Chaotic Mixing Analyzing in Continuous Mixer with Tracing the Morphology Development of a Polymeric Drop

Abstract

1. Introduction

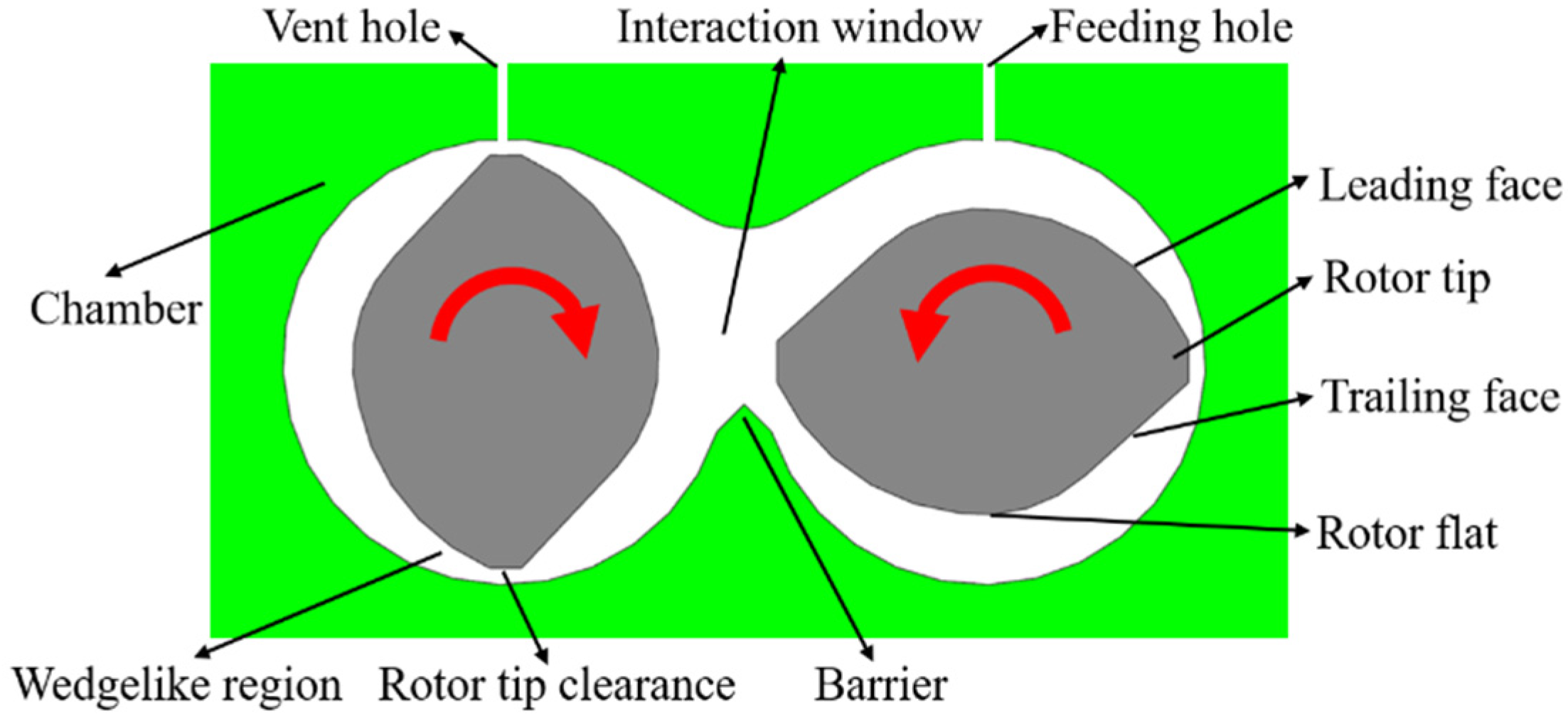

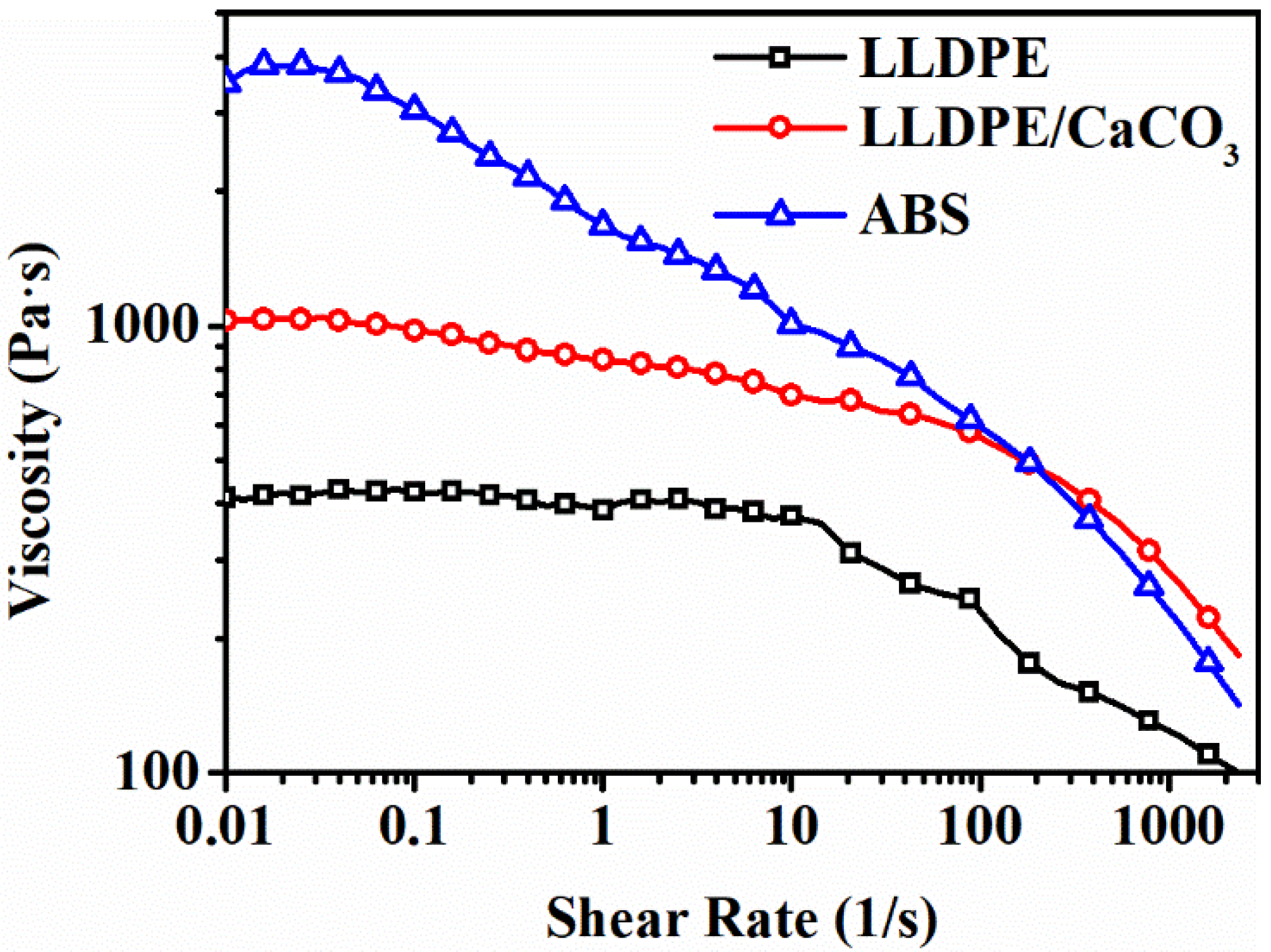

2. Materials and Methods

3. Results

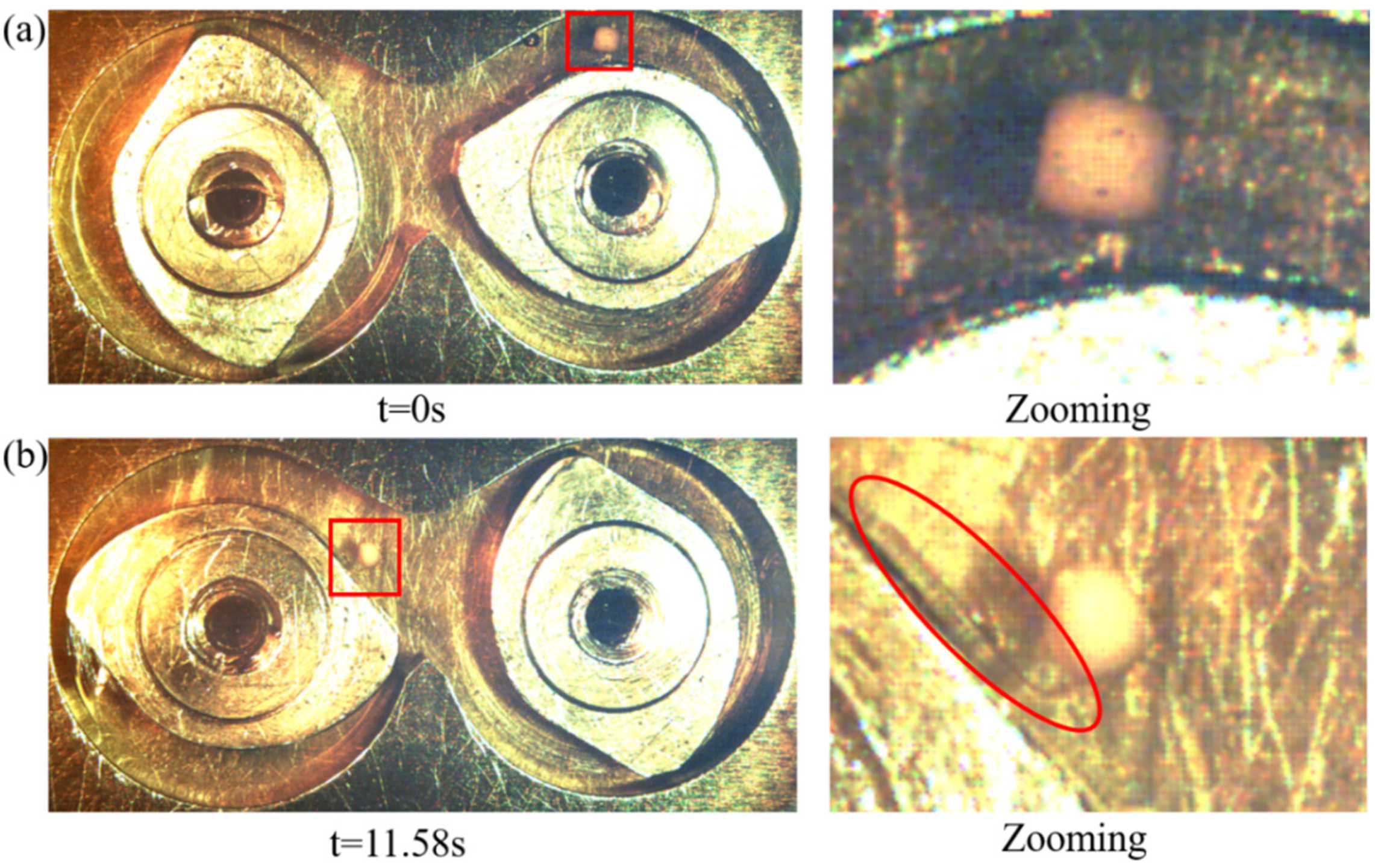

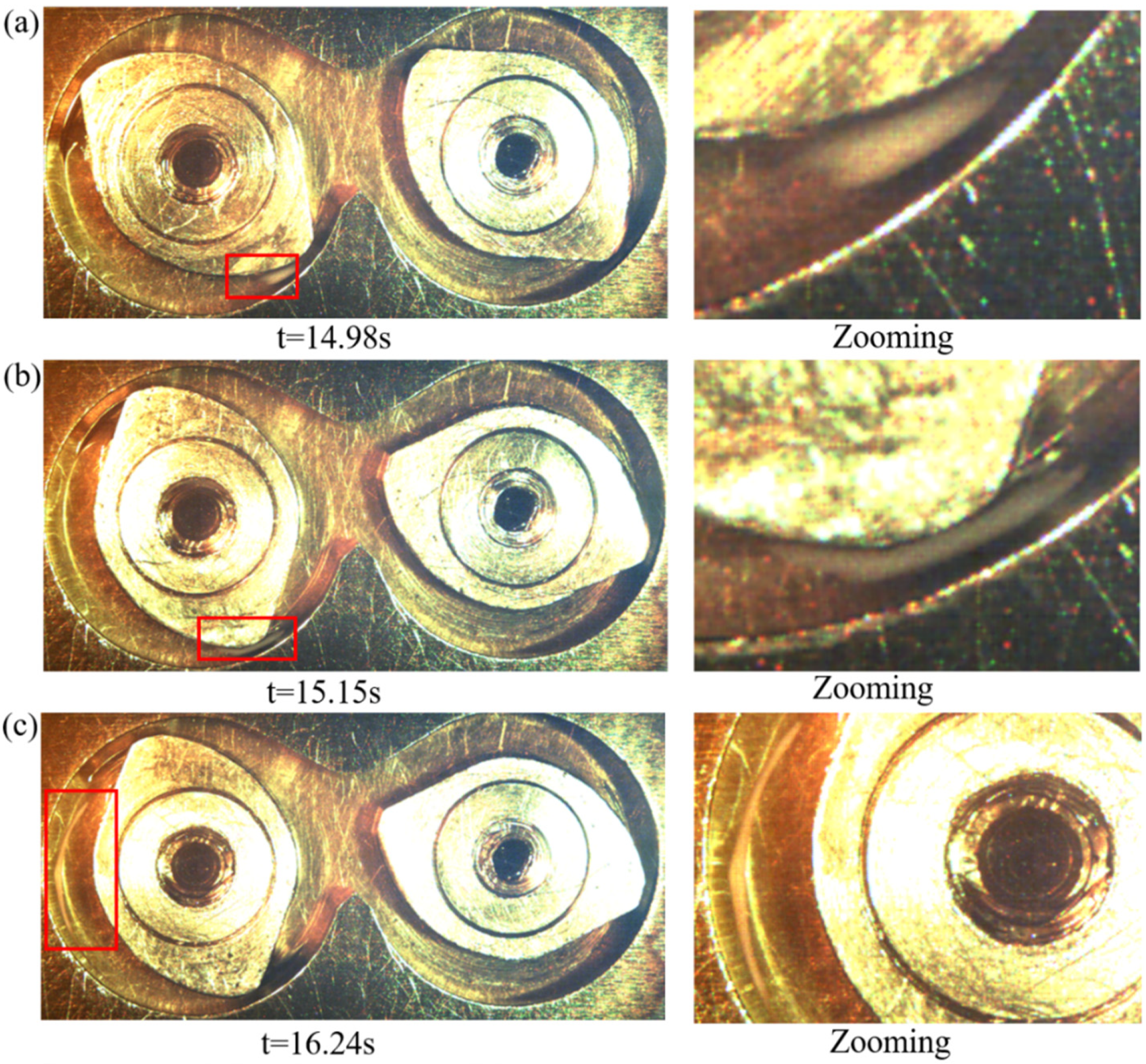

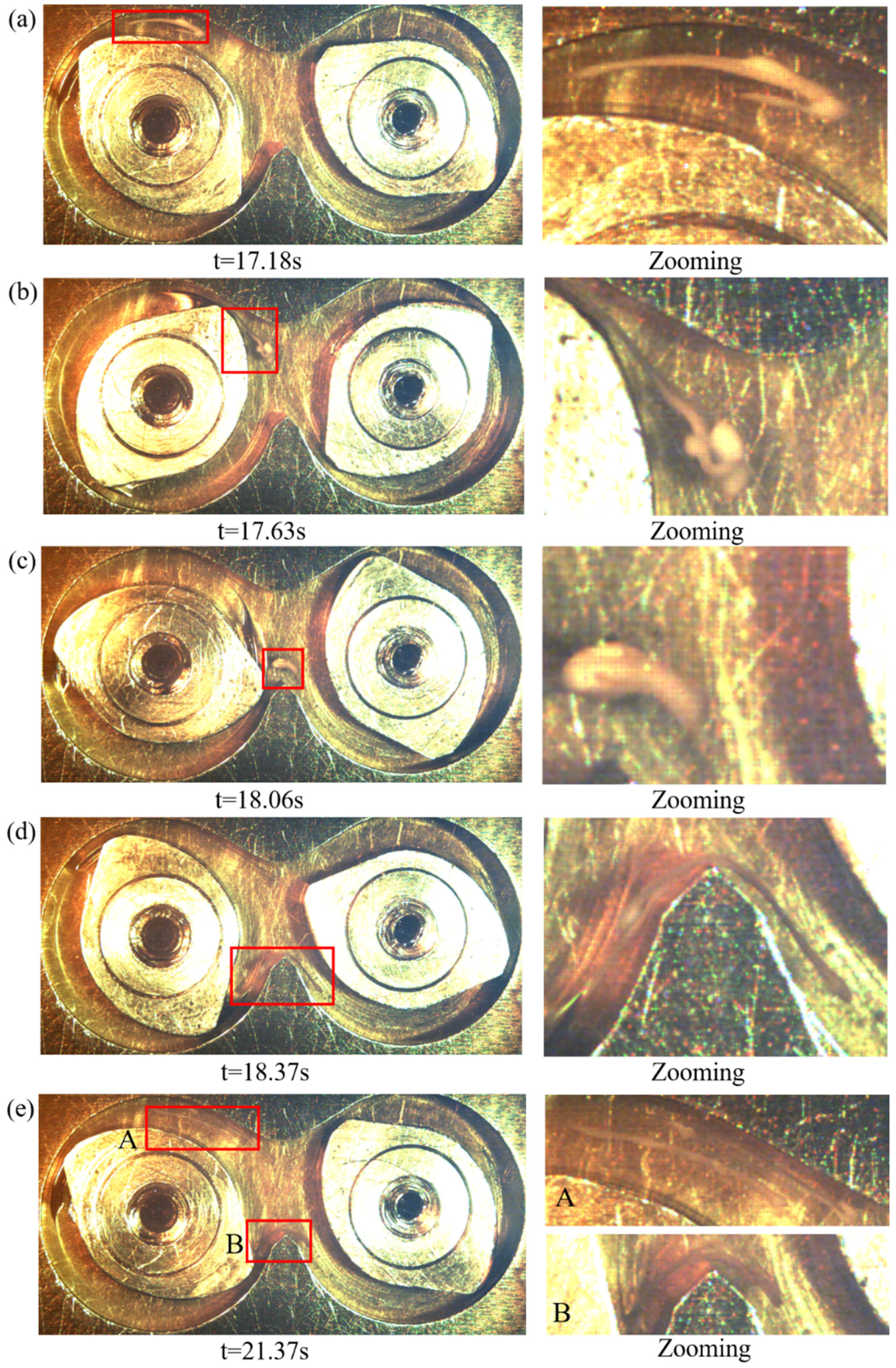

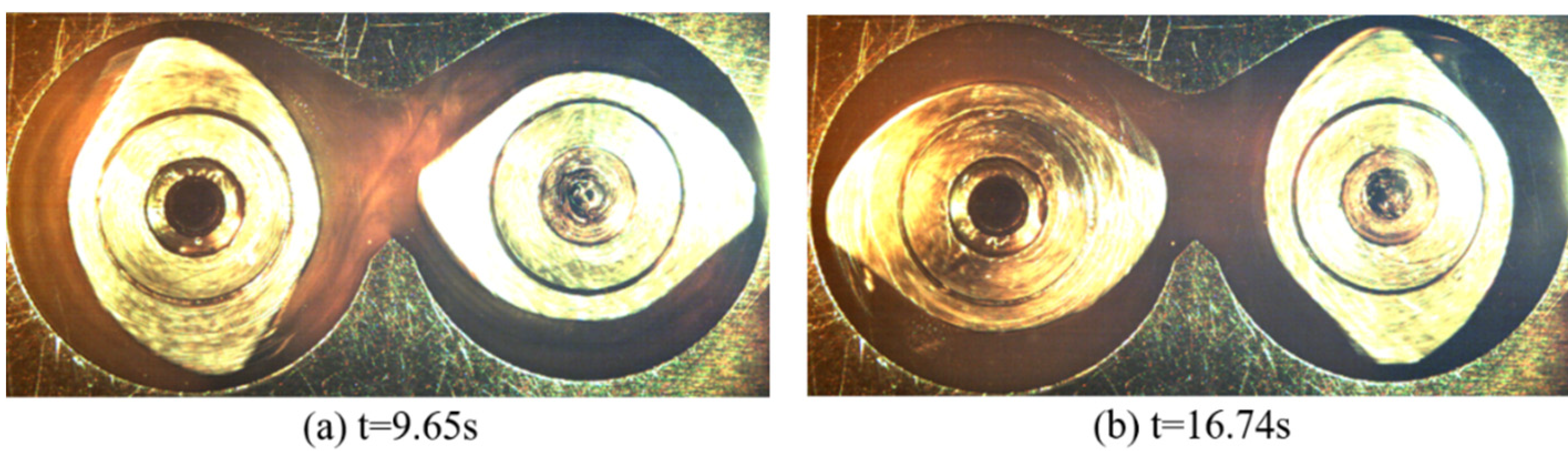

3.1. ABS Drop at 28.7 rpm

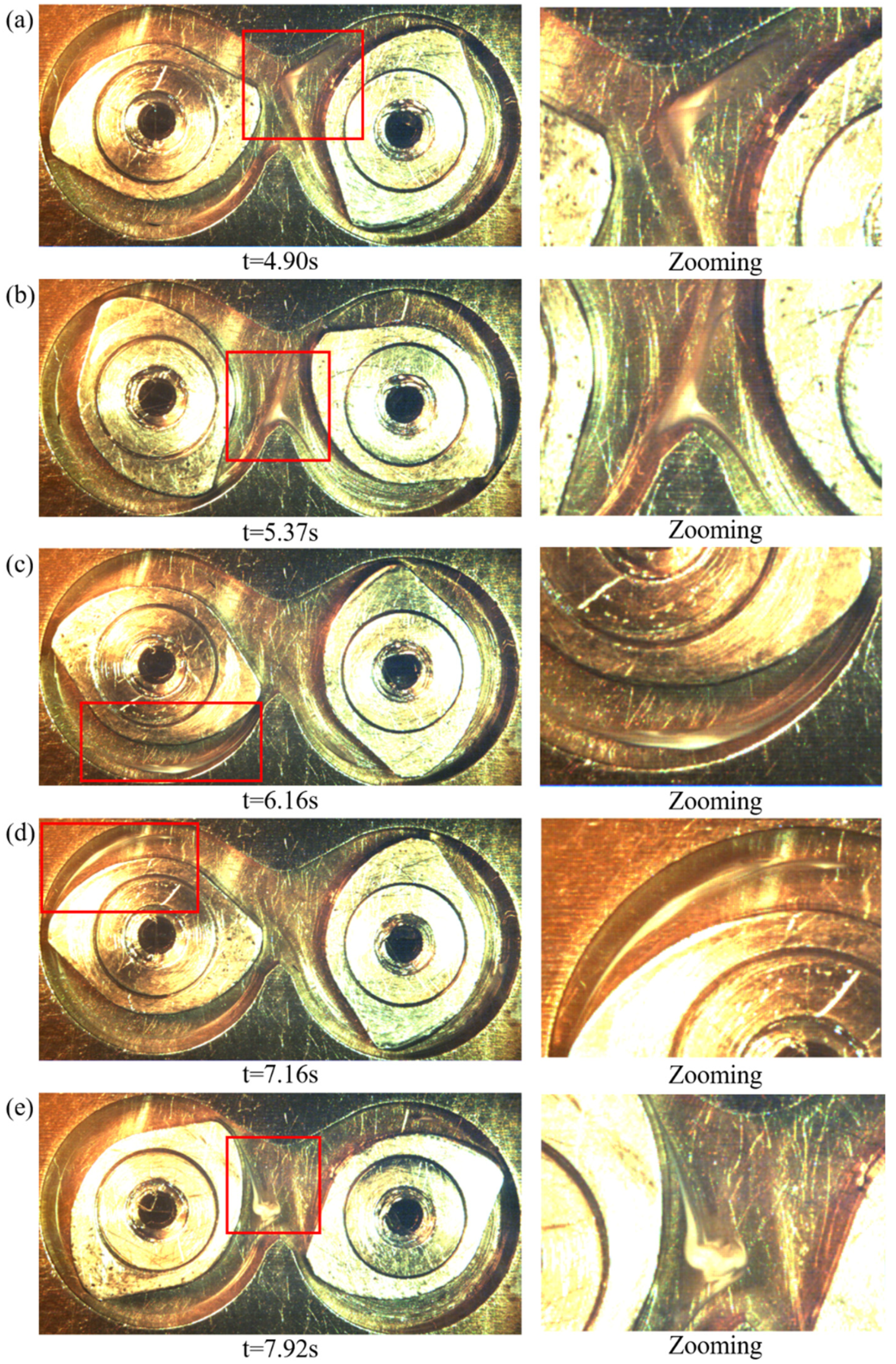

3.2. ABS Drop at 114.8 rpm

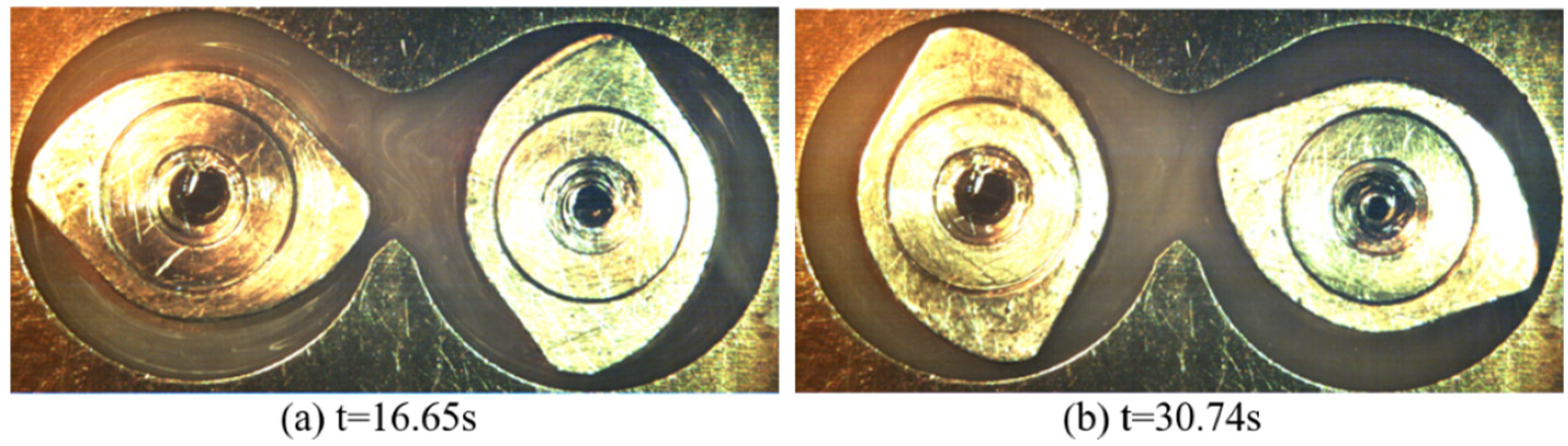

3.3. LLDPE/CaCO3 Drop at 28.7 rpm

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- García-Masabet, V.; Pérez, O.; Cailloux, J.; Abt, T.; Sánchez-Soto, M.; Carrasco, F.; Maspoch, L. PLA/PA Bio-blends: Induced morphology by extrusion. Polymers 2020, 12, 10. [Google Scholar] [CrossRef]

- Yin, B.; Zhao, Y.; Yu, R.; An, H.; Yang, M. Morphology Development of PC/PE blends during compounding in a twin-screw extruder. Poly. Eng. Sci. 2007, 47, 14–25. [Google Scholar] [CrossRef]

- Dong, T.; Jiang, S.; Wu, J.; Liu, H.; He, Y. Simulation of flow and mixing for highly viscous fluid in a twin screw extruder with a conveying element using parallelized smoothed particle hydrodynamics. Chem. Eng. Sci. 2020, 212. [Google Scholar] [CrossRef]

- Heeley, L.; Gough, T.; Hughes, J.; Bras, W.; Rieger, J.; Ryan, J. Effect of processing parameters on the morphology development during extrusion of polyethylene tape: An in-line small-angle X-ray scattering (SAXS) study. Polymer 2013, 54, 6580–6588. [Google Scholar] [CrossRef]

- Yin, B.; Lan, J.; Li, L.; Yang, M. Morphology evolution in PC/PE blends with and without compatibilization during twin-screw extrusion. Polym-Plast Technol. 2010, 49, 503–509. [Google Scholar] [CrossRef]

- Lin, B.; Mighri, F.; Huneault, A.; Sundararaj, U. Parallel breakup of polymer drops under simple shear. Macromol. Rapid Comm. 2003, 24, 783–788. [Google Scholar] [CrossRef]

- Lin, B.; Sundararaj, U.; Mighri, F.; Huneault, A. Erosion and breakup of polymer drops under simple shear in high viscosity ratio systems. Poly. Eng. Sci. 2003, 43, 891–904. [Google Scholar] [CrossRef]

- Lin, B.; Sundararaj, U. Sheet formation during drop deformation and breakup in polyethylene/polycarbonate systems sheared between parallel plates. Polymer 2004, 45, 7605–7613. [Google Scholar] [CrossRef]

- Mighri, F.; Huneault, A. In situ visualization of drop deformation, erosion, and breakup in high viscosity ratio polymeric systems under high shearing stress conditions. J. Appl. Polym. Sci. 2006, 100, 2582–2591. [Google Scholar] [CrossRef][Green Version]

- Scott, E.; Macosko, W. Model experiments concerning morphology development during the initial stages of polymer blending. Polym. Bull. 1991, 26, 341–348. [Google Scholar] [CrossRef]

- Sundararaj, U.; Macosko, W.; Rolando, J.; Chan, T. Morphology development in polymer blends. Poly. Eng. Sci. 1992, 32, 1814–1823. [Google Scholar] [CrossRef]

- Scott, E.; Macosko, W. Morphology development during the initial stages of polymer-polymer blending. Polymer 1995, 36, 461–470. [Google Scholar] [CrossRef]

- Salahudeen, A.; Elleithy, H.; AlOthman, O.; AlZahrani, M. Comparative study of internal batch mixer such as cam, banbury and roller: Numerical simulation and experimental verification. Chem. Eng. Sci. 2011, 66, 2502–2511. [Google Scholar] [CrossRef]

- Li, H.; Sundararaj, U. Morphology development of polymer blends in extruder: The effects of compatibilization and rotation rate. Macromol. Chem. Phys. 2009, 210, 852–863. [Google Scholar] [CrossRef]

- Chen, T.; Hao, Y.; Chen, X.; Zhao, H.; Sha, J.; Ma, Y.; Xie, L. Mixing ability examination of three different rotor cross sections and rotor geometry quantification with pressurization coefficient. J. Appl. Polym. Sci. 2018, 135. [Google Scholar] [CrossRef]

- Min, K. Flow visualization of blending of elastomers and thermoplastics in an internal mixer. Adv. Polym. Tech. 1987, 7, 243–257. [Google Scholar] [CrossRef]

- Chen, H.; Sundararaj, U.; Nandakumar, K.; Wetzel, D. Erosion of polymer pellets during blending in a twin-screw extruder. AICHE J. 2006, 52, 1267–1270. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, H.; Chen, T.; Zhao, H.; Ji, H.; Ma, Y.; Sha, J.; Xie, L. The solid-state mixing characteristic of two rotor continuous mixer and its influence on microstructure of HDPE/CaCO3 composite. Polym. Compos. 2019, 40, 3296–3305. [Google Scholar] [CrossRef]

- Valsamis, N.; Canedo, L. Mixing, devolatilization, and reactive processing in the a Farrel continuous mixer. Int. Polym. Proc. 1989, 4, 247–254. [Google Scholar] [CrossRef]

- Bang, S.; White, L. New model of flow in a Farrel continuous mixer. Poly. Eng. Sci. 1997, 37, 1210–1216. [Google Scholar] [CrossRef]

- Yao, C.; Manas-Zloczower, I. Influence of design on dispersive mixing performance in an axial discharge continuous mixer-lcmax 40. Poly. Eng. Sci. 1998, 38, 936–946. [Google Scholar] [CrossRef]

- Canedo, L.; Valsamis, N. Continuous mixer. In Mixing and Compounding of Polymers: Theory and Practice, 2nd ed.; Manas-Zloczower, I., Ed.; Hanser Publishers: Cincinnati, OH, USA, 2009; pp. 1104–1138. [Google Scholar]

- Dhakal, P.; Das, R.; Poudyal, H.; Chandy, J. Numerical simulations of partially-filled rubber mixing in a 2-wing rotor-equipped chamber. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Galle, N.; White, L. Characterization of the behavior and blending performance of a continuous mixer. Int. Polym. Proc. 1999, 14, 241–246. [Google Scholar] [CrossRef]

- Lin, B.; Sundararaj, U. Visualization of poly(ether imide) and polycarbonate blending in an internal mixer. J. Appl. Polym. Sci. 2004, 92, 1165–1175. [Google Scholar] [CrossRef]

- Borzenski, J.; Valsamis, N. Optimizing mixing in the Farrel banbury mixer with wing function. Rubber World 2002, 226, 40–45. [Google Scholar]

- Avolio, R.; Gentile, G.; Avella, M.; Carfagna, C.; Errico, M. Polymer–filler interactions in PET/CaCO3 nanocomposites: Chain ordering at the interface and physical properties. Eur. Polym. J. 2013, 49, 419–427. [Google Scholar] [CrossRef]

- Avella, M.; Errico, M.; Gentile, G. PMMA based nanocomposites filled with modified CaCO3 nanoparticles. Macromol. Symp. 2007, 247, 140–146. [Google Scholar] [CrossRef]

- Avolio, R.; Castaldo, R.; Avella, M.; Cocca, M.; Gentile, G.; Fiori, S.; Errico, M. PLA-based plasticized nanocomposites: Effect of polymer/plasticizer/filler interactions on the time evolution of properties. Compos. Part. B-Eng. 2018, 152, 267–274. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.; Guo, H.; Li, G.; Ji, H.; Xie, L.; Yang, Y. Chaotic Mixing Analyzing in Continuous Mixer with Tracing the Morphology Development of a Polymeric Drop. Processes 2020, 8, 1308. https://doi.org/10.3390/pr8101308

Chen T, Guo H, Li G, Ji H, Xie L, Yang Y. Chaotic Mixing Analyzing in Continuous Mixer with Tracing the Morphology Development of a Polymeric Drop. Processes. 2020; 8(10):1308. https://doi.org/10.3390/pr8101308

Chicago/Turabian StyleChen, Tao, Hao Guo, Guo Li, Huajian Ji, Linsheng Xie, and Yu Yang. 2020. "Chaotic Mixing Analyzing in Continuous Mixer with Tracing the Morphology Development of a Polymeric Drop" Processes 8, no. 10: 1308. https://doi.org/10.3390/pr8101308

APA StyleChen, T., Guo, H., Li, G., Ji, H., Xie, L., & Yang, Y. (2020). Chaotic Mixing Analyzing in Continuous Mixer with Tracing the Morphology Development of a Polymeric Drop. Processes, 8(10), 1308. https://doi.org/10.3390/pr8101308