Abstract

Use of corn fractionation techniques in dry grind process increases the number of coproducts, enhances their quality and value, generates feedstock for cellulosic ethanol production and potentially increases profitability of the dry grind process. The aim of this study is to develop process simulation models for eight different wet and dry corn fractionation techniques recovering germ, pericarp fiber and/or endosperm fiber, and evaluate their techno-economic feasibility at the commercial scale. Ethanol yields for plants processing 1113.11 MT corn/day were 37.2 to 40 million gal for wet fractionation and 37.3 to 31.3 million gal for dry fractionation, compared to 40.2 million gal for conventional dry grind process. Capital costs were higher for wet fractionation processes ($92.85 to $97.38 million) in comparison to conventional ($83.95 million) and dry fractionation ($83.35 to $84.91 million) processes. Due to high value of coproducts, ethanol production costs in most fractionation processes ($1.29 to $1.35/gal) were lower than conventional ($1.36/gal) process. Internal rate of return for most of the wet (6.88 to 8.58%) and dry fractionation (6.45 to 7.04%) processes was higher than the conventional (6.39%) process. Wet fractionation process designed for germ and pericarp fiber recovery was most profitable among the processes.

1. Introduction

Increased risk of extinction of fossil fuel resources has encouraged production of renewable fuel alternatives. Bioethanol is a high potential renewable liquid fuel which is already used in transportation sector in United States and Brazil. The United States is the biggest producer (16.1 billion gallons in 2018) of ethanol in world and use corn as major feedstock [1]. With more than 200 commercial plants, dry grind is most commonly used process to produce ethanol (more than 90% production). Typically corn consists of 72% starch, 4% oil, 10% protein and 10% other components. In the conventional dry grind process, starch in the corn kernel is hydrolyzed to produce glucose and fermented into ethanol. In addition to ethanol, Distiller’s dried grains with solubles (DDGS) and corn oil are coproducts of conventional dry grind process. Unfermented components in corn dry grind process are recovered as DDGS which is sold primarily as an ingredient in ruminant diets. Oil recovered from the unfermented components is sold as an ingredient in poultry diets and biodiesel production. Coproducts offset the costs required for ethanol production in the dry grind process [2,3] and contribute towards sustainability of the process. Thus, increasing the value and number of coproducts would improve profitability of dry grind process. Due to high fiber and low protein content in the DDGS, its use is limited to mainly for the ruminants. Decreasing fiber content in DDGS could widen its market utilization to the poultry and swine industry, and improve its economic value. Similarly, high free fatty acid content in the oil recovered post-fermentation makes it unsuitable for human consumption, and reduces its market value. Separation of corn pericarp (mostly fiber) and germ (containing maximum oil) using fractionation technologies can potentially address these challenges and provide additional coproducts in the process [4,5]. The separated germ and fiber can be further processed to produce high value products, such as fiber gum [6,7], fiber oil [4,8] and high quality germ oil [9]. Moreover, corn fiber consists of 18 to 20% cellulose, 30 to 50% arabinoxylan and 11 to 23% starch [10,11] which can be hydrolyzed and fermented to produce additional ethanol, and help in Renewable fuel standard compliance. Pretreatment conditions required for conversion of corn fiber to ethanol are relatively mild compared to other biomass [12,13]. High conversion efficiencies have been observed in fermentation of corn fiber produced in wet and dry fractionation processes using conventional and genetically engineered yeasts [14,15,16]. These factors make corn fiber a potential feedstock for cellulosic ethanol production. Corn germ meal, a coproduct of corn oil extraction from germ can also be used as a raw material for cellulosic ethanol production [16].

Wet fractionation techniques such as quick germ [17], quick germ quick fiber [18,19] and enzymatic milling processes involve soaking corn kernel in water for 6 to 12 h and coarse grinding to separate germ (in all processes), pericarp fiber (quick germ quick fiber, enzymatic milling) and fine fiber (enzymatic milling) prior to fermentation in dry grind process [5]. Soaking corn in water loosens the attachment between corn components and facilitates their separation through coarse grinding [4,17]. Dry fractionation involves tempering of corn kernel with hot water or steam for relatively short period of time (15 to 30 min) followed by coarse milling and separation of individual components [20,21,22]. Dry fractionation requires lower capital costs compared to wet fractionation processes, however, due to inefficient separation, coproducts in the dry fractionation process have a lower quality than wet fractionation. For example, the oil content in the germ produced through dry fractionation was 18% compared to 39% in wet fractionation [23]. High loss of starch in coproducts is another disadvantage in dry fractionation processes. Loss of nutrients to coproducts in dry fractionation leads to low fermentation efficiency. Modifications in dry fractionation process such as protease addition, germ soak water addition and partial germ addition, have addressed these challenges and improved fermentation rate and efficiency [21,24,25] of the process. Thus, a detailed techno-economic analysis is required for comparing process advantages of different fractionation techniques and costs associated with these retrofits.

Various researchers have performed techno-economic analysis of conventional dry grind process [26,27,28]. Similarly, techno-economic analysis of certain wet [29,30,31,32,33,34] and dry [35] fractionation technologies has been conducted. However, comparison of all the technologies at a unified platform keeping same assumptions is required to understand trade-off among various options and determine an optimum process. Thus, the objectives of our study were to (1) develop process models for front-end corn fractionation technologies in dry grind ethanol process and (2) compare conventional and modified dry grind processes for corn fractionation in terms of economic feasibility.

2. Materials and Methods

2.1. Process Description

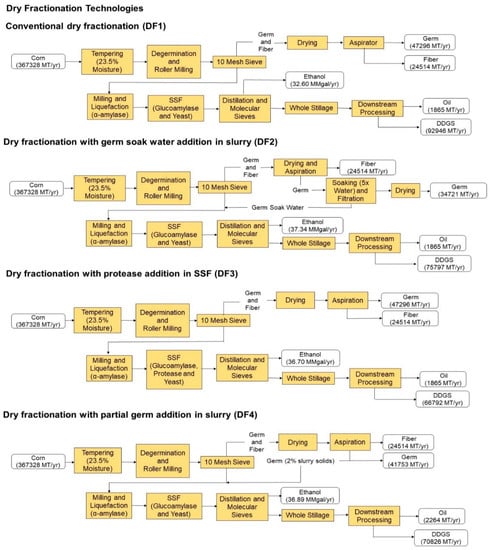

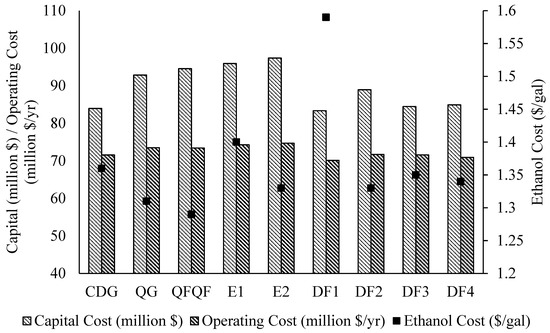

Techno-economic analysis of the conventional dry grind and fractionation processes was performed by developing process simulation models for conventional dry grind process, four dry fractionation technologies, and four wet fractionation technologies in SuperPro designer (Intelligen, Inc., Scotch Plains, NJ, USA) (Table 1; Figure 1 and Figure 2). Corn was assumed to be containing 72% starch, 4% oil, 10% protein, 10% fiber and 4% of other (unfermentable) components on dry basis with 15% moisture content [36]. It was assumed that pericarp and endosperm fiber constituted 90% and 10% of total fiber, respectively [15]. Pericarp fiber is the corn pericarp whereas endosperm fiber is fiber associated with cellular matrix in corn. In this study pericarp and endosperm fiber will be referred by their generic names, fiber and fine fiber, respectively. Corn processing capacity (1113 MT/day) was kept same in all the models and plant operation period for all models was assumed as 330 days per year. Ethanol, DDGS and corn oil yields/compositions were dependent on assumptions during front end recovery steps. Front end coproduct yields and compositions were obtained from the previous laboratory studies. Table 2 summarizes compositions of coproducts in conventional and modified processes.

Figure 1.

Schematic for conventional dry grind process and wet fractionation processes.

Figure 2.

Schematic for dry fractionation processes.

2.2. Economic Analysis

The process details and equipment costs for conventional dry grind process were based on the model developed by Somavat et al. [37]. Equipment costs used in the modified dry grind models were from the previous process models of corn wet milling [38,39] and oil extraction [40]. Other than main equipment purchase costs, total capital estimates also include costs associated with installations, piping, electrical facilities, engineering, construction, project contingencies and other indirect costs. These additional costs were assumed as 300% of equipment purchase costs [26,37,41]. Direct capital costs (DFC) was estimated as 400% of equipment costs taking equipment and additional costs into account. Total capital investment (TCI) were estimated as summation of working capital (5% of DFC) and DFC. Since equipment capacities vary among different processes, exponential scaling equation [37,41,42,43] was used to extrapolate the cost of equipment used in current models.

Operating costs include costs of raw materials, utilities, labor, coproducts and facility dependent costs. Purchase price of corn was assumed to be $3.36/bushel (average price of corn in 2017) [44]. Purchase prices of enzymes and yeasts were assumed to be $2.25 and $1.86/kg, respectively [37]. Purchase prices of steam, natural gas, chilled water and electricity were assumed to be $12.86/MT, $3.51/million BTU, $0.4/kg and $0.07/kWh, respectively [37].

A model correlating protein content, fiber content and corn prices to the price of coproducts with varying compositions (DDGS, corn gluten meal, corn gluten feed and soybean meal) was developed. High correlation was observed between coproduct price and protein content. Thus, the model used for estimation of coproduct prices were S = 0.1082P2 (R2 = 0.99), where S is the selling price of the coproduct in dollars ($/MT) and P is the protein content (on dry basis) of the coproduct. Selling price of germ in the modified processes was estimated using the correlation in Johnston et al. [23] which correlated price of germ with oil and protein content, corn oil price, corn gluten feed price and oil removal efficiency. Price of post-fermentation corn oil and ethanol were assumed to be $0.56/kg and $1.45/gal, respectively. Selling prices of all coproducts used in the model (Table 2) were based on selling prices in the year 2016–17 reported by U.S. Department of Agriculture (USDA) economic research service [44].

Table 1.

Summary of conventional dry grind process and wet fractionation processes.

Table 1.

Summary of conventional dry grind process and wet fractionation processes.

| Name | Process | Coproducts | Description | Reference |

|---|---|---|---|---|

| CDG | Conventional dry grind | DDGS, Corn oil | The corn was cleaned, milled and mixed with water to produce of slurry with 32% solids. Corn starch was hydrolyzed to glucose and converted to ethanol in liquefaction and simultaneous saccharification and fermentation (SSF) steps. Pure ethanol was recovered using distillation and molecular sieve systems and denatured by adding octane. The unfermented material (whole stillage) was processed to recover corn oil and DDGS. Whole stillage was centrifuged to produce wet grains and thin stillage. Thin stillage was concentrated (known as syrup) and centrifuged to recover oil. Defatted syrup was mixed with wet grains and dried to produce DDGS. | [26,37] |

| QG | Quick germ | DDGS, Corn oil, Germ | Corn was soaked in water (27% solids) at 59 °C for 12 h [29]. Soaked corn was coarsely ground and incubated with α-amylase (0.6 g/kg corn) at 55 °C for 4 h at pH 4.5 [5]. The process design for germ recovery was similar to Ramirez et al. [38,39]. Slurry was passed through two set of hydrocyclones with feed to underflow ratio of 80% and 70% for the first and second hydrocyclones, respectively. Germ was recovered in the overflow of first hydrocyclone and the remaining slurry was passed through second hydrocyclone. Germ was washed using water recycled from dry grind process. Amount of water used germ washing was twice the amount solids in the germ stream. Washed germ was dewatered to 50% moisture and dried to 10% moisture. Filtrate stream from dewatering step and overflow of second hydrocyclone was added to corn soaking step. The slurry recovered from underflow of second hydrocyclone was processed similar to CDG. | [5,29,38,39] |

| QGQF | Quick germ quick fiber | DDGS, Corn oil, Germ, Fiber | Corn soaking (29% solids), grinding, incubation and coproduct recovery steps were similar to QG. Germ and fiber mixture was recovered in the overflow of first hydrocyclone due to higher specific gravity in QGQF compared to QG (due to higher solids). Washing, dewatering and drying steps were similar to QG. Germ and fiber were separated using set of aspirators. Stream recovered from underflow of second hydrocyclone was processed similar to CDG. | [5,38,39] |

| E1 | Enzymatic milling with front end fine fiber recovery | DDGS, Corn oil, Fiber, Germ, Fine fiber | Corn soaking and grinding steps were similar to QGQF. Ground corn was incubated with α-amylase (0.6 g/kg corn) at 55 °C for 2 h followed by incubation with protease (1 g/kg corn) at 45 °C for 2 h. Germ and coarse fiber were separated with process similar to QGQF. Compositions of germ and fiber in E1 were different than QGQF due to incubation with protease. The underflow from second hydrocyclone was passed through 200 mesh screen to separate fine fiber from the mash. Fine fiber was washed and dewatered similar to germ and fiber washing step. Fine fiber was dried in rotary drum dryer [38,39]. Water separated during filtration was recycled in corn soaking step. The underflow from 200 mesh screen was processed similar to CDG. | [5,38,39] |

| E2 | Enzymatic milling with post-fermentation fine fiber recovery | DDGS, Corn oil, Fiber, Germ, Fine fiber | Soaking, grinding, enzyme incubation and germ and fiber separation steps were similar to E1 process. The underflow from second hydrocyclone was processed similar to CDG till the ethanol recovery step. Whole stillage was passed through 200 mesh screen to separate fine fiber (overflow) from whole stillage. Separated fine fiber was washed and dewatered similar to E1. The underflow from 200 mesh screen was processed with downstream process similar to CDG. | [5,38,39] |

| DF1 | Conventional dry fractionation | DDGS, Corn oil, Germ, Fiber | Corn was tempered with water for 18 min to raise corn moisture to 23.5% and ground using degermination mill. The degermed corn was passed through a roller mill and sieved through 10 mesh sieve. Germ and pericarp (overflow) were separated from endosperm particles (underflow) during the sieving step. The underflow of the sieve was processed similar to the conventional dry grind process. The germ and pericarp particles were dried to 10% moisture and separated using aspirator. Separation of germ in the DF1 process lead to incomplete utilization of glucose [21,24]. Fermentation efficiency (89%) was adjusted to account for the post-fermentation residual glucose [21]. | [20,21,24] |

| DF2 | Dry fractionation with germ soak water addition in slurry | DDGS, Corn oil, Germ, Fiber | Dry fractionation process model (DF1) was modified to incorporate utilization of germ soak water in the slurry making (DF2). Germ produced in the dry fractionation was soaked in water for 12 h at 30 °C with 1:5 germ to water ratio. Soaked germ was dewatered to 25% moisture using a screen and dried to 10% moisture in a fluidized bed dryer. The underflow of filter was processed similar to conventional dry grind process. Changes in germ composition post-soaking were adjusted according to Juneja et al. [24]. Complete conversion of glucose to ethanol was assumed in the SSF step [21,24]. | [20,21,24] |

| DF3 | Dry fractionation with protease addition in SSF | DDGS, Corn oil, Germ, Fiber | Dry fractionation process model (DF1) was modified to incorporate protease addition in the fermentation process (DF3). Commercially recommended dose of protease (1 g/kg corn) was added in the fermentation tank [45]. Complete conversion of glucose to ethanol was assumed in the SSF step [21,24]. | [20,21,24,45] |

| DF4 | Dry fractionation with partial germ addition in slurry | DDGS, Corn oil, Germ, Fiber | Dry fractionation process model (DF1) was modified to incorporate partial germ addition during slurry making (DF4). Dry germ equivalent to 2% solids in slurry was added during slurry making process. Complete conversion of glucose to ethanol was assumed in the SSF step [21,25]. | [20,21,25] |

Table 2.

Yield, composition and prices of coproducts in modified dry grind processes.

Table 2.

Yield, composition and prices of coproducts in modified dry grind processes.

| Process | Coproduct | Yield a (%) | Oil b (%) | Protein b (%) | Fiber b (%) | Starch b (%) | Revenue ($/MT) | Reference |

|---|---|---|---|---|---|---|---|---|

| CDG | DDGS | 33.12 | 6.79 | 33.31 | 30.11 | 6.50 | 120.26 | |

| Oil | 1.74 | 100 | 560.00 | |||||

| QG | Germ | 6.78 | 36.45 | 20.86 | 19.92 | 6.13 | 311.96 | [5,23] |

| DDGS | 28.04 | 3.05 | 34.27 | 30.73 | 7.64 | 126.76 | ||

| Oil | 0.66 | 100 | 560.00 | |||||

| QGQF | Germ | 6.78 | 36.46 | 20.95 | 19.92 | 6.13 | 312.10 | [5,23] |

| Fiber c | 9.02 | 1.07 | 10.38 | 62.33 | 14.58 | 11.66 | [5,14] | |

| DDGS | 20.27 | 3.95 | 42.67 | 14.80 | 10.37 | 197.03 | ||

| Oil | 0.62 | 100 | 560.00 | |||||

| E1 | Germ | 7.15 | 39.05 | 18.64 | 18.91 | 11.72 | 328.76 | [5,23] |

| Fiber c | 10.00 | 5.29 | 11.71 | 50.27 | 20.31 | 14.73 | [5,15] | |

| Fine Fiber c | 4.40 | 0.64 | 13.91 | 19.00 | 54.91 | 20.88 | [5,15] | |

| DDGS | 18.11 | 1.99 | 43.29 | 15.23 | 11.09 | 203.24 | ||

| Oil | 0.28 | 100 | 560.00 | |||||

| E2 | Germ | 7.15 | 39.05 | 18.64 | 18.91 | 11.71 | 328.76 | [5,23] |

| Fiber c | 10.00 | 5.29 | 11.70 | 50.26 | 20.30 | 14.73 | [5,15] | |

| Fine Fiber c | 5.22 | 2.59 | 22.22 | 53.05 | 2.67 | 53.40 | [5,46] | |

| DDGS | 15.14 | 1.99 | 48.41 | 5.51 | 12.74 | 254.01 | ||

| Oil | 0.23 | 100 | 560.00 | |||||

| DF1 | Germ | 13.64 | 18.36 | 17.75 | 25.02 | 20.98 | 160.18 | [5,23] |

| Fiber | 7.07 | 1.65 | 7.49 | 39.50 | 47.51 | 6.00 | [20] | |

| DDGS | 26.79 | 2.88 | 29.42 | 14.06 | 7.34 | 93.68 | ||

| Oil | 0.60 | 100 | 560.00 | |||||

| DF2 | Germ | 10.00 | 25.01 | 17.00 | 34.08 | 17.29 | 212.59 | [23,24] |

| Fiber | 7.07 | 1.65 | 7.49 | 39.50 | 47.51 | 6.00 | [20] | |

| DDGS | 21.85 | 3.53 | 39.94 | 17.25 | 9.16 | 172.21 | ||

| Oil | 0.60 | 100 | 560.00 | |||||

| DF3 | Germ | 13.64 | 18.36 | 17.75 | 25.02 | 20.98 | 160.18 | [5,23] |

| Fiber | 7.07 | 1.65 | 7.49 | 39.50 | 47.51 | 6.00 | [20] | |

| DDGS | 19.25 | 4.01 | 41.51 | 19.58 | 10.22 | 186.91 | ||

| Oil | 0.60 | 100 | 560.00 | |||||

| DF4 | Germ | 12.03 | 18.36 | 17.75 | 25.02 | 20.98 | 160.18 | [5,23] |

| Fiber | 7.07 | 1.65 | 7.49 | 39.50 | 47.51 | 6.00 | [20] | |

| DDGS | 20.42 | 4.59 | 40.55 | 20.41 | 9.68 | 178.02 | ||

| Oil | 0.73 | 100 | 560.00 |

a Yield calculated as percentage dry coproduct per unit dry corn b Composition calculated on dry basis c It was assumed that starch free and protein free fiber was composed of 80% polysaccharides (cellulose and hemicellulose) and 20% other materials on dry basis.

Ethanol production cost ($/gal) was calculated as the ratio of net operating costs (difference of gross operating costs and coproducts credits) and annual ethanol production. Profitability analysis was performed by estimating internal rate of return (IRR) for conventional and modified processes. and 40% DFC in second year) was assumed. Income tax was assumed to be 35% of taxable income. Depreciation was estimated using modified accelerated cost recovery systems (MACRS) 7-year depreciation schedule with 0% equipment salvage value [37,41].

3. Results and Discussion

3.1. Process Yields

The annual ethanol production capacities (million gallons) and ethanol yields (gallon/bushel corn) estimated from all processes simulated are presented in Figure 1 and Table S1, respectively. Ethanol production capacities for all fractionation processes were found lower compared to conventional dry grind process due to loss of starch in various coproducts. Among wet fractionation, ethanol production in QG, QGQF, E1 and E2 processes were lower by 0.6, 2.5, 7.4 and 4.0% compared to conventional dry grind process, respectively. Although the starch content was similar in the coproducts from QGQF and QG processes, relatively high amounts of coproducts resulted in overall high loss of starch and lower yields for QGQF process. Higher number of coproducts and proportion of starch in the coproducts in enzymatic milling compared to QGQF resulted in lower ethanol yield in enzymatic milling processes. Percent starch in fine fiber processed using E1 was higher than fine fiber produced using E2 as fine fiber was fractionated at the front-end in E1 whereas fine fiber was fractionated post-fermentation in E2. Starch loss to fine fiber in process E1 was responsible for lower ethanol yield compared to E2. The ethanol yields were further lower (7.1 to 18.9% lower compared to conventional process) for dry fractionation processes, because of relatively inefficient corn fractionation and high starch loss compared to wet fractionation processes. Ethanol yield and productivity for DF1 process was minimum among all processes. This was observed because of incomplete fermentation of glucose produced from corn starch. Corn germ is a vital source of nutrients (lipids, amino acids, micronutrients) required by yeast during fermentation. Removal of germ in dry fractionation processes leads to deficiency of these nutrients and results in inefficient fermentation [21]. Ethanol yields in all other dry fractionation processes (DF2–DF4) were relatively higher, because this nutrient limitation was addressed by addition of germ soak water (DF2), protease enzyme addition (DF3) or adding some fraction of germ back in the process (DF4). DF2 had higher ethanol yield compared to DF3 due to leaching of glucose (accounted in terms of starch) in the germ soak water which was used in dry grind process (Figure 1). Similarly, DF4 had higher ethanol yield than DF3 as starch associated with recycled germ was fermented to ethanol in DF4.

Amounts of germ recovered were higher for dry fractionation processes compared to wet fractionation processes, however, the oil percentages were relatively lower in all cases (Table 2). This was due to inefficient separations and high amount of starch in the germ fractions recovered in dry fractionation processes. Germ yields in enzymatic milling (7.15% corn dry weight) processes were higher than QG and QGQF processes (6.78% corn dry weight). Enzymatic milling also produced germ with higher oil content (39.05%) compared to QG (36.45%) and QGQF (36.46%) processes (Table 2). In dry fractionation, loss of protein and starch in germ soak water was responsible for higher oil content in DF2 germ (25.02%) compared to other dry fractionation processes (18.36%) (Table 2). As the market price of germ is proportional to its oil and protein contents [23], germ produced through wet fractionation had a higher market value compared to germ produced through dry fractionation (Table 2).

Fiber yield was higher in wet fractionation (31,277 to 34,673 MT/year) compared to dry fractionation (24,514 MT/year) (Figure 1). Similar to the case of germ, the fiber fractions from dry processes contained higher starch content (47.51%) compared to wet fractionation (14.58 to 20.30%) (Table 2). Although corn fiber has diverse applications, the purchase price of fiber depends on its use as a ruminant feed and thus heavily depends on protein content [2]. Price of fiber was assumed to be constant in other studies [35,37]. However, as composition of fiber varied amongst processes extensively, price model similar to DDGS was used for estimating selling price of fiber in the current study. Higher amounts of starch in the dry-fractionated fiber resulted in relatively lower protein content (7.49%) compared to wet fractionation (10.38 to 11.71%) (Table 2). Fiber produced through enzymatic milling and QGQF processes had comparable protein contents. Fine fiber produced in enzymatic milling had higher protein content compared to fiber. Fine fiber produced in E1 had higher starch content compared to E2 as fine fiber was fractionated prior to fermentation in E1 whereas fine fiber was fractionated post-fermentation in E2. Thus, higher starch content in E1 fine fiber was responsible for lower protein content in E1 (13.97%) compared to E2 (22.22%) fine fiber. The selling prices of fiber coproducts correlated with their protein contents with highest price for E2 fine fiber ($53.40/MT) and lowest price for dry fractionated fiber ($6.00/MT) (Table 2).

DDGS yields were higher for conventional dry grind process (114,882 MT/year) compared to fractionation processes (Figure 1). Loss of corn components to fractionation products was responsible for decrease in DDGS yields in fractionation processes. In the wet fractionation processes, DDGS yields decreased with increase in number of coproducts thus, yields for enzymatic milling (18.11% and 15.14% corn dry weight) were lower than QGQF (20.27% corn dry weight) and QG process (28.04% corn dry weight) (Table 2). Lower amount of unfermentable material in whole stillage for E2 resulted in reduced DDGS yields compared to E1. DDGS yield for DF1 process was higher compared to other dry fractionation processes due to a large amount of unfermented glucose in DDGS (Figure 1). Purchase price of DDGS was dependent on its protein content. DDGS produced in all fractionation technologies except DF1 (29.42% protein content) had higher protein content (34.27 to 48.41%) compared to DDGS produced in conventional dry grind process (33.31%). QGQF (42.67%) and enzymatic milling (43.29% for E1 and 48.41% for E2) had higher protein in DDGS compared to QG (34.27%) due to fiber separation (Table 2). These results were in agreement with previous studies. Taylor et al. [29] observed approximately similar protein content for quick germ and dry grind process (33.3% for CDG vs. 34.3% for QG in our study). Lin et al. [35] and Rajagopalan et al. [30] observed 34.6 and 43.5% increase in DDGS protein content in QGQF process compared to conventional. In this study protein content in DDGS of QGQF was found 26% higher compared to protein in DDGS from CDG process. Differences in corn composition, processing steps such as oil recovery and coproduct compositions might be responsible for the differences in yield.

Similar to DDGS yields, the oil yields were observed lower from the simulation results of fractionation processes compared to conventional process (Figure 1). These results were expected due to removal of germ (major oil source in corn) as a separate coproduct.

3.2. Capital Investments

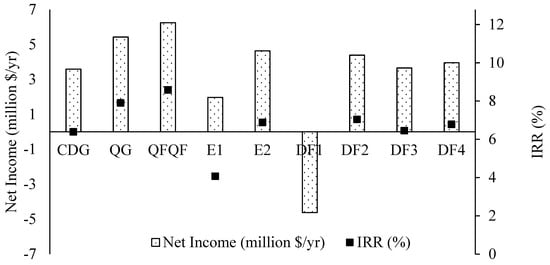

Process economics in terms of total capital costs, operating costs and ethanol production costs for conventional and modified dry grind processes have been illustrated in Figure 3. Capital investment for the conventional dry grind facility was ($83.95 million) was lower than all fractionation processes except DF1 process. Capital investment for all wet fractionation processes were higher than conventional process due to additional equipment requirement for separation of germ and fiber. Capital investments for QG, QGQF, E1 and E2 were 10.6 to 16% higher than CDG (Figure 1). Our results were in agreement with Rajagopalan et al. [30] who observed 13.5% increase in capital costs in quick germ quick fiber process compared to conventional dry grind process. Lin et al. [35] also observed 42.5% increase in capital cost for QGQF process compared to dry grind process. Due to one additional operation of fine fiber separation, the capital investment for enzymatic milling process was higher compared to other wet fractionation processes. Similarly, additional equipment capacity for fiber separation in QGQF was responsible for higher capital investment than QG. Capital investments for DF2, DF3 and DF4 were 6, 0.6 and 1.1% higher than CDG, respectively, whereas capital investment for DF1 was 0.7% lower than CDG (Figure 1). Equipment costs required for germ and fiber separation in DF2, DF3 and DF4 processes was lower than wet fractionation processes. This was observed because of relatively lower amount of water used in tempering step (23.5% water in mixture) during dry fractionation compared to very large amount of water used for soaking in wet fractionation processes. As germ and fiber were separated prior to corn liquefaction, lower material was passed through the dry grind stages which decreased the capacity requirement for the processes. Thus, factors such as low equipment costs for front end coproduct separation and low equipment capacity in dry grind stages were responsible for low capital costs in the dry fractionation processes. The capital cost of DF2 process was higher compared to other dry fractionation processes due to additional equipment required for germ soaking, filtration and drying. DF3 had higher capital cost in comparison to DF1 due to additional storage requirement for protease enzyme and higher material flow in ethanol recovery operations (distillation and molecular sieves). DF4 involved partial recycle of germ in the dry grind stages which increased equipment capacity in these stages. Higher equipment capacity in dry grind stages resulted in DF4 having higher capital cost compared to DF1 and DF3. Lin et al. [35] observed 36.6% increase in capital cost for dry fractionation in comparison to conventional dry grind due to higher corn input in dry fractionation.

Figure 3.

Summary of capital costs, operating costs and ethanol production costs in conventional and modified processes.

3.3. Operating Costs

Operating costs for conventional dry grind process were ($71.56 million/year) was lower than wet fractionation processes. Operating costs for wet fractionation was higher than conventional process due to two factors: (1) Higher utility requirement due to additional soaking and coproduct separation steps and (2) higher raw material costs due to enzyme requirements for germ and fiber separation. Operating costs for QG, QGQF, E1 and E2 were 2.7, 2.6, 3.8 and 4.4% higher than CDG, respectively (Figure 3). Enzymatic milling required higher operating costs than other wet fractionation processes due to higher enzyme requirements for fine fiber separation. QG (73% post-soaking moisture) required higher water input than QGQF (71% post-soaking moisture) which increased front-end equipment throughput. Secondly, corn starch to ethanol conversion process steps (dry grind stages) included energy intensive operations such as liquefaction, jet cooking and fermenter cooling. The slurry volumes processed through dry grind stages in QGQF process were relatively lower compared to QG process due to removal of fiber in addition to germ, which resulted in lower operating costs for QGQF process. Total operating costs for QGQF were higher than conventional process by 12.9 and 14.7% in the studies by Lin et al. [35] and Rajagopalan et al. [30]. Operating costs for DF1 and DF4 were 2 and 1% lower than CDG, respectively whereas operating costs for DF2 were higher than CDG (Figure 2). Utilities required for germ and fiber separation in DF1, DF3 and DF4 processes were lower than wet fractionation processes (Figure 1). As germ and fiber were separated prior to liquefaction, low throughput for dry grind stages in DF1, DF3 and DF4 compared to other processes decreased the total operating cost for the processes. Operating costs for DF3 were higher than DF1 due to higher enzyme requirements (protease addition) in DF3. Higher utility requirements in DF2 for germ soaking and drying operations and higher throughput in dry grind stages compared to other dry fractionation processes increased operating costs of DF2. Higher throughput in the dry grind stages was responsible for higher operating costs in DF4 in comparison to DF1. Lin et al. [35] observed 13.7% increase in operating costs in dry fractionation in comparison to conventional dry grind process. Increased corn input rate assumption for fractionation processes in Lin et al. [35] and Rajagopalan et al. [30] were responsible for the differences.

Operating costs can be classified as raw material, utility and miscellaneous (labor and facility dependent) costs. In all processes, raw material costs were greater than 70% of gross operating costs. Corn contributed to more than 85% of total raw material costs in all processes. As the corn processing capacity (1113 MT/day) and purchase cost of corn ($3.36/bushel) was assumed same in all process models, annual costs incurred in corn purchase ($48.58 million/year) remained same in all processes. Enzymes (2.01 to 5.07%) and denaturant (3.76 to 3.12%) were other significant contributors to the raw material costs in case of conventional process. These results were consistent with other studies where feedstock contributed to majority of the raw material costs [26,28,37,42,47] followed by denaturant [28] and enzymes [26]. Raw material costs for QG and QGQF processes were higher by 1.1 and 1% than conventional dry grind processes, respectively whereas E1 and E2 processes required 2.2 and 2.4% higher raw material costs (Table 3). Higher enzyme requirement was responsible for higher raw material costs in wet fractionation processes compared to conventional process. Additional protease requirement in E1 and E2 increased the total raw material costs of these processes compared to QG and QGQF. As ethanol yield in E1 was lower than E2, lower quantity of denaturant was required in E1. Lower denaturant requirement resulted in lower raw material cost in E1 compared to E2. In the study by Rajagopalan et al. [30], raw materials cost for QGQF process was 16.2% higher in comparison to dry grind process, due to higher scale of operation for modified process compared to conventional process. However, increase in raw material costs per unit corn for QGQF in the study by Rajagopalan et al. [30] (1.22%) was similar to our study (1%). Raw material costs for DF1, DF2 and DF4 were 0.7, 0.3 and 0.3% lower than CDG, respectively whereas DF3 had 1.2% higher raw material cost compared to CDG (Table 3). As enzyme requirements for CDG, DF1, DF2 and DF4 were similar, lower denaturant requirement (due to lower ethanol yields) in DF1, DF2 and DF4 was responsible for lower raw material prices. Additional protease requirement in DF3 was responsible for its higher raw material cost compared to CDG.

Table 3.

Summary of raw material costs in conventional and modified dry grind processes.

Utility requirements for wet fractionation ($11.03 to $11.35 million/year) were higher than CDG ($10.39 million/year) due to additional processing required for corn soaking, enzyme incubation and coproduct separation processes (Table 4). Low water use in fractionation and low material flow through energy intensive dry grind stages (due to high front-end coproduct yields) were factors responsible for lower utility requirements in dry fractionation processes ($9.40 to $10.36 million/year). Steam was the main contributor to utility costs and contributed to more than 45% of total utility costs in all processes. Liquefaction, jet cooking and distillation were major contributors to steam requirements, thus steam requirements in wet fractionation processes increased with increase in material flow in these stages. Thus, CDG had highest steam requirement ($6.1 million/year) and contribution to utilities (58.8%). Steam requirements for wet fractionation processes were 3.6 to 10.0% lower than CDG (Table 4). QG had the highest steam requirements ($5.89 million/year) among fractionation processes due highest material flow in the dry grind stages as only germ was recovered at front-end. Steam requirements for dry fractionation processes ($4.85 to $5.39 million/year) were lower than other processes due to high front-end coproduct yields and lower material flow through dry grind stages (Table 4). Electricity was the second major contributor to utilities, similar to the studies by Somavat et al. [37] and Wood et al. [28]. Annual electricity costs for modified processes were higher than CDG ($2.05 million/year) due to electricity requirements for fractionation (Table 4). Equipment (sieves and hydrocyclones) in corn fractionation stages were major contributors towards electricity. Natural gas contributed towards 7.32% of total utilities in conventional dry grind process. Front-end coproduct drying increased natural gas requirements in wet fractionation ($0.89 to $1.24 million/year) compared to CDG ($0.76 million/year) (Table 4). Natural gas and electricity requirements increased with the yield and number of coproducts in wet fractionation due to increase energy requirement for coproduct recovery and drying. Lower water use in dry fractionation lead to lower material throughput in corn fractionation and lowered electricity ($2.64 to $2.84 million/year) and natural gas requirements ($0.83 to $0.75 million/year) in the dry fractionation processes compared to wet fractionation. Electricity and natural gas requirements were highest for DF2 among dry fractionation processes due to electricity requirements for additional filtration and drying after germ soaking step. Major requirement of cooling agents (cooling, chilled and cooling tower (CT) water) was in fermentation and distillation steps and thus was dependent on material flow through dry grind stages. CDG had highest cooling requirements ($1.45 million/year) followed by wet fractionation ($1.43 to $1.29 million/year) and dry fractionation ($1.17 to $1.28 million/year) (Table 4). Cooling agent costs decreased with increase in number of fractionation products in wet fractionation. Cooling agent costs in DF2 was higher than other dry fractionation processes as cooling water was required for cooling germ soak tank from 70 °C to 52 °C. Total utility requirements were highest for E2 and DF2 among wet and dry fractionation processes, respectively. Although steam requirements were higher for QG process, high natural gas and electricity requirements for coproduct separation were responsible for high utility costs in E2. Additional processing steps involved in germ soaking, filtration and drying in DF2 were responsible for higher utility cost compared to other dry fractionation processes.

Table 4.

Summary of utility costs in conventional and modified dry grind processes.

Annual labor costs were $3.27 million in all the processes as the number and salary of laborers was assumed to be constant. Facility dependent costs were proportional to DFC (6.55% of DFC) and increased with increase in capital costs. Facility dependent costs in CDG were $5.24 million/year, ranged from $5.79 to $6.08 million/year in wet fractionation and ranged from $5.20 to $5.55 million/year in dry fractionation.

3.4. Ethanol Production Costs and Profitability Analysis

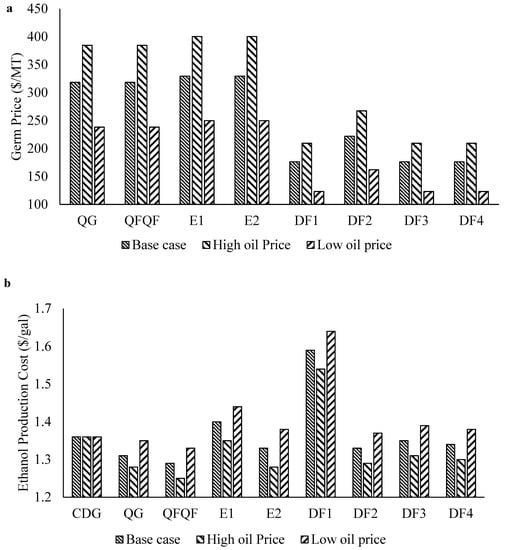

The ethanol production costs for CDG, QG and QGQF processes were estimated $1.36, $1.31 and $1.29/gal, respectively (Figure 3). Gross operating costs for QG and QGQF processes (Figure 3) were higher than CDG and ethanol production for these processes was lower than CDG. However, the coproduct credits for QG and QGQF were higher than CDG by 25 and 35%, respectively (Table 5) which decreased the ethanol production costs for these processes. Ethanol production costs for E1 and E2 were $1.40 and $1.33/gal, respectively. Although the coproduct credits were higher for E1 (32% higher than CDG) and E2 (39% higher than CDG) (Table 5), high operating costs (Figure 3) and low ethanol production (Figure 3) was responsible for higher ethanol production costs for these processes compared to QG and QGQF processes. Results in the current study were in agreement with other studies on corn fractionation processes. Taylor et al. [29] predicted a 4 cent/gal decrease in ethanol production costs for quick germ process. In the study by Rajagopalan et al. [30], ethanol production cost was $1.03, $1.00 and $0.98/gal for conventional, QGQF and QGQF with germ oil extraction processes. Rodriguez et al. [31] observed a 13.5 cents/gal decrease in ethanol production costs for QGQF process. In the study by Rodriguez et al. [31], higher corn input in QGQF compared to dry grind process increased the scale of operation in QGQF. Higher scale of operation in Rodriguez et al. [31] was responsible for higher decrease ethanol production cost compared to our study. The ethanol production costs for DF1, DF2, DF3 and DF4 were $1.59, $1.33, $1.35 and $1.34/gal, respectively (Figure 3). Germ produced through dry fractionation had lower value than that of wet fractionation due to lower oil content. Ethanol yield in dry fractionation processes was lower than wet fractionation processes due to loss of starch to coproducts. Although, operating costs were lower for dry fractionation than wet fractionation, low coproduct credits (Table 5) (due to low coproduct value) and low ethanol yields were responsible for high ethanol production costs. Ethanol production costs for DF1 were the highest among conventional and modified processes due to low ethanol yields (due to incomplete fermentation) and low coproduct value. DF2 had lower ethanol costs compared to other dry fractionation processes due to higher gross operating costs (Figure 3), ethanol yields (Figure 1) and coproduct credits (Table 5). High operating costs due to protease addition and low ethanol yields in DF3 resulted in higher ethanol production costs in comparison to DF4 although coproduct credits for DF3 were higher than DF4.

Table 5.

Summary of revenue generation in conventional and modified dry grind processes.

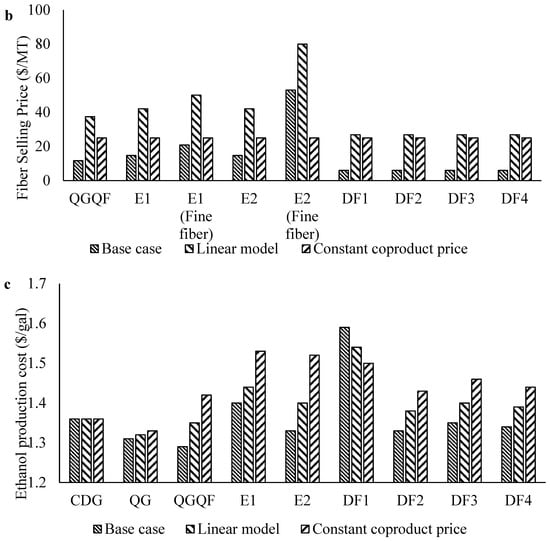

Internal rate of return (IRR) accounted for parameters such as plant income, depreciation, capital investment and time value of money, integral for assessing economic performance of the processes. Ethanol was the primary product of dry grind process and contributed to more than 70% of revenue in all processes. Among all processes, ethanol generated highest annual revenue ($58.3 million) in CDG. However, DDGS (15 to 18% of total revenue) and germ (9 to 12% of total revenue in modified processes) also had significant contribution towards revenue in conventional and modified processes. Although ethanol yield was highest for CDG (Figure 1), IRR for both wet and dry fractionation processes (except E1 and DF1) was higher due to production of high value coproducts such as germ and enhanced DDGS. IRR for QG and QGQF processes was higher than enzymatic milling processes (Figure 4) due to higher annual revenue (Figure 4) and lower capital investment (Figure 3). High operating costs for coproduct separation (Figure 3) and low revenue due to low ethanol yields (Figure 1) were responsible for low annual income in enzymatic milling processes. Revenue generated from germ in enzymatic processes ($8.2 million/year) was higher than other wet fractionation process ($7.5 million/year) due to higher yield and selling price. However, revenue from ethanol had higher contribution towards total revenue in the processes resulting in lower revenue generation. E1 had lower IRR (4.07%) compared to CDG (6.39%) and other wet fractionation processes due to relatively low ethanol and DDGS yields and high investments involved in enzymatic milling. Revenue from DDGS was dependent on DDGS yield and selling price. Although selling price for DDGS was high in E1, low DDGS yield was responsible for low revenue. QGQF process had highest IRR (8.58%) among all the processes considered in the study due to high revenue generation from coproducts. DDGS yield and price combination achieved in QGQF process generated highest revenue among the processes (Table 5). Although ethanol yields were higher for QG and CDG (Figure 1), high revenue generation from DDGS increased the total revenue in QGQF (Table 5). Our results were in agreement with other studies, Rajagopalan et al. [30] and Rodriguez et al. [31] estimated higher return of investment and net present value for QGQF compared to CDG, respectively. Although, IRR for dry fractionation processes (except DF1) was higher than CDG, low ethanol yields and coproduct value in dry fractionation processes were responsible for lower IRR compared to QG and QGQF processes. Net annual income for DF1 was negative ($ −4.62 million/year) due to low ethanol yields (inefficient fermentation) and DDGS price (low protein). IRR for DF1 could not be estimated due to negative annual income. DF2 process had higher annual income ($4.39 million/year) and IRR (7.04%) compared to other dry fractionation processes (Table 5). Irrespective of relatively high capital and operating costs, high revenue generation from ethanol and DDGS improved profitability of DF2 in comparison to other dry fractionation processes. Low revenue from DDGS and ethanol in comparison with DF2 was responsible for lower IRR in DF3 (6.45%) and DF4 (6.78%) processes. Similar to process E1, low DDGS yields in DF3 and DF4 were responsible for lower revenue generation compared to DF2 irrespective of higher DDGS selling price.

Figure 4.

Summary of net annual income and internal rate of return for conventional and modified dry grind processes. IRR for DF1 could not be estimated due to negative annual income.

3.5. Sensitivity Analysis

Sensitivity analysis helps in identifying the critical parameters and inputs to which process outputs (yields or costs) are highly dependent. Also, as the costs of several raw materials and products varies over the time or with locations, it is critical to determine the effect of cost variations of major inputs and outputs on the process profitability.

3.5.1. Effect of Protease Prices on Ethanol Production Cost

With the progress of technology, the costs of enzymes have decreased significantly over time and the trend is expected to continue. Thus, protease cost was assumed similar to other enzymes ($2.25/kg) throughout the study. To assess the economic barriers in fractionation due to high protease costs, ethanol production costs for E1, E2 and DF3 processes were estimated by assuming 0 to 300% increase in protease costs ($2.25 to $9/kg protease). Ethanol production costs increased with increase in protease price (Figure 5). Ethanol costs for E1 were higher than CDG for all cases and ranged between $1.39 and $1.46/gal. Ethanol production costs for DF3 process increased from $1.35 to $1.42/gal with increase in enzyme cost from $2.25 to $9/kg. Ethanol production costs for DF3 were lower than CDG only for $2.25/kg protease cost case. Ethanol production costs in E2 were lower than ethanol production costs in CDG for $2.25 and $4.50/kg protease cases, and increased in comparison to CDG with further increase in protease prices. Ethanol production costs in E2 were less sensitive to protease costs compared to DF3 and E1. Higher coproduct credit generation in E2 was responsible for lower dependence of ethanol production cost on protease enzyme costs.

Figure 5.

Effect of protease purchase cost on ethanol production price in CDG, E1, E2 and DF3 processes.

3.5.2. Effect of Coproduct Price Model on Ethanol Production Cost

A quadratic relationship was assumed between coproduct (DDGS and fiber) selling price and protein content of coproduct. However, several studies have assumed a linear relationship between coproduct cost and protein content [32,37,48]. Moreover, it is possible that coproduct prices did not vary with protein content. Thus, ethanol production costs were calculated for all processes considering three cases: (1) Base case (quadratic relation between protein content and coproduct price); (2) Linear model assumption: the model used for estimation of coproduct prices was S = 3.6078P, where S is the selling price of the coproduct in dollars ($/MT) and P is the protein content (on dry basis) of the coproduct; (3) Constant coproduct price assumption: DDGS and fiber prices were assumed as $120.26 and $25/MT. Models (linear and constant price) were developed such that price of DDGS in CDG ($120.26/MT) remained constant for all cases for the ease of comparison.

DDGS and fiber selling prices had higher sensitivity to protein content with base case (quadratic) model assumption in comparison to linear model assumption. Thus, a relatively large difference in selling price was observed with change in protein content for base case model in comparison to linear model. Thus, larger increase in selling price was observed with base case compared to linear model for DDGS (higher protein content compared to CDG) produced in modified processes (except DF1) (Figure 6a). Similarly, larger decrease in selling price was observed with base case compared to linear model for fiber and DDGS produced in DF1 (lower protein content compared to CDG). Ethanol production costs for modified processes increased with linear model assumption except DF1 (Figure 6c). Increase in ethanol production costs was attributed to low DDGS selling price. Although revenue from fiber was higher in most modified process (Figure 6b), due to relatively high contribution (17% vs. 2%) of DDGS in total revenue, ethanol production costs increased with decrease in DDGS price. Among all fractionation processes, QG ($1.32/gal) and QGQF ($1.35/gal) processes had lower ethanol production costs than CDG with linear DDGS cost assumption. QG had lower ethanol production cost in comparison to QGQF due to higher revenue generation from DDGS. DDGS selling prices decreased by 2.2% and 21.9% for QG and QGQF processes, respectively when linear model was compared with base case. The large decrease in DDGS selling price in case of QGQF was responsible for decrease in DDGS revenue generation. DF1 had a lower ethanol production cost compared to base case due to higher DDGS and fiber selling price but had the highest ethanol production cost among modified processes due to low revenue generation from ethanol. Ethanol production costs for wet fractionation ranged from $1.32 to $1.44/gal whereas production costs ranged from $1.54 to $1.38/gal for dry fractionation. All dry fractionation and enzymatic milling processes had higher ethanol production costs in comparison to CDG due to low revenue generation from DDGS.

Figure 6.

Effect of coproduct revenue model on (a) DDGS selling price; (b) fiber selling price and (c) ethanol production costs in conventional and modified dry grind processes.

In comparison to base case and linear model assumptions, DDGS selling prices in the modified processes were lower (except DF1) with constant price assumption. Ethanol production costs for modified processes increased with constant coproduct price assumption except DF1 (Figure 6c). Increase in ethanol production costs compared to other models was attributed to low revenue generation from DDGS due to low DDGS selling price. DF1 had a lower ethanol production price compared to other cases due to higher revenue generation from DDGS. Enzymatic milling processes had higher ethanol production costs in comparison to DF1 due to low revenue generation from DDGS. Only QG process had lower ethanol production cost compared to CDG with constant coproduct price assumption. Ethanol production costs for wet fractionation ranged from $1.33 to $1.53/gal whereas production costs ranged from $1.50 to $1.43/gal for dry fractionation processes. The trend for ethanol production costs for other processes was similar to linear model assumption for coproduct price estimation (Figure 6c).

3.5.3. Effect of Germ Selling Price on Ethanol Production Cost

In addition to DDGS, germ also contributed to significant portion (9 to 12%) of revenue in modified processes. Germ selling price was dependent on value of corn oil which changed significantly in the decade (60.76 to 30.75 cents/lb) [49]. Effect of corn oil selling price on ethanol production cost was performed by varying corn oil price by 25% from the price used in the base case model. Germ prices calculated by varying the corn oil price by 25% ($617.56 and $1029.33/MT) and germ prices in the base case have been summarized in Figure 7a. At corn oil selling price of $1029.33/MT, ethanol production costs for wet fractionation ranged from $1.25 to $1.35/gal and were lower than CDG (Figure 7b). Similar to the base case, ethanol production costs were the lowest for QGQF process and highest for E1. Costs for dry fractionation were in range of $1.29 to $1.54/gal at corn oil price of $1029.33/MT (Figure 7b). Processes DF2, DF3 and DF4 had ethanol production costs lower than CDG whereas DF1 had the highest ethanol production costs among the processes. Ethanol production costs ranged from $1.34 to $1.45/gal for wet fractionation and $1.39 to $1.67/gal for dry fractionation assuming $617.56/MT corn oil price (Figure 7b). In modified processes, QG and QGQF had ethanol production costs lower than CDG, whereas all other modified processes had ethanol production costs higher than CDG. Similar to base case, E1 ($1.44/gal) had highest production cost among wet fractionation processes whereas DF1 ($1.64/gal) had highest production cost among dry fractionation processes. DF2 had the lowest ethanol production cost among dry fractionation processes for all the assumptions of corn oil price.

Figure 7.

Effect of corn oil selling price on (a) germ selling price and (b) ethanol production costs in conventional and modified dry grind processes.

4. Conclusions

In this study, nine comprehensive process models for conventional dry grind process and modified dry grind processes including various front-end fractionation technologies were developed using SuperPro Designer. Capital costs for wet fractionation and dry fractionation processes were estimated $92.85 to $97.38 million and $83.35 to $84.91 million, respectively, compared to $83.95 million for the conventional process. Most of the fractionation processes had higher IRR in comparison to conventional dry grind process due to high value of coproducts such as enhanced DDGS and germ. Wet fractionation technology designed for the separation of pericarp fiber and germ (QGQF) had highest IRR and was most economically sustainable among the models evaluated in the study. Process modifications such as germ soak water, partial germ or protease addition in fermentation improved the profitability of conventional dry fractionation in comparison to conventional process. Protease costs had significant effect on profitability of enzymatic milling process. Low protease costs made the enzymatic milling process cost-effective. Although corn fiber had a low contribution towards revenue, it serves as a promising raw material for cellulosic ethanol production.

Supplementary Materials

The following are available online at https://www.mdpi.com/2227-9717/7/9/578/s1, Table S1: Annual ethanol production in conventional and modified dry grind processes.

Author Contributions

C.K. developed models, analyzed data and wrote the manuscript. D.K. revised models and helped in developing models. V.S. and D.K. designed the study, reviewed results and edited the manuscript.

Funding

This work was funded by the DOE Center for Advanced Bioenergy and Bioproducts Innovation (U.S. Department of Energy, Office of Science, Office of Biological and Environmental Research under Award Number DE-SC0018420). Any opinions, findings, and conclusions or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the views of the U.S. Department of Energy.

Conflicts of Interest

The authors declare no conflict of interest.

References

- RFA. Powered with Energy; RFA: Ellisville, MO, USA; RFA: Washington, DC, USA, 2019; Available online: https://ethanolrfa.org/wp-content/uploads/2019/02/RFA2019Outlook.pdf. (accessed on 9 July 2019).

- Rausch, K.D.; Belyea, R.L. The future of coproducts from corn processing. Appl. Biochem. Biotechnol. 2006, 128, 47–86. [Google Scholar] [CrossRef]

- Bothast, R.J.; Schlicher, M.A. Biotechnological processes for conversion of corn into ethanol. Appl. Microbiol. Biotechnol. 2005, 67, 19–25. [Google Scholar] [CrossRef]

- Singh, V.; Moreau, R.A.; Doner, L.W.; Eckhoff, S.R.; Hicks, K.B. Recovery of Fiber in the Corn Dry-Grind Ethanol Process: A Feedstock for Valuable Coproducts. Cereal Chem. 1999, 76, 868–872. [Google Scholar] [CrossRef]

- Singh, V.; Johnston, D.B.; Naidu, K.; Rausch, K.D.; Belyea, R.L.; Tumbleson, M.E. Comparison of Modified Dry-Grind Corn Processes for Fermentation Characteristics and DDGS Composition. Cereal Chem. 2005, 82, 187–190. [Google Scholar] [CrossRef]

- Yadav, M.P.; Johnston, D.B.; Hotchkiss, A.T.; Hicks, K.B. Corn fiber gum: A potential gum arabic replacer for beverage flavor emulsification. Food Hydrocoll. 2007, 21, 1022–1030. [Google Scholar] [CrossRef]

- Singh, V.; Doner, L.W.; Johnston, D.B.; Hicks, K.B.; Eckhoff, S.R. Comparison of coarse and fine corn fiber for corn fiber gum yields and sugar profiles. Cereal Chem. 2000, 77, 560–561. [Google Scholar] [CrossRef]

- Moreau, R.A.; Powell, M.J.; Hicks, K.B. Extraction and Quantitative Analysis of Oil from Commercial Corn Fiber. J. Agric. Food Chem. 1996, 44, 2149–2154. [Google Scholar] [CrossRef]

- Moreau, R.A. Corn Oil. In Bailey’s Industrial Oil and Fat Products; John Wiley & Sons: Hobaken, NJ, USA, 2005. [Google Scholar]

- Kim, S.M.; Li, S.; Pan, S.-C.; Ding, Y.; Basu, R.; van Egmond, P.; Singh, V. A whole stillage sieving process to recover fiber for cellulosic ethanol production. Ind. Crop. Prod. 2016, 92, 271–276. [Google Scholar] [CrossRef]

- Gáspár, M.; Kálmán, G.; Réczey, K. Corn fiber as a raw material for hemicellulose and ethanol production. Proc. Biochem. 2007, 42, 1135–1139. [Google Scholar] [CrossRef]

- Mosier, N.S.; Hendrickson, R.; Brewer, M.; Ho, N.; Sedlak, M.; Dreshel, R.; Welch, G.; Dien, B.S.; Aden, A.; Ladisch, M.R. Industrial scale-up of pH-controlled liquid hot water pretreatment of corn fiber for fuel ethanol production. Appl. Biochem. Biotechnol. 2005, 125, 77–97. [Google Scholar] [CrossRef]

- Shrestha, P.; Khanal, S.K.; Pometto, A.L.; van Leeuwen, J. Ethanol production via in situ fungal saccharification and fermentation of mild alkali and steam pretreated corn fiber. Bioresour. Technol. 2010, 101, 8698–8705. [Google Scholar] [CrossRef]

- Dien, B.S.; Nagle, N.; Hicks, K.B.; Singh, V.; Moreau, R.A.; Tucker, M.P.; Nichols, N.N.; Johnston, D.B.; Cotta, M.A.; Nguyen, Q.; et al. Fermentation of “Quick Fiber” produced from a modified corn-milling process into ethanol and recovery of corn fiber oil. Appl. Biochem. Biotechnol. 2004, 115, 937–949. [Google Scholar] [CrossRef]

- Dien, B.S.; Johnston, D.B.; Hicks, K.B.; Cotta, M.A.; Singh, V. Hydrolysis and Fermentation of Pericarp and Endosperm Fibers Recovered from Enzymatic Corn Dry-Grind Process. Cereal Chem. 2005, 82, 616–620. [Google Scholar] [CrossRef]

- Dien, B.S.; Hespell, R.B.; Ingram, L.O.; Bothast, R.J. Conversion of corn milling fibrous co-products into ethanol by recombinant Escherichia coli strains K011 and SL40. World J. Microbiol. Biotechnol. 1997, 13, 619–625. [Google Scholar] [CrossRef]

- Singh, V.; Eckhoff, S. Effect of soak time, soak temperature, and lactic acid on germ recovery parameters. Cereal Chem. 1996, 73, 716–720. [Google Scholar]

- Wahjudi, J.; Xu, L.; Wang, P.; Singh, V.; Buriak, P.; Rausch, K.D.; McAloo, A.; Tumbleson, M.E.; Eckhoff, S. Quick fiber process: Effect of mash temperature, dry solids, and residual germ on fiber yield and purity. Cereal Chem. 2000, 77, 640–644. [Google Scholar] [CrossRef]

- Wahjudi, J.; Xu, L.; Wang, P.; Buriak, P.; Singh, V.; Tumbleson, M.; Rausch, K.; Eckhoff, S. The “quick fiber” process: Effect of temperature, specific gravity, and percentage of residual germ. Cereal Chem. 2000, 77, 640–644. [Google Scholar] [CrossRef]

- Rausch, K.D.; Pruiett, L.E.; Wang, P.; Xu, L.; Belyea, R.L.; Tumbleson, M.E. Laboratory Measurement of Yield and Composition of Dry-Milled Corn Fractions Using a Shortened, Single-Stage Tempering Procedure. Cereal Chem. 2009, 86, 434–438. [Google Scholar] [CrossRef]

- Murthy, G.S.; Singh, V.; Johnston, D.B.; Rausch, K.D.; Tumbleson, M.E. Evaluation and Strategies to Improve Fermentation Characteristics of Modified Dry-Grind Corn Processes. Cereal Chem. 2006, 83, 455–459. [Google Scholar] [CrossRef]

- Murthy, G.S.; Sall, E.D.; Metz, S.G.; Foster, G.; Singh, V. Evaluation of a dry corn fractionation process for ethanol production with different hybrids. Ind. Crop. Prod. 2009, 29, 67–72. [Google Scholar] [CrossRef]

- Johnston, D.B.; McAloon, A.J.; Moreau, R.A.; Hicks, K.B.; Singh, V. Composition and economic comparison of germ fractions from modified corn processing technologies. J. Am. Oil Chem. Soc. 2005, 82, 603–608. [Google Scholar] [CrossRef]

- Juneja, A.; Kumar, D.; Singh, V. Germ soak water as nutrient source to improve fermentation of corn grits from modified corn dry grind process. Bioresour. Bioprocess. 2017, 4, 38. [Google Scholar] [CrossRef]

- Ramchandran, D.; Wang, P.; Dien, B.; Liu, W.; Cotta, M.A.; Singh, V. Improvement of Dry-Fractionation Ethanol Fermentation by Partial Germ Supplementation. Cereal Chem. 2015, 92, 218–223. [Google Scholar] [CrossRef]

- Kwiatkowski, J.R.; McAloon, A.J.; Taylor, F.; Johnston, D.B. Modeling the process and costs of fuel ethanol production by the corn dry-grind process. Ind. Crop. Prod. 2006, 23, 288–296. [Google Scholar] [CrossRef]

- McAloon, A.; Taylor, F.; Yee, W.; Ibsen, K.; Wooley, R. Determining the Cost of Producing Ethanol from Corn Starch and Lignocellulosic Feedstocks; National Renewable Energy Laboratory: Lakewood, CO, USA, 2010. [Google Scholar]

- Wood, C.; Rosentrater, K.A.; Muthukumarappan, K. Techno-economic modeling of a corn based ethanol plant in 2011/2012. Ind. Crop. Prod. 2014, 56, 145–155. [Google Scholar] [CrossRef]

- Taylor, F.; Mcaloon, A.J.; Craig, J.C.; Yang, P.; Wahjudi, J.; Eckhoff, S.R. Fermentation and costs of fuel ethanol from corn with quick-germ process. Appl. Biochem. Biotechnol. 2001, 94, 41–49. [Google Scholar] [CrossRef]

- Rajagopalan, S.; Ponnampalam, E.; McCalla, D.; Stowers, M. Enhancing profitability of dry mill ethanol plants. Appl. Biochem. Biotechnol. 2005, 120, 37–50. [Google Scholar] [CrossRef]

- Rodríguez, L.F.; Li, C.; Khanna, M.; Spaulding, A.D.; Lin, T.; Eckhoff, S.R. An engineering and economic evaluation of quick germ–quick fiber process for dry-grind ethanol facilities: Analysis. Bioresour. Technol. 2010, 101, 5282–5289. [Google Scholar] [CrossRef]

- Li, C.; Rodríguez, L.F.; Khanna, M.; Spaulding, A.D.; Lin, T.; Eckhoff, S.R. An engineering and economic evaluation of quick germ–quick fiber process for dry-grind ethanol facilities: Model description and documentation. Bioresour. Technol. 2010, 101, 5275–5281. [Google Scholar] [CrossRef]

- Singh, V.; Eckhoff, S.R. Economics of Germ Preseparation for Dry-Grind Ethanol Facilities. Cereal Chem. 1997, 74, 462–466. [Google Scholar] [CrossRef]

- Singh, V.; Rausch, K.D.; Yang, P.; Shapouri, H.; Belyea, R.L.; Tumbleson, M.E. Modified Dry Grind Ethanol Process; Departments of Agricultural Engineering, University of Illinois at Champaign-Urbana, UILU: Urbana, IL, USA, 2001. [Google Scholar]

- Lin, T.; Rodríguez, L.F.; Li, C.; Eckhoff, S.R. An engineering and economic evaluation of wet and dry pre-fractionation processes for dry-grind ethanol facilities. Bioresour. Technol. 2011, 102, 9013–9019. [Google Scholar] [CrossRef]

- Kelsall, D.; Pigott, R. Grain milling and cooking for alcohol production: Designing option in dry milling. In The Alcohol Textbook: A Reference for the Beverage, Fuel and Industrial Alcohol Industries, 5th ed.; Ingledew, W.M., Kelsall, D.R., Austin, G.D., Kluhspies, C., Eds.; Nottingham University Press: Nottingham, UK, 2009; pp. 161–175. [Google Scholar]

- Somavat, P.; Kumar, D.; Singh, V. Techno-economic feasibility analysis of blue and purple corn processing for anthocyanin extraction and ethanol production using modified dry grind process. Ind. Crop. Prod. 2018, 115, 78–87. [Google Scholar] [CrossRef]

- Ramírez, E.C.; Johnston, D.B.; McAloon, A.J.; Singh, V. Enzymatic corn wet milling: Engineering process and cost model. Biotechnol. Biofuels 2009, 2, 2. [Google Scholar] [CrossRef]

- Ramirez, E.C.; Johnston, D.B.; McAloon, A.J.; Yee, W.; Singh, V. Engineering process and cost model for a conventional corn wet milling facility. Ind. Crop. Prod. 2008, 27, 91–97. [Google Scholar] [CrossRef]

- Cheng, M.-H.; Rosentrater, K.A. Economic feasibility analysis of soybean oil production by hexane extraction. Ind. Crop. Prod. 2017, 108, 775–785. [Google Scholar] [CrossRef]

- Huang, H.; Long, S.; Singh, V. Techno-economic analysis of biodiesel and ethanol co-production from lipid-producing sugarcane. Biofuels Bioprod. Biorefin. 2016, 10, 299–315. [Google Scholar] [CrossRef]

- Kumar, D.; Murthy, G.S. Impact of pretreatment and downstream processing technologies on economics and energy in cellulosic ethanol production. Biotechnol. Biofuels 2011, 4, 27. [Google Scholar] [CrossRef]

- Kumar, D.; Long, S.P.; Singh, V. Biorefinery for combined production of jet fuel and ethanol from lipid-producing sugarcane: A techno-economic evaluation. GCB Bioenergy 2018, 10, 92–107. [Google Scholar] [CrossRef]

- ERS. Feed Grains Data Delivery System; Economic Research Service, USDA: Washington, DC, USA, 2019. Available online: https://www.ers.usda.gov/db/feedgrains/ (accessed on 20 March 2019).

- Vidal, B.C., Jr.; Rausch, K.D.; Tumbleson, M.E.; Singh, V. Protease Treatment to Improve Ethanol Fermentation in Modified Dry Grind Corn Processes. Cereal Chem. 2009, 86, 323–328. [Google Scholar] [CrossRef]

- Arora, A.; Dien, B.S.; Belyea, R.L.; Wang, P.; Singh, V.; Tumbleson, M.E.; Rausch, K.D. Ultrafiltration of Thin Stillage from Conventional and E-Mill Dry Grind Processes. Appl. Biochem. Biotechnol. 2011, 164, 58–67. [Google Scholar] [CrossRef]

- Wang, K.; Ou, L.; Brown, T.; Brown, R.C. Beyond ethanol: A techno-economic analysis of an integrated corn biorefinery for the production of hydrocarbon fuels and chemicals. Biofuels Bioprod. Biorefin. 2015, 9, 190–200. [Google Scholar] [CrossRef]

- Srinivasan, R.; Singh, V.; Belyea, R.L.; Rausch, K.D.; Moreau, R.A.; Tumbleson, M.E. Economics of Fiber Separation from Distillers Dried Grains with Solubles (DDGS) Using Sieving and Elutriation. Cereal Chem. 2006, 83, 324–330. [Google Scholar] [CrossRef]

- Ash, M.; Matias, M. Oil Crops Outlook; Economic Research Service, USDA: Washington, DC, USA, 2018.

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).