the APS plasma spray process. Comput. Mater. Sci. 1996, 7, 109–114. [Google Scholar] [CrossRef]

- Guessasma, S.; Montavon, G.; Coddet, C. Modeling of the APS plasma spray process using artificial neural networks: Basis, requirements and an example. Comput. Mater. Sci. 2004, 29, 315–333. [Google Scholar] [CrossRef]

- Sahab, A.R.M.; Saad, N.H.; Kasolang, S.; Saedon, J. Impact of Plasma Spray Variables Parameters on Mechanical and Wear Behaviour of Plasma Sprayed Al2O3 3%wt TiO2 Coating in Abrasion and Erosion Application. Procedia Eng. 2012, 41, 1689–1695. [Google Scholar] [CrossRef]

- Aruna, S.T.; Balaji, N.; Shedthi, J.; Grips, V.K.W. Effect of critical plasma spray parameters on the microstructure, microhardness and wear and corrosion resistance of plasma sprayed alumina coatings. Surf. Coat. Technol. 2012, 208, 92–100. [Google Scholar] [CrossRef]

- Yugeswaran, S.; Selvarajan, V.; Vijay, M.; Ananthapadmanabhan, P.V.; Sreekumar, K.P. Influence of critical plasma spraying parameter (CPSP) on plasma sprayed Alumina–Titania composite coatings. Ceram. Int. 2010, 36, 141–149. [Google Scholar] [CrossRef]

- Michalak, M.; Łatka, L.; Sokołowski, P.; Niemiec, A.; Ambroziak, A. The Microstructure and Selected Mechanical Properties of Al2O3 + 13 wt % TiO2 Plasma Sprayed Coatings. Coatings 2020, 10, 173. [Google Scholar] [CrossRef]

- Łatka, L.; Niemiec, A.; Michalak, M.; Sokołowski, P. Tribological Properties of Al2O3 + TiO2 Coatings Manufactured by Plasma Spraying. Bimon. Tribol. 2019, 283, 19–24. [Google Scholar] [CrossRef]

- Chochowski, A.; Obstawski, P. The use of thermal-electric analogy in solar collector thermal state analysis. Renew. Sustain. Energy Rev. 2017, 68, 397–409. [Google Scholar] [CrossRef]

- Aleksiejuk, J.; Chochowski, A.; Reshetiuk, V. Analog model of dynamics of a flat-plate solar collector. Sol. Energy 2018, 160, 103–116. [Google Scholar] [CrossRef]

- Salat, R.; Awtoniuk, M. Black box modeling of PIDs implemented in PLCs without structural information: A support vector regression approach. Neural Comput. Appl. 2015, 26, 723–734. [Google Scholar] [CrossRef][Green Version]

- Chmiel, J.; Jasionowski, R.; Zasada, D. Cavitation erosion and corrosion of pearlitic gray cast iron in non-standardized cavitation conditions. Solid State Phenom. 2015, 225, 19–24. [Google Scholar] [CrossRef]

- Cui, Z.D.; Man, H.C.; Cheng, F.T.; Yue, T.M. Cavitation erosion–corrosion characteristics of laser surface modified NiTi shape memory alloy. Surface Coat. Technol. 2003, 162, 147–153. [Google Scholar] [CrossRef]

- Amarendra, H.J.; Chaudhari, G.P.; Nath, S.K. Synergy of cavitation and slurry erosion in the slurry pot tester. Wear 2012, 290–291, 25–31. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, J.; Ma, F. Cavitation–silt erosion in sand suspensions. J. Mech. Sci. Technol. 2018, 32, 5697–5702. [Google Scholar] [CrossRef]

- Su, K.; Wu, J.; Xia, D. Classification of regimes determining ultrasonic cavitation erosion in solid particle suspensions. Ultrason. Sonochem. 2020, 68, 105214. [Google Scholar] [CrossRef]

- Da Silva, F.N.; de Oliveira, P.M.; Araújo, N.M.d.F.T.d.S.; de Carvalho Filho, E.T.; da Cunha, J.D.; da Silva, D.R.; de Medeiros, J.T.N. Corrosion-cavitation-erosion: Surface morphology study of a carbon steel in a multiphasic saline bath. Matéria 2019, 24. [Google Scholar] [CrossRef]

- Liang, L.; Pang, Y.; Tang, Y.; Zhang, H.; Liu, H.; Liu, Y. Combined wear of slurry erosion, cavitation erosion, and corrosion on the simulated ship surface. Adv. Mech. Eng. 2019, 11, 1687814019834450. [Google Scholar] [CrossRef]

- Tocci, M.; Pola, A.; Girelli, L.; Lollio, F.; Montesano, L.; Gelfi, M. Wear and Cavitation Erosion Resistance of an AlMgSc Alloy Produced by DMLS. Metals 2019, 9, 308. [Google Scholar] [CrossRef]

- Hattori, S.; Ishikura, R. Revision of cavitation erosion database and analysis of stainless steel data. Wear 2010, 268, 109–116. [Google Scholar] [CrossRef]

- Steller, J. International Cavitation Erosion Test and quantitative assessment of material resistance to cavitation. Wear 1999, 233–235, 51–64. [Google Scholar] [CrossRef]

- Szala, M.; Dudek, A.; Maruszczyk, A.; Walczak, M.; Chmiel, J.; Kowal, M. Effect of atmospheric plasma sprayed TiO2-10% NiAl cermet coating thickness on cavitation erosion, sliding and abrasive wear resistance. Acta Phys. Pol. A 2019, 136, 335–341. [Google Scholar] [CrossRef]

- Jasionowski, R.; Przetakiewicz, D.; Przetakiewicz, W. Cavitation Erosion Resistance of Alloys Used in Cathodic Protection of Hulls of Ships. Arch. Metall. Mater. 2014, 59, 241–245. [Google Scholar] [CrossRef]

- Mann, B.S.; Arya, V. An experimental study to corelate water jet impingement erosion resistance and properties of metallic materials and coatings. Wear 2002, 253, 650–661. [Google Scholar] [CrossRef]

- Krella, A.K.; Zakrzewska, D.E. Cavitation Erosion—Phenomenon and Test Rigs. Adv. Mater. Sci. 2018, 18, 15–26. [Google Scholar] [CrossRef]

- García, G.L.; López-Ríos, V.; Espinosa, A.; Abenojar, J.; Velasco, F.; Toro, A. Cavitation resistance of epoxy-based multilayer coatings: Surface damage and crack growth kinetics during the incubation stage. Wear 2014, 316, 124–132. [Google Scholar] [CrossRef]

- Dular, M.; Bachert, B.; Stoffel, B.; Sirok, B. Relationship between cavitation structures and cavitation damage. Wear 2004, 257, 1176–1184. [Google Scholar] [CrossRef]

- Szala, M. Application of computer image analysis software for determining incubation period of cavitation erosion—preliminary results. ITM Web Conf. 2017, 15, 06003. [Google Scholar] [CrossRef]

- Gireń, B.G. Kawitacyjne Niszczenie Warstw Ukształtowanych Wiązką Promieniowania Laserowego; Wydawn. IMP PAN: Gdańsk, Poland, 2006. [Google Scholar]

- Szala, M.; Łatka, L.; Walczak, M.; Winnicki, M. Comparative Study on the Cavitation Erosion and Sliding Wear of Cold-Sprayed Al/Al2O3 and Cu/Al2O3 Coatings, and Stainless Steel, Aluminium Alloy, Copper and Brass. Metals 2020, 10, 856. [Google Scholar] [CrossRef]

- Will, C.R.; Capra, A.R.; Pukasiewicz, A.G.M.; Chandelier, J.d.G.; Paredes, R.S.C. Comparative study of three austenitic alloy with cobalt resistant to cavitation deposited by plasma welding. Weld. Int. 2012, 26, 96–103. [Google Scholar] [CrossRef]

- Maksimović, V.M.; Devečerski, A.B.; Došen, A.; Bobić, I.; Erić, M.D.; Volkov-Husović, T. Comparative Study on Cavitation Erosion Resistance of A356 Alloy and A356FA5 Composite. Trans. Indian Inst. Met. 2017, 70, 97–105. [Google Scholar] [CrossRef]

- Hattori, S.; Ishikura, R.; Zhang, Q. Construction of database on cavitation erosion and analyses of carbon steel data. Wear 2004, 257, 1022–1029. [Google Scholar] [CrossRef]

- Tzanakis, I.; Bolzoni, L.; Eskin, D.G.; Hadfield, M. Evaluation of Cavitation Erosion Behavior of Commercial Steel Grades Used in the Design of Fluid Machinery. Metall. Mater. Trans. A 2017, 48, 2193–2206. [Google Scholar] [CrossRef]

- Gao, G.; Zhang, Z.; Cai, C.; Zhang, J.; Nie, B. Cavitation Damage Prediction of Stainless Steels Using an Artificial Neural Network Approach. Metals 2019, 9, 506. [Google Scholar] [CrossRef]

- Szala, M.; Awtoniuk, M. Neural modelling of cavitation erosion process of 34CrNiMo6 steel. IOP Conf. Ser. Mater. Sci. Eng. 2019, 710, 012016. [Google Scholar] [CrossRef]

- Jafarzadeh, K.; Valefi, Z.; Ghavidel, B. The effect of plasma spray parameters on the cavitation erosion of Al2O3–TiO2 coatings. Surface Coat. Technol. 2010, 205, 1850–1855. [Google Scholar] [CrossRef]

- Łatka, L.; Szala, M.; Michalak, M.; Pałka, T. Impact of atmospheric plasma spray parameters on cavitation erosion resistance of Al2O3-13%TiO2 coatings. Acta Phys. Pol. A 2019, 136, 342–347. [Google Scholar] [CrossRef]

- Szala, M.; Awtoniuk, M.; Łatka, L.; Macek, W.; Branco, R. Artificial neural network model of hardness, porosity and cavitation erosion wear of APS deposited Al2O3 -13 wt % TiO2 coatings. J. Phys. Conf. Ser. 2021. in print. [Google Scholar]

- Pierlot, C.; Pawlowski, L.; Bigan, M.; Chagnon, P. Design of experiments in thermal spraying: A review. Surf. Coat. Technol. 2008, 202, 4483–4490. [Google Scholar] [CrossRef]

- Szala, M.; Walczak, M.; Łatka, L.; Gancarczyk, K.; Özkan, D. Cavitation Erosion and Sliding Wear of MCrAlY and NiCrMo Coatings Deposited by HVOF Thermal Spraying. Adv. Mater. Sci. 2020, 20, 26–38. [Google Scholar] [CrossRef]

- Maruszczyk, A.; Dudek, A.; Szala, M. Research into Morphology and Properties of TiO2—NiAl Atmospheric Plasma Sprayed Coating. Adv. Sci. Technol. Res. J. 2017, 11, 204–210. [Google Scholar] [CrossRef]

- Łatka, L.; Michalak, M.; Jonda, E. Atmospheric Plasma Spraying of Al2O3 + 13% TiO2 Coatings Using External and Internal Injection System. Adv. Mater. Sci. 2019, 19, 5–17. [Google Scholar] [CrossRef]

- ASTM G32-10: Standard Test Method for Cavitation Erosion Using Vibratory Apparatus; ASTM International: West Conshohocken, PA, USA, 2010.

- Tangirala, A.K. Principles of System Identification: Theory and Practice; CRC Press: Boca Raton, FL, USA, 2015; ISBN 978-1-4398-9599-3. [Google Scholar]

- Łatka, L.; Pawłowski, L.; Winnicki, M.; Sokołowski, P.; Małachowska, A.; Kozerski, S. Review of Functionally Graded Thermal Sprayed Coatings. Appl. Sci. 2020, 10, 5153. [Google Scholar] [CrossRef]

- Meghwal, A.; Anupam, A.; Murty, B.S.; Berndt, C.C.; Kottada, R.S.; Ang, A.S.M. Thermal Spray High-Entropy Alloy Coatings: A Review. J. Therm. Spray Tech. 2020, 29, 857–893. [Google Scholar] [CrossRef]

- Yılmaz, R.; Kurt, A.O.; Demir, A.; Tatlı, Z. Effects of TiO2 on the mechanical properties of the Al2O3–TiO2 plasma sprayed coating. J. Eur. Ceram. Soc. 2007, 27, 1319–1323. [Google Scholar] [CrossRef]

- Matikainen, V.; Niemi, K.; Koivuluoto, H.; Vuoristo, P. Abrasion, Erosion and Cavitation Erosion Wear Properties of Thermally Sprayed Alumina Based Coatings. Coatings 2014, 4, 18–36. [Google Scholar] [CrossRef]

- Davis, J.R. Handbook of Thermal Spray Technology; ASM International: Almere, The Netherlands, 2004; ISBN 978-0-87170-795-6. [Google Scholar]

- Coello, C.C.; Lamont, G.B.; van Veldhuizen, D.A. Evolutionary Algorithms for Solving Multi-Objective Problems, 2nd ed.; Genetic and Evolutionary Computation; Springer: New York, NY, USA, 2007; ISBN 978-0-387-33254-3. [Google Scholar]

- Chen, Q.; Hu, P.; Pu, J.; Wang, J.H. Sensitivity analysis and multi-objective optimization of double-ceramic-layers thermal barrier system. Ceram. Int. 2019, 45, 17224–17235. [Google Scholar] [CrossRef]

| Sample Code | Stand-Off Distance, h (mm) | Torch Velocity, V (mm∙s−1) |

|---|---|---|

| AT13-1 | 80 | 300 |

| AT13-2 | 80 | 500 |

| AT13-3 | 90 | 400 |

| AT13-4 | 100 | 300 |

| AT13-5 | 100 | 500 |

| Sample Code | Hardness, H (HV0.1) | Porosity, P (%) |

|---|---|---|

| AT13-1 | 1237 ± 105 | 2.30 ± 0.37 |

| AT13-2 | 885 ± 108 | 5.59 ± 0.63 |

| AT13-3 | 1059 ± 112 | 2.91 ± 0.51 |

| AT13-4 | 1028 ± 118 | 4.28 ± 0.60 |

| AT13-5 | 984 ± 108 | 4.16 ± 0.57 |

| Output Signal | Fit Index (%) | |

|---|---|---|

| Learning Dataset | Testing Dataset | |

| H | 100 | 98.4 |

| P | 100 | 84.6 |

| MDE | 100 | 82.6 |

| Solution Number | Decision Variables x* | Objective Function J | |||

|---|---|---|---|---|---|

| h (mm) | V (mm∙s−1) | H (HV0.1) | P (%) | MDE (µm) | |

| 1 | 80.0 | 371 | 1203 | 2.28 | 12.7 |

| 2 | 84.0 | 347 | 1316 | 2.38 | 11.0 |

| 3 | 86.9 | 304 | 1377 | 2.46 | 10.1 |

| 4 | 82.7 | 370 | 1250 | 2.32 | 11.9 |

| 5 | 83.7 | 356 | 1299 | 2.36 | 11.2 |

| 6 | 82.7 | 360 | 1263 | 2.33 | 11.8 |

| 7 | 80.4 | 357 | 1212 | 2.28 | 12.6 |

| 8 | 81.8 | 353 | 1244 | 2.31 | 12.1 |

| 9 | 82.8 | 334 | 1294 | 2.35 | 11.3 |

| 10 | 85.1 | 307 | 1366 | 2.42 | 10.2 |

| 11 | 82.5 | 344 | 1274 | 2.33 | 11.6 |

| 12 | 85.4 | 333 | 1356 | 2.42 | 10.3 |

| 13 | 83.1 | 323 | 1313 | 2.37 | 11.0 |

| 14 | 83.9 | 304 | 1349 | 2.40 | 10.5 |

| 15 | 84.3 | 307 | 1354 | 2.41 | 10.4 |

| 16 | 83.1 | 356 | 1280 | 2.34 | 11.5 |

| 17 | 87.3 | 304 | 1377 | 2.48 | 10.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szala, M.; Łatka, L.; Awtoniuk, M.; Winnicki, M.; Michalak, M. Neural Modelling of APS Thermal Spray Process Parameters for Optimizing the Hardness, Porosity and Cavitation Erosion Resistance of Al2O3-13 wt% TiO2 Coatings. Processes 2020, 8, 1544. https://doi.org/10.3390/pr8121544

Szala M, Łatka L, Awtoniuk M, Winnicki M, Michalak M. Neural Modelling of APS Thermal Spray Process Parameters for Optimizing the Hardness, Porosity and Cavitation Erosion Resistance of Al2O3-13 wt% TiO2 Coatings. Processes. 2020; 8(12):1544. https://doi.org/10.3390/pr8121544

Chicago/Turabian StyleSzala, Mirosław, Leszek Łatka, Michał Awtoniuk, Marcin Winnicki, and Monika Michalak. 2020. "Neural Modelling of APS Thermal Spray Process Parameters for Optimizing the Hardness, Porosity and Cavitation Erosion Resistance of Al2O3-13 wt% TiO2 Coatings" Processes 8, no. 12: 1544. https://doi.org/10.3390/pr8121544

APA StyleSzala, M., Łatka, L., Awtoniuk, M., Winnicki, M., & Michalak, M. (2020). Neural Modelling of APS Thermal Spray Process Parameters for Optimizing the Hardness, Porosity and Cavitation Erosion Resistance of Al2O3-13 wt% TiO2 Coatings. Processes, 8(12), 1544. https://doi.org/10.3390/pr8121544