Pelletization of Sunflower Seed Husks: Evaluating and Optimizing Energy Consumption and Physical Properties by Response Surface Methodology (RSM)

Abstract

1. Introduction

2. Materials and Methods

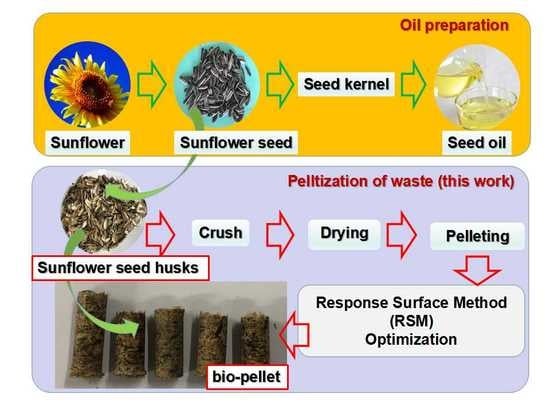

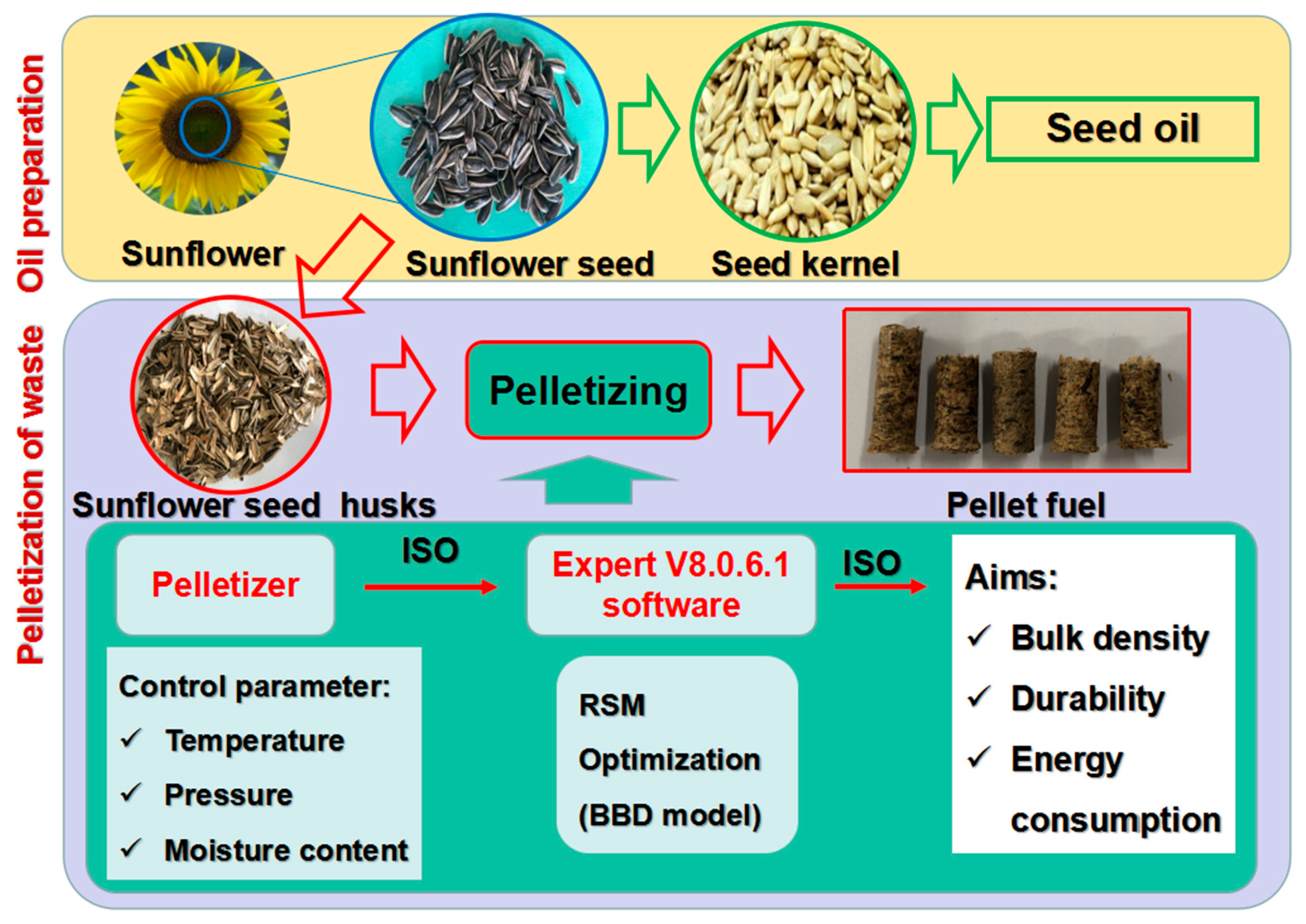

2.1. Feedstock of Sunflower Seed Husk and Methodology

2.2. Pelletization and Sample Preparation

2.3. Energy Consumption and Characterization of Pellets

2.4. Analysis of Response Surface Methodology

2.5. Statistics Analysis

3. Results and Discussions

3.1. Composition of Raw Materials

3.2. Effects of Different Factors on Physical Properties of Pellets

3.2.1. Effect of Temperature on Physical Properties of Sample

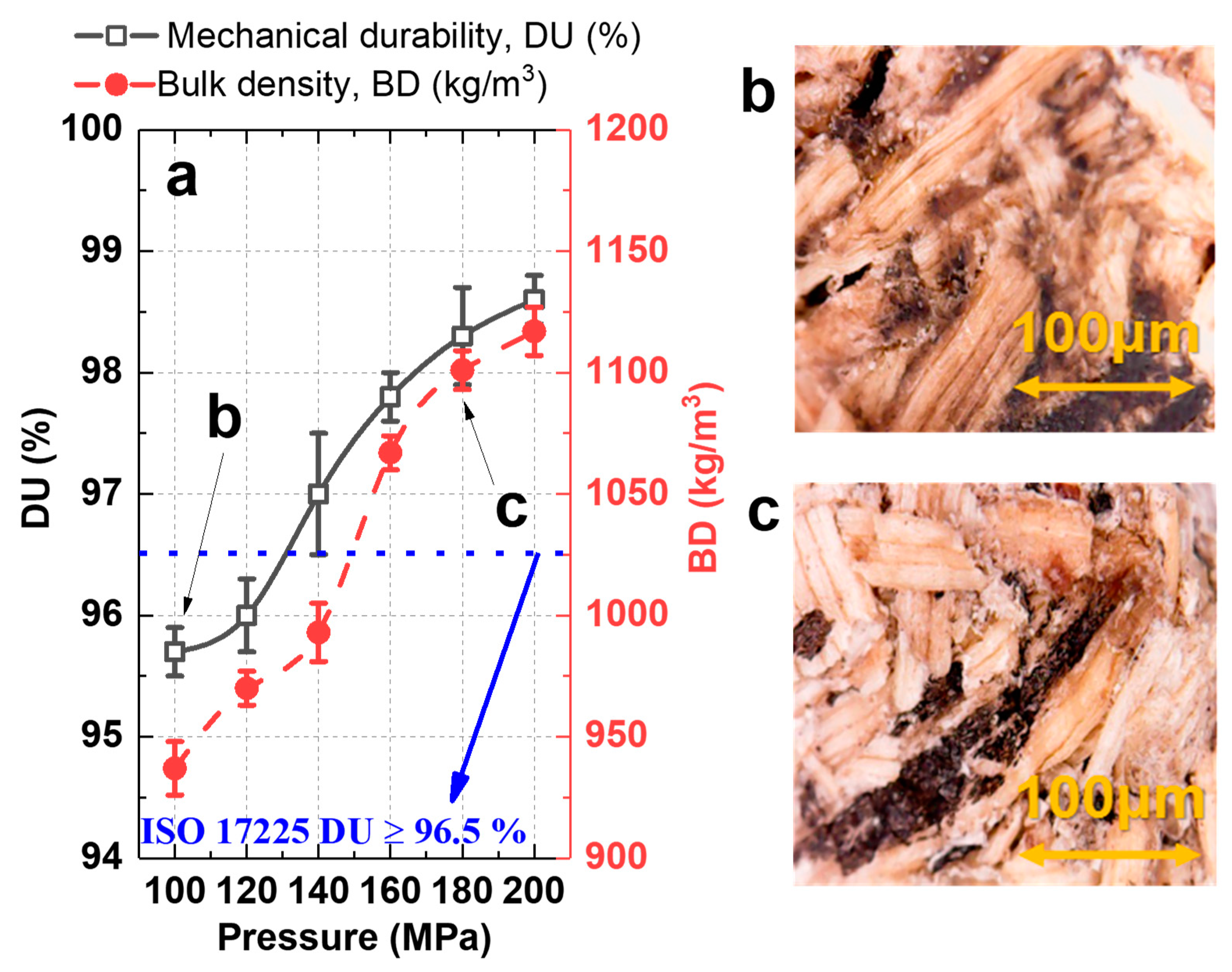

3.2.2. Effect of Pressure on Physical Properties of Sample

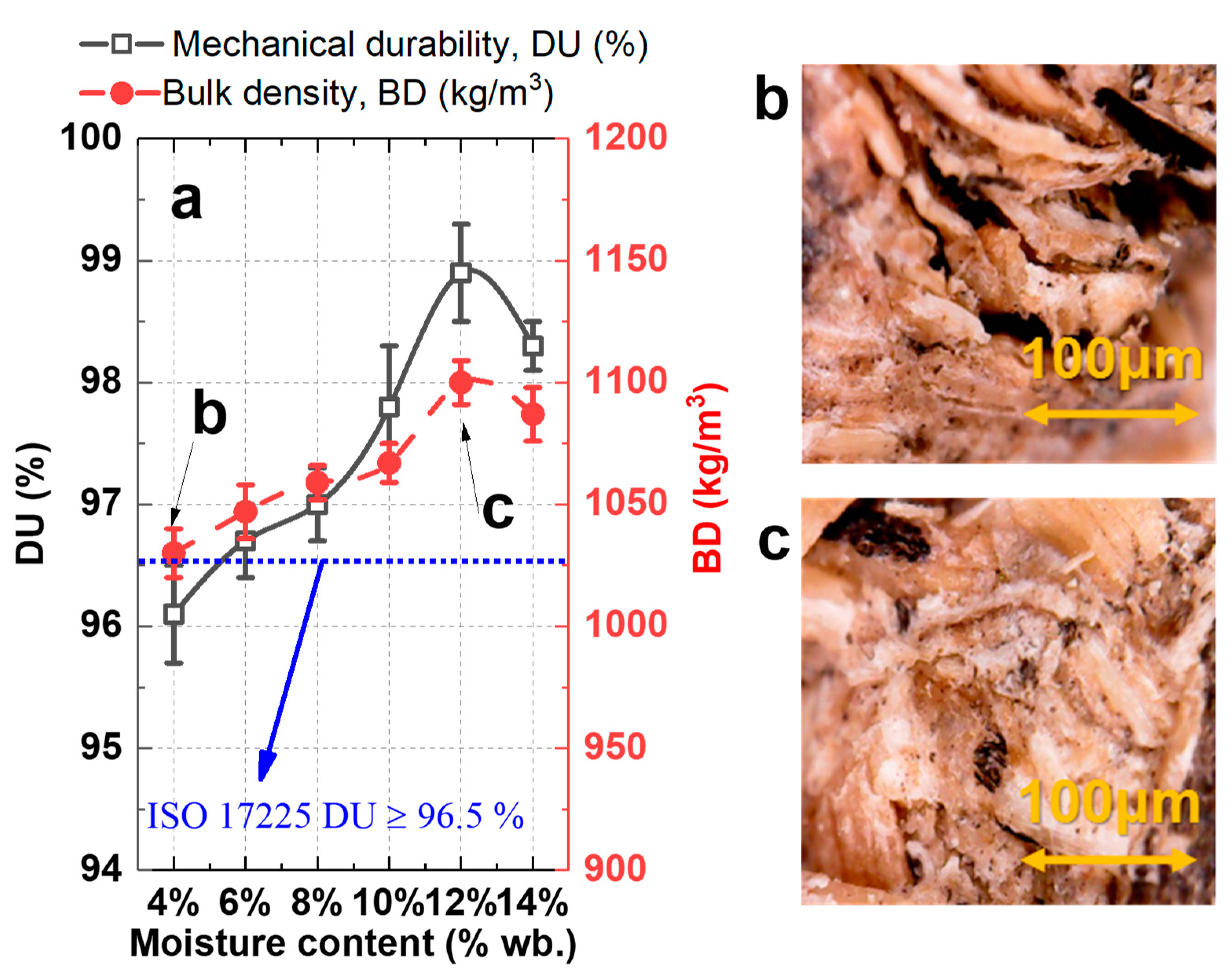

3.2.3. Effect of Moisture Content on Physical Properties of Sample

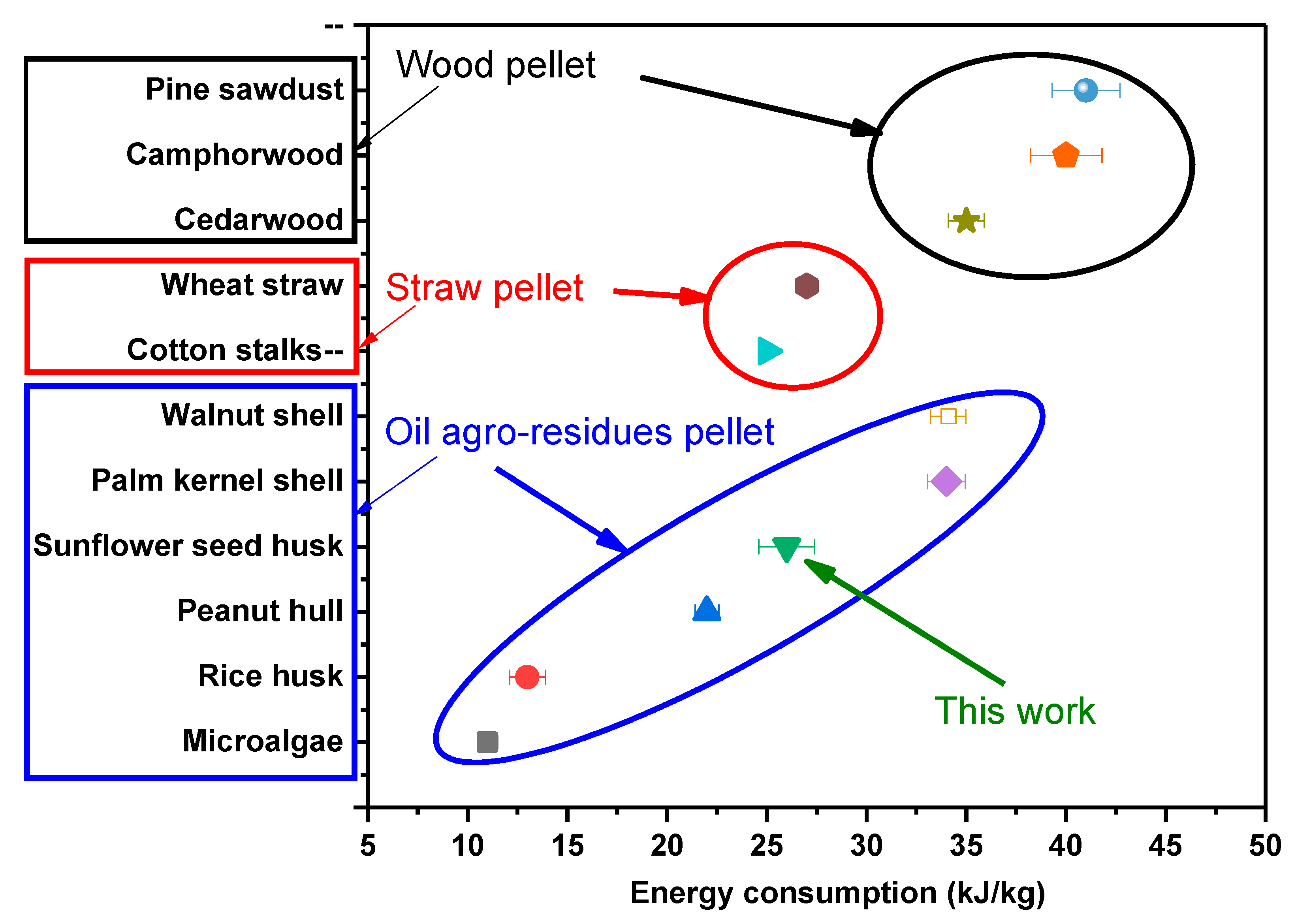

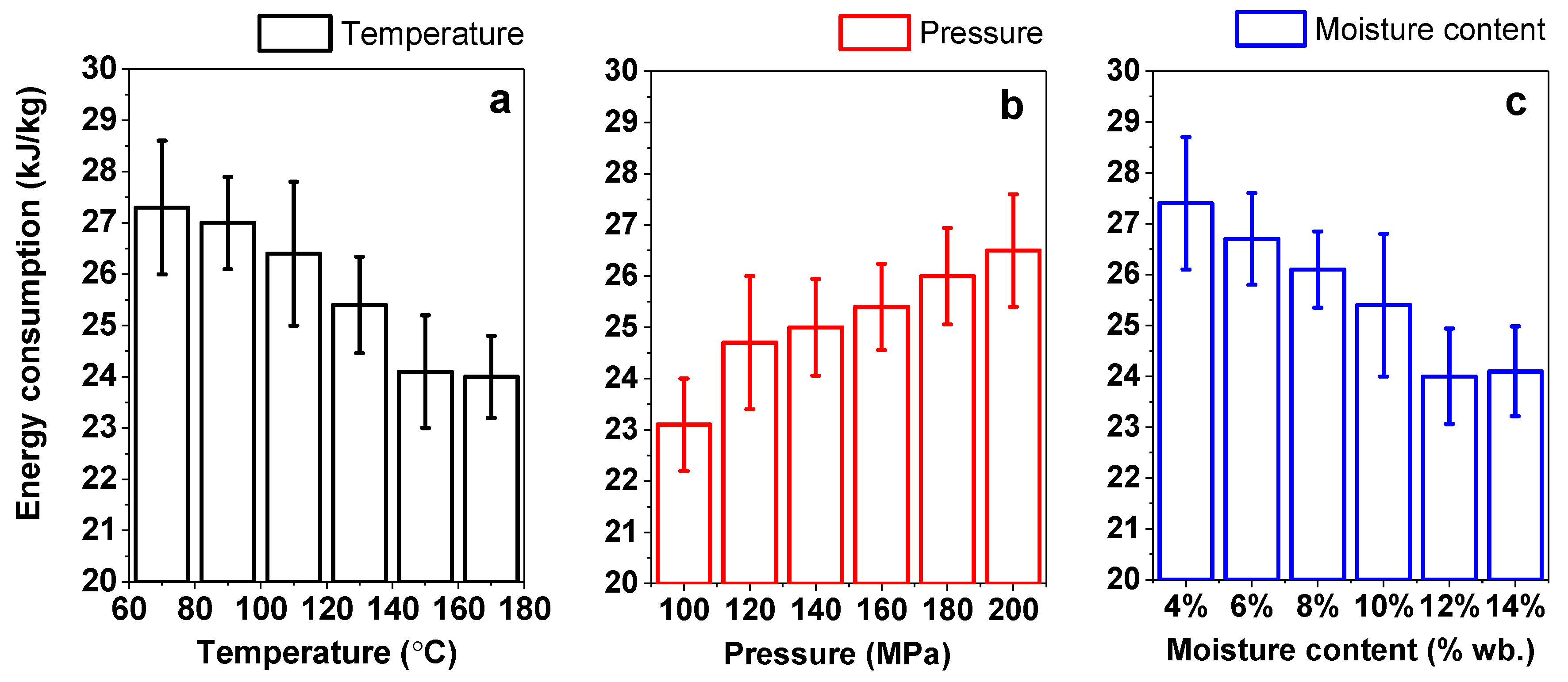

3.3. Effects of Different Factors on Energy Consumption of Pelletization

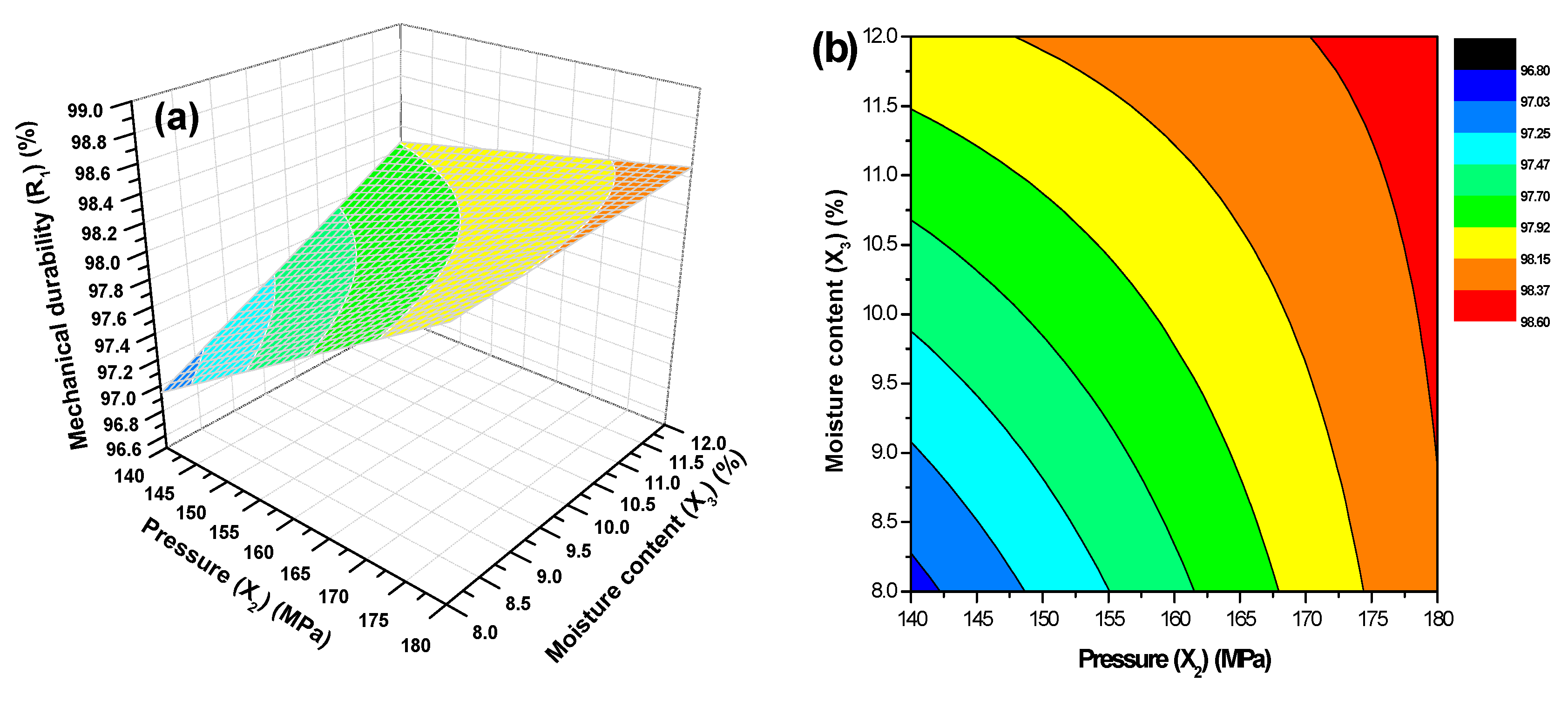

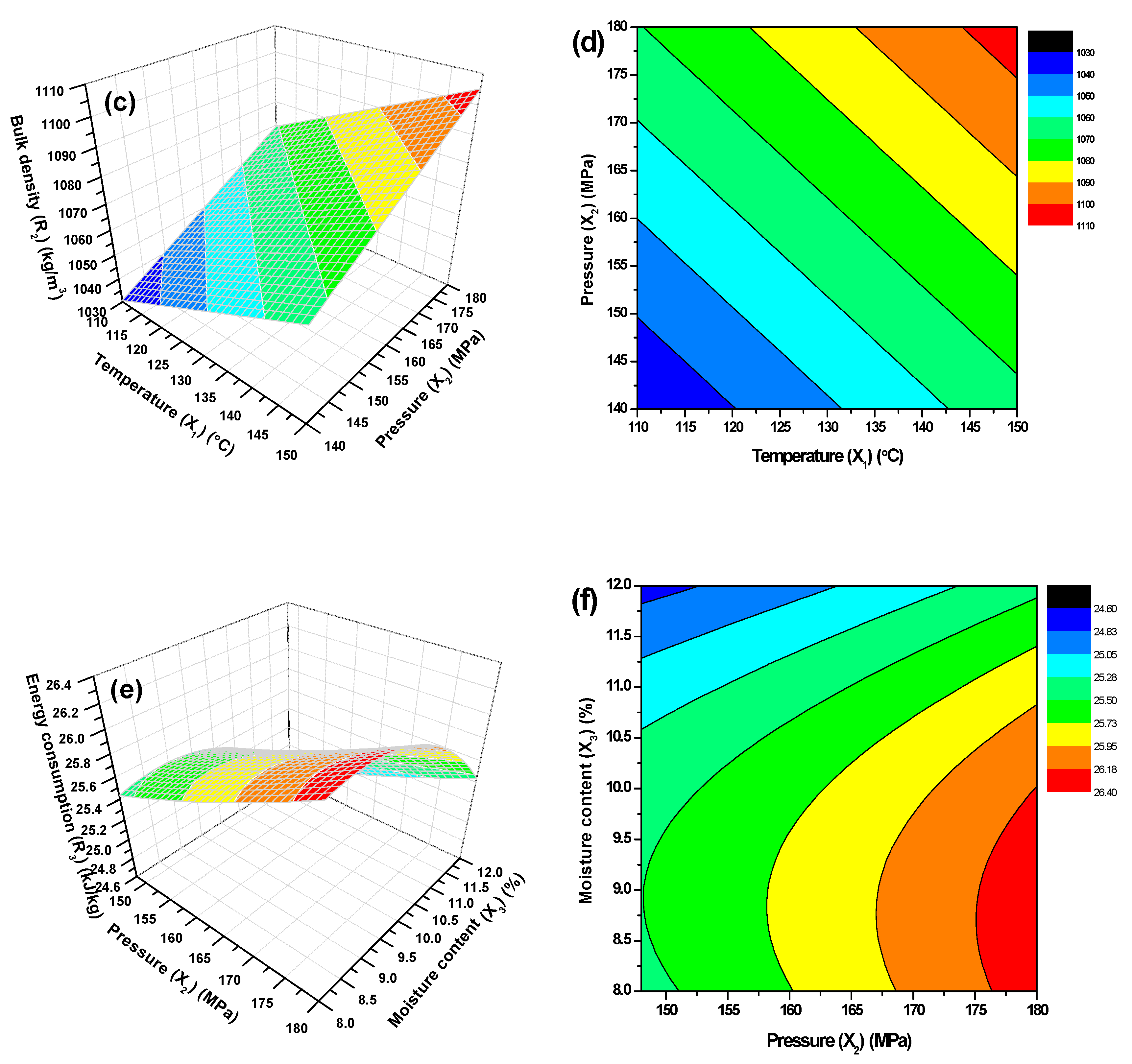

3.4. RSM Optimization of Energy Consumption and Physical Properties

3.5. Comparison of Characterization of Raw Materials Based on ISO Standard

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Praeger, F.; Paczkowski, S.; Sailer, G.; Derkyi, N.S.A.; Pelz, S. Biomass sources for a sustainable energy supply in Ghana—A case study for Sunyani. Renew. Sustain. Energy Rev. 2019, 107, 413–424. [Google Scholar] [CrossRef]

- Li, Q.; Qi, J.; Jiang, J.; Wu, J.; Duan, L.; Wang, S.; Hao, J. Significant reduction in air pollutant emissions from household cooking stoves by replacing raw solid fuels with their carbonized products. Sci. Total Environ. 2019, 650, 653–660. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Bentsen, N.S.; Nilsson, D.; Larsen, S. Agricultural residues for energy—A case study on the influence of resource availability, economy and policy on the use of straw for energy in Denmark and Sweden. Biomass Bioenergy 2018, 108, 278–288. [Google Scholar] [CrossRef]

- Schroeder, P.; Beckers, B.; Daniels, S.; Gnaedinger, F.; Maestri, E.; Marmiroli, N.; Mench, M.; Millan, R.; Obermeier, M.M.; Oustriere, N.; et al. Intensify production, transform biomass to energy and novel goods and protect soils in Europe—A vision how to mobilize marginal lands. Sci. Total Environ. 2018, 616, 1101–1123. [Google Scholar] [CrossRef] [PubMed]

- Azargohar, R.; Soleimani, M.; Nosran, S.; Bond, T.; Karunakaran, C.; Dalai, A.K.; Tabil, L.G. Thermo-physical characterization of torrefied fuel pellet from co-pelletization of canola hulls and meal. Ind. Crop. Prod. 2019, 128, 424–435. [Google Scholar] [CrossRef]

- Mostafa, M.E.; Hu, S.; Wang, Y.; Su, S.; Hu, X.; Elsayed, S.A.; Xiang, J. The significance of pelletization operating conditions: An analysis of physical and mechanical characteristics as well as energy consumption of biomass pellets. Renew. Sustain. Energy Rev. 2019, 105, 332–348. [Google Scholar] [CrossRef]

- Dai, X.; Theppitak, S.; Yoshikawa, K. Pelletization of Carbonized Wood Using Organic Binders with Biomass Gasification Residue as an Additive. Energy Fuels 2019, 33, 323–329. [Google Scholar] [CrossRef]

- Adhikari, B.B.; Chae, M.; Zhu, C.; Khan, A.; Hayfield, D.; Choi, P.; Bressler, D.C. Pelletization of Torrefied Wood Using a Proteinaceous Binder Developed from Hydrolyzed Specified Risk Materials. Processes 2019, 7, 229. [Google Scholar] [CrossRef]

- Frodeson, S.; Berghel, J.; Stahl, M.; Granstrom, K.; Romlin, C.; Thelander, A. The Potential for a Pellet Plant to Become a Biorefinery. Processes 2019, 7, 233. [Google Scholar] [CrossRef]

- Krizan, P.; Matus, M.; Soos, L.; Beniak, J. Behavior of Beech Sawdust during Densification into a Solid Biofuel. Energies 2015, 8, 6382–6398. [Google Scholar] [CrossRef]

- Miranda, M.T.; Sepulveda, F.J.; Arranz, J.I.; Montero, I.; Rojas, C.V. Physical-energy characterization of microalgae Scenedesmus and experimental pellets. Fuel 2018, 226, 121–126. [Google Scholar] [CrossRef]

- Miranda, M.T.; Sepulveda, F.J.; Arranz, J.I.; Montero, I.; Rojas, C.V. Analysis of pelletizing from corn cob waste. J. Environ. Manag. 2018, 228, 303–311. [Google Scholar] [CrossRef] [PubMed]

- Djatkov, D.; Martinov, M.; Kaltschmitt, M. Influencing parameters on mechanical-physical properties of pellet fuel made from corn harvest residues. Biomass Bioenergy 2018, 119, 418–428. [Google Scholar] [CrossRef]

- Azocar, L.; Hermosilla, N.; Gay, A.; Rocha, S.; Diaz, J.; Jara, P. Brown pellet production using wheat straw from southern cities in Chile. Fuel 2019, 237, 823–832. [Google Scholar] [CrossRef]

- Stelte, W.; Barsberg, S.T.; Clemons, C.; Morais, J.P.S.; de Freitas Rosa, M.; Sanadi, A.R. Coir Fibers as Valuable Raw Material for Biofuel Pellet Production. Waste Biomass Valorization 2018, 9, 1–9. [Google Scholar] [CrossRef]

- Larsson, S.H.; Samuelsson, R. Prediction of ISO 17831-1:2015 mechanical biofuel pellet durability from single pellet characterization. Fuel Process. Technol. 2017, 163, 8–15. [Google Scholar] [CrossRef]

- Barbanera, M.; Lascaro, E.; Stanzione, V.; Esposito, A.; Altieri, R.; Bufacchi, M. Characterization of pellets from mixing olive pomace and olive tree pruning. Renew. Energy 2016, 88, 185–191. [Google Scholar] [CrossRef]

- Zhang, Q.; Shi, Z.; Zhang, P.; Zhang, M.; Li, Z.; Chen, X.; Zhou, J. Ultrasonic-Assisted Pelleting of Sorghum Stalk: Predictive Models for Pellet Density and Durability Using Multiple Response Surface Methodology. Energies 2018, 11, 1214. [Google Scholar] [CrossRef]

- Ramezanzade, M.; Moghaddam, A.G. Optimizing the Production Parameters for Pellets Made from Pistachio Tree Pruning Using Multi-Response Optimization. Waste Biomass Valorization 2018, 9, 1213–1221. [Google Scholar] [CrossRef]

- Gonzalez-Garcia, S.; Bacenetti, J. Exploring the production of bio-energy from wood biomass. Italian case study. Sci. Total Environ. 2019, 647, 158–168. [Google Scholar] [CrossRef] [PubMed]

- Moreno-Lopez, M.; Alarcon-Herrera, M.T.; Martin-Dominguez, I.R. Feasibility of Pelletizing Forest Residues in Northern Mexico. Waste Biomass Valorization 2017, 8, 923–932. [Google Scholar] [CrossRef]

- Lisowski, A.; Pajor, M.; Swietochowski, A.; Dabrowska, M.; Klonowski, J.; Mieszkalski, L.; Ekielski, A.; Stasiak, M.; Piatek, M. Effects of moisture content, temperature, and die thickness on the compaction process, and the density and strength of walnut shell pellets. Renew. Energy 2019, 141, 770–781. [Google Scholar] [CrossRef]

- Bai, X.; Wang, G.; Gong, C.; Yu, Y.; Liu, W.; Wang, D. Co-pelletizing characteristics of torrefied wheat straw with peanut shell. Bioresour. Technol. 2017, 233, 373–381. [Google Scholar] [CrossRef] [PubMed]

- Lam, P.S.; Lam, P.Y.; Sokhansanj, S.; Lim, C.J.; Bi, X.T.; Stephen, J.D.; Pribowo, A.; Mabee, W.E. Steam explosion of oil palm residues for the production of durable pellets. Appl. Energy 2015, 141, 160–166. [Google Scholar] [CrossRef]

- Lai, Z.Y.; Goh, S.M. Mechanical strength of binary oil palm kernel shell and HZSM-5 zeolite fuel pellets. Fuel 2015, 150, 378–385. [Google Scholar] [CrossRef]

- Perea-Moreno, M.; Manzano-Agugliaro, F.; Perea-Moreno, A. Sustainable Energy Based on Sunflower Seed Husk Boiler for Residential Buildings. Sustainability 2018, 10, 3407. [Google Scholar] [CrossRef]

- Spirchez, C.; Lunguleasa, A.; Croitoru, C. Ecological briquettes from sunflower seed husk. In E3S Web of Conferences; Cui, W., Ed.; EDP Sciences: Paris, France, 2019; Volume 80. [Google Scholar]

- ISO. Solid Biofuels—Fuel Specifications and Classes; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- ISO. Solid Biofuels—Particle Size Distribution of Disintegrated Pellets; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- ISO. ISO 18134-1/2 Solid Biofuels—Determination of Moisture Content—Oven Dry Method-Part ½; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Zhang, J.; Guo, Y. Physical properties of solid fuel briquettes made from Caragana korshinskii Kom. Powder Technol. 2014, 256, 293–299. [Google Scholar] [CrossRef]

- Cao, L.; Yuan, X.; Li, H.; Li, C.; Xiao, Z.; Jiang, L.; Huang, B.; Xiao, Z.; Chen, X.; Wang, H.; et al. Complementary effects of torrefaction and co-pelletization: Energy consumption and characteristics of pellets. Bioresour. Technol. 2015, 185, 254–262. [Google Scholar] [CrossRef]

- ISO. ISO 16948, Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- ISO. ISO 16994, Solid Biofuels—Determination of Total Content of Sulfur and Chlorine; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Li, S.G.; Xu, S.P.; Liu, S.Q.; Yang, C.; Lu, Q.H. Fast pyrolysis of biomass in free-fall reactor for hydrogen-rich gas. Fuel Process. Technol. 2004, 85, 1201–1211. [Google Scholar] [CrossRef]

- ISO. ISO 18122, Solid Biofuels—Determination of Ash Content; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- ISO. ISO 18125, Solid Biofuels—Determination of Calorific Value; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- ISO. ISO 17831-1, Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes; ISO: Geneva, Switzerland, 2015; Volume B. [Google Scholar]

- ISO. ISO 17828, Solid Biofuels—Determination of Bulk Density; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Tumuluru, J.S. Pelleting of Pine and Switchgrass Blends: Effect of Process Variables and Blend Ratio on the Pellet Quality and Energy Consumption. Energies 2019, 12, 1198. [Google Scholar] [CrossRef]

- Box, G.E.; Wilson, K.B. On the experimental attainment of optimum conditions. J. R. Stat. Soc. Ser. B (Methodol.) 1951, 13, 1–38. [Google Scholar] [CrossRef]

- Iftikhar, M.; Asghar, A.; Ramzan, N.; Sajjadi, B.; Chen, W. Biomass densification: Effect of cow dung on the physicochemical properties of wheat straw and rice husk based biomass pellets. Biomass Bioenergy 2019, 122, 1–16. [Google Scholar] [CrossRef]

- Song, X.; Zhang, M.; Pei, Z.J.; Wang, D. Ultrasonic vibration-assisted pelleting of wheat straw: A predictive model for energy consumption using response surface methodology. Ultrasonics 2014, 54, 305–311. [Google Scholar] [CrossRef] [PubMed]

- Lu, D.; Tabil, L.G.; Wang, D.; Wang, G.; Wang, Z. Optimization of binder addition and compression load for pelletization of wheat straw using response surface methodology. Int. J. Agric. Biol. Eng. 2014, 7, 67–78. [Google Scholar]

- Demirbas, A. Effect of temperature on pyrolysis products from four nut shells. J. Anal. Appl. Pyrolysis 2006, 76, 285–289. [Google Scholar] [CrossRef]

- Hosseinizand, H.; Sokhansanj, S.; Lim, C.J. Co-pelletization of microalgae Chlorella vulgaris and pine sawdust to produce solid fuels. Fuel Process. Technol. 2018, 177, 129–139. [Google Scholar] [CrossRef]

- Bilgic, E.; Yaman, S.; Haykiri-Acma, H.; Kucukbayrak, S. Limits of variations on the structure and the fuel characteristics of sunflower seed shell through torrefaction. Fuel Process. Technol. 2016, 144, 197–202. [Google Scholar] [CrossRef]

- Matin, A.; Majdak, T.; Kricka, T.; Grubor, M. Valorization of sunflower husk after seeds convection drying for solid fuel production. J. Cent. Eur. Agric. 2019, 20, 389–401. [Google Scholar] [CrossRef]

- Li, H.; Jiang, L.; Li, C.; Liang, J.; Yuan, X.; Xiao, Z.; Xiao, Z.; Wang, H. Co-pelletization of sewage sludge and biomass: The energy input and properties of pellets. Fuel Process. Technol. 2015, 132, 55–61. [Google Scholar] [CrossRef]

- Porter, D.; Vollrath, F. Water mobility, denaturation and the glass transition in proteins. Biochim. Biophys. Acta-Proteins Proteom. 2012, 1824, 785–791. [Google Scholar] [CrossRef] [PubMed]

- Kaliyan, N.; Morey, R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresour. Technol. 2010, 101, 1082–1090. [Google Scholar] [CrossRef] [PubMed]

- Salmen, L.; Olsson, A.M. Interaction between hemicelluloses, lignin and cellulose: Structure-property relationships. J. Pulp Pap. Sci. 1998, 24, 99–103. [Google Scholar]

- Wongsiriamnuay, T.; Tippayawong, N. Effect of densification parameters on the properties of maize residue pellets. Biosyst. Eng. 2015, 139, 111–120. [Google Scholar] [CrossRef]

- Jiang, L.; Liang, J.; Yuan, X.; Li, H.; Li, C.; Xiao, Z.; Huang, H.; Wang, H.; Zeng, G. Co-pelletization of sewage sludge and biomass: The density and hardness of pellet. Bioresour. Technol. 2014, 166, 435–443. [Google Scholar] [CrossRef] [PubMed]

- Adapa, P.; Tabil, L.; Schoenau, G. Compaction characteristics of barley, canola, oat and wheat straw. Biosyst. Eng. 2009, 104, 335–344. [Google Scholar] [CrossRef]

- Gilvari, H.; de Jong, W.; Schott, D.L. Quality parameters relevant for densification of bio-materials: Measuring methods and affecting factors—A review. Biomass Bioenergy 2019, 120, 117–134. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Hu, Q.; Shao, J.; Yang, H.; Yao, D.; Wang, X.; Chen, H. Effects of binders on the properties of bio-char pellets. Appl. Energy 2015, 157, 508–516. [Google Scholar] [CrossRef]

- Song, X.; Yang, Y.; Zhang, M.; Zhang, K.; Wang, D. Ultrasonic pelleting of torrefied lignocellulosic biomass for bioenergy production. Renew. Energy 2018, 129, 56–62. [Google Scholar] [CrossRef]

- Si, Y.; Hu, J.; Wang, X.; Yang, H.; Chen, Y.; Shao, J.; Chen, H. Effect of Carboxymethyl Cellulose Binder on the Quality of Biomass Pellets. Energy Fuels 2016, 30, 5799–5808. [Google Scholar] [CrossRef]

- Jiang, L.; Yuan, X.; Xiao, Z.; Liang, J.; Li, H.; Cao, L.; Wang, H.; Chen, X.; Zeng, G. A comparative study of biomass pellet and biomass-sludge mixed pellet: Energy input and pellet properties. Energy Convers. Manag. 2016, 126, 509–515. [Google Scholar] [CrossRef]

- Kirsten, C.; Lenz, V.; Schroeder, H.; Repke, J. Hay pellets—The influence of particle size reduction on their physical-mechanical quality and energy demand during production. Fuel Process. Technol. 2016, 148, 163–174. [Google Scholar] [CrossRef]

- Garcia, R.; Gil, M.V.; Rubiera, F.; Pevida, C. Pelletization of wood and alternative residual biomass blends for producing industrial quality pellets. Fuel 2019, 251, 739–753. [Google Scholar] [CrossRef]

- Lu, D.; Tabil, L.G.; Wang, D.; Wang, G.; Emami, S. Experimental trials to make wheat straw pellets with wood residue and binders. Biomass Bioenergy 2014, 69, 287–296. [Google Scholar] [CrossRef]

- Gillespie, G.D.; Everard, C.D.; Fagan, C.C.; McDonnell, K.P. Prediction of quality parameters of biomass pellets from proximate and ultimate analysis. Fuel 2013, 111, 771–777. [Google Scholar] [CrossRef]

- Hamelinck, C.N.; Suurs, R.; Faaij, A. International bioenergy transport costs and energy balance. Biomass Bioenergy 2005, 29, 114–134. [Google Scholar] [CrossRef]

- Albashabsheh, N.T.; Stamm, J.L.H. Optimization of lignocellulosic biomass-to-biofuel supply chains with mobile pelleting. Transp. Res. Part E-Logist. Transp. Rev. 2019, 122, 545–562. [Google Scholar] [CrossRef]

- Graham, S.; Eastwick, C.; Snape, C.; Quick, W. Mechanical degradation of biomass wood pellets during long term stockpile storage. Fuel Process. Technol. 2017, 160, 143–151. [Google Scholar] [CrossRef]

| Independent Variable | ||

|---|---|---|

| X1: Temperature (°C) | X2: Pressure (MPa) | X3: Moisture Content (% wb) |

| 110 | 140 | 8 |

| 130 | 160 | 10 |

| 150 | 180 | 12 |

| This Work | [48] | [27] | [49] | |

|---|---|---|---|---|

| Proximate analysis (%, based on dry material) | ||||

| Volatile | 79.8 | 81 | - | 63.51 ± 1.25 |

| Ash | 1.8 | 1.8 | 2.1 | 2.99 ± 0.03 |

| Fixed carbon | 18.4 | 17.2 | - | 19.42 ± 0.58 |

| Ultimate analysis (%, based on dry ash free) | ||||

| C | 56.36 ± 0.4 | 46.5 | 44.2 ± 0.008 | 55.83 ± 0.96 |

| H | 5.03 ± 0.06 | 6.5 | 6.12 ± 0.015 | 4.56 ± 0.08 |

| O | 37.2 ± 0.36 | 46.4 | 48.92 ± 2.641 | 39.2 ± 0.05 |

| N | 1.17 ± 0.12 | 0.4 | 0.41 ± 0.061 | - |

| S | 0.14 ± 0.06 | 0.2 | 0.24 ± 0.003 | 0.15 ± 0.02 |

| LHV (MJ/kg) | 19.04 | - | 16.507 | 21.47 ± 0.36 |

| HHV (MJ/kg) | 20.2 | 18.3 | 17.884 | 22.46 ± 0.38 |

| Macromolecular analysis (%, based on dry material) | ||||

| Cellulose | 40.1 | 67.1 | - | - |

| Hemicellulose | 32.4 | - | - | |

| Lignin | 20.3 | 27.1 | - | - |

| Extractives | 5.5 | 5.3 | - | - |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F | Remarks | |

|---|---|---|---|---|---|---|---|

| R1 | Model | 4.21 | 6 | 0.7 | 31.06 | <0.0001 | Significant |

| X1 | 1.53 | 1 | 1.53 | 67.7 | <0.0001 | ||

| X2 | 1.62 | 1 | 1.62 | 71.63 | <0.0001 | ||

| X3 | 0.78 | 1 | 0.78 | 34.54 | 0.0002 | ||

| X1X2 | 0.003 | 1 | 0.01 | 0.44 | 0.5211 | ||

| X1X3 | 0.023 | 1 | 0.023 | 0.99 | 0.3421 | ||

| X2X3 | 0.25 | 1 | 0.25 | 11.05 | 0.0077 | ||

| Lack of fit | 0.14 | 6 | 0.023 | 1.05 | 0.5058 | Not significant | |

| R2 | Model | 6759.75 | 3 | 2253.25 | 5.85 | 0.0094 | Significant |

| X1 | 2556.13 | 1 | 2556.13 | 6.63 | 0.0023 | ||

| X2 | 3003.13 | 1 | 3003.13 | 7.79 | <0.0001 | ||

| X3 | 1200.5 | 1 | 1200.5 | 3.12 | 0.101 | ||

| Lack of fit | 5003.99 | 9 | 556 | 427.69 | 0.33 | Not significant | |

| R3 | Model | 3.14 | 9 | 0.35 | 10.54 | 0.0026 | Significant |

| X1 | 0.02 | 1 | 0.02 | 0.6 | 0.4627 | ||

| X2 | 1.62 | 1 | 1.62 | 48.88 | 0.0002 | ||

| X3 | 0.98 | 1 | 0.98 | 29.57 | 0.001 | ||

| X1X2 | 0.01 | 1 | 0.01 | 0.3 | 0.5999 | ||

| X1X3 | 0.16 | 1 | 0.16 | 4.83 | 0.5999 | ||

| X2X3 | 0.01 | 1 | 0.01 | 0.3 | 0.024 | ||

| X12 | 0.021 | 1 | 0.021 | 0.62 | 0.456 | ||

| X22 | 0.00168 | 1 | 0.00168 | 0.051 | 0.8281 | ||

| X32 | 0.33 | 1 | 0.33 | 9.96 | 0.016 | ||

| Lack of fit | 0.18 | 3 | 0.06 | 4.62 | 0.0868 | Not significant |

| Parameter | Mean | Std. Dev. | R2 | Adj R2 | C.V. % | Adeq Precision |

|---|---|---|---|---|---|---|

| DU (%) | 97.96 | 0.15 | 0.9491 | 0.9185 | 0.15 | 20.206 |

| BD (kg/m3) | 1067.94 | 19.63 | 0.9744 | 0.9762 | 1.84 | 7.824 |

| W (kJ/kg) | 25.57 | 0.18 | 0.9313 | 0.8429 | 0.71 | 11.459 |

| Unit | Method Standard (ISO) | Wood Pellets a | Microalgae Pellets b | Sample Pellets | A (Commercial) | B (Industrial) | ||

|---|---|---|---|---|---|---|---|---|

| BD (kg/m3 wb) | ISO 17828 | 710 ± 14 | 1482.00 | 1117.4 | ≥600 | √ | ≥600 | √ |

| DU (%) | ISO 17831-1 | 98.3 ± 0.48 | 98.3 | 98.8 | ≥96.5 | √ | ≥96.5 | √ |

| M (%) | ISO 18134-1/2 | 6.31 | 6.10 | 5.1 | ≤10 | √ | ≤10 | √ |

| L (mm) | ISO 17829 | 16.8 ± 4.0 | 23.41 | 13 | 3.15–40 | √ | 3.15–40 | √ |

| D (mm) | ISO 17829 | 6.10 ± 0.1 | 6.07 | 7 | 8 ± 1 | √ | 8 ± 1 | √ |

| N (% db) | ISO 16948 | <0.2 | 6.55 | 1.17 | ≤1.0 | √ | ≤0.6 | × |

| S (% db) | ISO 16994 | 0.07 | 0.48 | 0.14 | ≤0.05 | √ | ≤0.05 | √ |

| A (% db) | ISO 18122 | 0.42 | 18.02 | 1.8 | ≤2.0 | × | ≤3.0 | × |

| LHV (MJ/kg) | ISO 18125 | - | 17.98 | 19.04 | ≥4.6 | √ | - | - |

| HHV (MJ/kg) | ISO 14918 | 17.21 ± 0.37 | 17.98 | 20.2 | ≥16.5 | √ | ≥16.5 | √ |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, X.; Yang, J.; Shi, X.; Lei, W.; Huang, T.; Bai, C. Pelletization of Sunflower Seed Husks: Evaluating and Optimizing Energy Consumption and Physical Properties by Response Surface Methodology (RSM). Processes 2019, 7, 591. https://doi.org/10.3390/pr7090591

Cui X, Yang J, Shi X, Lei W, Huang T, Bai C. Pelletization of Sunflower Seed Husks: Evaluating and Optimizing Energy Consumption and Physical Properties by Response Surface Methodology (RSM). Processes. 2019; 7(9):591. https://doi.org/10.3390/pr7090591

Chicago/Turabian StyleCui, Xuyang, Junhong Yang, Xinyu Shi, Wanning Lei, Tao Huang, and Chao Bai. 2019. "Pelletization of Sunflower Seed Husks: Evaluating and Optimizing Energy Consumption and Physical Properties by Response Surface Methodology (RSM)" Processes 7, no. 9: 591. https://doi.org/10.3390/pr7090591

APA StyleCui, X., Yang, J., Shi, X., Lei, W., Huang, T., & Bai, C. (2019). Pelletization of Sunflower Seed Husks: Evaluating and Optimizing Energy Consumption and Physical Properties by Response Surface Methodology (RSM). Processes, 7(9), 591. https://doi.org/10.3390/pr7090591