Structure Property Investigation of Glass-Carbon Prepreg Waste-Polymer Hybrid Composites Degradation in Water Condition

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparations of Hybrid Composites

2.3. Material Characterization

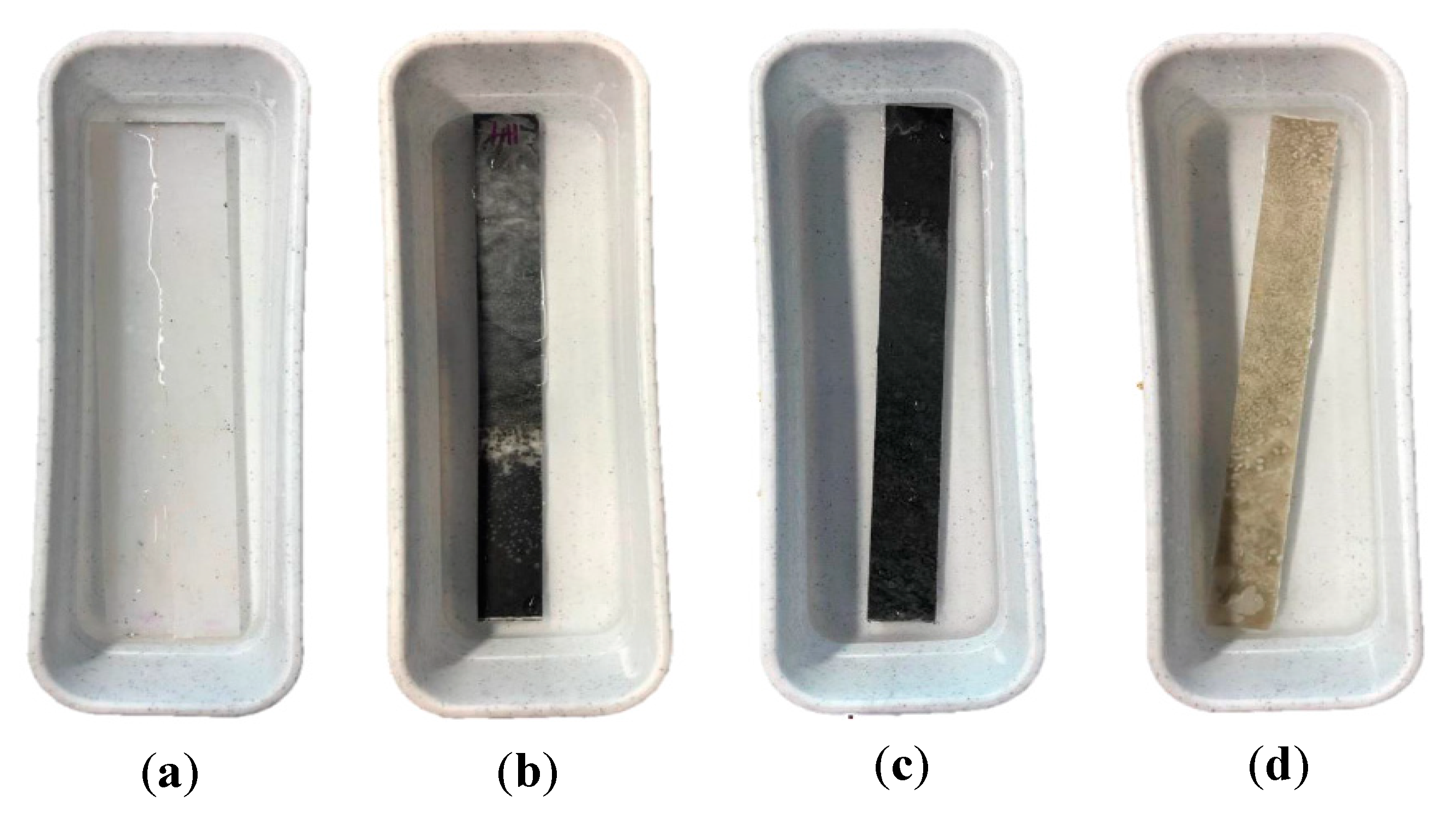

2.3.1. Water Immersion Tests

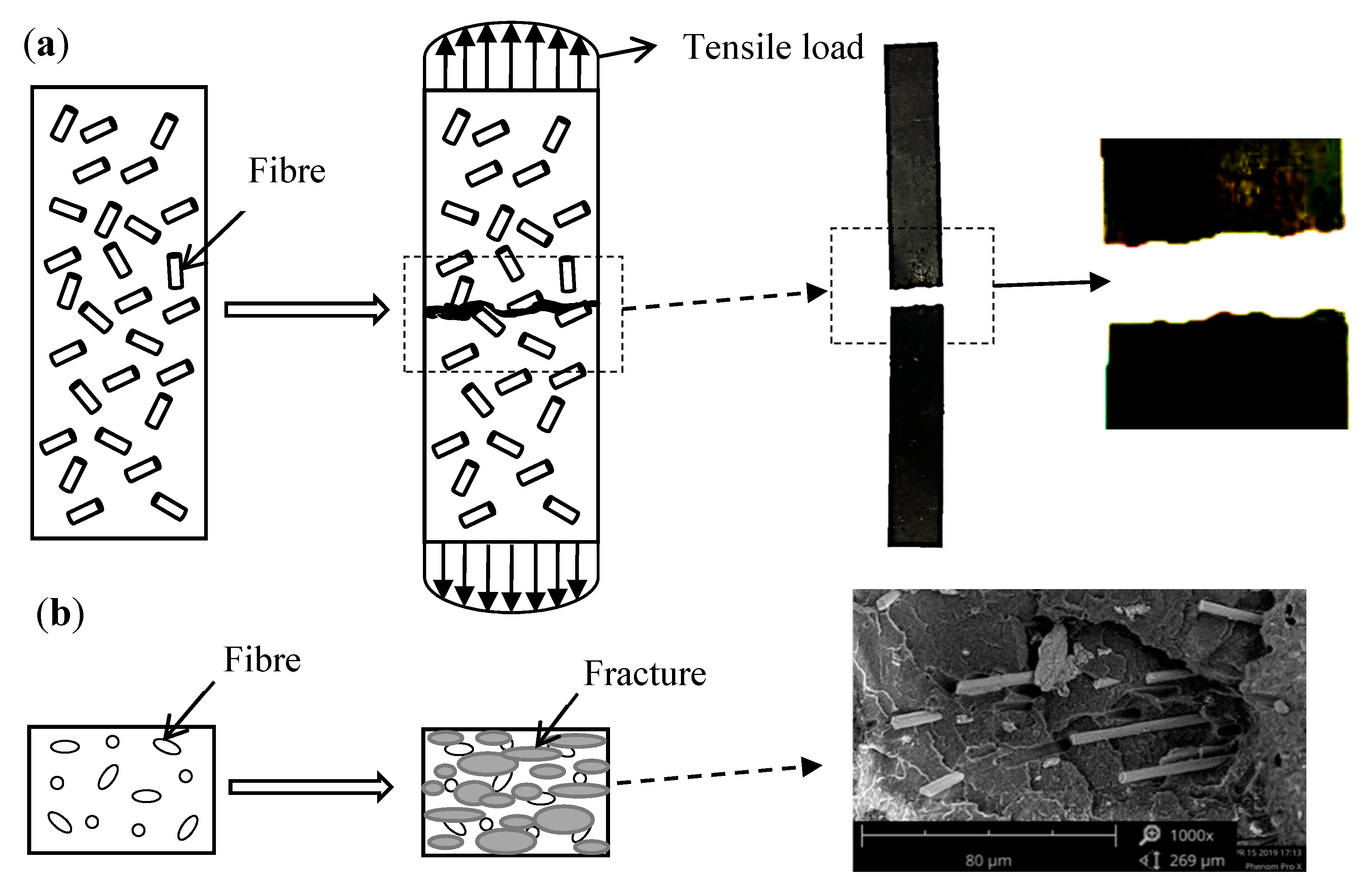

2.3.2. Tensile Test

2.3.3. Hardness Test

2.3.4. Morphology

3. Results and Discussion

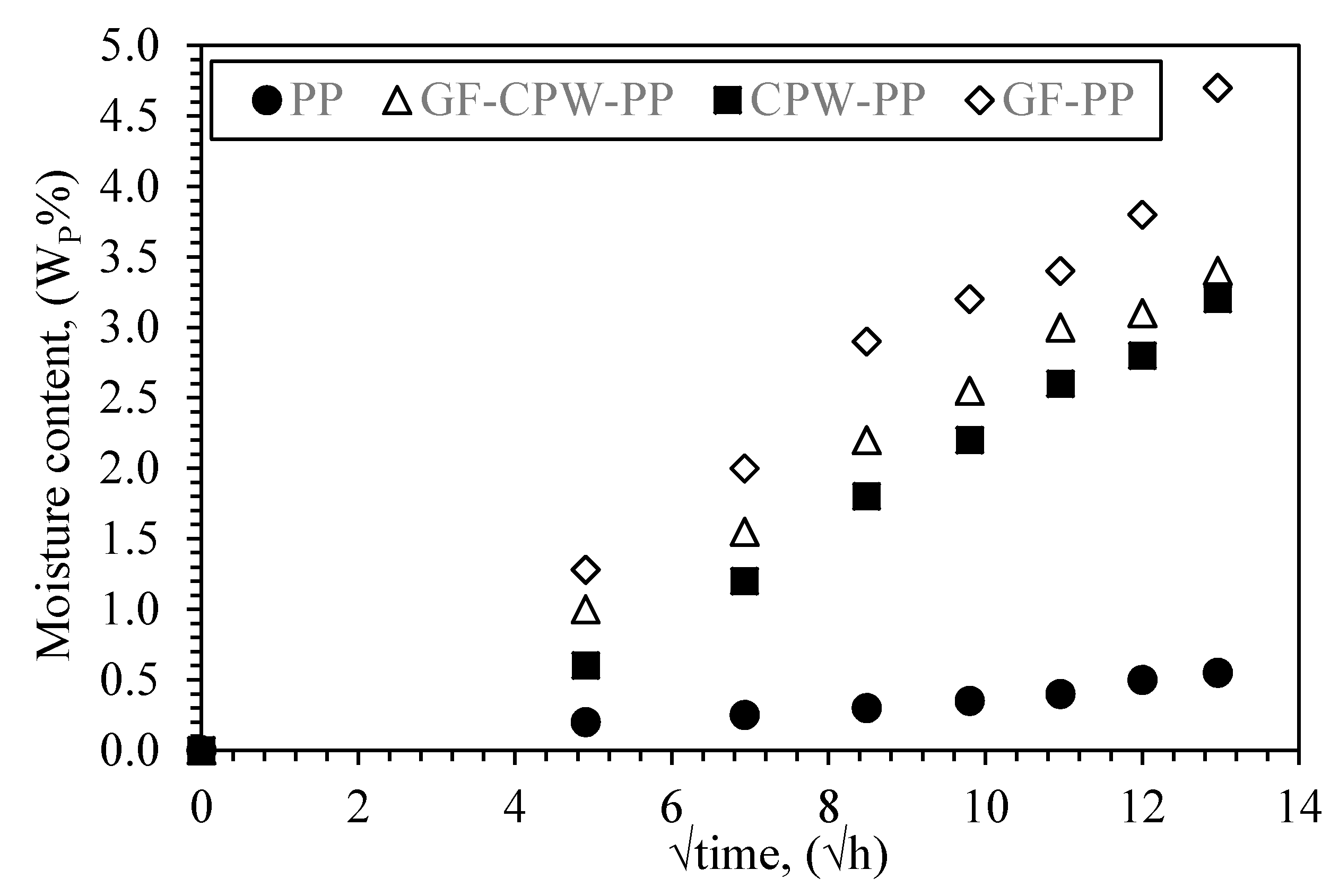

3.1. Water Immersion

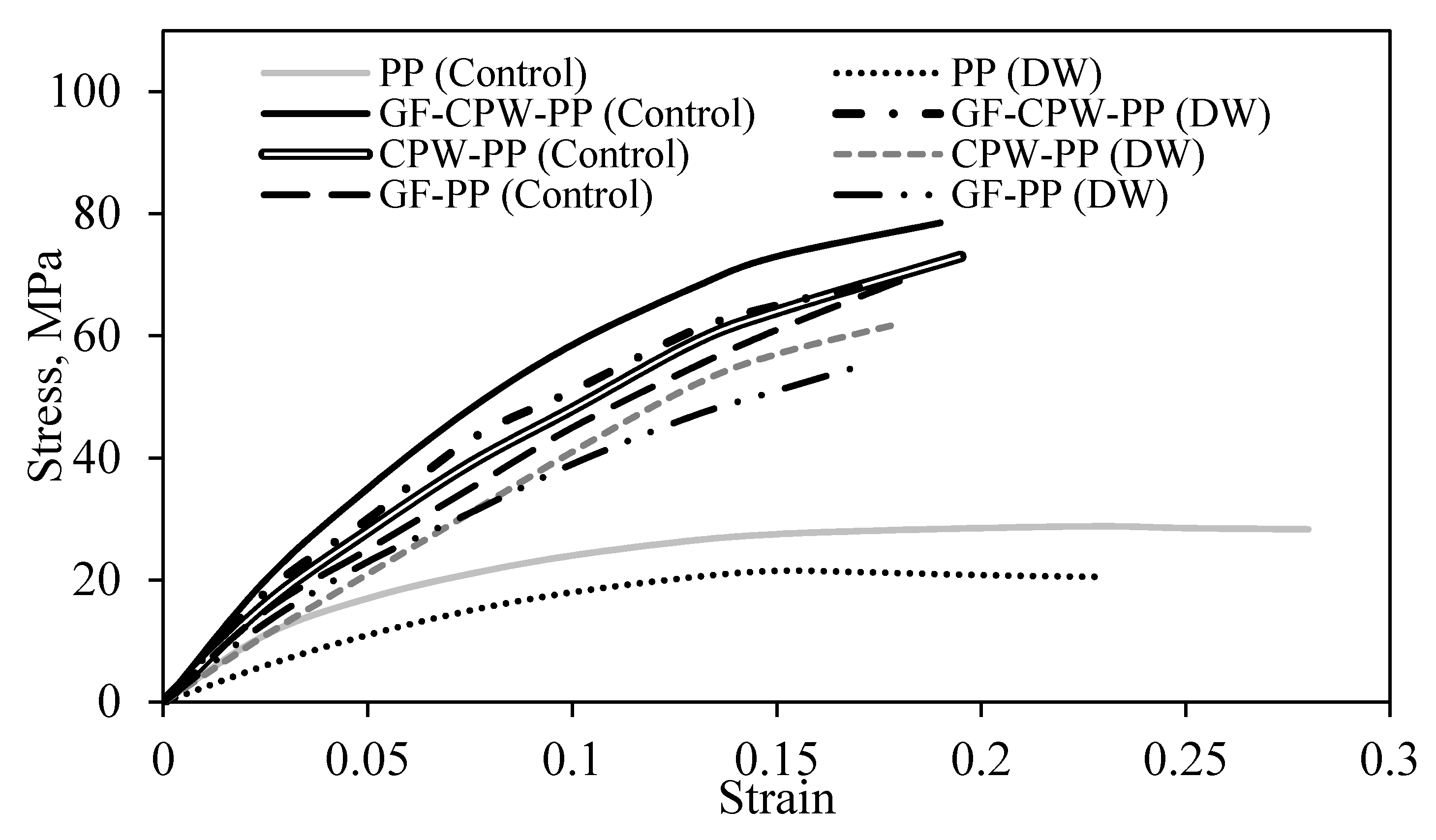

3.2. Tensile Test

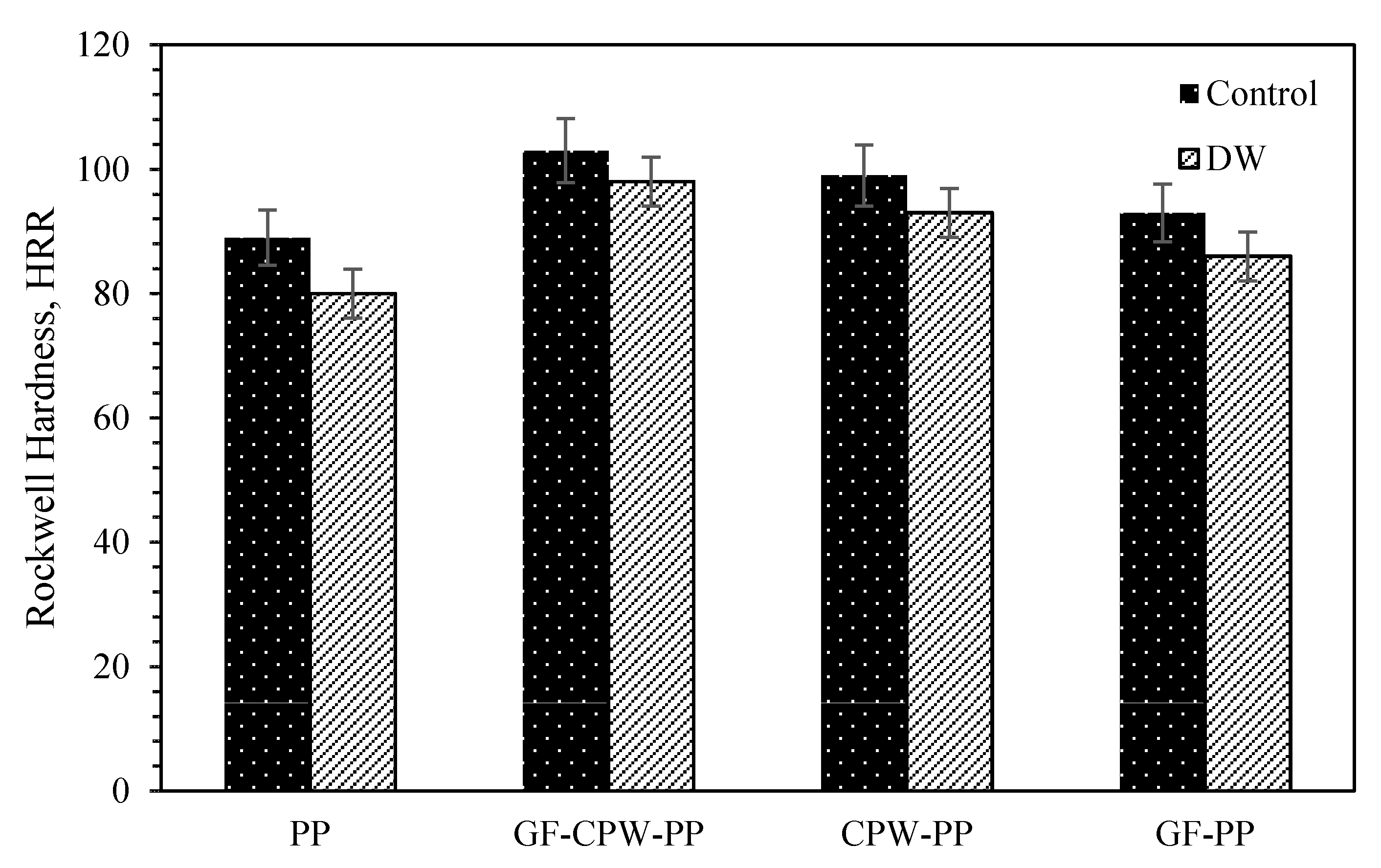

3.3. Hardness Test

3.4. Morphology

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chand, S. Review: Carbon fiber composites. J. Mater. Sci. 2000, 35, 1303–1313. [Google Scholar] [CrossRef]

- Taketa, I.; Kalinka, G.; Gorbatikh, L.; Lomov, S.V.; Verpoest, I. Influence of cooling rate on the properties of carbon fiber unidirectional composites with polypropylene, polyamide 6, and polyphenylene sulfide matrices. Adv. Compos. Mater. 2020, 29, 101–113. [Google Scholar] [CrossRef]

- Miao, C.; Hareesh, V.T. Effect of Loading Rate on Fracture Behavior of Carbon Fiber Reinforced Polymer Composites. In Challenges in Mechanics of Time Dependent Materials, Fracture, Fatigue, Failure and Damage Evolution; Springer: Berlin/Heidelberg, Germany, 2020; Volume 2, pp. 21–28. [Google Scholar]

- Capela, C.; Oliveira, S.E.; Ferreira, J.A. Fatigue behavior of short carbon fiber reinforced epoxy composites. Compos. Part. B Eng. 2019, 164, 191–197. [Google Scholar] [CrossRef]

- Xu, P.; Yu, Y.; Liu, D.; He, M.; Li, G.; Yang, X. Enhanced interfacial and mechanical properties of high-modulus carbon fiber composites: Establishing modulus intermediate layer between fiber and matrix based on tailored-modulus epoxy. Compos. Sci. Technol. 2018, 163, 26–33. [Google Scholar] [CrossRef]

- Huang, X. Fabrication and properties of carbon fibers. Materials 2009, 2, 2369–2403. [Google Scholar] [CrossRef]

- Pichler, D.; Mazumdar, S.; Benevento, M.; Seneviratine, W.; Liang, R.; Witten, E. The Carbon Fiber Market, Composites Manufacturing: 2020 State of the Industry Report, January–February Issue, 2020. Available online: http://compositesmanufacturingmagazine.com/2020/01/2020-state-of-the-industry-report/2/ (accessed on 3 January 2020).

- Witik, R.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Gopalraj, S.K.; Kärki, T. A review on the recycling of waste arbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2. [Google Scholar] [CrossRef]

- Yang, P.; Zhou, Q.; Li, X.Y.; Yang, K.K.; Wang, Y.Z. Chemical recycling of fiber-reinforced epoxy resin using a polyethylene glycol/NaOH system. J. Reinf. Plast. Compos. 2014, 33, 2106–2114. [Google Scholar] [CrossRef]

- Tomioka, M.; Ishikawa, T.; Okuyama, K.; Tanaka, T. Recycling of carbon-fiber-reinforced polypropylene prepreg waste based on palletization process. J. Compos. Mater. 2017, 51, 3847–3858. [Google Scholar] [CrossRef]

- Cauich-Cupul, J.I.; Perez-Pacheco, E.; Valadez-Gonzalez, A.; Herrera-Franco, P.J. Effect of moisture absorption on the micromechanical behavior of carbon fiber/epoxy matrix composites. J. Mater. Sci. 2013, 48, 1873–1882. [Google Scholar] [CrossRef]

- Eslami, S.; Hanorbakhsh-Raouf, A.; Eslami, S. Effects of moisture absorption on degradation of E-glass fiber reinforced Vinyl Ester composite pipes and modelling of transient moisture diffusion using finite element analysis. Corros. Sci. 2015, 90, 168–175. [Google Scholar] [CrossRef]

- Tsai, Y.I.; Bosze, E.J.; Barjasteh, E.; Nutt, S.R. Influence of hygrothermal environment on thermal and mechanical properties of carbon fiber/fiberglass hybrid composites. Compos. Sci. Technol. 2009, 69, 432–437. [Google Scholar] [CrossRef]

- Mahdi, A.S.; Mohsin, N.R. Water absorption and fatigue life of an Epoxy composite reinforced by glass fiber. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 454. [Google Scholar]

- Wang, L.; Wang, M.; Guo, M.; Ye, X.; Ding, T.; Liu, D. Numerical Simulation of Water Absorption and Swelling in Dehulled Barley Grains during Canned Porridge Cooking. Processes 2018, 6, 230–243. [Google Scholar] [CrossRef]

- Shiyuan, H.; Junjie, W.; Zhenfeng, Q.; Kai, K. Effects of cyclic wetting-drying conditions on elastic modulus and compressive strength of sandstone and mudstone. Processes 2018, 6, 234–250. [Google Scholar]

- Espert, A.; Francisco, V.; Sigbritt, K. Comparison of water absorption in natural cellulosic fibres from wood and one-year crops in polypropylene composites and its influence on their mechanical properties. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1267–1276. [Google Scholar] [CrossRef]

- Mohebby, B.; Younesi, H.; Ghotbifar, A.; Kazemi-Najafi, S. Water and moisture absorption and thickness swelling behavior in polypropylene/wood flour/glass fiber hybrid composites. J. Reinf. Plast. Compos. 2009, 29, 830–839. [Google Scholar] [CrossRef]

- Tuncdemir, A.R.; Aykent, F. Effect of fibers on the color change and stability of resin composites after accelerated aging. Dent. Mater. J. 2012, 31, 872–878. [Google Scholar] [CrossRef]

- Dhakal, H.N.; MacMullen, J.; Zhang, Z. Chapter 5: Moisture measurement and effects on the properties of marine composites. In Marine Applications of Advanced Fibre-Reinforced Composites; Woodhead Publishing: Cambridge, UK, 2015; pp. 103–122. [Google Scholar]

- Oliveux, G.; Bailleul, J.L.; La Salle, E.L.G.; Lefѐvre, N.; Biotteau, G. Recycling of glass fibre reinforced composites using subcritical hydrolysis: Reaction mechanisms and kinetics, influence of the chemical structure of the resin. Polym. Degrad. Stab. 2013, 98, 785–800. [Google Scholar] [CrossRef]

- Uthman, A.; Xian, G.; Thomas, S.; Wang, Y.; Zheng, Q.; Liu, X. Durability of an epoxy resin and its carbon fiber-reinforced polymer composite upon immersion in water, acidic, and alkaline solutions. Polymer 2020, 12, 614–637. [Google Scholar] [CrossRef] [PubMed]

- Masuelli, M.A. Chapter 1: Introduction of Fibre-Reinforced Polymers—Polymers and Composites: Concepts, Properties and Processes. In Fiber Reinforced Polymers—The Technology Applied for Concrete Repair; INTECH Open Access Publisher: Rijeka, Croatia, 2013. [Google Scholar]

- Colquhoun, R.; Tanner, K.E. Mechanical behaviour of degradable phosphate glass fibres and composites—A review. Biomed. Mater. 2016, 11, 014105. [Google Scholar] [CrossRef]

- Sethi, S.; Ray, B.C. Fibre/Polymer Interface Integrity on Structural Strength and Stability. Microscopy 2019. [Google Scholar]

- Available online: https://analyticalscience.wiley.com/do/10.1002/micro.2983/full/ (accessed on 18 September 2019).

- Zainal, Z.; Ismail, H. Polypropylene/(waste tire dust)/(short glass fiber composites): Effects of silane coupling agent and dynamic vulcanization. J. Vinyl Addit. Technol. 2011, 17, 245–253. [Google Scholar]

- Babu, R.R.; Naskar, K. Recent developments on thermoplastic elastomers by dynamic vulcanization. In Advanced Rubber Composites; Springer: Berlin/Heidelberg, Germany, 2010; pp. 219–247. [Google Scholar]

- Yamamoto, G.; Koizumi, K.; Okabe, T. Tensile Strength of Unidirectional Carbon Fiber-Reinforced Plastic Composites. In Strength of Materials; IntechOpen: London, UK, 2019. [Google Scholar]

- Okabe, T.; Takeda, N. Size effect on tensile strength of unidirectional CFRP composites—Experiment and simulation. Compos. Sci. Technol. 2002, 62, 2053–2064. [Google Scholar] [CrossRef]

- Vanegas-Jaramillo, J.D.; Patiño-Arcila, I.D. Fragmentation model for the tensile response of unidirectional composites based on the critical number of fiber breaks and the correction of the fiber-matrix interfacial strength. Lat. Am. J. Solids Struct. 2019, 16. [Google Scholar] [CrossRef]

- Truong, G.T.; Tran, H.V.; Choi, K.K. Tensile Behavior of Carbon Fiber-Reinforced Polymer Composites Incorporating Nanomaterials after Exposure to Elevated Temperature. J. Nanomater. 2019, 2019, 1–14. [Google Scholar] [CrossRef]

| Unit | PP | GF-CPW-PP | CPW-PP | GF-PP | |

|---|---|---|---|---|---|

| Diffusion Coefficient, DC, ×10−3 | mm2/s | 4.0 | 4.6 | 3.9 | 3.8 |

| Maximum Moisture Content, Mm | % | 0.5 | 3.4 | 3.2 | 4.7 |

| Unit | PP | GF-CPW-PP | CPW-PP | GF-PP | |

|---|---|---|---|---|---|

| Sorption Coefficient, SP | g/g | 0.0785 | 0.4478 | 0.4075 | 0.5985 |

| Permeability Coefficient, Pc | mm2/s | 0.0003 | 0.0021 | 0.0016 | 0.0023 |

| Tensile Strength (MPa) | Elastic Modulus (MPa) | Elongation at Break (%) | ||

|---|---|---|---|---|

| PP | Control | 28.8 ± 1.4 | 203.8 ± 8.1 | 28.0 ± 3.1 |

| DW | 21.5 ± 1.0 | 157.7 ± 6.3 | 23.0 ± 2.5 | |

| GF-CPW-PP | Control | 78.5 ± 2.3 | 640.0 ± 51.2 | 19.0 ± 2.1 |

| DW | 69.3 ± 2.0 | 573.3 ± 45.9 | 18.7 ± 1.7 | |

| CPW-PP | Control | 73.2 ± 5.8 | 520.0 ± 36.4 | 19.5 ± 1.8 |

| DW | 62.7 ± 5.1 | 420.0 ± 29.4 | 17.5 ± 1.4 | |

| GF-PP | Control | 69.5 ± 2.1 | 466.6 ± 32.6 | 18.0 ± 1.1 |

| DW | 55.1 ± 1.6 | 413.3 ± 28.9 | 17.2 ± 1.0 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nosbi, N.; Ahmad Marzuki, H.F.; Zakaria, M.R.; Wan Ali, W.F.F.; Javed, F.; Ibrar, M. Structure Property Investigation of Glass-Carbon Prepreg Waste-Polymer Hybrid Composites Degradation in Water Condition. Processes 2020, 8, 1434. https://doi.org/10.3390/pr8111434

Nosbi N, Ahmad Marzuki HF, Zakaria MR, Wan Ali WFF, Javed F, Ibrar M. Structure Property Investigation of Glass-Carbon Prepreg Waste-Polymer Hybrid Composites Degradation in Water Condition. Processes. 2020; 8(11):1434. https://doi.org/10.3390/pr8111434

Chicago/Turabian StyleNosbi, Norlin, Haslan Fadli Ahmad Marzuki, Muhammad Razlan Zakaria, Wan Fahmin Faiz Wan Ali, Fatima Javed, and Muhammad Ibrar. 2020. "Structure Property Investigation of Glass-Carbon Prepreg Waste-Polymer Hybrid Composites Degradation in Water Condition" Processes 8, no. 11: 1434. https://doi.org/10.3390/pr8111434

APA StyleNosbi, N., Ahmad Marzuki, H. F., Zakaria, M. R., Wan Ali, W. F. F., Javed, F., & Ibrar, M. (2020). Structure Property Investigation of Glass-Carbon Prepreg Waste-Polymer Hybrid Composites Degradation in Water Condition. Processes, 8(11), 1434. https://doi.org/10.3390/pr8111434